Chemically modified xylanase and preparation method and application thereof

A technology of xylanase and chemical modification, applied in the field of enzyme engineering, which can solve the problems of reducing enzyme activity and achieve the effect of increased affinity and high reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Expression and enzyme activity detection of xylanase described in embodiment 1

[0030] Using XylB derived from Aspergillus niger as a template, a mutant fragment containing EcoRI and SalI was designed and ligated to pET28a(+) by one-step cloning to obtain the target plasmid. The plasmid was transformed into Escherichia coli BL21(DE3), the transformation solution was spread on an LB plate and cultured at 37°C for 12 hours, and the single colony grown was the expression strain. Pick a single colony and inoculate it into 5mL LB medium for 12h at 37°C and 200rpm, and then inoculate it into 200mL LB medium for expansion. When the OD600 of the bacterial solution grows to 0.6-0.8, add 0.1mM IPTG to induce culture for 12h.

[0031] The upstream primer of XylB-F is: 5'-ATGGGTCGCGGATCCGAATTCATGTTTAAATTTA AAAAAAATTTC-3'

[0032] The upstream primer of XylB-R is: 5'-TGCGGCCGCAAGCTTGTCGACCCATACAGTCAC GTTAGAGCTA-3'

[0033] Enzyme activity detection: 0.2mL enzyme solution and 1mL ...

Embodiment 2

[0035] Fermentative production and purification of xylanase described in embodiment 2

[0036] Inoculate 50 μL of the seed-preserving bacteria solution into 5 mL of LB medium for 12 hours at 37°C and 200 rpm, and then inoculate into 200 mL of fermentation medium to expand the culture. When the OD600 of the bacteria solution grows to 0.6-0.8, add 0.1 mM IPTG to induce culture for 12 hours . After the fermentation, the fermentation broth was ultrasonically crushed, centrifuged to take the supernatant after crushing, and ammonium sulfate solution with 100% saturation of the same volume was added to it, stirred at 4°C for 2 hours, then stood still for 6 hours, centrifuged to obtain a precipitate, and added pH 7.0 Preserve the PBS dissolved pellet. The method and condition optimization of xylanase chemical modification described in embodiment 3

Embodiment 3

[0036] Inoculate 50 μL of the seed-preserving bacteria solution into 5 mL of LB medium for 12 hours at 37°C and 200 rpm, and then inoculate into 200 mL of fermentation medium to expand the culture. When the OD600 of the bacteria solution grows to 0.6-0.8, add 0.1 mM IPTG to induce culture for 12 hours . After the fermentation, the fermentation broth was ultrasonically crushed, centrifuged to take the supernatant after crushing, and ammonium sulfate solution with 100% saturation of the same volume was added to it, stirred at 4°C for 2 hours, then stood still for 6 hours, centrifuged to obtain a precipitate, and added pH 7.0 Preserve the PBS dissolved pellet. The method and condition optimization of xylanase chemical modification described in embodiment 3

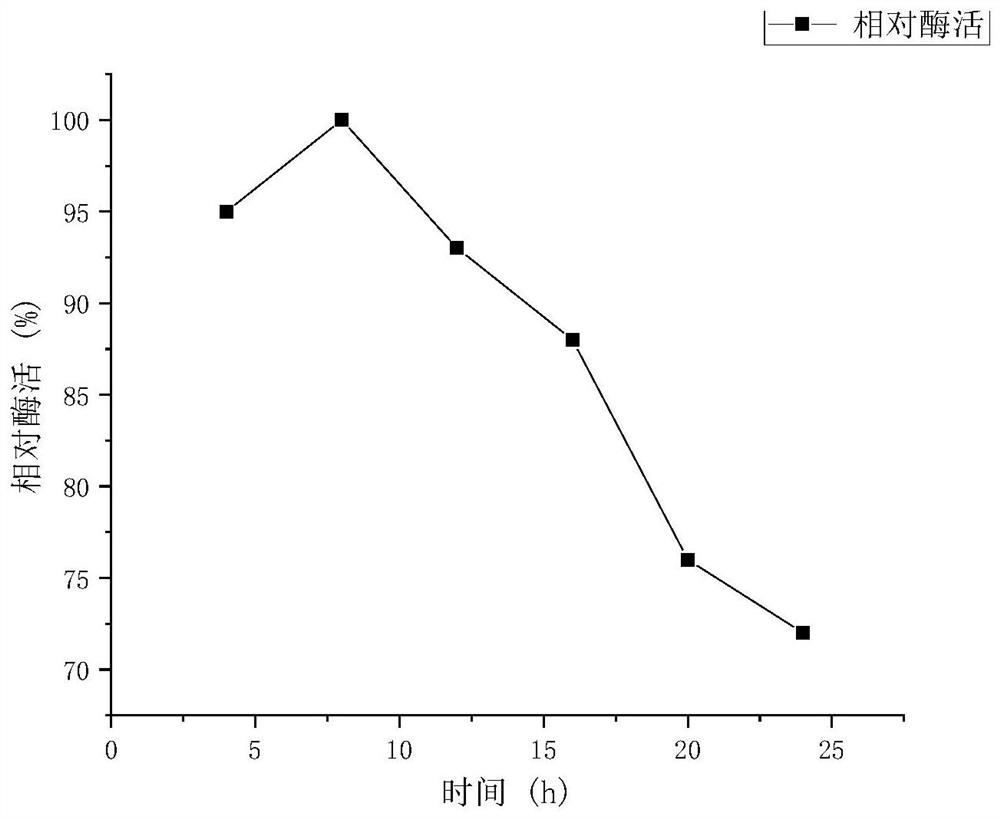

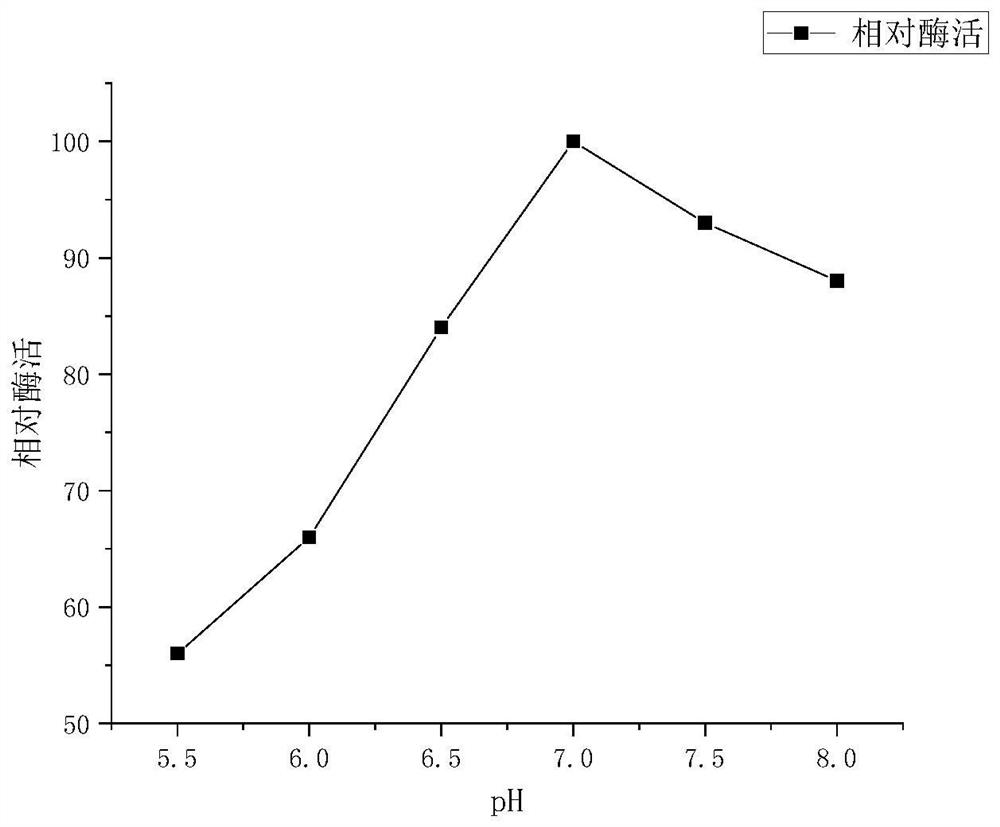

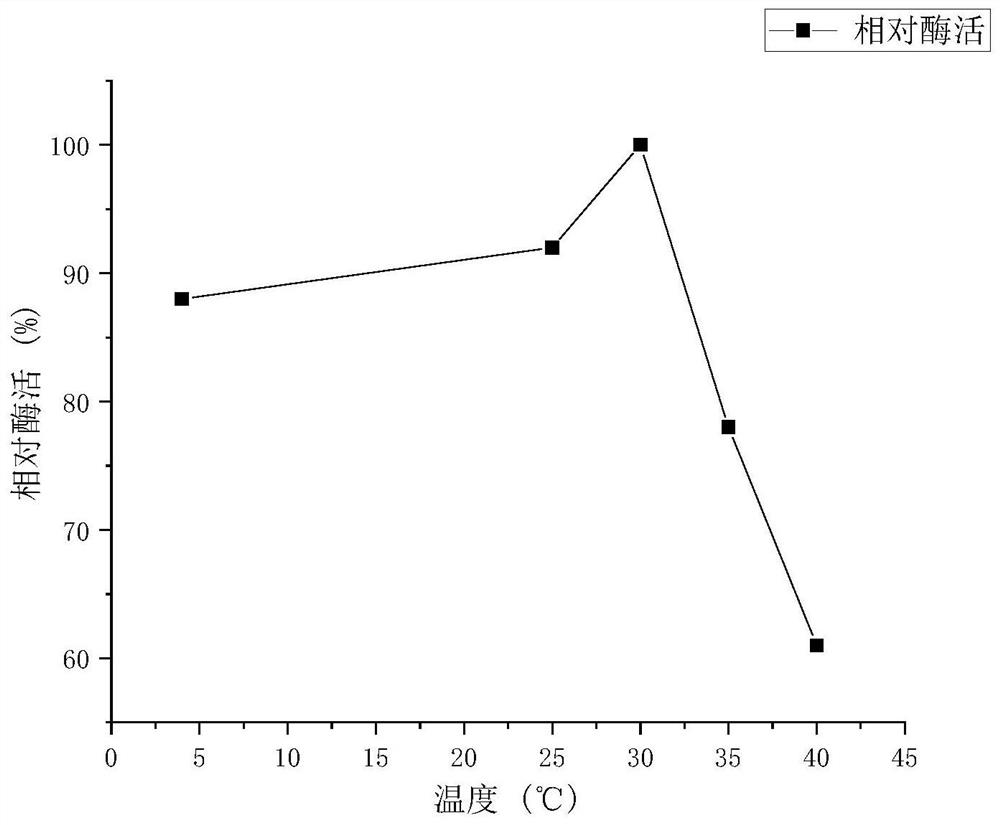

[0037] Oxidation of dextran: 2g of dextran with a molecular weight of 150kDa and 2.4g of NaIO 4 respectively dissolved in 10mL water, NaIO 4 Pour into the dextran solution, stir and react at 30°C in the dark for 6 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com