Isostatic pressing oil removal system

A technology of isostatic pressing and isostatic pressing, applied in the field of static pressure oil removal system, can solve the problems of inconvenient removal, affecting the sintering effect of magnets, difficult to remove isostatic oil, etc., to achieve the effect of ensuring the sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

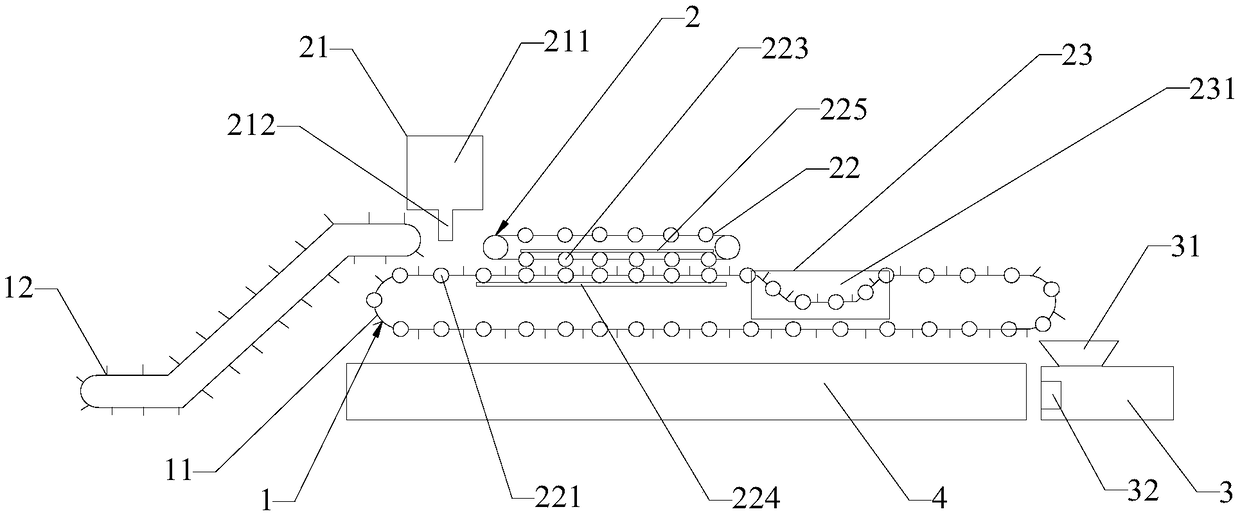

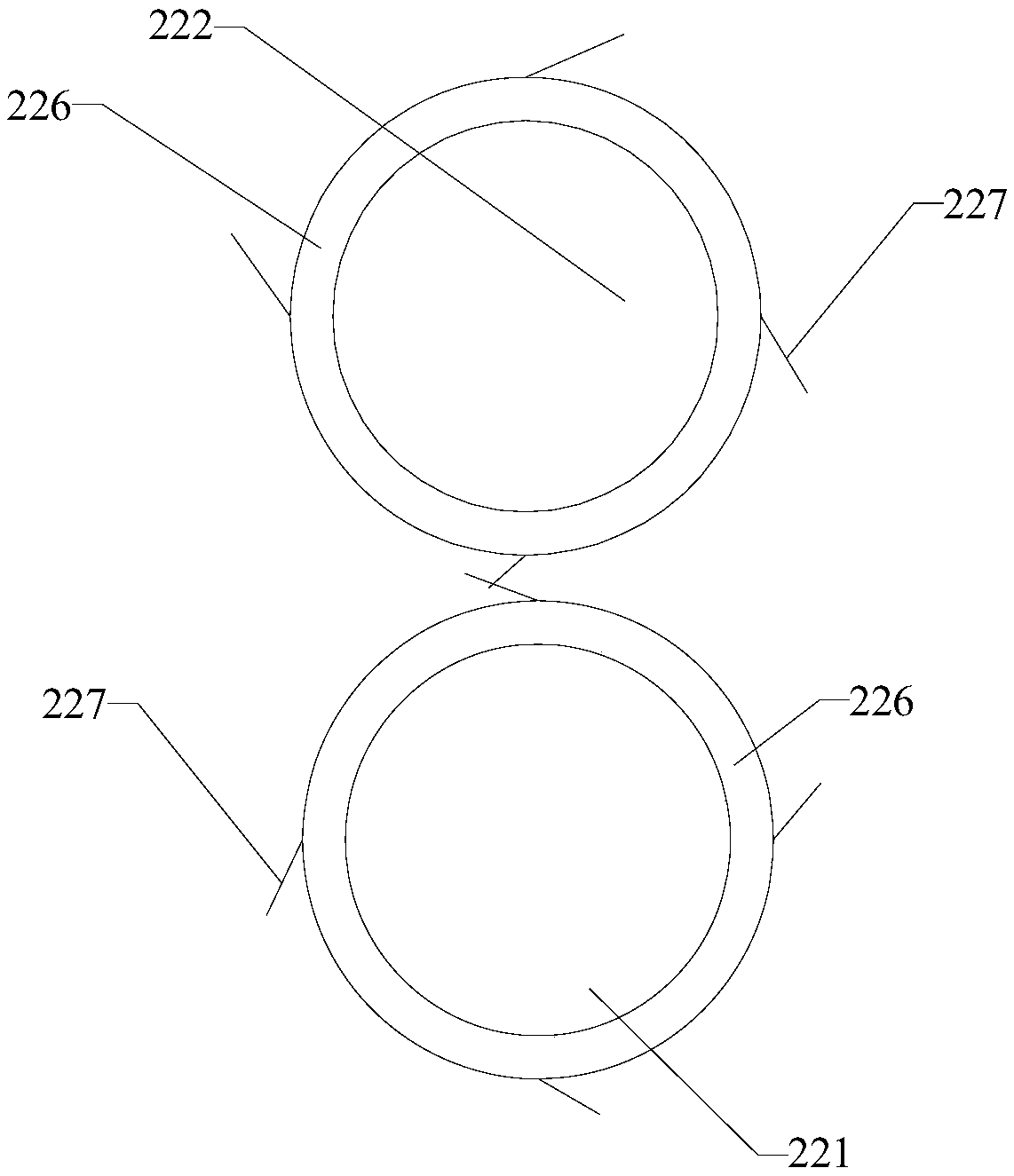

[0047] An isostatic oil removal system, comprising a conveying mechanism 1, a cleaning mechanism 2 and a drying mechanism 3; the conveying mechanism 1 includes a first conveyor belt 11, and the first conveyor belt 11 is uniformly provided with a grid, so The starting end of the first conveyor belt 11 is connected below the discharge port of the isostatic press; the cleaning mechanism 2 includes a spraying device 21, a scrubbing device 22 and a soaking device 23, and the spraying device 21 is located on the first conveyor belt Above the front section of 11, the spraying device 21 includes a liquid storage tank 211 and a spray gun 212 arranged at the bottom of the liquid storage tank 211; , the first friction belt 224 and the second friction belt 225; the second conveyor belt 223 is located above the middle section of the first conveyor belt 11, and the first conveyor belt 11 is provided with a plurality of first cleaning rollers 221, the The first cleaning roller 221 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com