A kind of modified fluorocarbon powder coating for aluminum surface and preparation method thereof

A modified fluorocarbon and powder coating technology, applied in powder coatings, coatings, etc., can solve the problems of poor impact resistance, poor adhesion, poor pigment and filler dispersibility, etc., to reduce costs, excellent weather resistance, and reduce van der Waals force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

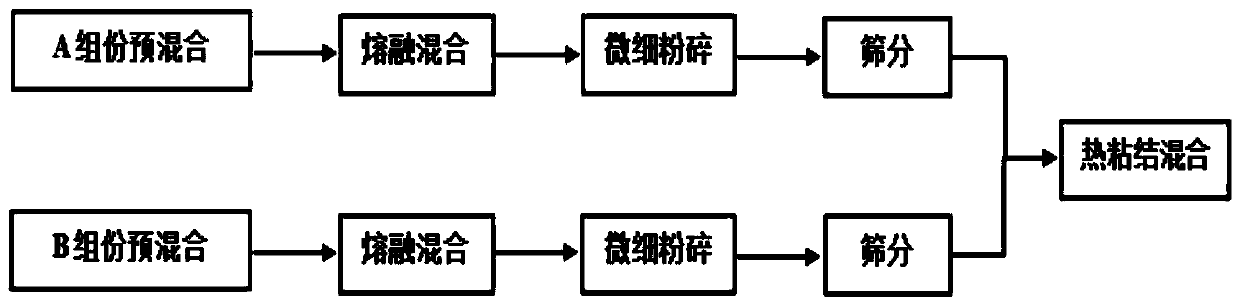

[0056] The preparation method of the modified fluorocarbon powder coating for the aluminum surface, its process is as attached figure 1 shown, including the following steps:

[0057] (1) The raw materials of the A and B component formulas are premixed according to their corresponding weight percentages;

[0058] (2) Melt and mix the raw materials of components A and B after premixing;

[0059] (3) Compress the materials of components A and B after extrusion, and then crush and finely pulverize them after cooling;

[0060] (4) Classifying and screening the finely pulverized component A and component B powders respectively;

[0061] (5) The modified fluorocarbon powder coating is prepared by thermally bonding and mixing the graded and screened powders of components A and B according to a weight ratio of 1:9 to 9:1.

[0062] The thermal bonding mixing process of the step (5) includes adding the A and B component powders into the mixing device according to the weight percentage...

Embodiment 1

[0065] Prepare modified fluorocarbon powder coating sample powder 1-6 for aluminum surface according to the following steps:

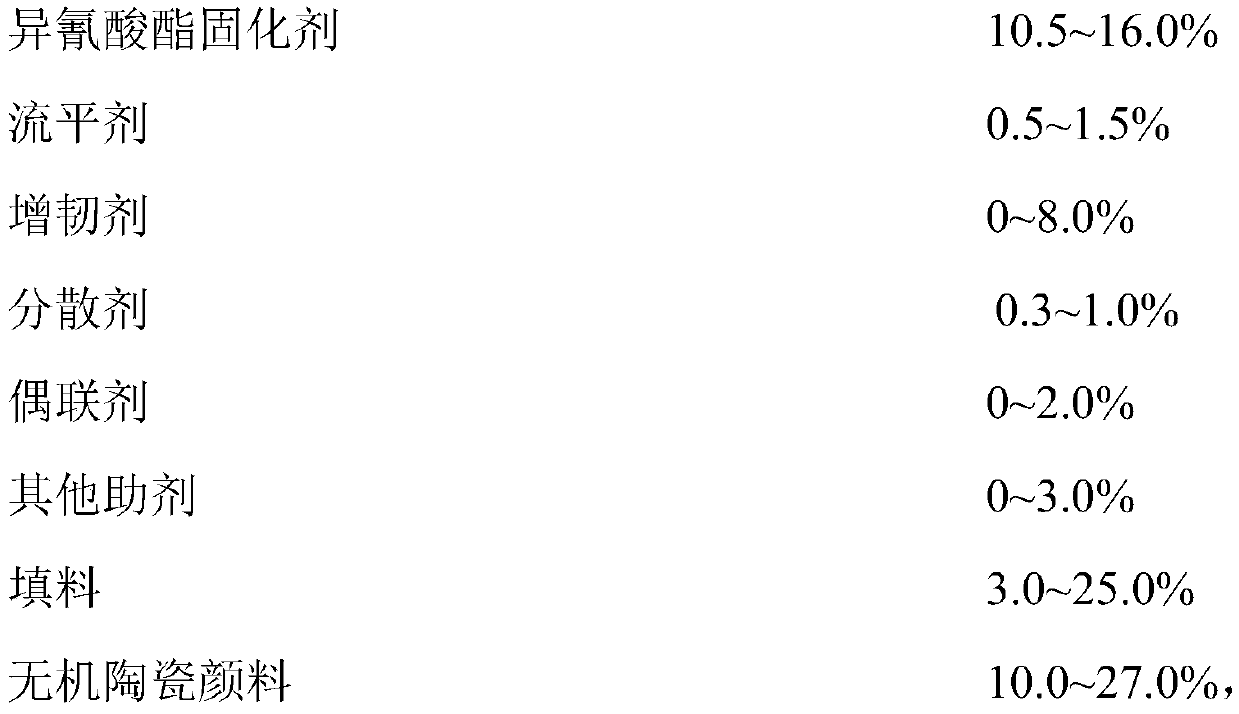

[0066] In the first step, pre-mix the raw materials of the following components A and B respectively according to the weight percentage,

[0067] A component name weight% Component B ingredient name weight% Thermosetting Fluorocarbon Resin 64.0 Acrylic 62.0 Isocyanate curing agent 16.0 Polycarboxylic acid (anhydride) 14.6 leveling agent 1.2 leveling agent 1.0 Toughener 0.3 Dispersing aid 0.3 Dispersant 0.3 Other additives 1.7 coupling agent 1.0 filler 8.4 Other additives 1.5 Inorganic Ceramic Pigments 12.0 filler 3.7 Inorganic Ceramic Pigments 12.0

[0068] In the second step, the pre-mixed component A and B raw materials are melted and mixed extruded with a twin-screw extruder, wherein the temperature of the extruder I zone is 110°C, and the temperatu...

Embodiment 2

[0074] Prepare modified fluorocarbon powder coating samples 7-9 according to the following steps:

[0075] In the first step, the raw materials in the following weight percentages are premixed,

[0076] Sample Powder Component Name Sample powder 7% by weight Sample powder 8% by weight Sample powder 9% by weight Thermosetting Fluorocarbon Resin 44.8 32.0 19.2 Isocyanate curing agent 11.2 8.0 4.8 Acrylic 19.4 32.4 45.4 Polycarboxylic acid (anhydride) 4.6 7.6 10.6 leveling agent 1.2 1.2 1.2 Toughener 0.3 0.3 0.3 Dispersant 0.3 0.3 0.3 coupling agent 1.0 1.0 1.0 Other additives 1.5 1.5 1.5 filler 3.7 3.7 3.7 Inorganic Ceramic Pigments 12.0 12.0 12.0

[0077] In the second step, the pre-mixed raw materials are melt-mixed and extruded with a twin-screw extruder. Zone I of the extruder is the melting and mixing section of the extruder, and zone II of the extruder is the feeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com