Patents

Literature

34results about How to "Achieve alloying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid-phase alloying method of aluminum-silicon powder under high-pressure condition

The invention discloses a solid-phase alloying method of aluminum-silicon powder under high-pressure condition. The applied aluminum-silicon alloy comprises the following components by weight percent: 10% to 80% of aluminum and the balance of silicon. Appropriate granularity proportion of aluminum powder and silicon powder is selected, the prepared aluminum powder and silicon powder are mixed together by using a rotational ball mill in the three-dimensional direction, are subsequently put into a vacuum heating furnace to be subjected to activation treatment, and are further put into a carbon steel sleeve to sinter under high pressure at a temperature lower than the melting point, the sintering time is controlled, and the alloying is realized depending on dispersion under the condition that the aluminum and the silicon are not molten. The solid-phase alloying method is an aluminum-silicon powder solid-phase alloying method that the process course is short, the cost is low and high-quality aluminum-silicon alloy can be obtained under high-pressure condition; and the prepared aluminum-silicon alloy can be widely applied to electronic device materials or functional coating materials.

Owner:ZHUZHOU SMELTER GRP +2

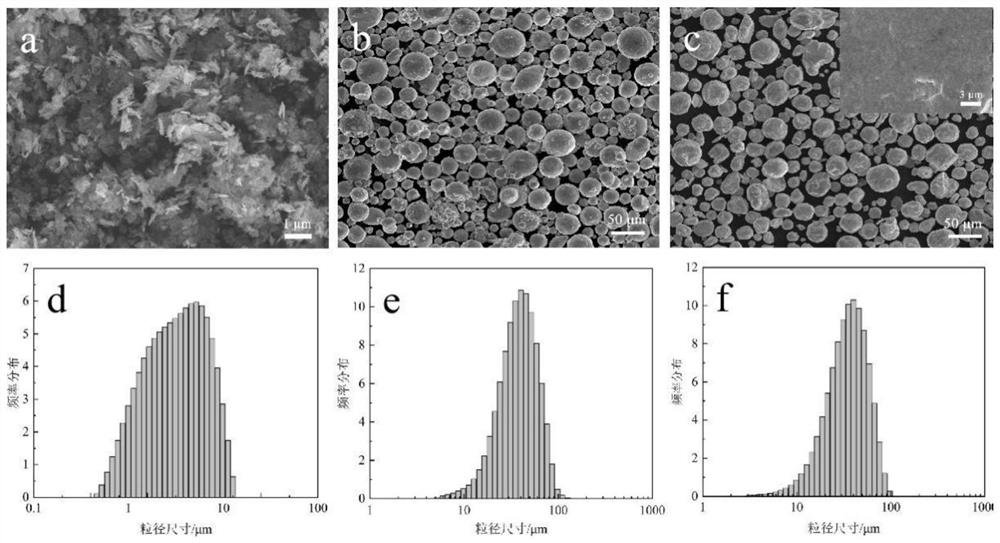

Method for preparing superfine high-purity high-solid-solubility tungsten-based alloy powder

ActiveCN113134612AImprove solid solubilityImprove uniformityTransportation and packagingMetal-working apparatusAlloyBall mill

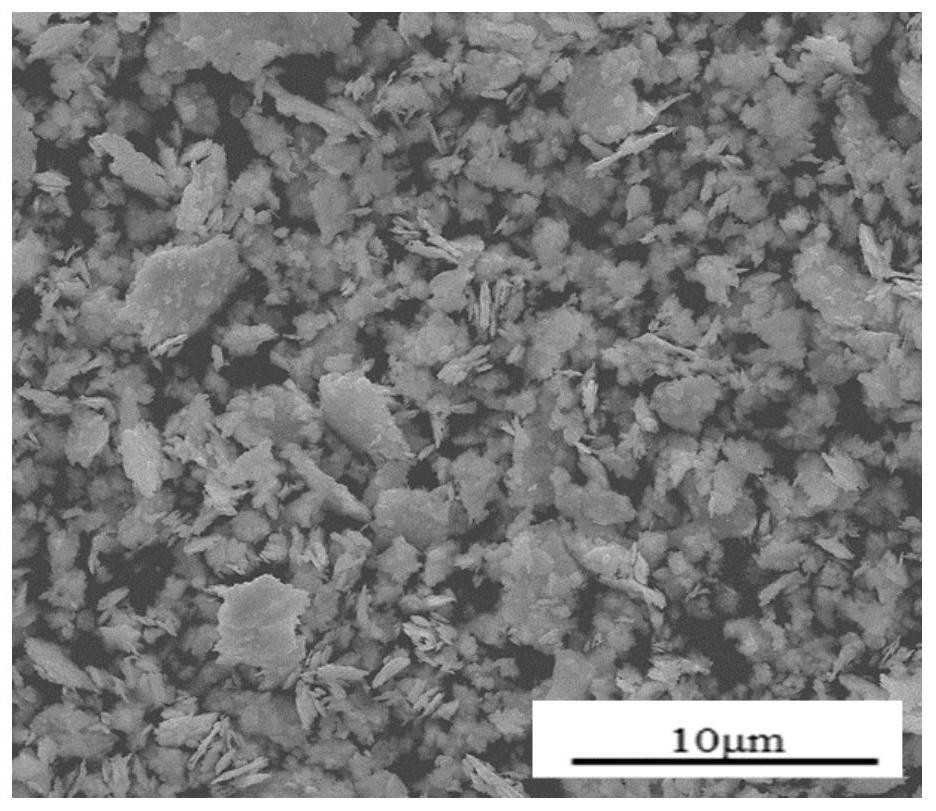

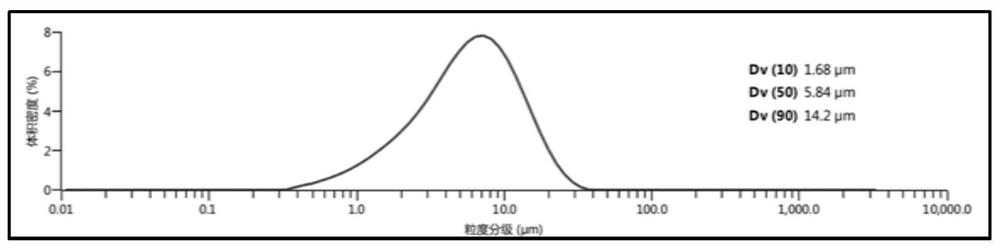

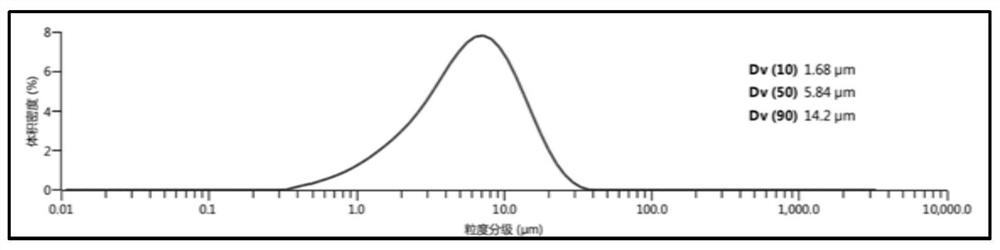

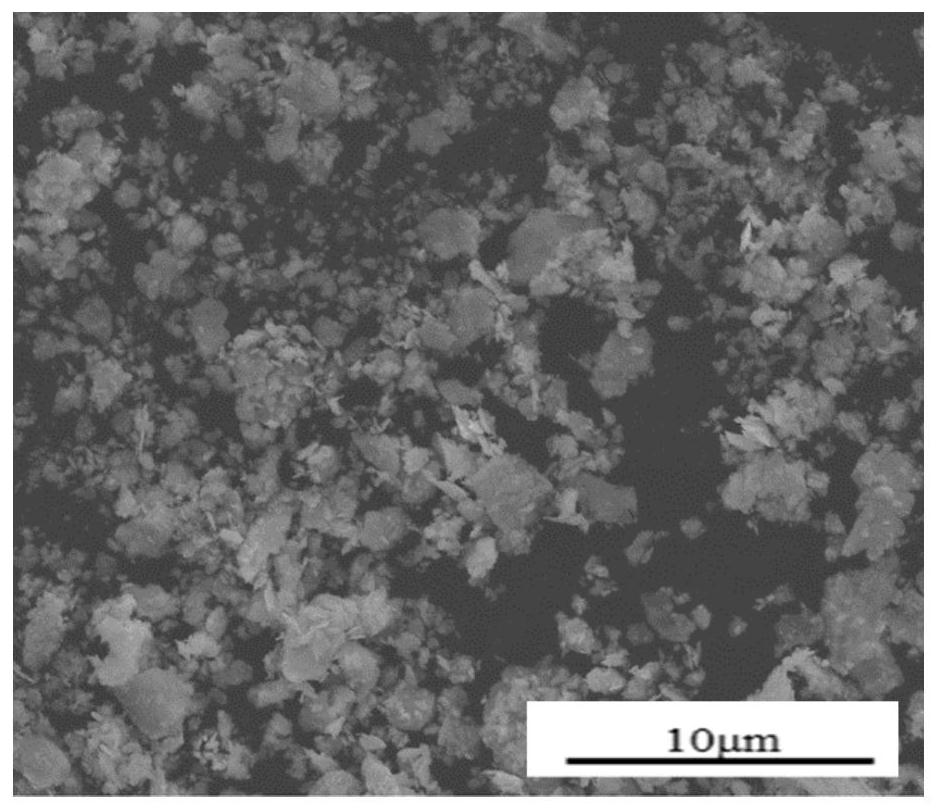

The invention belongs to the field of material preparation, and particularly relates to a method for preparing superfine high-purity high-solid-solubility tungsten-based alloy powder. According to the method, the content of adsorbed oxygen is reduced by combining multi-stage high-energy ball milling with a reduction heat treatment process, the introduction amount of solid solution elements is increased, a dislocation slippage mechanism of pure tungsten is effectively improved, tungsten particles are toughened, and the problem of low solid solubility of a traditional powder preparation method is solved. In the first stage, auxiliary materials are subjected to low-speed ball milling; and then prepared tungsten powder is added into ball milling equipment to be subjected to high-speed ball milling for a proper time, so that the problems of non-uniform particle size and impurity introduction of powder prepared through a traditional mechanical alloying method are effectively solved. The process is simple and controllable; and an obtained product is low in impurity content, narrow in particle size distribution, small in particle size and convenient for large-scale industrial application.

Owner:CENT SOUTH UNIV

Non-magnetic low nickel abrasion-resistant and corrosion-resistant high nitrogen stainless steel and processing method thereof

The invention discloses a non-magnetic low nickel abrasion-resistant and corrosion-resistant high nitrogen stainless steel. The non-magnetic low nickel abrasion-resistant and corrosion-resistant high nitrogen stainless steel is characterized by including, by mass percentage, 14%-15% of manganese, 14%-15% of chromium nitride, 0.002% of cobalt, 0.002% of niobium, 1% of silicon, 0.003% of phosphorus, 0.001% of sulfur, 0.2%-0.25% of nitrogen, 1.3%-1.5% of nickel, 0.01% of molybdenum, 0.002%-0.003% of vanadium, 0.004% of rich rare earth and the balance iron. The manganese and the nitrogen replace the nickel, direct application of a nitrogen alloy in stainless steel production is achieved, the strength of the stainless steel is improved, and it is guaranteed that no corrosion is generated in the usage period; the production and application cost of the stainless steel is reduced by 30% or above; and there is a very good promoting and leading effect on the stainless steel processing enterprise including transformation and upgrading and product structure adjustment of the screen cloth processing enterprise.

Owner:JIANGSU LIJIN NEW MATERIAL TECH CO LTD

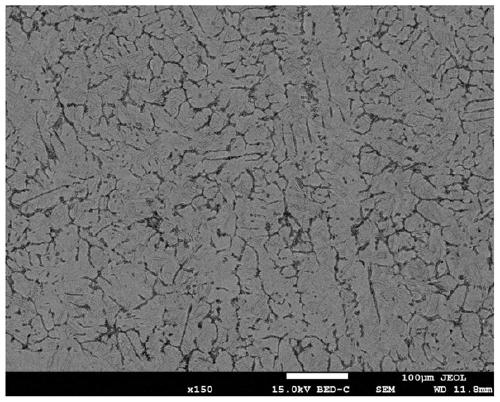

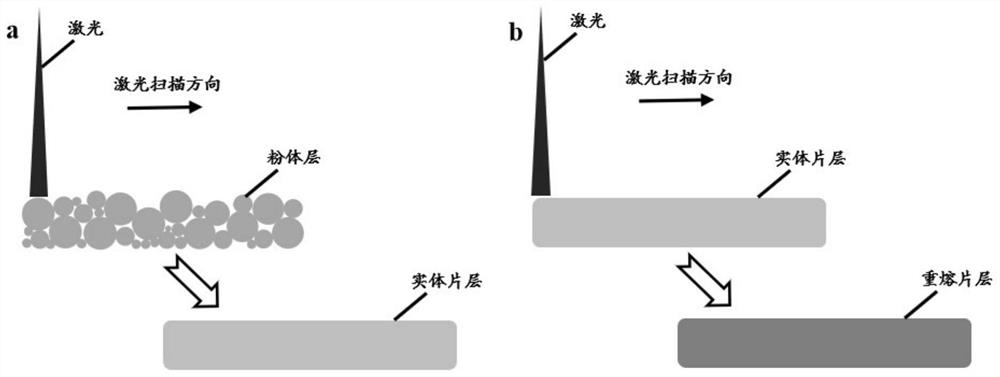

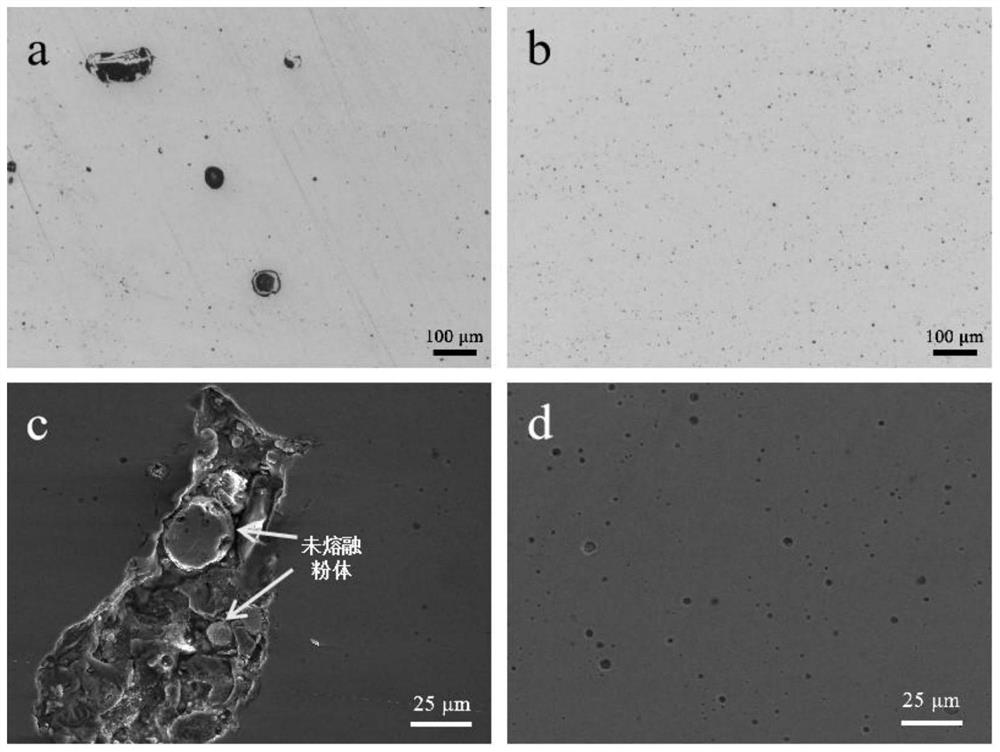

Laser additive manufacturing method of in-situ synthesized nano Al2O3 reinforced aluminum-based composite material

ActiveCN112176213AAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMg composite

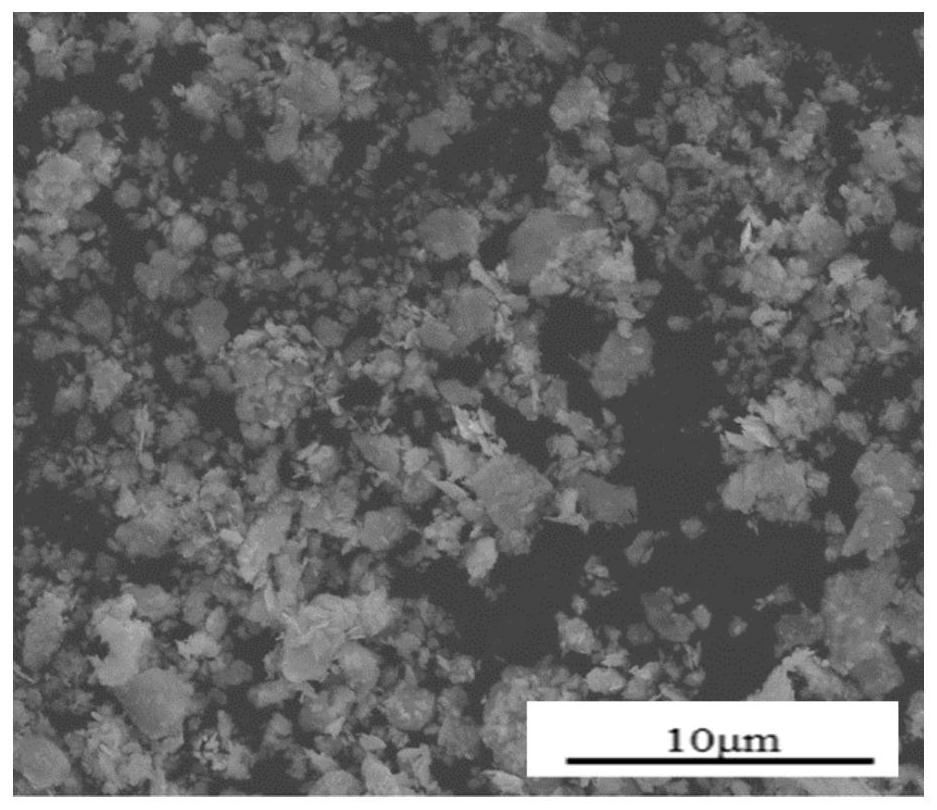

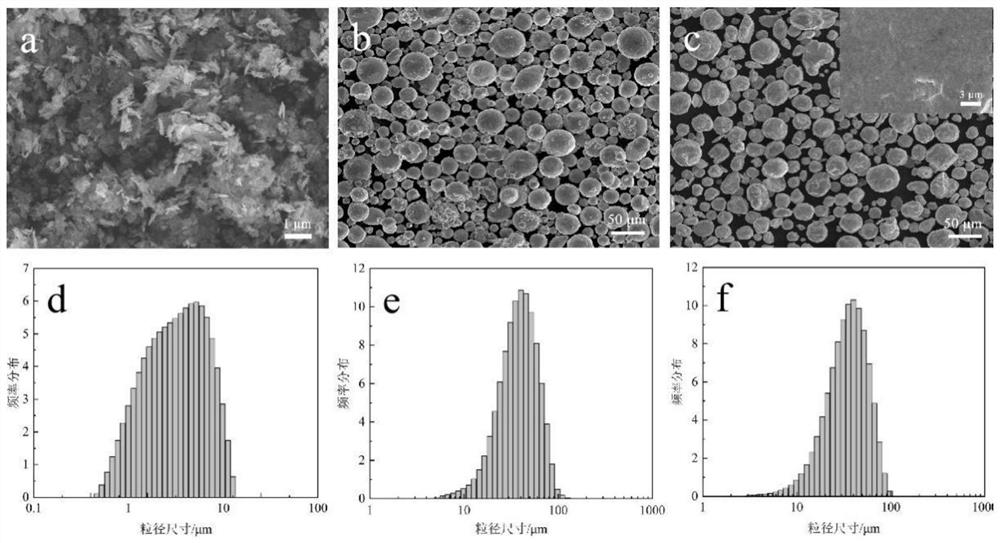

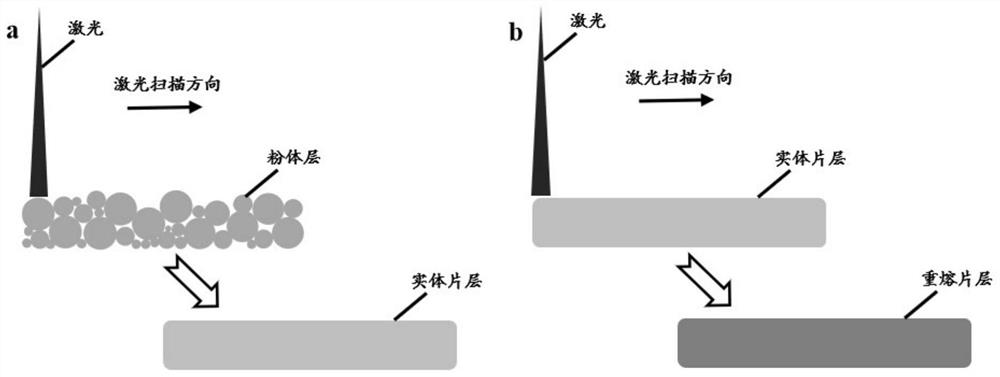

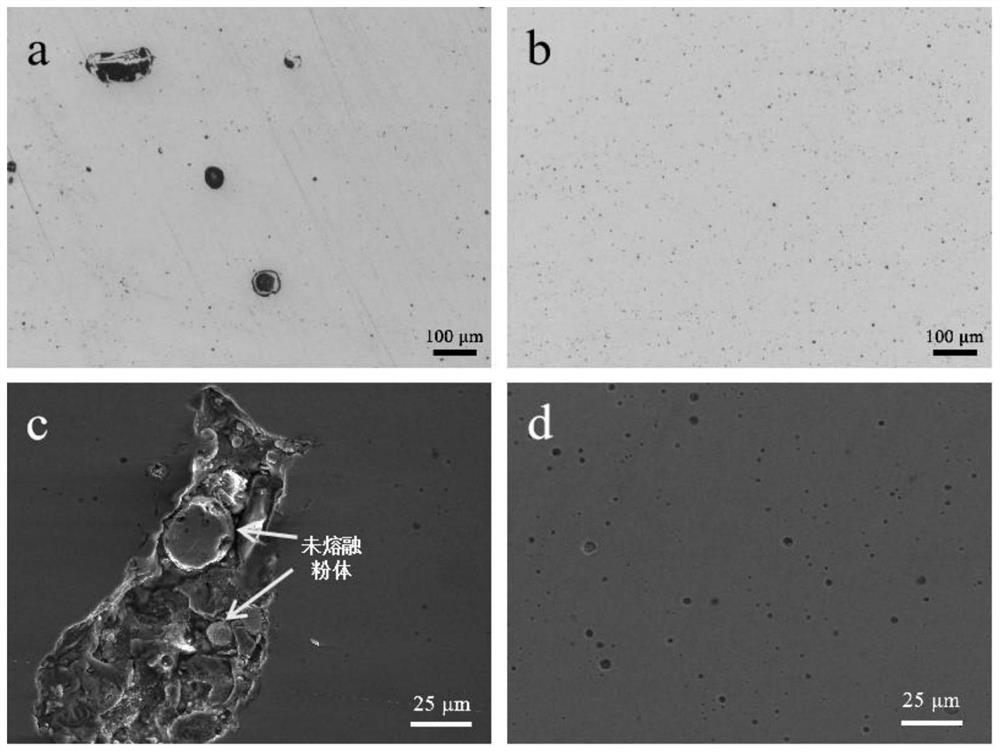

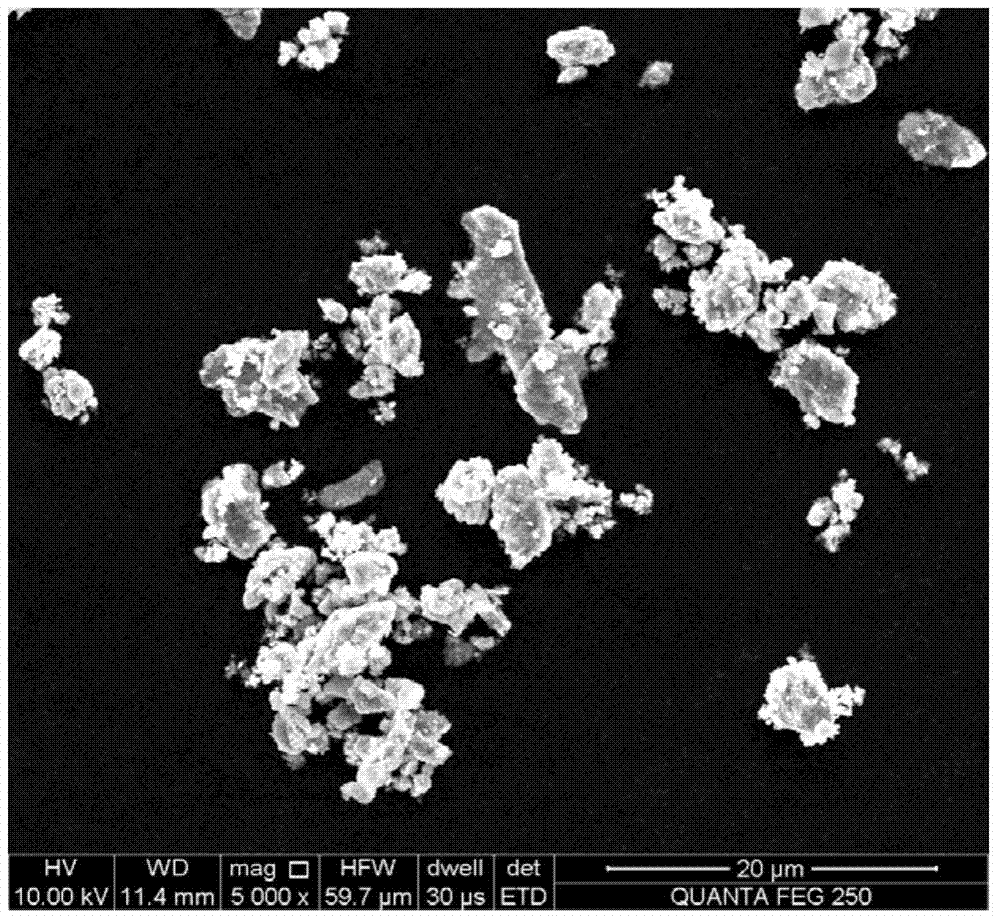

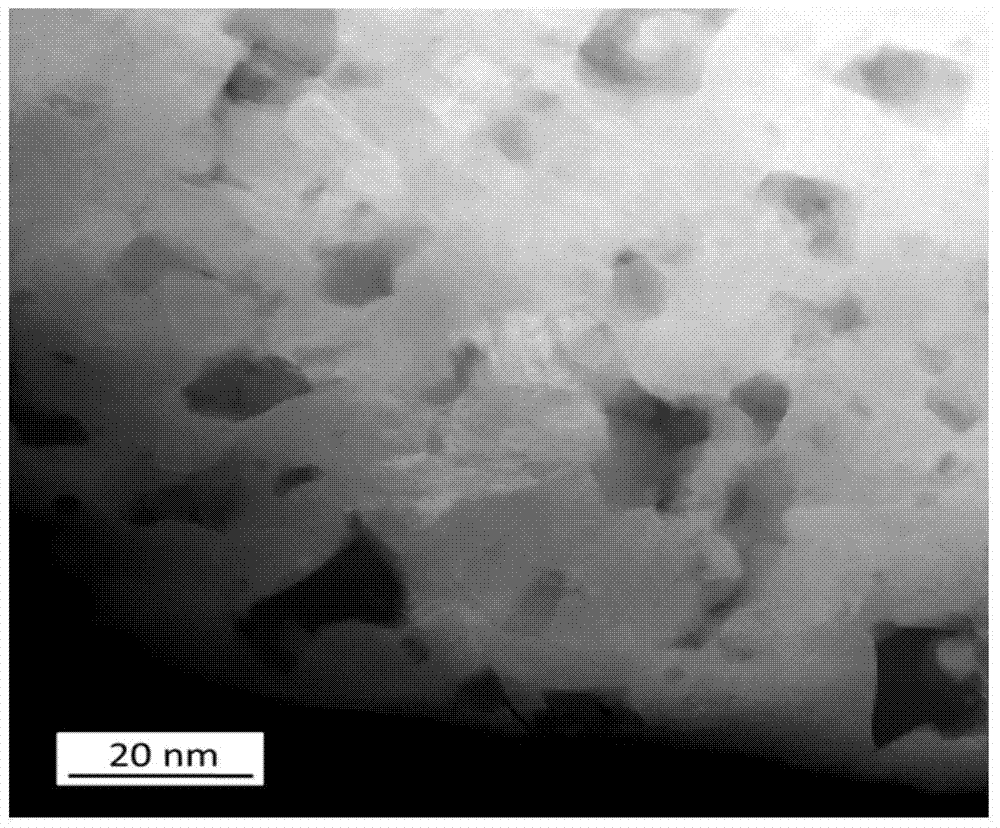

The invention discloses a laser additive manufacturing method of an in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. The method comprises the following steps of (1) mixingZnO ceramic powders and AlSi10Mg aluminum alloy powders, and carrying out ball milling to obtain ZnO / AlSi10Mg composite powders; (2) carrying out additive manufacturing forming on the composite powders by adopting a selective laser melting process to form a solid sheet layer; (3) carrying out laser scanning on the solid sheet layer again to form a remelting sheet layer; (4) repeating the steps (2)and (3), and finally forming to obtain the in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. A laser is used for exciting Al and ZnO to generate aluminothermic reactions between the Al and ZnO to generate Al2O3 ceramic particles in situ, the overall process design of the method is improved, selective laser melting and laser remelting scanning are matched, the prepared aluminum-based composite material is high in density and fine in microstructure, the in-situ synthesized Al2O3 particles are nanoscale in size and are uniformly distributed, and the phase interfaces ofthe Al2O3 particles are well combined with an aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Process for preparing (Ti,Al)BN ceramic amorphous-nanocrystalline wear-resistant anti-corrosion composite coating

InactiveCN102660732AAchieve alloyingImprove performanceVacuum evaporation coatingSputtering coatingMetallurgySputter deposition

The invention discloses a process for preparing a (Ti,Al)BN ceramic amorphous-nanocrystalline wear-resistant anti-corrosion composite coating. The process comprises the following steps of: performing dual-cathode plasma sputtering deposition; performing ionic nitriding, wherein the sputtered target is a powder metallurgy sintered plate of which the mass ratio of Ti to B to Al is 6:3:1, and which is prepared by a hot isostatic pressure process, and a workpiece material is titanium alloy. By a dual-cathode plasma sputtering technology, the (Ti,Al)BN amorphous-nanocrystalline composite coating is generated in situ by adjusting the ratio of the components of a target to gas. A preparation process is simplified, and the whole performance of the coating is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Al-Ti-B target material and powder solid phase alloying sintering method thereof

ActiveCN111455329AAvoid melting and flowingShort processVacuum evaporation coatingSputtering coatingAlloy elementBatch production

The invention provides an Al-Ti-B target material and a powder solid phase alloying sintering method thereof. The method comprises the following steps of firstly, weighing and mixing, secondly, ball grinding mechanical alloying, thirdly hot pressing sintering, fourthly, demolding, fifthly, annealing treatment and sixthly, forging. According to the Al-Ti-B target material and the powder solid phasealloying sintering method thereof, high-content Ti and B are added into an Al matrix to be prepared into the Al-Ti-B target material, the content of Ti can reach up to 80%, and the content of B can reach up to 20%; on the basis of an Al-Ti-B ternary alloy, other elements can be added to obtain the alloy target material with more elements; due to the fact that the low temperature and large pressure solid phase sintering method, melting and flowing of low-melting-point alloy elements are avoided, and through the diffusion action, alloying between high-melting-point alloy elements and low-melting-point alloy elements is achieved; and the technological process is short, product quality is stable, production cost is low, and the Al-Ti-B target material and the method are suitable for batched production.

Owner:CHANGSHA XUNYANG NEW MATERIAL TECH CO LTD +1

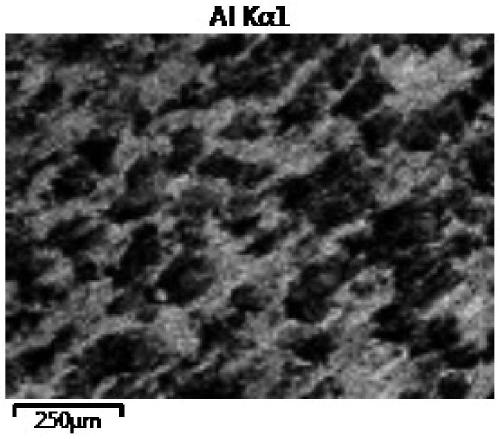

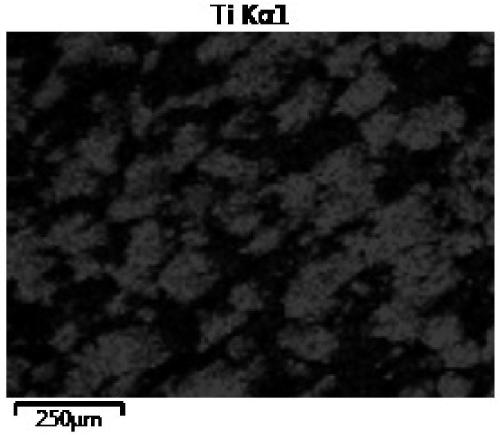

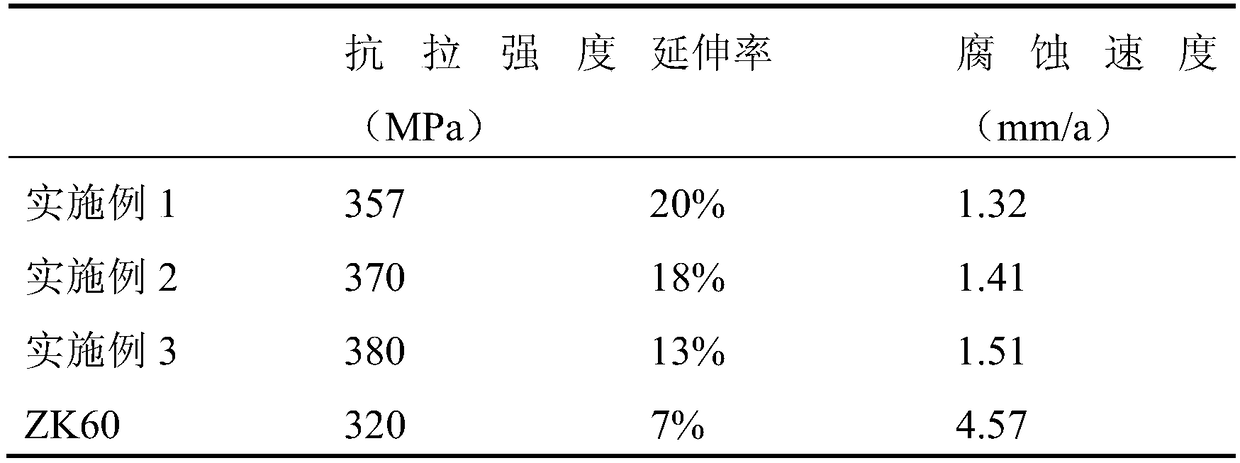

High-toughness corrosion-resistant biological magnesium alloy and preparation method thereof

The invention discloses a high-toughness corrosion-resistant biological magnesium alloy and a preparation method thereof. The composition of the magnesium alloy is Mg-Zn-Ca-Ti, wherein the mass fraction of Zn is 2%-8%, the mass fraction of Ca is 1%-3%, and the mass fraction ratio of Zn to Ca is 2 to 4, the mass fraction of Ti is 0.1%-0.8%, after the raw materials are smelted, a blank ingot of thecomposite material is prepared by adopting an injection deposition process, and the blank ingot is processed into a finished product. The prepared magnesium alloy is uniform in structure, fine in grain, mechanical property and corrosion resistance are excellent, the biocompatibility is excellent, and the magnesium alloy has a wide application prospect in the fields of engineering structural members and biological implantable devices.

Owner:NANJING INST OF TECH

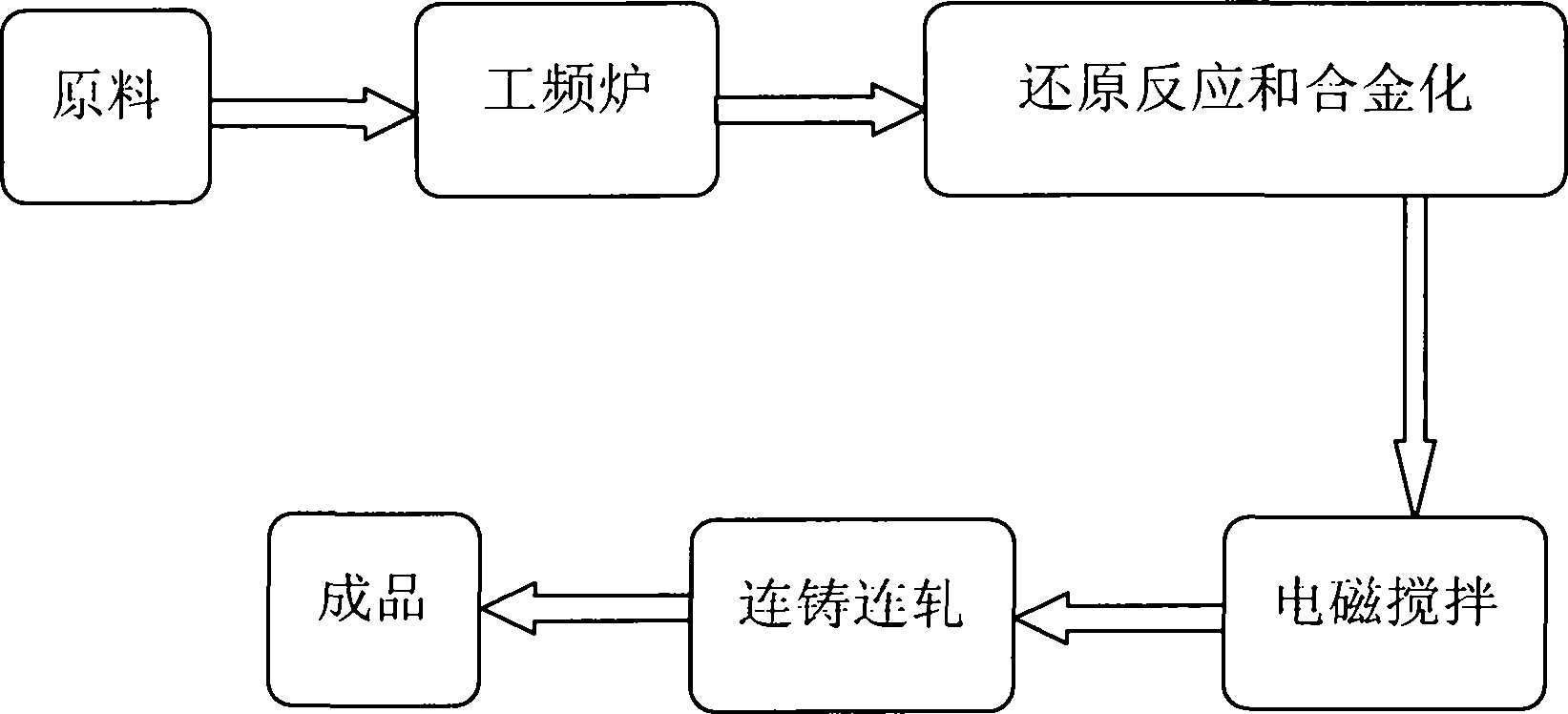

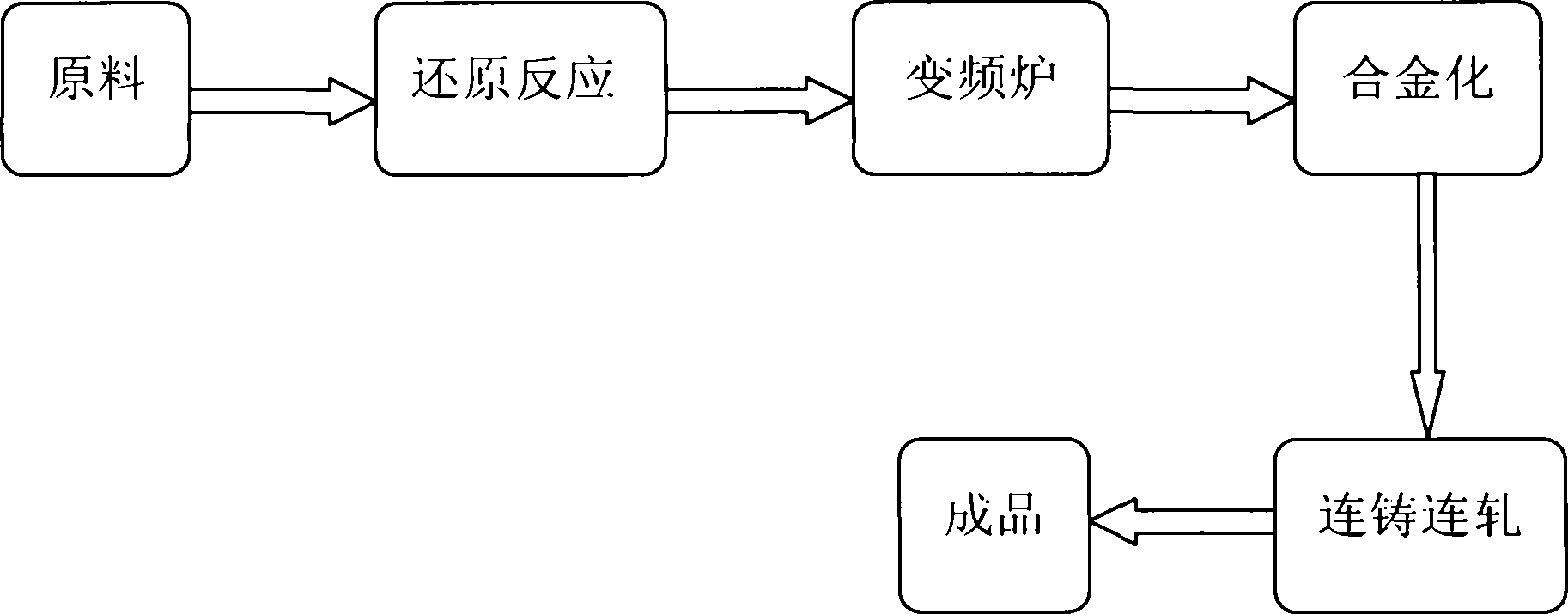

Aluminum-titanium-boron production process

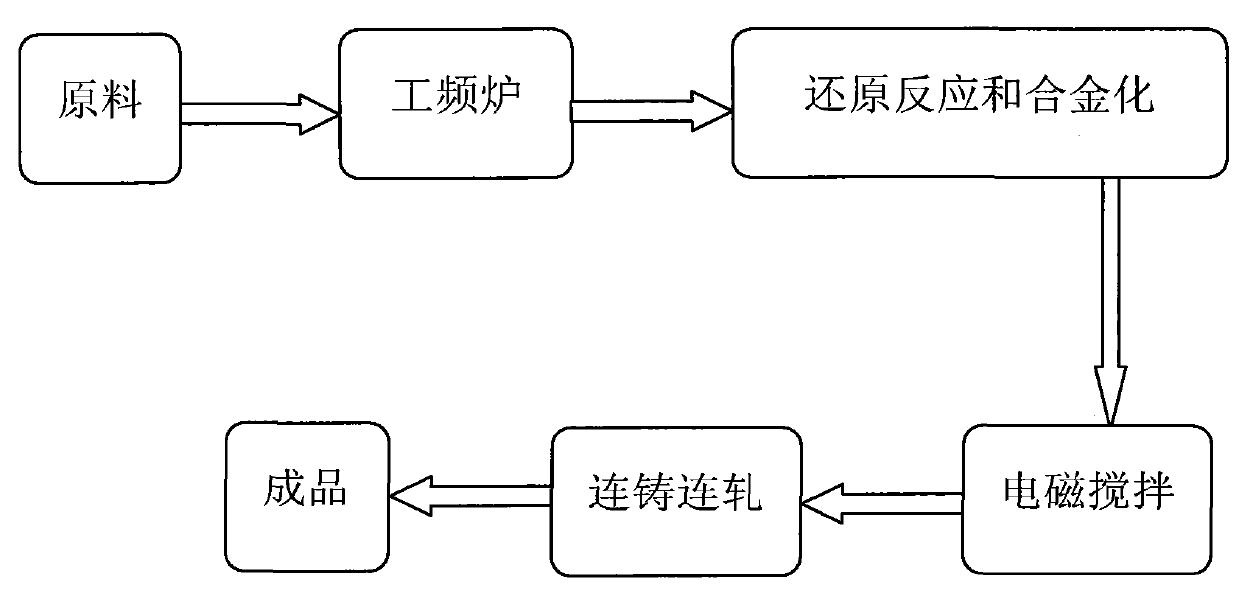

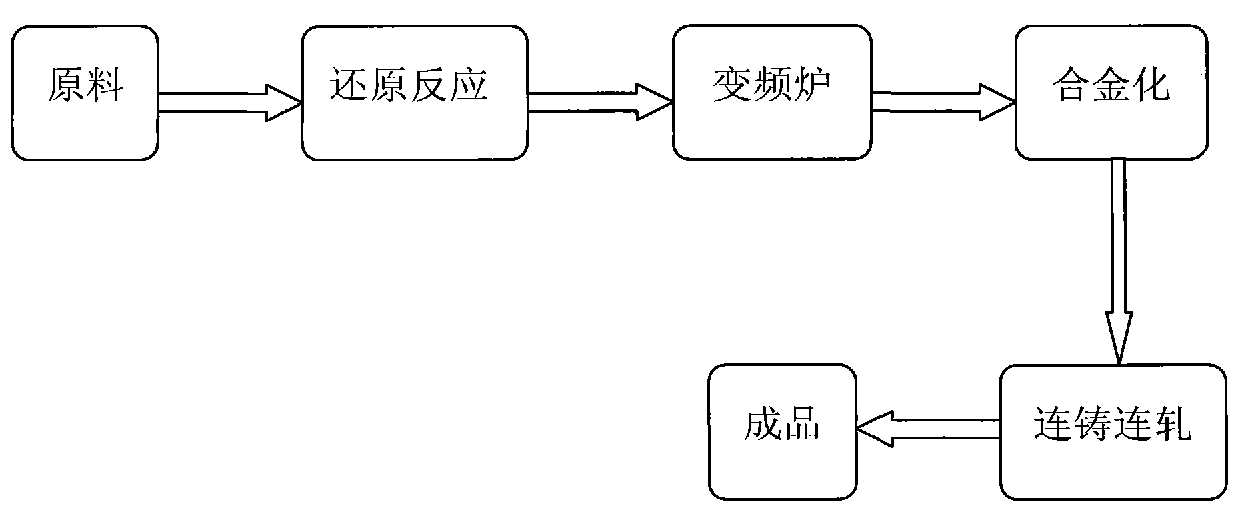

InactiveCN103952602AAchieve alloyingSufficient electromagnetic stirring capacityStirring devicesCrucibleTitanium

The invention discloses an aluminum-titanium-boron production process, comprising the following steps: firstly, carrying out reduction reaction on raw materials in a reduction platform package, and stirring by adopting a stirrer according to the requirements in reduction reaction; carry out alloying operation in an inverter frequency furnace after reduction reaction is ended; finally processing alloy aluminum liquid in a continuous casting and rolling process through a crucible, so as to obtain an aluminum-titanium-boron product, wherein the crucible is a crucible discharging aluminum liquid from the bottom, the inverter frequency furnace is a coreless induction furnace, and the electromagnetic stirring force inside a hearth is proportional to specific power density of an electric furnace and inversely proportional to square root of work frequency. Reduction reaction is separated from the alloy operation, the problem that the temperature sharply changes and cannot be controlled due to a lot of heat generated in reduction reaction is avoided, meanwhile, the hold-up time of the crucible is reduced, and the capacity is improved. Discharge of the aluminum liquid from the crucible is changed into a bottom discharge method, and electromagnetic stirring generated by the inverter frequency furnace can be utilized to prevent participation of titanium element, and therefore no holding furnace or electromagnetic stirrer are needed and investment in equipment is reduced.

Owner:ZUNYI ZHIPENG HI TECH ALUMINUM COMPANY

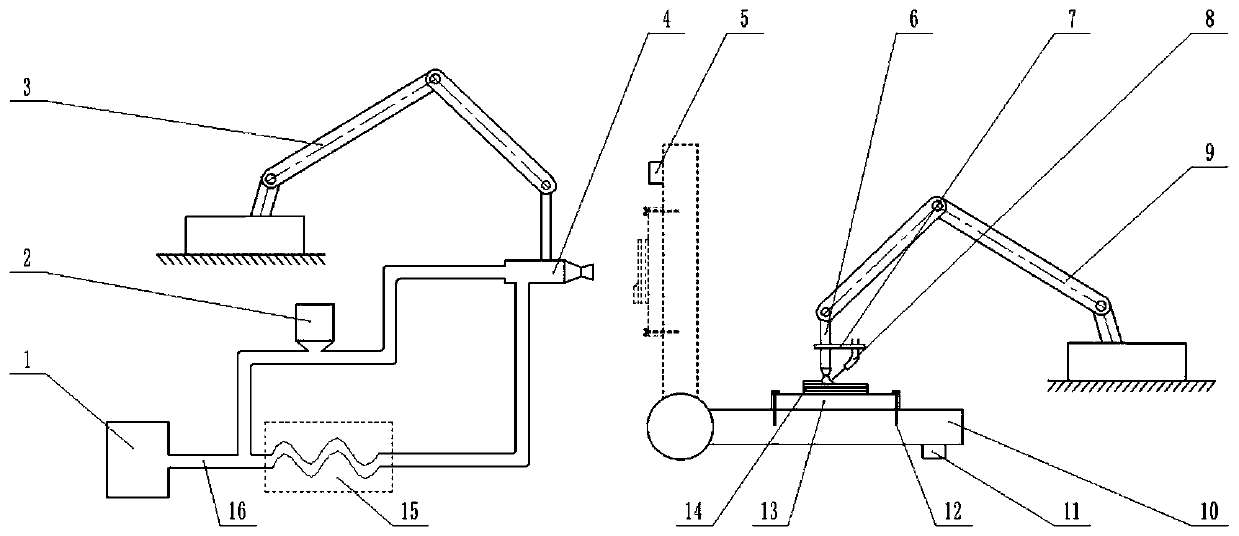

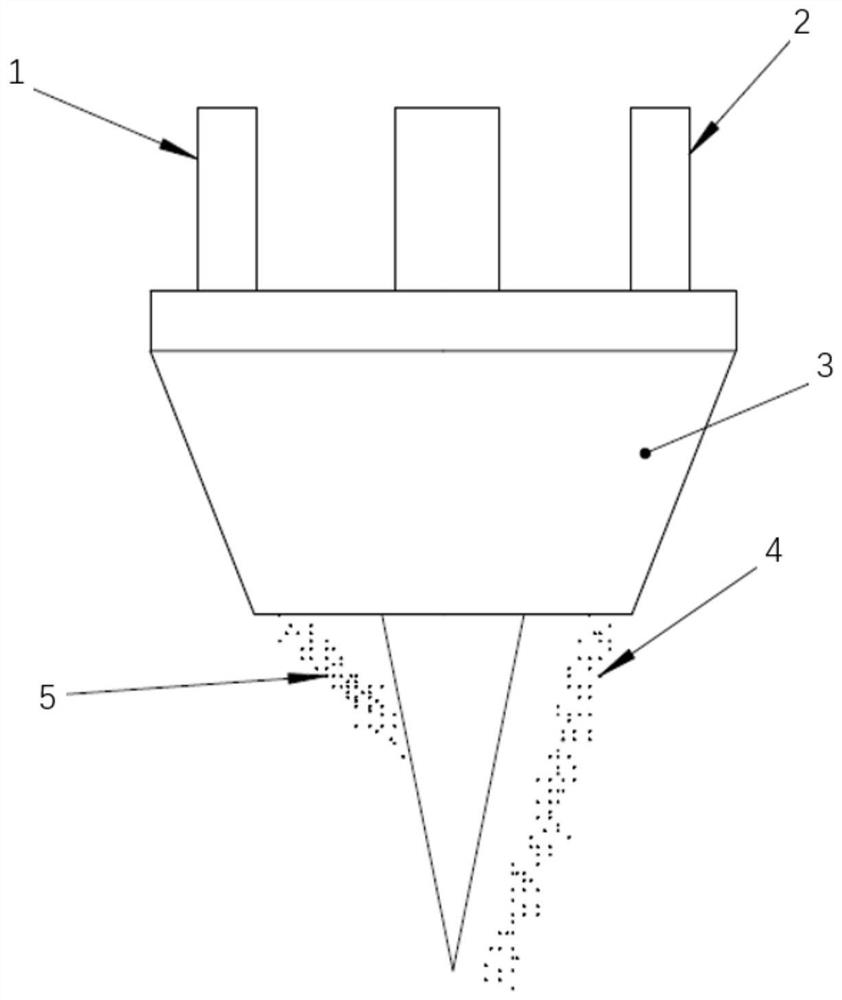

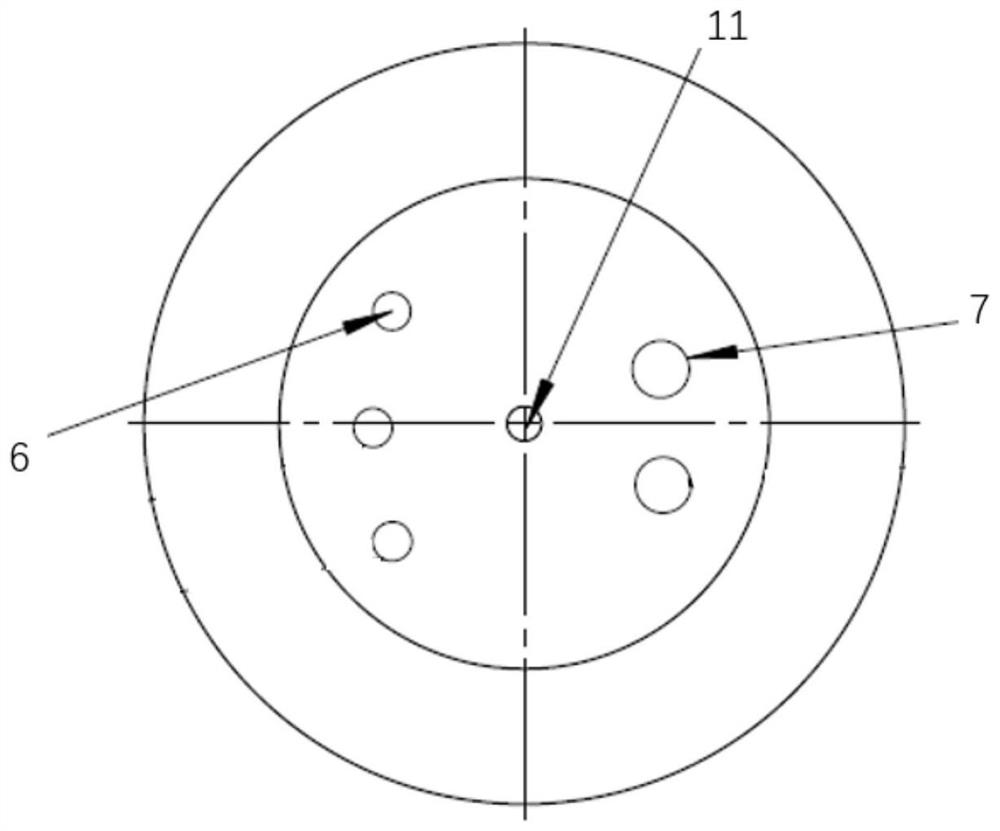

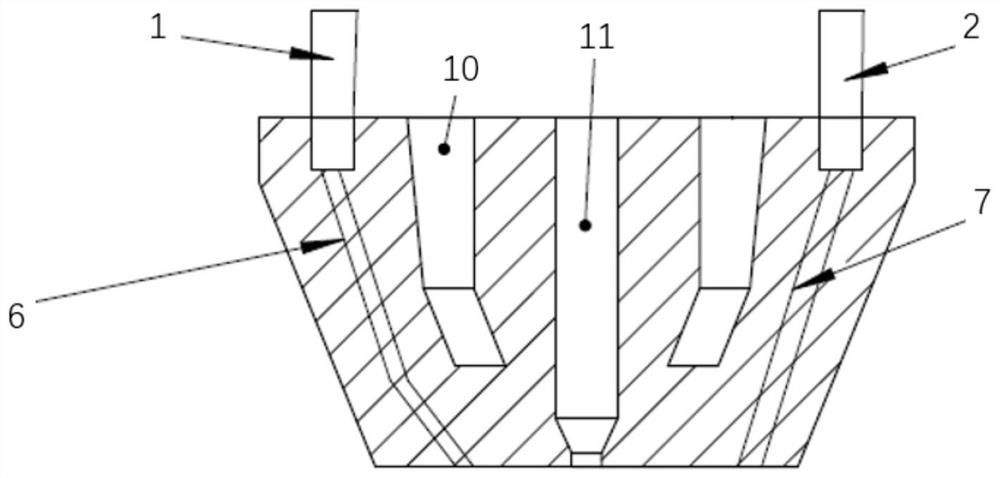

Arc additive manufacturing in-situ alloying device and method capable of achieving alternate wire melting and powder supply

PendingCN110004398AAchieve alloyingCompositeAdditive manufacturing apparatusMolten spray coatingArthrobotrysElectric arc

The invention discloses an arc additive manufacturing in-situ alloying device and method capable of achieving alternate wire melting and powder supply. The device comprises a spraying device, a wire melting device and a turnover workbench. Through the gas power spraying device, in-situ spraying of multiple kinds of pure metal powder, alloy powder and metal-ceramic composite powder can be achieved,and alloying and compounding of an arc additive manufacturing material can be achieved to the greatest degree. When the gas power spraying device carries out in-situ powder spraying, generated high-speed gas jet flow carrying powder particle impacts on the surface of a deposition layer, the function of stress peening is achieved, a pressure stress layer is introduced, surface roughness is reduced, and the structure performance of an arc additive manufacturing metal component is optimized. The device completely depends on existing welding equipment existing spraying equipment in the market, additional equipment research and development expenditures are not needed, the powder spraying process and the subsequent arc wire filling process are controlled by programming of a six-axis joint robot, automatic operation can be carried out, and the work efficiency is high.

Owner:TIANJIN UNIV

Hard alloy based on tungsten carbide and preparation method of hard alloy

The invention discloses a hard alloy based on tungsten carbide and a preparation method of the hard alloy. The hard alloy comprises a tungsten carbide hard phase and a binding phase, wherein the binding phase is a high-entropy alloy. The preparation method comprises the following steps of (1) weighing tungsten carbide powder in specific parts by mass and simple substance powder of each element in the high-entropy alloy; (2) mixing the tungsten carbide powder and the simple substance powder and then transferring into a ball mill to be subjected to ball milling, and obtaining a mixed material after drying; and (3) molding and sintering the mixed material to obtain the hard alloy based on tungsten carbide. According to the hard alloy, adverse effects of cobalt on health safety and environmental safety are reduced, the production cost of the hard alloy is reduced, and the bonding strength of the alloy is improved. According to the preparation method of the hard alloy, the process flow is reduced, the probability that the raw materials are polluted is reduced, and the preparation method has the advantages that the production cost of the hard alloy is reduced, and the quality of the hard alloy is improved.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

Nodulant for alloying nodular cast iron

The invention relates to a nodulant for alloying nodular cast iron, which comprises the following elements in percent by mass: 83.5-94 percent of Cu, 5-15 percent of Mg and 1.0-1.5 percent of RE. By using the nodulant, the nodular cast iron can be nodulized and alloyed. Because the nodulant does not contain Si, the consumption of scrap returns can be increased to lower the production cost.

Owner:HOHAI UNIV +1

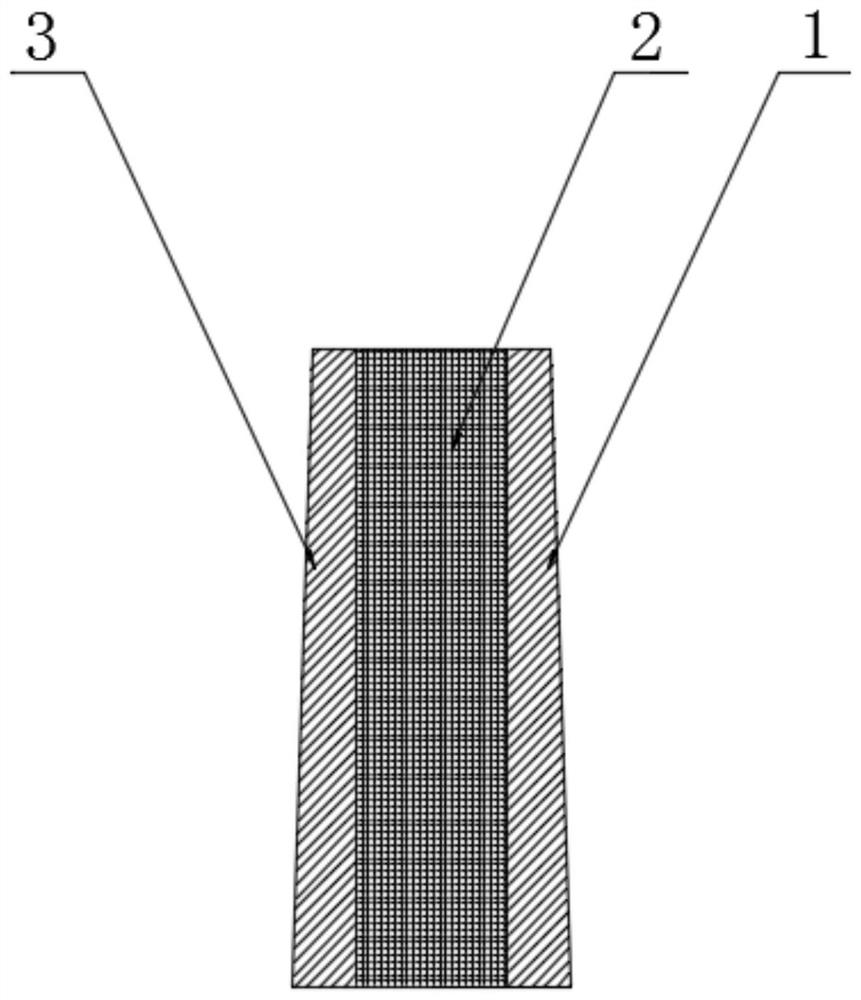

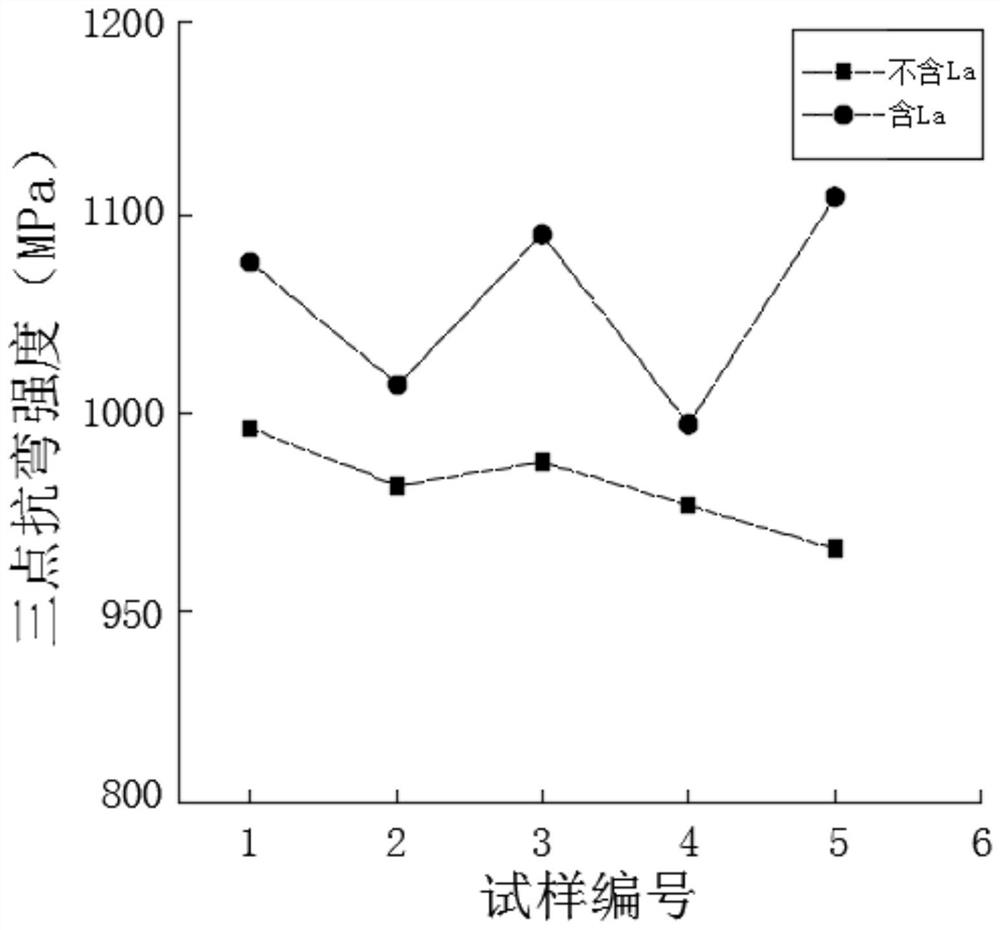

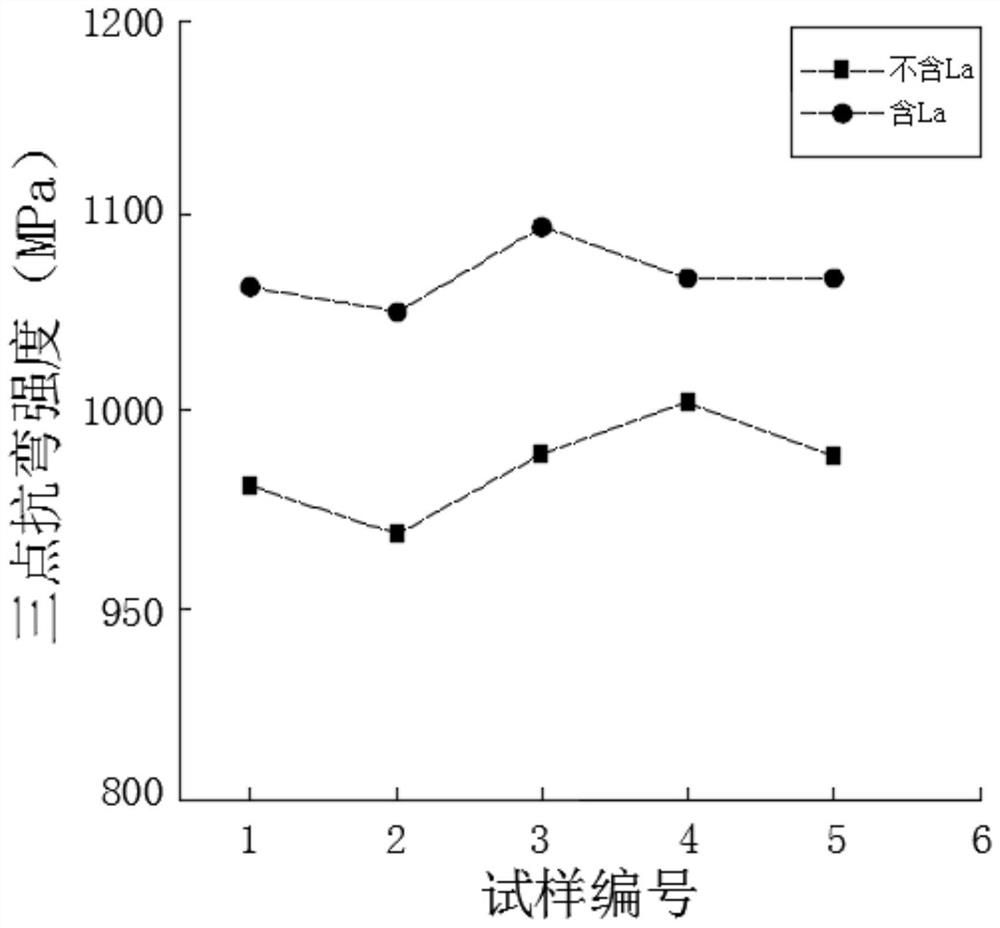

Low-price gang saw tool bit product and preparation method thereof

InactiveCN112091218AGuaranteed lifeGuaranteed sintering effectTransportation and packagingMetal-working apparatusTool bitRare-earth element

The invention discloses a low-price gang saw tool bit product and a preparation method thereof, and particularly relates to the field of gang saw tool bits. A tool bit material adopted by the tool bitproduct is formed by mixing and sintering metal powder, liquid paraffin and diamond, wherein the metal powder is prepared from the following powder raw materials in part by weight: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel and 0.8 part of La, the liquid paraffin accounts for 1-1.2 parts, and the diamond accounts for 30% of the volume of the tool bit material. According to the low-price gang saw tool bit product and the preparation method thereof, by adding different contents of Fe, Cu, Ni and Sn and a small amount of rare earth elements, the hardness HRB, the bending strength and the abrasion ratio of a matrix are kept, so that the mechanical property and the abrasion resistance of the gang saw tool bit to the matrix are met; and the characteristics of the matrix are matched by using the diamond with the fixed grade and granularity, the holding force of the matrix on the diamond and the edge exposure effect are ensured, and the cutting sharpness and the service life of a cobalt-based product are achieved by using a sintering process matched with the characteristics of the matrix.

Owner:QINGDAO SHINHAN DIAMOND INDUSTRY CO LTD

RE4TCd magnetic refrigeration material and preparation method thereof

ActiveCN114561580AReduce volatilityUniform tissueTransportation and packagingMetal-working apparatusRare-earth elementMischmetal

The invention discloses an RE4TCd magnetic refrigeration material. RE is one or a mixture of two of rare earth elements Dy, Ho and Tm, and T is one or a mixture of two of transition metal elements Ni and Cu. The invention also discloses a preparation method of the RE4TCd magnetic refrigeration material, which comprises the following steps: mixing and melting the rare earth metal and the transition metal into an RE4T alloy ingot, crushing the RE4T alloy ingot, mixing the crushed RE4T alloy ingot with Cd powder, sintering in a sealed mold at high pressure and low temperature, and carrying out heat treatment to obtain the RE4TCd material. According to the RE4TCd magnetic refrigeration material and the preparation method thereof, the magnetic entropy change value of the RE4TCd magnetic refrigeration material is 16.4-25.8 J / kg K under the magnetic field change of 0-5, the RE4TCd magnetic refrigeration material has large magnetic entropy change, and the application range of the low-temperature magnetic refrigeration material is widened.

Owner:HANGZHOU DIANZI UNIV

In situ self-generated nano al 2 o 3 Laser additive manufacturing method for reinforced aluminum matrix composites

ActiveCN112176213BAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMg compositeHigh density

The invention discloses an in-situ self-generated nano-Al 2 o 3 A laser additive manufacturing method for strengthening an aluminum-based composite material, the method comprising the following steps: (1) mixing ZnO ceramic powder and AlSi10Mg aluminum alloy powder and ball milling to obtain a ZnO / AlSi10Mg composite powder; (2) preparing the composite powder The laser selective melting process is used for additive manufacturing forming to form a solid sheet; (3) The laser re-scans the solid sheet to form a remelted sheet; (4) Repeat steps (2) and (3) to finally form the original self-generated nano-Al 2 o 3 Reinforced aluminum matrix composites. In the present invention, laser is used to excite Al and ZnO to generate aluminum thermal reaction between them in situ. 2 o 3 Ceramic particles, and by improving the overall flow process design of the method, combining laser selective melting and laser remelting scanning, the aluminum matrix composite material obtained has high density, fine microstructure, and in-situ self-generated Al 2 o 3 The particle size is nanoscale, uniformly distributed, and its phase interface is well combined with the aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

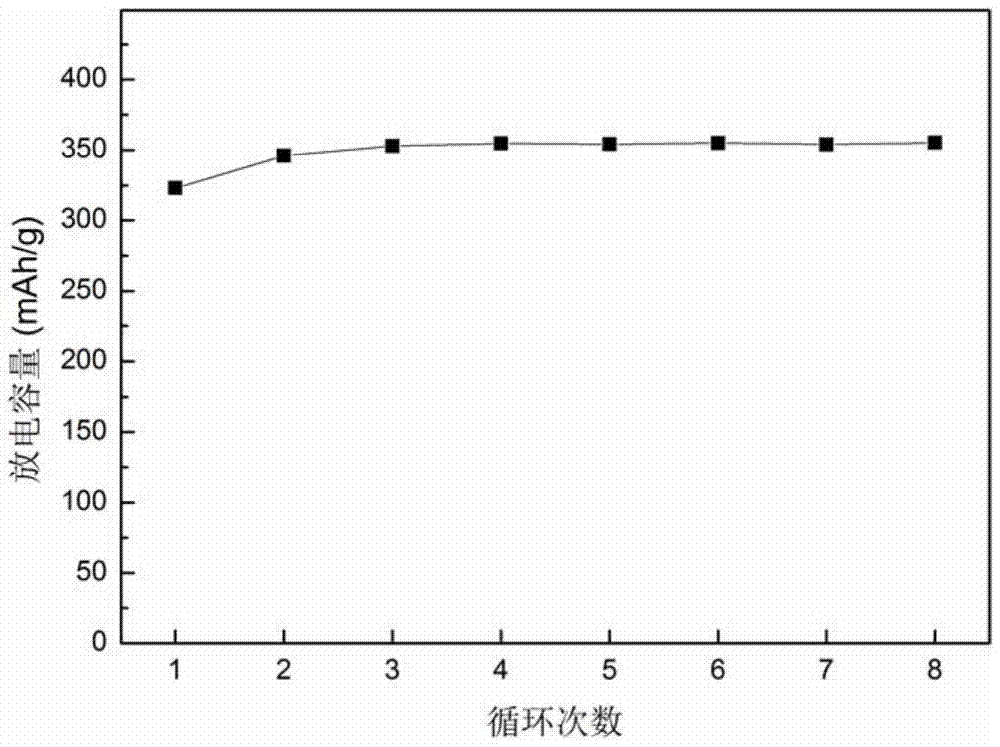

A kind of mg-ti hydrogen storage alloy powder and preparation method thereof

ActiveCN105170972BSolve Oxidation ProblemsAchieve alloyingCell electrodesMaterials preparationOrganic solvent

The invention relates to an Mg-Ti hydrogen storage alloy powder and a preparation method thereof, belonging to the technical field of new energy material preparation and development. The alloy designed by the invention comprises the following components in percentage by weight: 70-92 percent of Mg-Ti alloy, 5-16 percent of FeCl3 and 1-15 percent of carbon nano tubes; in the Mg-Ti alloy, the content of Mg is 65-85 atomic percent, and the rest is Ti. The preparation method comprises the following steps: adding a magnesium source and a titanium source prepared according to the designed components into a ball milling jar full of an organic solvent for ball milling, then carrying out drying, and thus obtaining Mg-Ti alloy powder; then, uniformly mixing the FeCl3 powder, the carbon nano tubes; and the Mg-Ti alloy powder prepared according to the designed components, and thus obtaining the Mg-Ti hydrogen storage alloy. The organic solvent is selected from one of alcohols and hydrocarbons. The preparation process is simple, and the obtained Mg-Ti hydrogen storage alloy powder has good performance and is convenient for industrial production and application.

Owner:CENT SOUTH UNIV

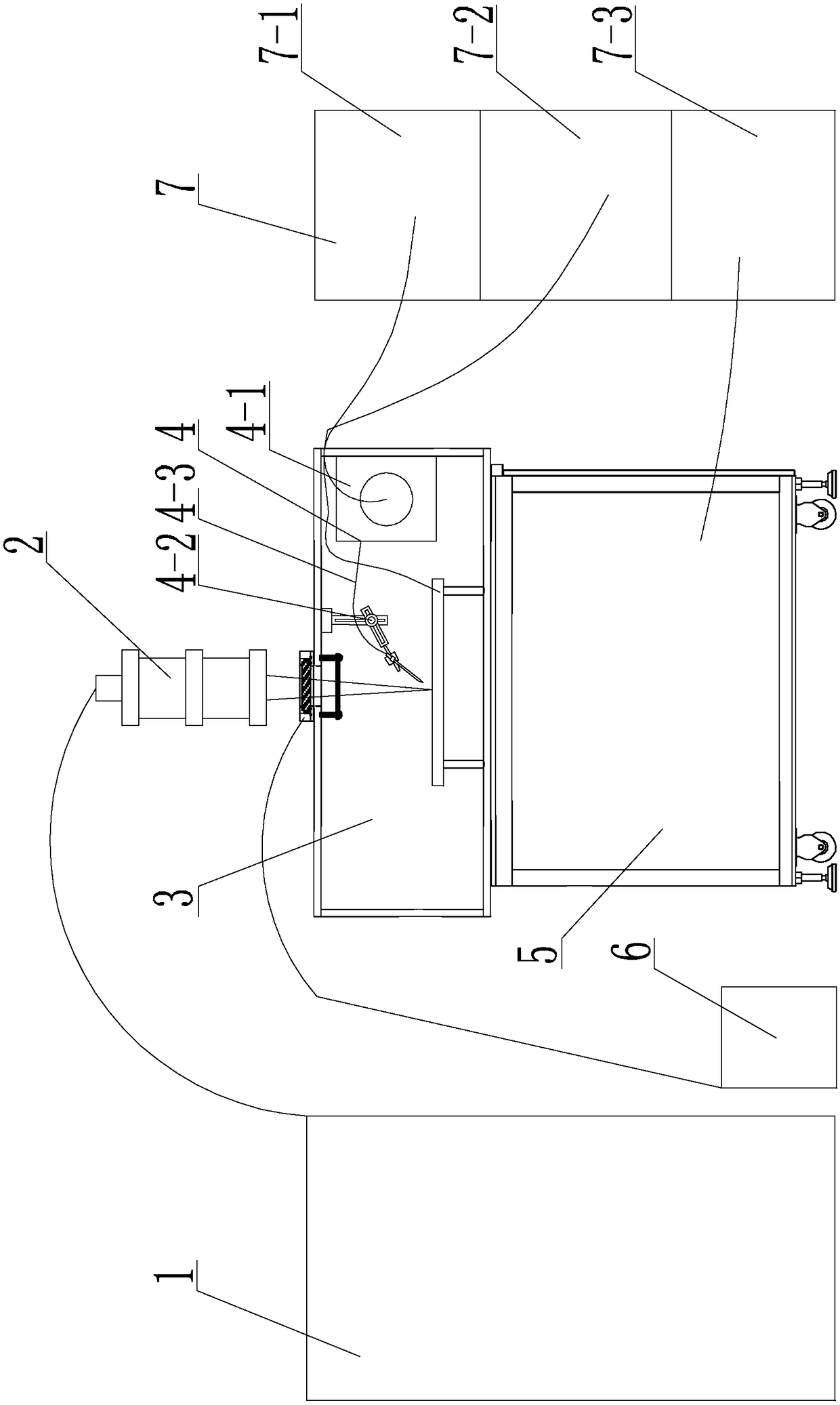

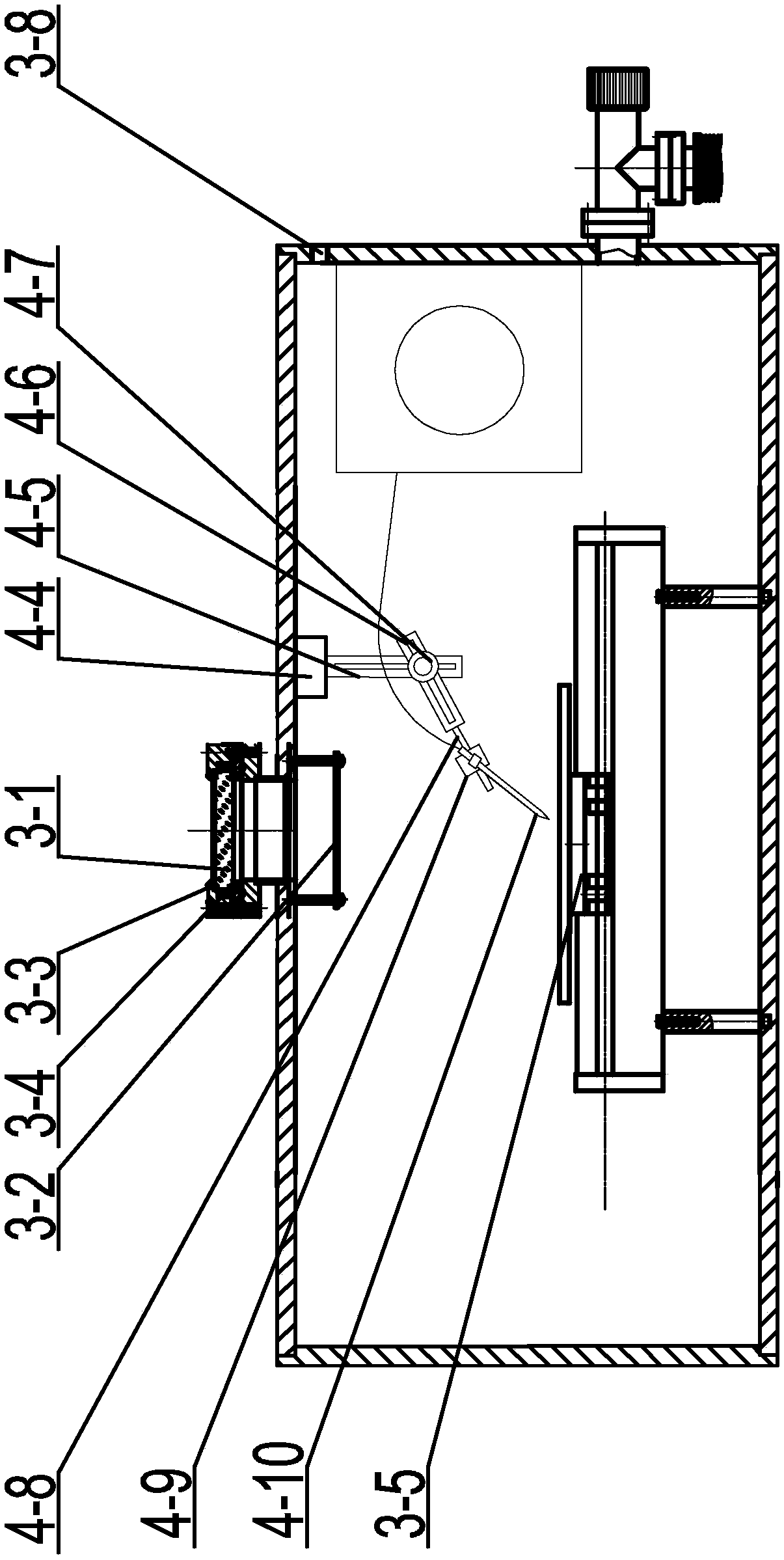

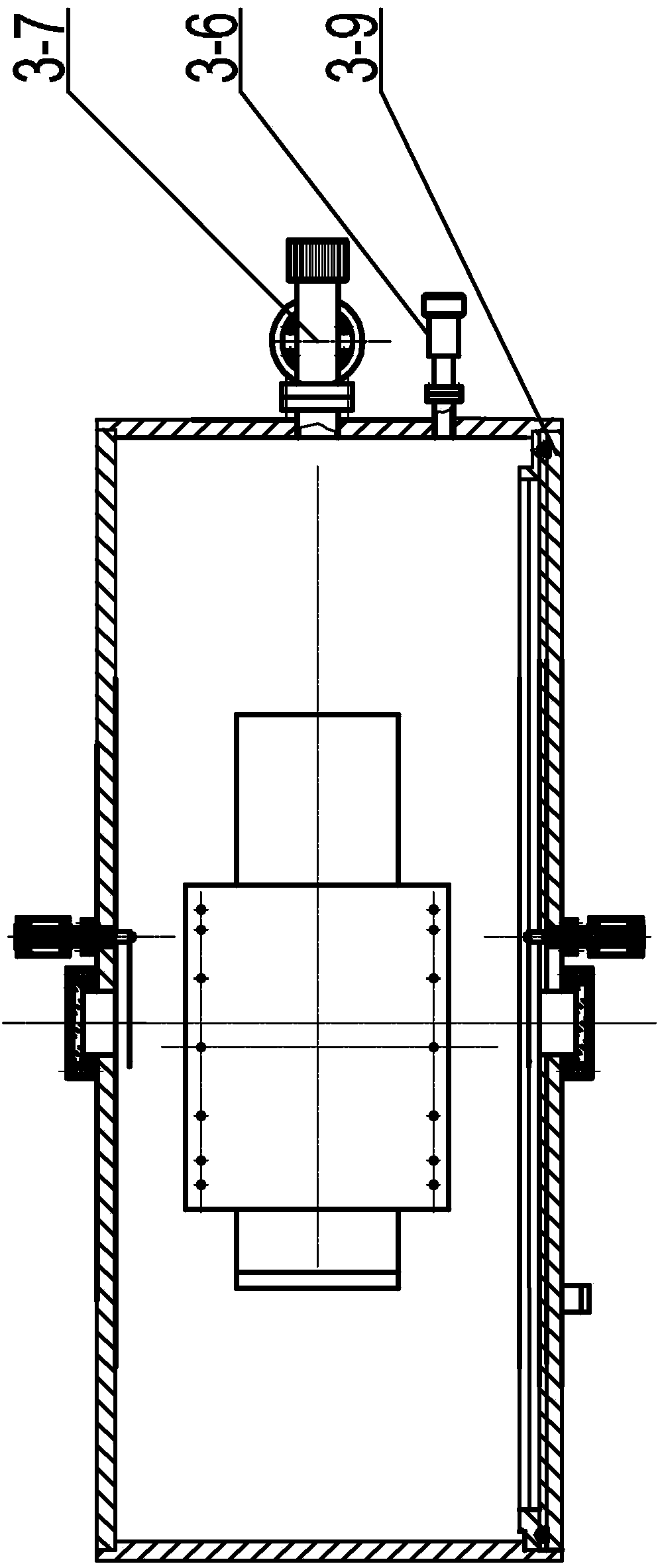

A vacuum laser wire filling processing device and a vacuum laser wire filling method

The invention relates to a laser processing device and method, in particular to a vacuum laser wire filling processing device and a vacuum laser wire filling method, and belongs to the field of vacuum laser processing. The problem that the device for realizing vacuum laser wire filling welding in the mode of introducing automatic alloying while drilling into the welding process and the method for realizing laser wire filling with the device are unavailable in the prior art is solved. The device comprises a laser unit, a laser processing head, a vacuum chamber component, a wire feeding component, a vacuum pumping mechanism, a water-cooling circulation mechanism and a digital control mechanism, the vacuum chamber component is arranged on the vacuum pumping mechanism, the laser processing head is arranged over the vacuum chamber component, the wire feeding component is installed in the vacuum chamber component, the laser unit is connected with the laser processing head through an optical fiber, a water-cooling circulation pipe of the water-cooling circulation mechanism is mounted at the top end of the vacuum chamber component, the laser unit and the water-cooling circulation mechanism are arranged near the vacuum pumping mechanism, and the digital control mechanism is connected with the vacuum chamber component, the wire feeding component and the vacuum pumping mechanism through cables.

Owner:HARBIN INST OF TECH

Nodulant for alloying nodular cast iron

The invention relates to a nodulant for alloying nodular cast iron, which comprises the following elements in percent by mass: 83.5-94 percent of Cu, 5-15 percent of Mg and 1.0-1.5 percent of RE. By using the nodulant, the nodular cast iron can be nodulized and alloyed. Because the nodulant does not contain Si, the consumption of scrap returns can be increased to lower the production cost.

Owner:HOHAI UNIV +1

A method for preparing ultrafine, high-purity, high-solid-solubility tungsten-based alloy powder

ActiveCN113134612BImprove solid solubilityImprove uniformityTransportation and packagingMetal-working apparatusAlloyTungsten

The invention belongs to the field of material preparation, and particularly relates to a method for preparing ultrafine, high-purity and high-solid-solubility tungsten-based alloy powder. The invention adopts multi-stage high-energy ball milling combined with reduction heat treatment process to reduce the content of adsorbed oxygen, increase the introduction amount of solid solution elements, effectively improve the dislocation slip mechanism of pure tungsten, toughen tungsten particles, and solve the problem of low solid solubility in traditional powder milling methods. question. In the present invention, the first stage of low-speed ball milling of auxiliary materials; then, the prepared tungsten powder is added to the ball-milling equipment for a suitable period of high-speed ball milling, which effectively improves the problems of uneven particle size and impurities in the traditional mechanical alloying method. The process of the invention is simple and controllable; the obtained product has low impurity content, narrow particle size distribution and small particle size, and is convenient for large-scale industrial application.

Owner:CENT SOUTH UNIV

A kind of aluminum titanium boron production process

InactiveCN103952602BAchieve alloyingSufficient electromagnetic stirring capacityStirring devicesElectric arc furnaceCrucible

The invention discloses a production process of aluminum, titanium and boron. Firstly, raw materials are put into a reduction table bag for reduction reaction, and a stirrer is used for stirring according to the needs of the reduction reaction; after the reduction reaction is completed, it is transferred into a frequency conversion furnace for alloy chemical operation; finally, the alloy aluminum water enters the continuous casting and rolling process through the crucible to obtain the finished product of aluminum titanium boron. The force is proportional to the specific power density of the electric furnace and inversely proportional to the square root of the operating frequency. The invention separates the reduction reaction from the alloy operation, avoids the uncontrollable drastic temperature change due to the generation of a large amount of heat in the reduction reaction, reduces the occupation time of the crucible, and improves the production capacity; changes the aluminum water out of the crucible to the bottom out method , The electromagnetic stirring generated by the frequency conversion furnace can be used to prevent the precipitation of titanium elements, so that there is no need to add a new holding furnace and electromagnetic stirrer, which reduces the investment in equipment.

Owner:ZUNYI ZHIPENG HI TECH ALUMINUM COMPANY

A pre-alloyed powder used in a composite binder abrasive tool for grinding hard and brittle materials, a preparation method thereof, and an abrasive tool

ActiveCN110508800BGuaranteed AlloyingEnsure that the mixed powder is alloyed within 0.5~8hTransportation and packagingAbrasion apparatusBronzeRaw material

The invention belongs to the technical field of abrasive tool bonds, and in particular relates to a prealloyed powder used in a composite bond abrasive tool for grinding hard and brittle materials, a preparation method thereof, and an abrasive tool. The pre-alloyed powder used in the composite bond abrasive tool for grinding hard and brittle materials of the present invention is made of MoS 2 powder and the following raw materials by volume: 40-75 parts of bronze powder, 5-45 parts of Sn powder, 1-20 parts of multi-component pre-alloyed powder, 1-20 parts of Ti powder; the MoS 2 The volume fraction of the powder is 8% to 20% of the sum of the volume fractions of the multi-component pre-alloyed powder and Ti powder; the multi-component pre-alloyed powder is composed of at least one of Co, Ni, Cu, Sn, Zn and Fe . When the pre-alloyed powder of the present invention is used as a bonding agent for abrasive tools, it helps to improve the sharpness and shape retention of the abrasive tools.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

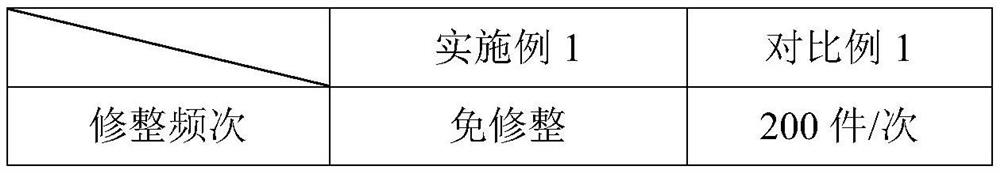

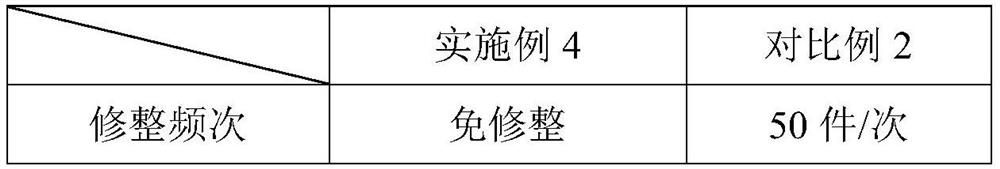

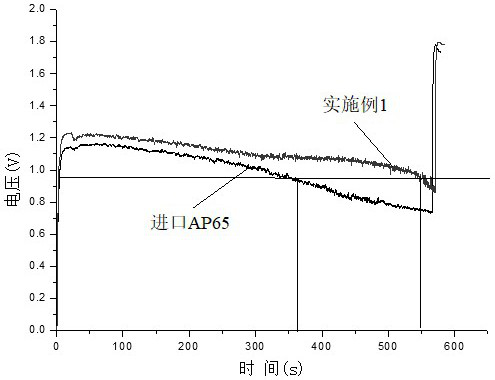

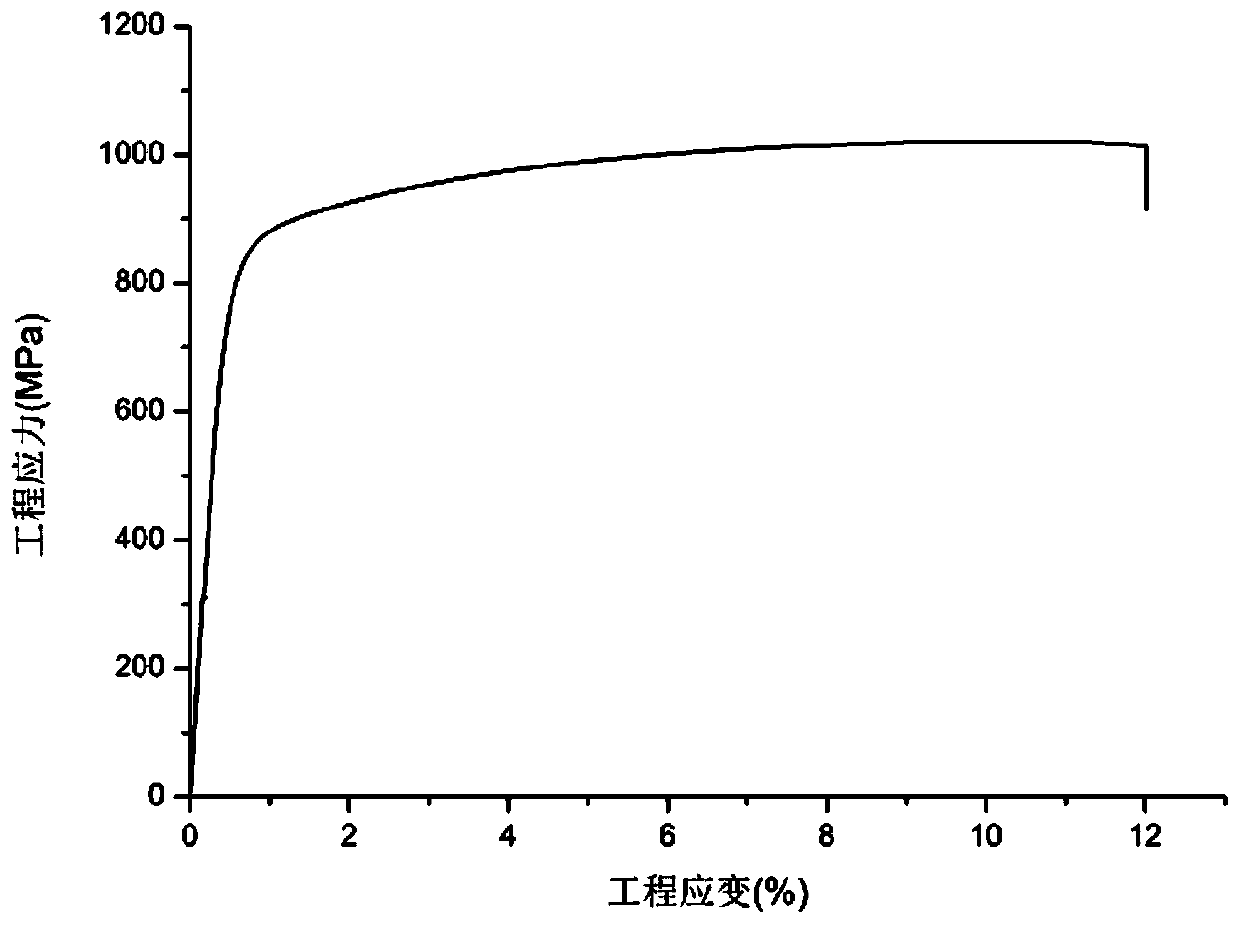

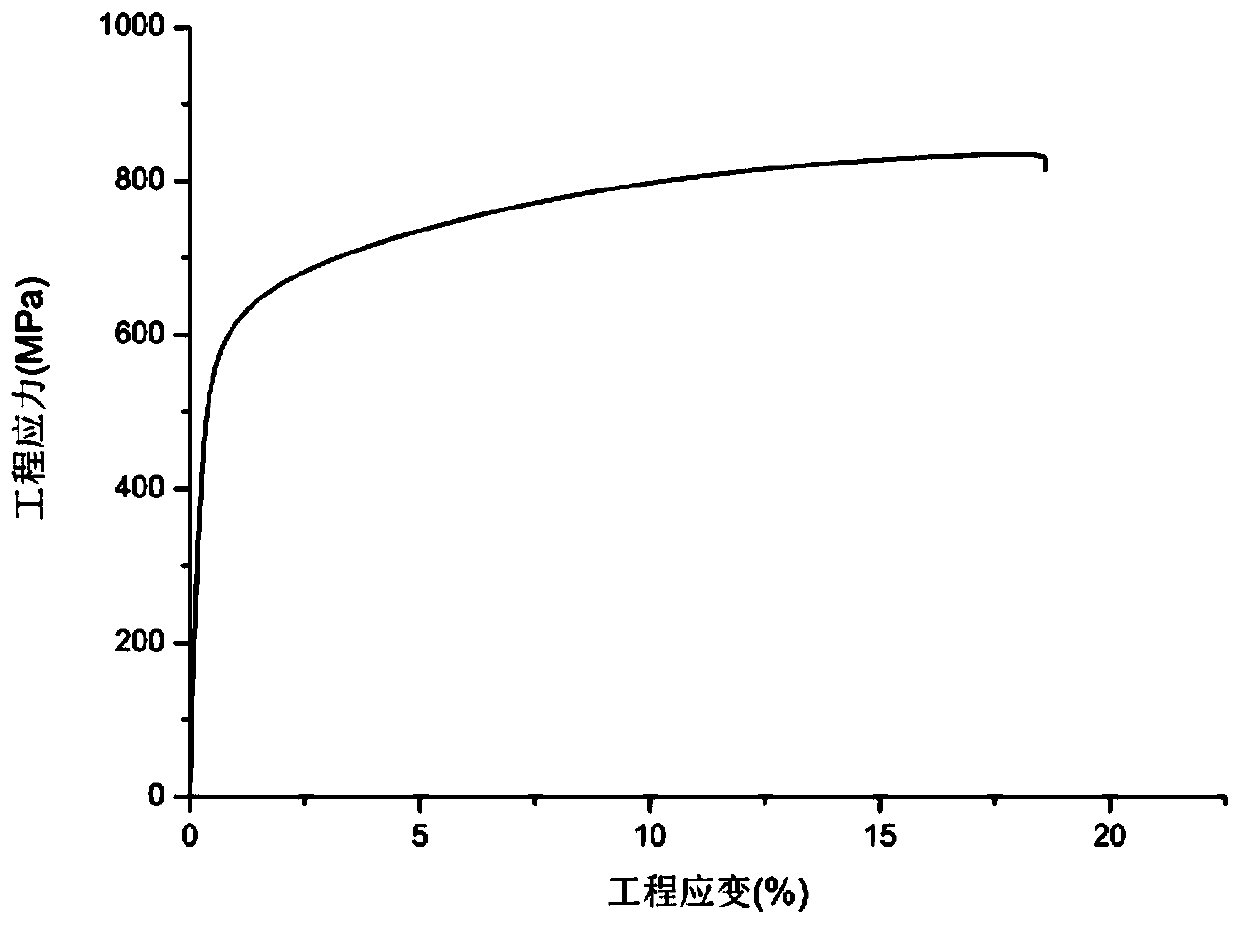

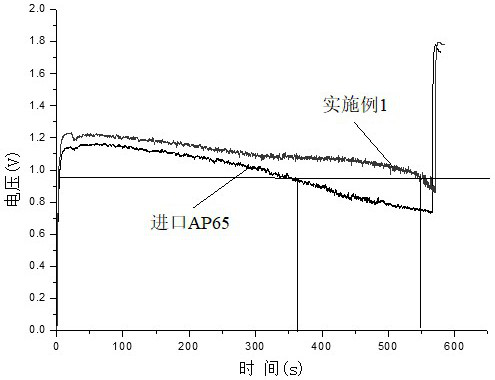

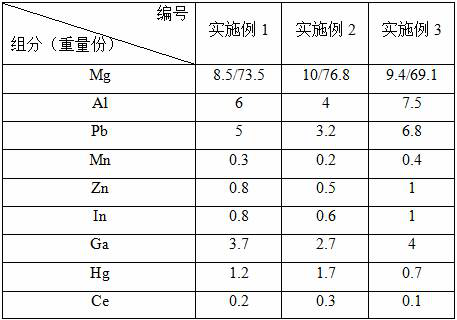

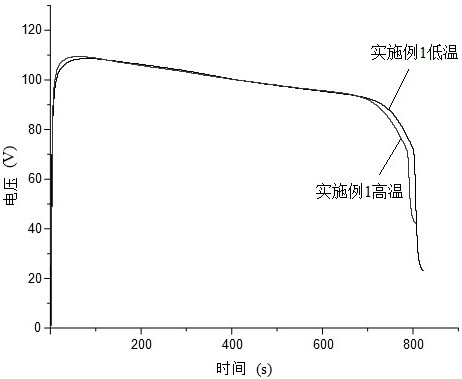

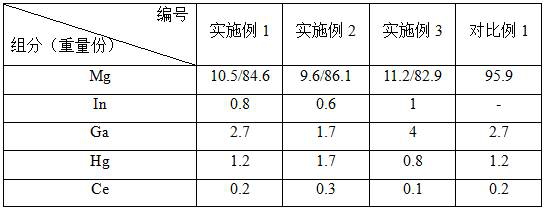

Multi-element negative material magnesium alloy and preparation method thereof

ActiveCN112746207AHigh activityHigh anti-polarizationFuel and primary cellsCell electrodesMetallurgyPolarization voltage

The invention discloses a multi-element negative material magnesium alloy and a preparation method thereof. The multi-element negative material magnesium alloy comprises the following components in percentage by mass: 4-8% of Al, 3-7% of Pb, 0.2-0.4% of Mn, 0.5-1.0% of Zn, 0.6-1.0% of In, 0.8-4.0% of Ga, 0.7-1.7% of Hg, 0.1-0.3% of Ce and the balance Mg. The preparation method comprises the steps that (1) an Mg-Hg intermediate alloy is prepared; (2) the Al, Pb, Mn, Zn, In, Ga, Mg-Hg intermediate alloy and Ce are sequentially added into Mg melt to be stirred and smelted, and heat preservation and still standing are conducted; and (3) semi-continuous casting, homogenizing annealing, hot extrusion breakdown and hot rolling are carried out, and the alloy is obtained. The multi-element negative material magnesium alloy is high in activity, resistant to polarization, high in voltage platform, short in activation time and long in discharge time. The method is simple, low in cost and suitable for industrial production.

Owner:CENT SOUTH UNIV

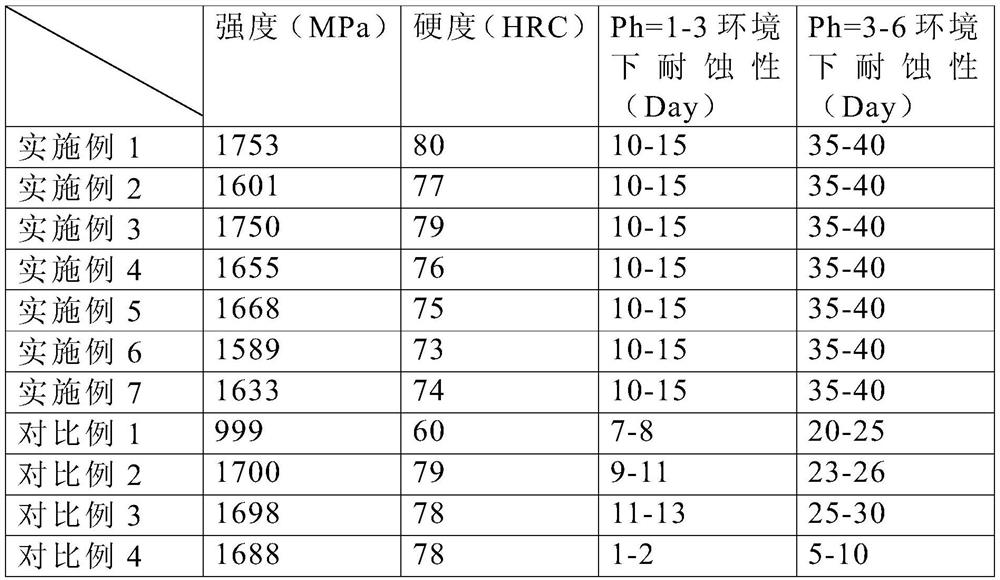

A processing method for corrosion-resistant metal shelves

ActiveCN107737933BHigh affinityHigh strengthMetallic material coating processesMetal machiningImpurity

Owner:NINGBO CITY XINGUANG SHELF

Method for surfacing high-temperature-resistant wear-resistant hard alloy on surface of blow-in drill bit cutting edge of steel mill

The invention discloses a method for surfacing high-temperature-resistant wear-resistant hard alloy on a surface of a blow-in drill bit cutting edge in a steel mill. The method comprises the following steps: 1) selecting a bonding phase; 2) selecting a hard phase; 3) preparing before welding; 4) editing a welding program; and 5) executing the welding process and the like. According to the high-temperature-resistant wear-resistant hard cobalt-based tungsten carbide alloy and the preparation method thereof, double-path powder feeding mixed welding is adopted, electric arc mixed powder material alloying during welding is achieved, a high-temperature cobalt base is adopted as a high-temperature-resistant bonding phase, WC with the hardness being 1800 HRC is adopted as the hard phase for abrasive particle wear, and the high-temperature-resistant and wear-resistant hard cobalt-based tungsten carbide alloy is obtained.

Owner:福尼斯(南京)表面工程技术有限公司

A kind of cocrfenimn high-entropy alloy reinforced by self-generated nanoparticles in situ and its preparation method

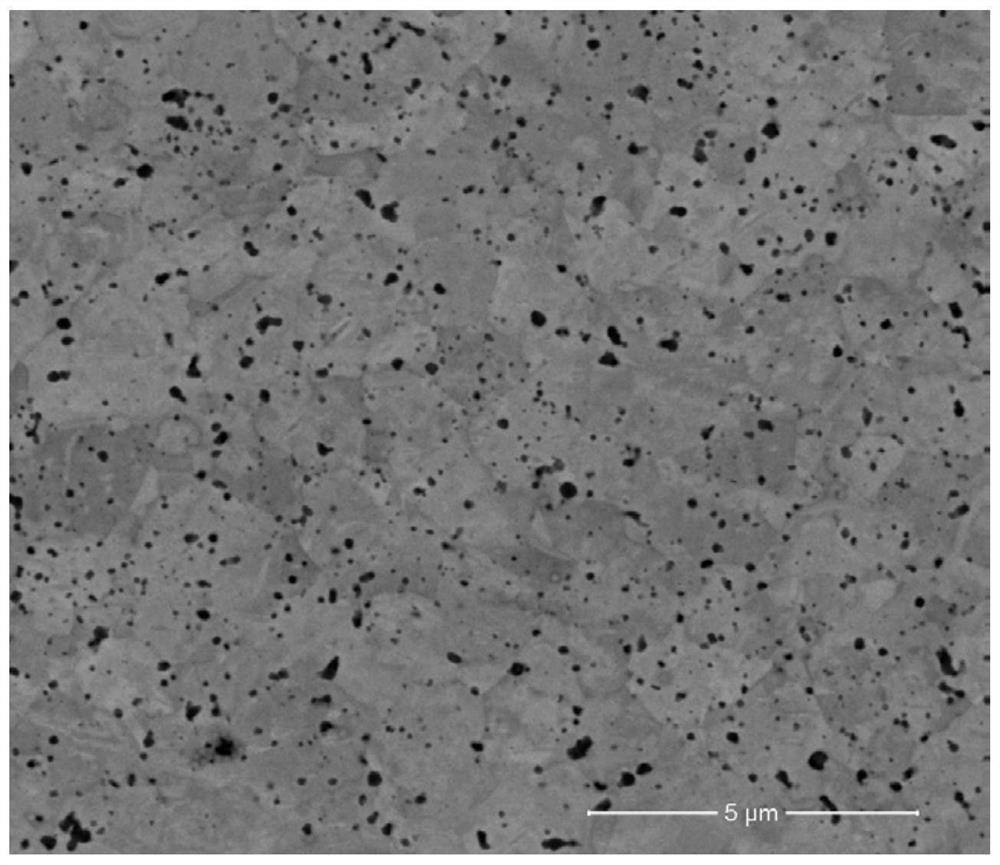

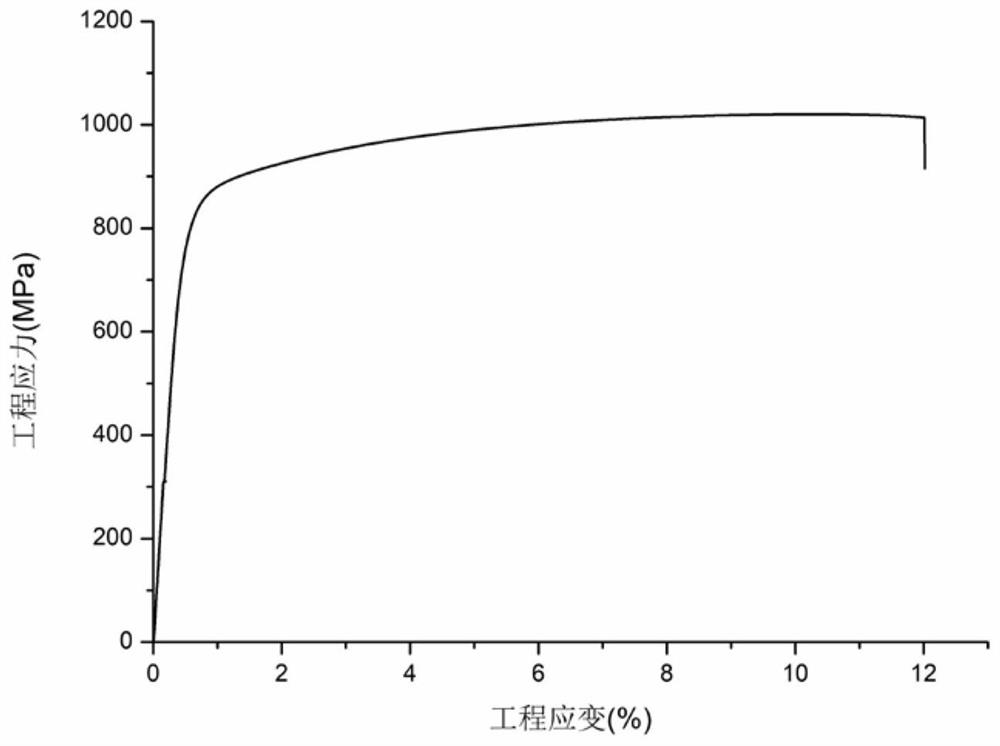

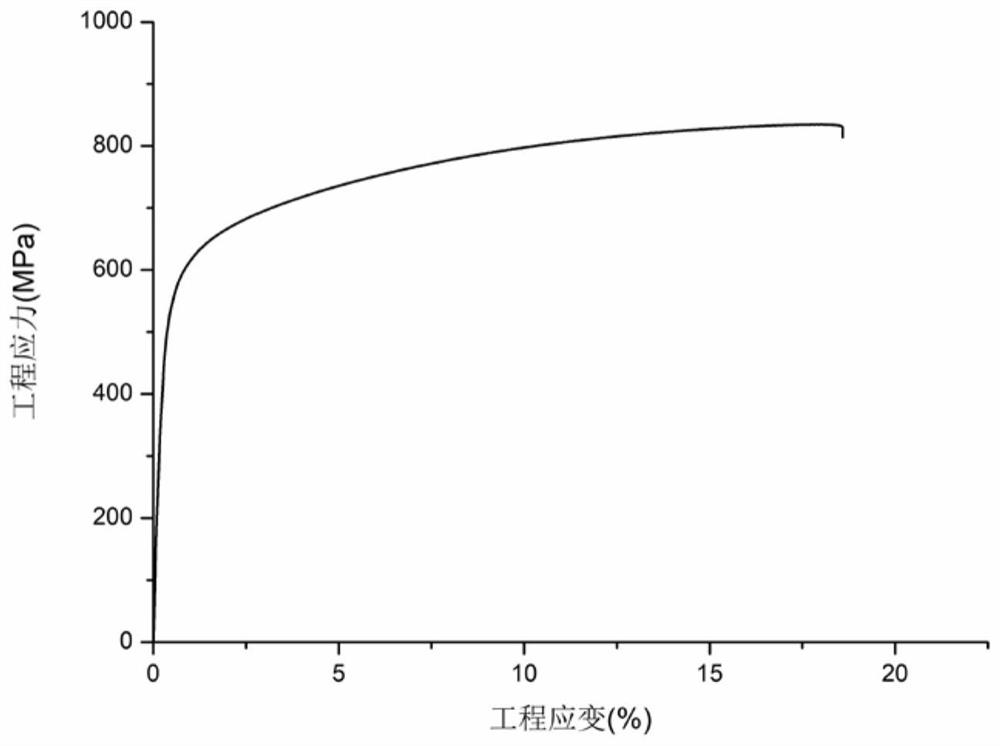

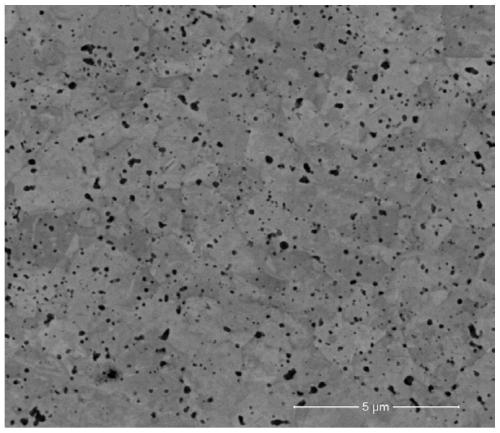

An in-situ nanoparticle-enhanced CoCrFeNiMn high-entropy alloy and a preparation method thereof. The CoCrFeNiMn high-entropy alloy combines fine-grain strengthening and particle strengthening at the same time, and the synergistic effect of the two effectively improves the strength of the material, and its yield strength Significantly higher than ordinary CoCrFeNiMn alloys. The preparation method of the CoCrFeNiMn high-entropy alloy combines high-energy ball milling and hot extrusion technology, and uses the high-energy ball milling method to achieve alloying of elements, avoids volatilization and segregation of elements in the process of melting and casting, and refines crystal grains; The hot extrusion process achieves rapid powder consolidation and in-situ self-generated nanoparticles to prepare CoCrFeNiMn high-entropy alloys with both nano-particles and fine-grained structures, which effectively improves the material strength of CoCrFeNiMn high-entropy alloys. In addition, the method can directly use the existing industrial equipment for producing ODS superalloy, the cost is low, the size is not limited, and it is suitable for industrial production.

Owner:SHANGHAI JIAOTONG UNIV

In-situ synthesized nanoparticle enhanced CoCrFeNiMn high-entropy alloy and preparation method thereof

The invention provides an in-situ synthesized nanoparticle enhanced CoCrFeNiMn high-entropy alloy and a preparation method thereof. Fine grain enhancement and particle enhancement are combined for theCoCrFeNiMn high-entropy alloy are the same time, the strength of the material is effectively improved through the synergistic effect of fine grain enhancement and particle enhancement, and the yieldstrength of the CoCrFeNiMn high-entropy alloy is remarkably higher than that of ordinary CoCrFeNiMn alloys. High-energy ball milling and the hot extrusion process are combined in the preparation method of the CoCrFeNiMn high-entropy alloy, and by means of the high-energy ball milling method, alloying of elements is achieved, volatilization and segregation of the elements in the smelting and casting process are avoided, and grains are refined; and due to the adoption of the hot extrusion process, rapid powder consolidation is achieved, nanoparticles are synthesized in situ, the CoCrFeNiMn high-entropy alloy with the nanoparticles and the fine grain structure is prepared, and the material strength of the CoCrFeNiMn high-entropy alloy is effectively improved. Furthermore, existing industrialized equipment for producing ODS high-temperature alloys can be directly adopted for the method, cost is low, sizes are not limited, and the in-situ synthesized nanoparticle enhanced CoCrFeNiMn high-entropy alloy and the preparation method are suitable for industrialized production.

Owner:SHANGHAI JIAO TONG UNIV

A kind of multi-element negative electrode material magnesium alloy and preparation method thereof

ActiveCN112746207BHigh activityHigh anti-polarizationFuel and primary cellsCell electrodesHigh activityContinuous casting

A multi-element negative electrode material magnesium alloy and a preparation method thereof, the multi-element negative electrode material magnesium alloy includes the following components in mass percentage: Al 4-8%, Pb 3-7%, Mn 0.2-0.4%, Zn 0.5-1.0% , In 0.6 ~ 1.0%, Ga 0.8 ~ 4.0%, Hg 0.7 ~ 1.7%, Ce 0.1 ~ 0.3%, the rest is Mg. The preparation method is as follows: (1) preparing Mg-Hg master alloy; (2) sequentially adding Al, Pb, Mn, Zn, In, Ga, Mg-Hg master alloy and Ce into the Mg melt, stirring and melting, and heat preservation Stand still; (3) semi-continuous casting, homogenizing annealing, hot extrusion billet opening, hot rolling, and it is ready. The multi-component negative electrode material magnesium alloy of the invention has high activity, anti-polarization, high voltage platform, short activation time and long discharge time; the invention has simple method, low cost and is suitable for industrialized production.

Owner:CENT SOUTH UNIV

A kind of sic/m2 powder high-speed steel composite material and preparation method thereof

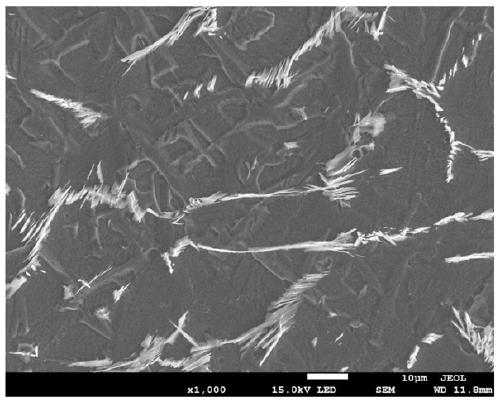

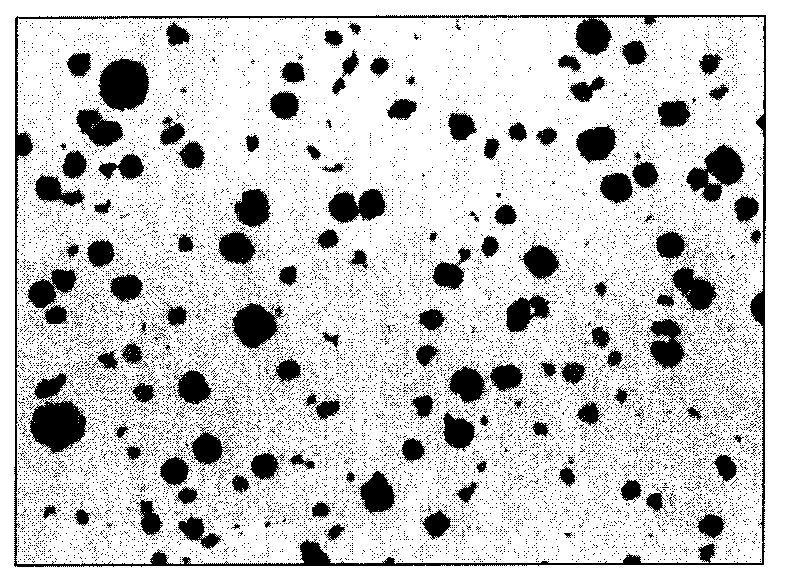

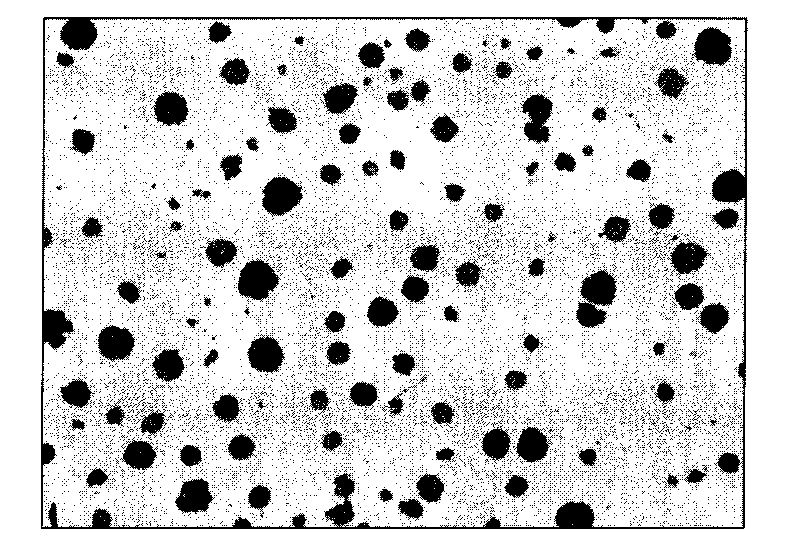

The invention relates to a SiC / M2 powder high-speed steel composite material. The composite material has a relative density of greater than 99% and hardness of 66-69HRC, and comprises nano-scale enhanced-phase particles SiC, submicron-scale hard-phase SiC and separated submicron-scale M6C type composite carbide, wherein the average particle size of the enhanced-phase particles SiC is 200nm, and the particle sizes of the hard-phase SiC and the M6C type composite carbide are not greater than 1[mu]m; and the matrix of the composite material is M2 high-speed steel, the particles SiC are uniformly distributed into the matrix in a dispersed manner as additional mass points, the composite material comprises the following raw material components with contents by volume percent: 85%-90% of M2 high-speed steel and 10%-15% of the particles SiC, the volume fraction of the particles SiC with particle sizes of not greater than 200nm in the particles SiC is 10%-20%, and the balance is particles with particle sizes of greater than 200nm and less than 1[mu]m. A preparation technology for a pre-alloyed composite powder is beneficial to obtaining the composite powder with a small and uniform particle size, preventing the agglomeration of the powder SiC, and realizing adequate alloying for the particles SiC and the matrix powder.

Owner:ANGANG STEEL CO LTD

A kind of solid-phase alloying method of Al-Si powder under high pressure condition

The invention discloses a solid-phase alloying method of aluminum-silicon powder under high-pressure condition. The applied aluminum-silicon alloy comprises the following components by weight percent: 10% to 80% of aluminum and the balance of silicon. Appropriate granularity proportion of aluminum powder and silicon powder is selected, the prepared aluminum powder and silicon powder are mixed together by using a rotational ball mill in the three-dimensional direction, are subsequently put into a vacuum heating furnace to be subjected to activation treatment, and are further put into a carbon steel sleeve to sinter under high pressure at a temperature lower than the melting point, the sintering time is controlled, and the alloying is realized depending on dispersion under the condition that the aluminum and the silicon are not molten. The solid-phase alloying method is an aluminum-silicon powder solid-phase alloying method that the process course is short, the cost is low and high-quality aluminum-silicon alloy can be obtained under high-pressure condition; and the prepared aluminum-silicon alloy can be widely applied to electronic device materials or functional coating materials.

Owner:ZHUZHOU SMELTER GRP +2

Processing Technology of High Nitrogen Wear-Resistant Stainless Steel Ore Screen Wire

The invention discloses a high-nitrogen abrasion-resistant stainless steel griddle wire processing technology. Manganese and nitrogen are adopted, vanadium-nitrogen alloy is added, the content of nitrogen in molten steel is increased, alloying of the nitrogen is achieved, the use amount of nickel is reduced, or the nickel does not exist, and the molten liquid is purified, refined and homogenized; the manganese and the nitrogen replace the nickel, direct application of nitrogen alloy in production of stainless steel is achieved, the strength of the stainless steel griddle wire is improved, magnetism does not exist, and corrosion resistance, abrasion resistance and the like are achieved; meanwhile, the cost of stainless steel production and application is reduced by over 30 percent.

Owner:JIANGSU LIJIN NEW MATERIAL TECH CO LTD

A kind of negative electrode material magnesium alloy and preparation method thereof

A negative electrode material magnesium alloy and a preparation method thereof. The negative electrode material magnesium alloy includes the following components in mass percentage: In 0.6-1.0%, Ga 0.8-4.0%, Hg 0.7-1.7%, Ce 0.1-0.3%, and for Mg. The preparation method is as follows: (1) preparing Mg-Hg master alloy; (2) sequentially adding In, Ga, Mg-Hg master alloy and Ce into Mg melt, stirring and smelting, heat preservation and standing to obtain a mixed melt; (3) Semi-continuous casting, homogenizing annealing, hot extrusion billet opening, hot rolling, and it is ready. The negative electrode material magnesium alloy of the invention has high activity, anti-polarization, high voltage platform and moderate hydrogen evolution capacity; the method of the invention has simple process and low cost, and is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com