Tunnel mesh belt sintering furnace

A mesh-belt sintering and tunnel-type technology, applied in furnaces, furnace types, ceramic material production, etc., can solve problems affecting furnace temperature uniformity and cleanliness, affecting material sintering quality, heavy bricks, etc., to achieve quality Lightweight, small bulk density, and improved temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

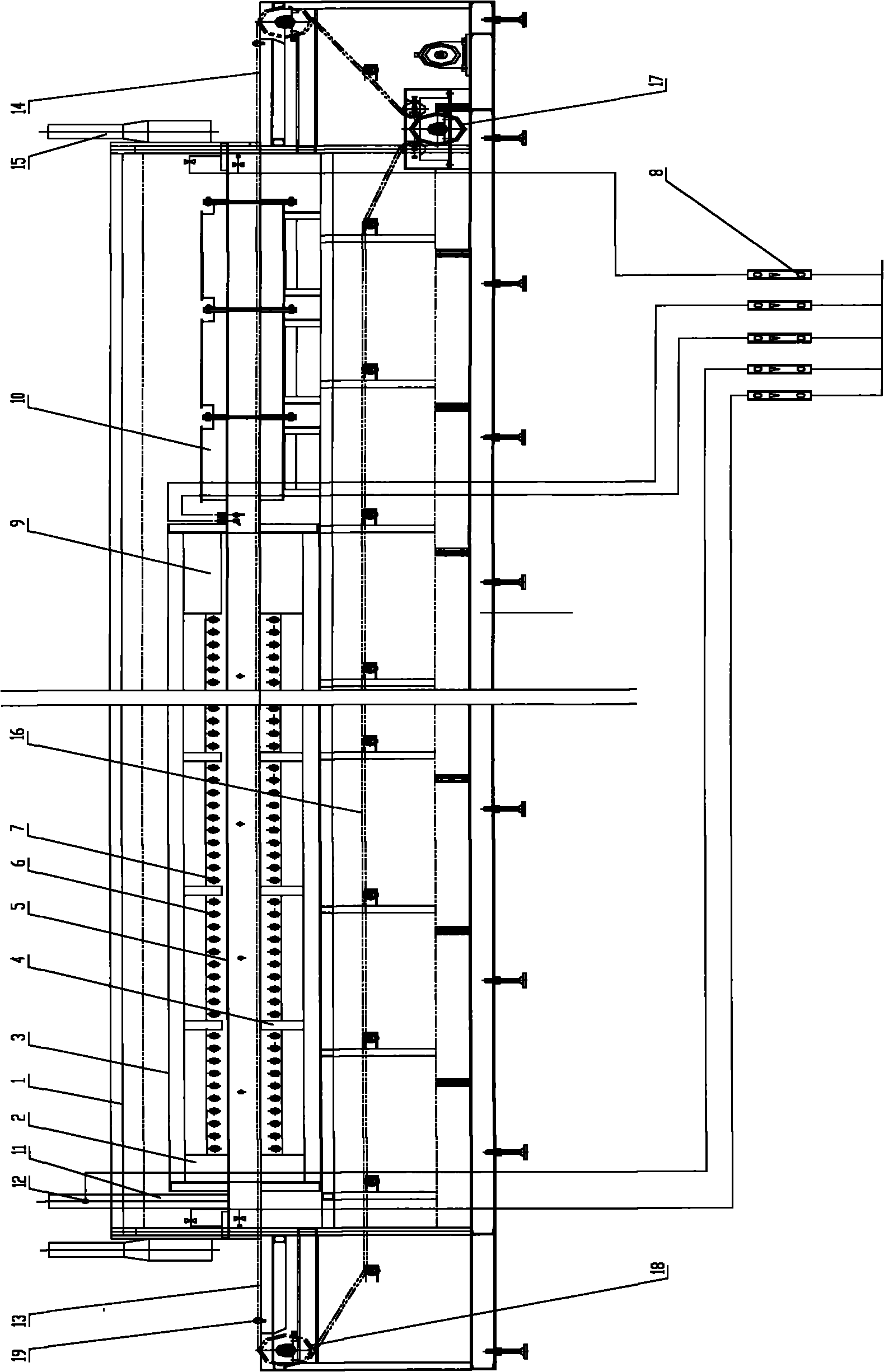

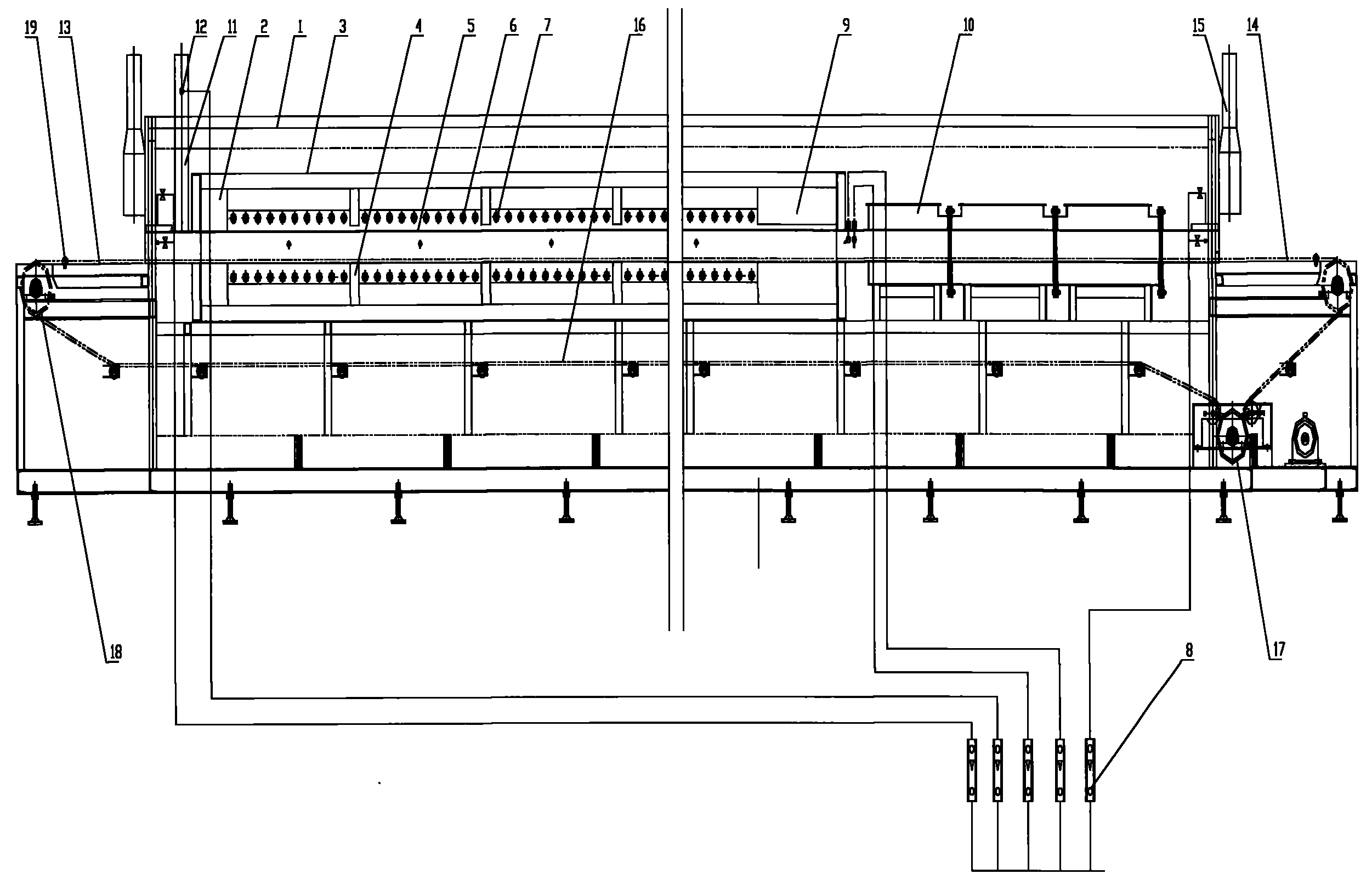

[0008] Such as figure 1 , a tunnel-type mesh belt sintering furnace, including a gas system, a conveying system and an electrical control system, the main structure is composed of a furnace body frame 1, a furnace 2 and so on. Furnace body frame 1 is used to fix the entire furnace 2, gas path system and conveying system. There is a hanging board outside the furnace 2. The hanging boards are all independently electrostatically sprayed to prevent accidental damage to the operator due to high temperature and form a solid structure of the equipment. In terms of overall appearance, the upper cover of the furnace 2 adopts a concave-convex sealing pattern in structural design. The same kind of light ceramic fiber boards 3 are installed around and on the top of the furnace 2 as heat insulation and heat preservation materials. Corundum tubes 6 are installed on the upper and lower positions of the ceramic fiber boards 3 on both sides of the furnace 2. The corundum tubes 6 are spirally w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com