Technique of pre-expanding treating cabo

A treatment process and pre-expansion technology, applied in the field of tobacco stem pre-expansion treatment process, can solve the problems of increasing the suction resistance of cigarettes, not significantly improving the filling value of cut stems, affecting the quality of cut stems, etc., and improving the uniformity of blending. , the effect of improving filling capacity and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

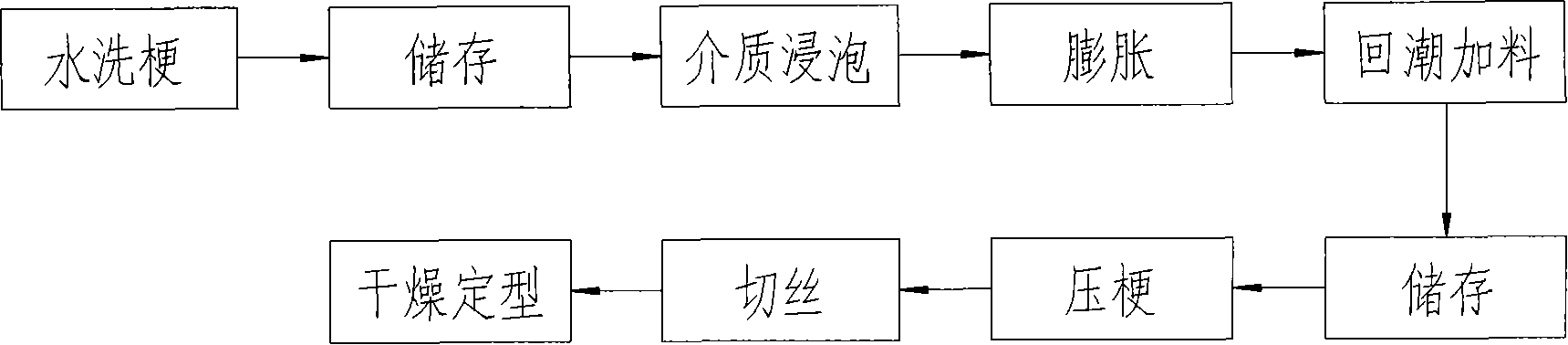

Method used

Image

Examples

Embodiment 1

[0016] Feed the threshed and rebaked tobacco stems evenly into the stem washing machine, moisten the stems through the HT (tunnel tobacco stem moisture regainer), and send them to the storage cabinet for temporary storage by the belt conveyor, with a moisture content of 24% to 26%, 2-4 One hour later, the belt conveyor is fed into the liquid carbon dioxide expander (soaking time in liquid carbon dioxide is 7.5 to 15 minutes, and the soaking pressure is 3.5MPa to 4.0MPa, and then the tobacco stems formed into dry ice clumps are cooled at 330°C-380°C, 15 m / s-20 m / s of superheated steam), the soaked and expanded tobacco stems are fed with super-moisture feed from the vibrating tank at a moisture content of 4% to 6% and a temperature of 90°C to 100°C Machine, after feeding, the moisture content is 24%-26%, the temperature is 35°C-60°C, and it is temporarily stored in the stem storage cabinet. After 4-6 hours, it will be pressed into stems, shredded, dried and shaped, and then blend...

Embodiment 2

[0018] Feed the threshed and rebaked tobacco stems evenly into the stem washing machine, moisten the stems through the HT (tunnel tobacco stem moisture regainer), and then send them to the storage cabinet for temporary storage by the belt conveyor, with a moisture content of 20% to 25%, 2- After 4 hours, the belt conveyor is fed into the R134a expander (the soaking time in R134a is 7.5 to 15 minutes, and the soaking pressure is 0.5MPa, and then the tobacco stems formed into ice-like clumps are heated at 150°C-180°C, 15m / second-20 m / s of superheated steam), the soaked and expanded tobacco stems are fed into the feeder from the vibrating tank at a moisture content of 10% to 15% and a temperature of 90°C to 100°C. The rate is 22% to 27%, the temperature is 50°C to 60°C, and it is temporarily stored in the stem storage cabinet. After 4-6 hours, the stems are pressed, shredded, dried and shaped, and then blended with shredded leaves to form finished cut tobacco.

Embodiment 3

[0020] The tobacco stems after threshing and rebaking are evenly fed into the stem washing machine, moistened by the HT (tunnel tobacco stem moisture regainer), and then sent to the storage cabinet by the belt conveyor for temporary storage, with a moisture content of 24% to 26%, 2- After 4 hours, the belt conveyor is fed into the liquid nitrogen expander (the immersion time in liquid nitrogen is 7.5-15 minutes, the immersion pressure is 76MPa, and then the tobacco stems formed into ice-like clumps are cooled at 300°C-380°C, 15m / h s-20 m / s of superheated steam), the soaked and expanded tobacco stems are fed into the super moisture resurgence feeder from the vibrating tank at a moisture content of 4% to 6% and a temperature of 90°C to 100°C. Finally, the moisture content is 24% to 26%, and the temperature is 35°C to 60°C. It is temporarily stored in the stem storage cabinet. After 4-6 hours, the stems are pressed, shredded, dried and shaped, and then blended with shredded leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com