Aluminum-titanium-boron production process

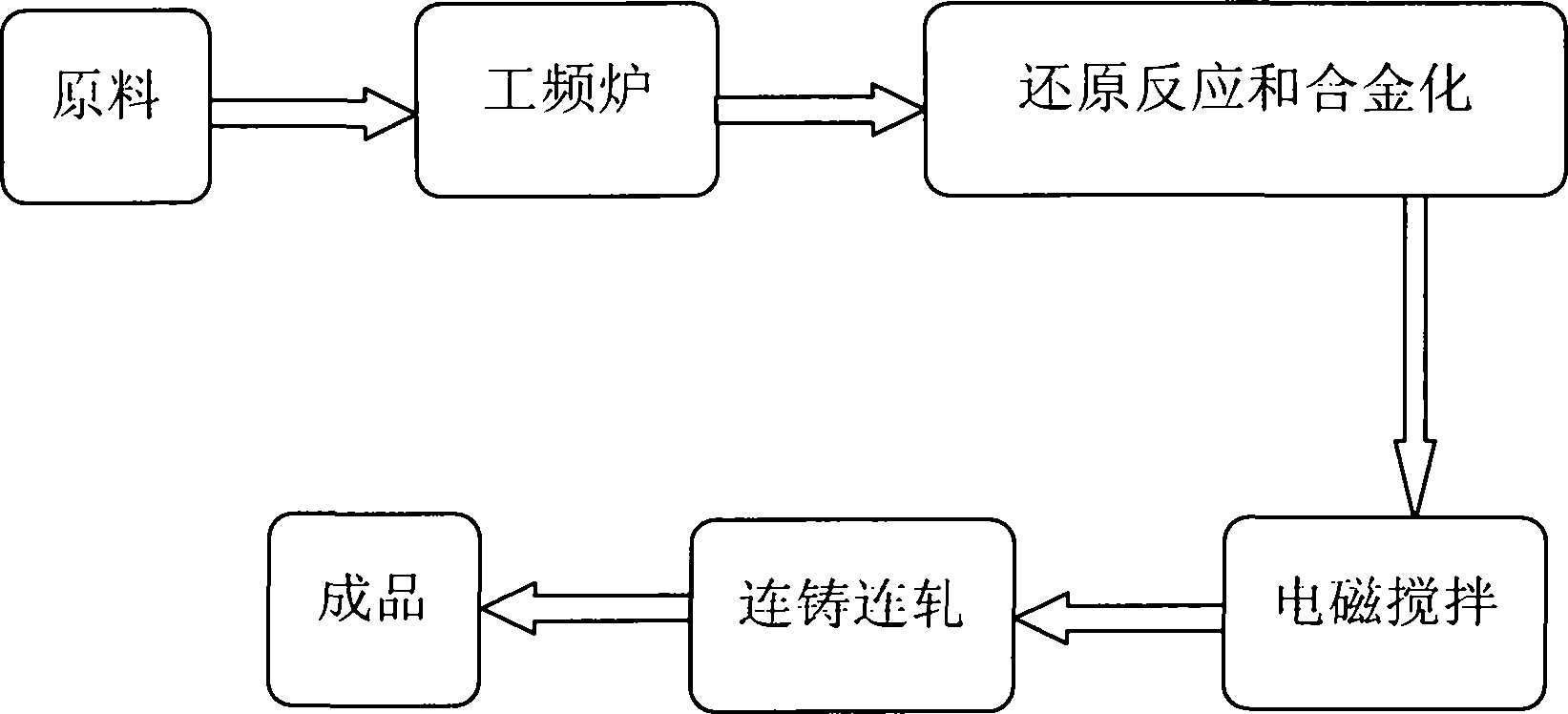

A production process, an aluminum-titanium-boron technology, applied in the field of aluminum-titanium-boron production technology, can solve the problems of inability to achieve effective control of the stirring force of aluminum water, inability to produce aluminum-titanium-boron alloy products, adding a holding furnace and an electromagnetic stirrer, etc. The effect of improving furnace production capacity, strict three-phase input current balance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the examples, but the scope of protection is not limited to the description.

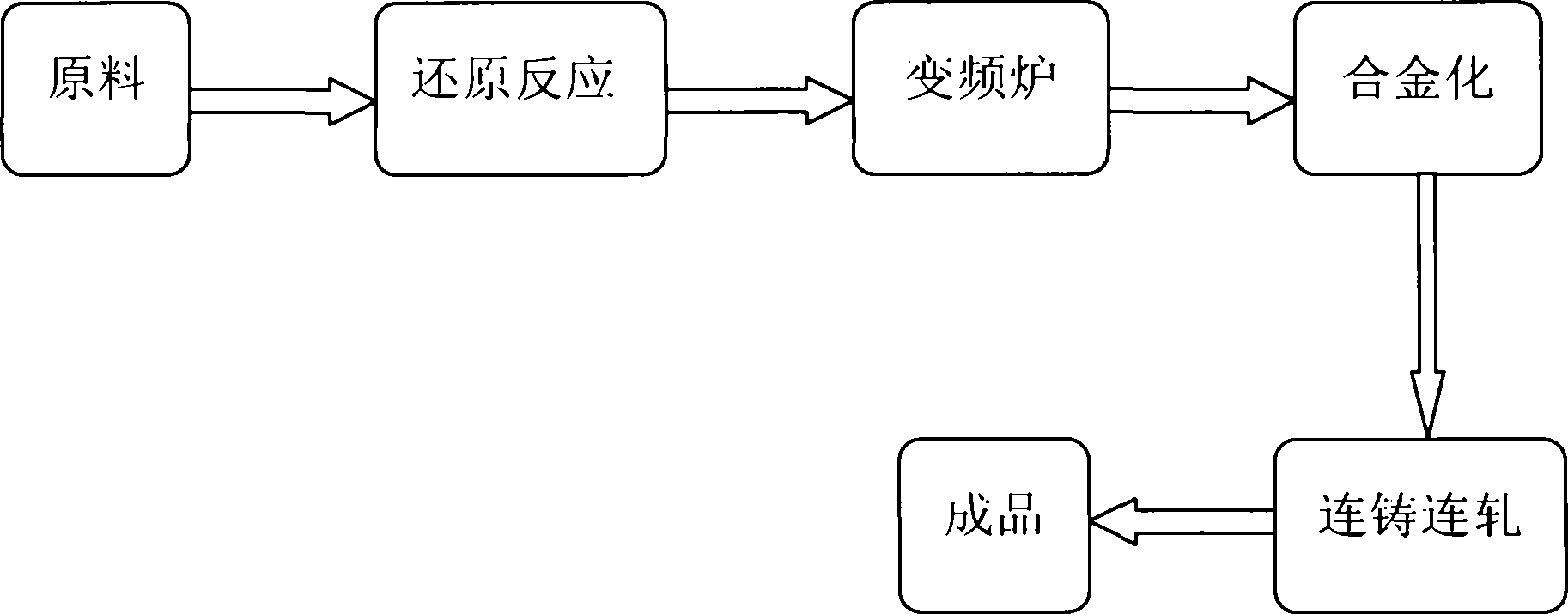

[0031] Such as figure 2 As shown, a kind of aluminum titanium boron production process described in the present invention first enters the raw material into the reduction table bag to carry out the reduction reaction, and uses the agitator to stir according to the needs in the reduction reaction; after the reduction reaction is completed, transfer to the frequency conversion The alloying operation is carried out in the furnace; finally, the alloyed aluminum water enters the continuous casting and rolling process through the crucible to obtain the finished product of aluminum, titanium and boron.

[0032] The crucible adopts a crucible that uses aluminum water from the bottom.

[0033] Using the above technical scheme, the original power frequency furnace is changed to a frequency conversion f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com