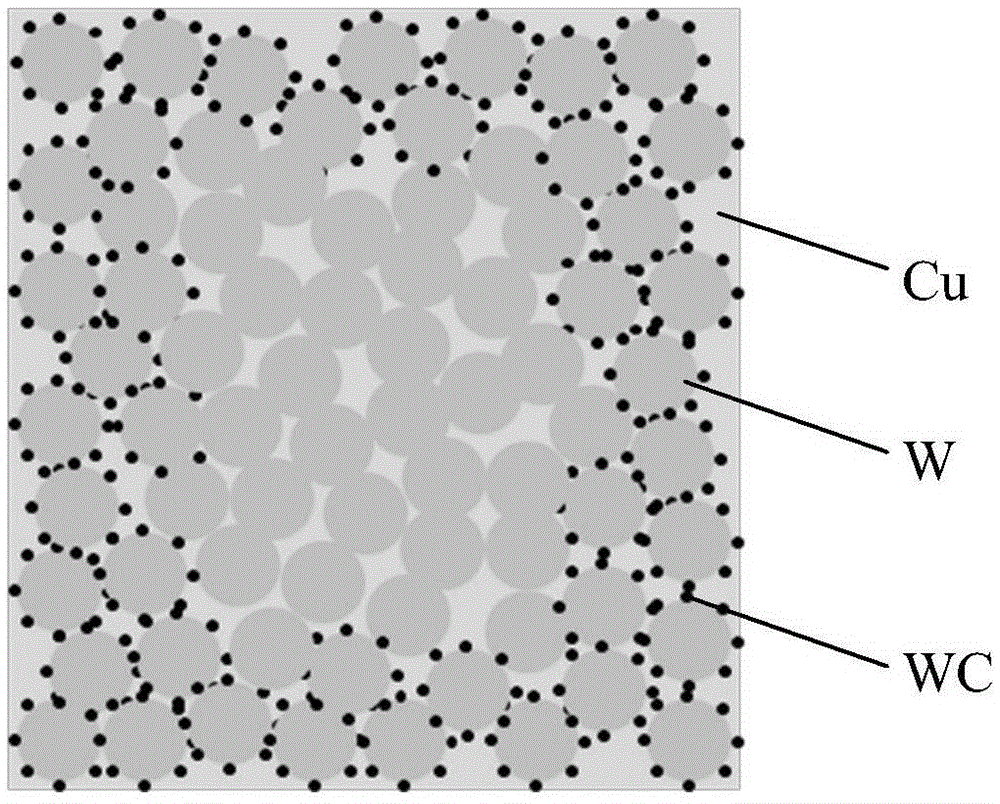

In-situ formation preparation method for gradient WC-strengthened CuW composite material

A composite material, in-situ self-generating technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of inability to meet the needs of use, poor electrical and thermal conductivity, poor copper alloy connection performance, etc. Achieve the effect of ensuring connection strength, improving high temperature strength and wear resistance, and improving high temperature strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

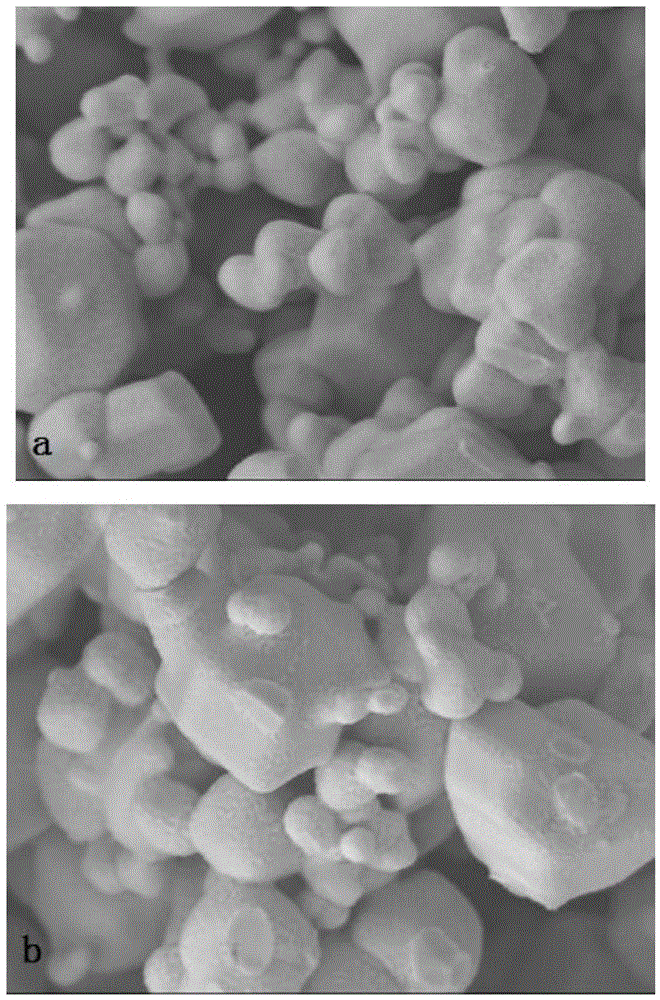

[0029] Step 1, prepare the W skeleton:

[0030] Mix W powder and 3% induced Cu powder through a V-type mixer and press on a hydraulic press to form a green body with a density of 70%, and then sinter in a hydrogen atmosphere protection furnace at 1300°C for 40 minutes to obtain a W skeleton;

[0031] Step 2, vacuum carburizing:

[0032] Heat the W skeleton obtained in step 1 to 900°C in a vacuum carburizing furnace under the protection of an inert atmosphere. After reaching the temperature, turn on the vacuum pump to pump the furnace body to 0.8 Pa, pass in 800 Pa acetylene, keep it for 5 minutes, and then pump the furnace body to 0.8 Pa. To 1Pa, keep warm for 20 minutes, repeat the above operation 3 times and keep warm for 60 minutes, then pass nitrogen gas to cool the sample with the furnace, and then get the WC gradient strengthened W skeleton;

[0033] Step 3, Infiltration:

[0034] The WC gradient strengthened W skeleton obtained in step 2 was infiltrated with copper at...

Embodiment 2

[0036] Step 1, prepare the W skeleton:

[0037] W powder, 3% inductive Cu powder and 1% activating element Ni powder were mixed by a V-type mixer and pressed on a hydraulic press to form a green body with a density of 70%. Sintering for 40min to obtain the W skeleton;

[0038] Step 2, vacuum carburizing:

[0039] Heat the W skeleton obtained in step 1 to 950°C in a vacuum carburizing furnace under the protection of an inert atmosphere. After reaching the temperature, turn on the vacuum pump to pump the furnace body to 1Pa, pass in 1000Pa acetylene, keep it for 2min, and then pump the furnace body to 1Pa, keep warm for 5min, repeat the above operation 10 times and keep warm for 40min, then pass nitrogen gas to cool the sample with the furnace, and then get the WC gradient strengthened W skeleton;

[0040] Step 3, Infiltration:

[0041] The WC gradient strengthened W skeleton obtained in step 2 was infiltrated with copper at 1350 ° C for 2 hours in a computer-programmed high-...

Embodiment 3

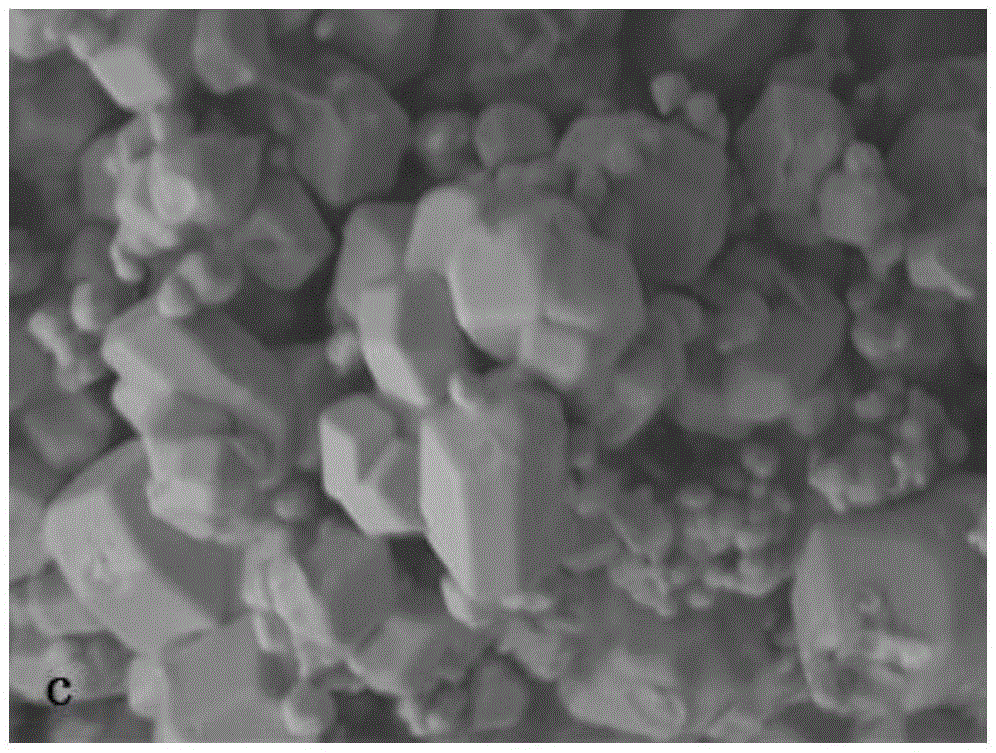

[0043] Step 1, prepare the W skeleton:

[0044] W powder, 3% inductive Cu powder and 1% activating element Ni powder were mixed by a V-type mixer and pressed on a hydraulic press to form a green body with a density of 70%. Sintering for 40min to obtain the W skeleton;

[0045] Step 2, vacuum carburizing:

[0046] Heat the W skeleton obtained in step 1 to 1100°C in a vacuum carburizing furnace under the protection of an inert atmosphere. After reaching the temperature, turn on the vacuum pump to pump the furnace body to 1.2Pa, pass in 1200Pa acetylene, keep it for 10min, and then pump the furnace body to 1.2Pa. To 1Pa, keep warm for 10min, repeat the above operation twice and keep warm for 30min, then pass nitrogen gas to cool the sample with the furnace, and then get the WC gradient strengthened W skeleton;

[0047] Step 3, Infiltration:

[0048] The WC gradient strengthened W skeleton obtained in step 2 was infiltrated with copper at 1400°C for 0.5h in a computer-programme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com