Complex metal oxide and its preparation process

A composite metal and oxide technology, applied in the field of electrochemistry, can solve the problems of poor particle uniformity and shape regularity, inability to be used as high-efficiency battery electrode materials, and unsatisfactory material conductivity, etc., to achieve a combination Strong and uniform, excellent electrochemical cycle performance, and good film processing behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

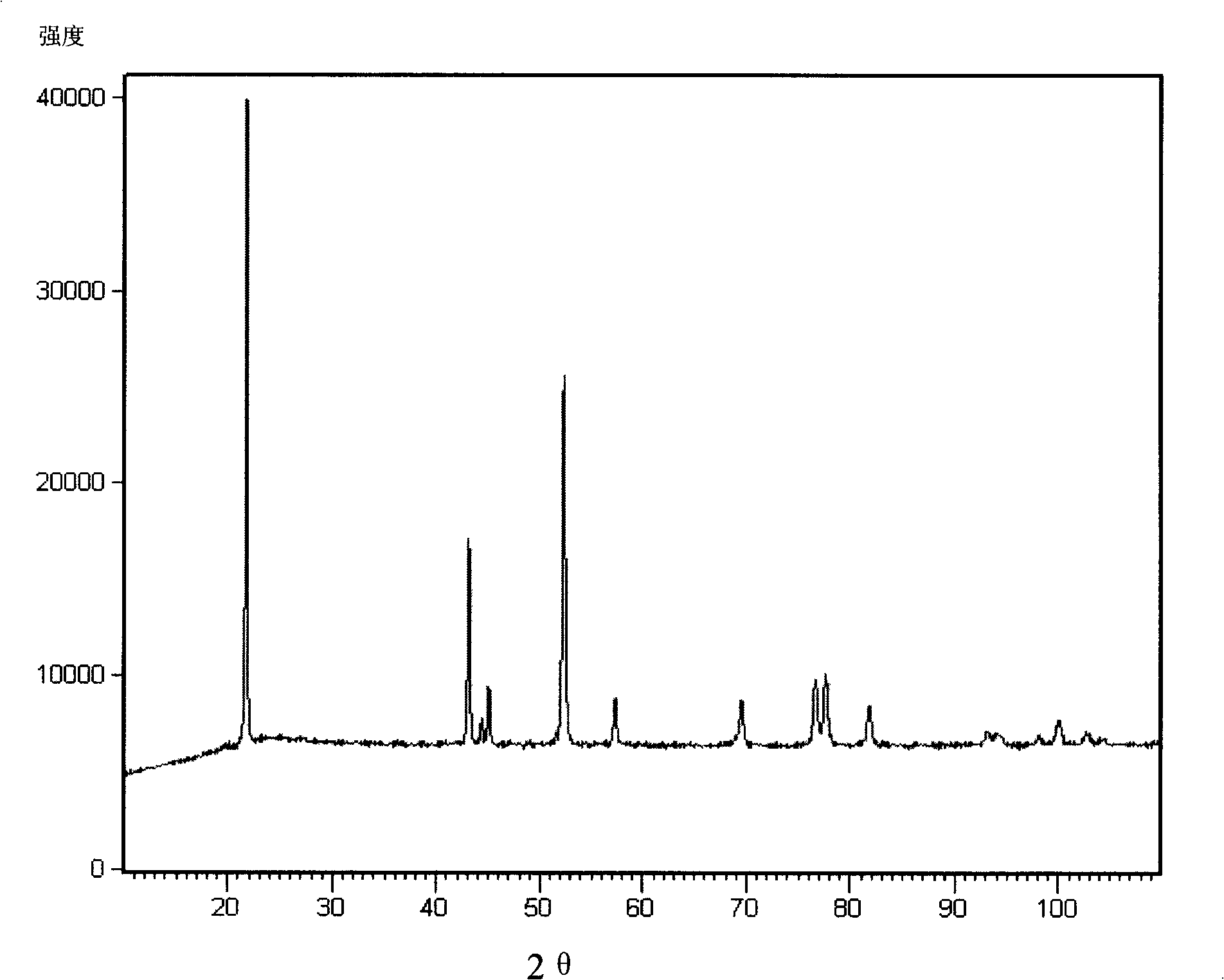

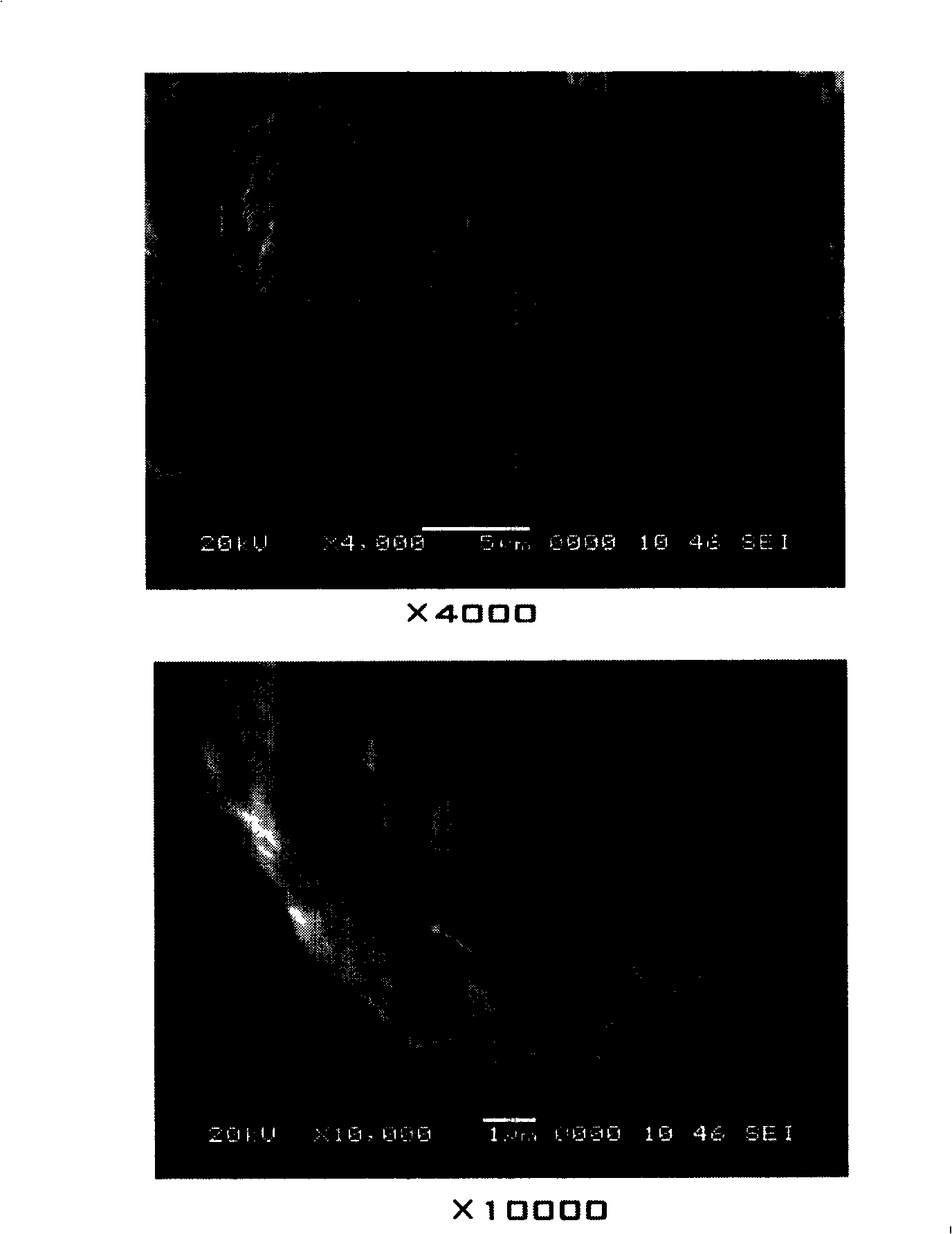

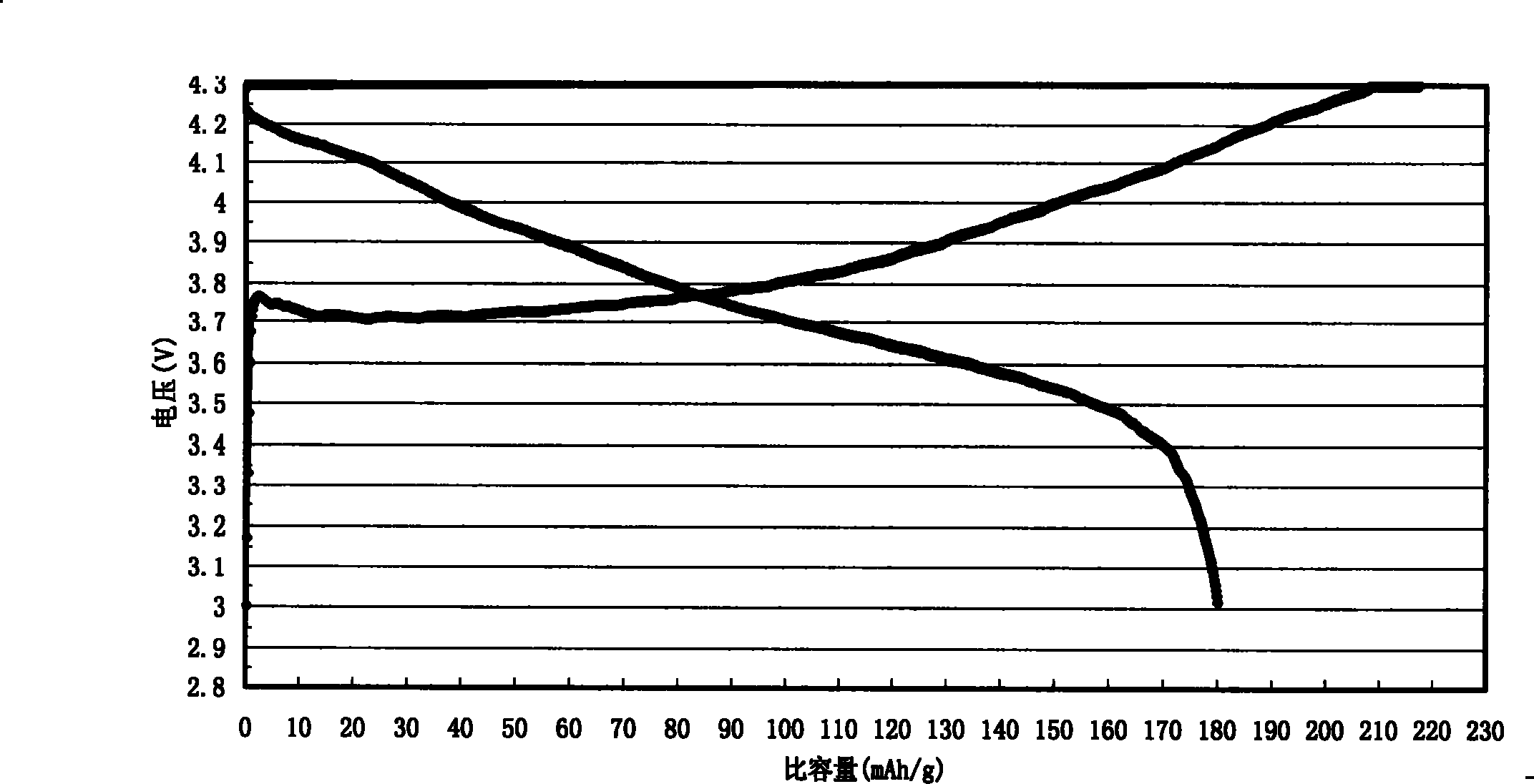

[0042] Take nickel (Ni), cobalt (Co) and manganese (Mn) sulfates at a molar ratio of 0.4:0.4:0.2 to make a 2M solution with 10 moles of nickel (Ni), cobalt (Co) and manganese (Mn) sulfate, and add water slowly under constant stirring. In a buffer solution with a pH value of 8, 10 L of nickel-cobalt-manganese-ammonia complex solution was prepared. Under the condition of constant stirring, slowly drop it and 10L, 4.4M NaOH aqueous solution into the reaction kettle filled with 7L aqueous solution and adjust its pH value to 11 with 4.4M pure NaOH solution, the reaction temperature is 40°C, and the stirring speed is 400rpm. After 6 hours, the Ni-Co-Mn composite hydroxide was isolated. After aging for 2 hours, it was washed several times with distilled water and then dried at 80°C for 16 hours. After grinding and sieving, the precursor was obtained, and its water content (by After determining the weighing weight of lithium hydroxide) and lithium hydroxide monohydrate (LiOH·H 2 O) ...

Embodiment 2

[0046] Take 5 moles of nickel (Ni), cobalt (Co) and magnesium (Mg) nitrates in a molar ratio of 0.5:0.3:0.2 and add water to form a 1M solution, and slowly add ammonia water and ammonium sulfate under constant stirring. In a buffer solution with a pH value of 10, 10L of nickel-cobalt-magnesium-ammonia complex solution was prepared. Under constant stirring, it was slowly dropped into 7L of aqueous solution with 2.2M pure NaOH at the same time. The solution was adjusted to a pH value of 11 in a reaction kettle, the reaction temperature was 50° C., and the stirring speed was 400 rpm. After 8 hours, the Ni-Co-Mg composite hydroxide was isolated. After aging for 2 hours, it was washed several times with distilled water and then dried at 80°C for 16 hours. After grinding and sieving, the precursor was obtained. Lithium carbonate is mixed and ground at a molar ratio of 1:0.55 and then placed in an intelligently controlled muffle furnace. In dry air, the temperature is raised to 320°C...

Embodiment 3

[0050] Take 8 moles of nickel (Ni), cobalt (Co) and manganese (Mn) carbonates at a molar ratio of 0.6:0.3:0.1 and add water to form a 1.5M solution, and slowly add ammonia water and sulfuric acid under constant stirring. In the buffer solution with a pH value of 8.5 prepared by amine, 10L of nickel-cobalt-manganese-ammonia complex solution was prepared. Under the condition of constant stirring, it was slowly dropped into 7L of aqueous solution with 3.3M NaOH solution at the same time. The pure NaOH solution is placed in a reaction kettle whose pH value is adjusted to 11.5, the reaction temperature is 55° C., and the stirring speed is 500 rpm. After 8 hours, the Ni-Co-Mn composite hydroxide was isolated. After aging for 2 hours, it was washed several times with distilled water and then dried at 80°C for 16 hours. After grinding and sieving, the precursor was obtained. Lithium acetate is mixed and ground at a molar ratio of 1:1.08 and then placed in an intelligently controlled m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com