A kind of cocrfenimn high-entropy alloy reinforced by self-generated nanoparticles in situ and its preparation method

A nano-particle and high-entropy alloy technology, applied in the field of metal processing, can solve the problems of uneven temperature distribution, improve powder consolidation, and small product size, and achieve the effects of avoiding volatilization and segregation, improving material strength and increasing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

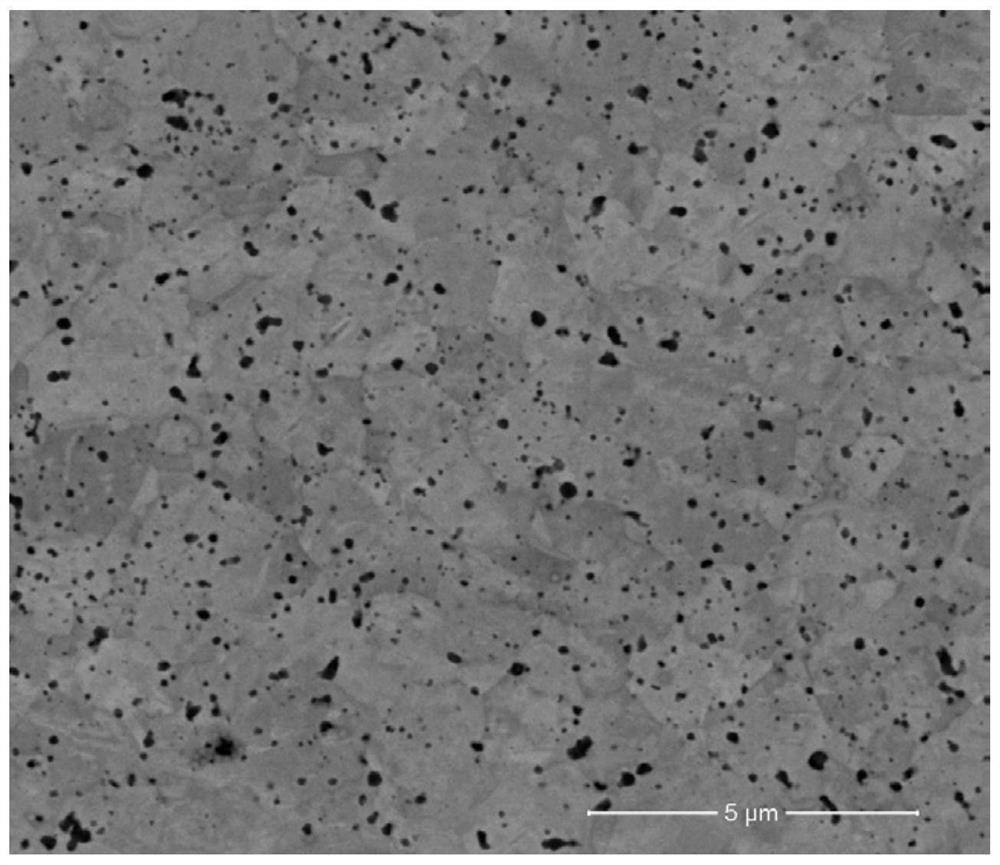

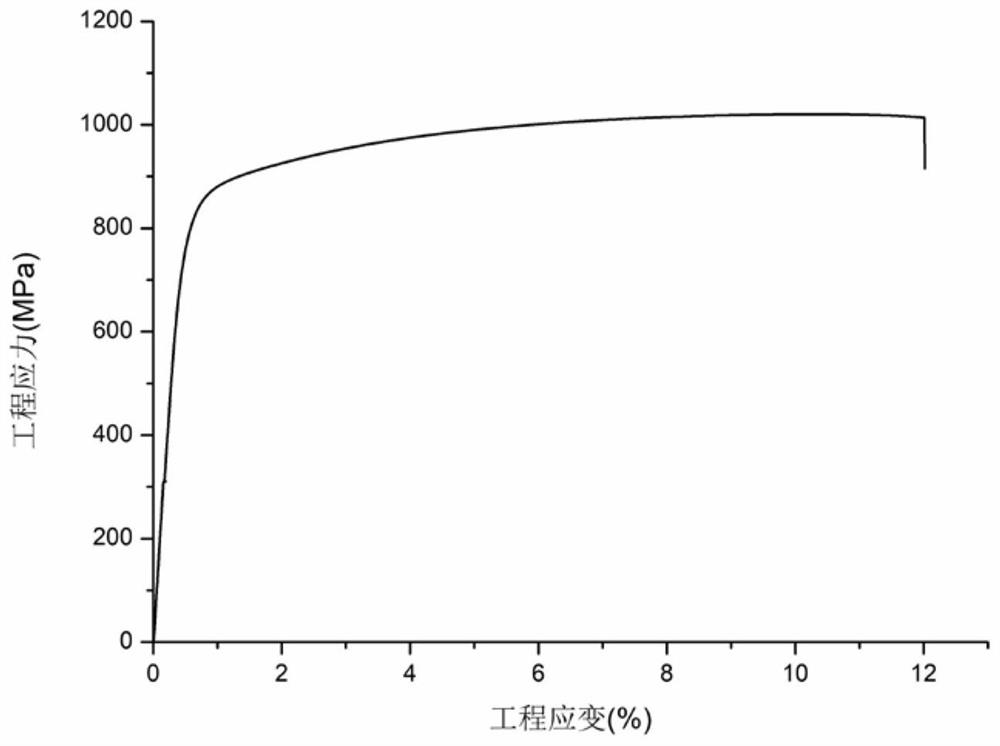

[0028] Example 1: Preparation of TiO(C) particle reinforced CoCrFeNiMn high-entropy alloy

[0029] Put Co, Cr, Fe, Ni, Mn, FeTi powder and 0.5wt% stearic acid into a planetary ball mill, first ball mill at 200rpm for 6 hours, and then at 400rpm for 66 hours. After ball milling, under an inert gas protective atmosphere, take an appropriate amount of ball-milled powder and put it into the first mold, and press it into a prefabricated block with a hydraulic press. The pressure of the hydraulic press is 1150 MPa, and the holding time is 5 minutes. Further, the prefabricated block was placed in a stainless steel sheath, and transferred to an induction heating coil for induction heating, with a heating temperature of 1150°C and a holding time of 2 minutes. Subsequently, put the heated prefabricated block into the second mold, and use a hydraulic press for hot extrusion. The preheating temperature of the second mold during extrusion is 450°C, and the extrusion ratio is 9:1. The cros...

Embodiment 2

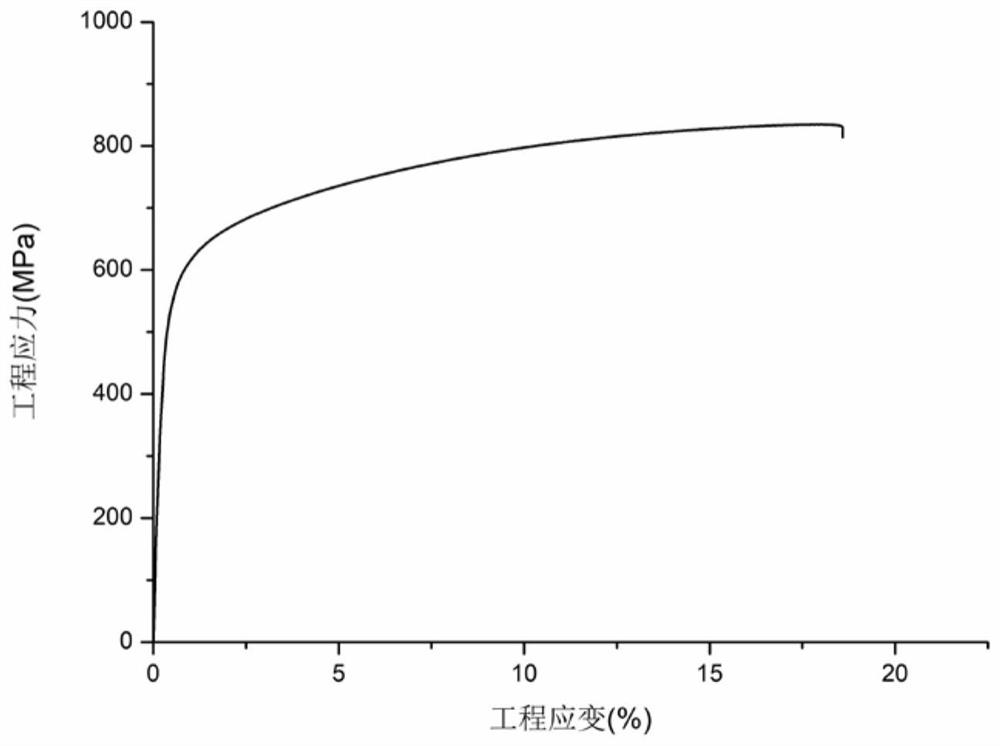

[0031] Embodiment two: (Cr, Mn) 3 o 4 Preparation of CoCrFeNiMn High Entropy Alloy Strengthened by +NbC Particles

[0032] Put Co, Cr, Fe, Ni, Mn, Nb powders and 0.5wt% stearic acid into a planetary ball mill, first ball mill at 200rpm for 6 hours, then at 400rpm for 66 hours. After ball milling, under an inert gas protective atmosphere, take an appropriate amount of ball-milled powder and put it into the first mold, and press it into a prefabricated block with a hydraulic press. The pressure of the hydraulic press is 1150 MPa, and the holding time is 5 minutes. Further, the prefabricated block was placed in a stainless steel sheath, and transferred to an induction heating coil for induction heating, with a heating temperature of 1150°C and a holding time of 2 minutes. Subsequently, put the heated prefabricated block into the second mold, and use a hydraulic press for hot extrusion. The preheating temperature of the second mold during extrusion is 450°C, and the extrusion ra...

Embodiment 3

[0034] Example 3: Preparation of TiO(C) particle reinforced CoCrFeNiMn high-entropy alloy

[0035]Put Co, Cr, Fe, Ni, Mn, FeTi powder and 0.5wt% stearic acid into a planetary ball mill, first ball mill at 200rpm for 6 hours, and then at 400rpm for 66 hours. After ball milling, under an inert gas protective atmosphere, take an appropriate amount of ball-milled powder and put it into the first mold, and press it into a prefabricated block with a hydraulic press. The pressure of the hydraulic press is 1150 MPa, and the holding time is 5 minutes. Further, the prefabricated block was placed in a stainless steel sheath, and transferred to an induction heating coil for induction heating. The heating temperature was 1050° C., and the holding time was 5 minutes. Subsequently, put the heated prefabricated block into the second mold, and use a hydraulic press for hot extrusion. The preheating temperature of the second mold during extrusion is 450°C, and the extrusion ratio is 9:1. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com