Patents

Literature

31results about How to "Guaranteed sintering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

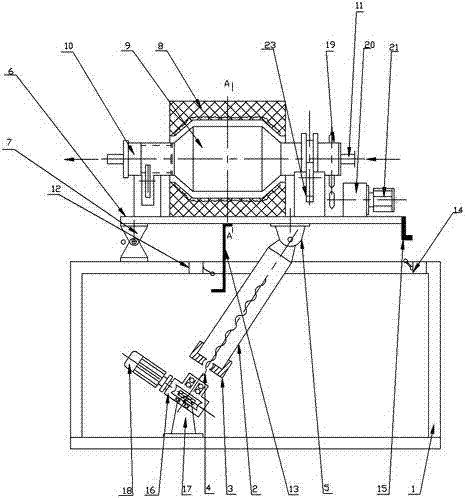

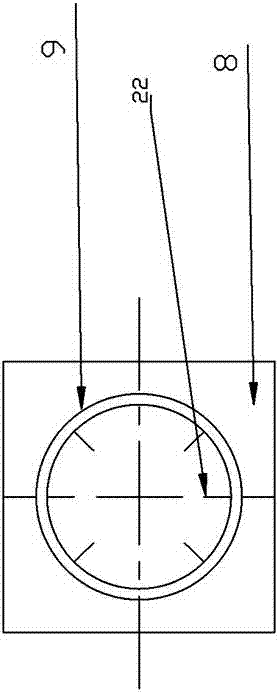

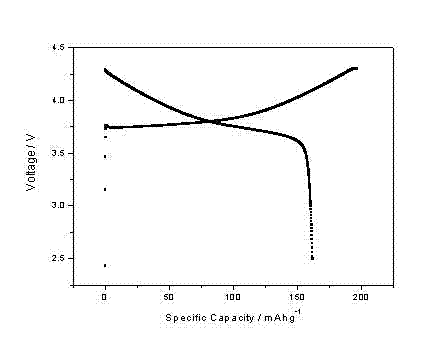

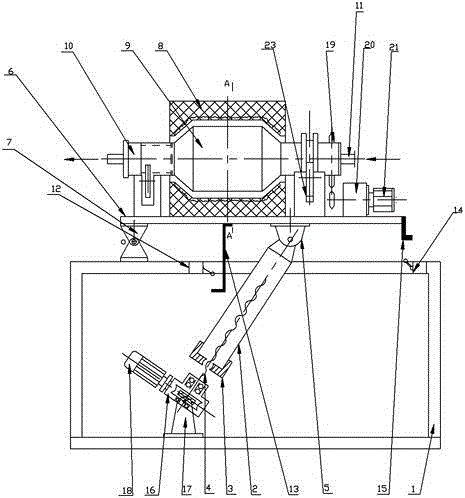

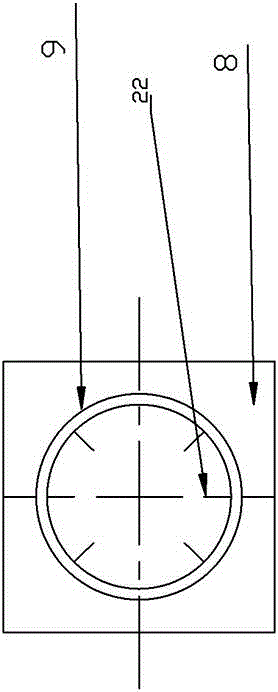

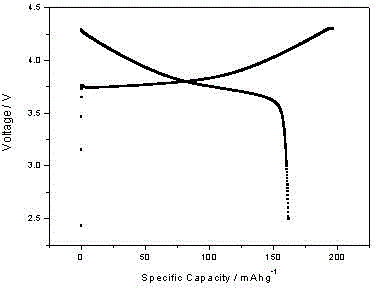

Method for preparing high-density lithium ion battery anode material-lithium nickel manganese cobalt and special calcinator

InactiveCN102709541AHigh tap densityAvoid shufflingCell electrodesRotary drum furnacesLithiumHigh density

The invention relates to a method for preparing a lithium ion battery anode material, in particular to a method for preparing a high-density lithium ion battery anode material-lithium nickel manganese cobalt. The method mainly solves the problems that in the prior art, a single physical and mechanical mixing mode is adopted to inevitably result in nonhomogeneity of materials, the materials without impurity phases are difficult to obtain, the particles and appearances are difficult in uniformity, the cycling performance of the materials is poor, and the like. The method disclosed by the invention comprises the following steps of: firstly preparing ammonium salt aqueous solution A, alkaline solution B and nickel manganese cobalt and metal ion mixed aqueous solution C; adding a certain amount of alkaline solution B to a reaction kettle; then adding ammonium salt aqueous solution A, alkaline solution B and nickel manganese cobalt and metal ion mixed aqueous solution C; reacting and aging to obtain a multivariate composite material precursor; mixing lithium salt with the precursor; cooling the mixture after pre-sintering; mixing again; slowly cooling the mixture under oxygen atmosphere after roasting at high temperature; and screening by stages to obtain the product.

Owner:杭州金马新能源科技有限公司

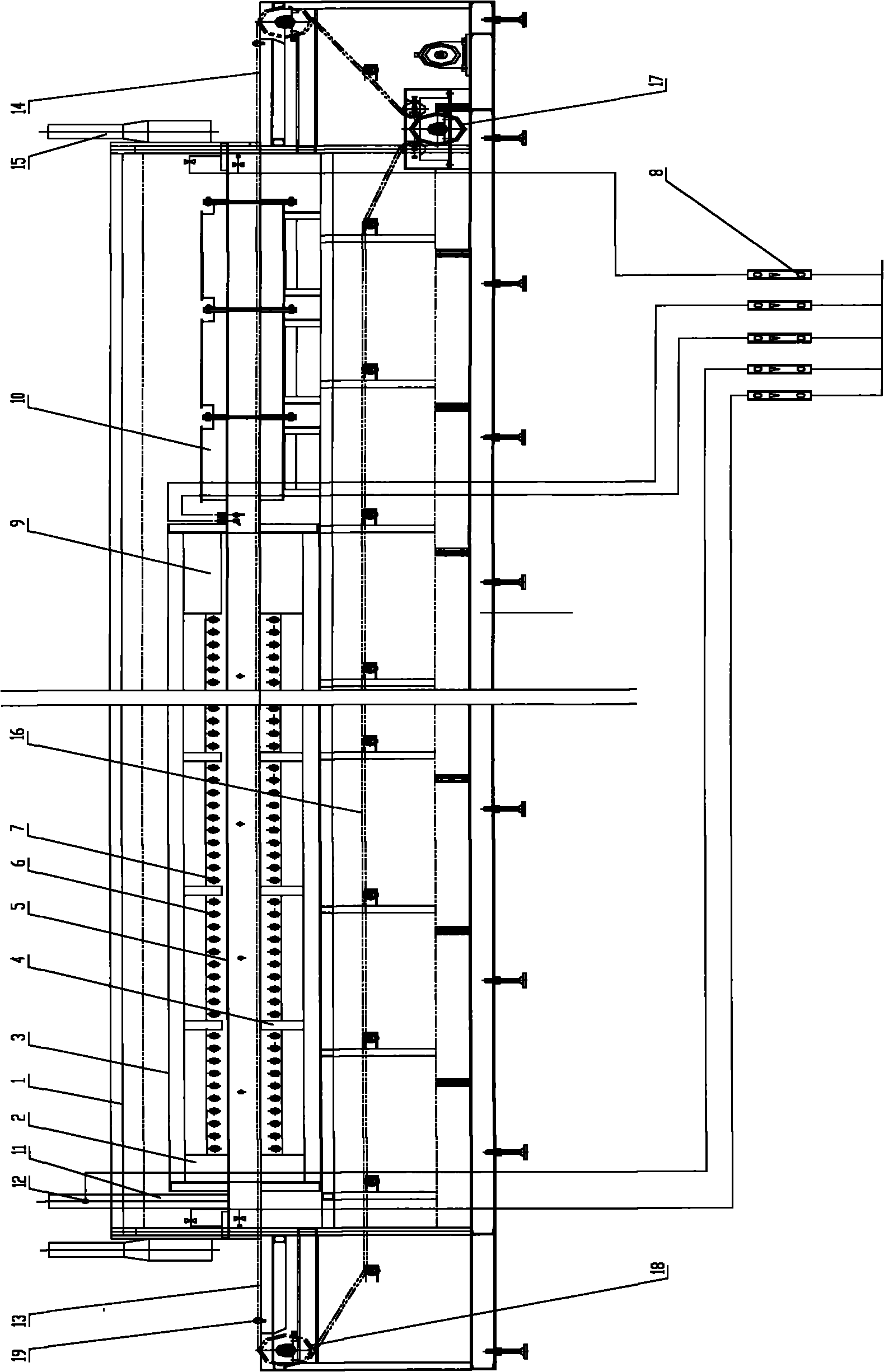

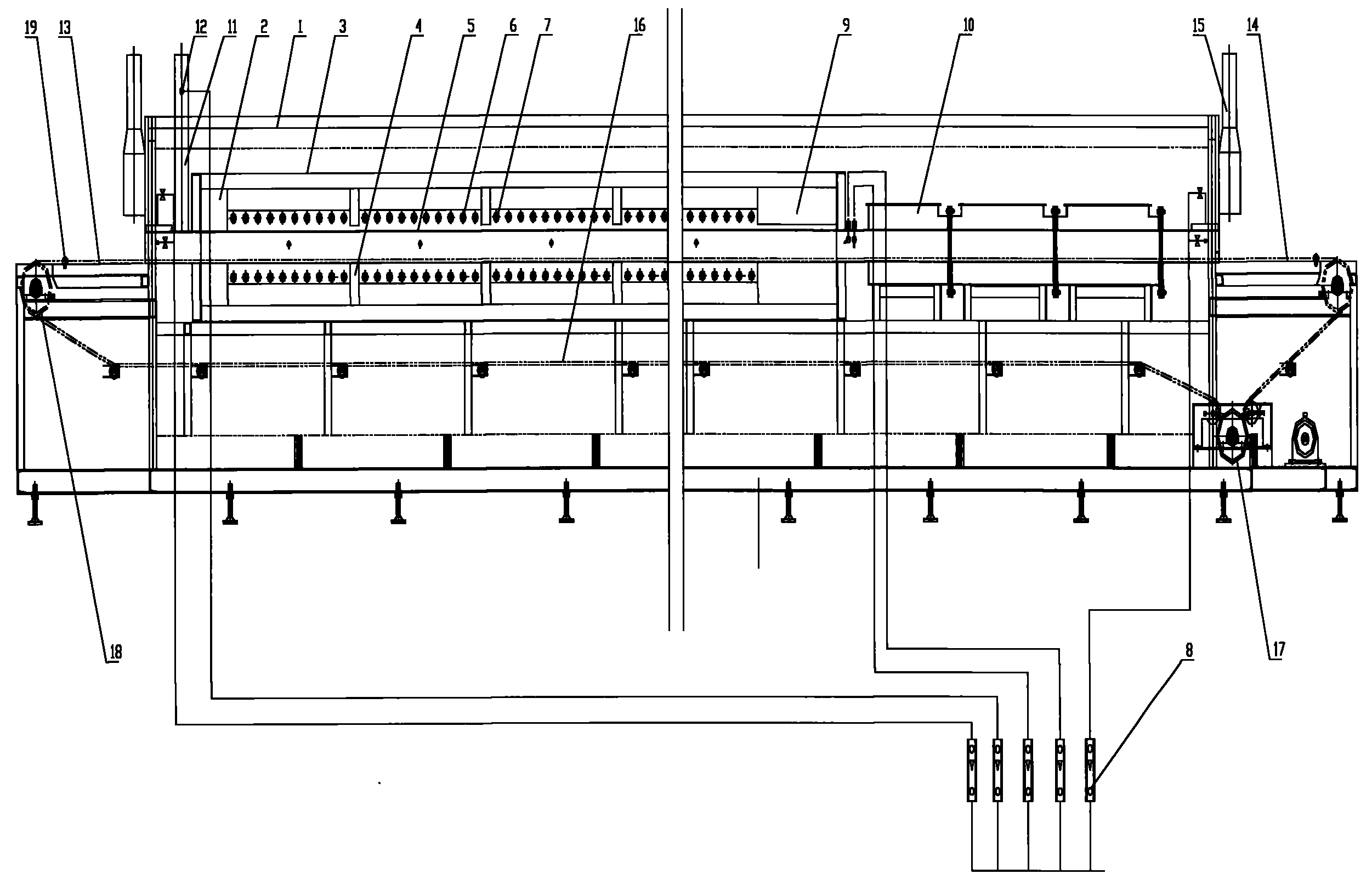

Tunnel mesh belt sintering furnace

InactiveCN101963451AGuaranteed smoothGuaranteed tightnessFurnace typesCeramic materials productionFiberTemperature control

The invention discloses a tunnel mesh belt sintering furnace, belongs to an industrial furnace, and in particular relates to the technical field of dehydrochlorination technology for silicon nitride, titanium nitride, aluminum nitride and other nano powder at 850 DEG C or below. The tunnel mesh belt sintering furnace is characterized in that: the periphery and the top of a hearth consist of ceramic fiber boards; the bottom is supported by light foamed bricks; an inner muff tube made of Cr25Ni20 heat-resistant stainless steel is arranged on the light foamed bricks; the hearth is communicated with five paths of process gas; each path is controlled by a float flow meter; a hearth opening cooling section is divided into two parts, namely a natural cooling section and a forced cooling section; the forced cooling adopts dipping bath type water cooling; and a unique limiting correction device is arranged on two sides of a transmission mesh belt of an equipment inlet platform and an equipment outlet platform. The tunnel mesh belt sintering furnace has the advantages of firm and stable structure, no roof fall, high temperature control accuracy, low energy consumption, clean hearth, uniform temperature, stable long-term work and the like, and is convenient and effective to operate,.

Owner:合肥高歌热处理应用技术有限公司

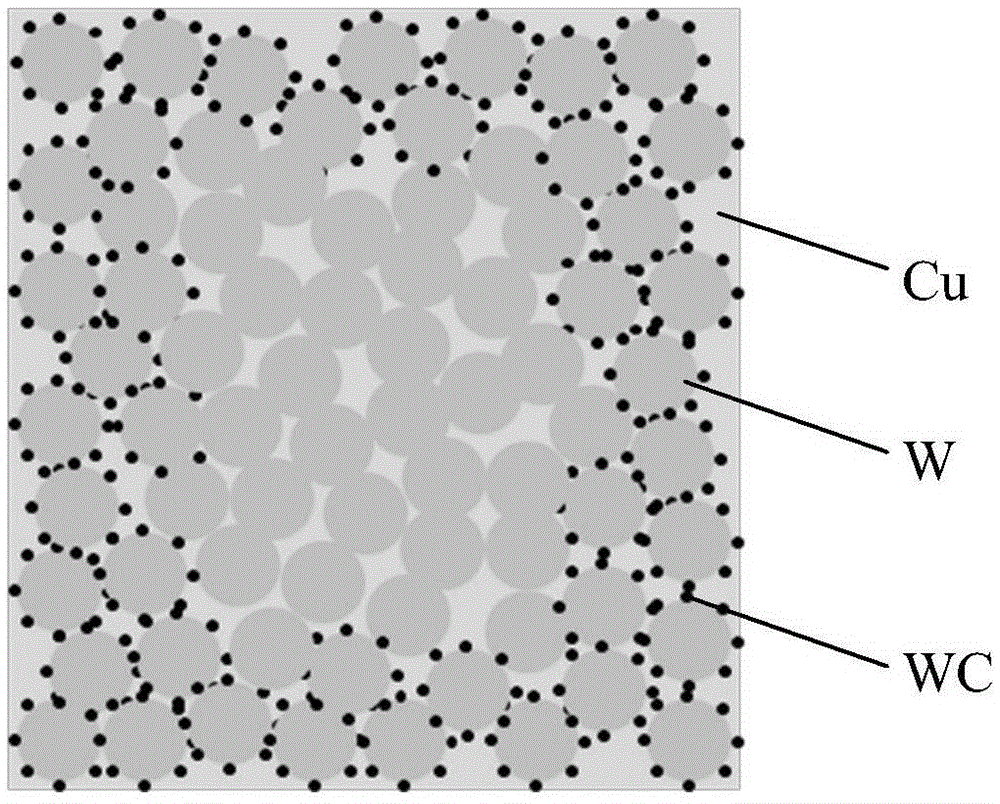

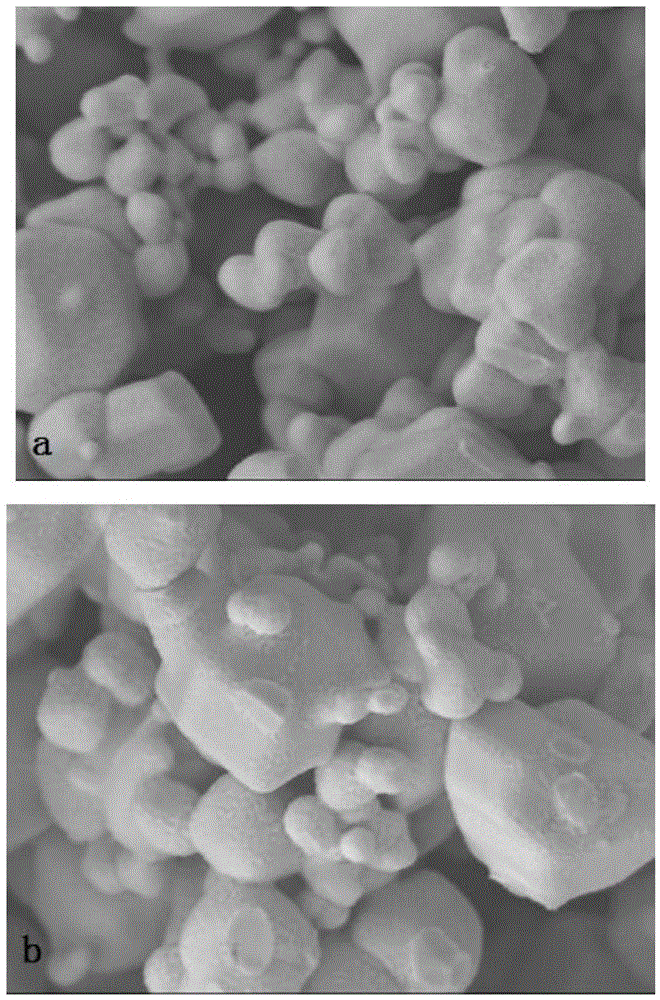

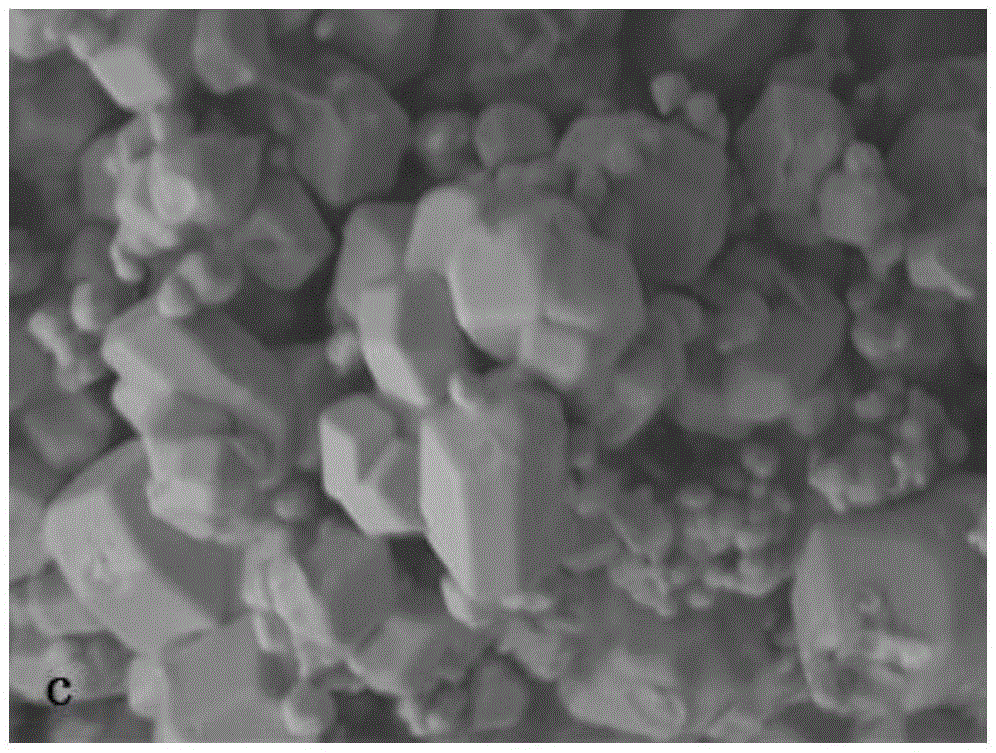

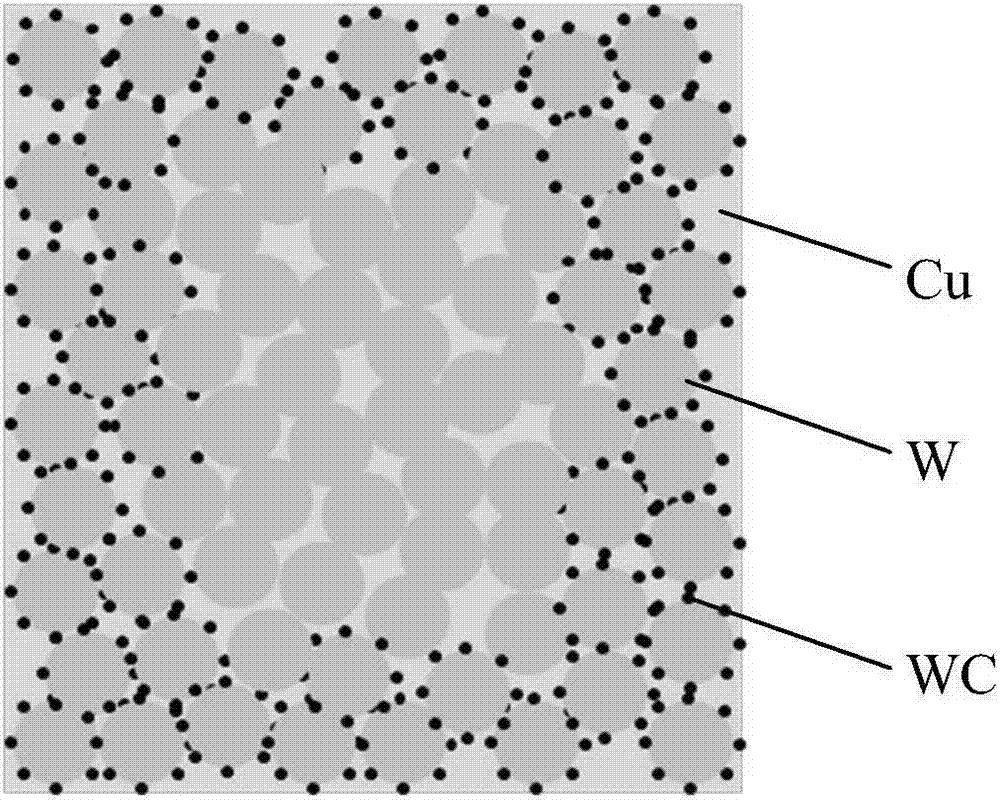

In-situ formation preparation method for gradient WC-strengthened CuW composite material

ActiveCN105568209ADoes not affect other performanceGuaranteed sintering effectSolid state diffusion coatingMicrocomputerCarbon potential

The invention discloses an in-situ formation preparation method for a gradient WC-strengthened CuW composite material. The in-situ formation preparation method for the gradient WC-strengthened CuW composite material comprises the steps that a tungsten framework is heated in a vacuum carburization furnace under the protection of argon, then a furnace body is vacuumized, acetylene is introduced into the furnace body, the furnace body is kept in the state for 2-10 min, the furnace body is vacuumized again till the pressure in the furnace body reaches 1 Pa, then heat preservation is conducted, heat preservation is conducted again after the operation is circulated, then nitrogen is introduced into the furnace body, and a sample is cooled along with the furnace, so that a gradient WC-strengthened W framework is obtained; and copper infiltration is conducted on the gradient WC-strengthened W framework in a microcomputer program-control sintering furnace in a high-temperature hydrogen atmosphere, and then the gradient WC-strengthened CuW composite material is obtained. By the adoption of the preparation method, the high-temperature strength and abrasion resistance of the W framework are improved; meanwhile, in the carburization process, the WC component gradient exists between the interior and the exterior of the framework under the influence of the carbon potential in the framework and the carbon potential outside the framework.

Owner:XIAN UNIV OF TECH

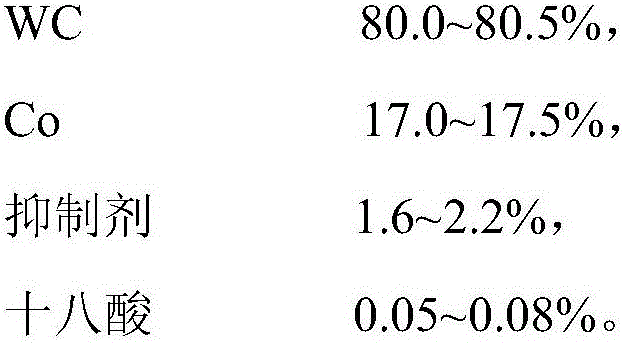

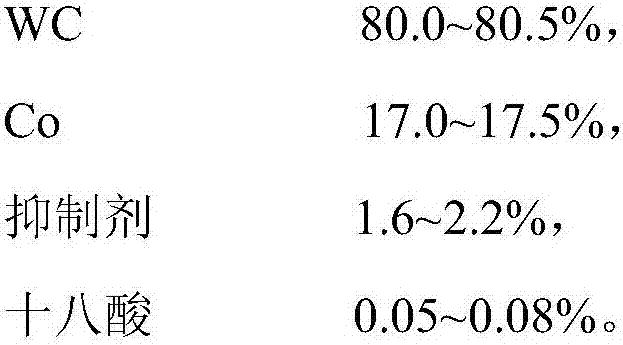

High-performance stripping and slitting knife adopting new hard alloy material and manufacturing method of stripping and slitting knife

ActiveCN105950938AHigh hardnessImprove wear resistanceTurbinesOther manufacturing equipments/toolsWear resistantAlloy

The invention discloses a high-performance stripping and slitting knife adopting a new hard alloy material and a manufacturing method of the stripping and slitting knife and belongs to the technical field of hard alloy cutters. The high-performance stripping and slitting knife adopting the new hard alloy material is manufactured with a powder metallurgy technology, and raw materials comprise components in percentage by mass as follows: 0.40%-0.50% of CT, 80.0%-80.5% of WC, 17.0%-17.5% of Co, 1.6%-2.2% of an inhibitor and 0.05%-0.08% of stearic acid. The manufacturing method of the stripping and slitting knife comprises steps as follows: blending; wet grinding; pressing; sintering; machining. On the basis that higher hardness and higher wear resistant property of a blade are guaranteed, the stripping and slitting knife can still keep excellent impact toughness and breakage resistance and can meet the slitting requirement of various metal sheets on the stripping and slitting knife, and the service life of the blade is remarkably prolonged.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Quick-acting furnace repairing method of converter

ActiveCN109136458ARaise the sintering temperatureGuaranteed sintering effectManufacturing convertersCombustionRepair time

The invention relates to a quick-acting furnace repairing method of a converter. The quick-acting furnace repairing method comprises the following steps: determining a furnace repairing position; increasing the final temperature of the prior converter before furnace repairing; increasing the content of MgO in converter final slags; performing deslagging; pouring furnace repairing materials; sintering the furnace materials; reinforcing the sintered furnace materials; after furnace repairing is performed for 40 minutes, enabling about two tons of molten iron to be slowly poured into the converter; gathering the molten iron to a furnace repairing material region through a shaking furnace; performing resintering on the furnace repairing materials for 5-10 minutes through high temperature molten iron; and after furnace repairing is completed, starting to prepare the smelting of the next converter. According to the quick-acting furnace repairing method disclosed by the invention, on one side, by a method of performing heat preservation with coal gas and adding oxygen for combustion-supporting, the sintering temperature of the furnace repairing materials is increased; and on the other side, in the later stage of furnace repairing, through the high-temperature molten iron, high melting point phase of the furnace repairing materials is sintered once again, so that the sintering effect of the furnace repairing materials is guaranteed. Compared with the furnace repairing time through a conventional furnace repairing technology, the furnace repairing time of the quick-acting furnace repairing method disclosed by the invention is shortened by 10-15 minutes; and after the technology is adopted, the durable converter number of the furnace repairing materials is prolonged by 3-5 times.

Owner:SD STEEL RIZHAO CO LTD

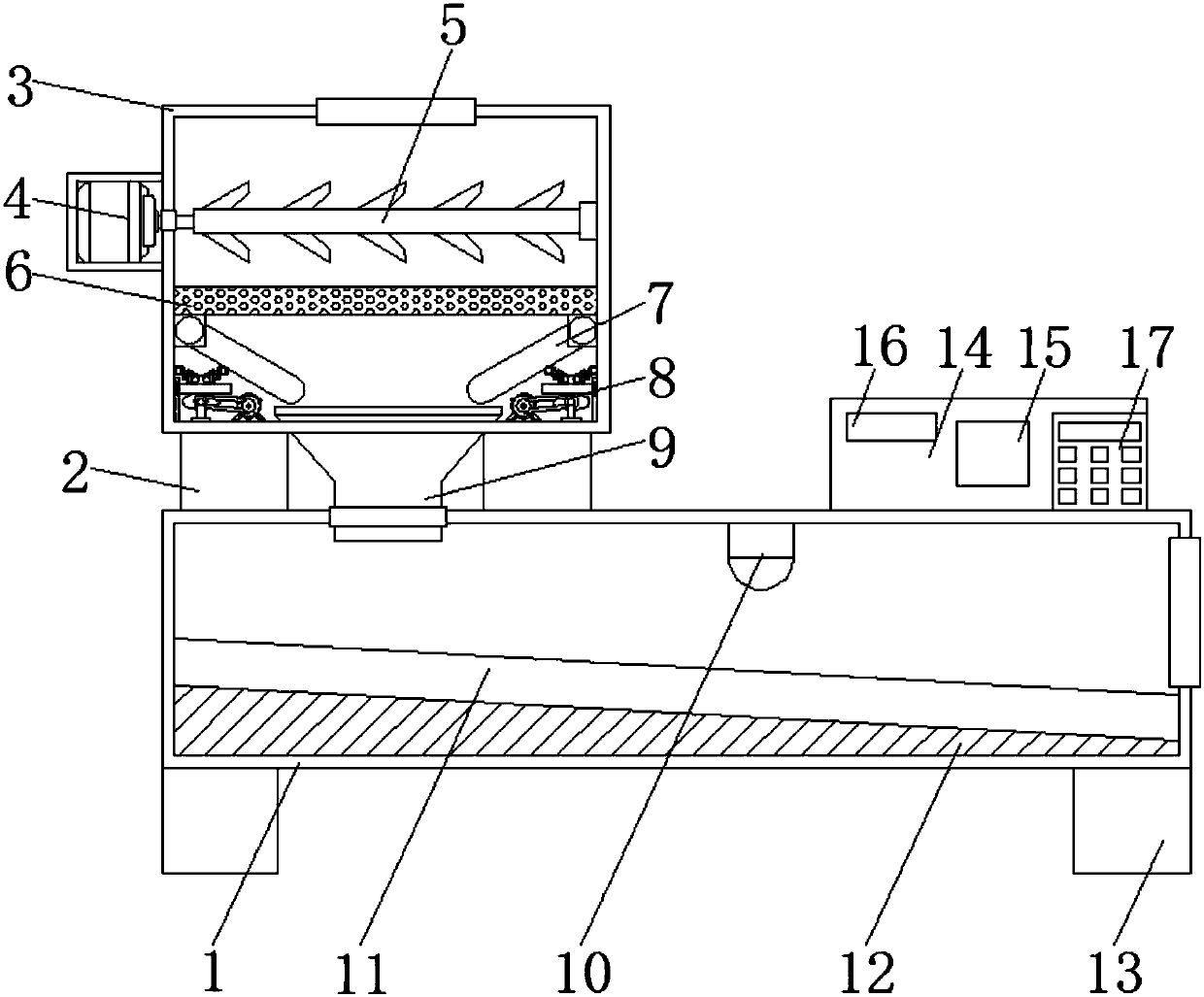

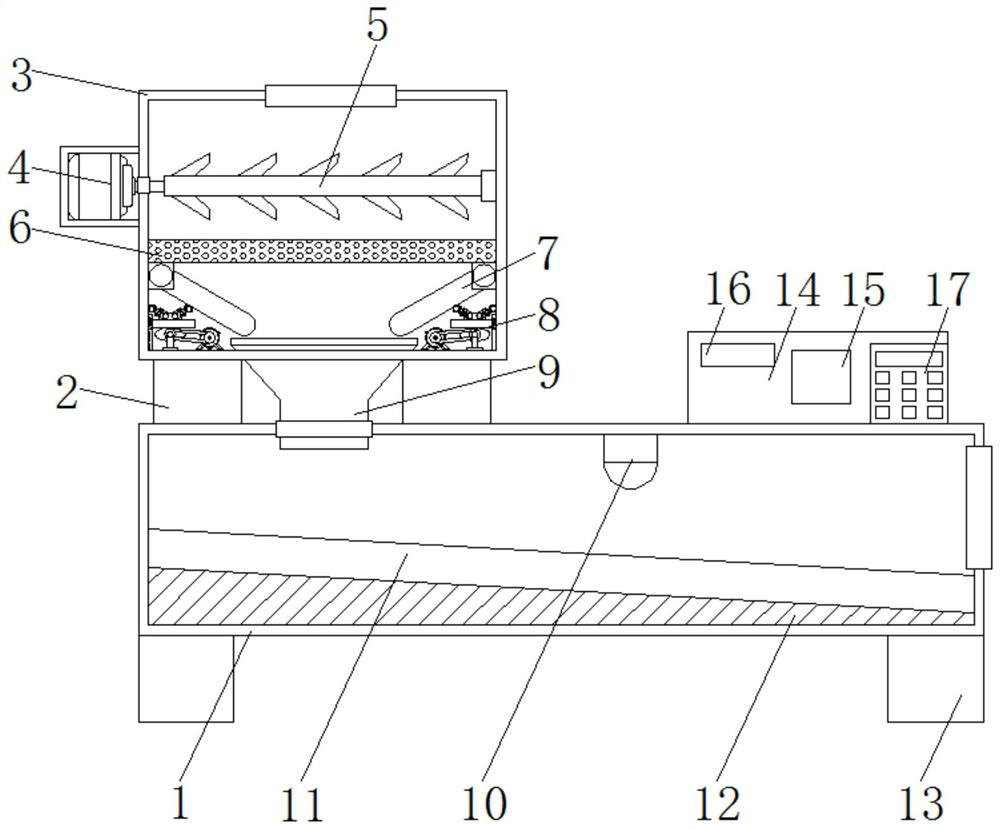

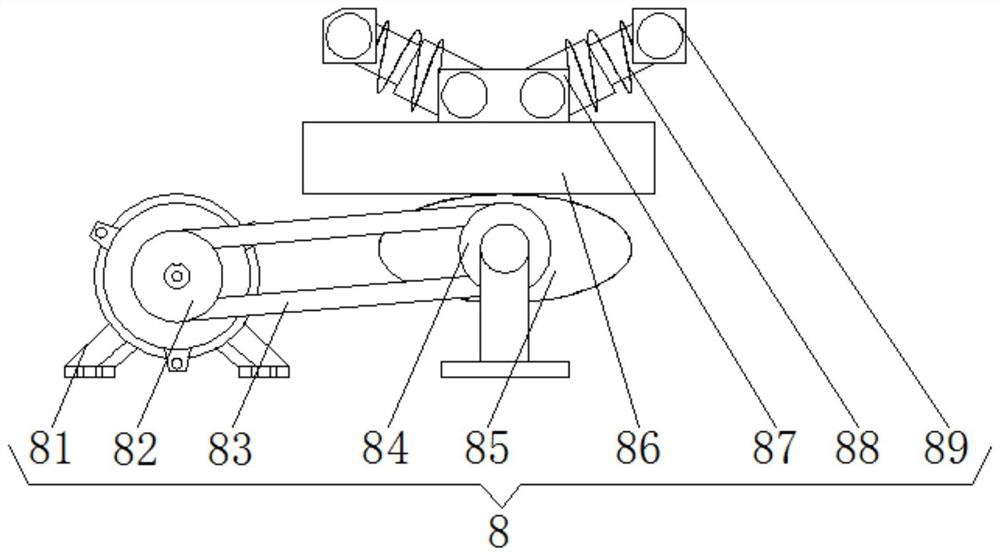

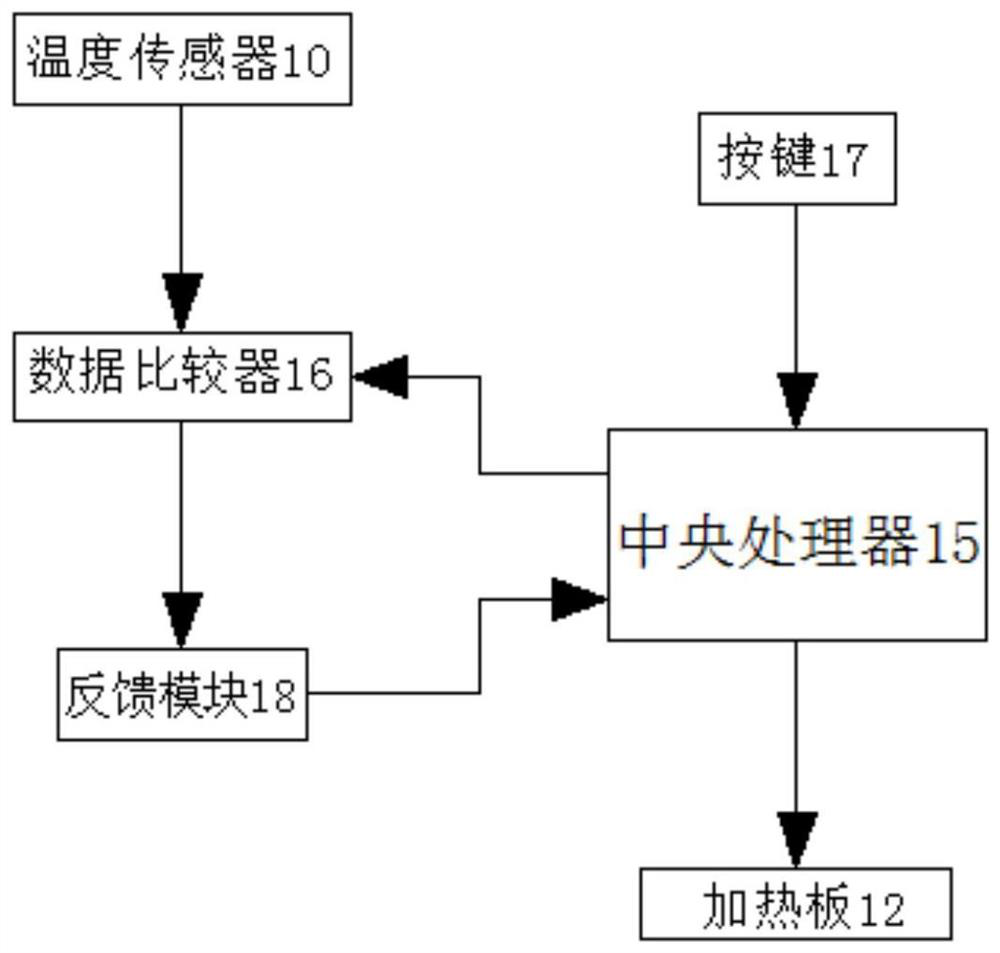

Sintering device for glass preparation

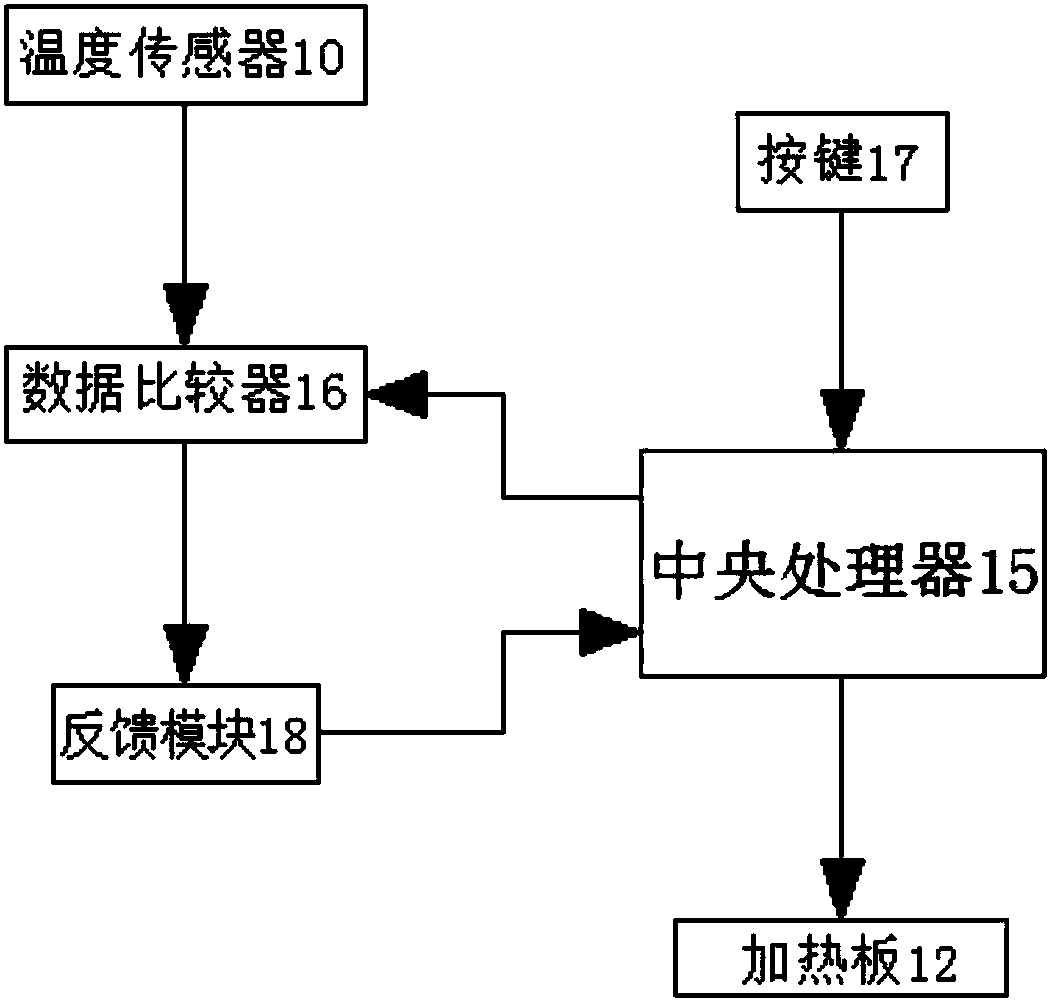

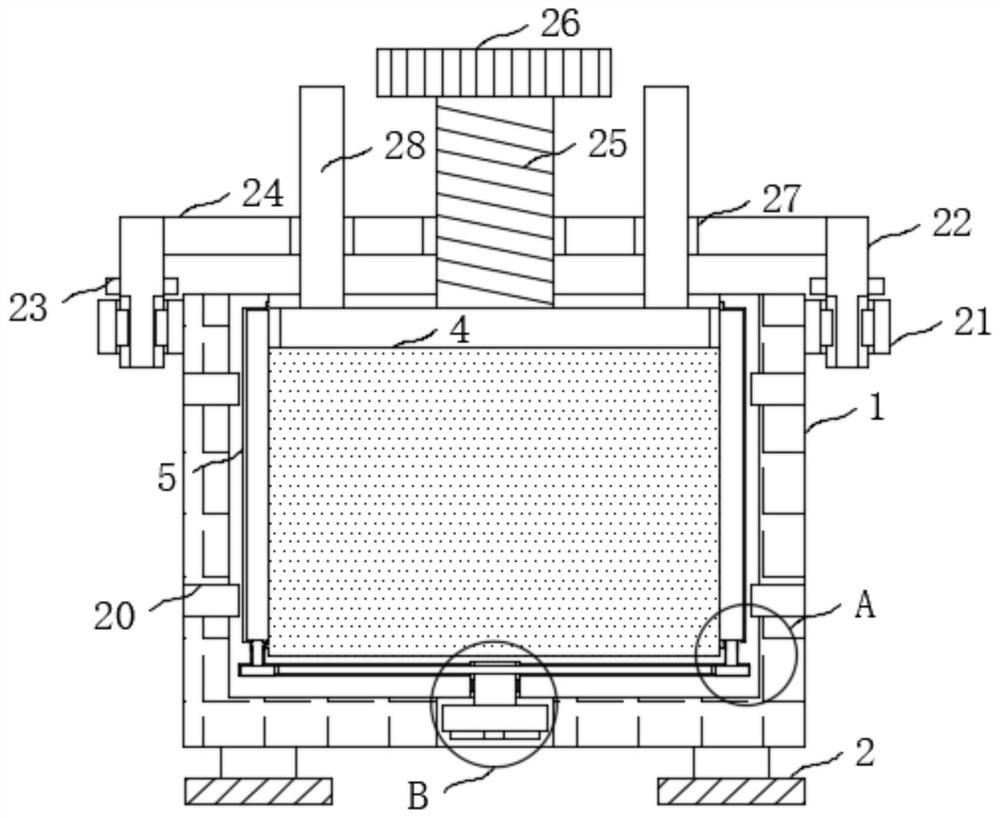

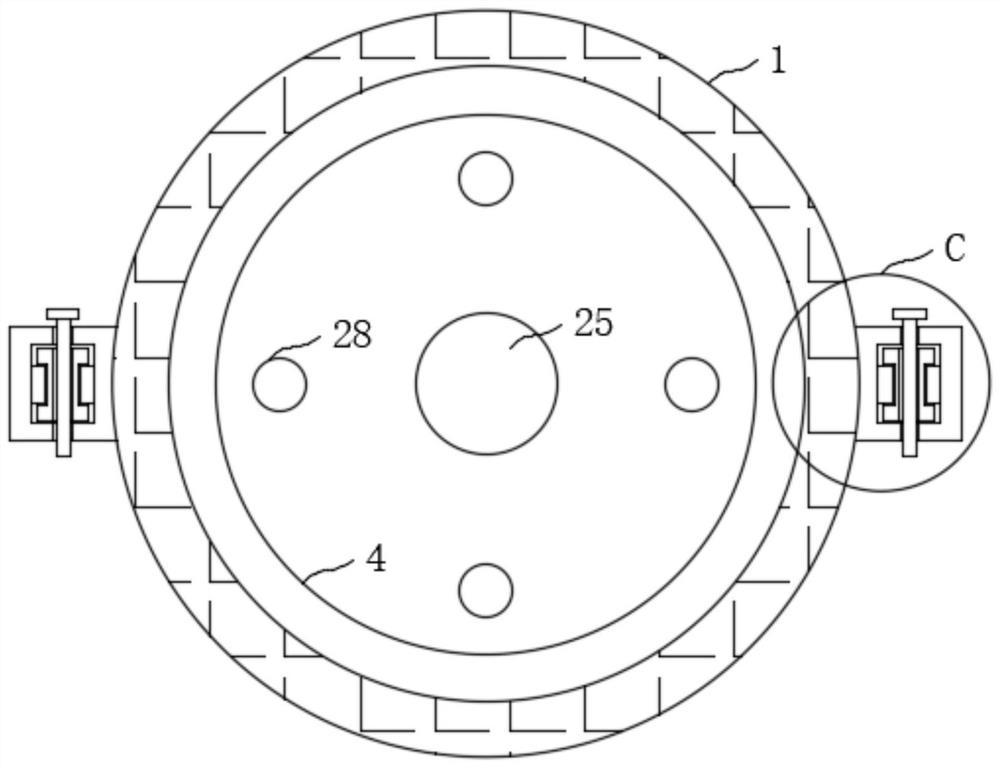

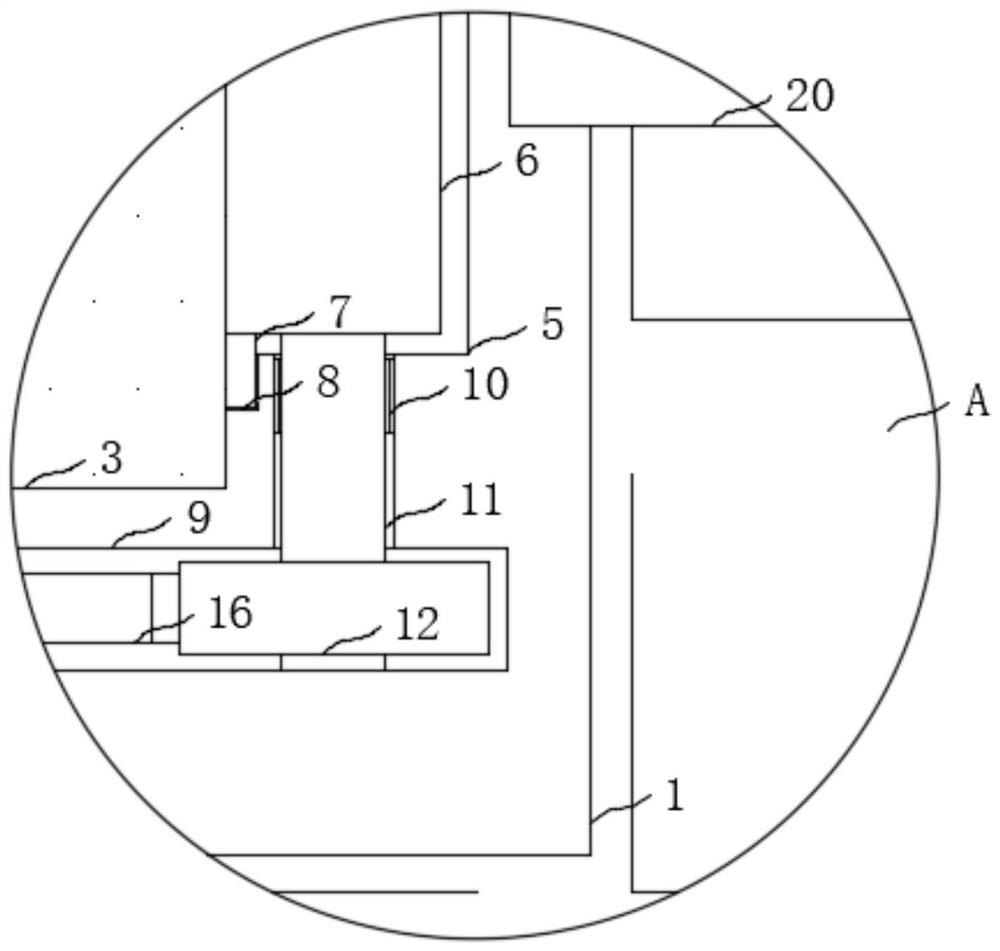

ActiveCN108033666AEasy to crushPromote sinteringCharging furnaceGlass furnace apparatusAutomatic controlEngineering

The invention discloses a sintering device for glass preparation. The sintering device comprises an outer frame, wherein the top of the outer frame is fixedly connected with a support column, the topend of the support column is fixedly connected with a top frame, the left side of the top frame is fixedly connected with a first motor, and one end of the output shaft of the first motor penetrates through the top frame and extends to the inside of the top frame. The invention relates to the technical field of glass preparation. The sintering device for glass preparation has the advantages that the purpose of conveniently pulverizing materials is achieved, a pulverizing device is integrated on the sintering device, production steps are simplified, the pulverizing degree is effectively controlled, subsequent sintering is facilitated, the use by people is facilitated, the increase of the discharge speed is facilitated, the materials are prevented from staying on a feed plate, the operationof the device is ensured, feeding of the materials is facilitated, furthermore, the operation of the device is effectively ensured, the working efficiency is increased, realization of automatic control of the sintering temperature is facilitated, manual control is not needed, the sintering effect is ensured, and the practicability of the device is increased.

Owner:安源玻璃有限公司

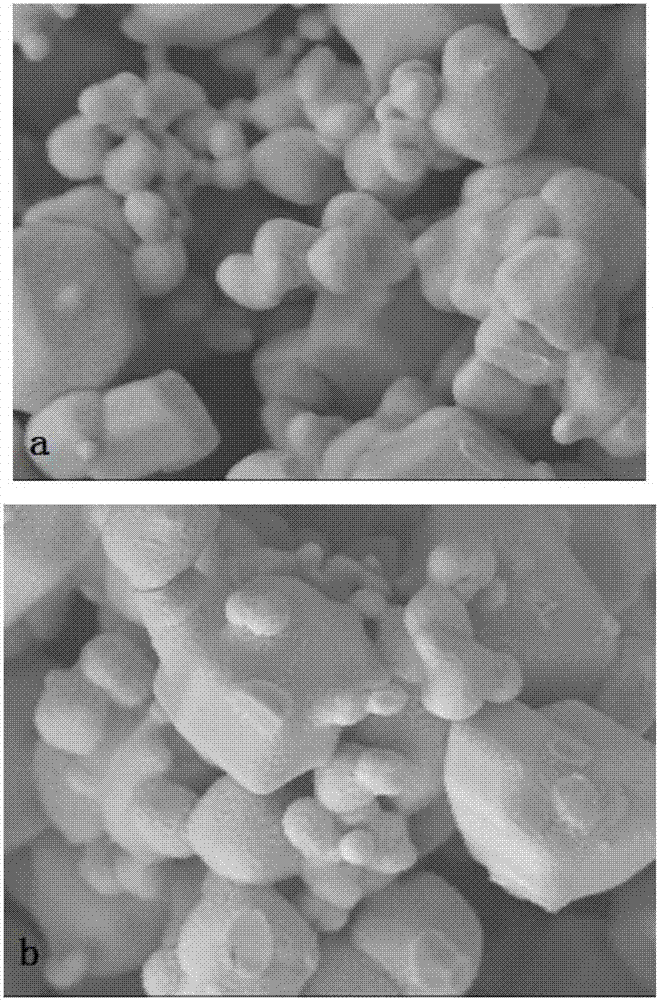

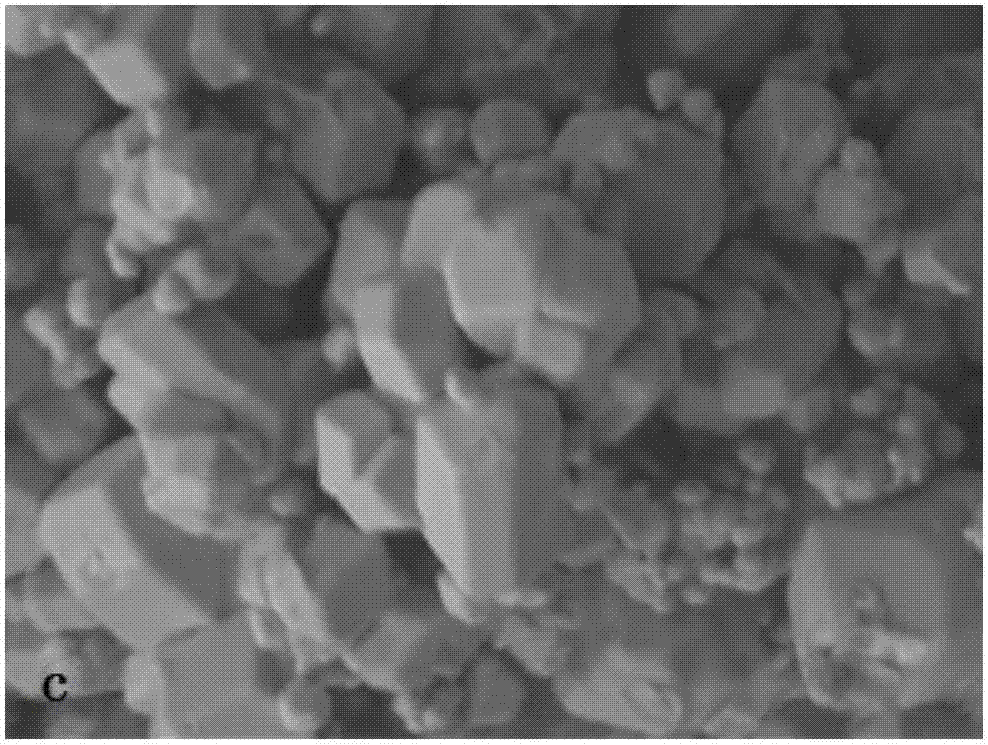

Method of preparing zirconium oxide ceramic by curtain coating method and product obtained by using the method

InactiveCN100519475CGuaranteed sintering effectSmall specific surface areaCyclohexanonePhosphoric Acid Esters

The invention discloses a method for preparing zirconia ceramics by a casting method. (1) pretreating zirconia micropowder with a partially stable tetragonal crystal phase produced by a wet chemical method at 600-800° C. for 1-3 hours, and (2) ) the pretreated zirconia micropowder is added to the ball mill, and then based on the weight of the zirconia powder, 1-3% of the dispersant, 50-60% of the solvent, and 0.5-3% of the leveling agent are added according to the weight percentage, and the ball mill is made for 10 hours. into a slurry. Then add 2-8% plasticizer and 3-10% adhesive to the above-mentioned primary slurry to make casting slurry after secondary ball milling for 10 hours. The above-mentioned dispersant is castor oil or phosphoric acid ester, and the adhesive It is polyvinyl butyral, the plasticizer is a mixture of dibutyl phthalate and dioctyl phthalate, the weight ratio is 1:1, the solvent is absolute ethanol, and the leveling agent is cyclohexanone , (3) After ball milling, the casting slurry is vacuum stirred and defoamed for 10-30 minutes, the viscosity of the slurry is controlled to 10000-30000mPa.s, and then cast on a large casting machine, while drying at 60°C-100°C After 2-3 hours, a zirconia ceramic green body is prepared, and the cast green body is placed on a setter plate from room temperature to 600 °C at a heating rate of 0.5-1.5 °C / min, kept for 4 hours to remove the glue, and then Sintering at less than 1540°C for 2-4 hours.

Owner:珠海粤科京华电子陶瓷有限公司

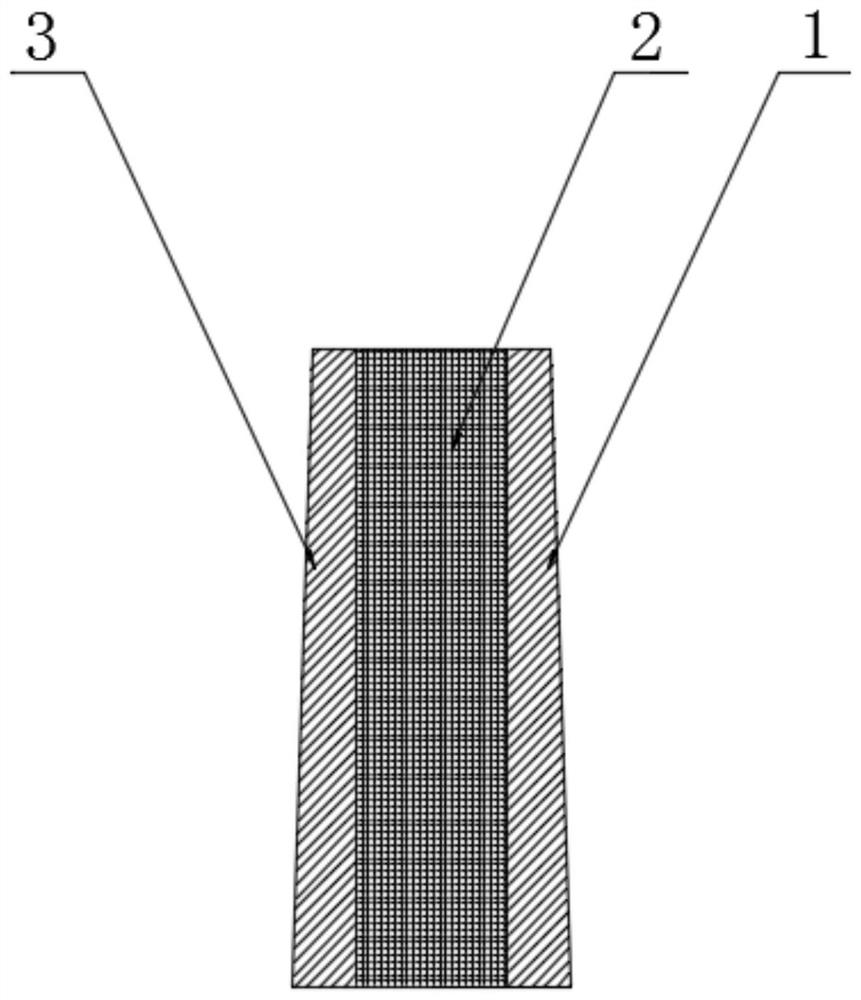

Spark plasma sintering mold adopting polycrystalline mullite fibers for heat preservation

The invention discloses a spark plasma sintering mold adopting polycrystalline mullite fibers for heat preservation, which comprises an inner mold fixedly arranged on outer layers ofpolycrystalline mullite fibers, a plurality of support legs are fixedly arranged on the outer layers of the polycrystalline mullite fibers, a pressing plate is connected to the inner mold in a sliding manner, an annular groove is formed in the side wall of the inner mold, a rotating ring is rotatably connected to the annular groove, a rotating mechanism is installed on the inner mold, the rotating mechanism is matched with the rotating ring, two fixing blocks are fixedly installed on the outer layers of the polycrystalline mullite fibers, connecting rods are installed on the two fixing blocks, and positioning mechanisms are installed between the two connecting rods and the two fixing blocks. The spark plasma sintering mold has the advantages that a certain degree of stirring effect can be applied to metal powder placed in the inner mold, so that the metal powder is more uniformly distributed in the inner mold, the quality of a sintered product is improved, and the mold has relatively low use requirements on auxiliary machinery and is convenient to move.

Owner:ZHEJIANG WEIYE CRYSTAL FIBER

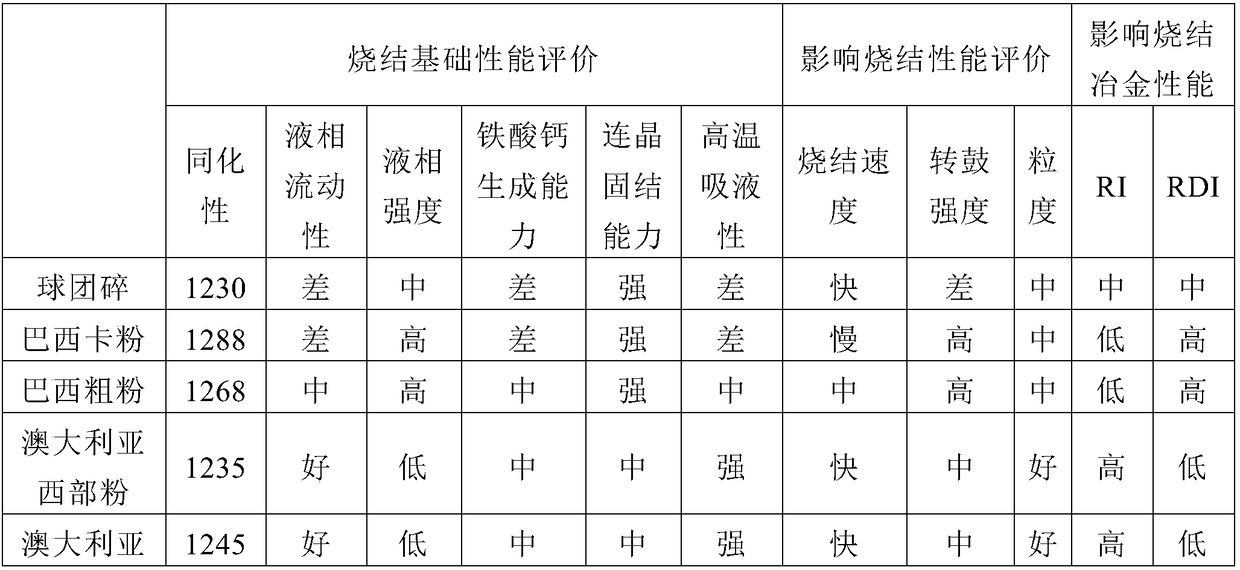

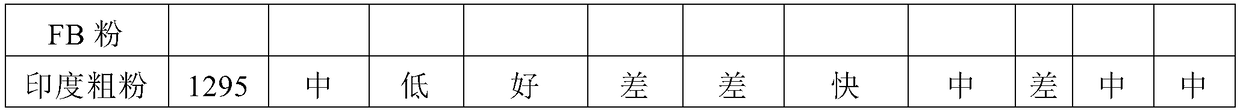

Iron ore well-blended powder with pelletizing undersize for reducing cost and improving efficiency

The invention discloses an iron ore well-blended powder with pelletizing undersize for reducing cost and improving efficiency. The iron ore well-blended powder includes, by weight, 5-15% of the pelletizing undersize, 15-30% of Brazilian Carajas sinter feed, 10-25% of Brazilian coarse iron ore powder, 15-25% of West Australian powder, 15-25% of Australian FB powder, and 5-15% of Indian coarse ironore powder. In the invention, the byproduct, pelletizing undersize, which is generated during a direct iron reduction production process, is successfully applied to sinter the well-blended ore; by matching proper iron ore, adverse factors, such as low assimilation temperature of the pelletizing undersize, poor liquid-phase flowability and poor generation capability of calcium ferrite, are overcome, thus guaranteeing the application effect of the pelletizing undersize.

Owner:上海慧安科技股份有限公司

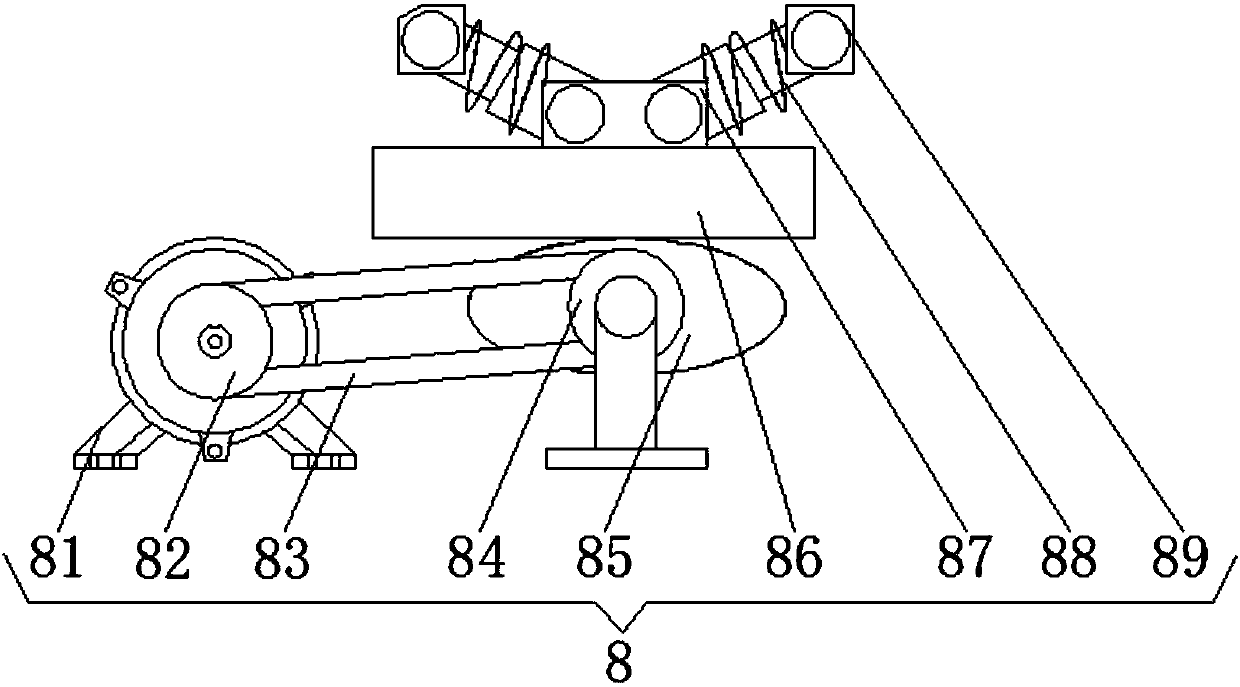

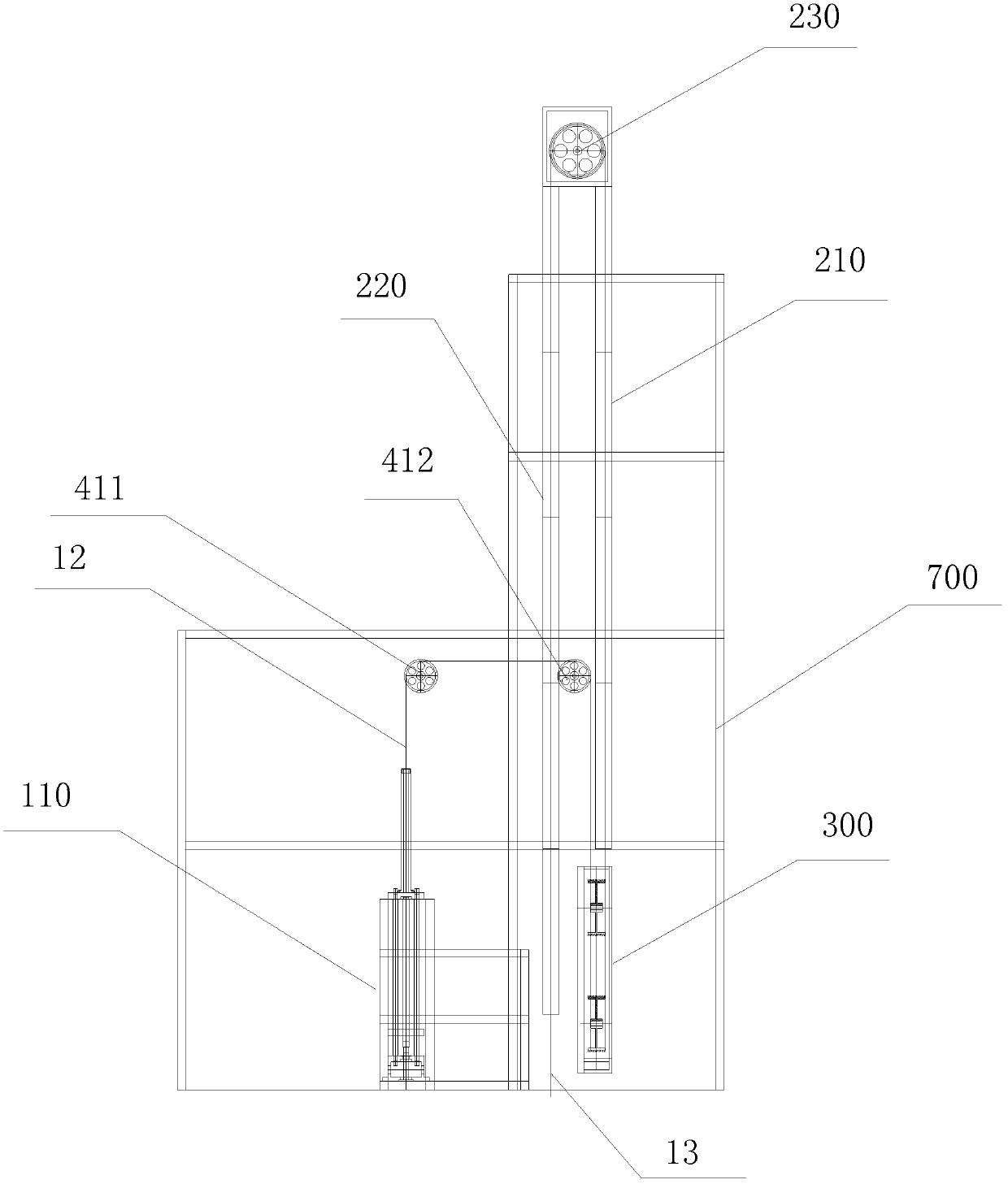

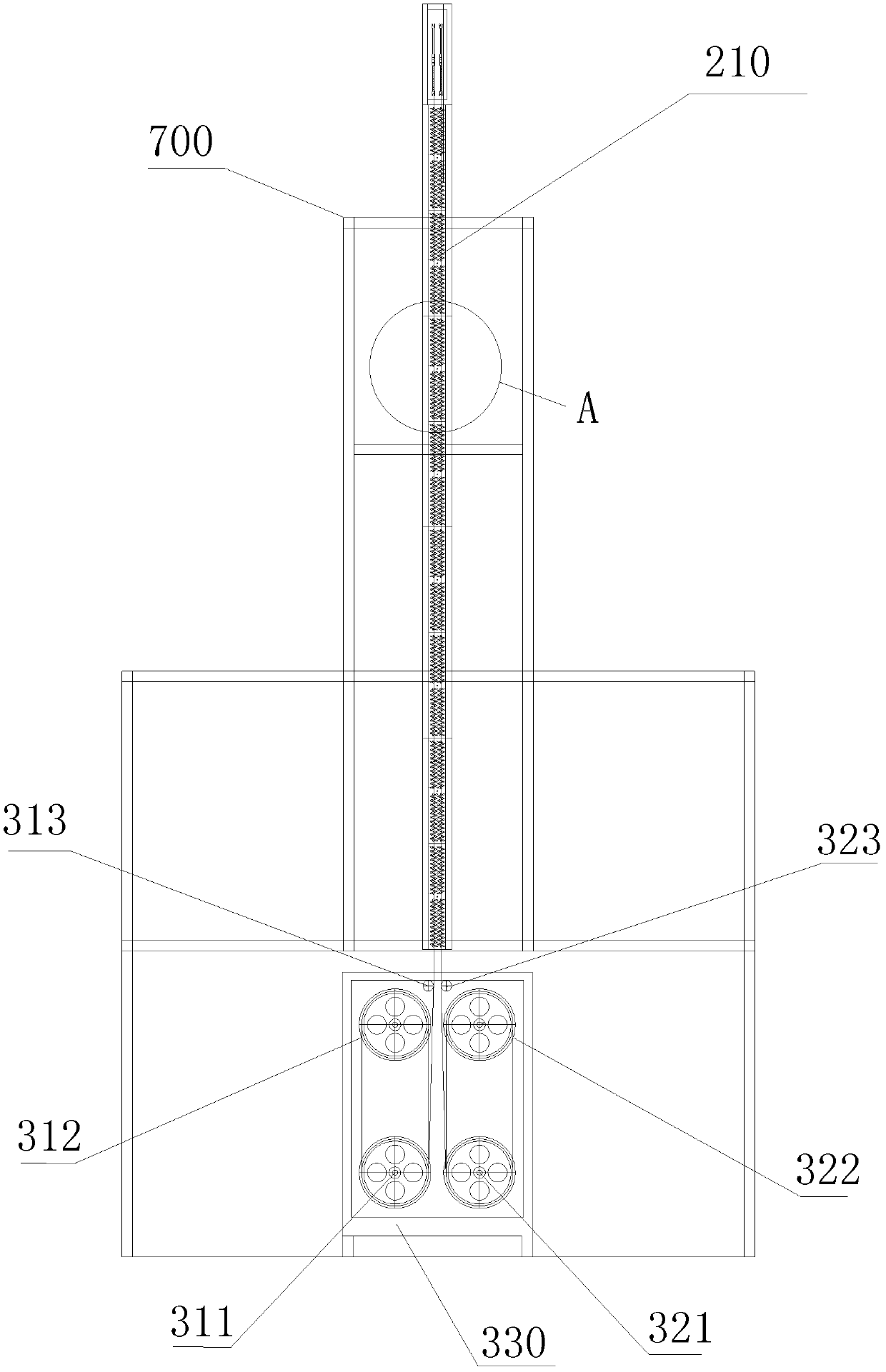

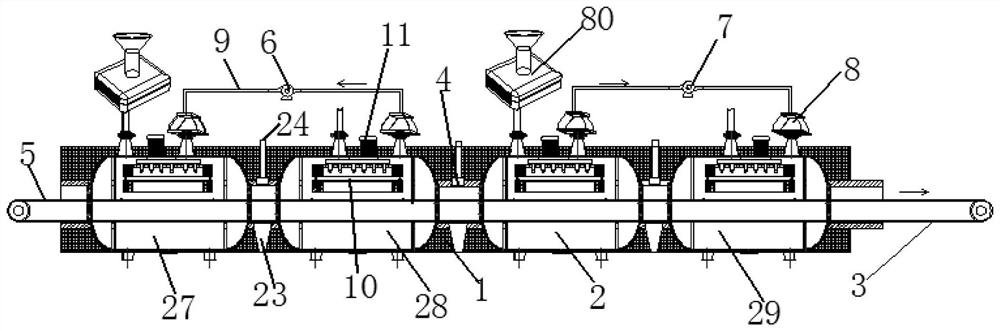

Water storage ceramsite sintering device

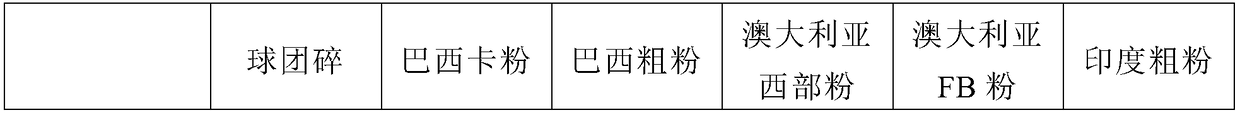

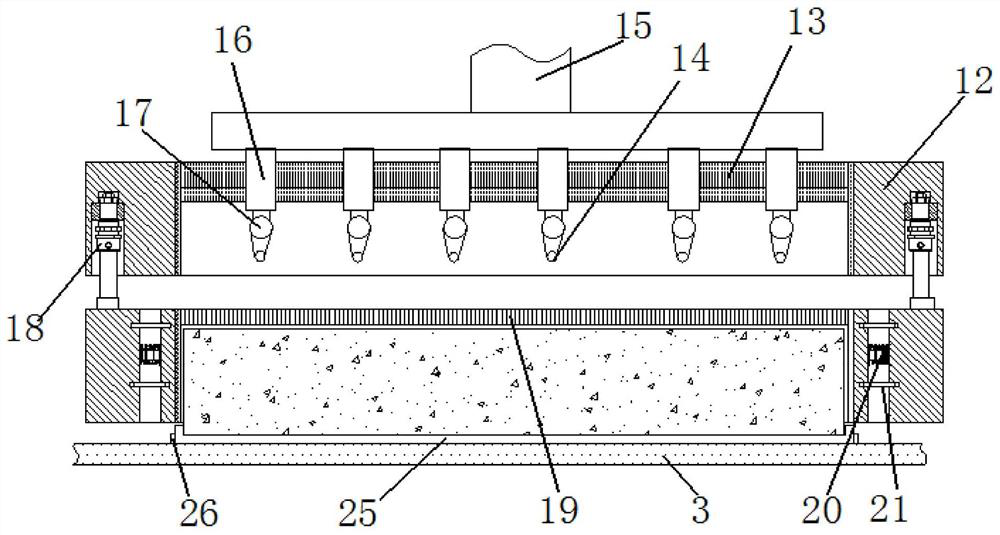

PendingCN112484484AImprove qualityIssues affecting qualityCharge treatment typeFurnace typesWater storageMetallurgy

The invention belongs to the technical field of water storage ceramsite sintering, and discloses a water storage ceramsite sintering device. The water storage ceramsite sintering device comprises a sintering furnace, a first conveying mesh belt, a second conveying mesh belt and a mesh belt driving assembly; the first conveying mesh belt and the second conveying mesh belt are fixed on the mesh beltdriving assembly, and the first conveying mesh belt and the second conveying mesh belt are arranged in the sintering furnace; and in the conveying direction, the tail end of the first conveying meshbelt is located above the second conveying mesh belt. According to the water storage ceramsite sintering device, the defect that the ceramsite sintering degree is not uniform can be overcome, the riskof adhesion and hardening is reduced, and the quality of the water storage ceramsite is improved.

Owner:武汉铭创新海生态科技有限公司

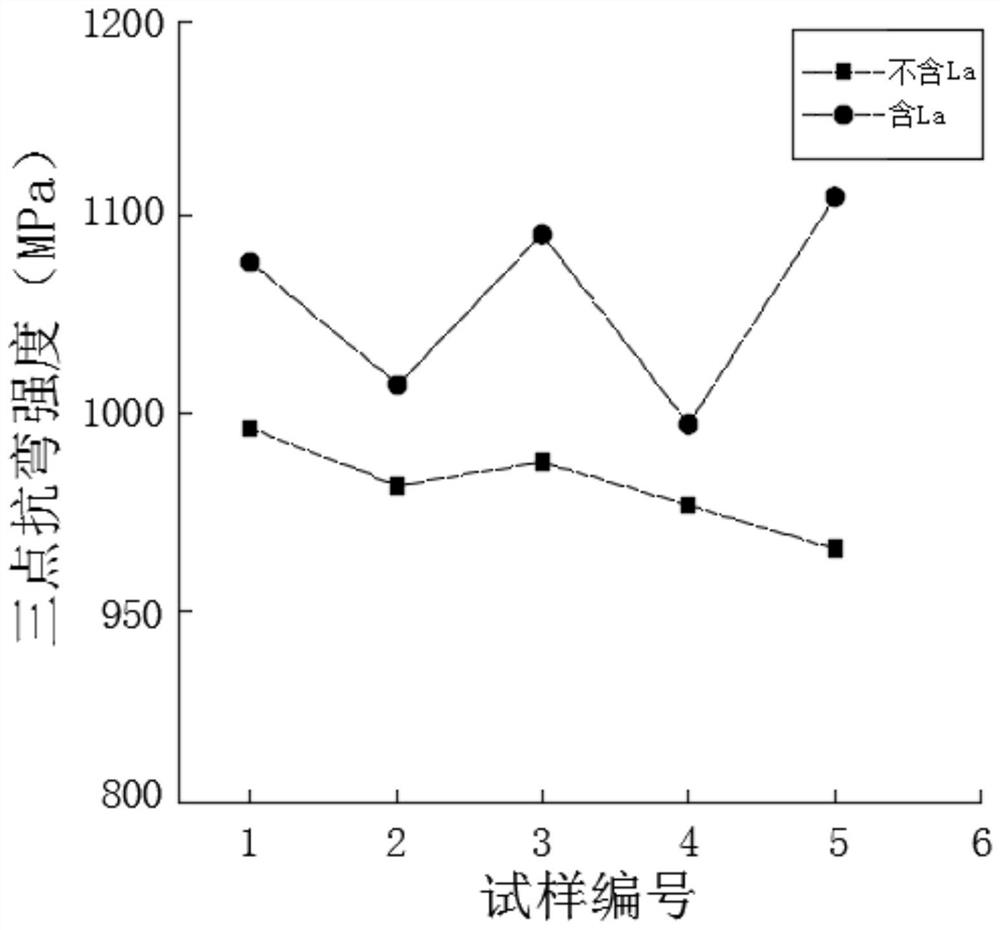

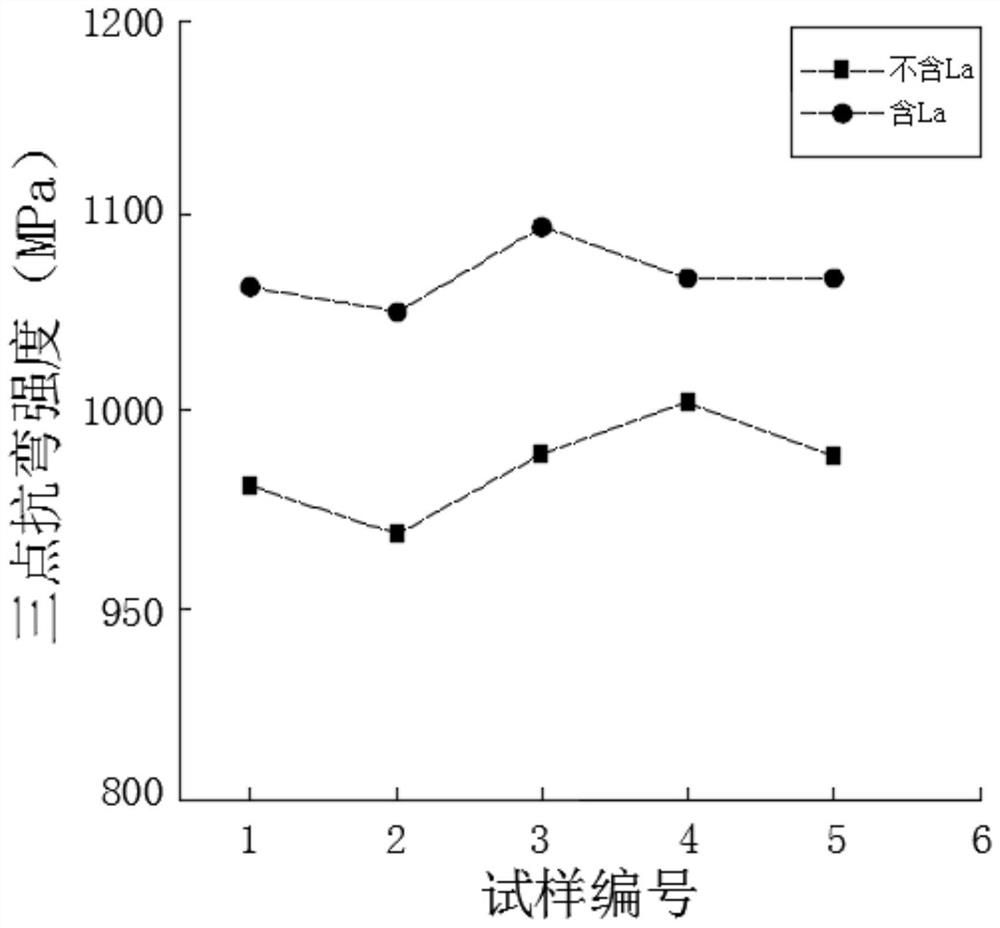

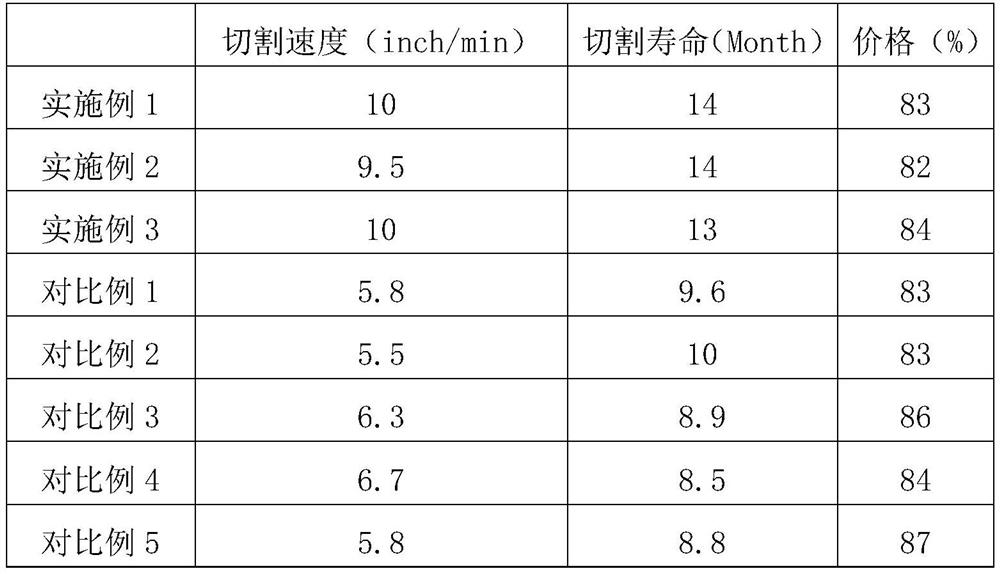

Low-price gang saw tool bit product and preparation method thereof

InactiveCN112091218AGuaranteed lifeGuaranteed sintering effectTransportation and packagingMetal-working apparatusTool bitRare-earth element

The invention discloses a low-price gang saw tool bit product and a preparation method thereof, and particularly relates to the field of gang saw tool bits. A tool bit material adopted by the tool bitproduct is formed by mixing and sintering metal powder, liquid paraffin and diamond, wherein the metal powder is prepared from the following powder raw materials in part by weight: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel and 0.8 part of La, the liquid paraffin accounts for 1-1.2 parts, and the diamond accounts for 30% of the volume of the tool bit material. According to the low-price gang saw tool bit product and the preparation method thereof, by adding different contents of Fe, Cu, Ni and Sn and a small amount of rare earth elements, the hardness HRB, the bending strength and the abrasion ratio of a matrix are kept, so that the mechanical property and the abrasion resistance of the gang saw tool bit to the matrix are met; and the characteristics of the matrix are matched by using the diamond with the fixed grade and granularity, the holding force of the matrix on the diamond and the edge exposure effect are ensured, and the cutting sharpness and the service life of a cobalt-based product are achieved by using a sintering process matched with the characteristics of the matrix.

Owner:QINGDAO SHINHAN DIAMOND INDUSTRY CO LTD

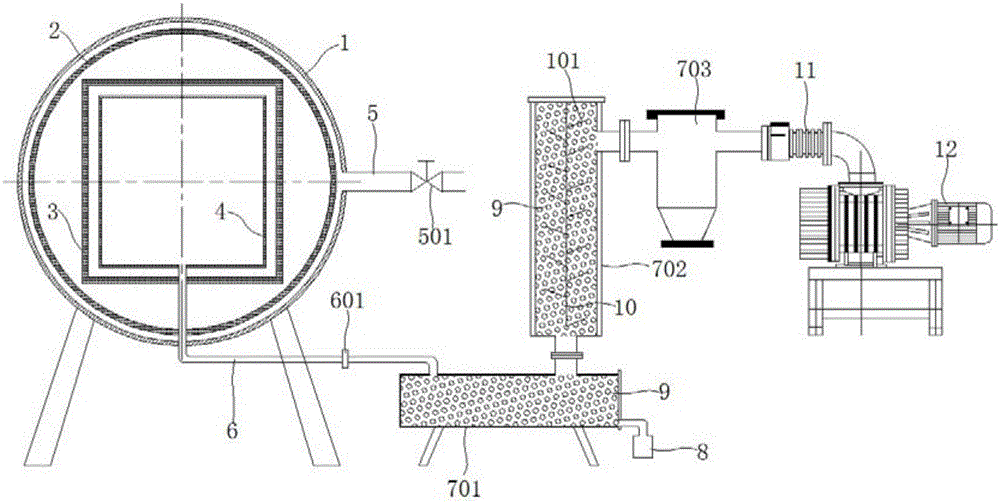

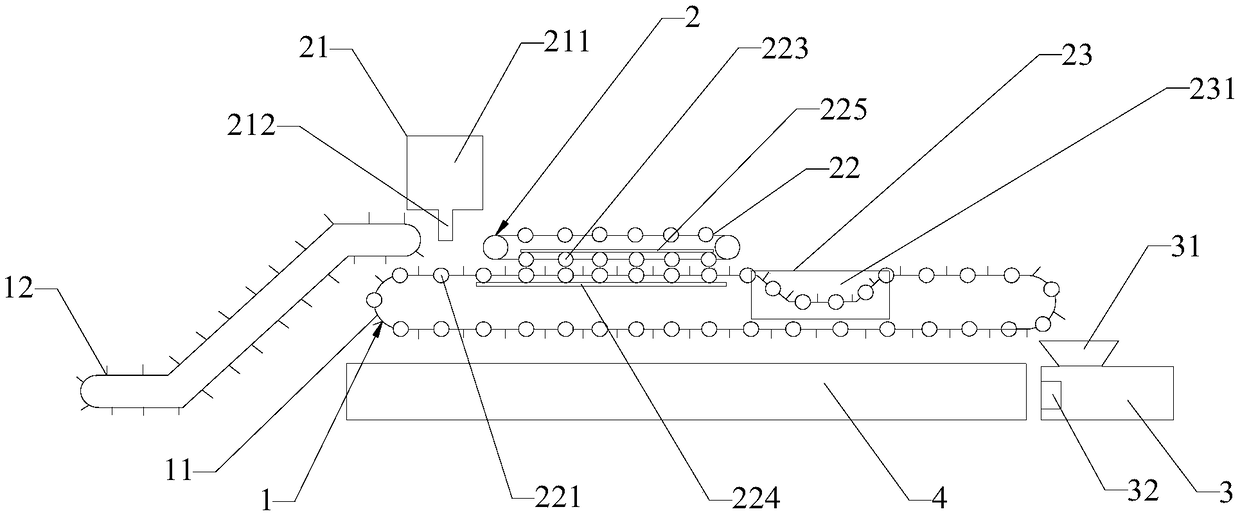

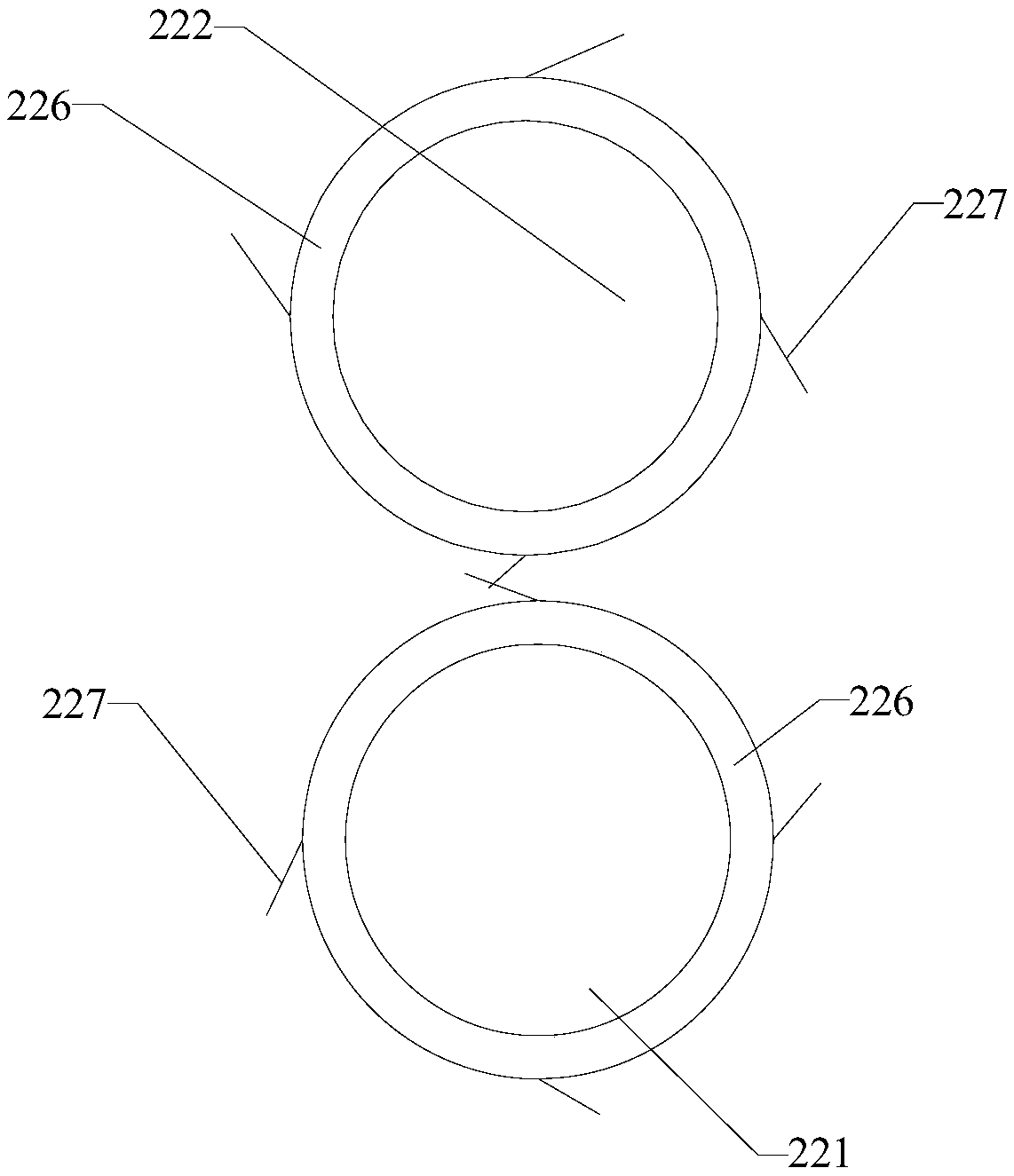

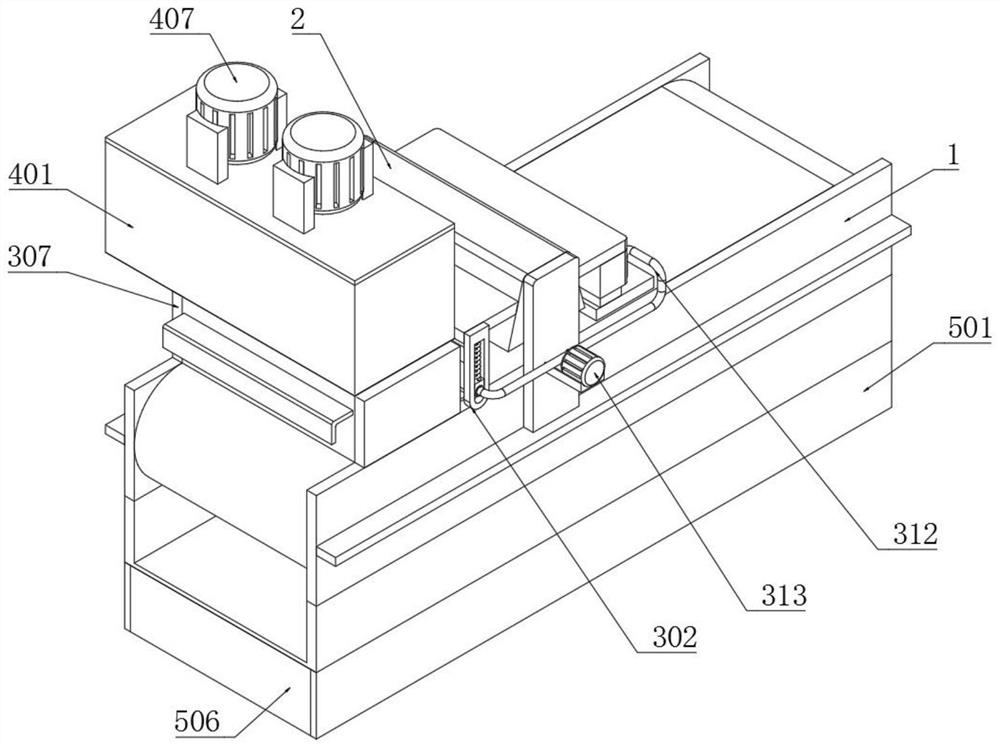

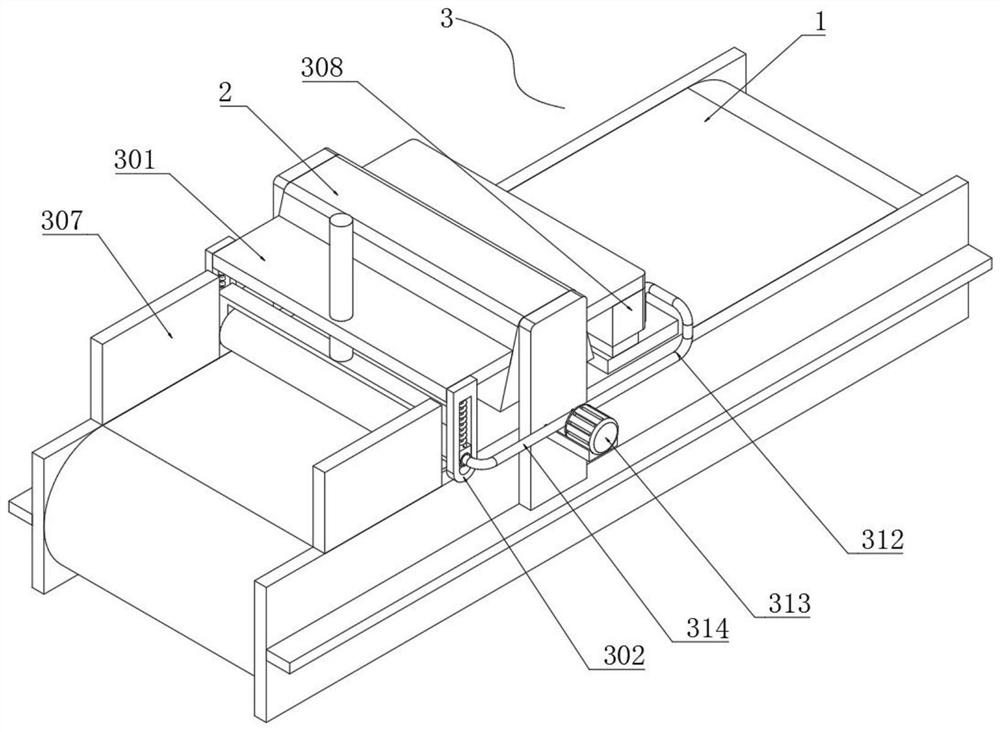

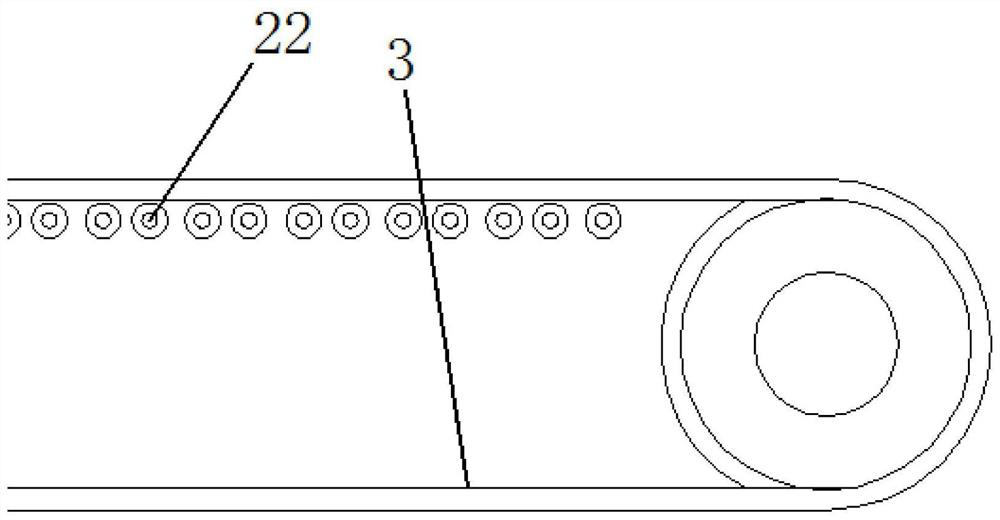

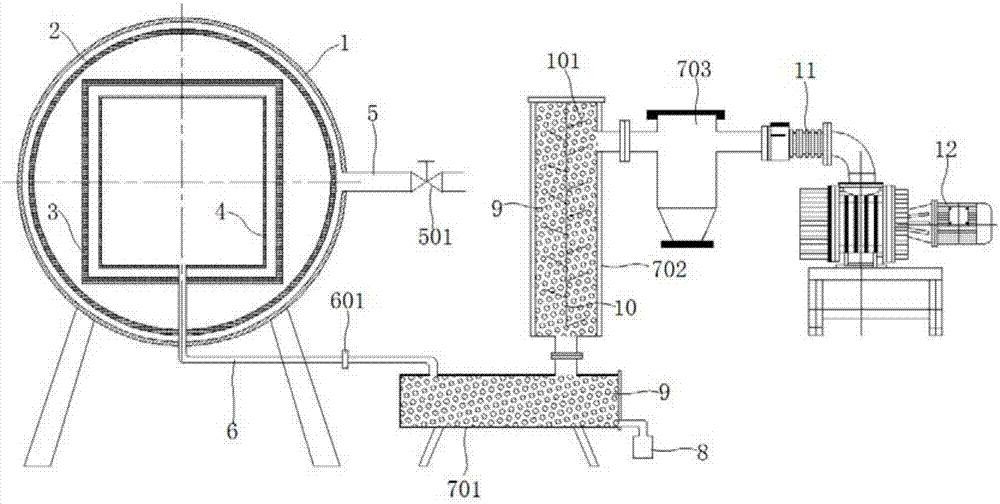

Isostatic pressing oil removal system

PendingCN108687028AFully removedGuaranteed sintering effectDrying gas arrangementsCleaning using toolsMagnetEngineering

The invention relates to the technical field of sintered NdFeB magnets, in particular to an isostatic pressing oil removal system. A first conveying belt with a grating is arranged, multiple first cleaning rollers are arranged on the first conveying belt, a second conveying belt synchronous with the first conveying belt is arranged above the middle segment of the first conveying belt, second cleaning rollers corresponding to the first cleaning rollers in position are arranged on the second conveying belt, the first cleaning rollers and the second cleaning rollers are driven by a friction beltto rotate, blocking of the grating is used, and therefore in the forward process of the first conveying belt, a magnet body pressing blank is subject to friction cleaning due to the first cleaning rollers and the second cleaning rollers, a washing solution can sufficiently dissolve isostatic pressing oil, and the isostatic pressing oil can be sufficiently removed.

Owner:宁德市星宇科技有限公司

Lead-free acoustic vibration piezoelectric transduction material and preparation method thereof

The invention provides a lead-free acoustic vibration piezoelectric transduction material and a preparation method thereof. The chemical composition of the lead-free acoustic vibration piezoelectric transduction material is (1-x) (K0. 5Na0. 5) (Nb0. 95Sb0. 05) O3-xBi0.5 (Na0.82K0.18)0.5HfO3, wherein x ranges from 0.03 to 0.05. The preparation process provided by the invention is simple, green andenvironment-friendly, and the prepared lead-free acoustic vibration piezoelectric transduction material has a good temperature stability characteristic within a certain temperature range while ensuring a high piezoelectric constant, and has a wide application value.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

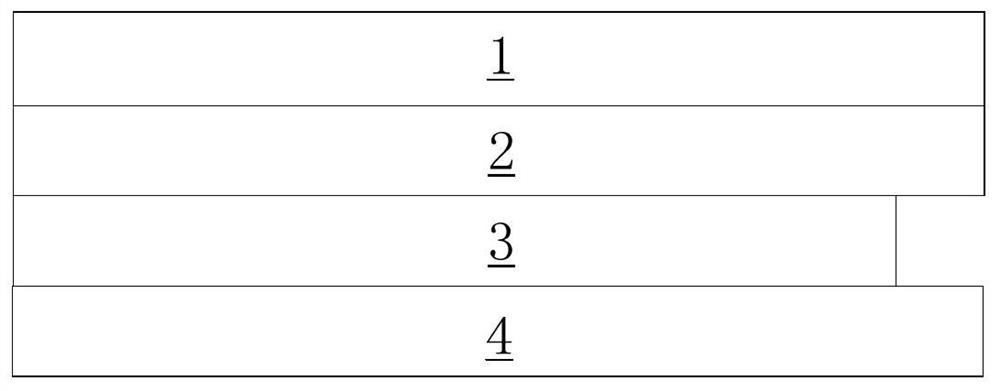

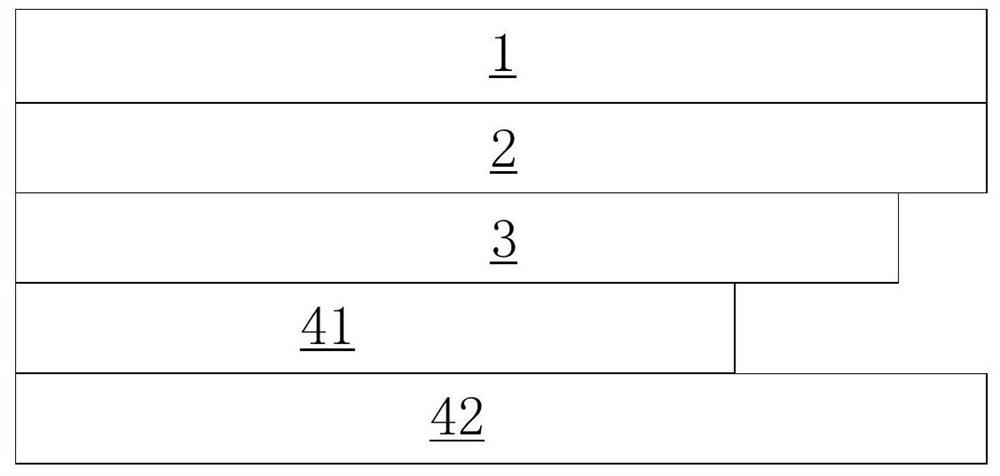

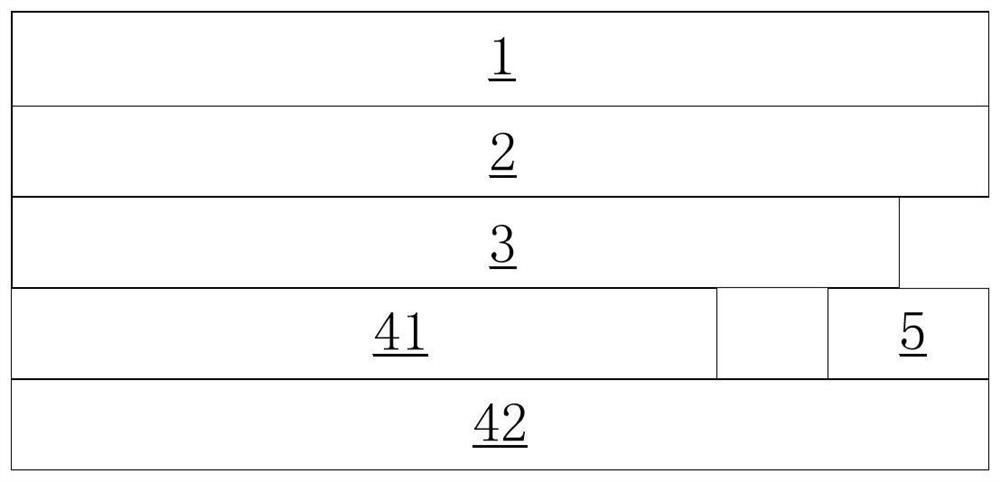

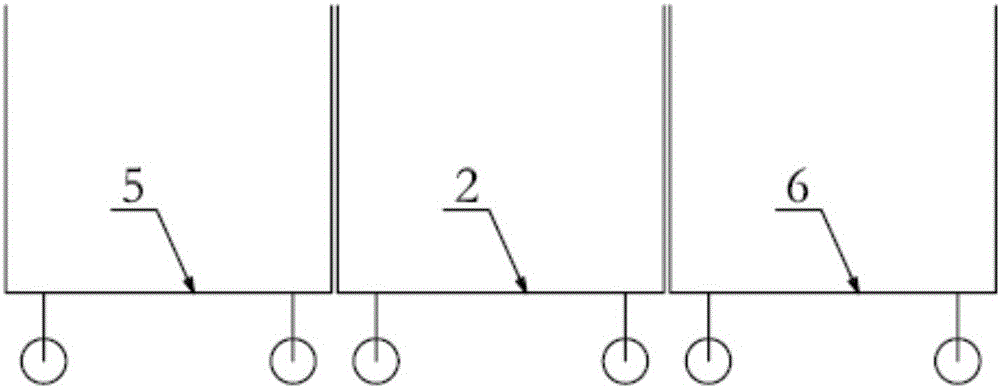

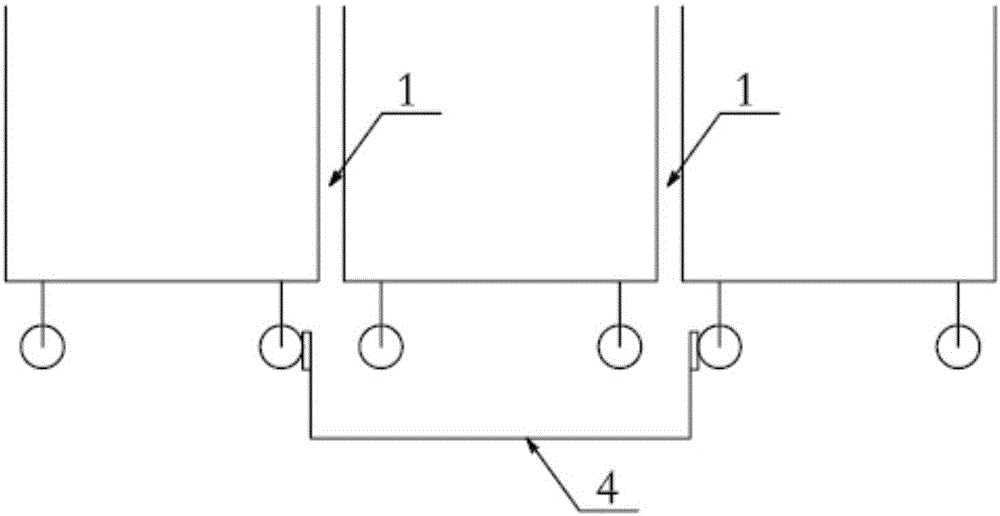

Organic light-emitting display panel and electronic equipment

ActiveCN113851601ASimple structureNormal productionSolid-state devicesSemiconductor/solid-state device manufacturingEnergy absorptionEngineering

The embodiment of the invention provides an organic light-emitting display panel and electronic equipment. The organic light-emitting display panel at least comprises an energy absorption layer, a cover plate, a packaging adhesive layer and a display substrate which are arranged in sequence, wherein the organic light-emitting display panel comprises a display area and a peripheral area, and the packaging adhesive layer is arranged in the peripheral area and surrounds the display area; the energy absorption layer is arranged on the cover plate, the orthographic projection of the energy absorption layer on the cover plate covers the orthographic projection of the packaging adhesive layer on the cover plate, and the energy absorption layer is used for absorbing heat energy in the laser sintering process. According to the embodiment of the invention, the structure of the cover plate is improved, the energy absorption layer is arranged on the cover plate, and the orthographic projection of the energy absorption layer on the cover plate covers the orthographic projection of the packaging adhesive layer on the cover plate, so that a part of heat energy in the laser sintering process can be taken away during laser sintering, the sintering effect is ensured, the problems of short circuit between the SD signal line and the frit sub and the like caused by deviation and widening of the packaging adhesive layer are solved.

Owner:BOE TECH GRP CO LTD +1

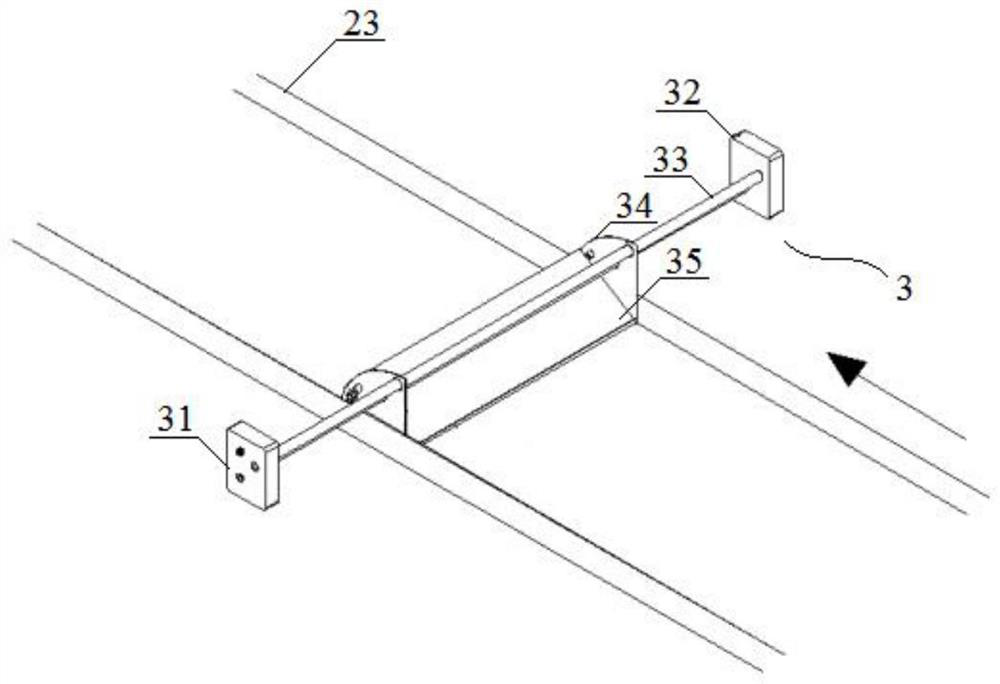

Online quick trolley changing method of sintering machine

ActiveCN105758183APrevent movementReduce replacement timeFurnace typesEconomic benefitsComputer science

The invention discloses an online quick trolley changing method of a sintering machine, belongs to the technical field of sintering machines and provides a method which is used for quick trolley change of the sintering machine in an online state and is more convenient to operate.A pull gap of 20-50 mm is formed in a tail swing frame in the tail direction through ejection.Therefore, when a trolley required to be changed is hoisted later, gaps of 10-20 mm can be reserved between the trolley required to be changed and front and back adjacent trolleys through front-and-back folding and pulling, and the trolley required to be changed can be more conveniently hoisted away.In addition, the trolleys in front and back of the trolley required to be changed can be also fixed by further arranging limiting parts, the phenomenon that the front and back adjacent trolleys move towards the middle after the trolley required to be changed is hoisted away can be avoided, and a standby trolley can be rapidly and accurately transferred to the position where the trolley required to be changed is located.Furthermore, a material corresponding to the upper portion of the trolley required to be changed can be also wetted to make ignition and sintering of the sintering machine unable, and further convenience is brought to better trolley operation.The online quick trolley changing method can bring huge economic benefits during actual work.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

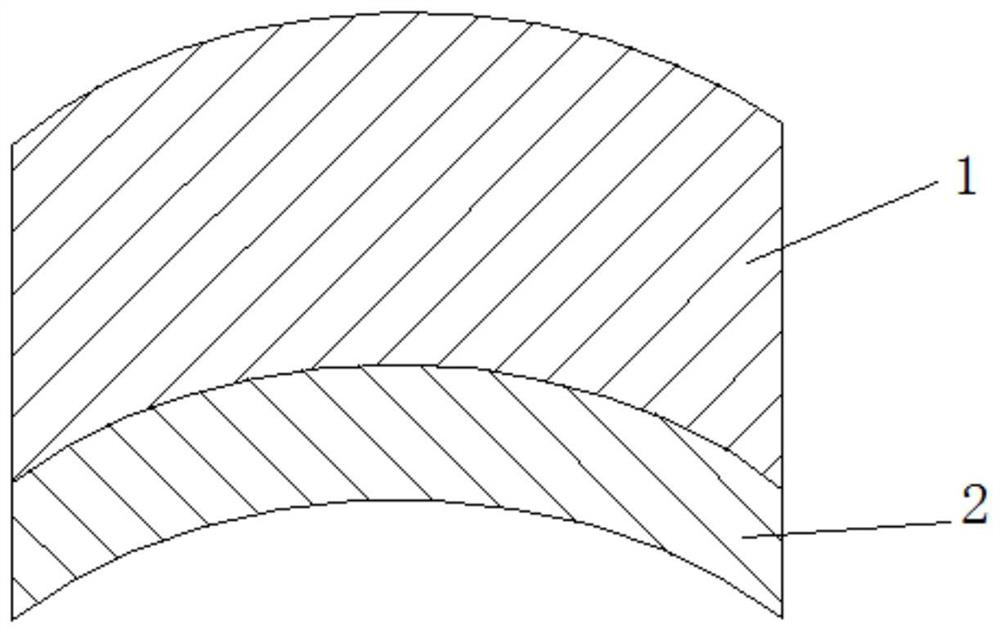

A low-cost universal saw blade and its preparation method

ActiveCN112743086BGuaranteed lifeGuaranteed sintering effectTransportation and packagingMetal-working apparatusMetal powderCopper alloy

The invention discloses a low-cost general-purpose saw blade and a preparation method thereof. The saw blade is sintered by mixing metal powder and diamond. The saw blade is divided into a working layer and a transition layer. The working layer consists of the following parts by weight: Composition of several powder raw materials: 15-25 parts of iron, 25-35 parts of copper, 1-5 parts of tin, 1-5 parts of nickel, 45-50 parts of iron-copper alloy, 1-5 parts of ferrophosphorus, 1 part of liquid paraffin; In the working layer, 10-15% of the powder raw material volume is also added with diamond; the transition layer is composed of the following powder raw materials in parts by weight: 60-80 parts of iron and 10-30 parts of nickel. The saw blade prepared by the invention is low in cost, sharp in cutting, long in service life and wide in versatility, and is used for cutting concrete, granite, building materials and other materials, and has good market application prospects.

Owner:QINGDAO SHINHAN DIAMOND INDUSTRY CO LTD

A spark plasma sintering mold using polycrystalline mullite fiber for heat preservation

The invention discloses a spark plasma sintering mold adopting polycrystalline mullite fiber for heat preservation, comprising an inner mold fixedly installed on an outer layer of polycrystalline mullite fiber, and the outer layer of said polycrystalline mullite fiber is fixedly installed on the outer layer. There are a plurality of supporting feet, a pressure plate is slidably connected to the inner mold, an annular groove is provided on the side wall of the inner mold, a rotating ring is rotatably connected to the annular groove, and a rotating mechanism is installed on the inner mold. The rotating mechanism cooperates with the rotating ring, two fixing blocks are fixedly installed on the outer layer of the polycrystalline mullite fiber, and connecting rods are installed on the two fixing blocks, and the two connecting rods are connected with the two connecting rods. A positioning mechanism is installed between the fixing blocks. The advantages are: the present invention can exert a certain degree of stirring effect on the metal powder placed in the inner mold, so that the metal powder is more uniformly distributed in the inner mold, and the quality of the sintered product is improved, and the mold has the requirements for the use of auxiliary machinery Low for easy movement.

Owner:德清县海杰包装有限公司

A quick-effect repairing method for converter

ActiveCN109136458BRaise the sintering temperatureGuaranteed sintering effectManufacturing convertersCombustionIndustrial engineering

The invention relates to a quick-effect repairing method for a converter, which comprises the following steps: determining the repairing position, increasing the end point temperature of the converter of the previous furnace, increasing the content of MgO in the final slag of the converter, pouring slag, repairing the furnace charge, sintering the furnace charge, strengthening For sintering charge, after 40 minutes of repairing the furnace, slowly pour about 2 tons of molten iron into the furnace, make the molten iron gather in the repairing charge area through the shaking furnace, and use high-temperature molten iron to re-sinter the repairing charge for 5 to 10 minutes, and repair the furnace After that, start preparing for the next furnace of smelting. On the one hand, the present invention improves the sintering temperature of the repair charge through the combustion-supporting method of gas and oxygen, and on the other hand re-sinters the high-melting-point phase of the repair charge through high-temperature molten iron in the later stage of repair to ensure the sintering effect of the repair charge. The furnace repairing time of the invention is shortened by 10-15 minutes compared with the conventional furnace repairing process, and the number of durable furnaces of the repairing charge is extended by 3-5 furnaces after the process is adopted.

Owner:SD STEEL RIZHAO CO LTD

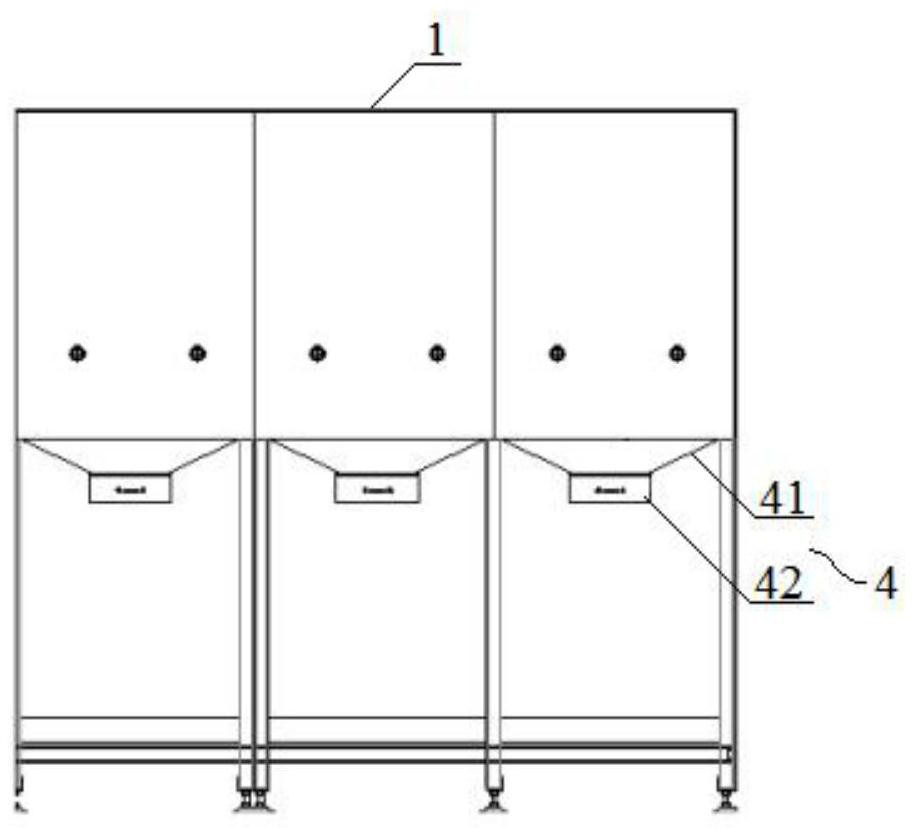

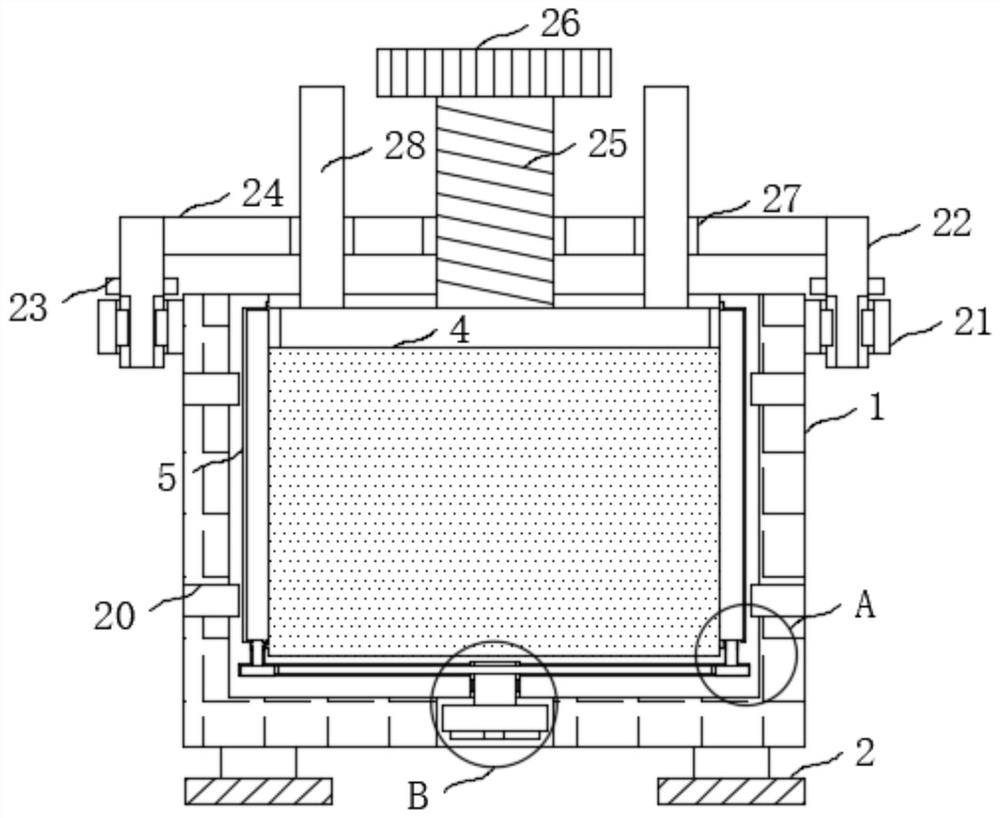

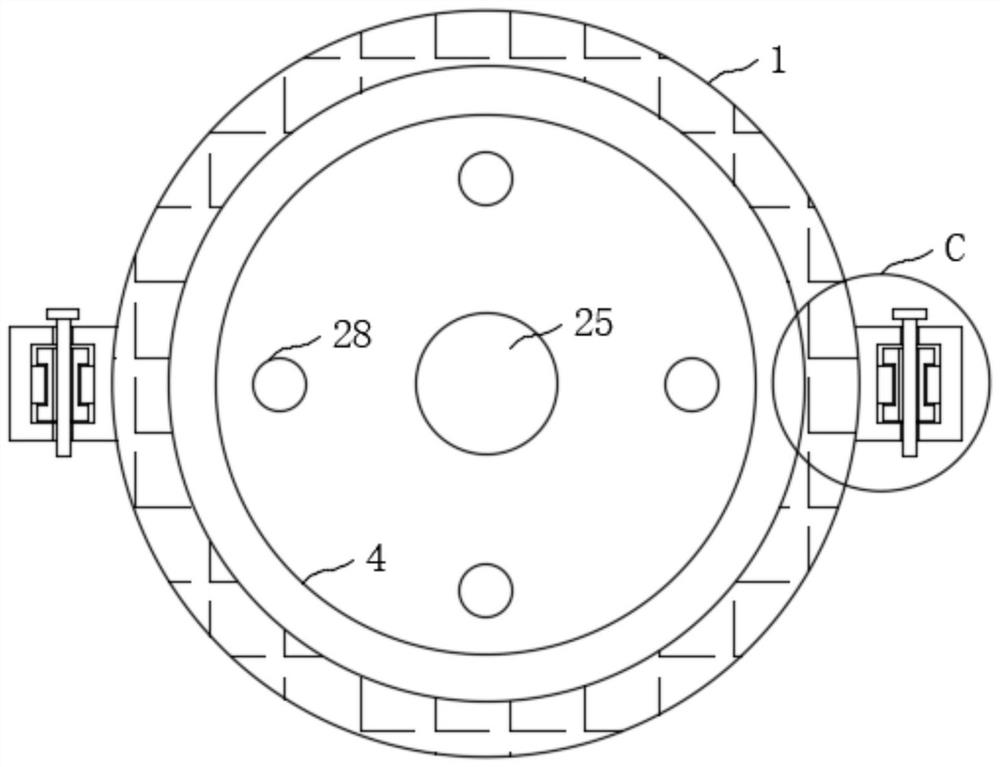

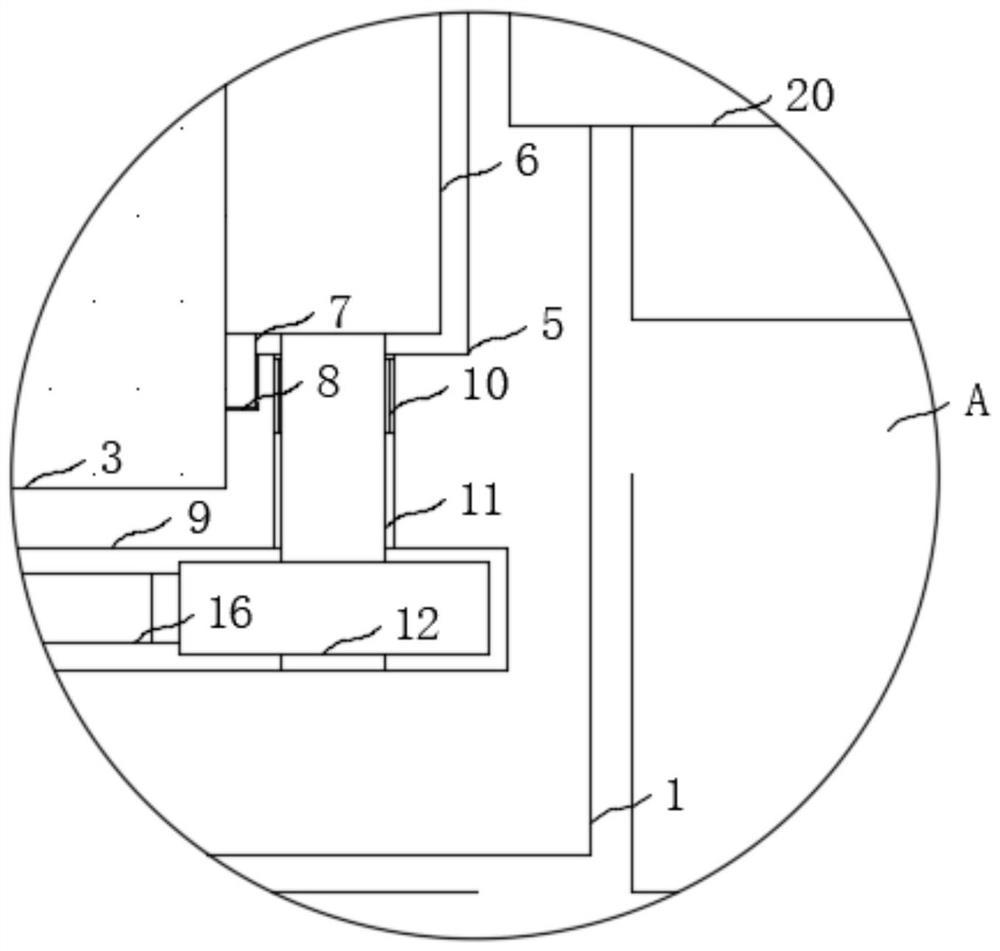

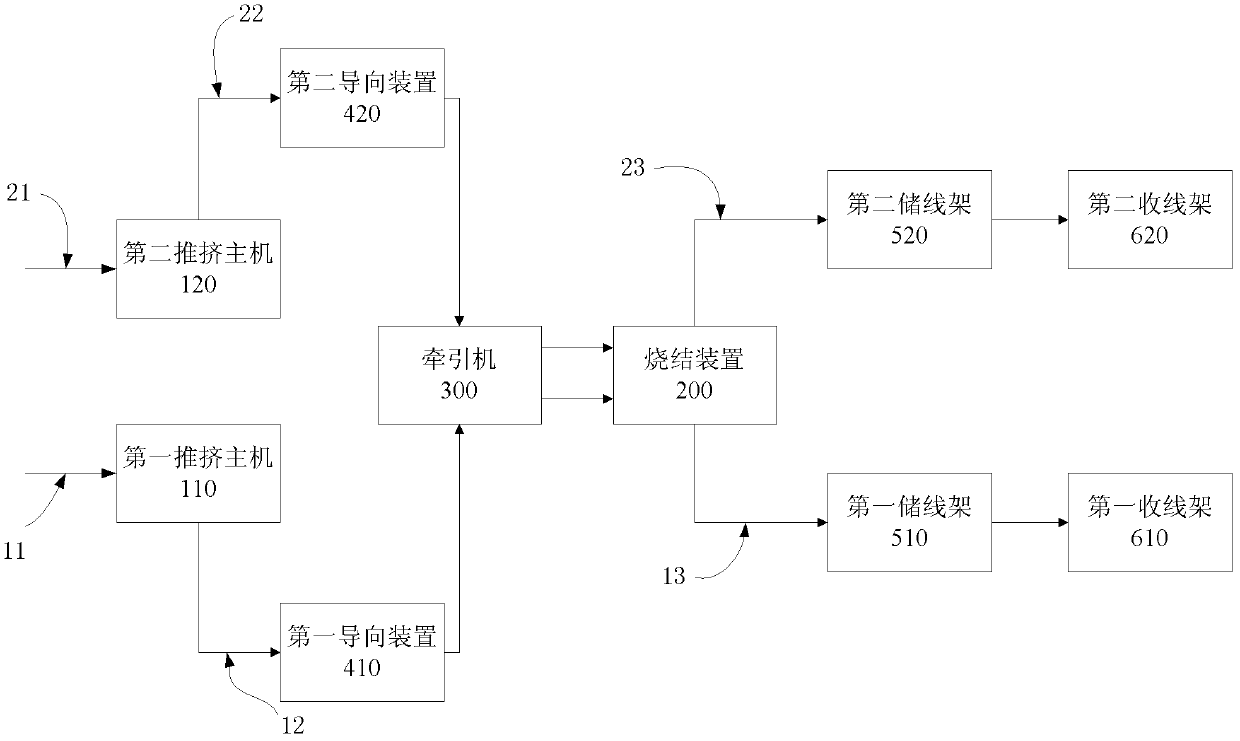

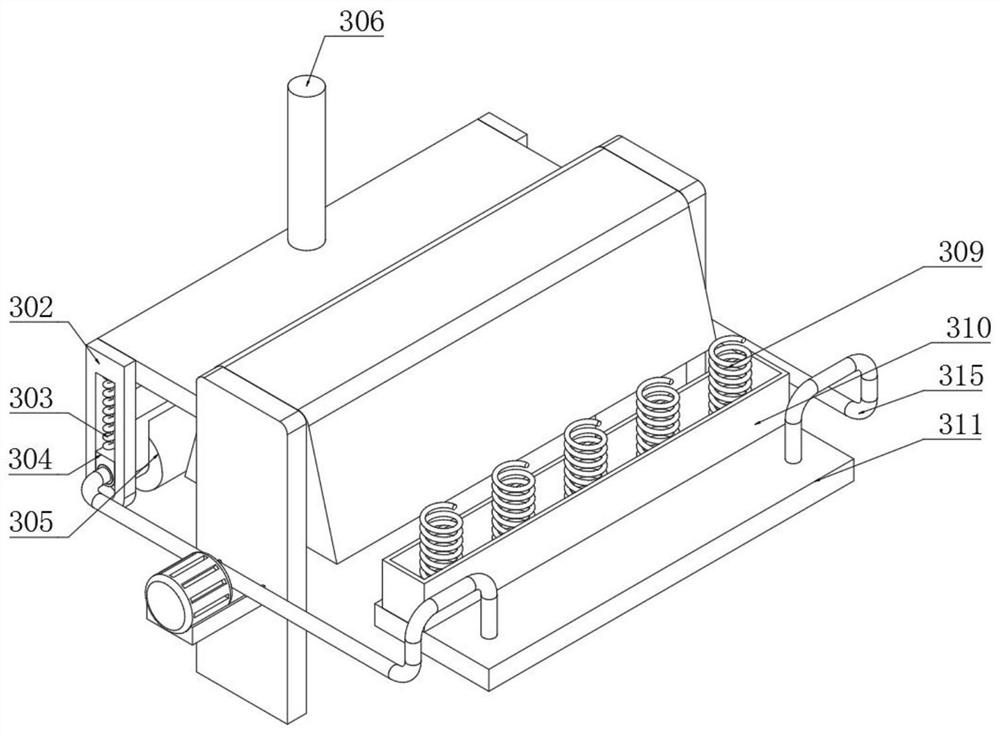

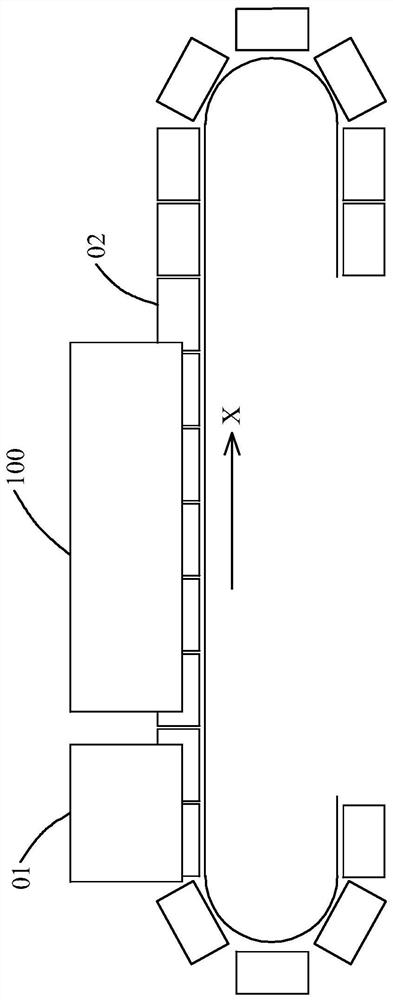

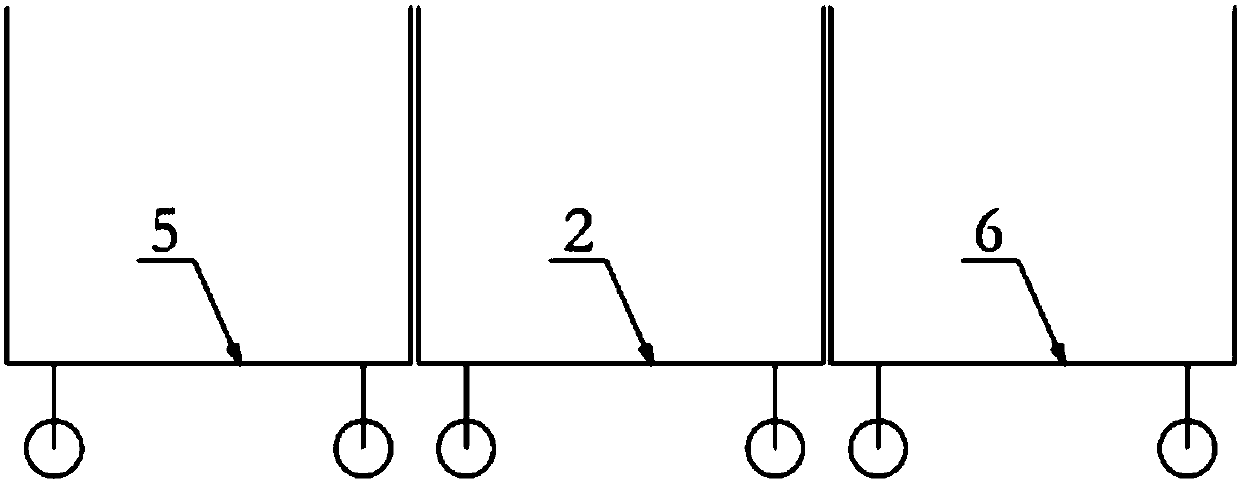

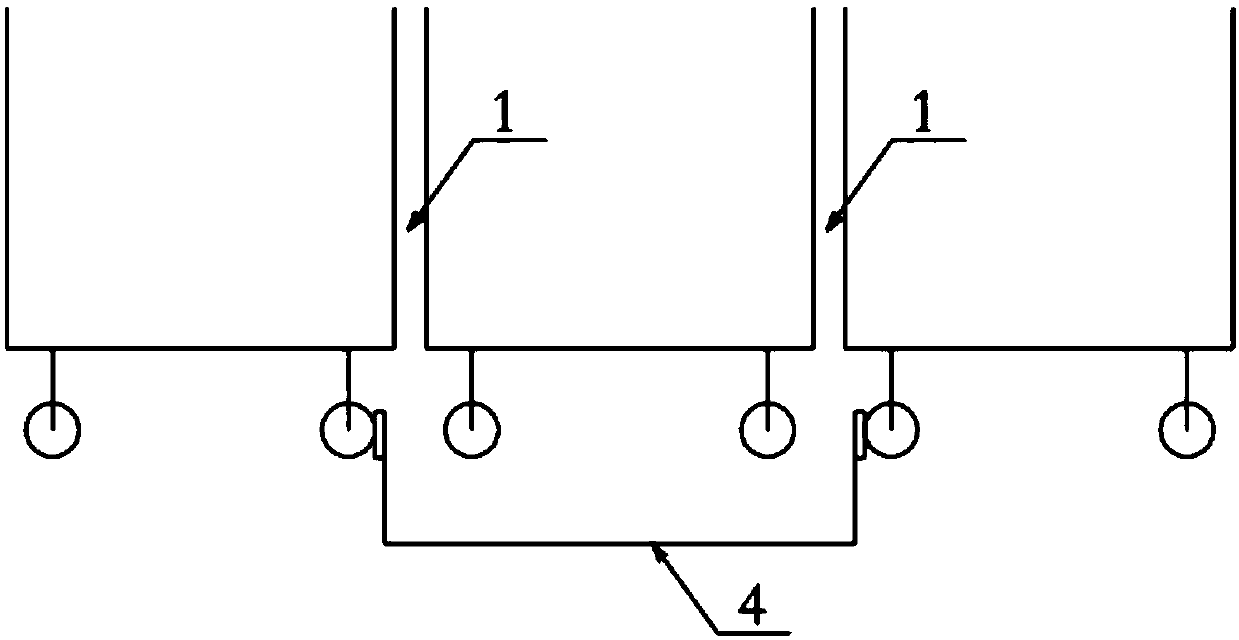

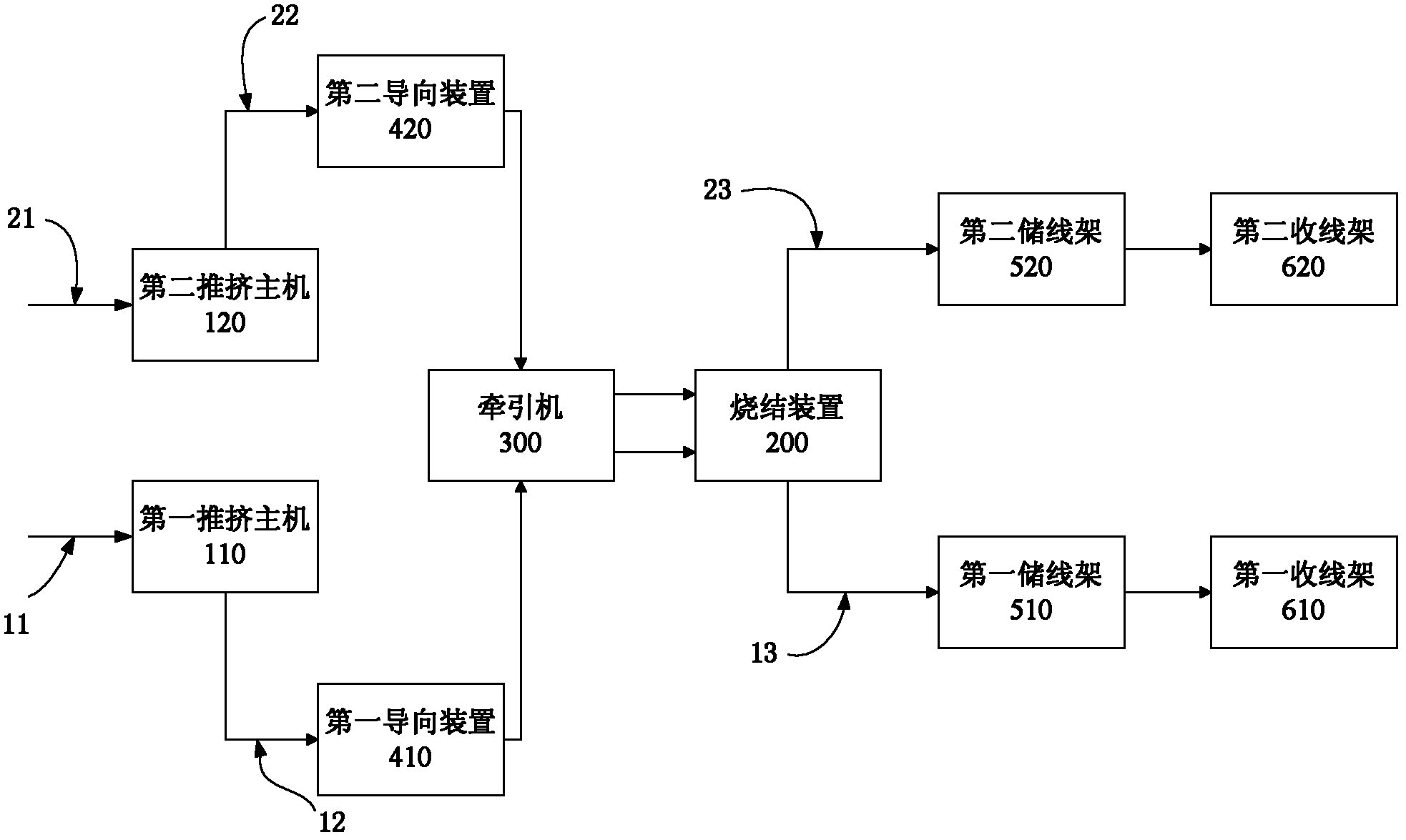

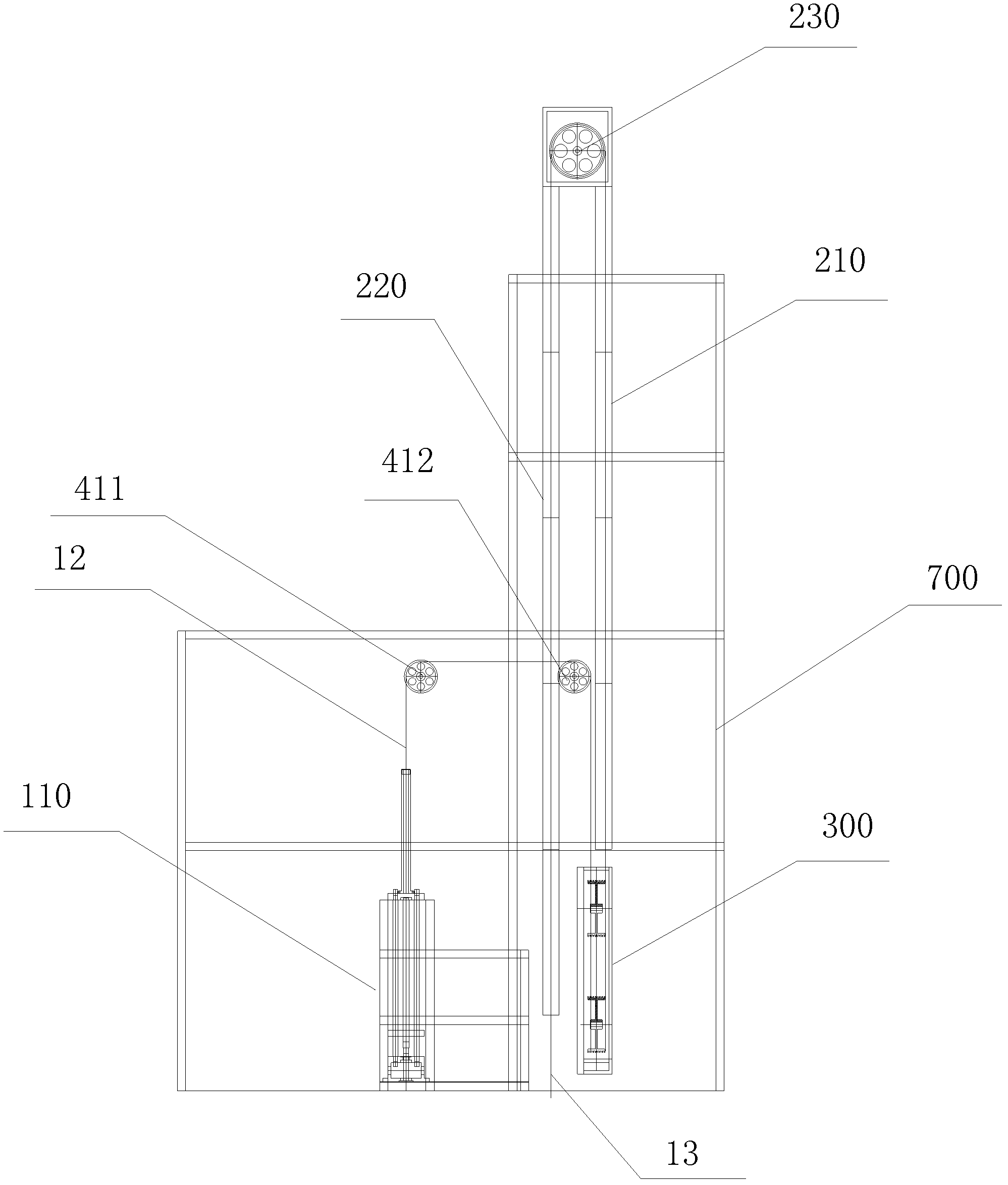

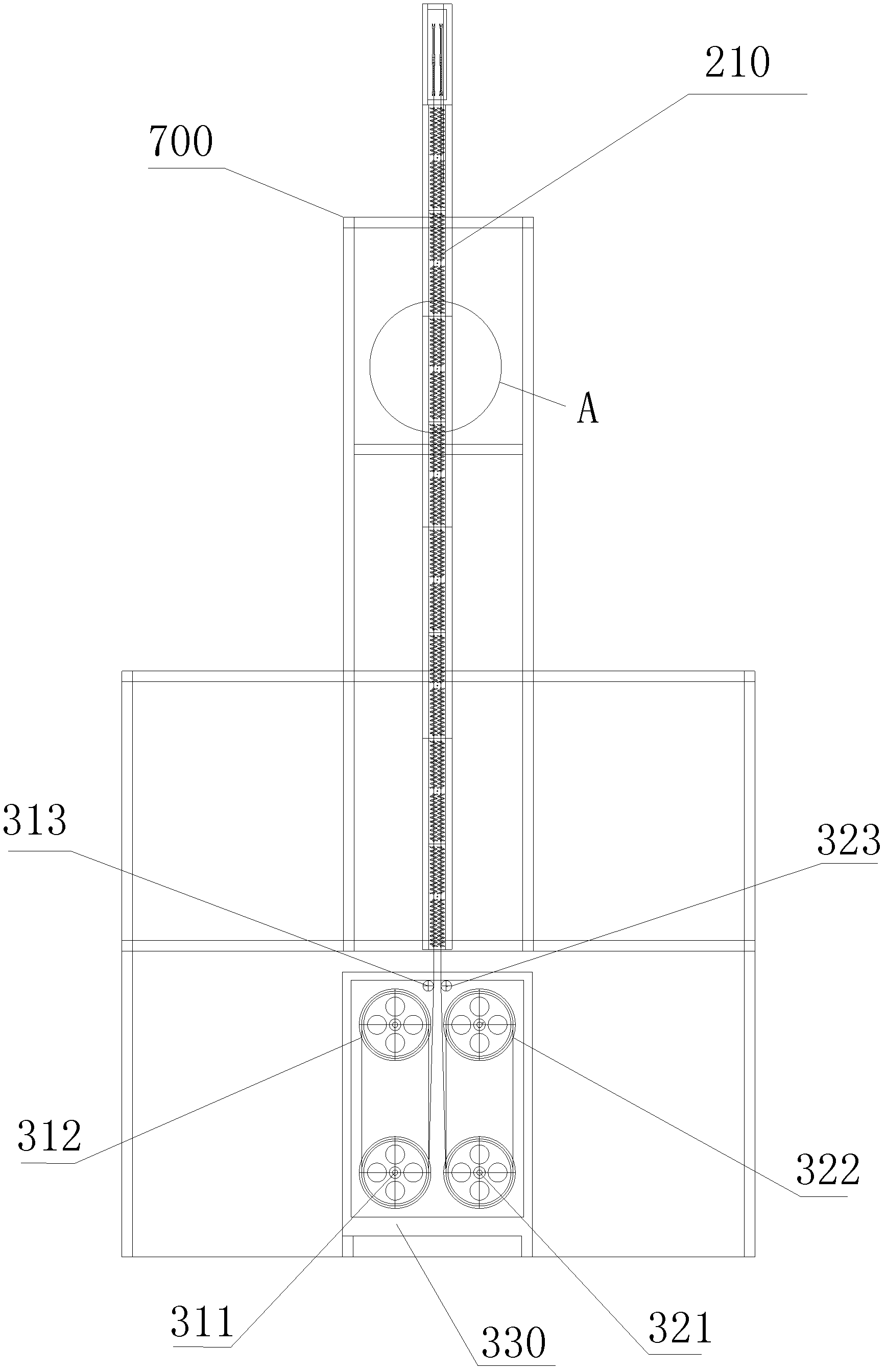

Pushing system

ActiveCN102623105BGuaranteed sintering effectReduce manufacturing costInsulating conductors/cablesMetallurgyElectric energy

The invention discloses a pushing system which comprises a plurality of pushing hosts, a sintering device and a traction machine, wherein the pushing hosts are used for squeezing PTFE insulating layers away from a plurality of conductors to respectively form a plurality of ecological core wires, the sintering device comprises a plurality of sintering parts used for sintering a plurality of ecological core wires so as to form a plurality of sintered core wires, and the traction machine is used for guiding a plurality of ecological core wires into the sintering parts to be sintered. The ecological core wires, which share a sintering device, are in the same sintering environment, and are independently sintered. Thus, the pushing system can ensure the sintering result, save at least one sintering device, save the manufacturing cost, meanwhile save the electric energy in use, and reduce the use cost.

Owner:KINGSIGNAL TECHNOLOGY CO LTD

Belt type sintering machine protection device capable of continuously working

ActiveCN113203289AAvoid accumulationAvoid collisionCharge manipulationIncrustation removal devicesThermodynamicsSpot welding

The invention discloses a belt type sintering machine protection device capable of continuously working, the bottom end of a pressing spring is in spot welding connection with an inner ring limiting frame, the side end of the inner ring limiting frame is rotationally connected with a pressing heat conduction cylinder, a limiting spring is welded at the bottom end of a fixed supporting box, and a heat conduction circulating box is welded at the bottom end of a fixed connecting box. A water outlet pipe penetrates through one side of the top end of the heat conduction circulating box, a backflow pipe penetrates through one end of the pressing heat conduction cylinder, the height of materials is limited through the pressing heat conduction cylinder and a limiting protection plate, meanwhile, a large number of materials are prevented from being stacked together, therefore the materials are prevented from colliding with a trolley in the conveying process, a heated effect of the materials can be guaranteed by flatly laying the materials, then the sintered materials are rapidly cooled through the heat conduction circulating box, heat obtained after heat dissipation flows into the pressing heat conduction cylinder, therefore the unsintered materials are preheated, and the situation that the materials are burst out due to the fact that the heating speed of the materials is too high is avoided.

Owner:河北新金钢铁有限公司

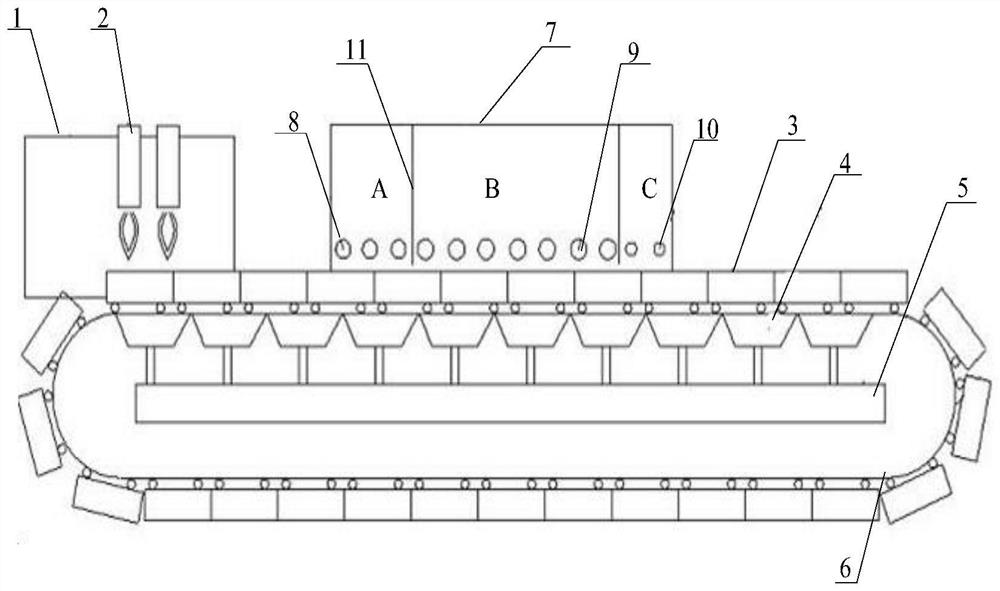

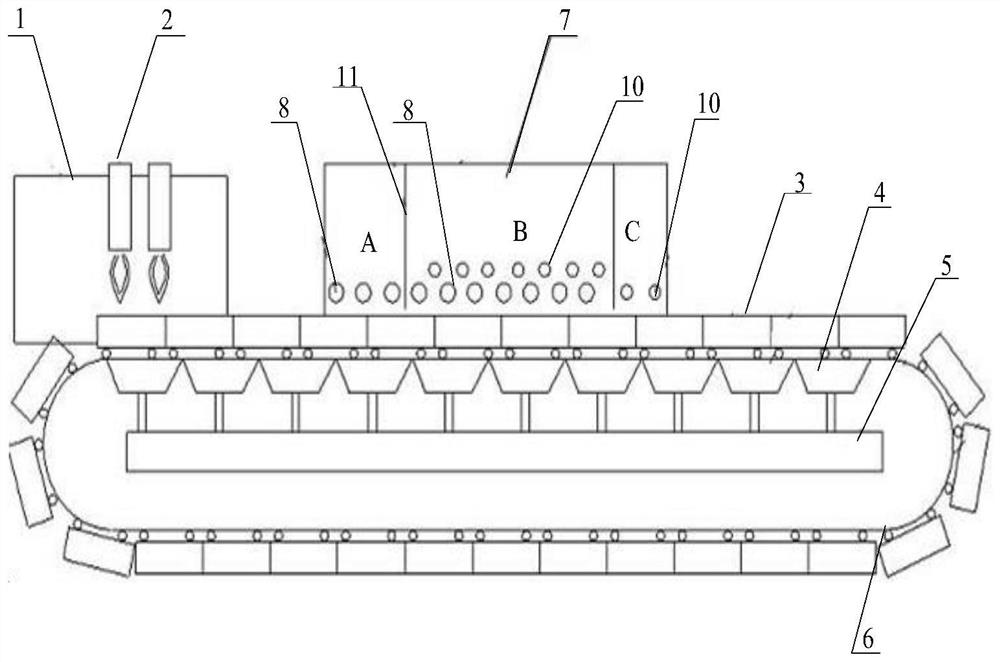

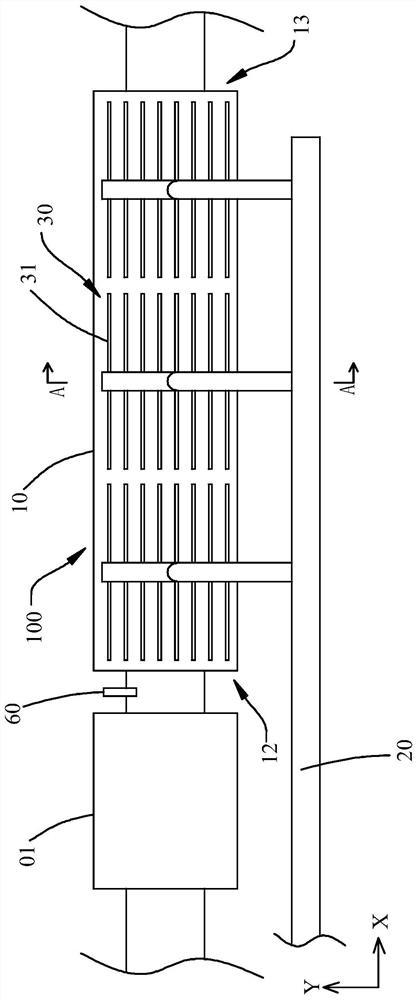

Fuel gas and steam coupled sintering machine

ActiveCN113969346ARemarkable effect of strengthening sinteringSinter defective rate decreasedCharge manipulationCharge treatment typeMetallurgySteam generation

The invention discloses a fuel gas and steam coupled sintering machine. The fuel gas and steam coupled sintering machine comprises a sintering trolley running in the sintering direction and an ignition furnace device arranged above the sintering trolley and further comprises a fuel gas and steam coupling device arranged above the sintering trolley and located behind the ignition furnace device in the sintering direction; the fuel gas and steam coupling device sequentially comprises a fuel gas injection unit, a fuel gas and steam coupling injection unit and a steam injection unit which are isolated from one another in the sintering direction. After overall carbon reduction of sintered ore, heat compensation is carried out on an upper-layer material area which is most required to be subjected to heat compensation through fuel gas injection. The gas injection starting time is reasonable, upper-layer materials are timely subjected to gas heat compensation, the quality of upper-layer finished product sintering ore is improved, the overall gas injection enhanced sintering effect is remarkable, and sintering is facilitated. In other words, heat compensation can be carried out on temperature drop generated by the steam through fuel gas injection, local high temperature generated by the fuel gas can be reduced through the steam, and therefore influences caused by the steam temperature drop and the local high temperature of the fuel gas can be eliminated, and the sintering effect is guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method for preparing high-density lithium ion battery anode material-lithium nickel manganese cobalt and special calcinator

InactiveCN102709541BHigh tap densityAvoid shufflingCell electrodesRotary drum furnacesLithiumHigh density

The invention relates to a method for preparing a lithium ion battery anode material, in particular to a method for preparing a high-density lithium ion battery anode material-lithium nickel manganese cobalt. The method mainly solves the problems that in the prior art, a single physical and mechanical mixing mode is adopted to inevitably result in nonhomogeneity of materials, the materials without impurity phases are difficult to obtain, the particles and appearances are difficult in uniformity, the cycling performance of the materials is poor, and the like. The method disclosed by the invention comprises the following steps of: firstly preparing ammonium salt aqueous solution A, alkaline solution B and nickel manganese cobalt and metal ion mixed aqueous solution C; adding a certain amount of alkaline solution B to a reaction kettle; then adding ammonium salt aqueous solution A, alkaline solution B and nickel manganese cobalt and metal ion mixed aqueous solution C; reacting and aging to obtain a multivariate composite material precursor; mixing lithium salt with the precursor; cooling the mixture after pre-sintering; mixing again; slowly cooling the mixture under oxygen atmosphere after roasting at high temperature; and screening by stages to obtain the product.

Owner:杭州金马新能源科技有限公司

High temperature tunnel furnace for powder material sintering

ActiveCN109764674BImprove sintering reliabilityExtended service lifeFurnace typesAbrasive machine appurtenancesHigh heatCrystallite

The invention discloses a high-temperature tunnel furnace for sintering and molding powder materials. By adopting the tunnel furnace, the invention can well improve the sintering reliability of powder materials, improve the service life of the sintering furnace, and realize automation The loading and unloading of the material; the present invention sets four sintering furnace units, and the corresponding setting of its temperature, sintering at a lower temperature at the beginning, and then use a higher sintering temperature after reaching a certain density Sintering can ensure the density of sintering and sintering performance. Before discharging, the temperature is further lowered and sintered gradually to prevent the adverse effects of temperature changes on the crystal grains; The powder material is slightly oscillated to ensure the compactness and refinement of the grain of the powder material after sintering, and to improve the molding reliability of the powder material.

Owner:安徽华淮澄膜科技有限公司

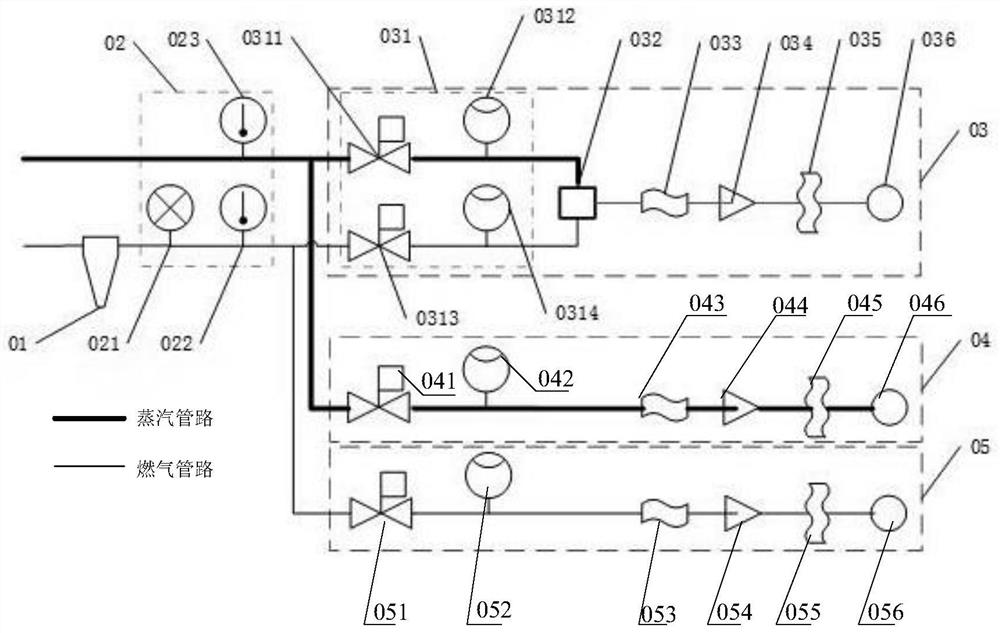

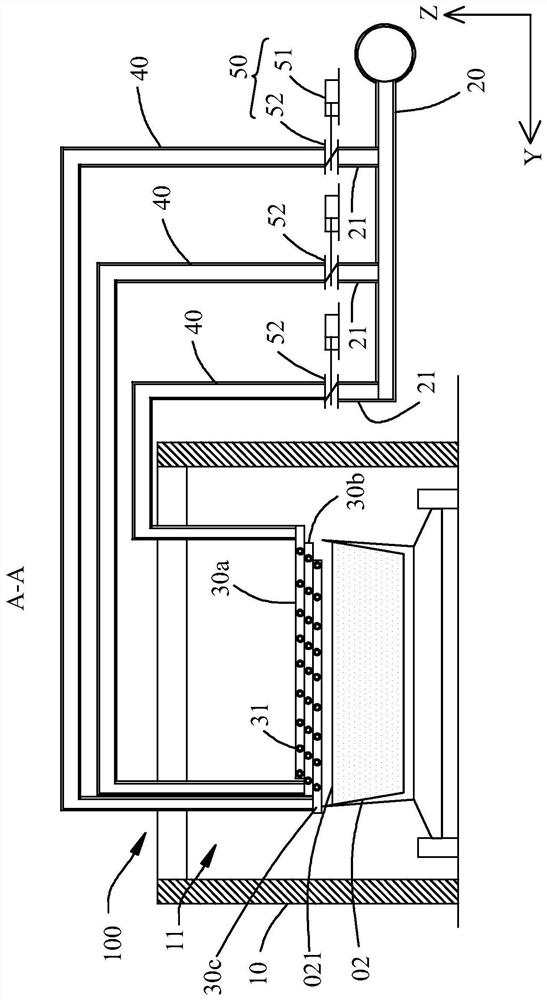

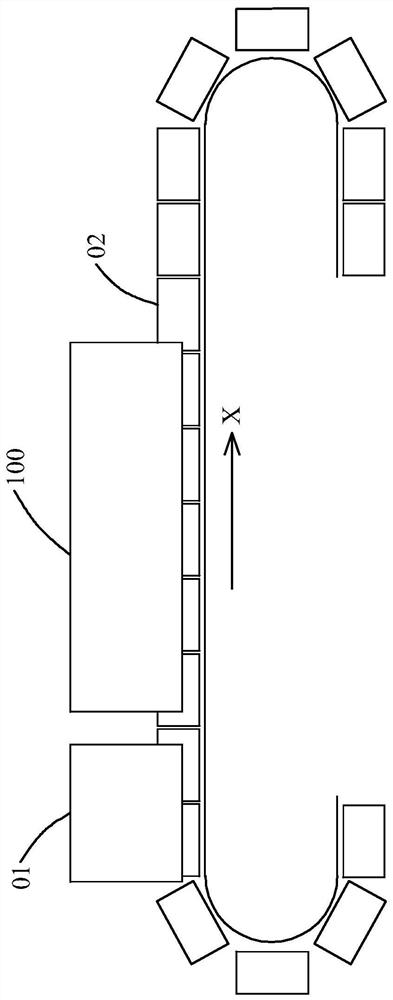

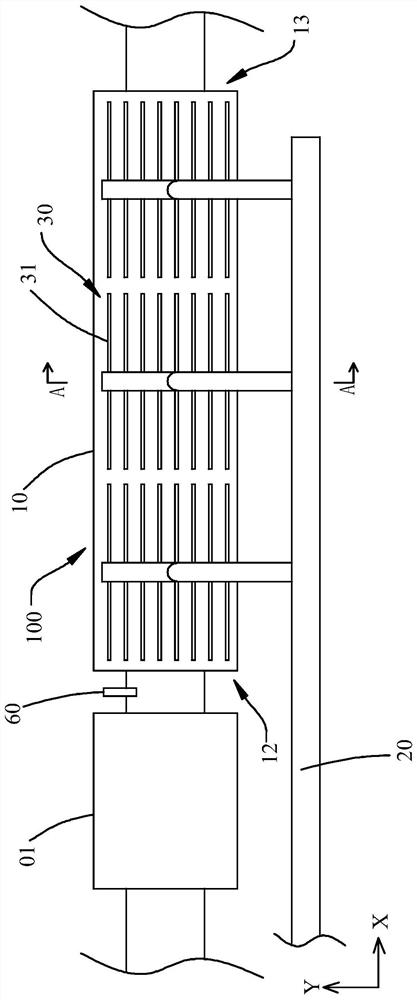

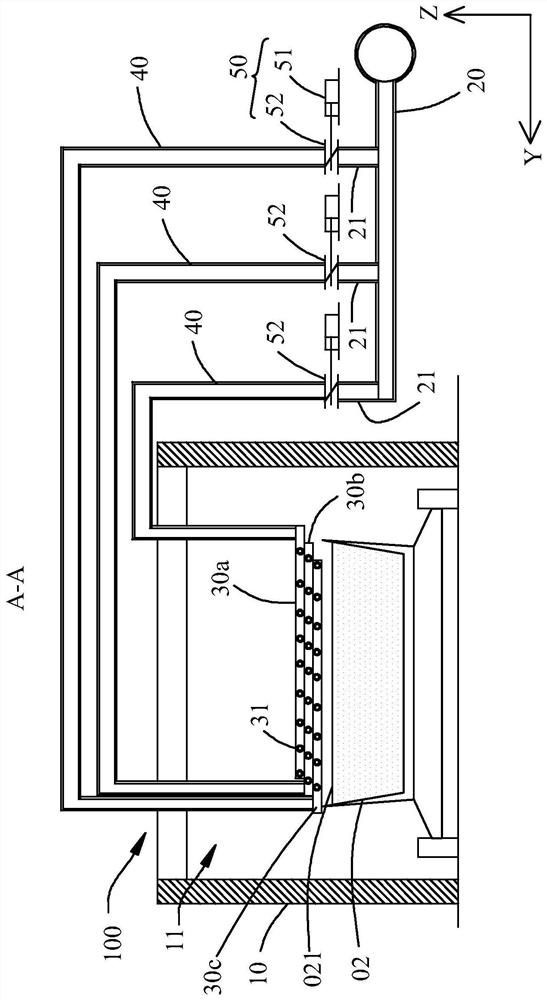

Fuel gas injection and distribution device and control method thereof

ActiveCN112033176AGood auxiliary effectImprove securityCharge treatment typeFurnace typesControl systemControl valves

The invention relates to a gas injection and distribution device and a control method thereof, and belongs to the technical field of sintering equipment. The fuel gas injection and distribution devicecomprises an injection cover, an injection branch pipe, multiple layers of injection pipe rows, a charge level negative pressure detector and a control system. One end of the injection branch pipe isconnected with an air source, and the other end of the injection branch pipe is provided with a plurality of branch pipes; The multiple layers of injection pipe rows are in one-to-one correspondencewith the multiple branch pipes respectively, the multiple layers of injection pipe rows are distributed at intervals in the Z direction, and each layer of injection pipe row is connected with one branch pipe through a flow control valve; the charge level negative pressure detector is arranged at the upstream of the injection cover and is used for detecting the charge level negative pressure of thesintering charge of a sintering machine trolley to enter the injection cover; and the control system is electrically connected with the charge level negative pressure detector and the flow control valves, and the control system is used for controlling the flow control valves to work in response to a charge level negative pressure value detected by the charge level negative pressure detector so asto realize fuel gas injection of at least one layer of injection pipe row. The fuel gas injection and distribution device is good in auxiliary effect and high in safety coefficient.

Owner:SGIS SONGSHAN CO LTD

Gas injection and distribution device and control method thereof

ActiveCN112033176BGood auxiliary effectImprove securityCharge treatment typeFurnace typesControl systemEngineering

The application relates to a gas injection and distribution device and a control method thereof, belonging to the technical field of sintering equipment. The gas injection and gas distribution device includes an injection hood, an injection branch pipe, a multi-layer injection pipe row, a material surface negative pressure detector and a control system. One end of the injection branch pipe is used to connect with the gas source, and the other end of the injection branch pipe has multiple branch pipes; Distributed at intervals, each row of injection pipes is connected to a branch pipe through a flow control valve; the material level negative pressure detector is installed upstream of the injection hood to detect the sintering material of the sintering machine trolley to enter the injection hood The material surface negative pressure; the control system is electrically connected with the material surface negative pressure detector and the flow control valve, and the control system is used to control the work of the flow control valve in response to the material surface negative pressure value detected by the material surface negative pressure detector, so as to achieve at least One layer of blowing pipes blows gas. The gas injection and distribution device has good auxiliary effect and high safety factor.

Owner:SGIS SONGSHAN CO LTD

A processing method of high-performance cemented carbide new material slitting and cutting knife

ActiveCN105950938BHigh hardnessImprove wear resistanceTurbinesOther manufacturing equipments/toolsWear resistantAlloy

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Method for quick online replacement of trolley for sintering machine

ActiveCN105758183BPrevent movementReduce replacement timeFurnace typesEconomic benefitsComputer science

The invention discloses an online quick trolley changing method of a sintering machine, belongs to the technical field of sintering machines and provides a method which is used for quick trolley change of the sintering machine in an online state and is more convenient to operate.A pull gap of 20-50 mm is formed in a tail swing frame in the tail direction through ejection.Therefore, when a trolley required to be changed is hoisted later, gaps of 10-20 mm can be reserved between the trolley required to be changed and front and back adjacent trolleys through front-and-back folding and pulling, and the trolley required to be changed can be more conveniently hoisted away.In addition, the trolleys in front and back of the trolley required to be changed can be also fixed by further arranging limiting parts, the phenomenon that the front and back adjacent trolleys move towards the middle after the trolley required to be changed is hoisted away can be avoided, and a standby trolley can be rapidly and accurately transferred to the position where the trolley required to be changed is located.Furthermore, a material corresponding to the upper portion of the trolley required to be changed can be also wetted to make ignition and sintering of the sintering machine unable, and further convenience is brought to better trolley operation.The online quick trolley changing method can bring huge economic benefits during actual work.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Pushing system

ActiveCN102623105AGuaranteed sintering effectReduce manufacturing costInsulating conductors/cablesMetallurgyElectric energy

The invention discloses a pushing system which comprises a plurality of pushing hosts, a sintering device and a traction machine, wherein the pushing hosts are used for squeezing PTFE insulating layers away from a plurality of conductors to respectively form a plurality of ecological core wires, the sintering device comprises a plurality of sintering parts used for sintering a plurality of ecological core wires so as to form a plurality of sintered core wires, and the traction machine is used for guiding a plurality of ecological core wires into the sintering parts to be sintered. The ecological core wires, which share a sintering device, are in the same sintering environment, and are independently sintered. Thus, the pushing system can ensure the sintering result, save at least one sintering device, save the manufacturing cost, meanwhile save the electric energy in use, and reduce the use cost.

Owner:KINGSIGNAL TECHNOLOGY CO LTD

A sintering device for glass preparation

ActiveCN108033666BEasy to crushPromote sinteringCharging furnaceGlass furnace apparatusElectric machineryIndustrial engineering

The invention discloses a sintering device for glass preparation, which comprises an outer frame, the top of the outer frame is fixedly connected with a support column, and the top of the support column is fixedly connected with a top frame, and the left side of the top frame is fixedly connected with a first motor , one end of the output shaft of the first motor passes through the top frame and extends to the inside of the top frame. The present invention relates to the technical field of glass preparation. The sintering device for glass preparation achieves the purpose of crushing materials conveniently. The crushing device is integrated into the sintering device, which simplifies the production steps and effectively controls the degree of crushing, which is convenient for subsequent sintering, which is convenient for people to use and improve The discharge speed prevents the material from staying on the feeding plate, ensures the operation of the device, facilitates the feeding of materials, and effectively ensures the operation of the device, improves the work efficiency, and facilitates the automatic control of the sintering temperature. Manual control ensures the sintering effect and improves the practicability of the device.

Owner:安源玻璃有限公司

A preparation method of in-situ self-generated gradient WC reinforced CUW composite material

ActiveCN105568209BDoes not affect other performanceGuaranteed sintering effectSolid state diffusion coatingMicrocomputerCarbon potential

The invention discloses an in-situ formation preparation method for a gradient WC-strengthened CuW composite material. The in-situ formation preparation method for the gradient WC-strengthened CuW composite material comprises the steps that a tungsten framework is heated in a vacuum carburization furnace under the protection of argon, then a furnace body is vacuumized, acetylene is introduced into the furnace body, the furnace body is kept in the state for 2-10 min, the furnace body is vacuumized again till the pressure in the furnace body reaches 1 Pa, then heat preservation is conducted, heat preservation is conducted again after the operation is circulated, then nitrogen is introduced into the furnace body, and a sample is cooled along with the furnace, so that a gradient WC-strengthened W framework is obtained; and copper infiltration is conducted on the gradient WC-strengthened W framework in a microcomputer program-control sintering furnace in a high-temperature hydrogen atmosphere, and then the gradient WC-strengthened CuW composite material is obtained. By the adoption of the preparation method, the high-temperature strength and abrasion resistance of the W framework are improved; meanwhile, in the carburization process, the WC component gradient exists between the interior and the exterior of the framework under the influence of the carbon potential in the framework and the carbon potential outside the framework.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com