Iron ore well-blended powder with pelletizing undersize for reducing cost and improving efficiency

A technology of applying balls and pellets, applied in the field of iron ore mixing powder, can solve the problems of reduced sinter strength, poor reducibility, and increased ore return rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment.

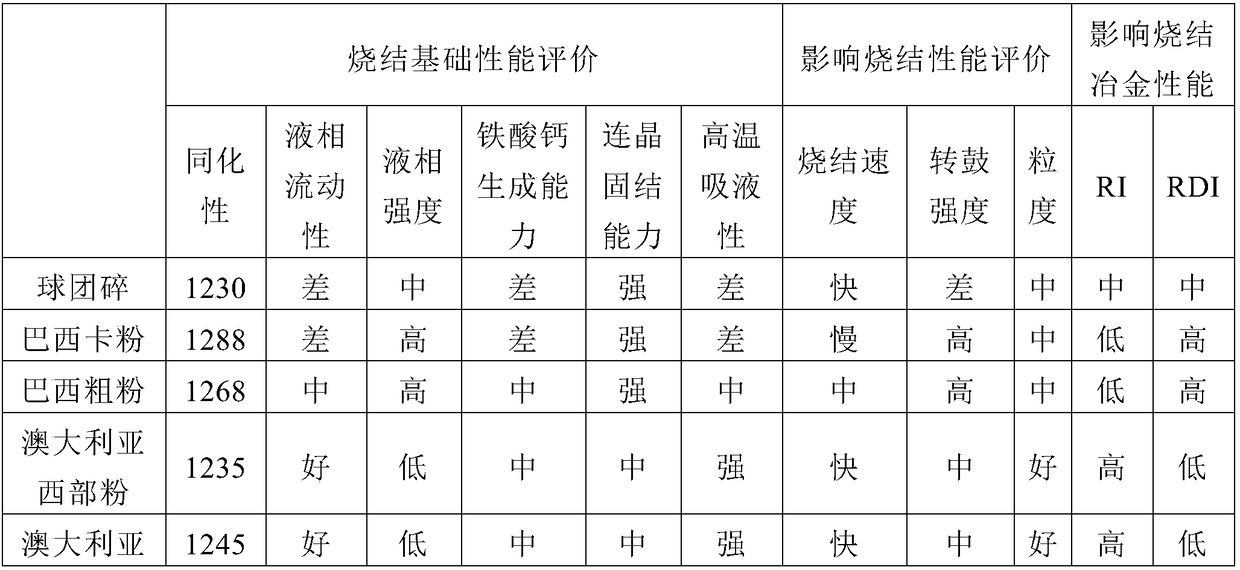

[0037] The iron ore powder mixture composition and weight percentage of Embodiment 1-4 of the present invention are as shown in Table 2, and the chemical indicators of various iron ores in the mixture formula are as shown in Table 3, and each iron ore is intelligentized through use. Advanced mixing material processing equipment is used for batching and mixing production to obtain iron ore powder mixture.

[0038] The chemical indicators of each chemical element, compound and particle size in the iron ore powder mixture obtained in Examples 1-4 are shown in Table 4.

[0039] The composition of the sinter produced by using the mixed powder of Examples 1-4 is shown in Table 5. The blast furnace is equipped with 15% lump ore (TFe63%) and 10% pellets (TFe62%). The indicators after smelting are as follows: Table 6 shows.

[0040] The iron ore mixed powder product produced by the inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com