Method for preparing high-density lithium ion battery anode material-lithium nickel manganese cobalt and special calcinator

A technology of nickel-cobalt lithium manganese oxide and lithium-ion batteries, which is applied in the field of preparation of lithium-ion battery cathode materials, can solve the problems of difficulty in obtaining materials without impurity phases, difficulty in uniform particle and appearance, and material capacity attenuation. Excellent chemical properties, simple process and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

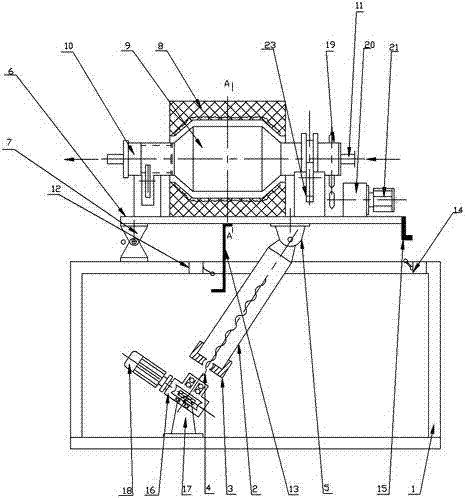

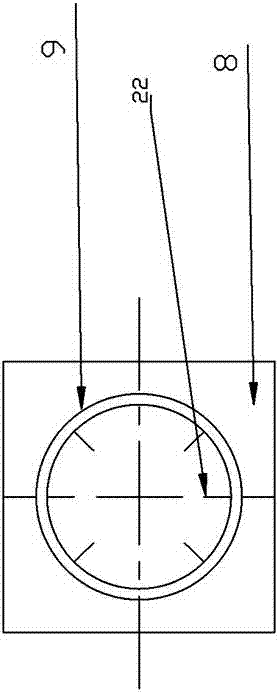

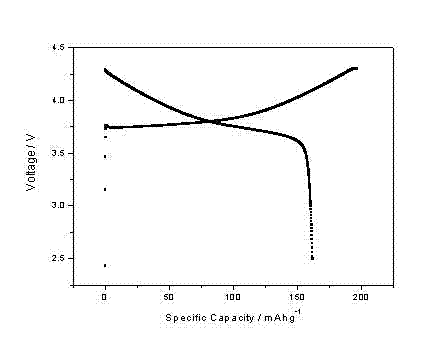

[0040] Embodiment 1: the preparation method of a kind of high-density lithium-ion battery anode material nickel-cobalt lithium manganese oxide of this example, its steps are:

[0041] a. Prepare NH 4+ Ammonium salt aqueous solution A with a concentration of 3mol / L; prepare NaOH alkaline solution B with a concentration of 2mol / L; prepare a molar ratio of Ni:Co:Mn=1:1:1, and a total metal ion concentration of 1mol / L nitric acid Nickel, cobalt nitrate, manganese nitrate mixed metal ion mixed aqueous solution C;

[0042] b. First add 5L of B solution to the reaction kettle, and then NH solution according to the molar ratio 4+ / (Ni+Co+Mn)=4:1 Add A and C, add B solution to control the pH value in the reactor to 12, the reaction temperature is 85°C, fully age for 20 hours after the reaction, and keep it in the process The pH value remains unchanged, and the precursor is obtained after washing and drying (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) (OH) 2 ;

[0043] c. Mix LiOH and the precurso...

Embodiment 2

[0051] Embodiment 2: the preparation method of a kind of high-density lithium-ion battery cathode material nickel cobalt lithium manganese oxide of this example, its steps are:

[0052] a. Prepare NH 4+ Ammonium salt solution A with a concentration of 4 mol / L; prepare NaOH alkaline solution B with a concentration of 2 mol / L; prepare a molar ratio of Ni:Co:Mn=5:2:3, and a total metal ion concentration of 0.8 mol / L Nickel sulfate, cobalt sulfate, manganese sulfate mixed metal ion mixed aqueous solution C;

[0053] b. First add 6L of B solution into the reactor, and then make NH according to the molar ratio 4+ / (Ni+Co+Mn)=8:1 Add A and C, add B solution to control the pH value in the reactor to 10, the reaction temperature is 75°C, fully age for 23 hours after the reaction, and maintain the pH during the process The value remains unchanged, and the precursor is obtained after washing and drying (Ni 0.5 co 0.2 mn 0.3 ) (OH) 2 ;

[0054] c. Will Li 2 CO 3 Take a total o...

Embodiment 3

[0062] Embodiment 3: the preparation method of a kind of high-density lithium-ion battery cathode material nickel cobalt lithium manganese oxide of this example, its steps are:

[0063] a. Prepare NH 4+ Ammonium salt solution A with a concentration of 8 mol / L; prepare NaOH alkaline solution B with a concentration of 8 mol / L; prepare a molar ratio of Ni:Co:Mn=5:2:3, and a total metal ion concentration of 3 mol / L sulfuric acid Nickel, cobalt sulfate, manganese sulfate mixed metal ion mixed aqueous solution C;

[0064] b. First add 8L of B solution into the reactor, and then make NH solution according to the molar ratio 4+ / (Ni+Co+Mn)=4:1 Add A and C, add B solution to control the pH value in the reactor to 11.5, the reaction temperature is 90°C, fully age for 18 hours after the reaction, and maintain the pH during the process The value remains unchanged, and the precursor is obtained after washing and drying (Ni 0.5 co 0.2 mn 0.3 ) (OH) 2 ;

[0065] c. Will Li 2 CO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com