Method for quick online replacement of trolley for sintering machine

A technology of sintering machine and trolley, applied in the field of sintering machine, can solve the problems of unreachable, reduced air flow, limited operating space, etc., and achieve the effect of ensuring the sintering effect and shortening the replacement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

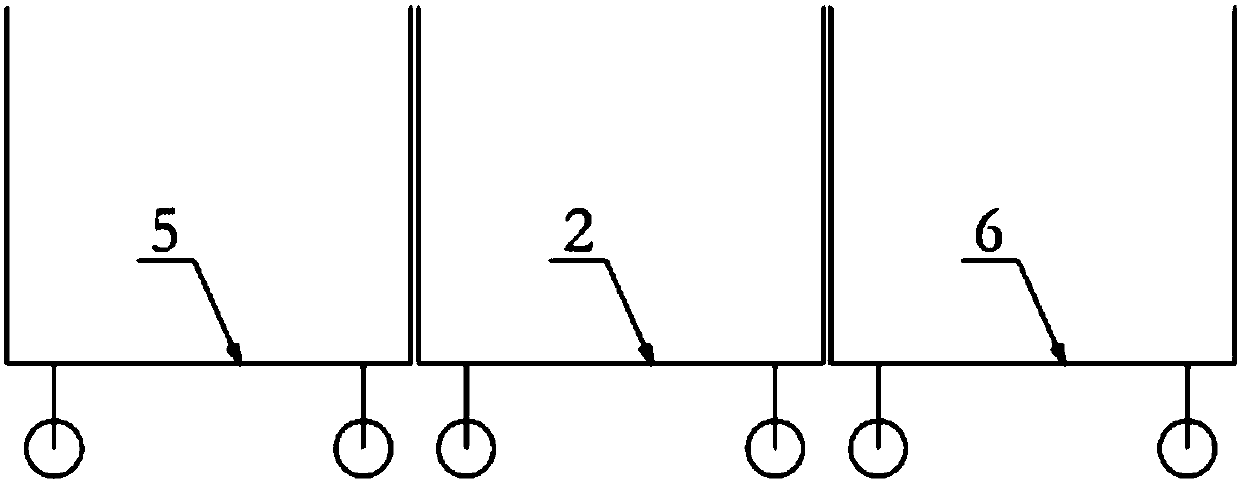

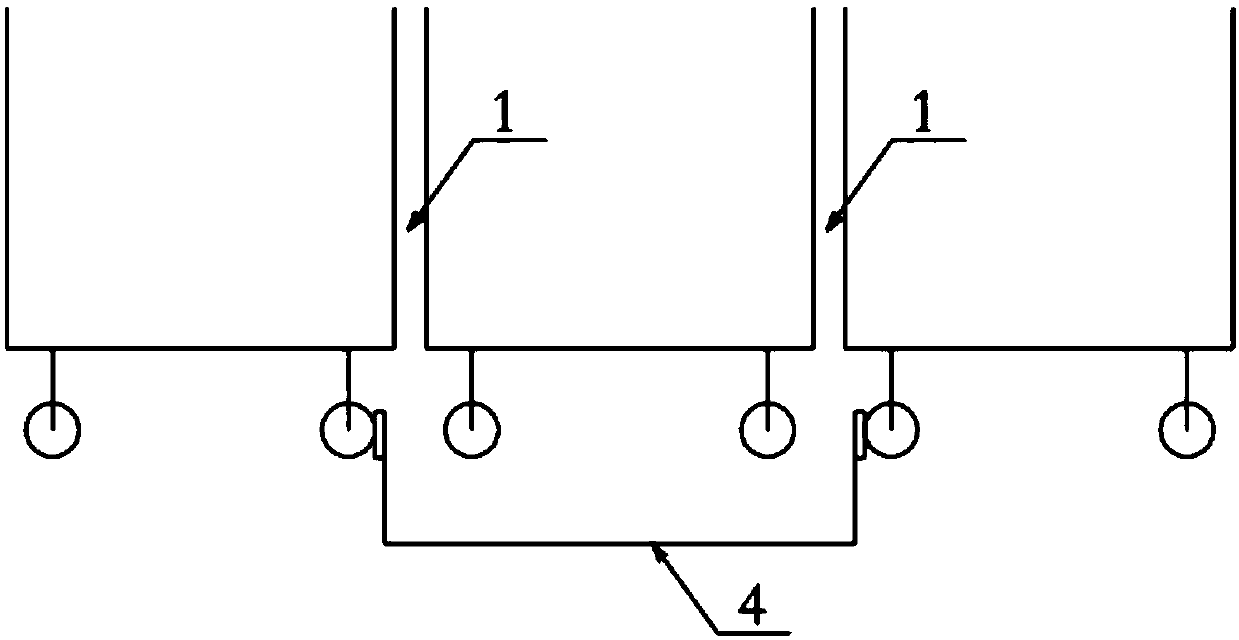

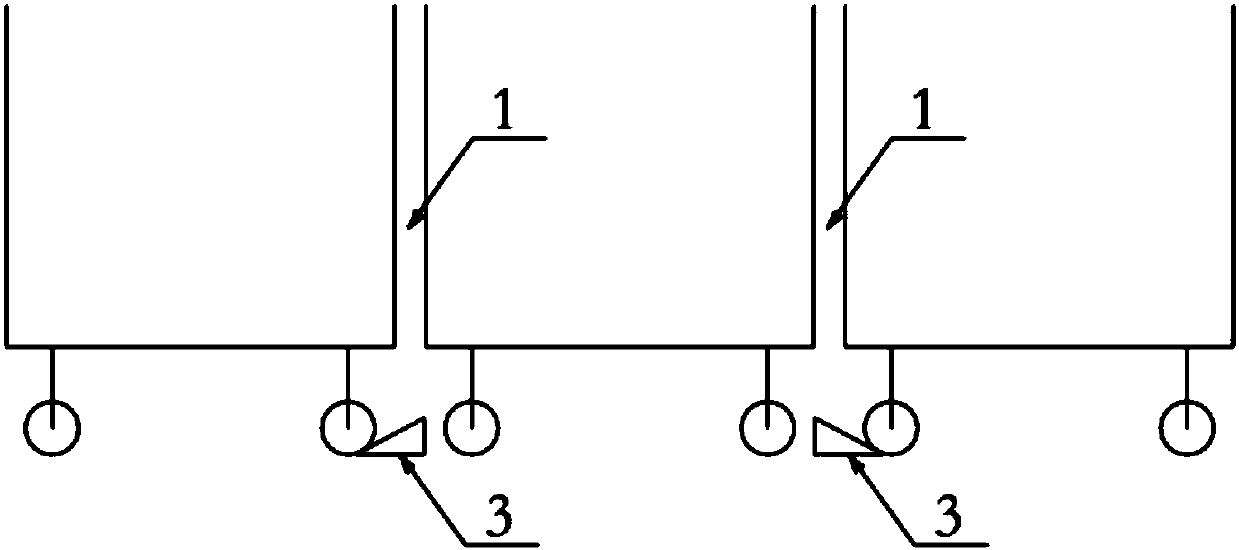

[0030] The method for quickly changing trolleys online for a sintering machine according to the present invention, wherein the sintering machine is installed horizontally, and the sintering machine is provided with a running track on which continuously installed trolleys are arranged; There is a bellows, the bellows are connected with the main exhaust fan through the main flue; a discharge port is provided at one end of the head of the sintering machine, and a discharge device is provided above the discharge port, and the discharge device is connected with the mixing bin; In the running direction of the sintering machine, an ignition device is arranged downstream of the feeding port, and a furnace is arranged in the ignition device; the method is carried out as follows:

[0031] Step 1. Determine the position of the trolley that needs to be rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com