Method for smelting steel plate with excellent performance in high-heat-input-welding heat affected zone

A technology of large heat input welding and smelting method, applied in the direction of manufacturing converters, etc., can solve the problems of slab center segregation, unpublished steelmaking process parameters, reducing the toughness of the base metal and welding heat affected zone, etc., to improve the performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

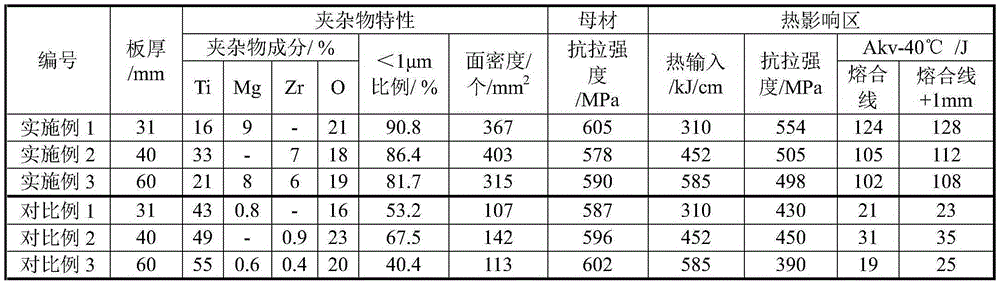

[0040] The present invention will be further described below in conjunction with embodiment.

[0041] The molten steel smelting procedure announced by the present invention is as follows:

[0042] Hot metal pretreatment → 180t combined blowing converter smelting → LF refining → RH refining → alloy cored wire feeding wire → continuous casting. Specifically:

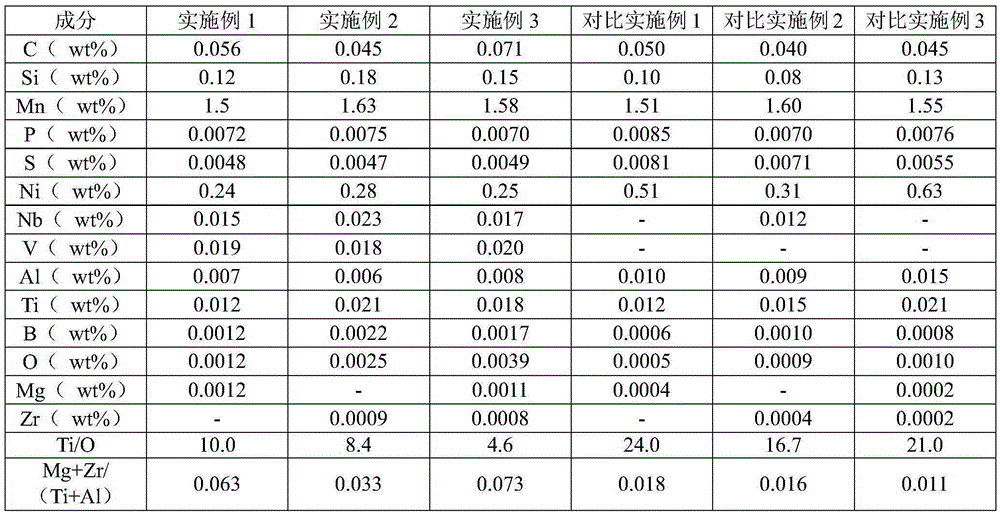

[0043] 1. The amount of molten steel for converter smelting and the proportion of clean scrap steel are 7.5, the temperature of molten iron is 1400°C, S≤0.003% by weight, the basicity of the final slag of the converter is 3.0-4.0, and the proportion of MgO is 8.0-10.0%. Constant oxygen tapping, adding ferromanganese, ferrosilicon and lime in sequence in about 1 / 3 of the furnace.

[0044] 2. The LF refining process uses calcium carbide to adjust the white slag, and the final slag is controlled as CaO / SiO 2 =1.8~2.5, then add metal manganese, ferroniobium, ferrovanadium, ferrosilicon, etc. to adjust the composition of mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com