A low-cost universal saw blade and its preparation method

A general-purpose, low-cost technology, applied in the field of powder metallurgy materials, can solve the problems of low cobalt reserves and increase the cost of sawtooth, and achieve the effect of speeding up the alloying process, improving life and efficiency, and ensuring sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

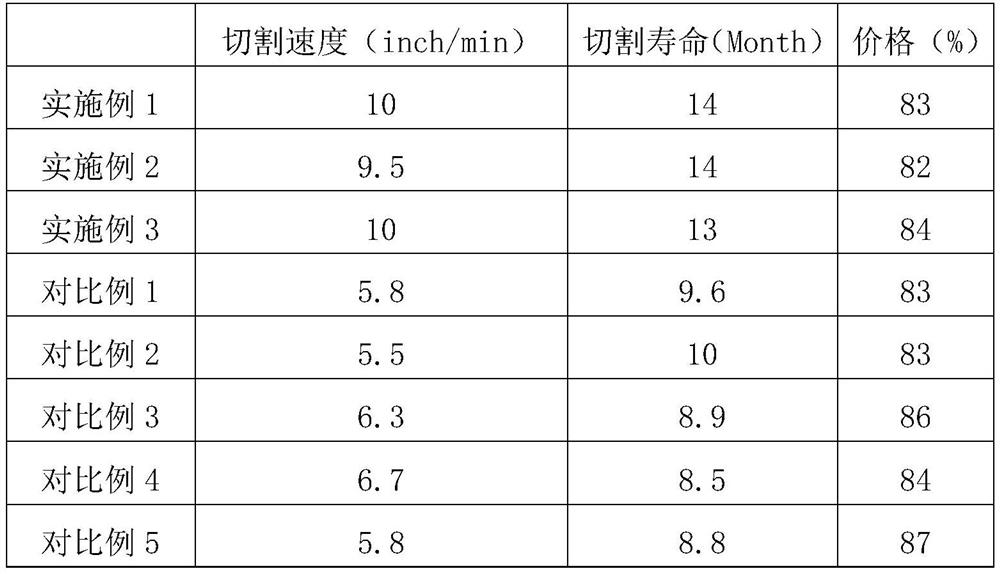

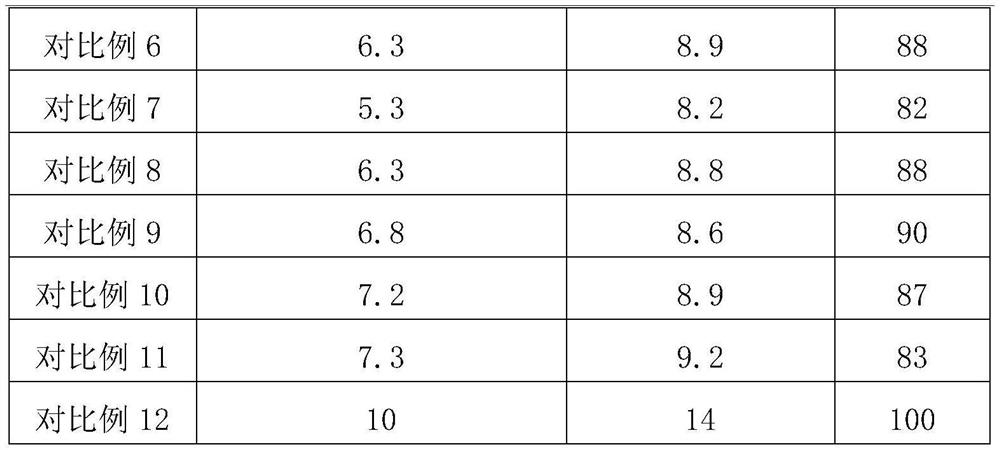

Embodiment 1

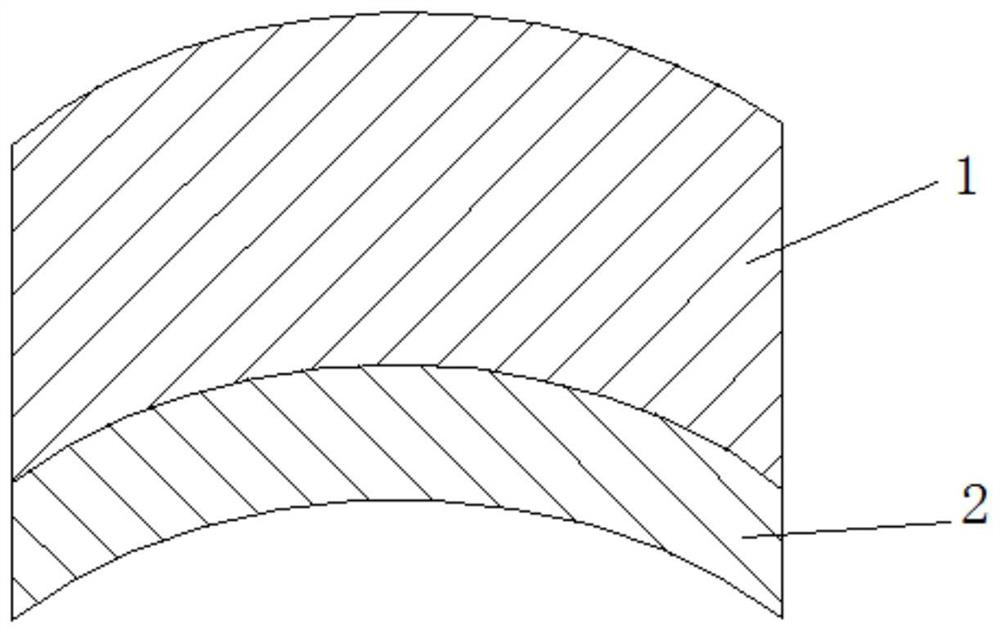

[0034] A low-cost general-purpose saw blade, which is sintered by mixing metal powder and diamond. The saw blade is divided into a working layer and a transition layer. The working layer is composed of powder raw materials with the following weights: 20 kg of iron, 25 kg of copper, tin 2kg, nickel 3kg, iron-copper alloy 47kg, ferrophosphorus 3kg, liquid paraffin 1kg, and diamond with 12.5% of the powder raw material volume added; the transition layer is composed of the following powder raw materials by weight: 70 kg iron, Nickel 30kg.

[0035] Among them, the weight ratio of iron in the iron-copper alloy composition is 80%, and the rest is copper.

[0036] In this embodiment, the iron used is carbonyl iron powder.

Embodiment 2

[0038] A low-cost general-purpose saw blade, which is sintered by mixing metal powder and diamond. The saw blade is divided into a working layer and a transition layer. The working layer is composed of powder raw materials with the following weights: 15 kg of iron, 35 kg of copper, tin 5 kg of nickel, 3 kg of nickel, 45 kg of iron-copper alloy, 3 kg of phosphorus iron, 1 kg of liquid paraffin, and diamond with 15% of the powder raw material volume; the transition layer is composed of the following powder raw materials by weight: 60 kg of iron, Nickel 25kg.

[0039] Among them, the weight ratio of iron in the iron-copper alloy composition is 70%, and the rest is copper.

[0040] In this embodiment, the iron used is carbonyl iron powder.

Embodiment 3

[0042] A low-cost general-purpose saw blade, which is sintered by mixing metal powder and diamond. The saw blade is divided into a working layer and a transition layer. The working layer is composed of powder raw materials with the following weights: 25 kg of iron, 28 kg of copper, and 28 kg of tin. 1 kg of nickel, 5 kg of nickel, 50 kg of iron-copper alloy, 1 kg of phosphorus iron, 1 kg of liquid paraffin, and diamond with 10% of the powder raw material volume; the transition layer is composed of the following powder raw materials by weight: 80 kg of iron, Nickel 20 kg.

[0043] Among them, the weight ratio of iron in the iron-copper alloy composition is 70%, and the rest is copper.

[0044] In this embodiment, the iron used is carbonyl iron powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com