Patents

Literature

73 results about "Mg composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst components in use for polymerizing ethylene, and catalyst

This invention relates to a method for preparing catalyst for ethylene homopolymerization or copolymerization with other alpha-olefins. The catalyst comprises at least one Mg composite, at least one Ti compound, at least one organic alcohol compound, and at least one Si compound. The general formula of the Si compound is R1xR2ySi (OR3) z, where R1 and R2 are alkyl or halogen; R3 is alkyl; x is 0-2; y is 0-2; z is 0-4; x + y + z = 4. The catalyst has such advantages as high catalytic activity, high hydrogen sensitivity and narrow particle size distribution of polymer. The catalyst is suitable for slurry polymerization of ethylene, and combined polymerization process where catalyst with high activity is needed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for nanoporous silicon

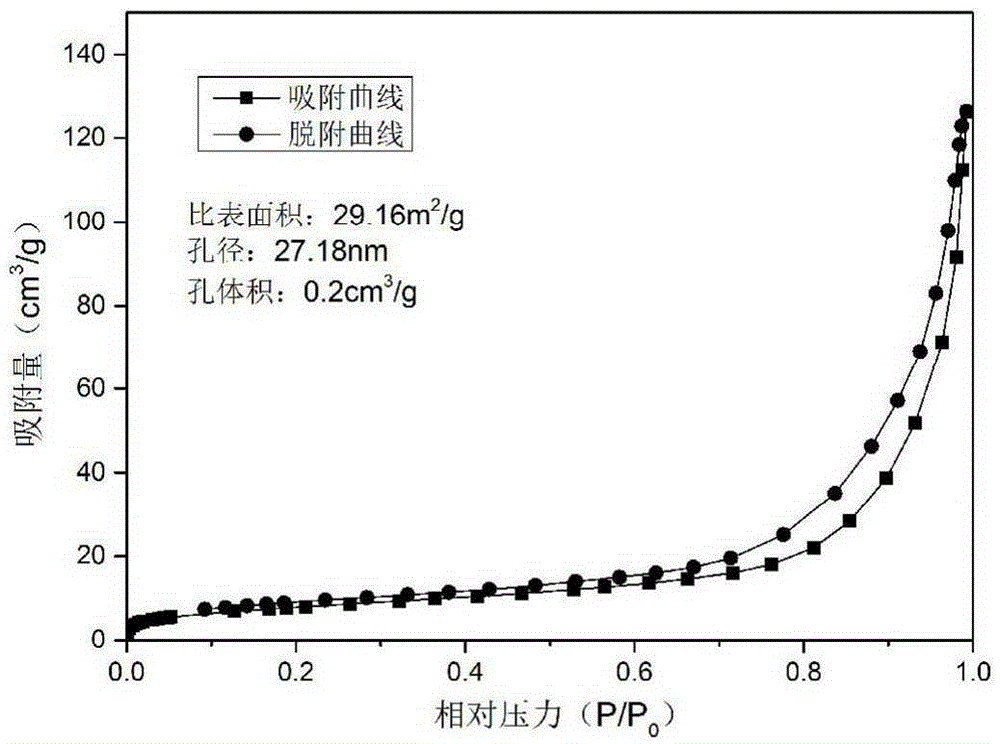

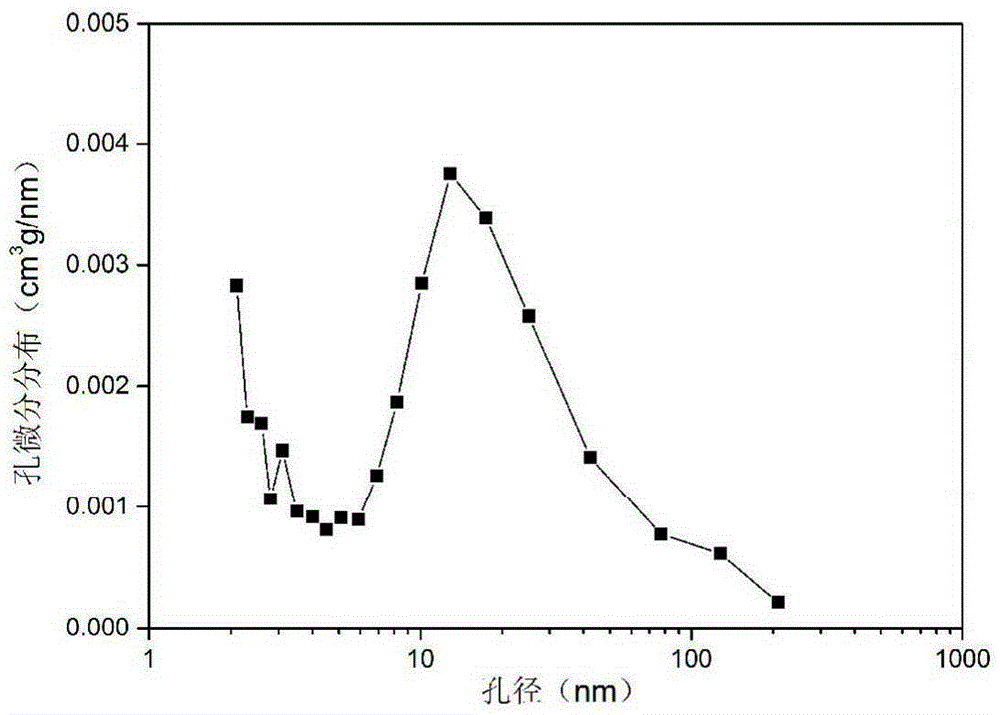

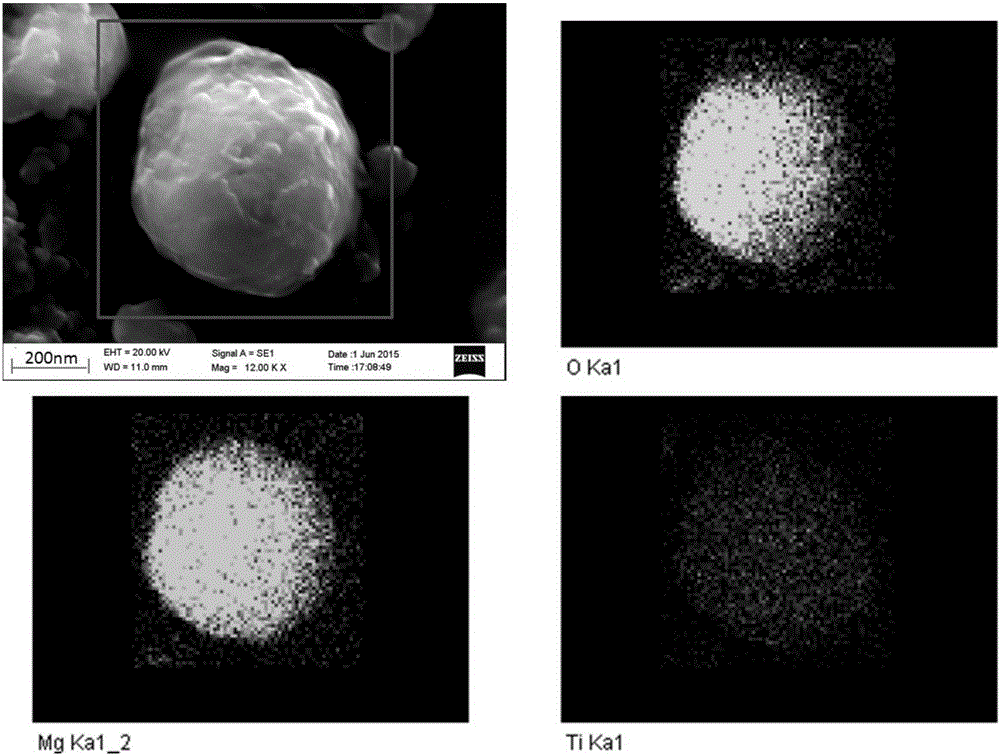

InactiveCN105399100ALarge specific surface areaUniform pore size distributionMaterial nanotechnologySilicon compoundsMg compositeCentrifugation

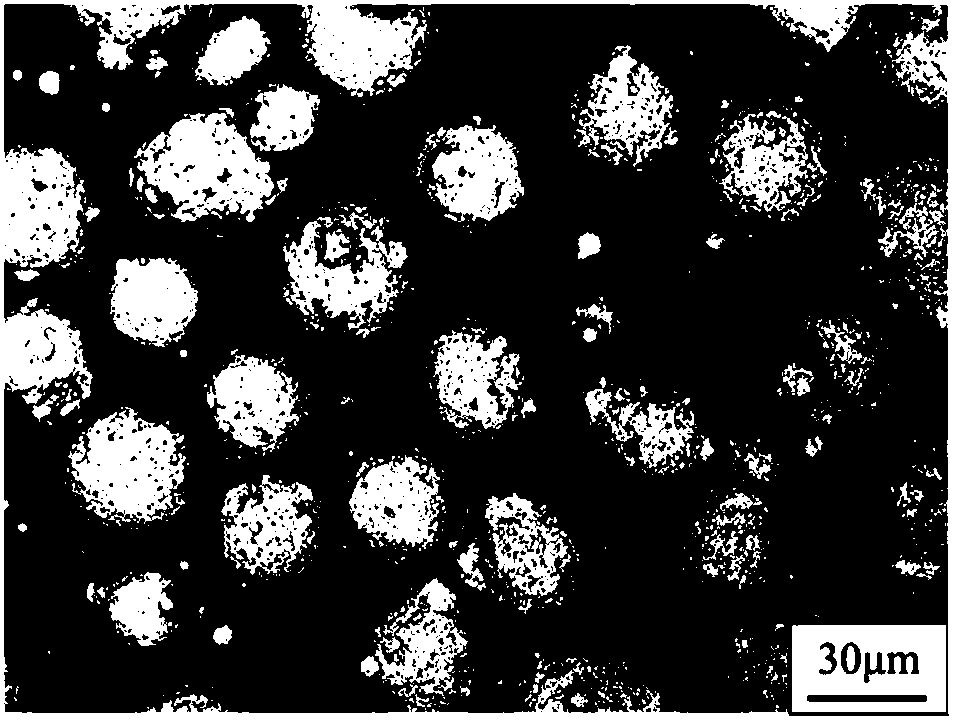

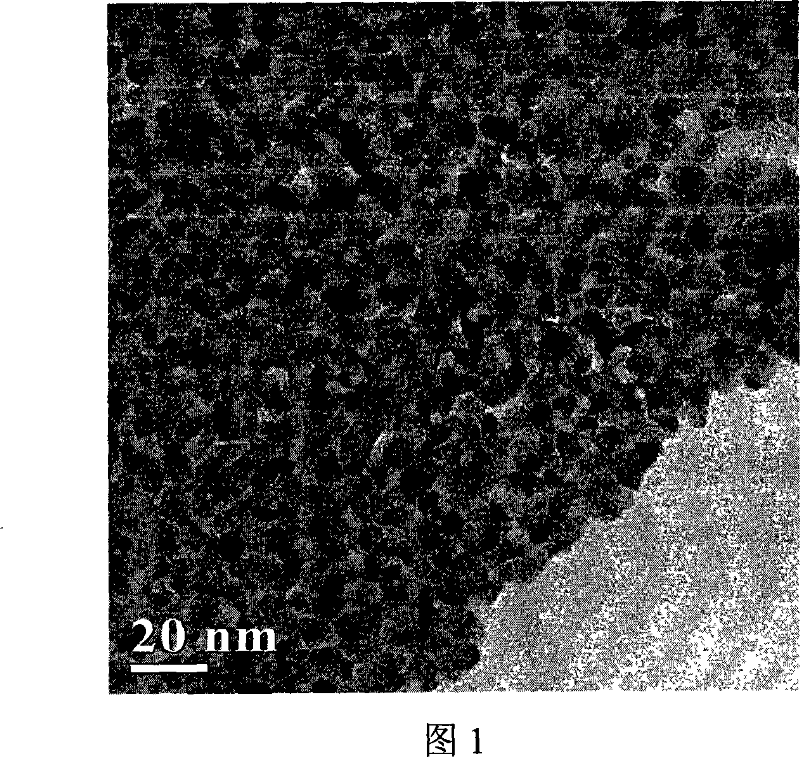

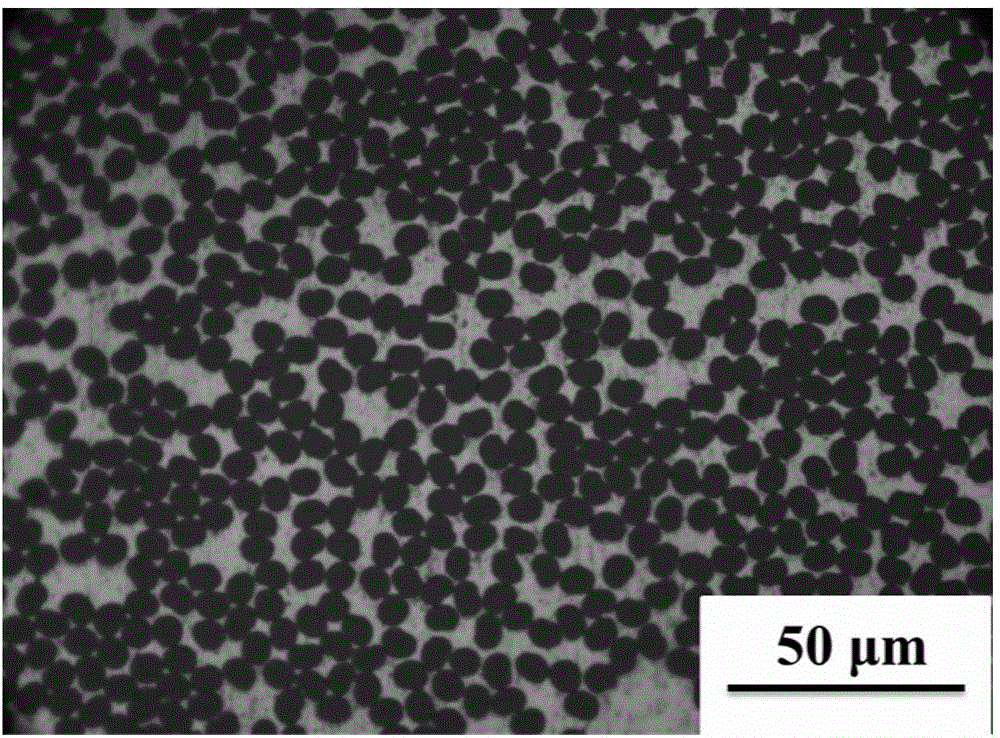

The invention provides a method for preparing nanoporous silicon with industrial silica powder as a raw material. Silica powder and magnesium powder are subjected to alloying treatment, a precursor Mg2Si / Mg composite material is prepared, then dealloying treatment is carried out, finally the prepared product is subjected to acid pickling, centrifugation and drying, and nanoporous silicon is prepared. The method can raise the utilization rate of industrial silica powder, achieves resource utilization of silica powder, raises the additional value of silica powder, and has characteristics of wide raw material sources, low cost and simple technology operation. The prepared nanoporous silicon has characteristics of uniform pore size distribution, large specific surface area and the like, and has wide application prospects.

Owner:SOUTHEAST UNIV

Method for smelting steel plate with excellent performance in high-heat-input-welding heat affected zone

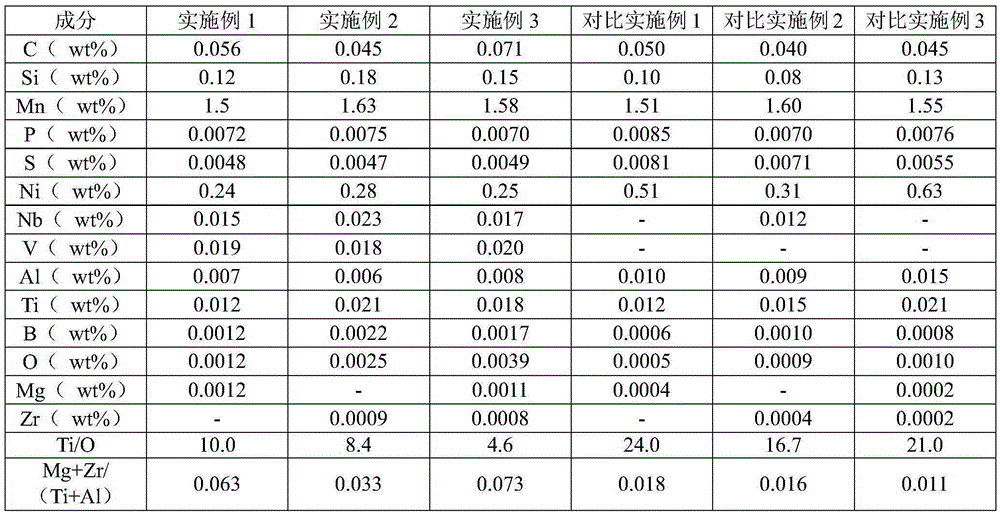

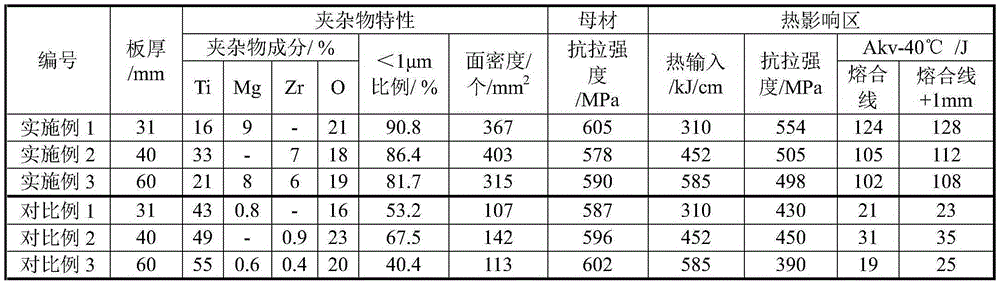

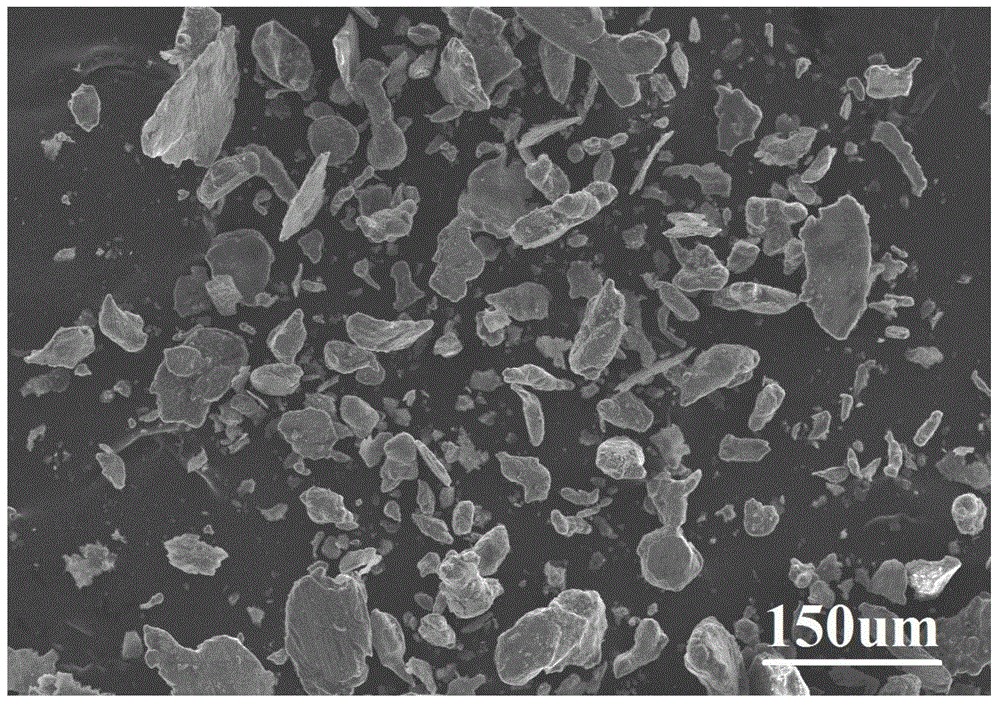

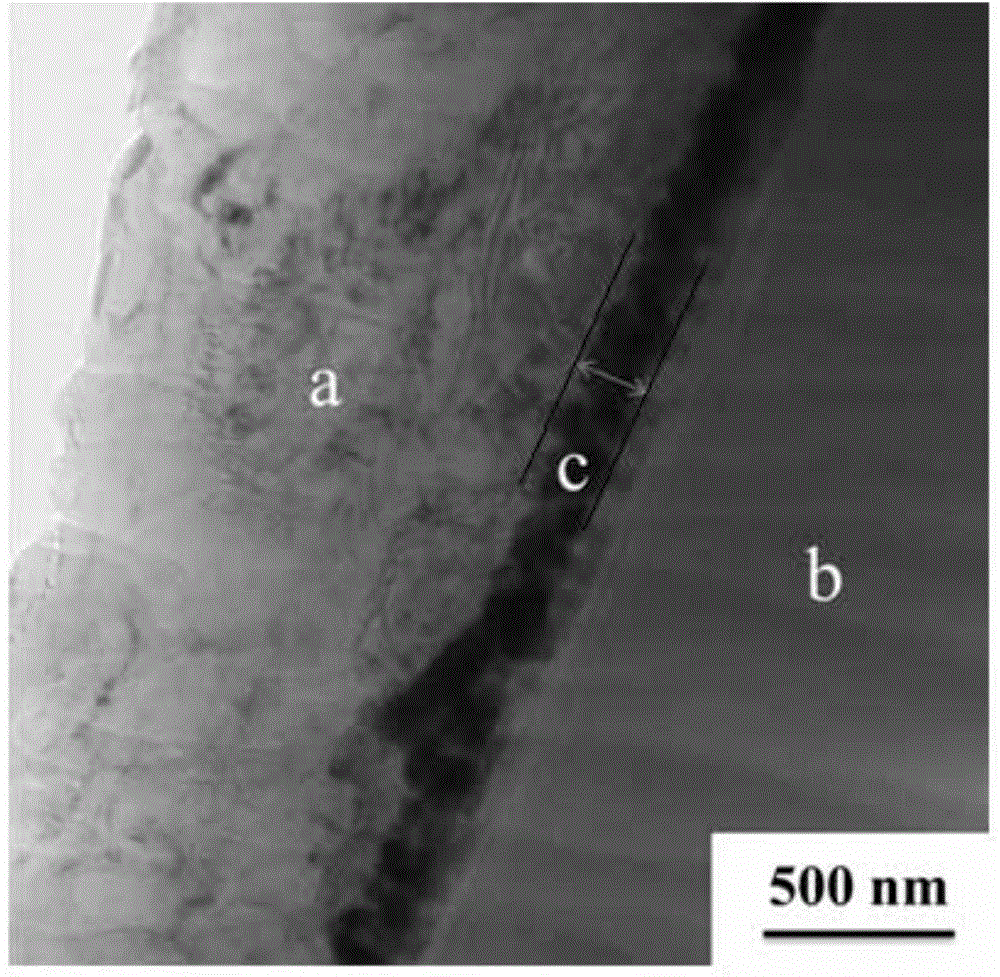

The invention discloses a method for smelting a steel plate with the excellent performance in a high-heat-input-welding heat affected zone. The method sequentially includes the steps of molten steel pretreatment, combined-blowing converter steelmaking, LF refining, RH vacuum refining, alloy cored wire feeding and continuous casting. According to the method, the content of oxygen in molten steel and the adding conditions of key alloy materials at key stations are controlled, the content of Ti, the content of O, the content of Mg and the content of Zr in the steel meet the design requirements accordingly and can meet the conditions that Ti / O is larger than 5 and smaller than 12, (Mg+Zr) / (Ti+Al) is larger than 0.02, and one or two kinds of a large quantity of Ti-Mg composite-oxide inclusions, a large quantity of Ti-Zr composite-oxide inclusions and a large quantity of Ti-Mg-Zr composite-oxide inclusions with the size smaller than 1 micron are contained in the steel accordingly; in addition, the mass percents of chemical compositions of the inclusions meet the conditions that the mass percent of Ti is larger than 2% and smaller than 40%, the mass percent of Mg is larger than 2% and smaller than 30%, the mass percent of Zr is larger than 2% and smaller than 30%, and the mass percent of O is larger than 5% and smaller than 50%; and the areal density is larger than 300 per mm<2>. Due to the inclusions, growth of austenite crystal grains of the welding heat affected zone can be effectively pinned; and meanwhile nucleus forming of needle-shaped ferrite in the grains is promoted, and therefore the excellent performance in the high-heat-input-welding heat affected zone is guaranteed.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for in-situ preparation of TiBO2 reinforced magnesium-based composite material

The invention relates to a method of in-situ preparing TiB2 granule strengthening Mg-based composite material in the composite material technical field. The steps are that: powder of K2TiF6, KBF4 and Na3AlF6 are mixed uniformly and then put into a kiln for drying, thus obtaining waterless powder. Aluminum ingot is melted in a resistance furnace with heat preservation and uniformity; the waterless powder after dried is added to the melting Al melt liquid by batch and then is stirred with a graphite disc, and scum on the surface of the melt liquid is removed after stirred and stewed, thus obtaining TiB2-Al intermediate alloy; magnesium alloy is smelted with the protection of SF6 and CO2 mixing gas, and flame retardant element beryllium is added; the TiB2-Al intermediate alloy is added into the magnesium alloy melting solution slowly, stirred, stewed and cast. The technology of the invention is comparatively simple, has low cost, and the density of TiB2 / Mg composite material is between 1.8-2.0g / cm<3> and tensile strength thereof is increased by more than 60 percent than base alloy.

Owner:SHANGHAI JIAO TONG UNIV

Degradable lamellar Zn-Mg composite material and preparation method thereof

ActiveCN108237214AGood biocompatibilityPromote degradationSurgeryMetallic material coating processesMg compositeMaterial Design

The invention discloses a degradable lamellar Zn-Mg composite material and a preparation method thereof. The outer layer of a lamellar medical metal composite material is made of pure zinc or zinc alloy, and the core part of the lamellar medical metal composite material is made of pure magnesium or magnesium alloy; the ratio of zinc or zinc alloy and magnesium or magnesium alloy is calculated according to volume percentage, zinc or zinc alloy accounts for 20%-50% of the total volume of the material, and the balance is magnesium or magnesium alloy. The lamellar composite material is prepared bycombining layered casting with nested extruding. The degradable lamellar Zn-Mg composite material has the advantages that: the selected magnesium alloy and the selected zinc alloy have good biocompatibility and degradability; mechanical properties and a degradation rate of the integral composite material are controlled by controlling a relative thickness of a Zn layer to a Mg layer, so that the composite material adapts to a service environment, and therefore, a condition that single metal is too quick or too slow in degradation is solved. The material design and the preparation method are simple and convenient, and the cost is low, so that industrial production is facilitated.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

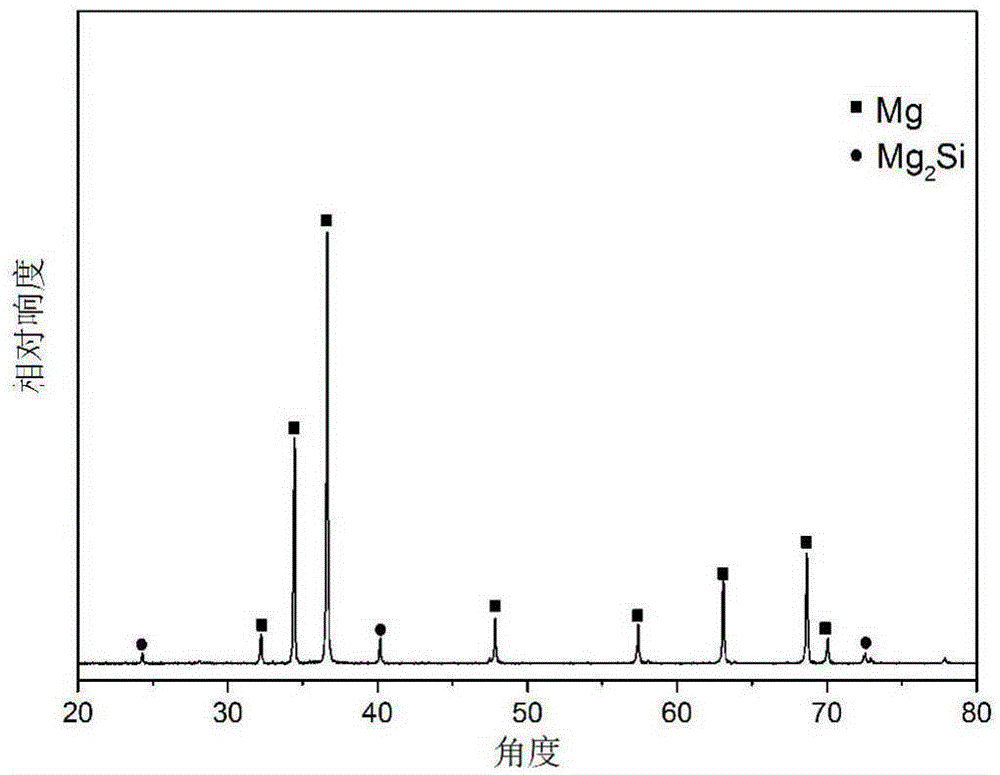

Method for preparing Mg2Si/Mg composites by recovered silicon powder

The invention relates to a method for preparing Mg2Si / Mg composites by recovered silicon powder, which is characterized by including steps of drying a crucible required by experiment into a drying oven, adding magnesium alloy into a pit furnace for heating, injecting SF6+CO2 mixed protection gas and heating to the temperature ranging from 750 DEG C to 1100 DEG C for 1 to 3 hours until the magnesium alloy is melted; adding industrial dust silicon powder with 70% to 75% of silicon dioxide into water, adding the silicon powder, which is 2.5-7.5wt% of the magnesium alloy and wrapped by aluminum foil, into the magnesium alloy melt, ; mixing so that the magnesium alloy and the silicon powder can be reacted sufficiently; modifying, cooling naturally, then pouring the melt to a preheated metal mold with the preheating temperature ranging from 100 DEG C to 400 DEG C. During the integral mixing and casting process, protection gas must be injected continuously, and accordingly the Mg2Si / Mg composites are prepared. The industrial dust silicon powder is used as a silicon source and in-situ chemical reaction of the magnesium and the silicon powder is realized by means of mixing and casting. Themethod for preparing Mg2Si / Mg composites is simple in process and low in preparation cost, and the prepared Mg2Si / Mg composites are excellent in performances.

Owner:INNER MONGOLIA 52 SPECIAL MATERIAL ENG TECH RES CENT

In-situ synthesized spinel whisker reinforced aluminum-based composite foam and preparation method thereof

The invention relates to a method for preparing spinel whisker reinforced aluminum-based composite foam by in-situ synthesis. The method comprises the following steps of preparing Al-Mg powder according to the mass ratio of 7.4-16 to 1; dropping PVA (Polyvinyl Alcohol) solution with the mass fraction of 3 to 5 percent into the Al-Mg powder according to the mass-to-volume ratio of 13-14g to 1-2ml, grinding the mixture and drying the mixture under the air condition to obtain composite powder, then uniformly mixing the composite powder and NaCl particles according to the mass ratio of 0.29 to 1.16 and pressing the mixture at room temperature and the pressure of 300 to 400MPa into bulk materials; raising the temperature of the bulk materials to be 600 to 800DEG C at the temperature rise rate of 5 to 10DEG C / Min under the atmosphere of argon gases, sintering the bulk materials at the above temperature for 1 to 4 hours and then cooling the sintered materials along with the furnace to obtain an Al-Mg composite material bulk; cleaning the Al-Mg composite material bulk. The method disclosed by the invention has the advantages that the process of preparing foamed aluminium is simple and controllable, and the porosity is adjustable.

Owner:TIANJIN UNIV

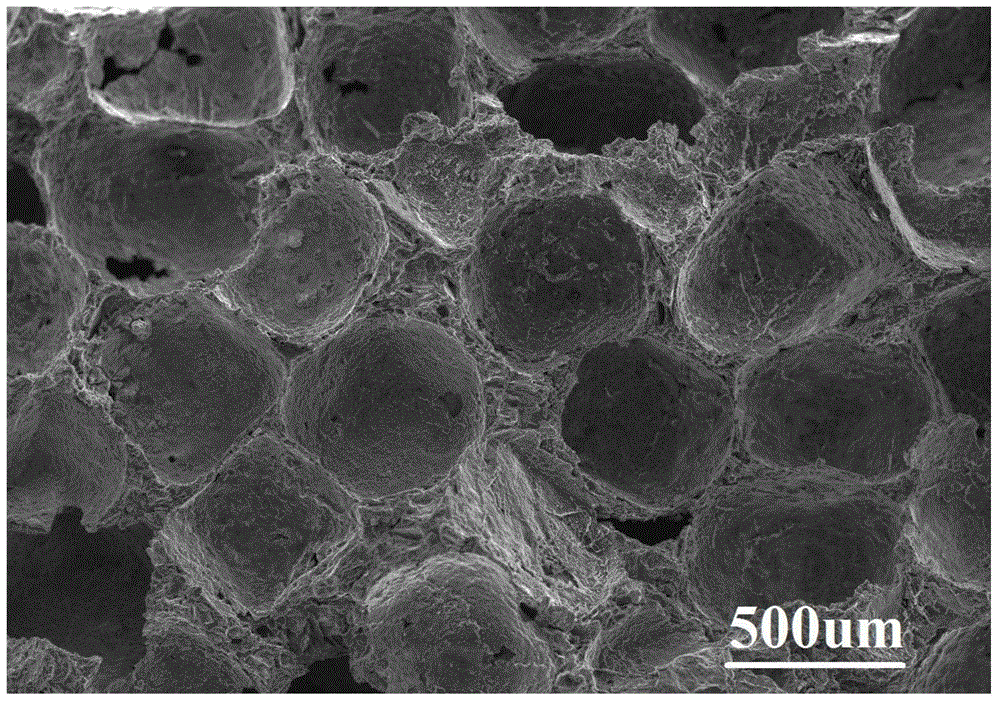

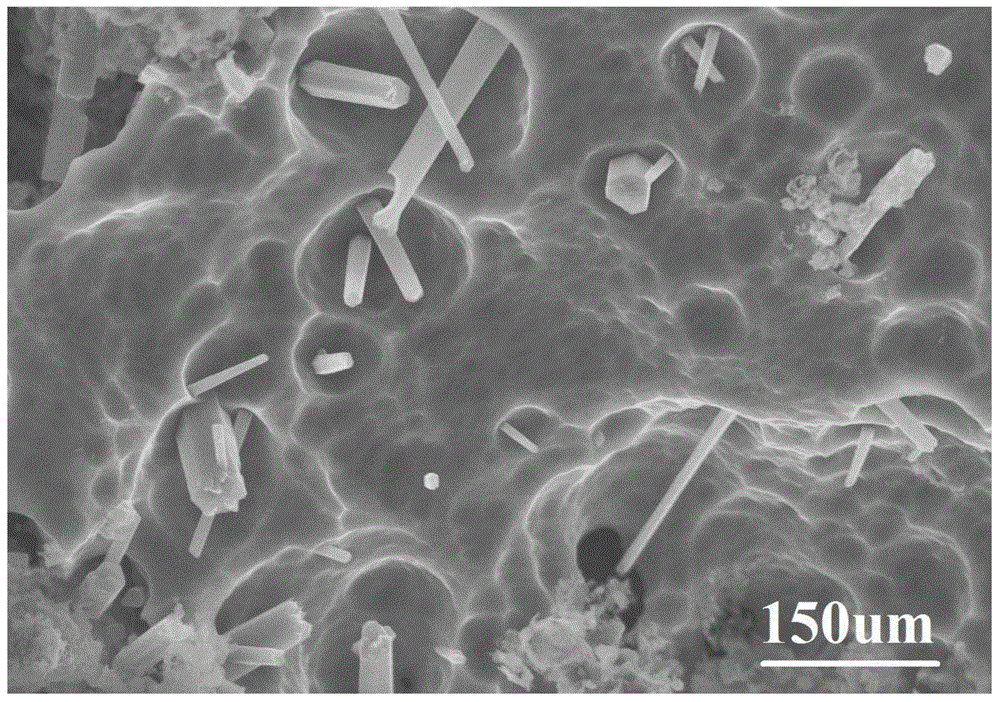

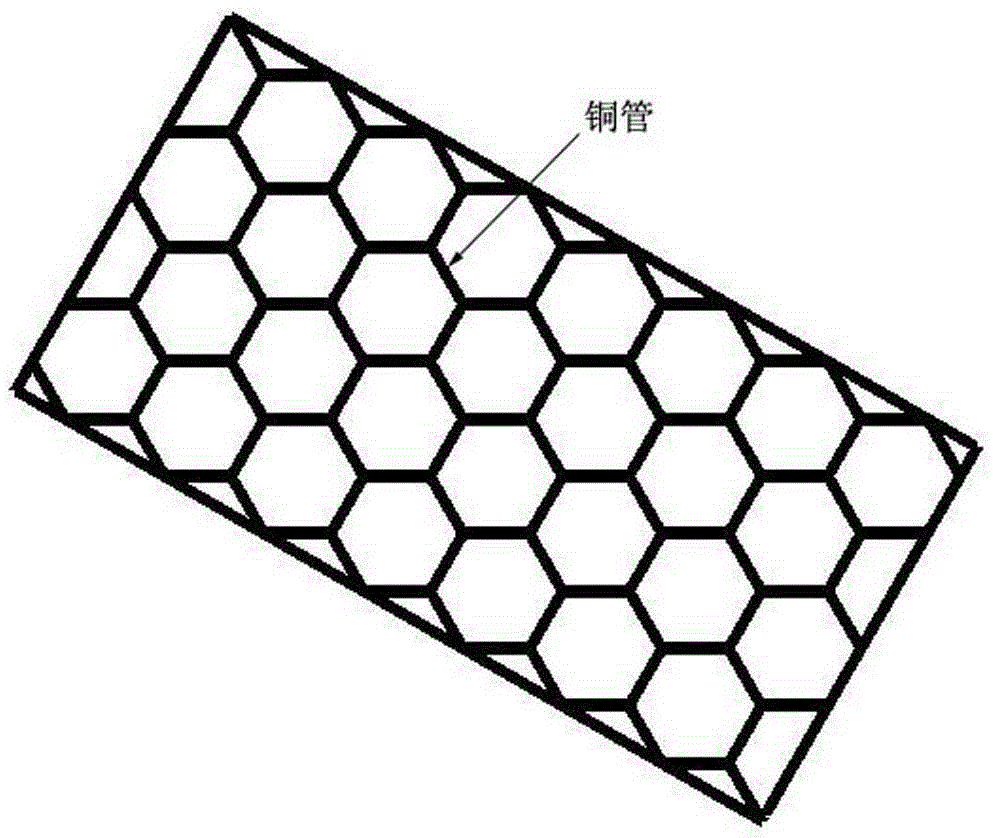

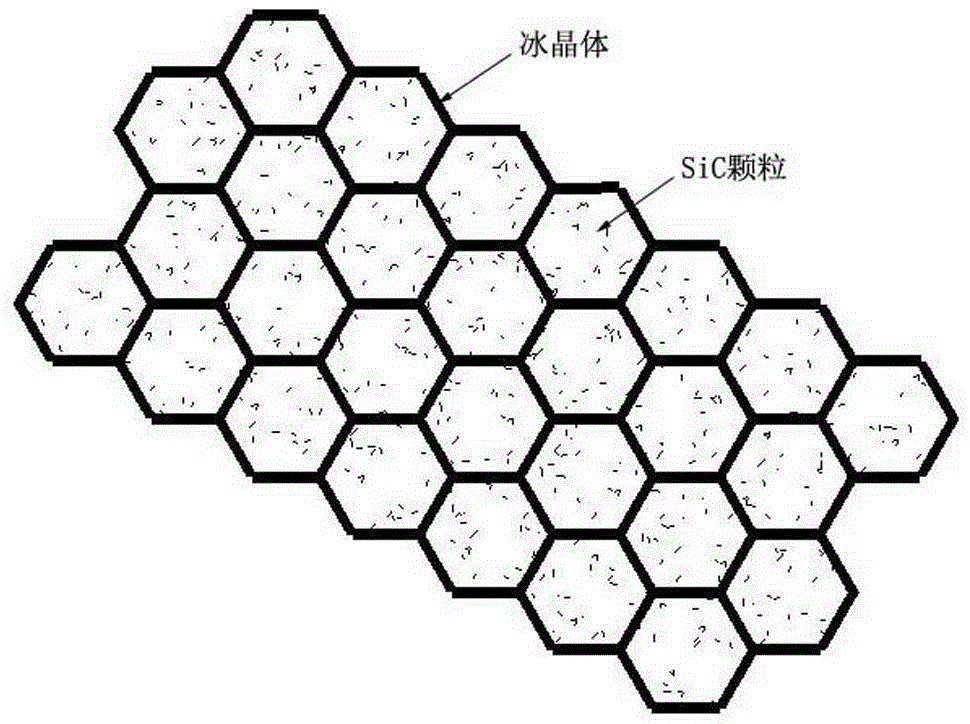

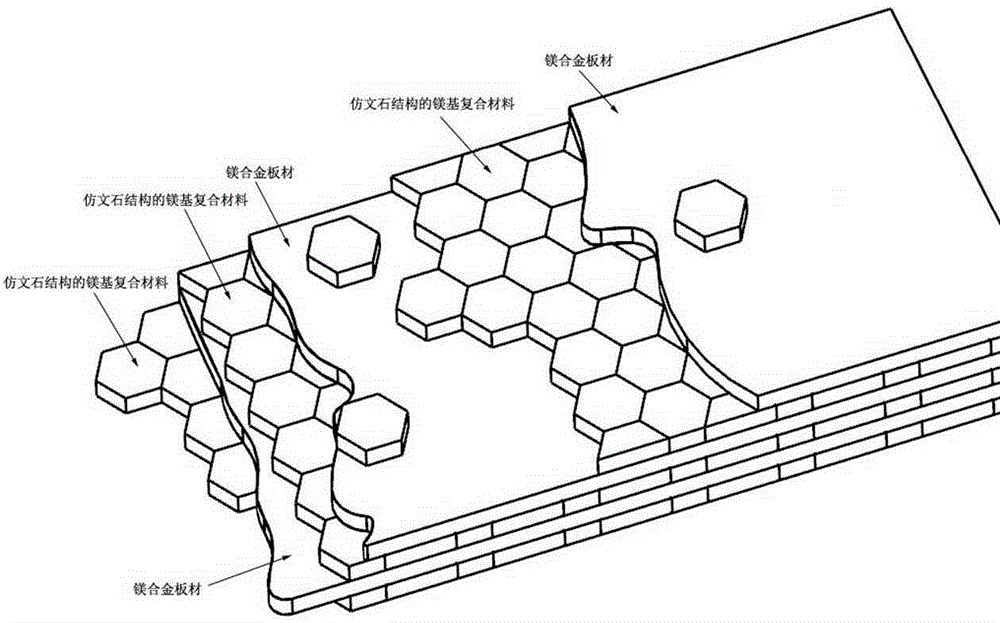

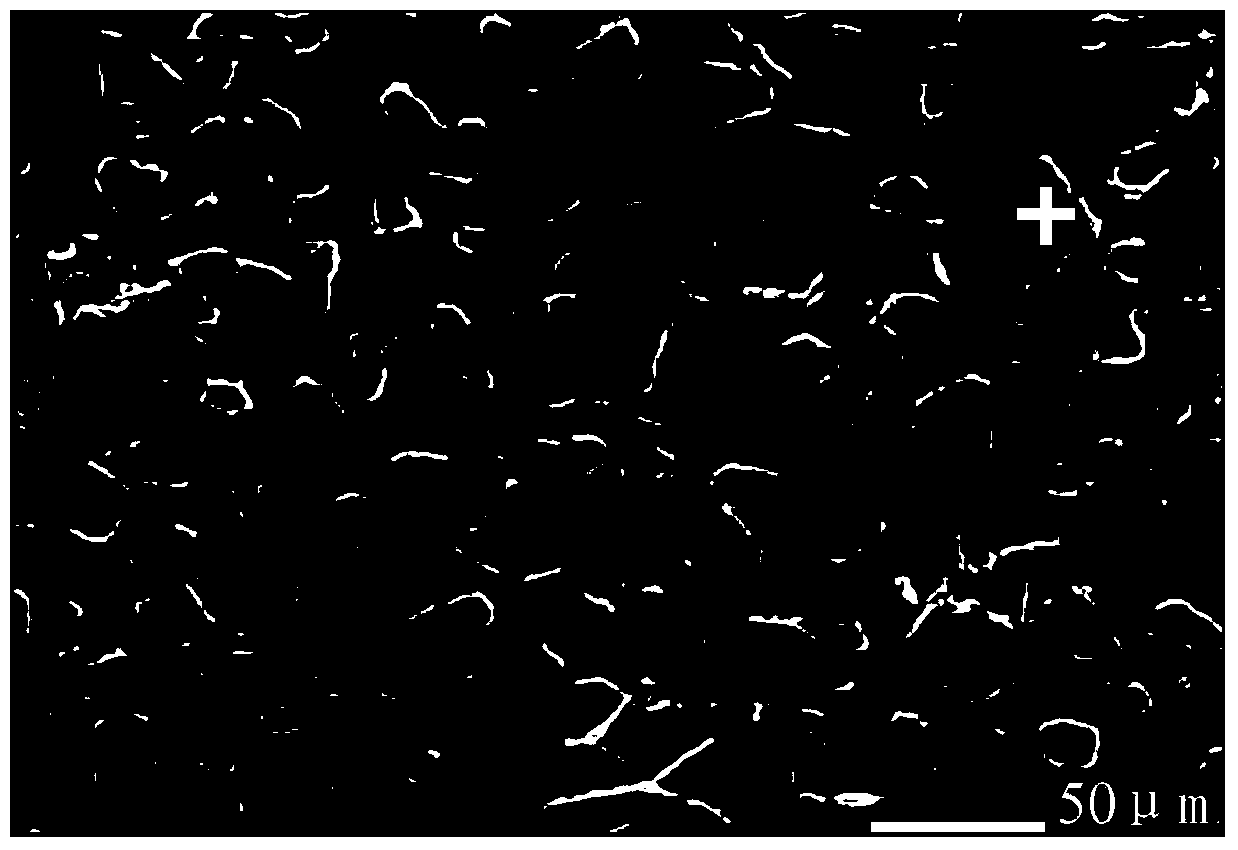

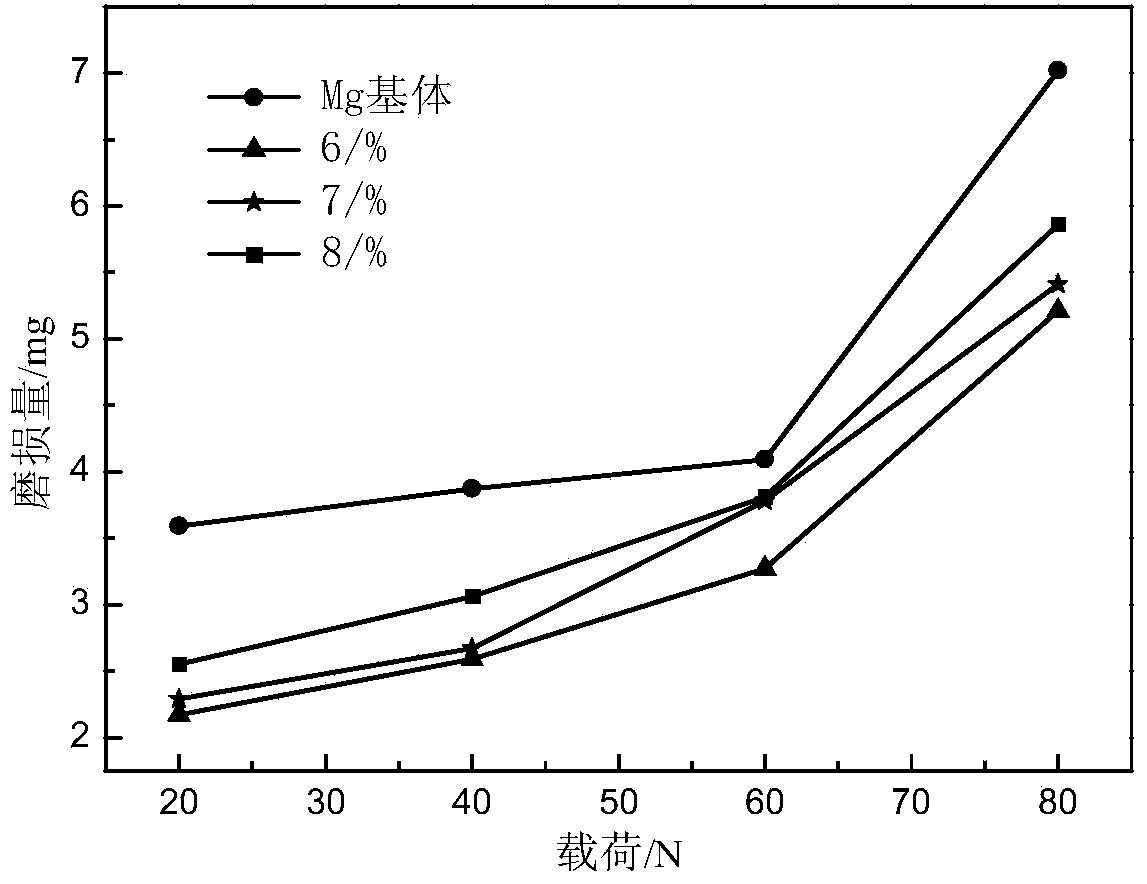

Preparation method for shell-nacreous-layer-imitating magnesium-based composite material

The invention discloses a preparation method for a shell-nacreous-layer-imitating magnesium-based composite material. A SiC particle reinforced magnesium-based composite material of a distinct shell-nacreous-layer structure can be prepared through the preparation method. A shell-nacreous-layer microstructure serves as a model, and a directional freeze thawing ice template method and a laminated hot pressing technique are adopted for preparing a biomimetic SiCp / Mg composite material with distinct shell-nacreous-layer microstructure characteristics and a controllable organizational structure. According to the novel preparation technique for biomimetic metal-based composite materials, the route is unique and the production efficiency is high. Compared with traditional magnesium-based composite materials, the prepared magnesium-based composite material of the shell-nacreous-layer-imitating structure not only has good mechanical properties such as high specific strength, high specific stiffness, good abrasion resistance, but also has good toughness and plasticity.

Owner:ZHONGBEI UNIV

Zn-Al-Mg composite anticorrosive coating and manufacturing method thereof for cast-iron pipelines

ActiveCN103375658AWide range of ingredientsMeet diversityMolten spray coatingCorrosion preventionPorosityMg composite

The invention discloses a Zn-Al-Mg composite anticorrosive coating and a manufacturing method thereof for cast-iron pipelines and relates to the technical field of corrosion prevention technology for metal materials. The Zn-Al-Mg composite anticorrosive coating comprises a Zn-Al-Mg alloy or Zn-Al-Mg pseudo alloy, and is characterized in that the Zn-Al-Mg alloy comprises, by weight, 90-97% of Zn, 2.0-9.5% of Al, 0.2-2.0% of Mg; the Zn-Al-Mg pseudo alloy comprises, by weight, 50-70% of Zn, 28-50% of Al and 1.5-5.0% of Mg; the Zn-Al-Mg alloy or Zn-Al-Mg pseudo alloy is prepared by electric arc spraying. The Zn-Al-Mg is mainly used for corrosion prevention for outer surfaces of the cast-iron pipelines and / or pipe fittings. The anticorrosive coating has advantages of high adhesion, low porosity, excellent corrosion resistance and low cost; the manufacturing method is simple, easy to operate and wide in material sources; therefore, economical benefit is good.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Catalyst components in use for polymerizing ethylene, and catalyst

This invention relates to components and preparation method for a composite carrier catalyst for ethylene homopolymerization or copolymerization with other alpha-olefins. The catalyst comprises at least one Mg composite, at least one Ti compound, at least one organic alcohol compound, at least one Si compound, and at least one inorganic inert carrier. The Mg composite is prepared by dissolving Mg compound in organic epoxy compound and organic phosphorus compound system. The catalyst has such advantages as high catalytic activity, high hydrogen sensitivity and narrow particle size distribution of polymer. The catalyst is suitable for slurry polymerization of ethylene, combined polymerization process where catalyst with high activity and good particle morphology is needed, and gas phase fluidized bed process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ceramic particle enhanced magnesium-based composite material and preparation method thereof

A method for preparing a magnesium-based composite material through a metal melt pressureless infiltration ceramic precast block is a preparation method which is low in cost, rapid and high-efficiency and realizes final forming. Because the wettability between ceramics and a metal system is low, the infiltration process is difficultly performed even cannot be performed. The invention provides a ceramic particle enhanced magnesium-based composite material and a preparation method thereof aiming at the problems. A small amount of the third-phase component metal Ti which has high melting point and is immiscible with a magnesium melt is added into the ceramic precast block to serve as a magnesium melt infiltration inducer, the wettability of a B4C / Mg composite material system is effectively improved, and a B4C / Mg series ultra-light wear-resistant ceramic particle enhanced magnesium-based composite material is prepared. The method comprises the following steps: mechanically and uniformly mixing B4C powder, Ti powder and an adhesive, performing cold pressing to prepare a ceramic precast block, putting the ceramic precast block and a pure magnesium ingot into an electric furnace for heating, melting the pure magnesium ingot, infiltrating the magnesium ingot into pores of the ceramic precast block, and preparing the ceramic particle enhanced magnesium-based composite material.

Owner:NORTHEASTERN UNIV

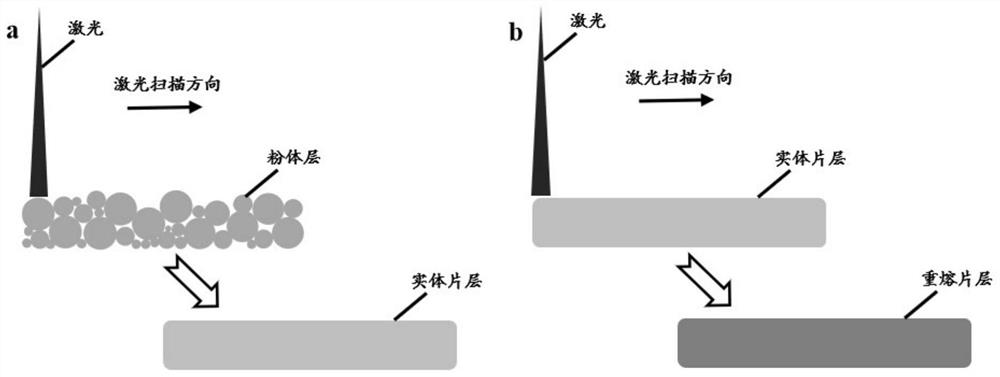

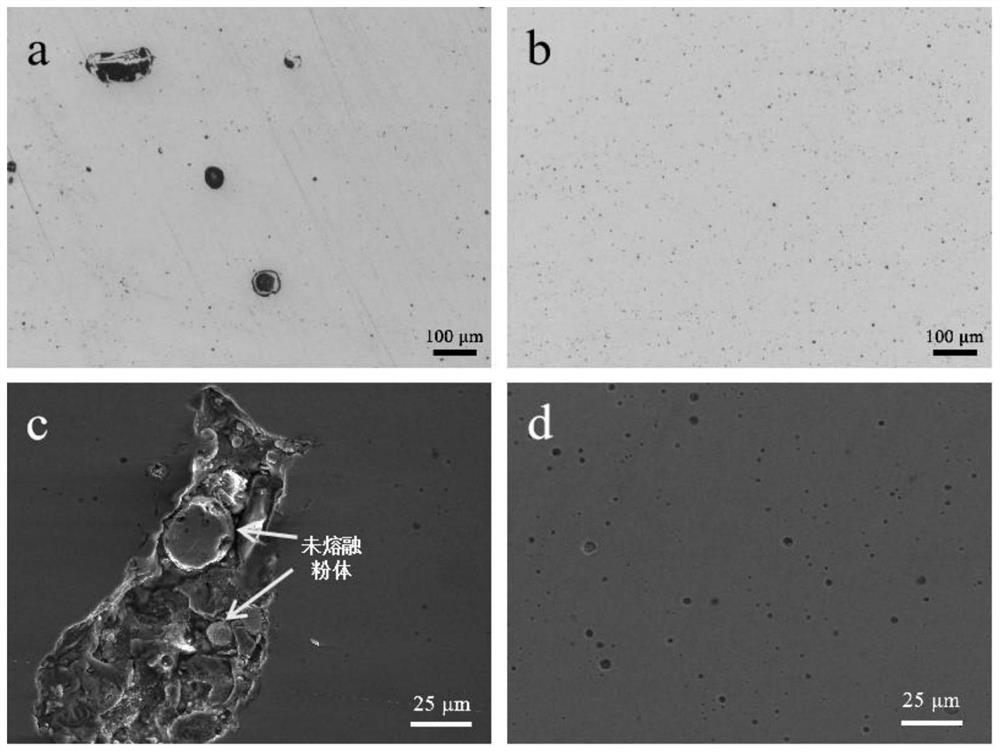

Method for preparing in-situ self-generated TiB2 reinforced composite material based on SLM

ActiveCN107937762AMicrostructure refinementGuaranteed plasticityAdditive manufacturing apparatusMg compositeUltimate tensile strength

The invention provides a method for preparing an in-situ self-generated TiB2 reinforced composite material based on SLM. The method comprises the following steps of A1, taking KBF4 and K2TiF6 powdersas raw materials, and using a mixed salt reaction method for preparing the in-situ self-generated TiB2 nano-particle reinforced Al7SiCu 0.5Mg composite material; A2, carrying out vacuum atomization onthe composite material obtained in the step A1 to obtain a composite material powder; and A3, carrying out 3D printing on the composite material powder to obtain a SLM sample. According to the methodfor preparing the in-situ self-generated TiB2 reinforced composite material, the SLM is adopted to prepare the in-situ self-generated TiB2 nano-particle reinforced Al7SiCu 0.5Mg composite material, the microstructure of the composite material is greatly refined, and obvious holes or cracks are not observed in the composite material; and moreover, the strength is greatly improved on the premise that the plasticity is guaranteed, and huge application potential is obtained in the aerospace field.

Owner:SHANGHAI JIAO TONG UNIV

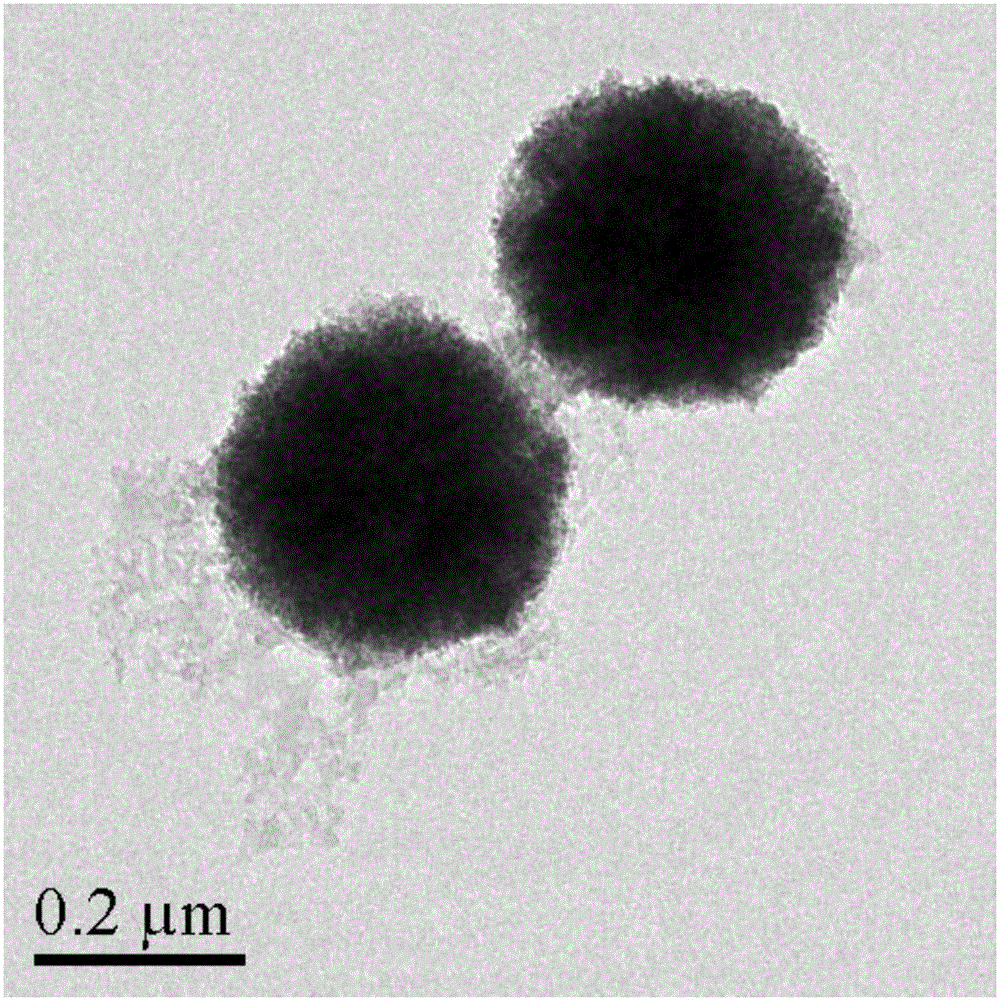

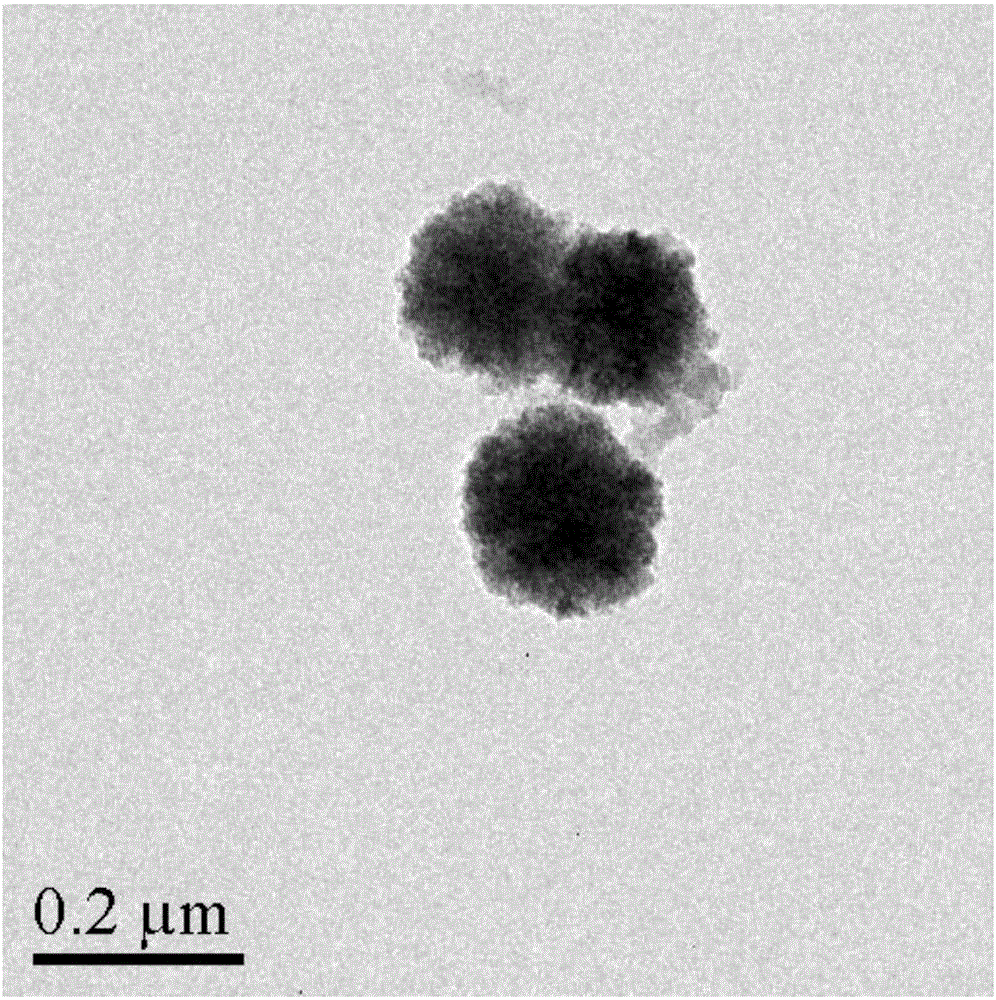

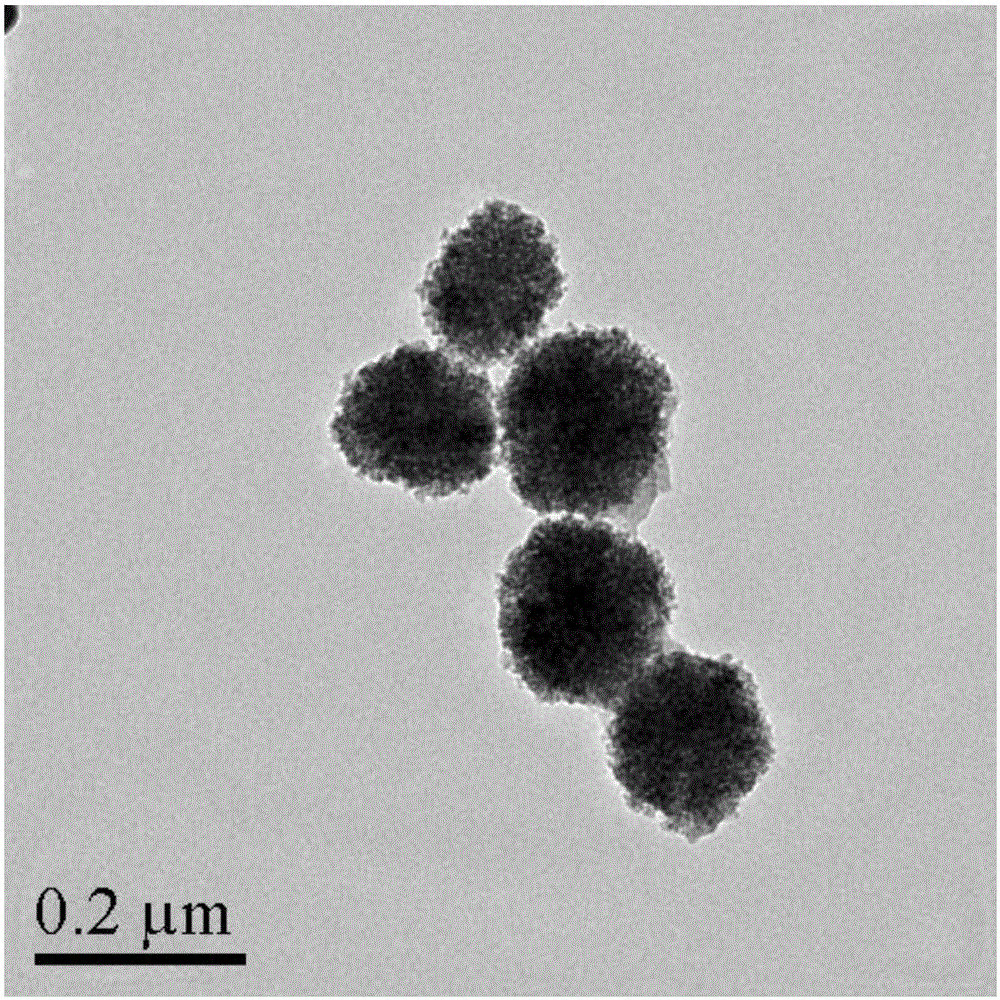

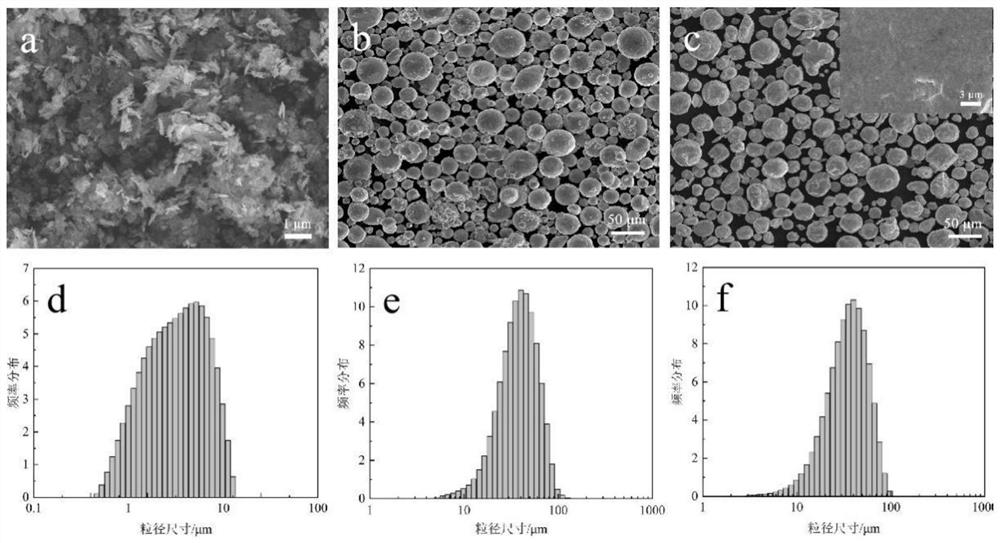

Composite magnetic nanoparticles Fe3O4/MPS/PAA/NTA-Ni<2+> and preparation method and application thereof in separation and purification of histidine-tagged proteins

InactiveCN105837766AStrong magnetismImprove stabilityPeptide preparation methodsMg compositeMagnetite Nanoparticles

The invention relates to composite magnetic nanoparticles Fe3O4 / MPS / PAA / NTA-Ni<2+> and a preparation method and an application thereof in separation and purification of histidine-tagged proteins, and belongs to the technical fields of nano magnetic materials and biological analysis. Fe3O4 magnetic nanoparticles with an average hydration particle size of 100-400 nm are used as a core, MPS surface modification is adopted for making the surface rich in double bonds, polycarboxyl-structure magnetic nanoparticles with an average hydration particle size of 100-600 nm are obtained through PAA coating, and then furthermore, the polycarboxyl-structure magnetic nanoparticles are coupled with NTA-Ni<2+> to obtain the composite magnetic nanoparticles Fe3O4 / MPS / PAA / NTA-Ni<2+> having fast magnetic field response. The prepared composite magnetic nanoparticles enable the thickness of a coating layer to be controlled in nanometer scale; the prepared composite magnetic nanoparticles have the advantages of uniform size distribution, strong magnetic and low cost, have higher ability of enrichment and separation purification of the histidine-tagged proteins, and have the purification efficiency of the histidine-tagged proteins as high as 40-70 [mu]g / mg composite magnetic nanoparticles; and the composite magnetic nanoparticles can be repeatedly used.

Owner:HUBEI UNIV OF TECH

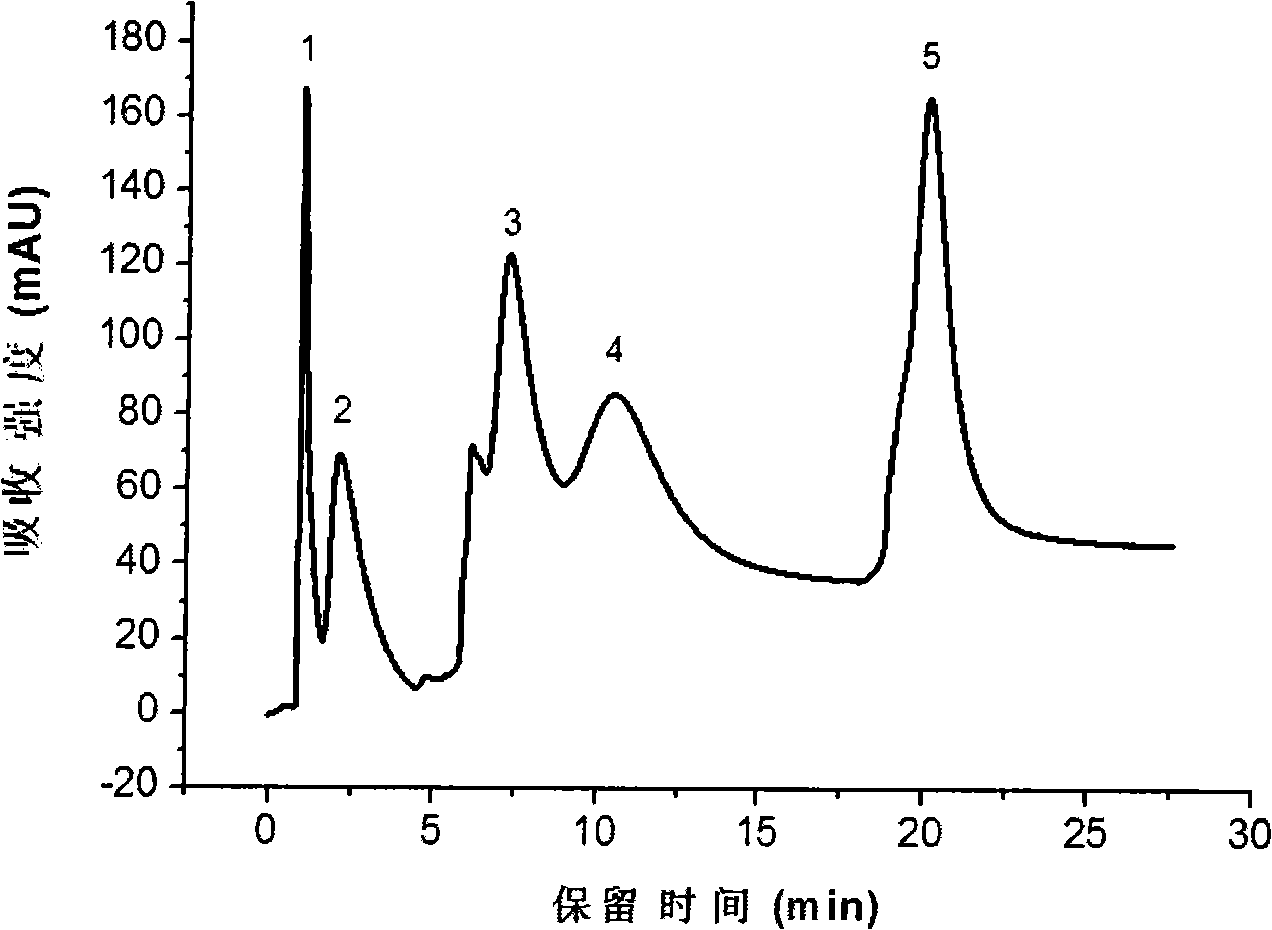

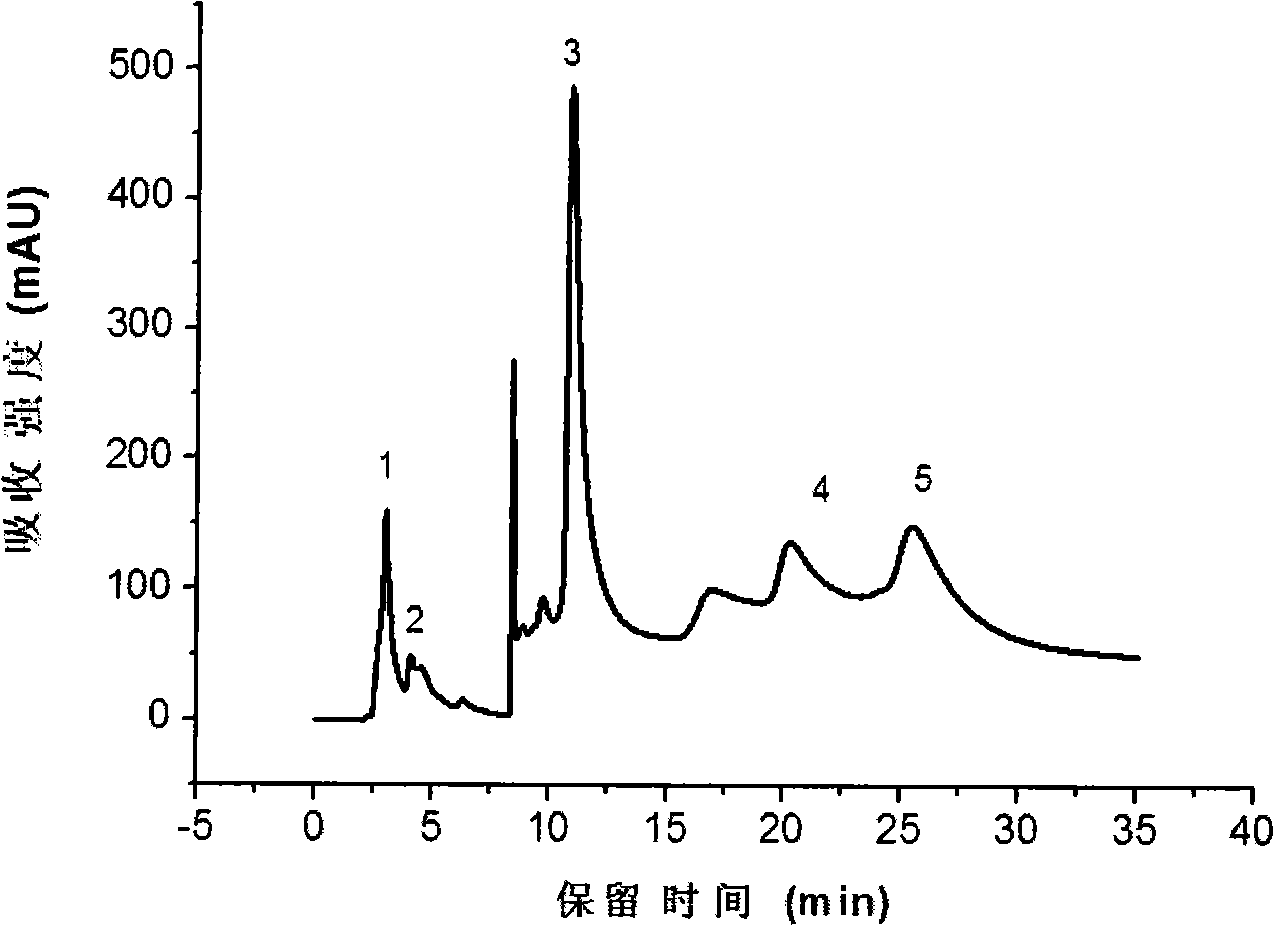

Ion exchange chromatography fixed phase, preparing method and application of the same

InactiveCN101254458AAchieve separationReduce non-specific adsorptionOther chemical processesAmphoteric ion-exchangersMg compositeApatite

A stationary phase for ion-exchange chromatography is provided. The stationary phase comprises a chromatographic matrix superficially coated with hydroxyapatite. The stationary phase for ion-exchange chromatography has good biocompatibility and bioaffinity and higher mechanical strength. The stationary phase for ion-exchange chromatography is prepared by the following steps: activating an inorganic chromatographic matrix material such as silica gel or Zr / Mg composite oxide, immersing the matrix material into an oversaturated calcium / phosphorus solution, standing for deposition at 36.5 plus or minus 0.5 DEG C to obtain hydroxyapatite coating, washing with water twice, and drying to obtain the hydroxyapatite-coated stationary phase for ion-exchange chromatography in the protein separation. The method is also used to prepare a coating on the inner wall of a capillary tube to reduce the non-specific adsorption of proteins and simultaneously to provide an ion-exchange function for improvement of separation selectivity.

Owner:WUHAN UNIV

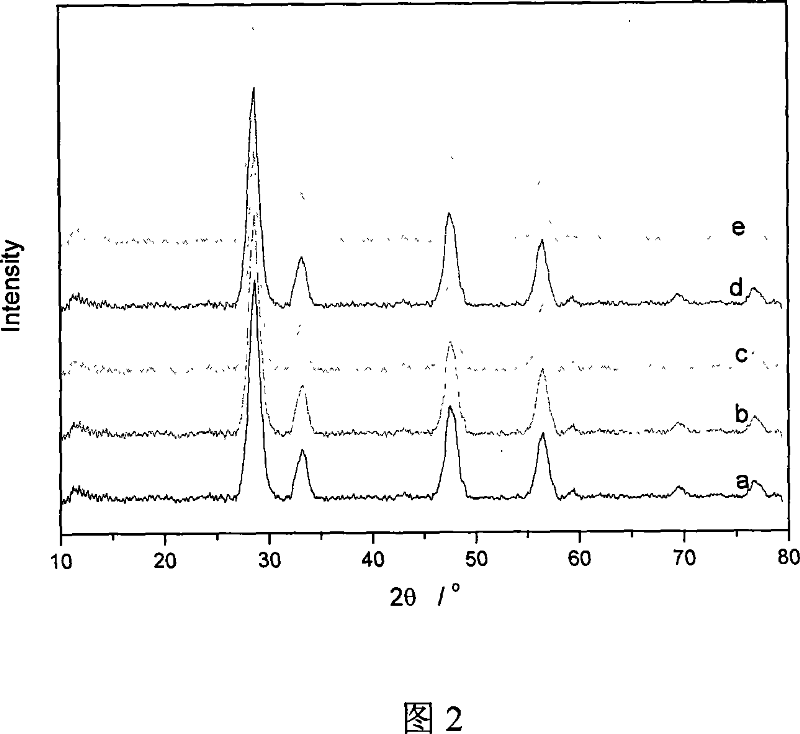

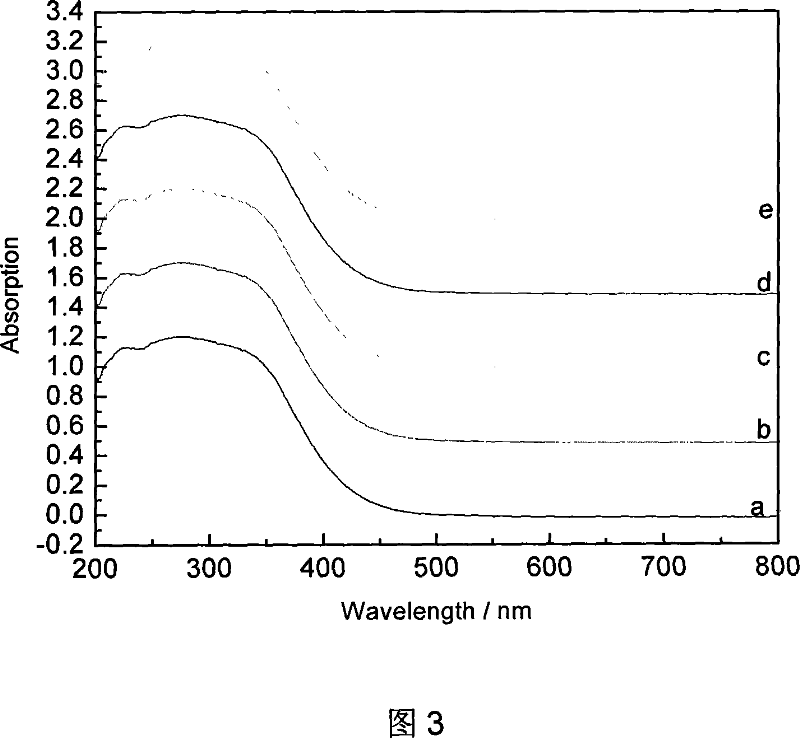

Method for preparing nano-Ce-Magnesium coumpoud oxide

InactiveCN101036881ASmall particle sizeEvenly dispersedMagnesium compoundsRare earth metal compoundsMg compositeSolvent

The present invention relates to two methods for preparing nanometre Ce-Mg composite oxide, which belongs to the superfine Ce-Mg composite oxide powder preparation field. Sol gel method has the reaction material of cerium nitrate hexahydrate and basic magnesium carbonate, and has a complexing agent of malic acid, wherein the cerous nitrate and the basic magnesium carbonate are dissolved in water respectively and then are mixed with each other, then malic acid is added therein before agitating at room temperature, and then ammonia liquor is dropped therein to adjust the pH value, so as to obtain nanometre Ce-Mg composite oxide after evaporating solvent, drying and calcining. The self-propagating combustion method has reaction substrate of cerium nitrate hexahydrate and magnesium nitrate, and has a complexing agent of malic acid, wherein the malic acid is dissolved in water, then cerous nitrate and magnesium nitrate are added therein synchronously before agitating at room temperature, and then ammonia liquor is dropped therein to adjust the pH value, so as to obtain nanometre Ce-Mg composite oxide after evaporating solvent, drying and calcining. The two methods can all obtain Ce-Mg composite oxide powder having a small particle diameter, a uniform dispersion and a large specific surface.

Owner:EAST CHINA NORMAL UNIV

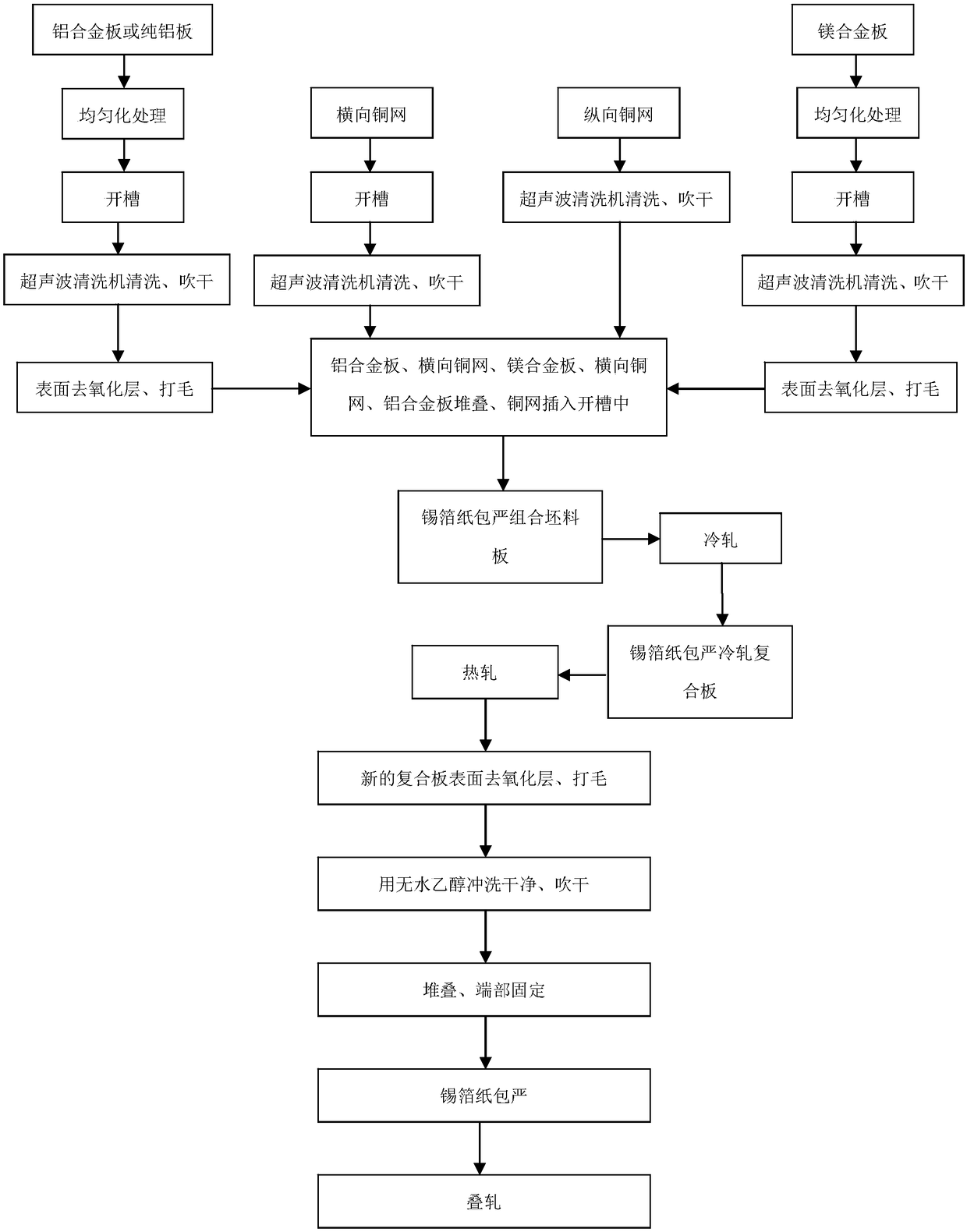

Al/Cu/Mg composite sheet rolling preparation method

ActiveCN109174966AImprove corrosion resistanceIncrease surface areaRoll force/gap control deviceTemperature control deviceMg compositeMegasonic cleaning

The invention discloses a Al / Cu / Mg composite sheet rolling preparation method. The method comprises the following steps (1) homogenization treatment is carried out on aluminum alloy or pure aluminum billets, and magnesium alloy billets; (2) slotting is conducted on the corresponding position of the aluminum alloy or the pure aluminum billets, the magnesium alloy billets and a horizontal copper net; (3) oxide layers on the surfaces of the aluminum alloy or the pure aluminum billets, and the magnesium alloy billets are removed, surface coarsen treatment is carried out, then absolute ethyl alcohol is added to an ultrasonic cleaner to clean and dry, and impurities at the composite material interface joints are removed; (4) the billets are stacked in the order of the aluminum alloy or the purealuminum billets, the horizontal copper net, the magnesium alloy billets, the horizontal copper net, the aluminum alloy or the pure aluminum billets, and a vertical copper net is inserted into a stacked billet groove to form composite billets; (5), cold rolling is carried out; (6) hot rolling is carried out; and (7) ply rolling is carried out. The Al / Cu / Mg composite sheet material rolling preparation method can improve the interface bonding strength of a magnesium and aluminum composite plate, and enhance the impact toughness of materials, so that the integrated mechanical performance of composite materials is improved.

Owner:HUNAN UNIV OF SCI & TECH

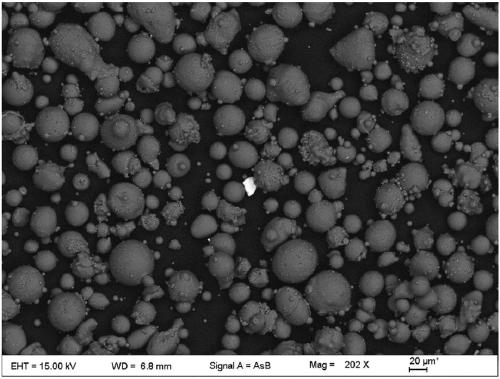

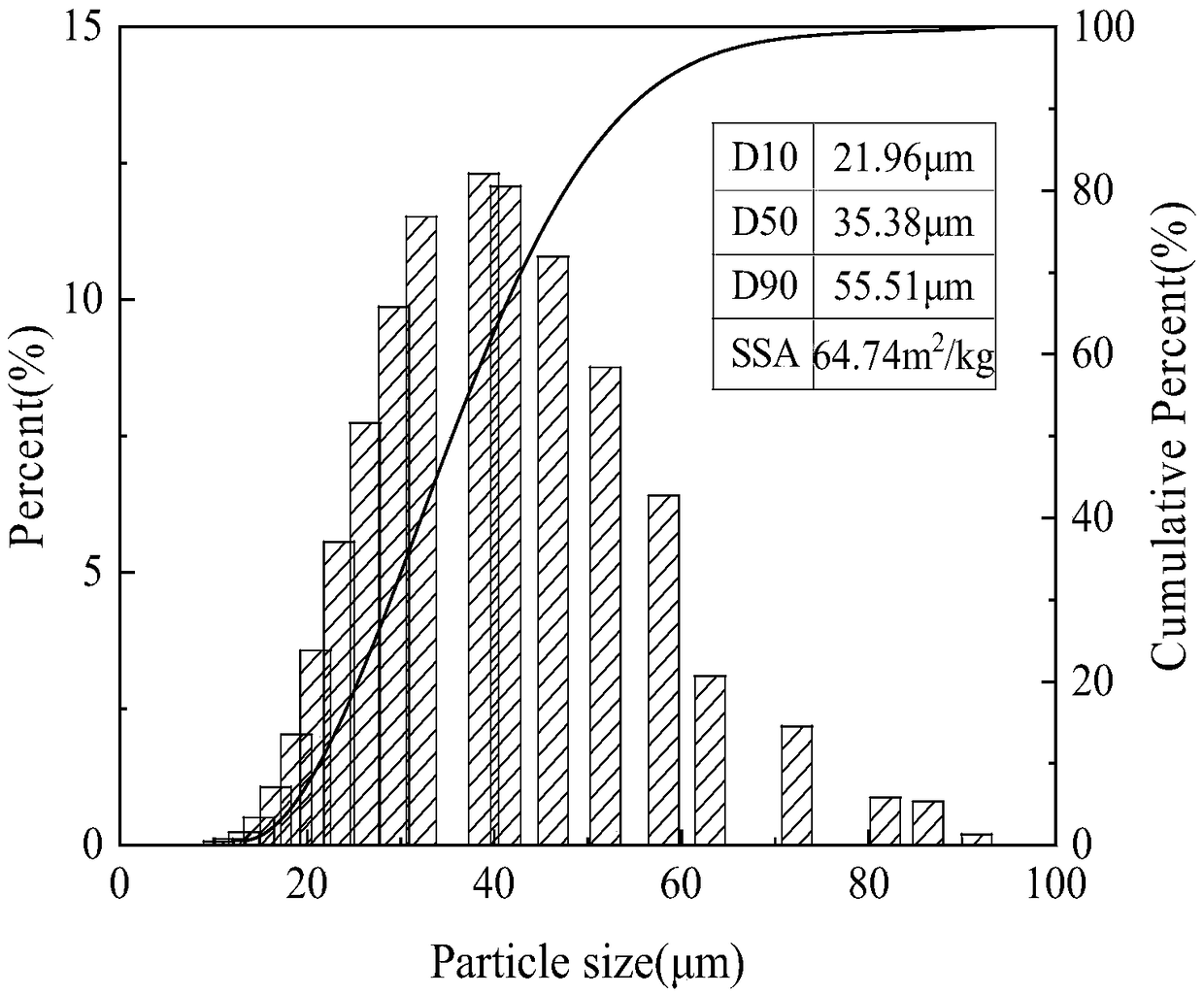

Strengthened type nanometer WC/AlSi10Mg composite powder and additive manufacturing technology

InactiveCN109434096AGood powder sphericityDense growthAdditive manufacturing apparatusIncreasing energy efficiencyMg compositeManufacturing technology

The invention discloses strengthened type nanometer WC / AlSi10Mg composite powder and an additive manufacturing technology and belongs to the technical field of additive manufacturing. The additive manufacturing technology comprises the following steps of adding 0.1 percent of nanometer WC in AlSi10Mg powder, performing mixing on the two powders for 20min with a GH-17 type three-dimensional motionefficient mixer, and then performing drying for 10h with a vacuum drying tank to obtain the strengthened type nanometer WC / AlSi10Mg composite powder. The composite powder has the characteristics of better mobility, high sphericity degree, high printing stability and the like; and by melting and solidifying the composite powder with laser, the plasticity of AlSi10Mg alloy is improved while the strength of the AlSi10Mg is improved.

Owner:NANCHANG UNIV

Preparation method for preparing aluminum-based composite material based on laser selective melting

InactiveCN108330347AImprove performanceImprove microstructureAdditive manufacturingIncreasing energy efficiencyMg compositeMechanical property

The invention provides a preparation method for preparing an aluminum-based composite material based on laser selective melting. The preparation method comprises the following steps: S1, with KBF4 andK2TiF6 powders as raw materials, an in-situ self-generated TiB2 / AlSi10Mg composite material is prepared by a mixed salt reaction method (LSM), and a composite material powder is prepared by vacuum gas atomization of the in-situ self-generated TiB2 / AlSi10Mg composite material; S2, an SLM sample is prepared by laser selective melting of the composite material powder; and S3, the SLM sample is subjected to single aging treatment. The in-situ self-generated TiB2 particle reinforced AlSi10Mg composite material is prepared by the SLM, crystal grains are greatly refined, the mechanical properties ofthe material are further improved by the single aging treatment, and the composite material has great potential in the technical field of aviation and aerospace.

Owner:SHANGHAI JIAO TONG UNIV

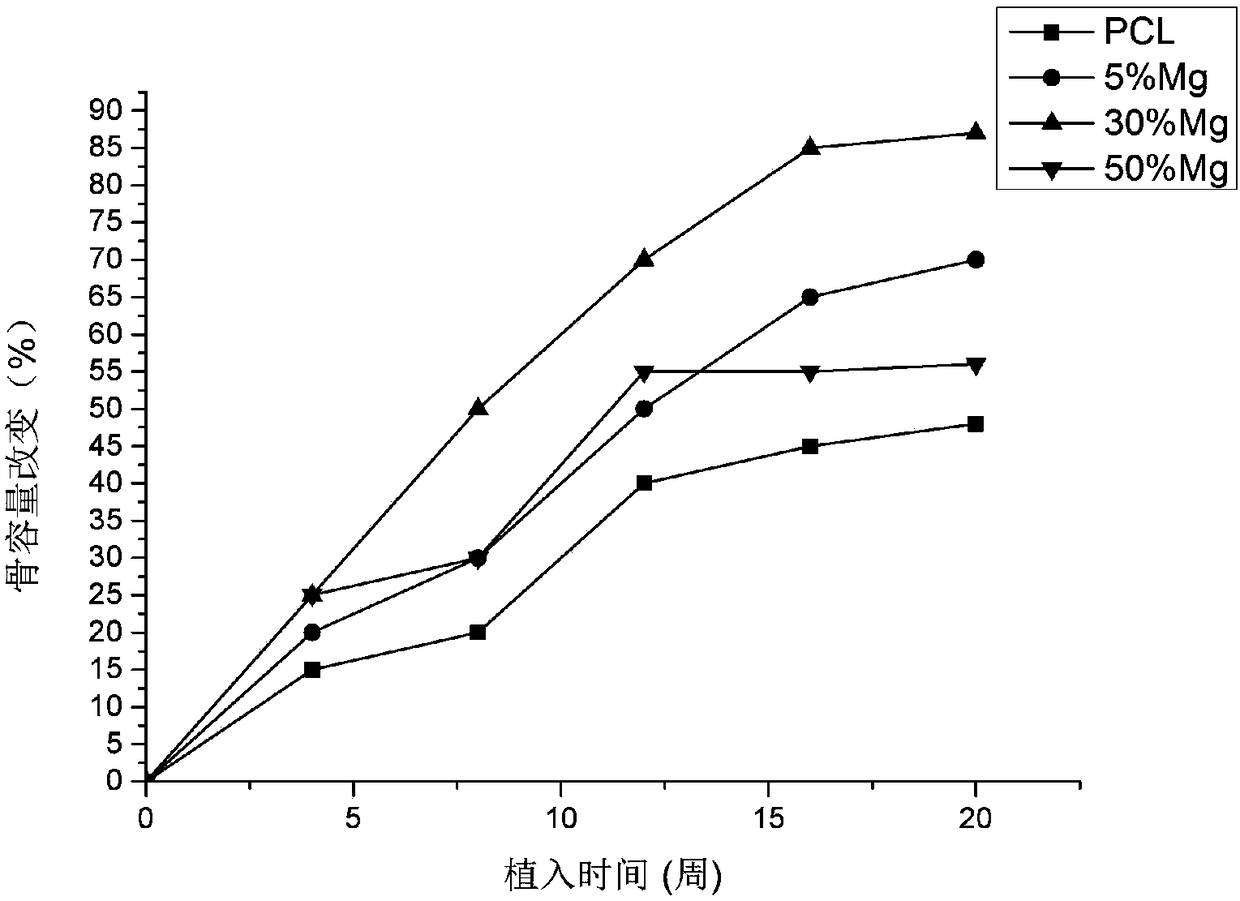

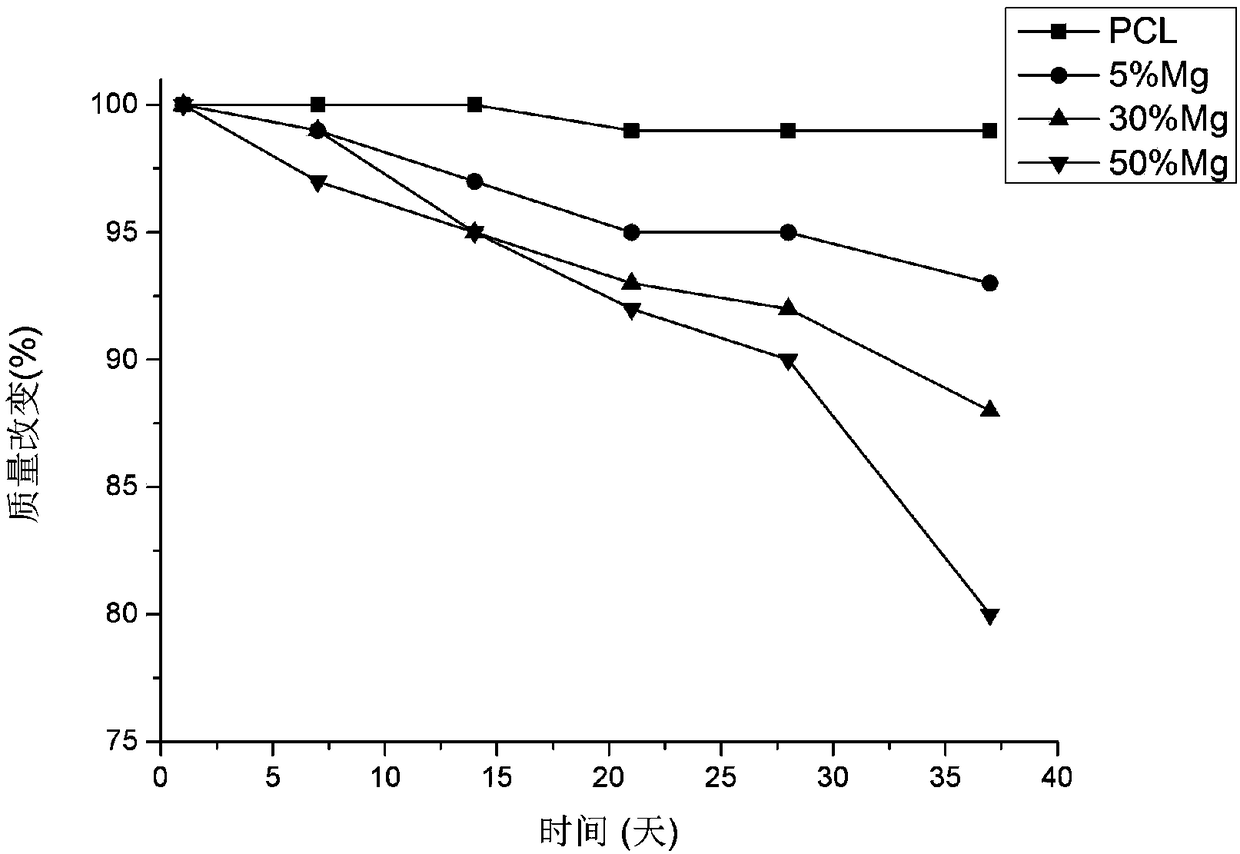

Preparation process of biodegradable PCL (polycaprolactone)/Mg composite material FDM (fused deposition modeling) consumable

InactiveCN108453927APromote degradationEnhance the ability of proliferation and differentiationAdditive manufacturing apparatusProsthesisMg compositeFused deposition modeling

The invention discloses a preparation process of a biodegradable PCL (polycaprolactone) / Mg composite material FDM (fused deposition modeling) consumable. The preparation process comprises the following steps: mixing raw materials Mg and PCL for granulation through a parallel double-screw extruder, directly performing mixing, extrusion and granulation through a single-screw extruder or performing mixing and granulation with a solution method, thus obtaining the biodegradable PCL / Mg composite material FDM consumable. The Mg in the raw materials accounts for 5 to 50 percent of the mass of the PCL. The prepared biodegradable PCL / Mg composite material FDM consumable has the advantages that the degradation time in a human body is controllable, and the bone repair effect is better than that of pure PCL.

Owner:XI AN JIAOTONG UNIV

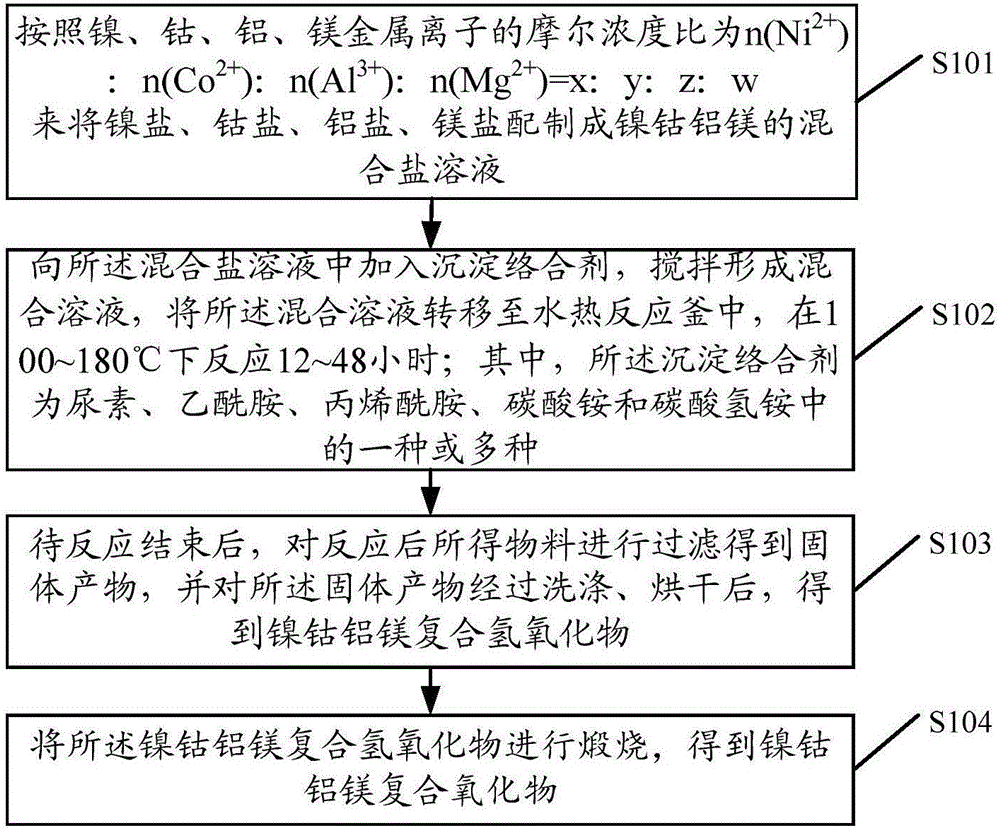

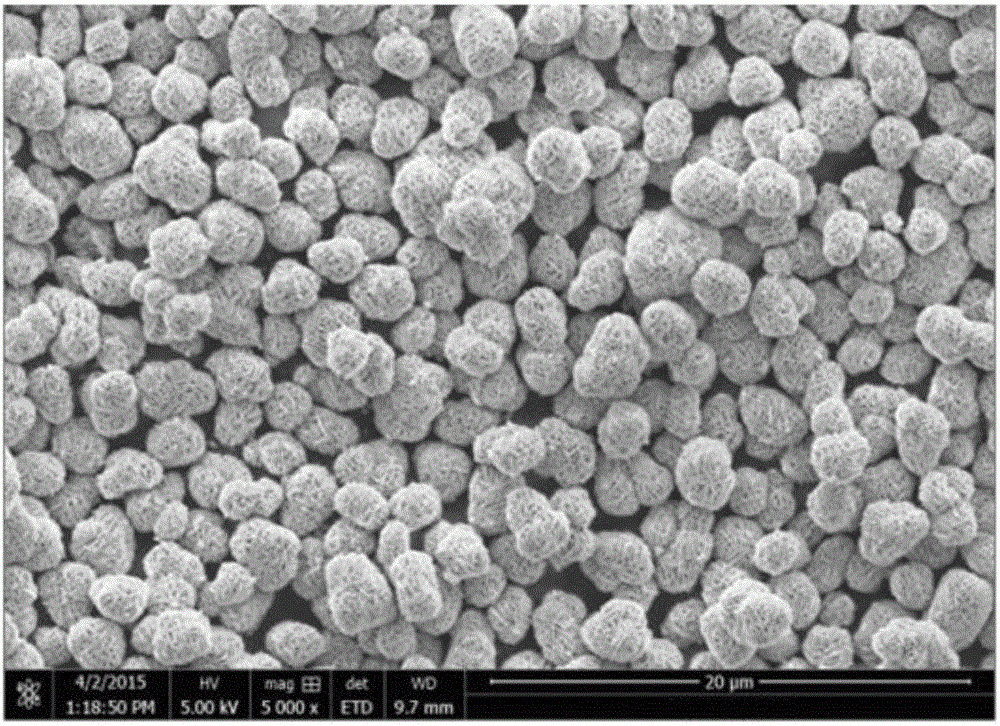

Ni-Co-Al-Mg composite hydroxide, preparation method and application thereof

InactiveCN106571464AImprove solubilityImprove consistencyCell electrodesSecondary cellsMg compositeAluminum Ion

Owner:JINGMEN GEM NEW MATERIAL

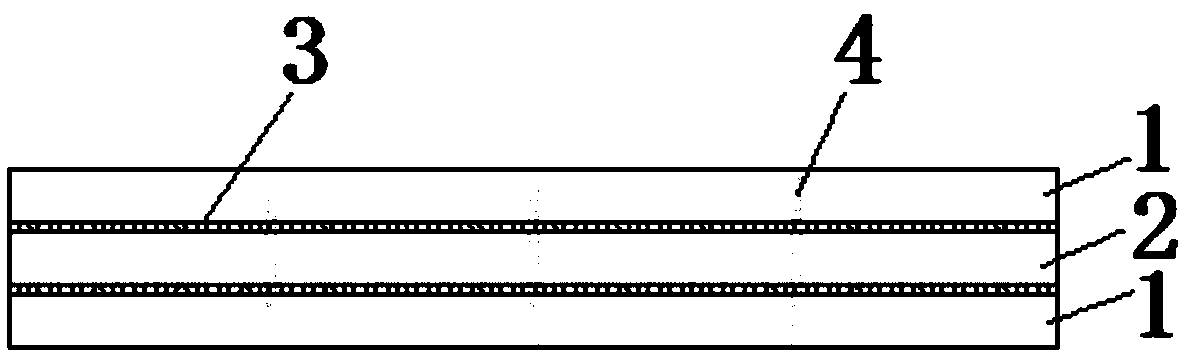

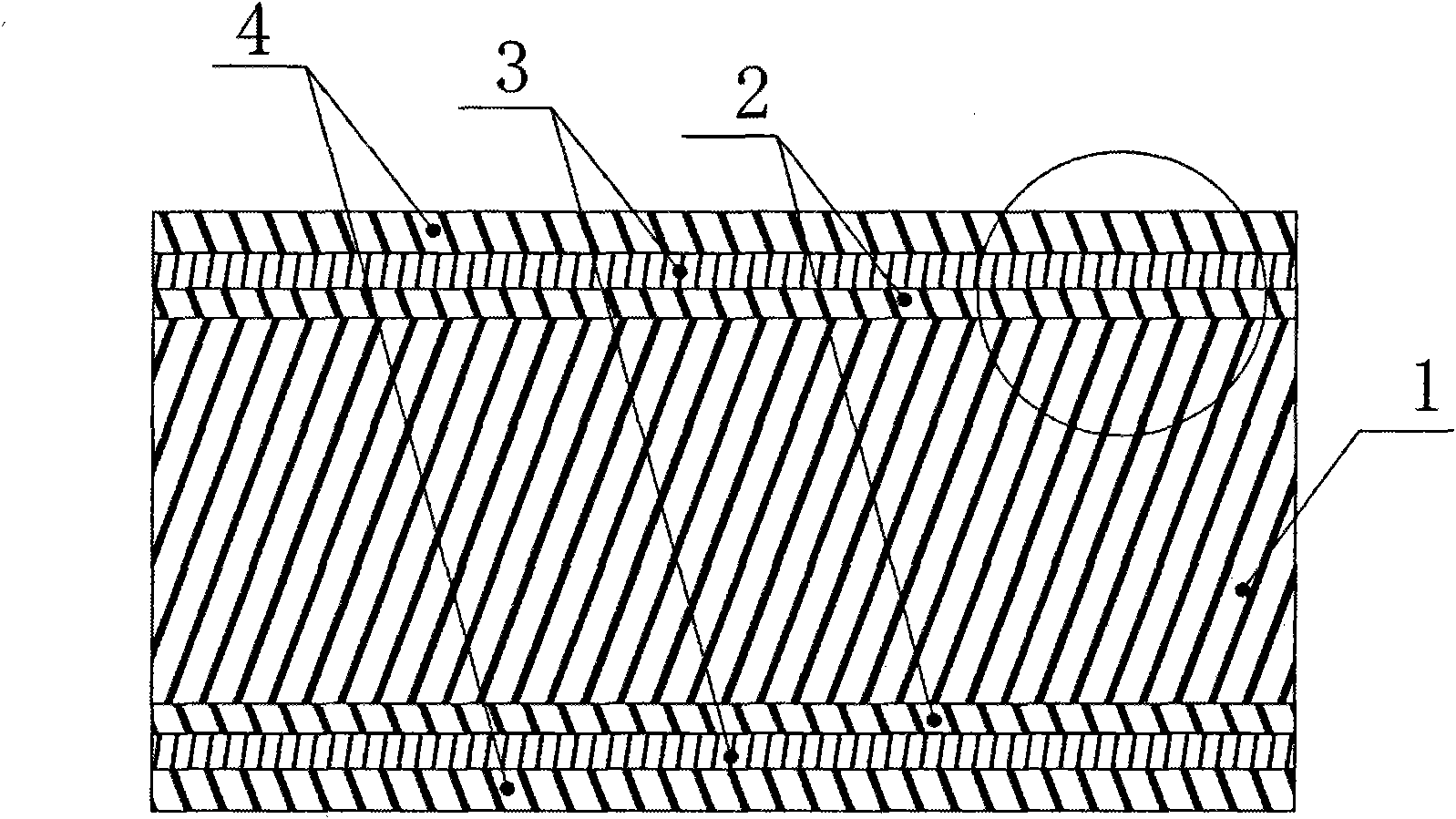

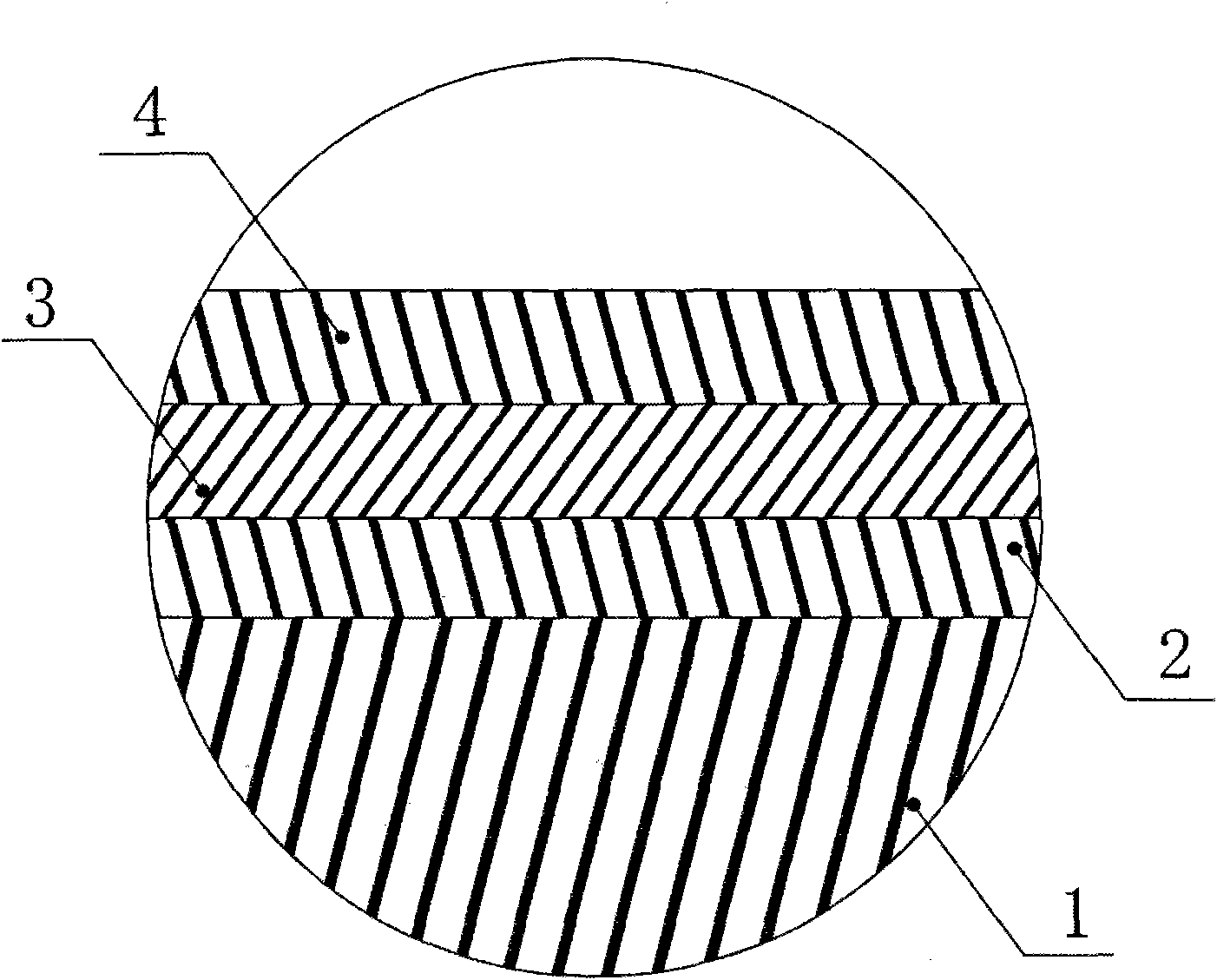

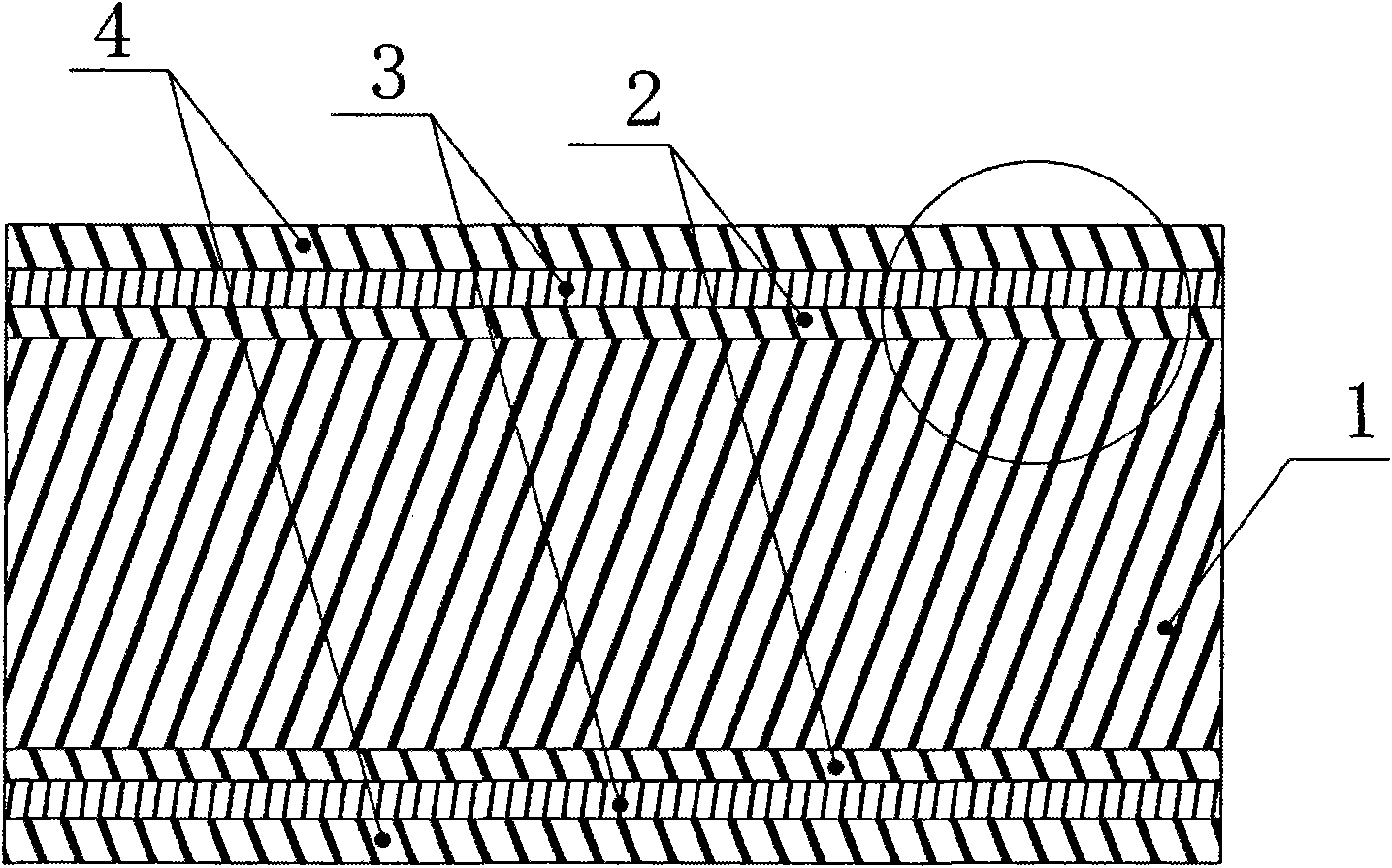

Si-Mg composite insulation board and production method thereof

InactiveCN101850640AImprove flexural performanceImprove fitWater-setting substance layered productMg compositeAdhesive

The invention discloses an Si-Mg composite insulation board and a production method thereof. The Si-Mg composite insulation board comprises a composite silicate insulation board, and the upper face and the lower face of the composite silicate insulation board are sequentially provided with a first magnesium oxychloride cement layer, a non-woven mesh fabric and a second magnesium oxychloride cement layer from inside to outside. The production method comprises the following steps of: sequentially coating first magnesium oxychloride cement slurry, adhering the non-woven mesh fabric and coating second magnesium oxychloride cement slurry on both sides of the composite silicate insulation board from inside to outside, and then naturally airing under normal temperature. In the invention, any adhesive is not used at the same time of enhancing the flexural strength of the composite silicate insulation board, therefore, the cost is reduced, and the problems of surface dregs and high requirements to the adhesives of the composite silicate insulation board are also solved; the production method is simple and easy to operate; and the production process is not restricted by the environment and is simple and convenient.

Owner:何世雄

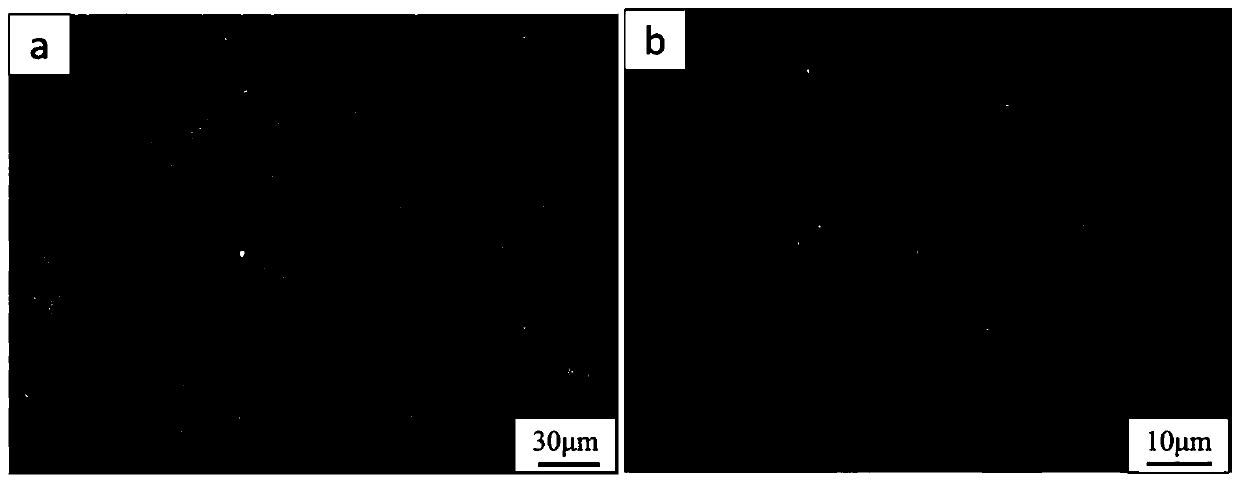

Laser additive manufacturing method of in-situ synthesized nano Al2O3 reinforced aluminum-based composite material

ActiveCN112176213AAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMg composite

The invention discloses a laser additive manufacturing method of an in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. The method comprises the following steps of (1) mixingZnO ceramic powders and AlSi10Mg aluminum alloy powders, and carrying out ball milling to obtain ZnO / AlSi10Mg composite powders; (2) carrying out additive manufacturing forming on the composite powders by adopting a selective laser melting process to form a solid sheet layer; (3) carrying out laser scanning on the solid sheet layer again to form a remelting sheet layer; (4) repeating the steps (2)and (3), and finally forming to obtain the in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. A laser is used for exciting Al and ZnO to generate aluminothermic reactions between the Al and ZnO to generate Al2O3 ceramic particles in situ, the overall process design of the method is improved, selective laser melting and laser remelting scanning are matched, the prepared aluminum-based composite material is high in density and fine in microstructure, the in-situ synthesized Al2O3 particles are nanoscale in size and are uniformly distributed, and the phase interfaces ofthe Al2O3 particles are well combined with an aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

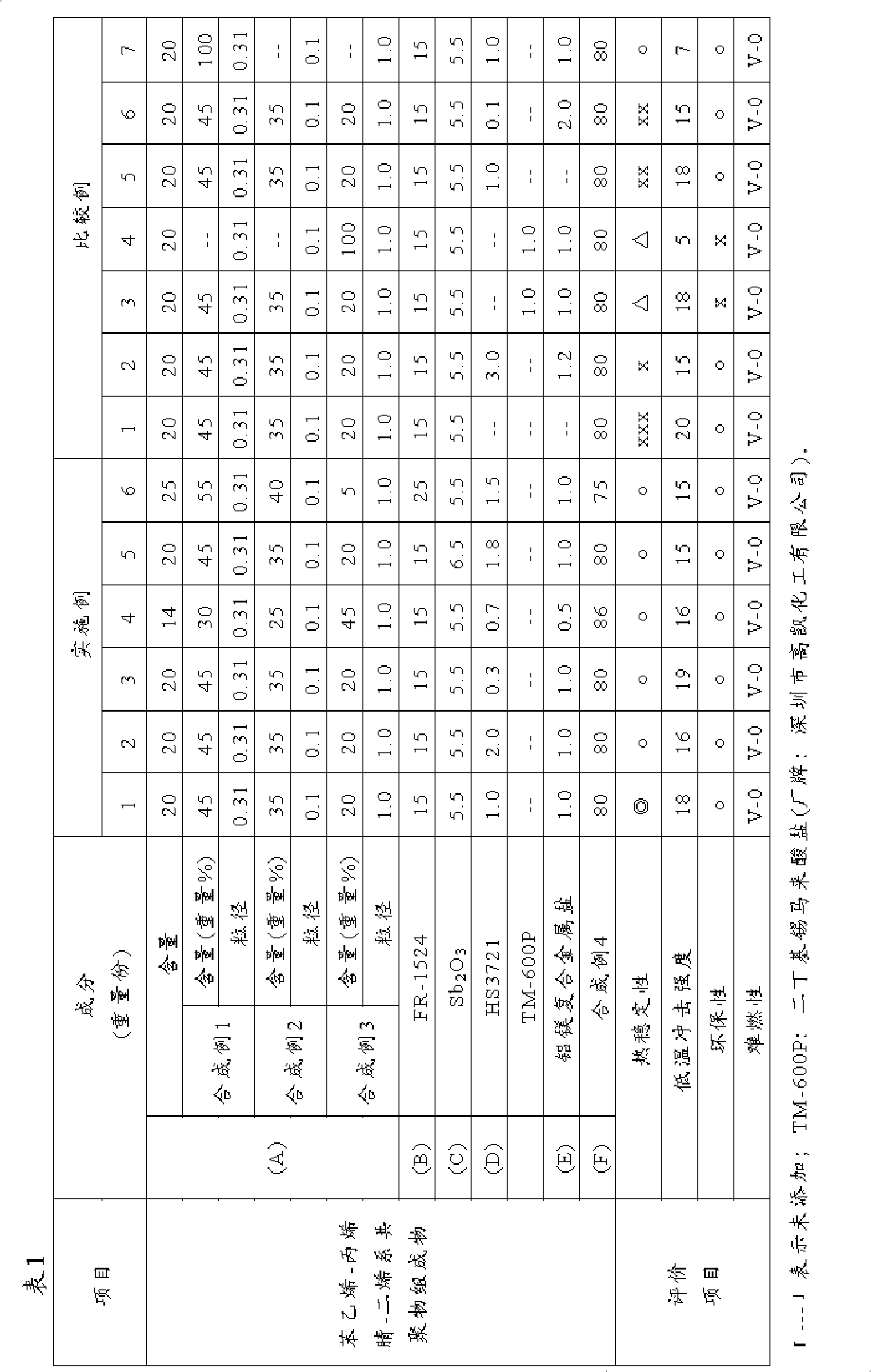

Styrene-acrylonitrile- diene copolymer compound and formed product made of the compound

ActiveCN103183880AImprove thermal stabilityGood low temperature impact strengthMg compositeAcrylonitrile

The invention provides a styrene-acrylonitrile- diene copolymer compound includes 5 to 40 parts by weight of copolymer mixture (A); 5 to 30 parts by weight of halogen fire retardant (B); 1 to 10 parts by weight of antimonial oxide (C); 0.2 to 2.5 parts by weight of di-methyltin mercaptide maleate polymer (D); 0.2 to 1.5 parts by weight of al-mg composite metal salt (E); and 60 to 95 parts by weight of vinyl benzene- acrylonitrile copolymer (F). The copolymer mixture (A) is formed by mixing first copolymer component (A1), second copolymer component (A2) and third copolymer component (A3). The vinyl benzene- acrylonitrile copolymer has good thermo-stability, low-temperature impact strength and flame retardancy.

Owner:CHI MEI CORP

Method for preparing in-situ Al matrix composite

Owner:SHANGHAI JIAOTONG UNIV +1

High-interface-strength Cf/Mg composite material and preparation method thereof

ActiveCN104451474AIncreased shear strengthMeet the requirements of different working conditionsMg compositeWinding machine

The invention discloses a high-interface-strength Cf / Mg composite material and a preparation method thereof, belongs to the field of light structural materials and particularly relates to a high-interface-strength Cf / Mg composite material and a preparation method thereof. The high-interface-strength Cf / Mg composite material disclosed by the invention is used for solving the problem that an existing Cf / Mg composite material is low in interface bonding strength. The high-interface-strength Cf / Mg composite material is prepared from carbon fibers and magnesium-yttrium alloy, wherein the magnesium-yttrium alloy is prepared from pure yttrium alloy and pure magnesium. The preparation method comprises the following steps: (1) preparing a carbon fiber reinforcement prefabricated member by using a fiber winding machine; (2) smelting pure magnesium and pure yttrium to obtain a magnesium-yttrium alloy melt solution; (3) pressing the carbon fiber reinforcement prefabricated member into a cavity of a forming mold, then filling the magnesium-yttrium alloy melt solution into the forming mold and then pressing to obtain a fiber reinforced magnesium-based composite material; and (4) cooling the fiber reinforced magnesium-based composite material to room temperature along with the mold, demolding and then mechanically removing excess magnesium-yttrium alloy from the edge to obtain the Cf / Mg composite material.

Owner:哈尔滨龙卓新材料合伙企业(有限合伙)

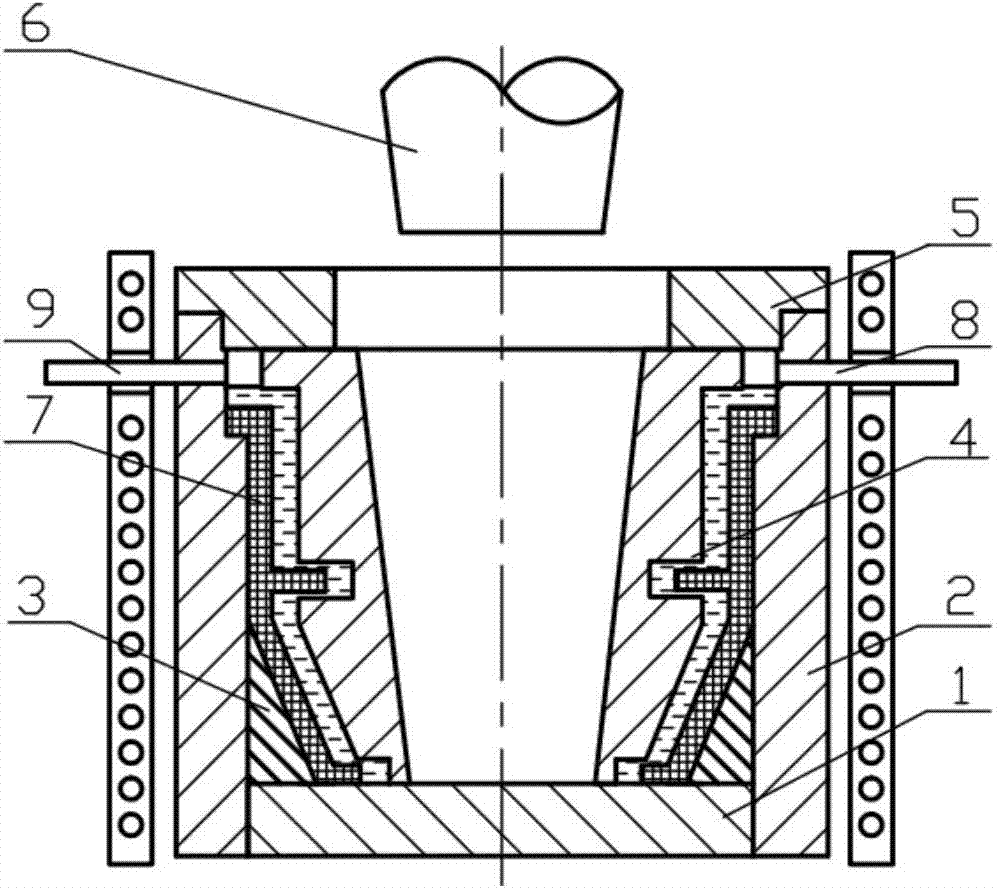

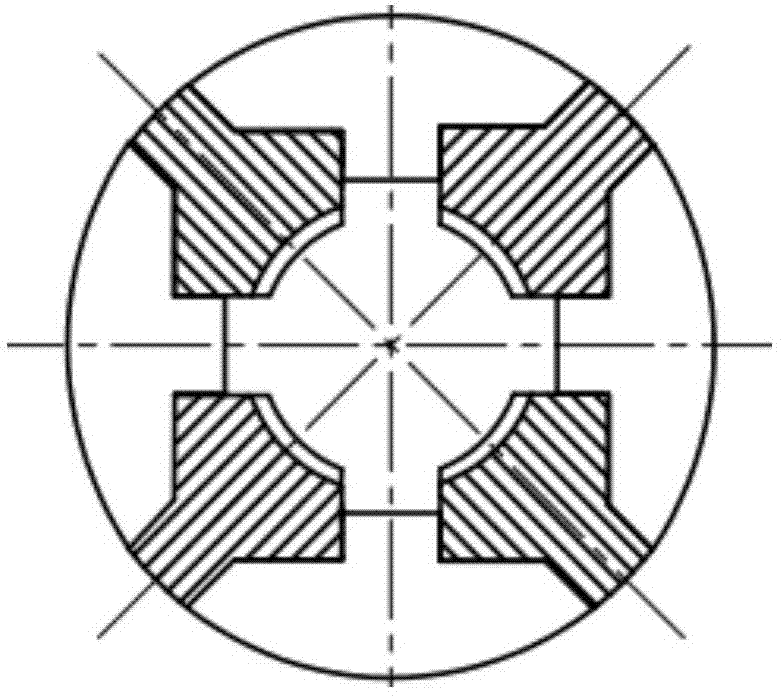

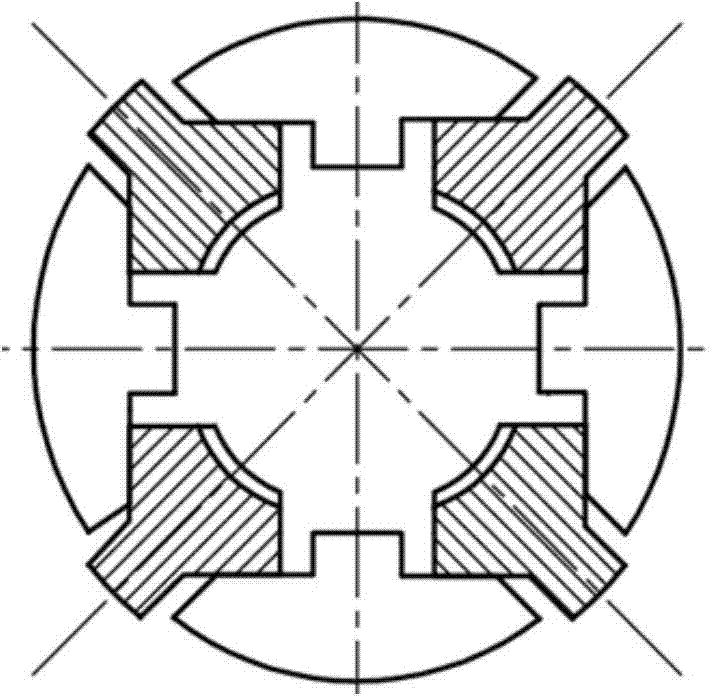

Liquid-solid pressure formation device and method for thin-wall special-shaped parts made of Cf-Mg composite materials

The invention discloses a liquid-solid pressure formation device and method for thin-wall special-shaped parts made of Cf-Mg composite materials. The liquid-solid pressure formation device and method for the thin-wall special-shaped parts made of the Cf-Mg composite materials are used for solving the technical problem that prefabricated parts with complex inner wall structures are difficult to form by an existing fiber-reinforced intermetallic compound composite part manufacturing device. According to the technical scheme, a split insert structure replaces an integrated mandrel to shape the prefabricated parts. Compared with the integrated mandrel, the inner side of an insert set is hollow, a male mould is small, and the overall weight of a formation device can be reduced; magnesium alloy fluid is prompted to permeate the prefabricated parts evenly through the radial movement generated by stress on inserts; the surfaces of the inserts are tightly attached to the inner walls of the prefabricated parts, and the sizing effect is remarkable; near-net forming of the different-shape thin-wall special-shaped parts made of the Cf-Mg composite materials can be achieved by changing the shapes of sections of the inserts; the inserts are separated after extrusion is completed to achieve demoulding, and the technical problems that the prefabricated parts with the complex inner wall structures are high in sizing difficulty, and demoulding is difficult are effectively solved, and forming of the thin-wall special-shaped parts made of the Cf-Mg composite materials is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

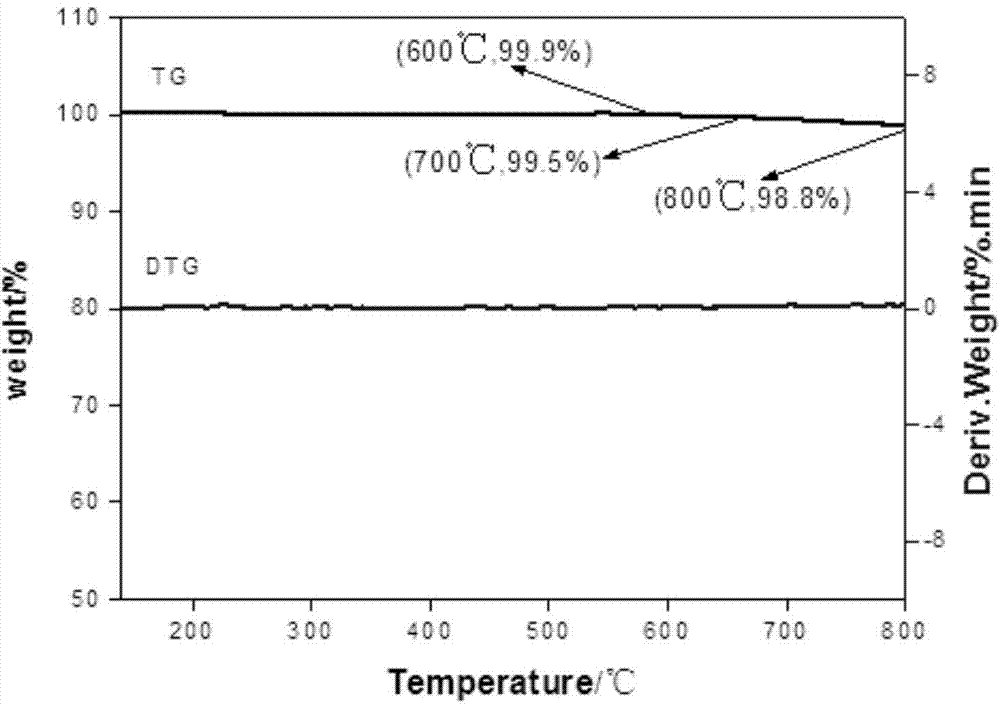

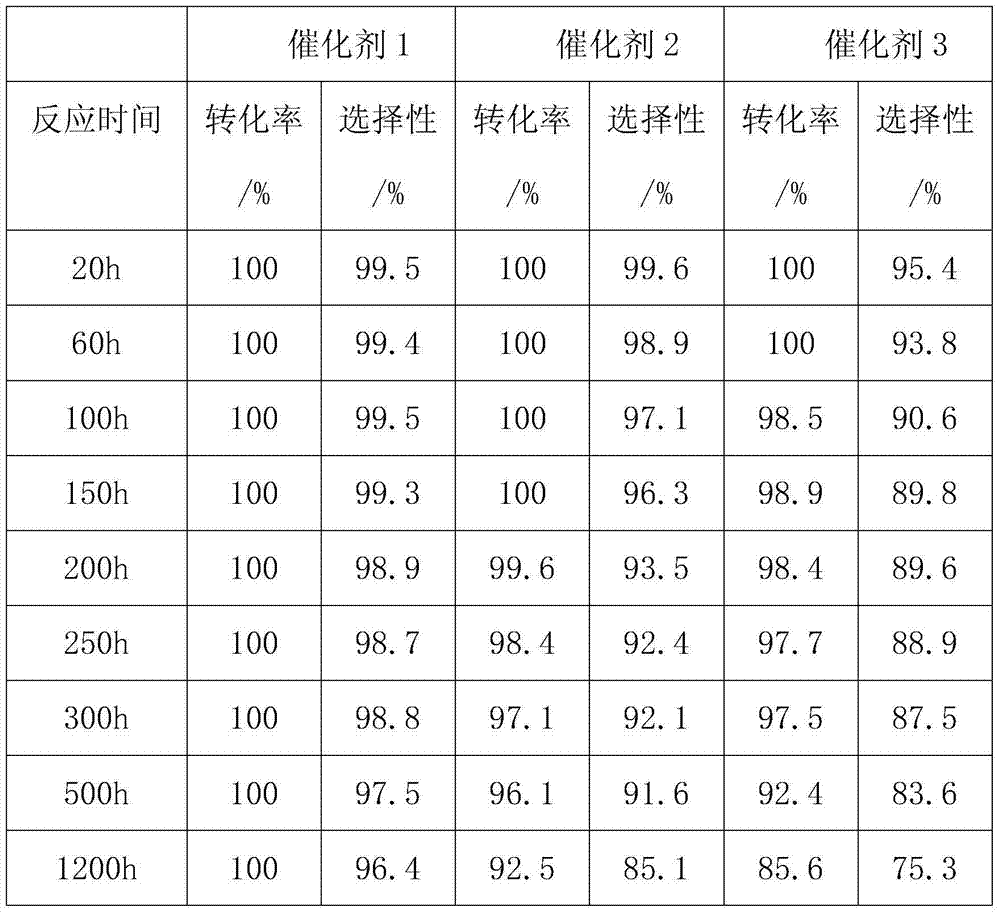

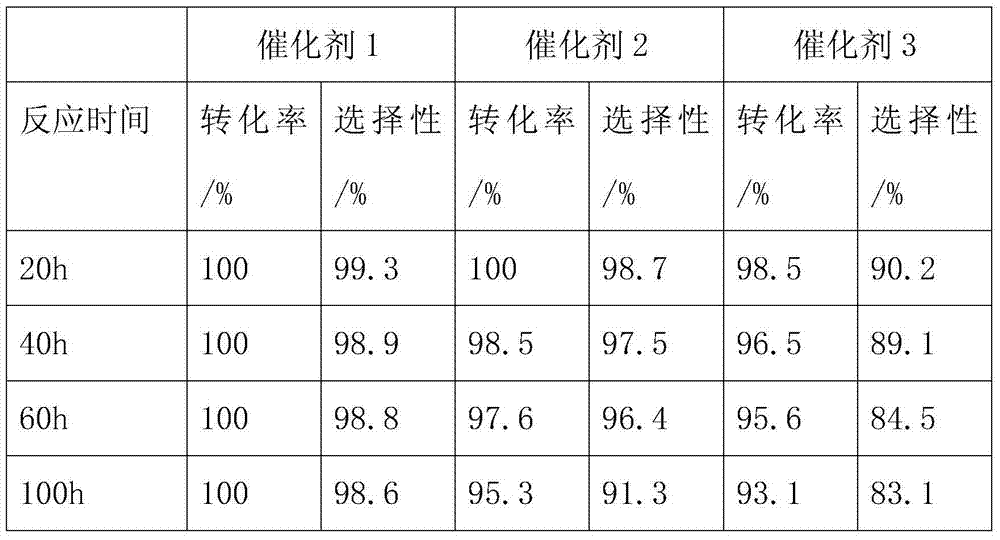

Method for preparing 2-chloro-3,3,3-trifluoropropylene catalyst by gas phase fluorination

ActiveCN104707608AIncrease the areaHigh pore volumePreparation by halogen replacementChemical recyclingMg compositeGas phase

The invention discloses a method for preparing a 2-chloro-3,3,3-trifluoropropylene catalyst by gas phase fluorination. The method comprises the following steps of preparing a mixed solution from a ferric soluble salt and a magnesium soluble salt according to a certain mole ratio of Fe / Mg, adding a precipitating agent into the mixed solution, carrying out aging, drying and roasting for a certain time to obtain a Fe-Mg composite oxide, blending the Fe-Mg composite oxide and magnesium carbonate according to a certain mass ratio, carrying out grinding and pressing molding to obtain a catalyst precursor, carrying out roasting and carrying out HF gas fluorination to obtain the fluorination catalyst. The 2-chloro-3,3,3-trifluoropropylene catalyst prepared by gas phase fluorination has a service life more than 1200h, has strong stability, can be regenerated after catalyst performance reduction so that catalyst performances are recovered and can be recycled.

Owner:XIAN MODERN CHEM RES INST

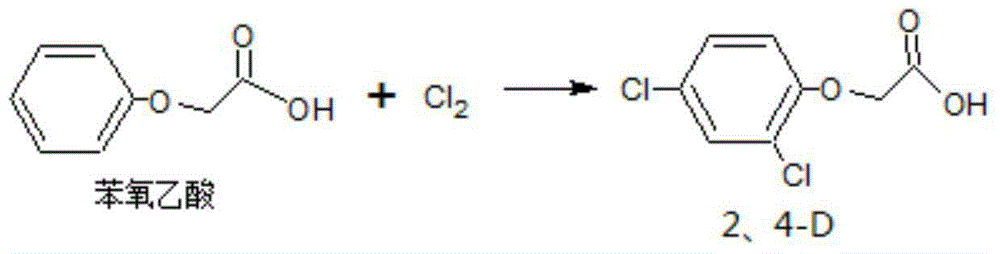

2,4-dichlorphenoxyacetic acid preparation method

InactiveCN104402707AImprove solubilityIncrease profitOrganic compound preparationCarboxylic compound preparationMg compositeSodium bicarbonate

The invention discloses a 2,4-dichlorphenoxyacetic acid preparation method which comprises the following special steps: adding chloroacetic acid into a sodium hydroxide solution, stirring, adding into phenol, and regulating the PH value to 11 with sodium bicarbonate; then heating for 40 minutes at 100 DEG C; adding into hydrochloric acid to regulate the PH value to 4; finally cooling in an ice-water bath, and washing and drying the obtained solid to obtain phenoxyacetic acid; adding into the phenoxyacetic acid into an acetic acid and water mixed solution, adding into an Ni-Al-Mg composite oxide, stirring and mixing, wherein the mass of the Ni-Al-Mg composite oxide is 0.05% of that of phenoxyacetic acid; then introducing chlorine to carry out chlorination; reacting for 20-40 minutes, and finishing the chlorination; then cooling the reaction product, and filtering to obtain a solid; at last, drying the solid to obtain the 2,4-dichlorphenoxyacetic acid. The product prepared by the method disclosed by the invention is high in quality, yield and purity; the preparation process is simple, convenient and stable, the industrial cost is low, and the environment is protected.

Owner:常熟市尚登新材料有限公司

A kind of preparation method of degradable layered zn-mg composite material

ActiveCN108237214BLow elastic modulusSolve the difficult problem of galvanizingSurgeryMetallic material coating processesMg compositeMaterial Design

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Preparation method of hydrodesulfurization catalyst

ActiveCN103801316BHigh speedImprove hydrogenation performanceMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsMg compositeHydrodesulfurization

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com