Special carbon-base slow release fertilizer for corn and preparation method thereof

A corn-specific, carbon-based technology, applied in fertilizer mixtures, nitrogen fertilizers, applications, etc., can solve the problems of increased soil fertility, high cost, little pore and adsorption capacity, etc., and achieves high fertilizer utilization, simple preparation process, and economical The effect of fertilization cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: carbonization furnace

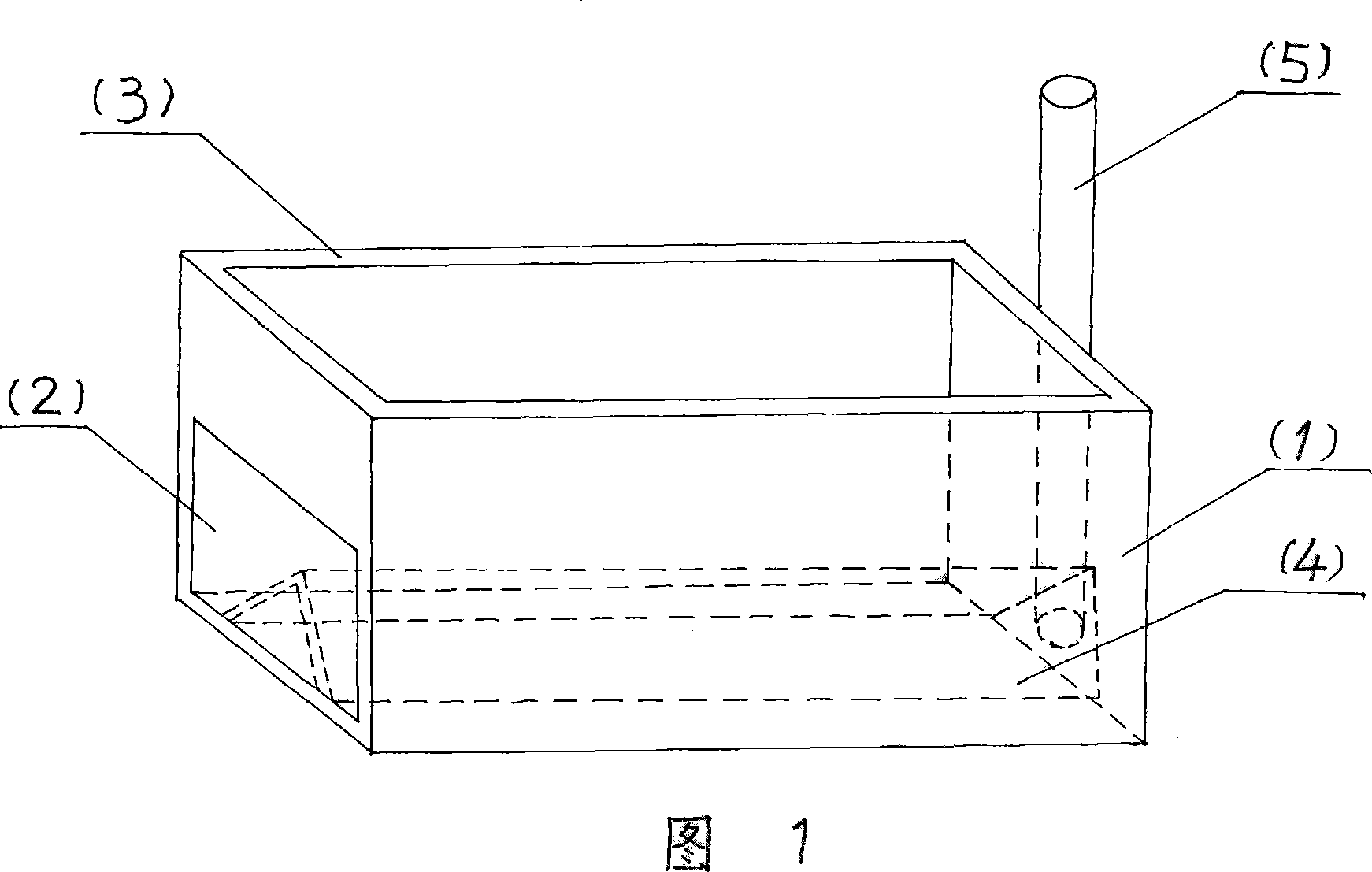

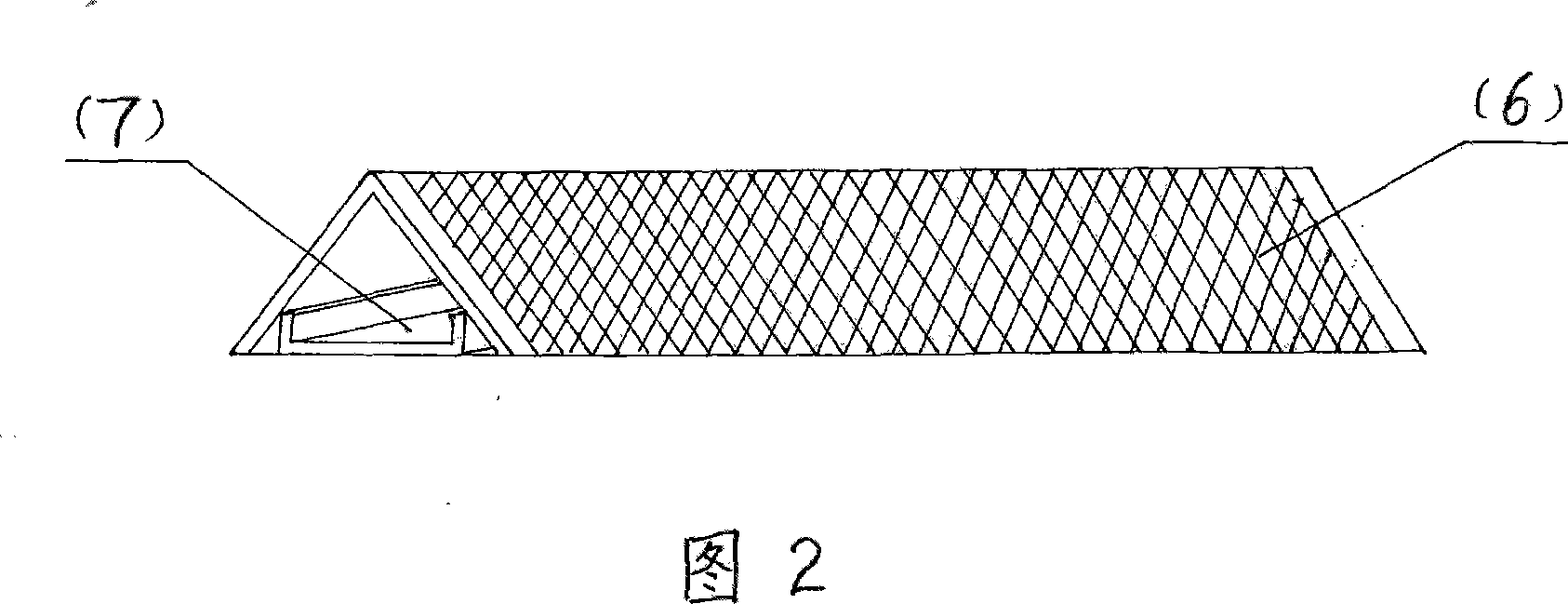

[0071] The carbonization furnace consists of a furnace body 1, a burner 4, an exhaust port 5, and a discharge port 2, as shown in Figure 1. The body of the carbonization furnace is made of 8mm thick double-layer steel plate, and asbestos silk is used as the middle insulation interlayer. The furnace body is in the shape of a cuboid. The furnace body is semi-closed, with no cover on the top. The specific parameters of the special carbonization furnace for corncob granular carbon are shown in the table below. At the bottom of the narrower side of the furnace body 1, there is a discharge opening 2 for discharging and igniting the burner from the discharge opening. The outlet is square or semicircular. The size of the discharge port can be designed according to the volume of the furnace body. In principle, it is determined that the furnace body does not automatically drop after the material is loaded. There is no sliding door outsid...

Embodiment 2

[0074] Embodiment 2 corn cob granular carbon production method

[0075] The method for producing corncob granular carbon using the carbonization furnace described in Example 1 includes steps such as material selection, material processing, furnace charging for carbonization, cooling out of the furnace, and metering and packaging.

[0076] Material selection: Naturally air-dry the corncobs of agricultural by-products to reduce the water content to below 20%.

[0077] Material processing: use any crushing method in the prior art to process and crush the above-mentioned qualified corncobs, and the diameter of the crushed corncobs is 2-10mm. The crushed corn cob particles can be sieved, and the corn cob particles that do not meet the requirements can be reprocessed.

[0078] Furnace charging and carbonization: put the processed corn cob particles into the furnace body, and the initial amount of material added is to cover the burner by 10-25 cm. Ignite the igniter in the ignition...

Embodiment 3

[0081] Embodiment 3: production process of special disposable base fertilizer for corn

[0082] Follow the steps below to mix in weight ratio or weight percentage:

[0083](1) The nitrogen (N) amount is 46% large particle urea, 80 mesh corn cob granular carbon particles and binder, mixed in the ratio of 50%, 35% and 15%, and then use KP-300 type organic fertilizer A granulator (commonly used machinery in the fertilizer preparation process) performs pressure granulation to make a slow-release nitrogen fertilizer with a nitrogen (N) content of 23%.

[0084] (2) The content of N is 11% and P 2 o 5 Amount of 46% monoammonium phosphate powder, 80 mesh corn cob granular carbon particles and binding agent are mixed in proportions of 70%, 20% and 10%, and pressure granulated with a KP-300 type organic fertilizer granulator, Made of nitrogen (N) content of 7.7%, containing available phosphorus (P 2 o 5 ) amount of 32.2% nitrogen-phosphorus compound fertilizer.

[0085] (3) will c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com