Nodulant for alloying nodular cast iron

A technology of nodular cast iron and nodularizer, which is applied in the field of nodular cast iron production. It can solve problems such as the limitation of the amount of recycled materials, reduce the low-temperature impact toughness of nodular cast iron, achieve less oxidation slag inclusions, improve purity and performance, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

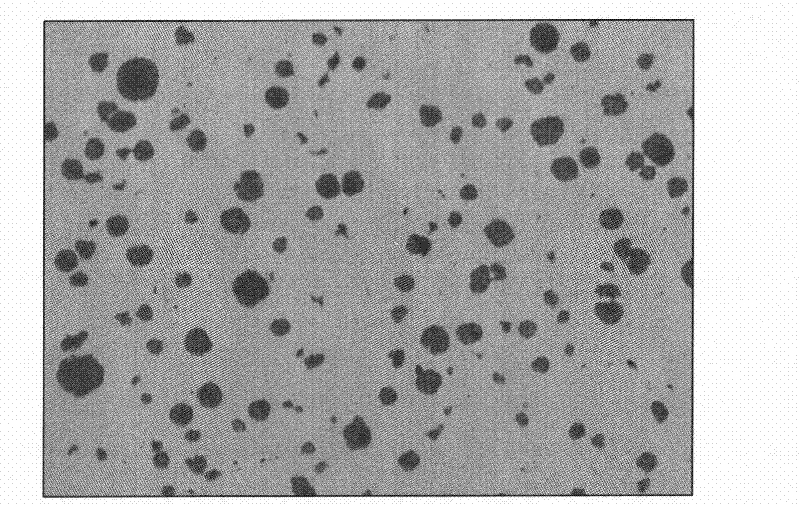

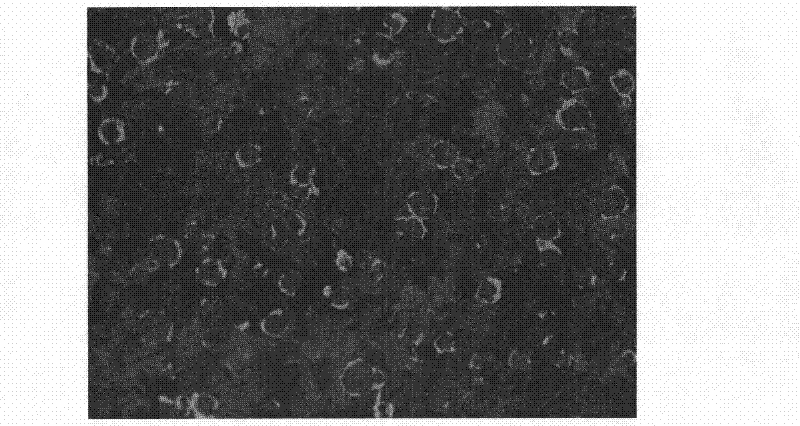

Examples

Embodiment 1

[0019] ① Melt molten iron in a 500Kg intermediate frequency induction furnace by conventional methods.

[0020] ② Use Cu-Mg-RE nodulizer, the nodulizer composition is: 85wt% Cu, 14wt% Mg, 1.0wt% RE, the addition amount is 0.6wt% of molten iron.

[0021] ③Spheroidizing the original molten iron of ductile iron by the flushing method, the temperature of the molten iron is 1480°C, and the composition of the original molten iron is: 3.95wt%C, 1.25wt%Si, 0.20wt%Mn, 0.03wt%P, 0.022wt% S.

[0022] ④Using secondary inoculation treatment, the inoculant is 75wt% Si-Fe. In the first bag inoculation, the amount of inoculant added is 0.8wt% of the molten iron, and for the second inoculation with flow, the amount of inoculant added is 0.15wt% of the molten iron.

[0023] ⑤ Pouring castings and 70mm Y-shaped test blocks, furan resin sand casting molds, the pouring temperature is 1340 ℃ ~ 1360 ℃.

[0024] ⑥ Cut the sample on the 70mm Y-shaped test block and process it into The tensile sam...

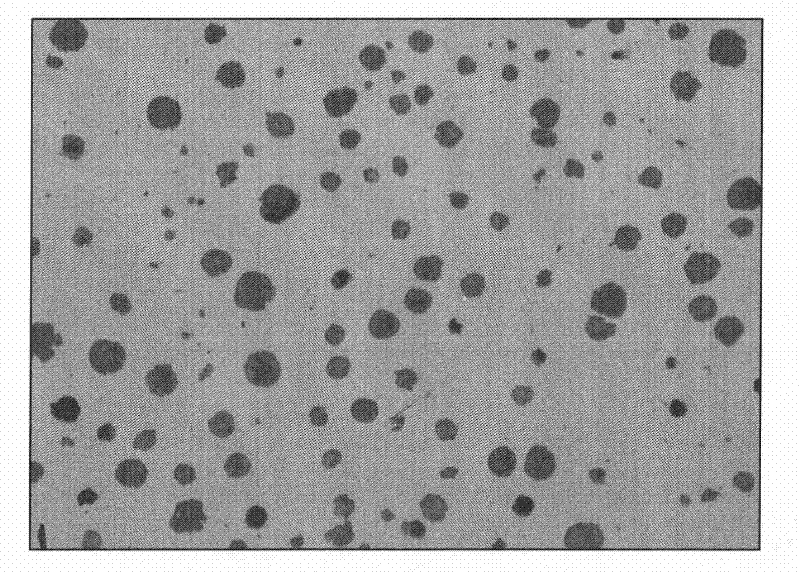

Embodiment 2

[0026] ① Melt molten iron in a 500Kg intermediate frequency induction furnace by conventional methods.

[0027] ② Use Cu-Mg-RE nodulizer, the nodulizer composition is: 92.5wt% Cu, 6.0wt% Mg, 1.5wt% RE, the addition amount is 1.2wt% of molten iron.

[0028] ③Spheroidizing the original molten iron of ductile iron by the flushing method, the temperature of the molten iron is 1500°C, and the composition of the original molten iron is: 3.90wt%C, 1.35wt%Si, 0.25wt%Mn, 0.025wt%P, 0.020wt% S.

[0029] ④Using secondary inoculation treatment, the inoculant is 75wt% Si-Fe. In the first bag inoculation, the amount of inoculant added is 0.8wt% of the molten iron, and for the second inoculation with flow, the amount of inoculant added is 0.15wt% of the molten iron.

[0030] ⑤ Pouring castings and 70mm Y-shaped test blocks, furan resin sand casting molds, the pouring temperature is 1340 ℃ ~ 1360 ℃.

[0031] ⑥ Cut the sample on the 70mm Y-shaped test block and process it into The tensile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com