Liquid-solid pressure formation device and method for thin-wall special-shaped parts made of Cf-Mg composite materials

A technology of composite materials and special-shaped parts, which is applied in the field of Cf/Mg composite thin-walled special-shaped parts forming devices, can solve the problems of difficult to form prefabricated inner wall structures, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

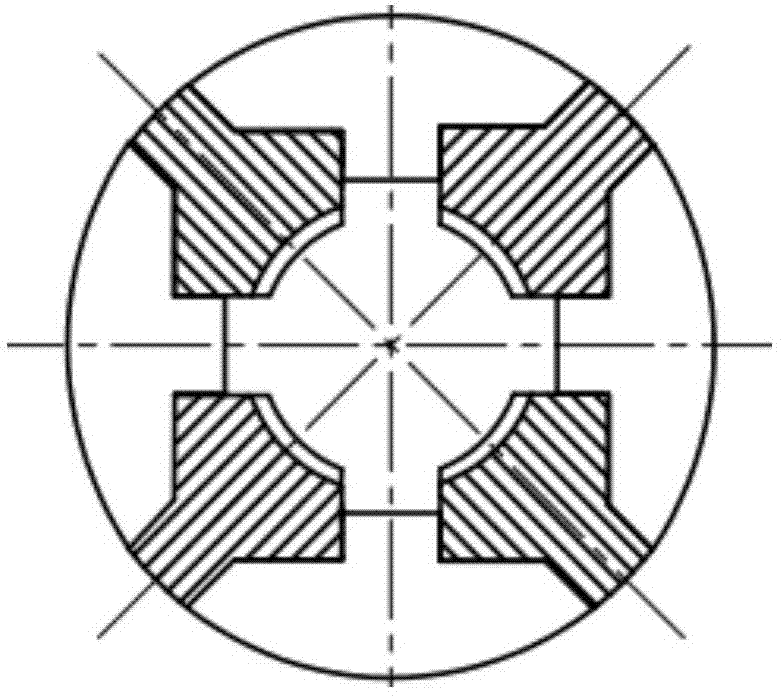

[0025] Method Example 1: A C f / Mg composite material thin-wall special-shaped parts manufacturing method, choose AZ91D magnesium alloy, Taili T36 carbon fiber prefabricated body.

[0026] Step 1: Preparation of thin-walled special-shaped prefabricated body. Wind 12K unidirectional carbon fiber 0° / 90° into shaped parts and stitch them in the thickness direction. The prepared preform is placed in a chemical vapor deposition furnace for chemical vapor deposition, the preform is cured and a pyrolytic carbon coating is deposited on the surface of the fiber.

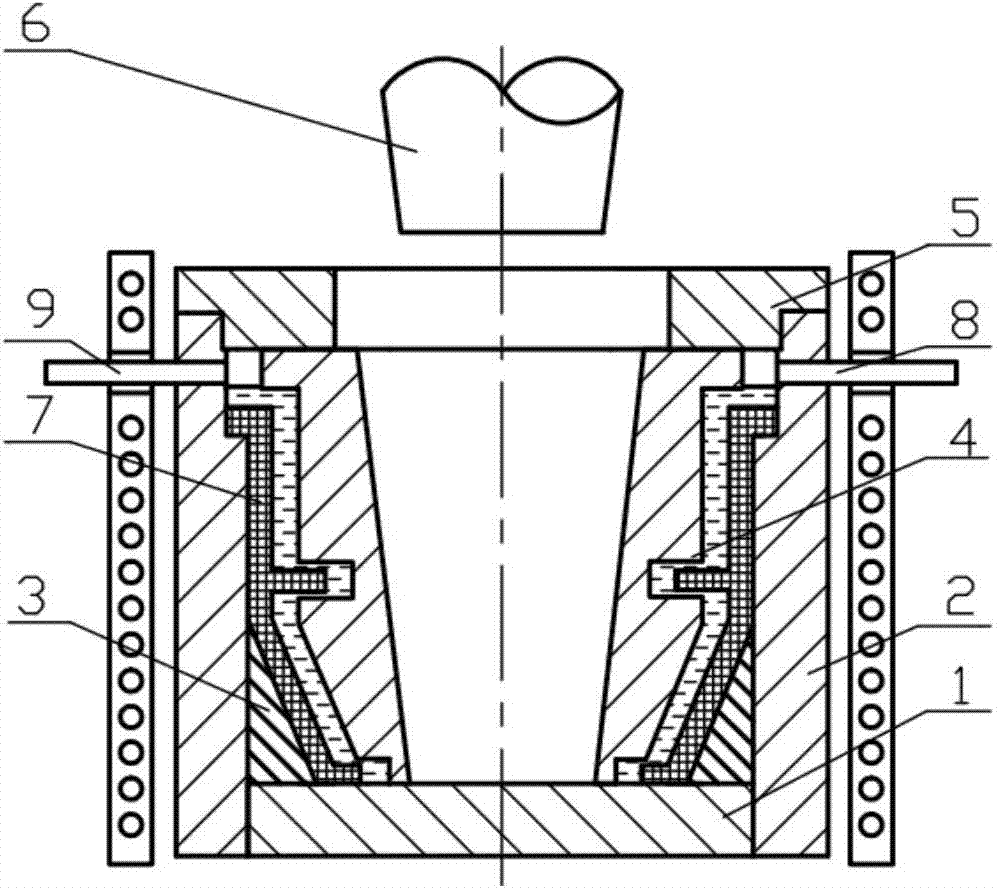

[0027] Step 2: Installation of forming device. Fix the punch 6 on the slider of the four-column hydraulic press to ensure that its center line is perpendicular to the plane of the slider; fully insert the inner pad 1 into the extrusion cylinder 2, and closely match the inner wall of the extrusion cylinder 2; process according to the size of the prefabricated outer wall The graphite mold 3 is installed on the upper part of ...

Embodiment 2

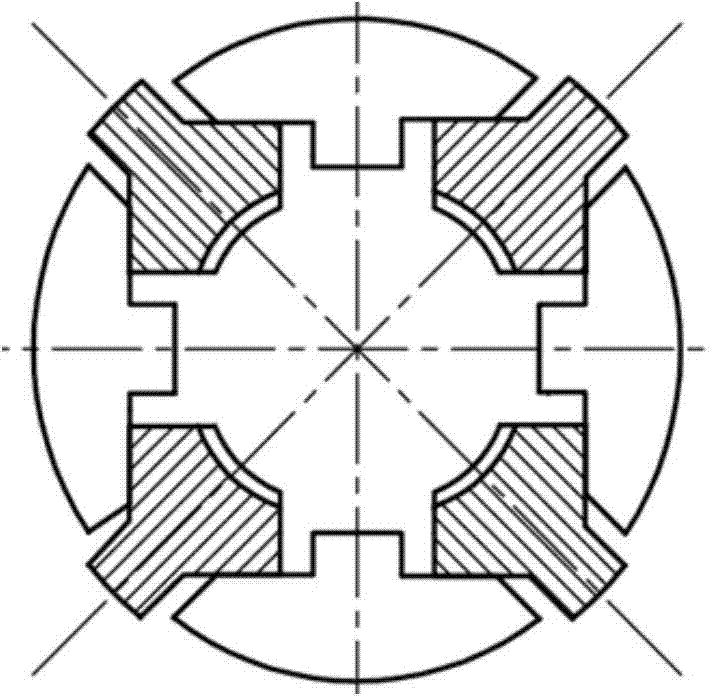

[0031] Method Example 2: A C with inner and outer flanges f / Mg composite material thin-wall special-shaped parts manufacturing method, choose AZ91D magnesium alloy, Toray T700 carbon fiber prefabricated body.

[0032] The difference between this embodiment and Embodiment 1 lies in the cross-sectional shape of the forming part of the insert group 4 and the shape of the carbon fiber preform, that is, the present invention can be used to realize C with different cross-sectional shapes. f Preparation of thin-walled special-shaped parts of / Mg composites. Other device components, connections and implementation steps are the same as those in Embodiment 1. C with inner and outer flanges is formed by machining f / Mg composite thin-walled profiled parts, followed by heat treatment and finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com