Preparation process of biodegradable PCL (polycaprolactone)/Mg composite material FDM (fused deposition modeling) consumable

A composite material and biodegradable technology, which is applied in the field of preparation technology of biodegradable PCL/Mg composite FDM consumables, can solve problems such as limited application and difficulty in providing mechanical support, so as to improve secondary surgery, facilitate attachment and increase value. , the effect of enhancing the ability of proliferation and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation process for biodegradable PCL / Mg composite material FDM consumables, the raw material Mg and PCL are mixed and granulated by a solution method to obtain biodegradable PCL / Mg composite material FDM consumables, and Mg in the raw material accounts for 50% of the PCL mass, Solution mixing granulation, including the following steps:

[0031] 1) Dissolve PCL in N,N-dimethylacetamide (DMA), the mass of both N,N-dimethylacetamide (DMA) and PCL is 100g, heat in a water bath, the heating temperature is 80°C, and the heating time is 30min;

[0032] 2) Dissolving 50g Mg powder in 50g DMA, magnetic stirring to form a suspension, the magnetic stirring time is 30min, and the magnetic stirring speed is 600rpm;

[0033] 3) pour the suspension formed in step 2) into the solution of step 1), pour the solution into the tin foil box after magnetic stirring, the magnetic stirring time is more than 60min, and the rotating speed is 600rpm;

Embodiment 2

[0039] A preparation process of biodegradable PCL / Mg composite material FDM consumables, the raw material Mg and PCL are mixed and granulated by a parallel twin-screw extruder to obtain biodegradable PCL / Mg composite material FDM consumables, and Mg in the raw materials accounts for the mass of PCL. 30% of;

[0040] It specifically includes the following steps: take 200g of PCL and 60g of Mg and put them into the hopper of a parallel twin-screw extruder, the screw length-diameter ratio of the parallel twin-screw extruder is 20:1, the extrusion temperature is 80°C, and the extrusion process After the pellets are put into the hopper, the operation is repeated several times until the Mg is uniformly dispersed in the PCL substrate.

Embodiment 3

[0042] A preparation process for biodegradable PCL / Mg composite material FDM consumables. The raw material Mg and PCL are directly mixed and extruded through a single screw extruder to obtain biodegradable PCL / Mg composite material FDM consumables. 5% of PCL mass;

[0043] Specifically include the following steps: take 20g of PCL and 1g of Mg into the hopper of the single-screw extruder, set the temperature of the extrusion section to 70 °C, and set the temperature of the mixing section to 80 °C; Then put it into the hopper and repeat the operation several times until the Mg is uniformly dispersed in the PCL substrate.

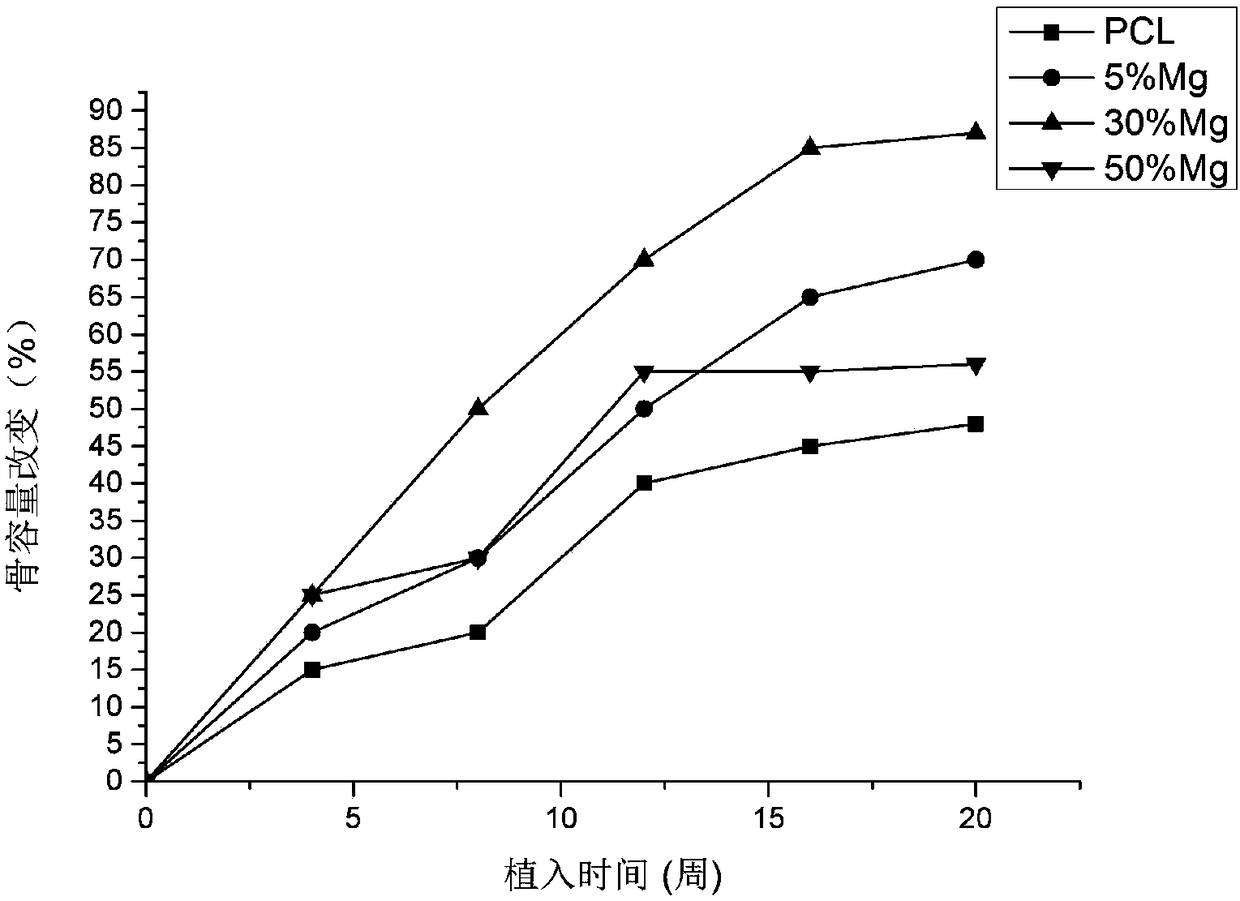

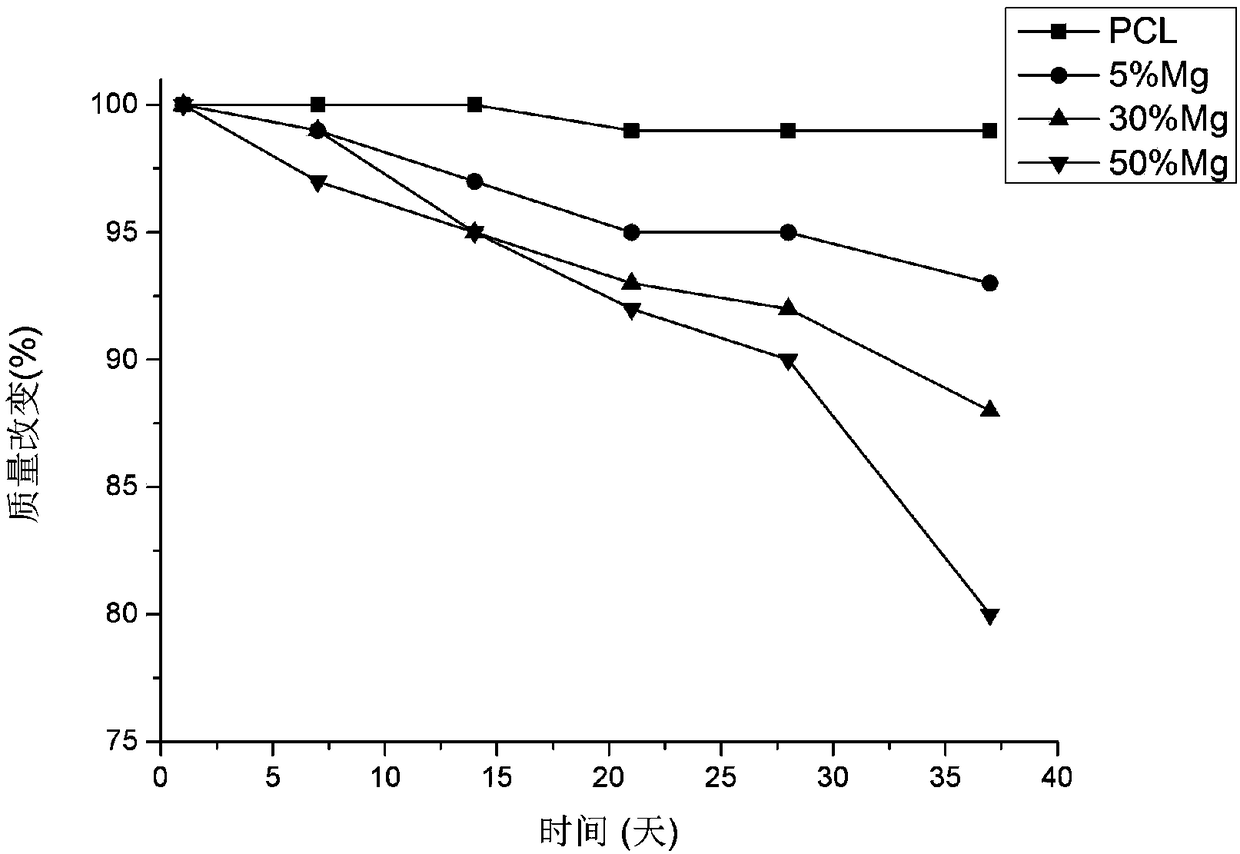

[0044] refer to figure 1 , figure 1 It is the trend diagram of the change of bone volume with time after adding different mass fractions of Mg to the PCL of Example 1, Example 2 and Example 3, from figure 1 It can be seen that the addition of Mg with different mass fractions in PCL has a higher degree of increase in bone volume than pure PCL, and 30% mass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com