High-performance stripping and slitting knife adopting new hard alloy material and manufacturing method of stripping and slitting knife

A technology of cemented carbide and processing methods, applied in other manufacturing equipment/tools, engine components, turbines, etc., can solve the problem that the performance of cemented carbide slitting knives cannot be fully satisfied, the service life of blades needs to be further improved, processing efficiency and Low processing accuracy and other problems, to achieve the effect of ensuring compactness and uniformity, reducing pores, and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

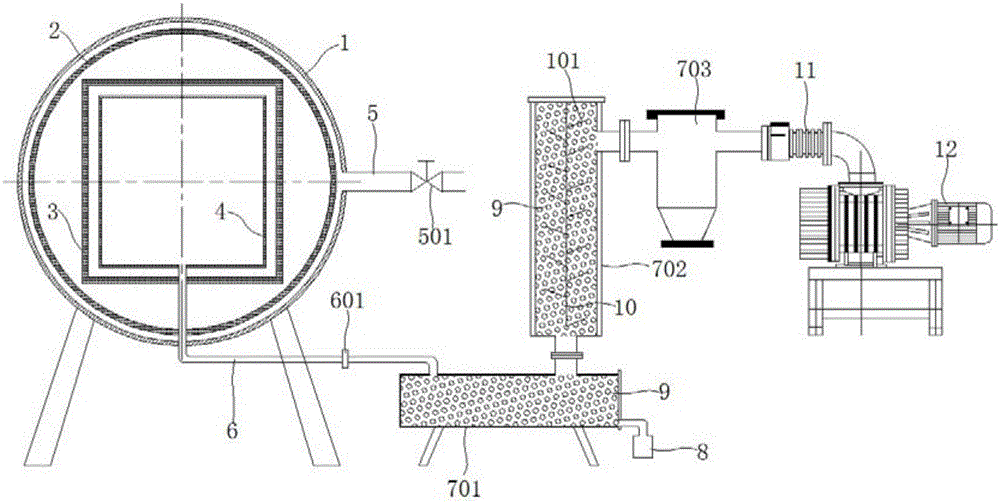

Image

Examples

Embodiment 1

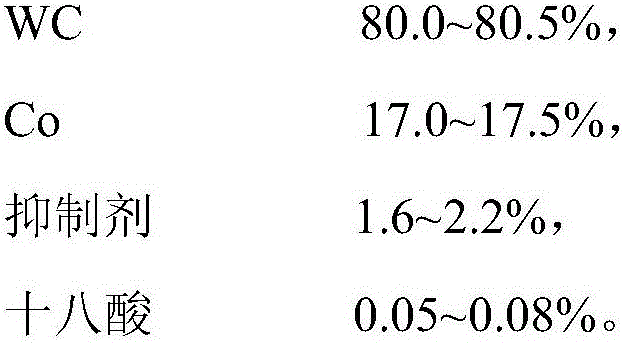

[0047] A kind of high-performance cemented carbide new material slitting and cutting knife of this embodiment, the slitting and slitting knife is made by powder metallurgy process, and each component of its raw material is composed according to the following mass percentage:

[0048]

[0049] The above-mentioned inhibitor is a multi-component compound inhibitor, which is composed of the following components in mass percentage: 0.7% VC, 0.6% Cr 3 C 2 and 0.3% TaC. Wherein, Co of the present embodiment refers to cobalt powder, VC refers to vanadium carbide, Cr 3 C 2 refers to chromium carbide, TaC refers to tantalum carbide, CT refers to catechol, and WC refers to tungsten carbide powder. In this example, according to the powder metallurgy process, ultra-fine grain hard carbide WC and bonding metal Co powder are selected, trace elements are added as inhibitors (carbides) according to conditions, and octadecanoic acid is added as activation according to the grinding mechani...

Embodiment 2

[0078] A kind of high-performance cemented carbide new material slitting and cutting knife of this embodiment, the slitting and slitting knife is made by powder metallurgy process, and each component of its raw material is composed according to the following mass percentage:

[0079]

[0080] The above-mentioned inhibitor is a multi-component compound inhibitor, which is composed of the following components in mass percentage: 0.5% VC, 0.8% Cr 3 C 2 and 0.5% TaC.

[0081] The processing method of the above-mentioned high-performance cemented carbide new material slitting and cutting knife of the present embodiment is characterized in that: the processing of the slitting and slitting knife comprises the following steps:

[0082] Step 1. Ingredients: Weigh and mix the components of the slitting knife according to the mass percentage;

[0083] Step 2, wet grinding and pressing: mix the components weighed in step 1 and put them into a wet mill for wet grinding. The wet grindi...

Embodiment 3

[0095] A kind of high-performance cemented carbide new material slitting and cutting knife of this embodiment, the slitting and slitting knife is made by powder metallurgy process, and each component of its raw material is composed according to the following mass percentage:

[0096]

[0097] The above-mentioned inhibitor is a multi-component compound inhibitor, which consists of the following components in mass percentage: 0.6% VC, 1.0% Cr 3 C 2 and 0.4% TaC.

[0098] The processing method of the above-mentioned high-performance cemented carbide new material slitting and cutting knife of the present embodiment is characterized in that: the processing of the slitting and slitting knife comprises the following steps:

[0099] Step 1. Ingredients: Weigh and mix the components of the slitting knife according to the mass percentage;

[0100] Step 2. Wet grinding and pressing: Mix the components weighed in step 1 and put them into a wet mill for wet grinding. The wet grinding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com