Process for preparing (Ti,Al)BN ceramic amorphous-nanocrystalline wear-resistant anti-corrosion composite coating

A composite coating and nanocrystalline technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor bonding force of the substrate and high brittleness of the coating, so as to improve the overall performance and simplify the The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The process of preparing (Ti,Al)BN ceramic-based amorphous-nanocrystalline wear-resistant and corrosion-resistant composite coating, the steps are:

[0020] a. First, double-cathode plasma sputtering deposition is carried out, and the process parameters are as follows: target voltage 800 V, workpiece voltage 400 V, distance between target and workpiece 20 mm, working pressure 35 Pa, deposition temperature 500 °C;

[0021] b. Then perform ion nitriding, the process parameters are as follows: workpiece voltage 800V, workpiece temperature 500°C, working pressure 35Pa, nitrogen partial pressure 0.5 Pa; ion nitriding for 1.5 hours.

[0022] c. The type of target material for sputtering: the mass ratio of the ingredients prepared by the hot isostatic pressing process is Ti:B:Al=6:3:1 powder metallurgy sintered plate;

[0023] d. The type of workpiece material: titanium alloy.

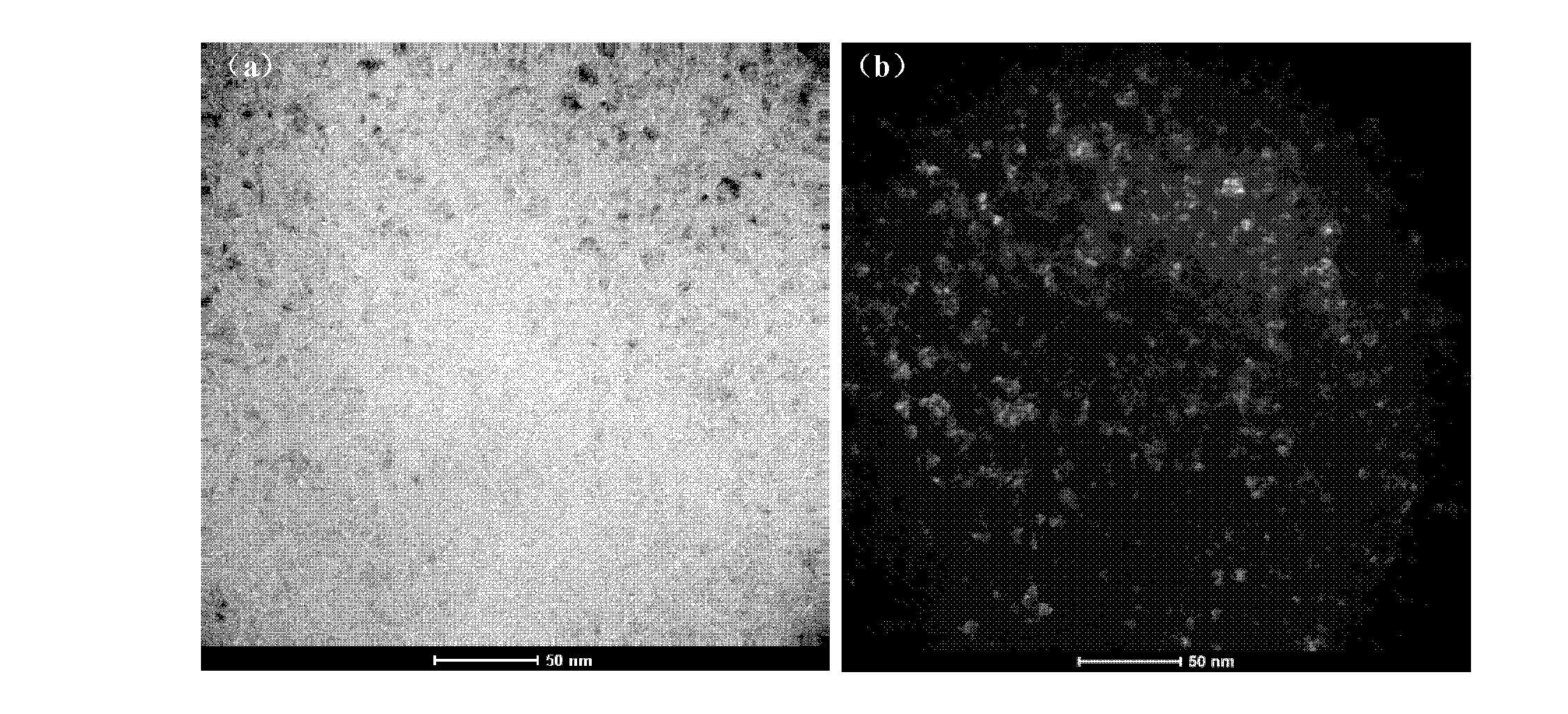

[0024] figure 1 The composition ratio of Ti:B:Al=6:3:1 powder metallurgy sintered plate prep...

Embodiment 2

[0028] The process of preparing (Ti,Al)BN ceramic-based amorphous-nanocrystalline wear-resistant and corrosion-resistant composite coatings is as follows: first, double-cathode plasma sputtering deposition is carried out, and the process parameters are as follows: target voltage 1000 V, workpiece voltage 450 V , the distance between the target and the workpiece is 30 mm, the working pressure is 45Pa, and the deposition temperature is 650°C; then ion nitriding is performed, and the process parameters are as follows: the workpiece voltage is 850V, the nitriding temperature is 600°C, the working pressure is 45Pa, and the nitrogen partial pressure is 1 Pa; 2 hours; the type of sputtering target: the mass ratio of components prepared by hot isostatic pressing is Ti:B:Al=6:3:1 powder metallurgy sintered plate; the type of workpiece material: titanium alloy. The properties of the resulting coating were slightly lower than in Example 1.

[0029]

Embodiment 3

[0031] The process of preparing (Ti,Al)BN ceramic-based amorphous-nanocrystalline wear-resistant and corrosion-resistant composite coatings is as follows: first, double-cathode plasma sputtering deposition is carried out, and the process parameters are as follows: target voltage 500 V, workpiece voltage 300 V , the distance between the target and the workpiece is 10 mm, the working pressure is 20 Pa, and the deposition temperature is 450°C; then ion nitriding is carried out, and the process parameters are as follows: the workpiece voltage is 650V, the nitriding temperature is 450°C, the working pressure is 20Pa, and the nitrogen partial pressure is 0.1 Pa; 1 hour; the type of sputtering target: the mass ratio of components prepared by hot isostatic pressing is Ti:B:Al=6:3:1 powder metallurgy sintered plate; the type of workpiece material: titanium alloy. The properties of the resulting coating were slightly lower than in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com