Low-price gang saw tool bit product and preparation method thereof

A cutter head product and a saw blade technology, which are applied in the field of low-cost gang saw cutter head products and their preparation, can solve the problems of rising prices of pure cobalt-based products, inability to deliver on time, etc., achieve excellent cutting ability, and reduce hole defects , and life-span equal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

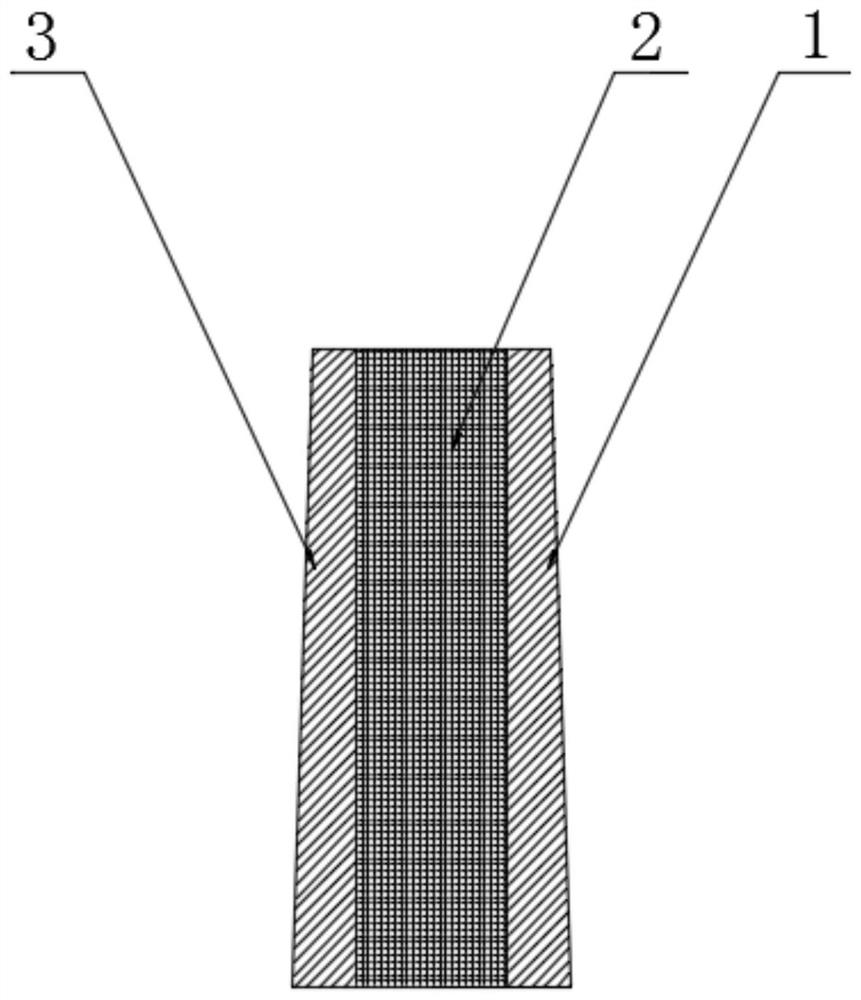

[0030] according to figure 1 A low-priced gang saw cutter head product is shown, the cutter head material used in the cutter head product is sintered after mixing metal powder, liquid paraffin and diamond, and the metal powder (by weight) is composed of the following powders Raw material composition: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel, 0.8 parts of La, 1-1.2 parts of the liquid paraffin, and the volume of the diamond in the cutter head material The ratio is 30%, and the diamond is added according to the volume percentage of the cutter head material;

[0031] Further, the cutter head material (in parts by weight) is composed of the following raw materials: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel, 2-8 parts of tin, 0.8 part of La, 1-1.2 part of liquid paraffin, and a volume ratio of 30% diamond, the diamond is added according to the volume percentage of the cutter head material; ...

Embodiment 2

[0042] according to figure 1 A low-priced gang saw cutter head product is shown, the cutter head material used in the cutter head product is sintered after mixing metal powder, liquid paraffin and diamond, and the metal powder (by weight) is composed of the following powders Raw material composition: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel, 0.8 parts of La, 1-1.2 parts of the liquid paraffin, and the volume of the diamond in the cutter head material The ratio is 30%, and the diamond is added according to the volume percentage of the cutter head material;

[0043] Further, the cutter head material (in parts by weight) is composed of the following raw materials: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel, 2-8 parts of tin, 0.8 part of La, 1-1.2 part of liquid paraffin, and a volume ratio of 30% diamond, the diamond is added according to the volume percentage of the cutter head material; ...

Embodiment 3

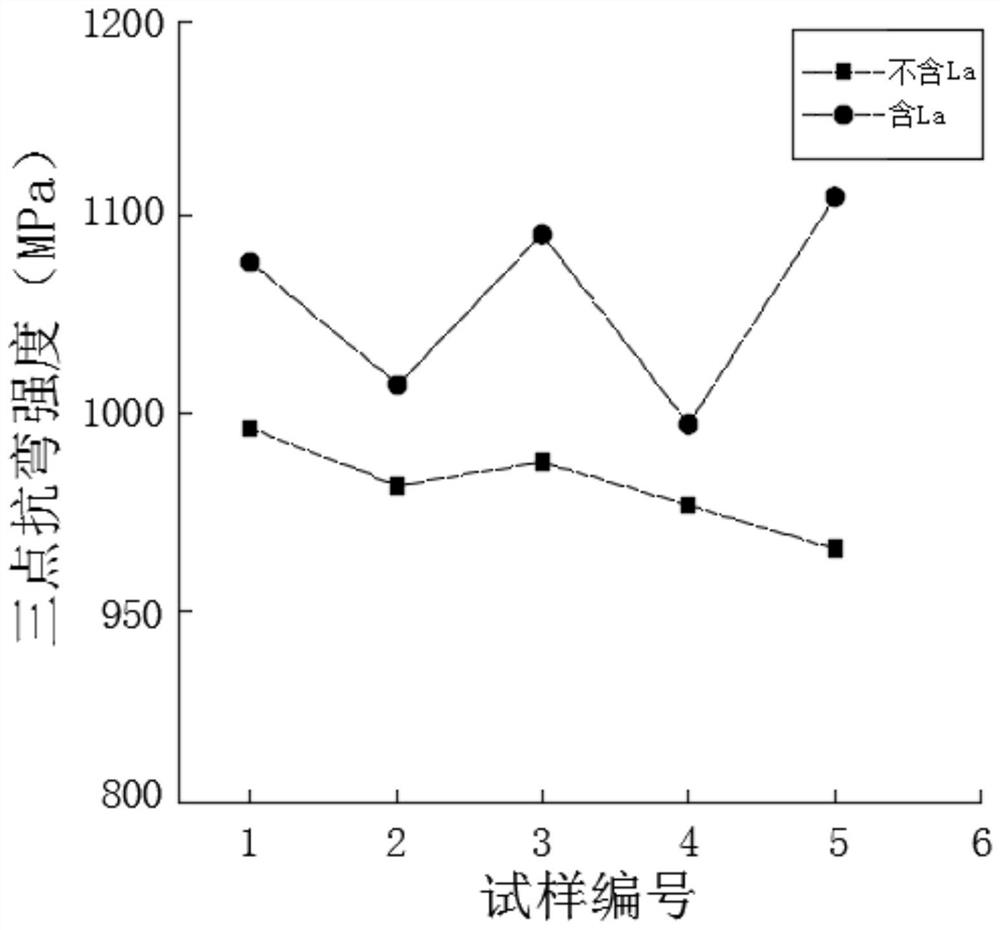

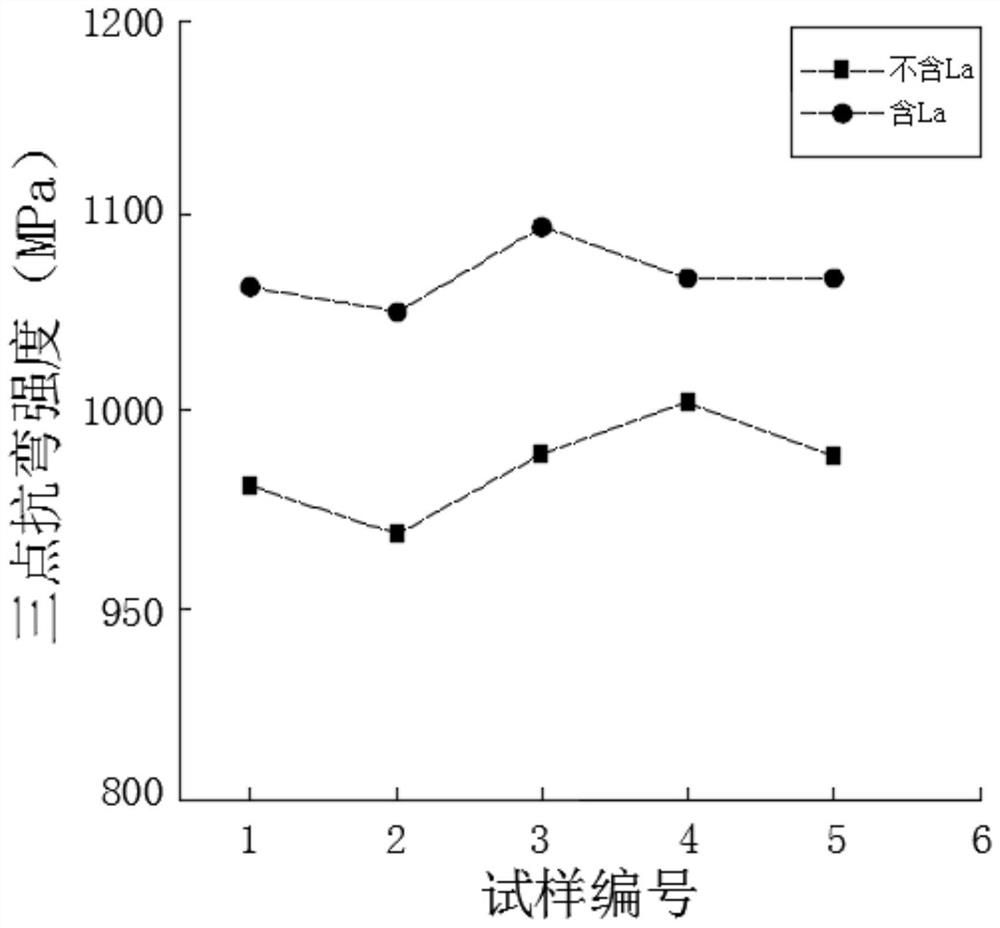

[0058] The present invention adds an appropriate amount of rare earth elements to the cutter head material based on trial and error. The research shows that the blank carcass sample containing La and the corresponding carcass sample added with diamond have higher flexural strength than the carcass sample without La. The average three-point flexural strength of the blank carcass containing La is about 120MPa higher than that of the blank carcass not containing La. The average three-point flexural strength of the diamond matrix sample containing La is about 80MPa higher than that without La. see details figure 2 and 3 .

[0059] From a chemical point of view, there is also a reason for the increase in carcass strength by adding La:

[0060] 1) Strong reducing property of La element. La is a very active rare earth metal, and it is easy to undergo oxidation-reduction reactions with impurity elements such as O and S. After the reaction, the particles of La oxides and sulfides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com