Patents

Literature

59results about How to "Does not affect elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

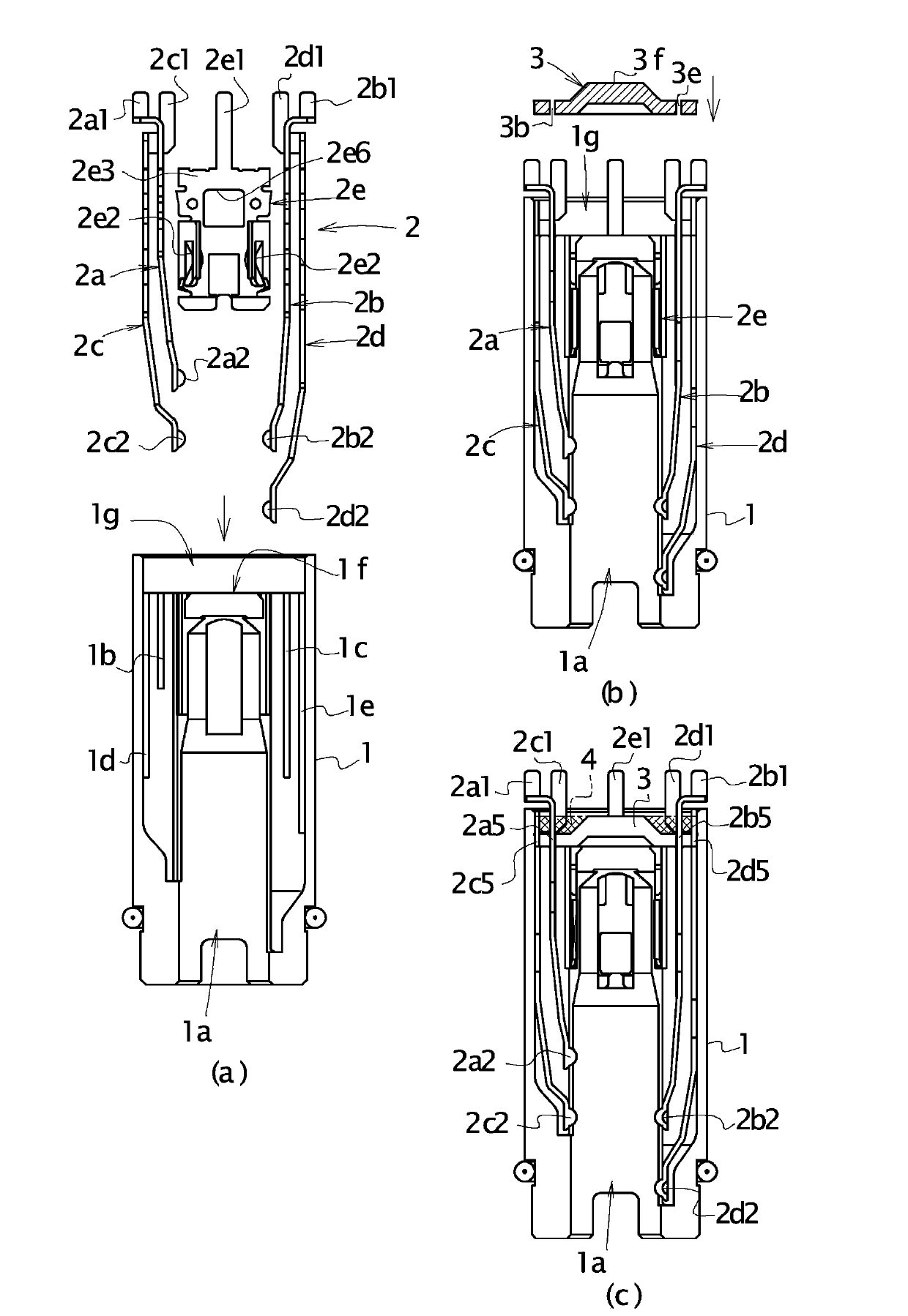

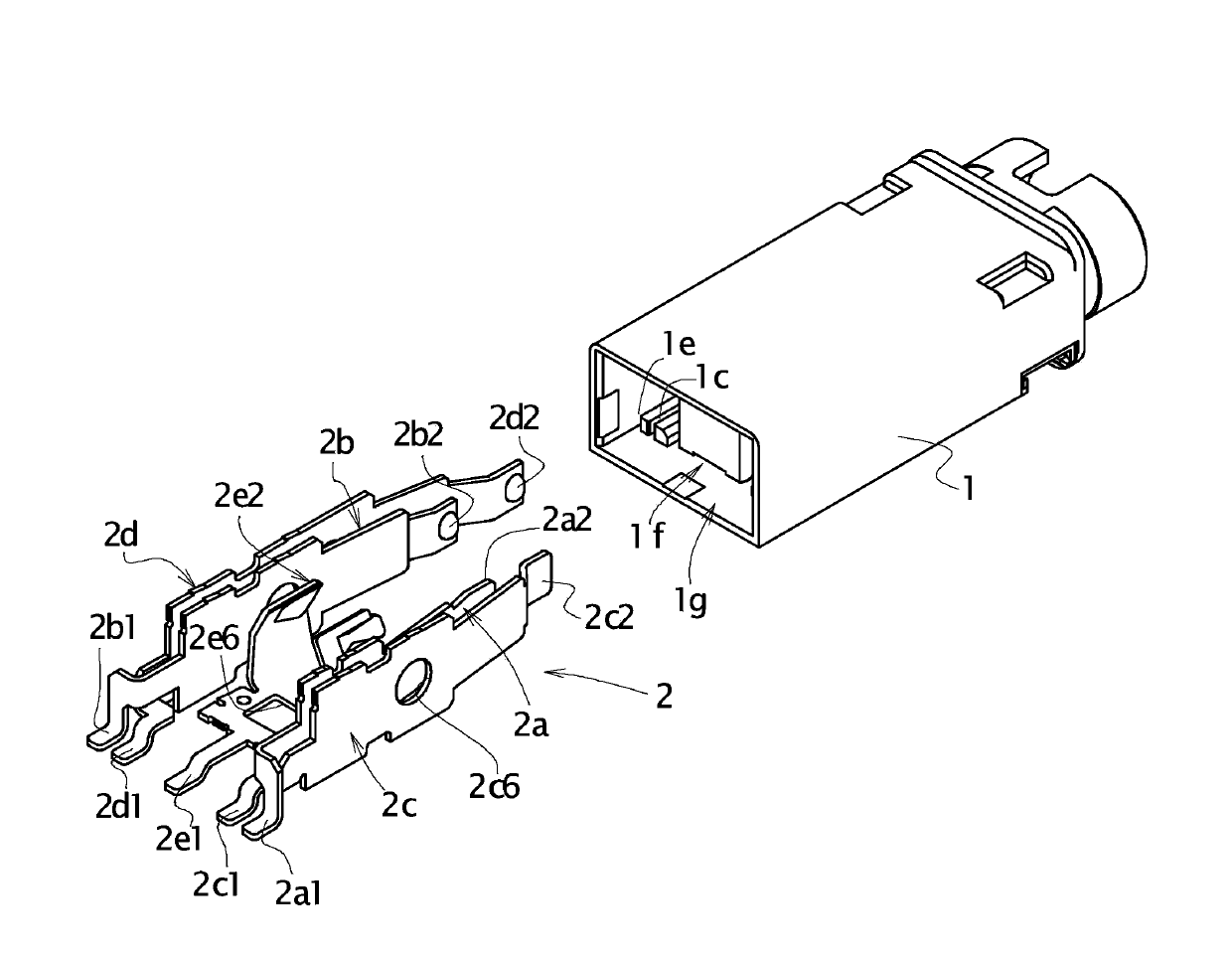

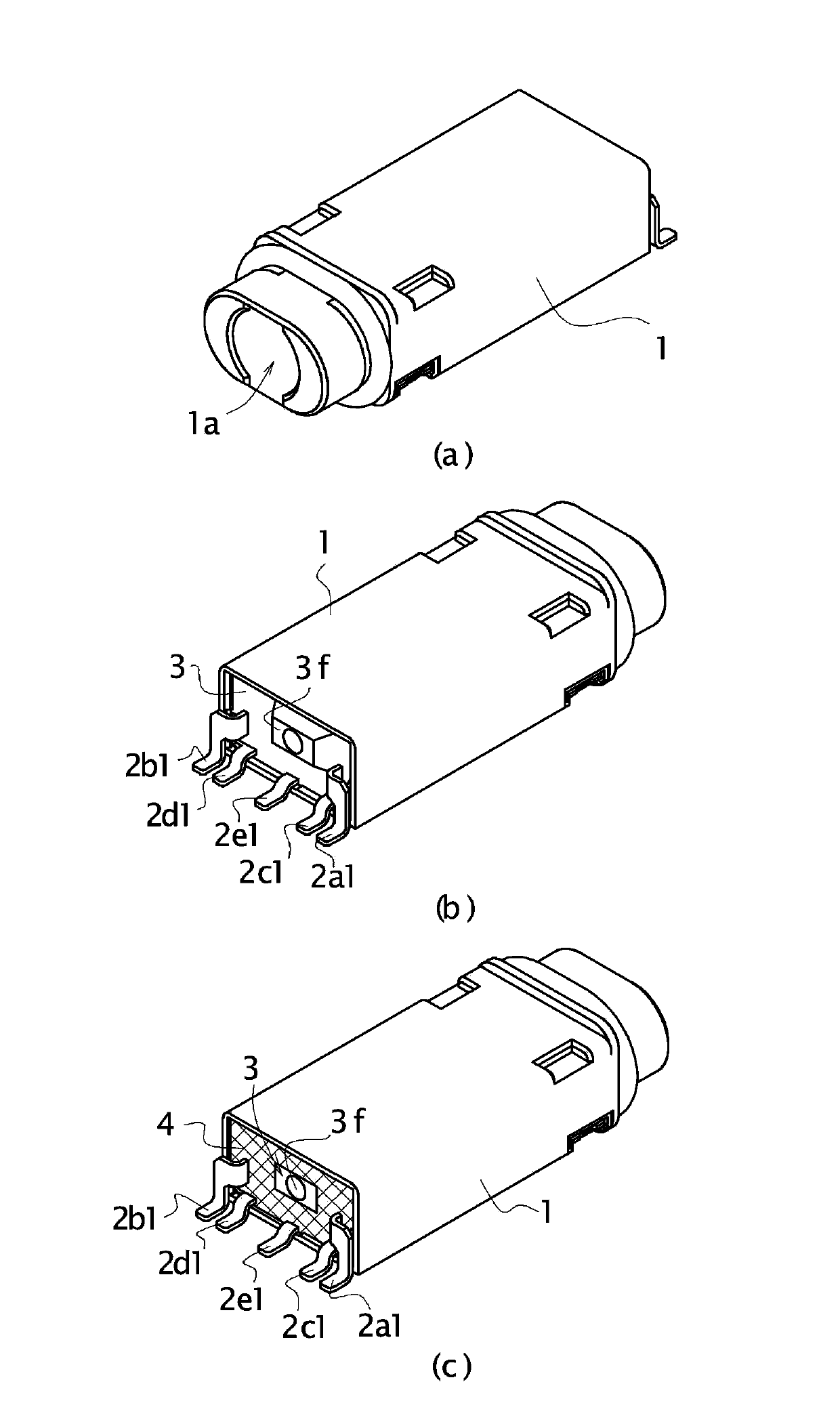

Waterproof socket

InactiveCN103378472APoor contactAvoid the problem of poor contactCoupling contact membersCouplings bases/casesEngineeringAdhesive

Owner:SMK CO LTD

Ham sausage and production method thereof

The invention provides a ham sausage which is characterized in that raw material composition contains buckwheat flour and buckwheat grains. The production steps are as follows: pork and / or chicken are proportionally ground, and then common salt and the like are added for salting for 1 to 2 days; buckwheat grains are added with water with the volume being 1.2 to 1.8 times of the volume of buckwheat grains, and then the mixture is steamed; the steamed buckwheat grains, buckwheat flour, carrageenin, seasoners, monascus pigment, spices and water are added into material of the first step to be evenly stirred; a natural casing is used for clystering, shortening, sterilizing at high temperature, cooling and preserving. The ham sausage produced with the production method has good flavor, good elasticity, good flakiness, low content of starch and certain health care function, and is not only edible for common people, but also edible for diabetics.

Owner:SHANXI UNIV

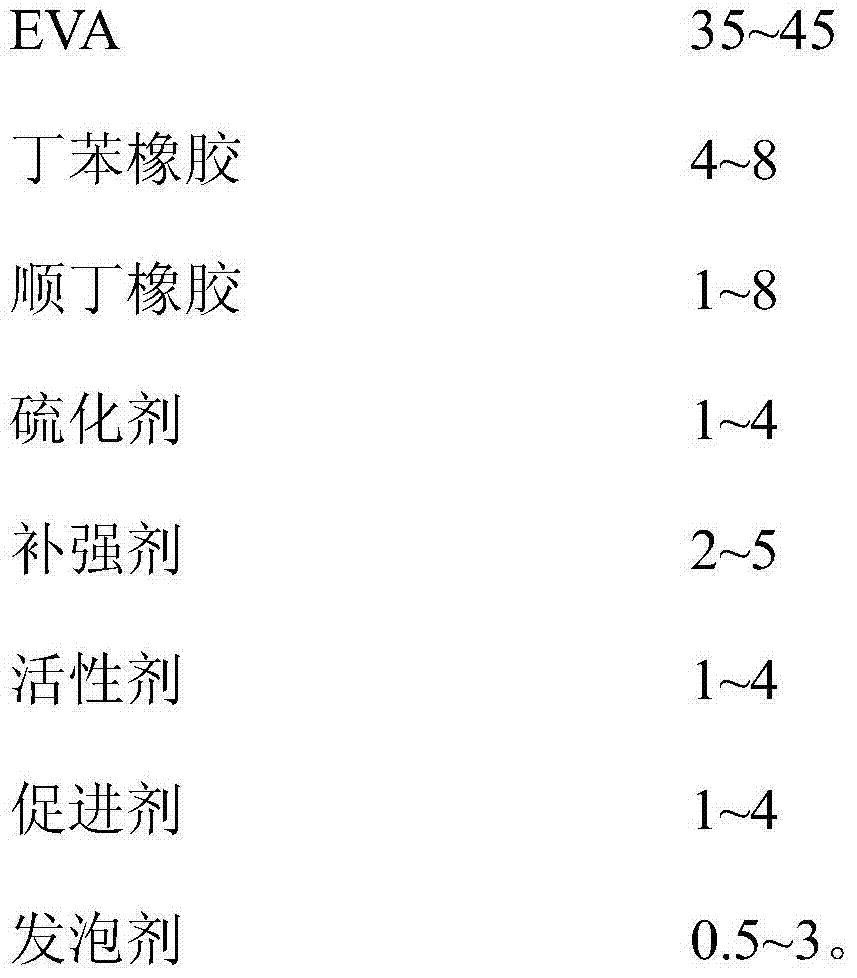

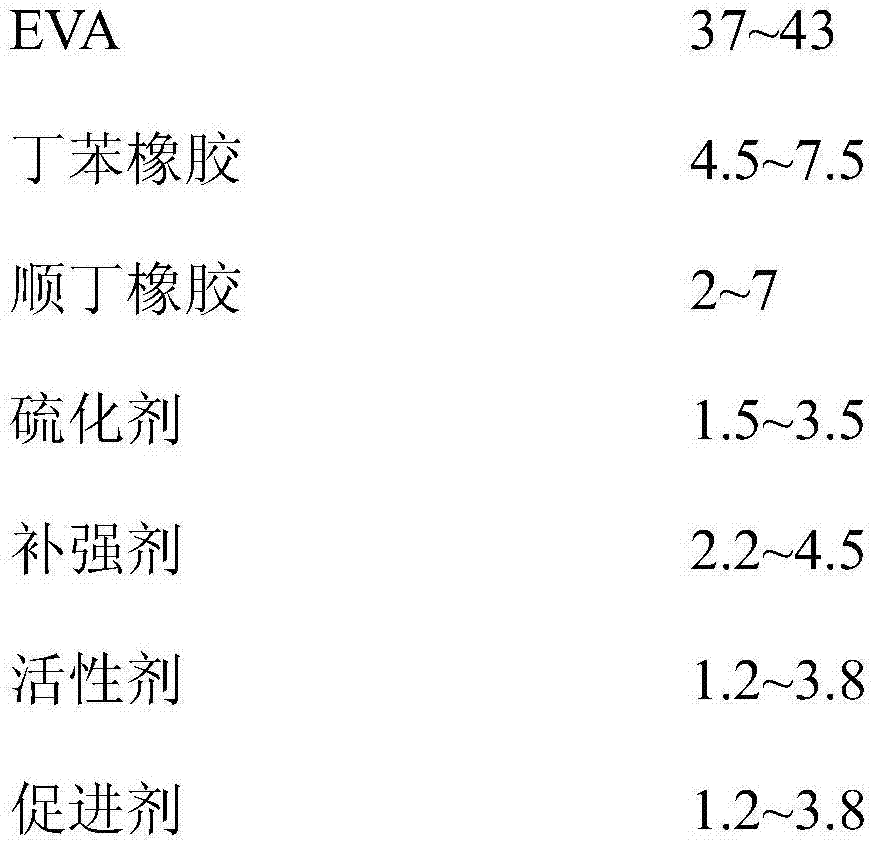

Wear resistant sole material

InactiveCN103483677AImprove wear resistanceGood rebound performanceSolesEnvironmental resistanceWear resistant

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:昆山纯柏精密五金有限公司

Anti-aging antibacterial sole material

InactiveCN102863797ADoes not affect elasticityImprove antibacterial propertiesSolesAging resistanceDiethylene glycol

The invention discloses an anti-aging antibacterial sole material which is prepared by the following raw materials in parts by weight: 60-65 parts of butadiene-styrene rubber, 65-70 parts of silicon rubber, 10-20 parts of diethylene glycol, 8-12 parts of aniline, 12-14 parts of dicumyl peroxide, 6-8 parts of thiosulfate, 10 parts of white carbon black and 20-30 parts of white oil. With the adoption of the anti-aging antibacterial sole material, antibacterial property and ageing resistance of soles can be substantially improved on the premise of being free of influences on elasticity, hardness and other performance; and the anti-aging antibacterial sole material is applicable to industrial production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

Method for preparing wear-resistant sole

InactiveCN102504416ADoes not affect elasticityWithout compromising comfortSolesPolyvinyl alcoholPolystyrene

The invention discloses a method for preparing a wear-resistant sole, which comprises the following steps of weighing the following materials in weight parts: 70-78 parts of ethylene propylene diene rubber, 11-13 parts of carbon black, 5-7 parts of aluminum triethyl, 10-12 parts of p-nitrophenol, 10-12 parts of polystyrene, 30-35 parts of natural 3L rubber, 5-8 parts of polyvinyl alcohol and 11 parts of talcum powder; mixing the weighed raw materials together and then putting the materials into an internal mixer for banburying; pouring out the mixture after all the raw materials are evenly mixed when the temperature reaches 110-113 DEG C; then pelletizing the banburied mixture via a pelletizer to obtain granules, and then putting the granules into a water tank for cooling and then drying the granules under room temperature; finally injection molding the dried granules so as to obtain the sole. The sole prepared by the invention is greatly improved in wear resistance on the premise of not influencing the elasticity, comfort and other properties, and the sole has no toxic or polluting effects and also guarantees safety and environmental friendliness.

Owner:WUJIANG TIANYUAN PLASTIC

Wear-resistant antibacterial sole material

The invention discloses a wear-resistant antibacterial sole material. The sole material is prepared from, by weight, 90-96 parts of isoprene rubber, 76-80 parts of hydrogenated nitrile rubber, 20-24 parts of methylpropanediol, 8-9 parts of aniline, 12-14 parts of ethyl acetate, 10-12 parts of calcium zinc salt, 8-9 parts of white carbon black and 20-24 parts of naphthenic oil. The sole material enables antimicrobial and wear-resistant performances of soles to be greatly improved without affecting due elasticity, hardness and other performances of the soles, and is applicable to industrial production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

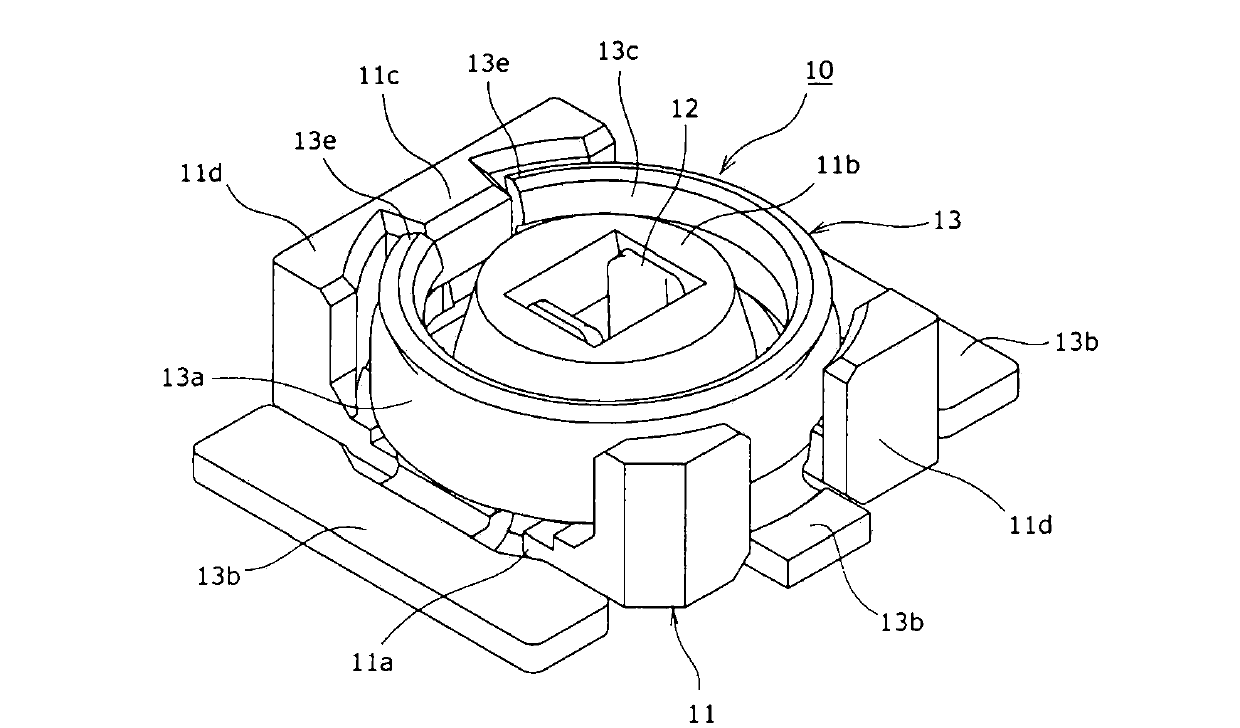

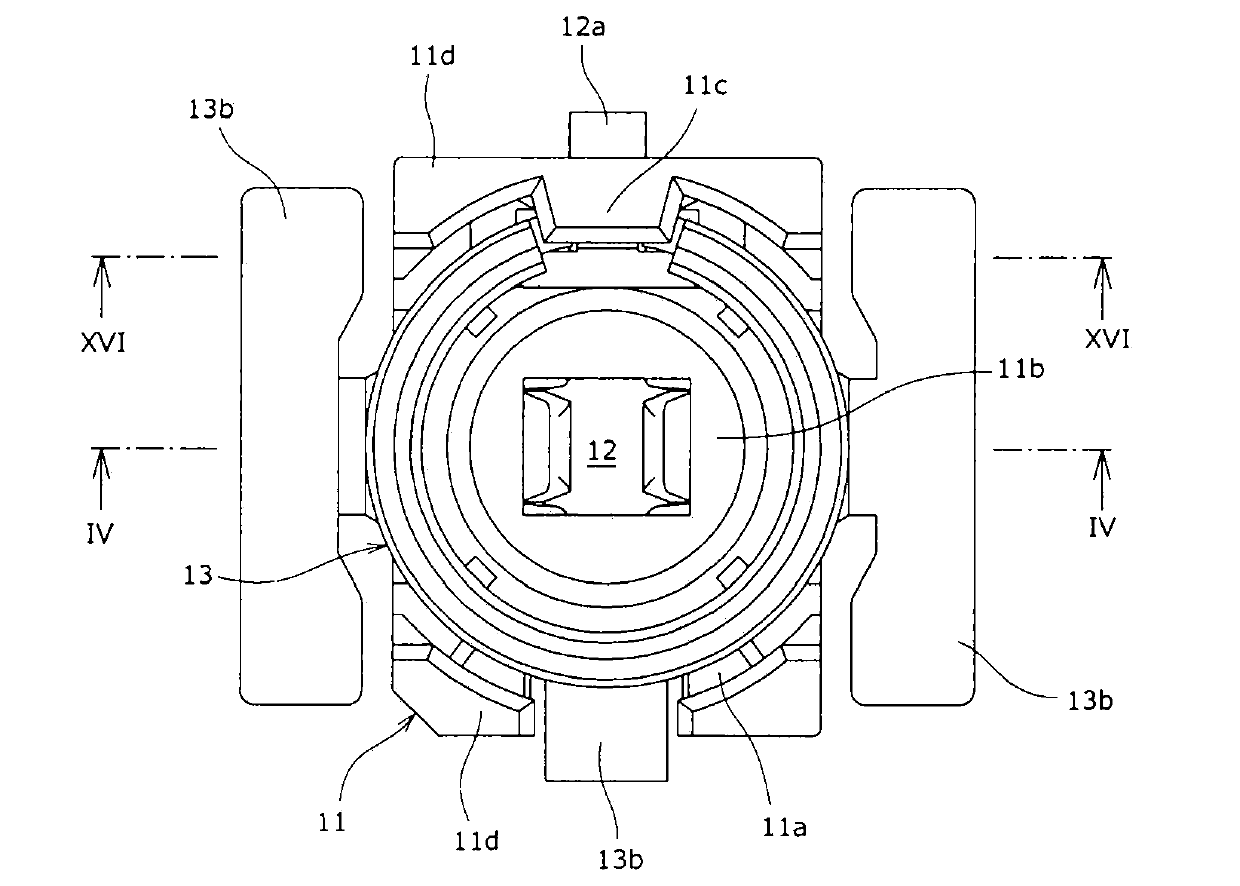

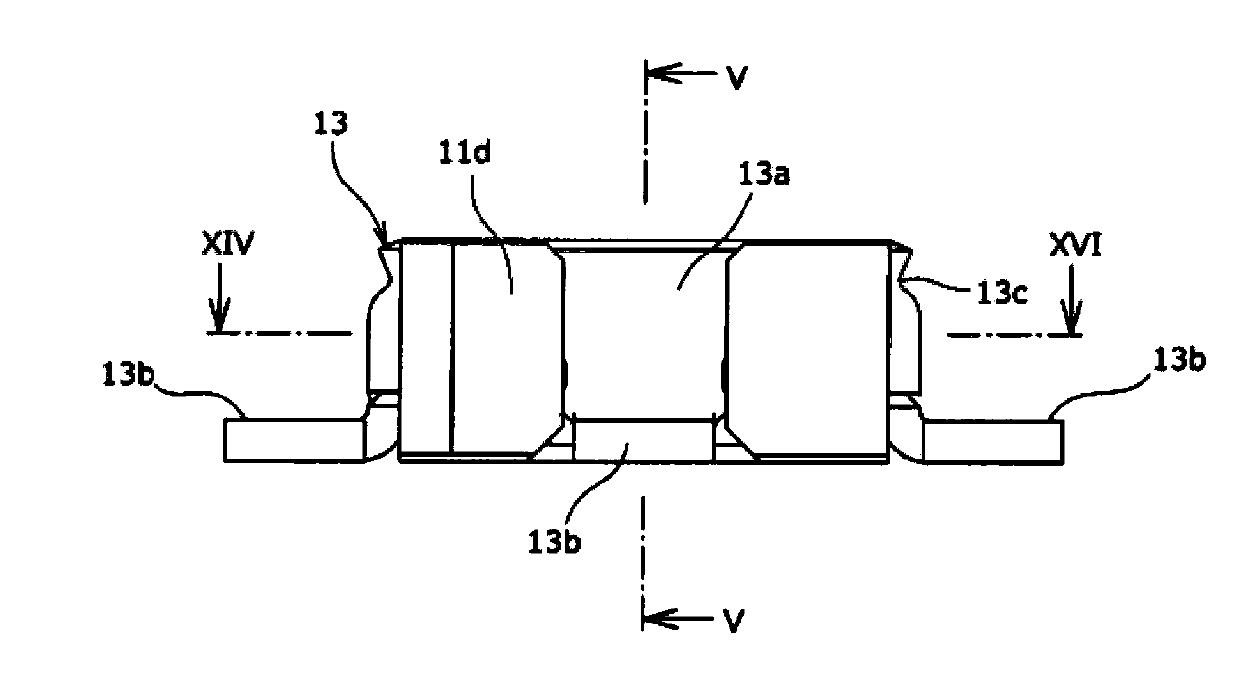

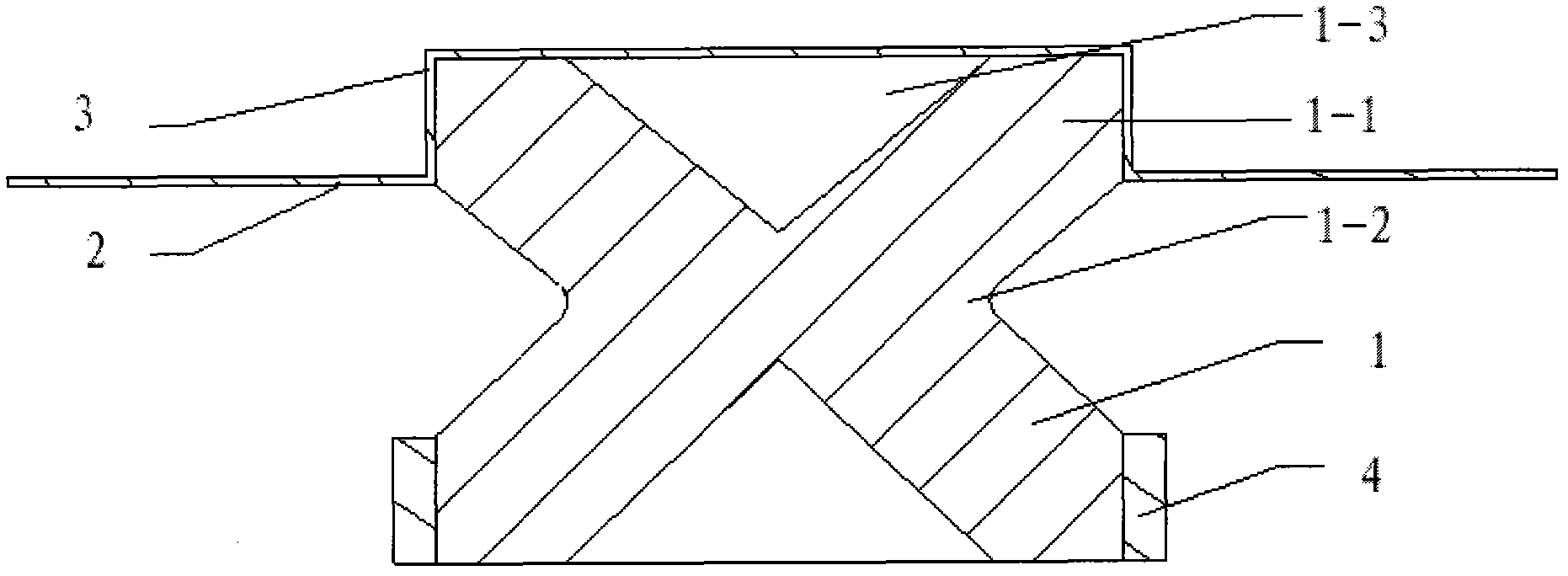

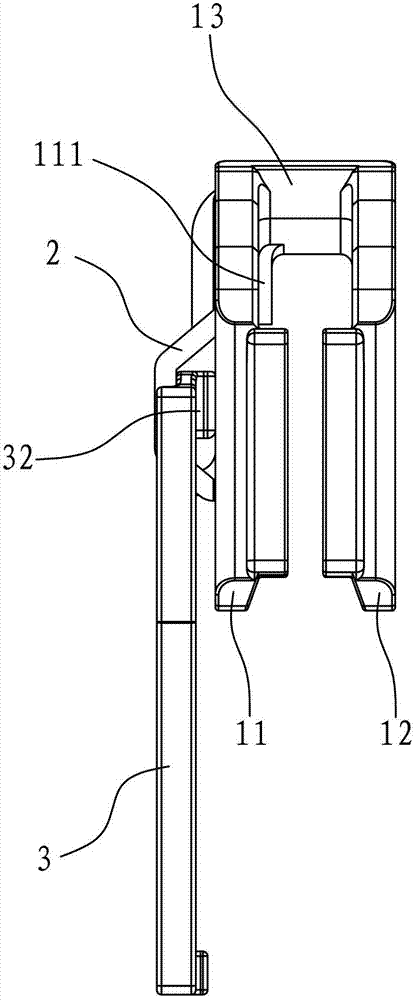

Coaxial electrical connector

InactiveCN103378517AImprove reliabilityDoes not affect elasticityEngagement/disengagement of coupling partsElectrically conductive connectionsElectrical connectorMechanical engineering

An annular contact (13) is enabled to be firmly retained by an insulating housing (11) without affecting the mating force or removing force between there and a matching connector (20) with a simple configuration. Divided end parts (13e) of the annular contact (13) attached to the insulating housing (11) are provided with contact retaining parts that abut part of the insulating housing (11) and retain the annular contact (13) at the insulating housing (11) when removal with respect to the matching connector (20) is carried out, so that the shapes and sizes of the contact retaining parts are not affected by elastic force of the annular contact (13), in other words, mating force or removing force with respect to the matching connector (20) almost at all to facilitate adjustment of the mating force or removing force between there and the matching connector (20).

Owner:I PEX CO LTD

Hollow seal and lamp

InactiveCN102042408ADoes not affect elasticityDoes not affect speedEngine sealsGas-tight/water-tight arrangementsEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Anti-aging antistatic sole material

InactiveCN102863664ADoes not affect elasticityDoes not affect hardnessSolesAdhesiveMaterials science

The invention discloses an anti-aging antistatic sole material which is prepared by raw materials in parts by weight: 80-86 parts of chloroprene rubber adhesive, 75-78 parts of chlorosulfonated polyethylene adhesive, 5-10 parts of diethylene glycol, 6-8 parts of dimethylformamide, 2-3 parts of dicumyl peroxide, 16-18 parts of carbon black, 12-14 parts of calcium sulfate and 20-25 parts of naphthenic oil. With the adoption of the anti-aging antistatic sole material, antistatic property and anti-aging property are substantially improved on the premise of being free of influences on elasticity, hardness and other performances; and the anti-aging antistatic sole material is applicable to industrial production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

Air-permeable sole material and preparation method thereof

The invention relates to an air-permeable sole material and a preparation method thereof. The air-permeable sole material comprises the following components in parts by weight: 88 parts of ethylene-propylene-diene monomer, 20 parts of carbon black, 22 parts of petroleum wax, 36 parts of polystyrene, 67 parts of natural 3L rubber, 8 parts of magnesia and 11 parts of calcium-zinc salt. The preparation method of the air-permeable sole material comprises the following steps of: mixing the raw materials according to the parts by weight, adding the mixture to an internal mixer for internal mixing, then granulating the mixture after internal mixing through a granulator to obtain granules, cooling the granules in a water tank, and drying at room temperature. By using the material provided by the invention, on the premise of not influencing the elasticity, hardness and other properties of the sole, the air permeability of the sole is greatly improved; and the material is nontoxic and pollution-free as well as safe and environment-friendly.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

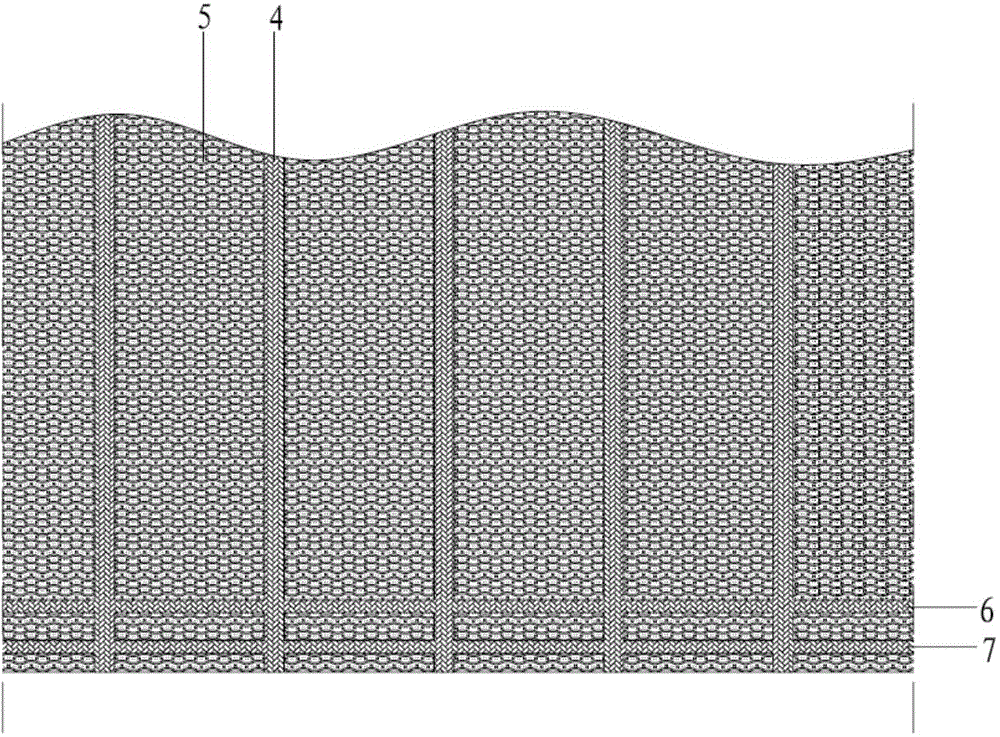

Fabric and curtain interwoven with hot-melt yarn

The invention discloses fabric interwoven with hot-melt yarn. The fabric comprises warp and weft which are interwoven, wherein full hot-melt yarn is arranged in the warp or the weft at intervals. The invention further discloses a curtain interwoven with the hot-melt yarn. The curtain is formed by weaving the warp and the weft and comprises thick fabric sections and thin fabric sections which are distributed at intervals in the weft direction, and full hot-melt yarn is arranged in the warp or the weft at intervals. By the aid of the hot-melt yarn interwoven with the fabric weave at intervals, good hand feeling and softness are kept while the fabric hardness is improved. After the fabric is applied to the folding curtain, the thick fabric sections are thicker, the smoothness of the curtain in the vertical direction is kept, the thin fabric sections are soft, and the curtain is convenient to fold and unfold.

Owner:绍兴游龙窗饰有限公司

Anti-puncturing sole material

InactiveCN102863778AImprove puncture resistanceDoes not affect elasticitySolesCarbon blackTriethanolamine

The invention discloses an anti-puncturing sole material which is prepared by the following raw materials in partsby weight: 50-55 parts of hydrogenation nitrile butadiene rubber, 75-80 parts of thermoplastic polyurethane, 20-23 parts of methylpropanediol, 12-15 parts of triethanolamine, 8-9 parts of acetone, 6-7 parts of carbon black, 3-5 parts of calcium sulfate and 15-20 parts of naphthenic oil. With the adoption of the anti-puncturing sole material, anti-puncturing property is improved on the premise of being free of influences on elasticity, hardness and other performance; and the anti-aging anti-puncturing sole material is applicable to industrial production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

Damping pin for computer chassis

InactiveCN102053678AIncrease elasticityMaintain textureSpringsDigital processing power distributionElastomerResonance

The invention discloses a damping pin for a computer chassis. The damping pin is characterized by comprising an elastic body of the pin, wherein the elastic body is in a longitudinal symmetric shape, the middle section of the elastic body is a concave arc cylinder, two ends of the elastic body are in a circular truncated cone shape; and except the part of the middle section, the inside of two ends of the elastic body is hollow in accordance with the appearance. Hardness of the elastic body of the pin of the structure ensures excellent elasticity to absorb vibration and sufficient weight to endure a supporting body, so the pin cannot be deformed remarkably. A hollow cylinder on one end of the elastic body of the pin is inserted into a corresponding pin hole on a back plate of the chassis, while a hollow cylinder on the other end of the elastic body of the pin is inserted in a spacing ring. The special structure of the damping pin can greatly reduce vibration and noise. The damping pin can be applied to vibration of the computer chassis, and also can be used in instruments in any weight without excessive resonance noise.

Owner:王一川

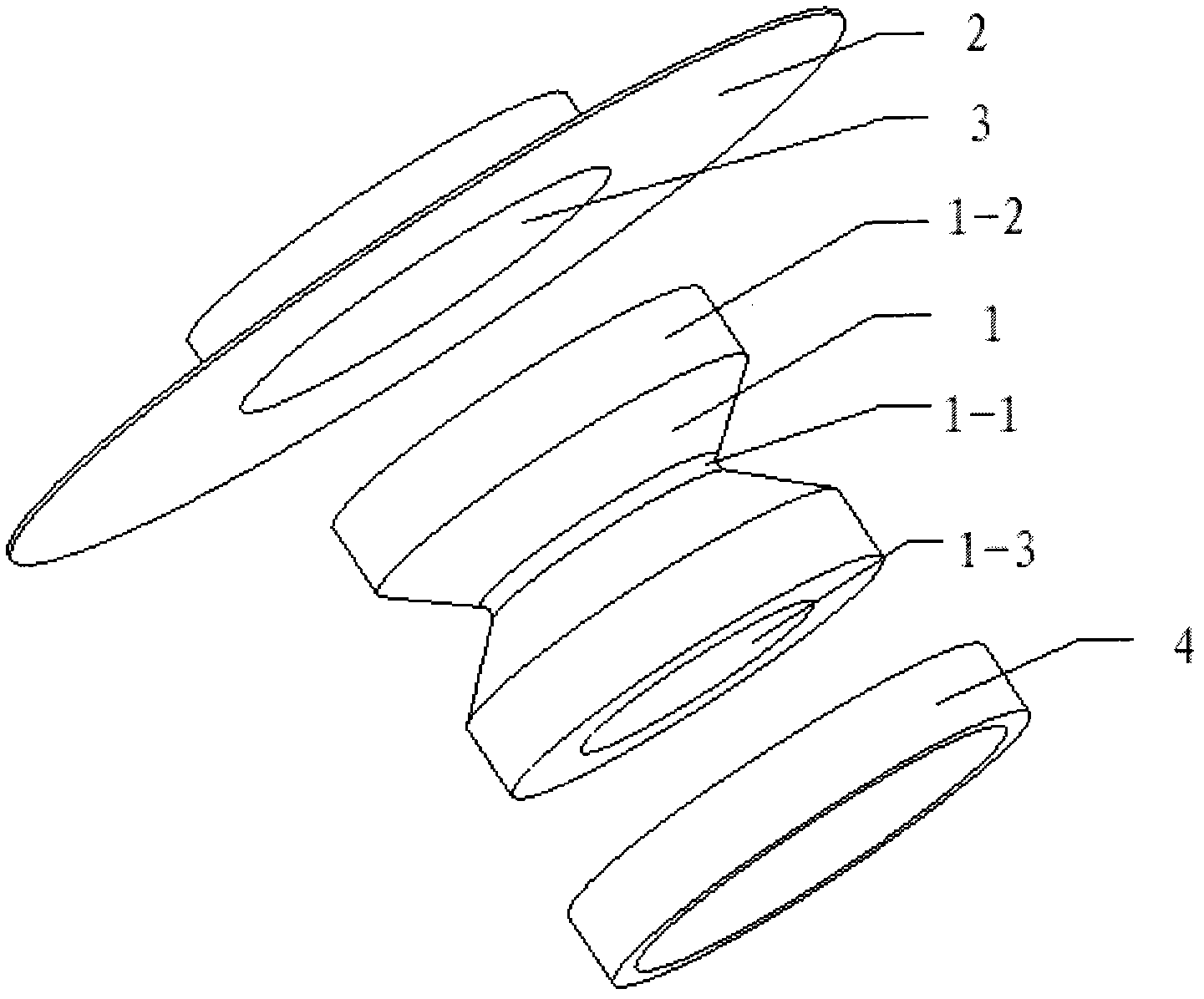

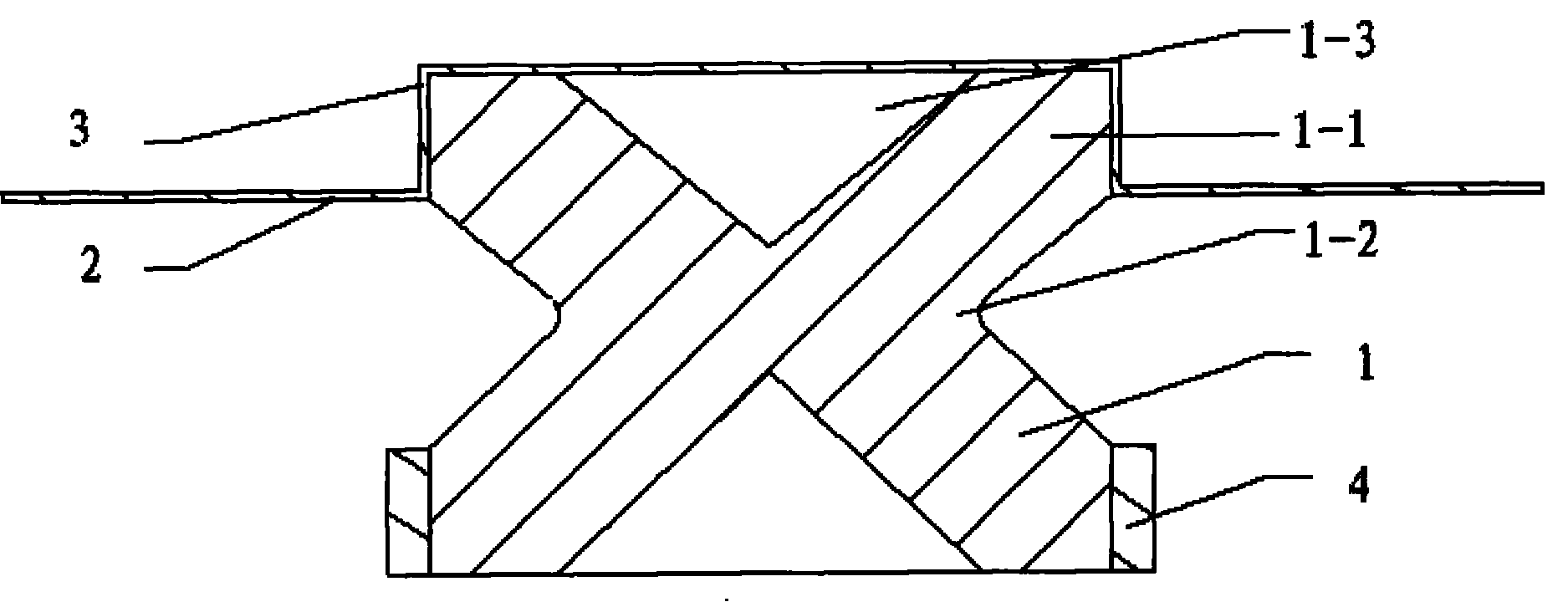

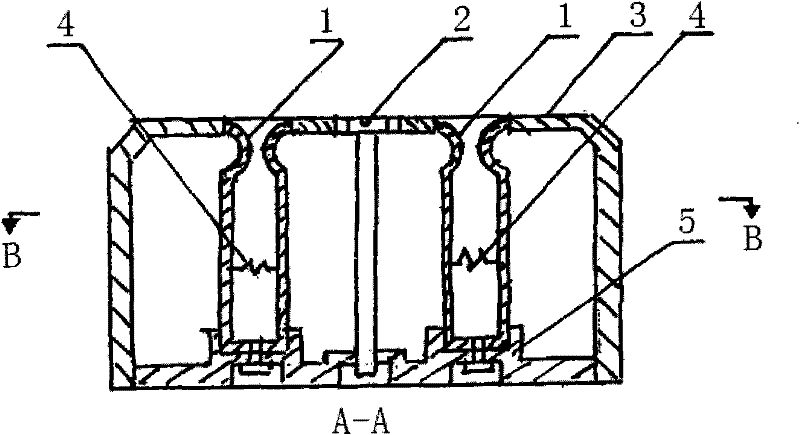

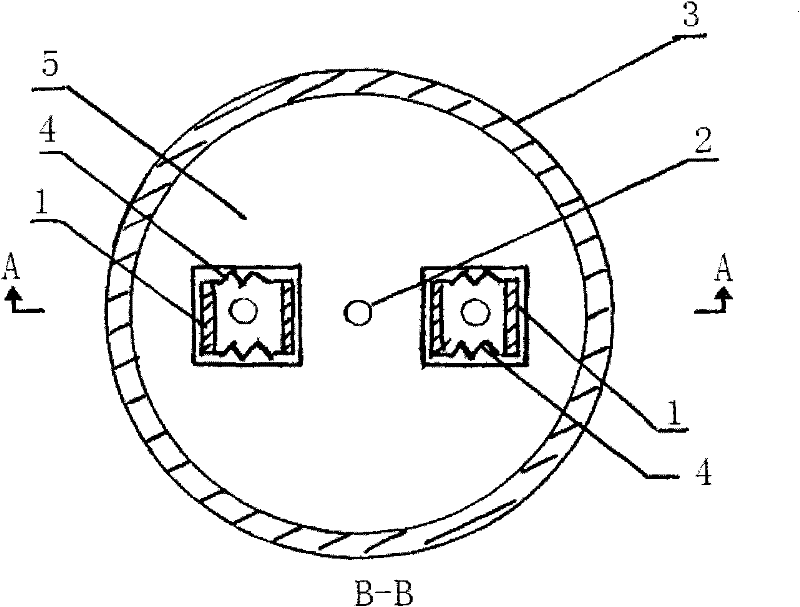

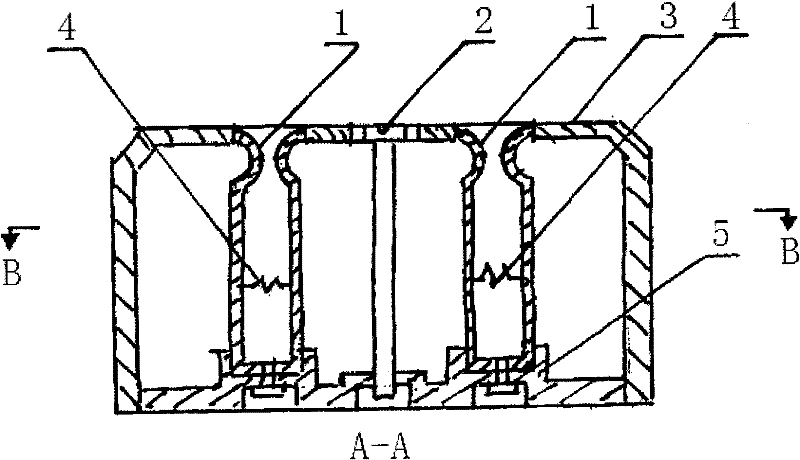

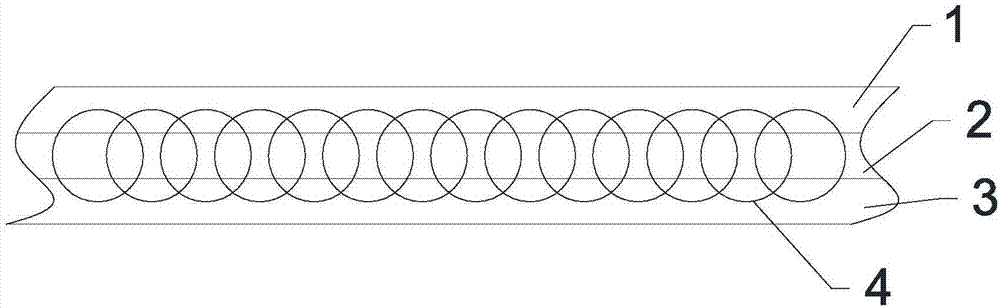

Rubber spring

InactiveCN104019170AAvoid wear and tearImprove interoperabilityHigh internal friction springsEngineering

The invention discloses a rubber spring. The rubber spring comprises a rubber body. The rubber body is of an annular structure. A protruding ring is arranged in the center of the outer wall of the rubber body, a thread groove is formed in the inner wall of the rubber body, a spring body is embedded in the thread groove, and the upper end and the lower end of an inner ring of the rubber body are respectively provided with a lantern ring. Because the spring body and the rubber body are in embedding fit through the thread groove, not only can matching action between the spring body and the rubber body be achieved, but also the spring body can be separated away to be replaced; abrasion to the spring body can be prevented through the lantern rings, and thus the overall elasticity is not influenced.

Owner:JIANGYIN CHANGLE NEW TECH POWER SUPPLY

Cashmere fabric anti-pilling finishing liquor containing modified sericin and preparation method of finishing liquor

InactiveCN106592229APrevent pillingDoes not affect the feelBiochemical treatment with enzymes/microorganismsAbrasion resistant fibresEmulsionChemistry

The invention discloses cashmere fabric anti-pilling finishing liquor containing modified sericin and a preparation method of the finishing liquor. The finishing liquor is prepared from, by weight, 24-48 parts of modified sericin, 11-25 parts of SXA-amino silicone elastomer, 12-26 parts of protease, 8-15 parts of sodium chloride, 3-11 parts of keratin, 5-21 parts of polyethylene wax emulsion, 4-16 parts of magnesium sulfate, 4-15 parts of zinc chloride and 3-11 parts of hydrogen peroxide. The cashmere fabric anti-pilling finishing liquor containing modified sericin can form a protective film on the surface of cashmere fabric aiming at the characteristics of the cashmere fabric, and the cashmere fabric is prevented from pilling; the cashmere fabric anti-pilling finishing liquor containing modified sericin does not affect the hand feeling, elasticity, dyeing fastness and gloss of the fabric.

Owner:JIANGSU AIXISHI TECH SERVICE CONSULTATION CO LTD

Anti-skid sole material and its preparation method

An anti-skid sole material and its preparation method. The anti-skid sole material comprises the following components of: by weight, 130 parts of PS; 118 parts of PE; 120 parts of raw rubber; 20 parts of oil-extended TPE; 12 parts of 2-methyl-1,3-propanediol; 36 parts of zine stearate; 7 parts of dicumyl peroxide and 40 parts of sulphur. The preparation method of the above anti-skid sole material comprises the following steps of: mixing the above materials in proportion, placing a mixture into an internal mixer for smelting, carrying out granulation on the smelted mixture by the use of a comminutor to obtain granules, placing the granules into a water tank, cooling, and drying at the temperature of 80 DEG C. Without the influence on the elasticity, stability, portability and other performance of soles, the material provided by the invention is used to raise skid resistance of soles and reduce the production cost. The preparation method provided by the invention is nontoxic and nonpolluting, and is suitable for large scale production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

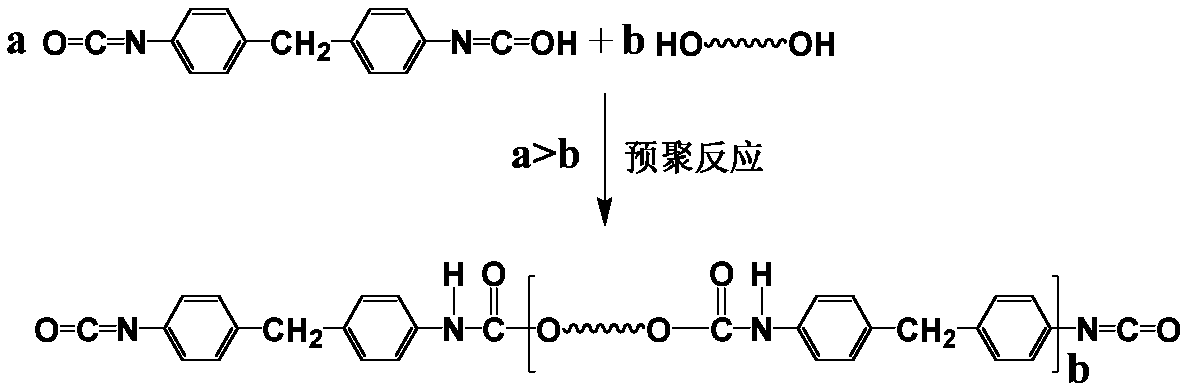

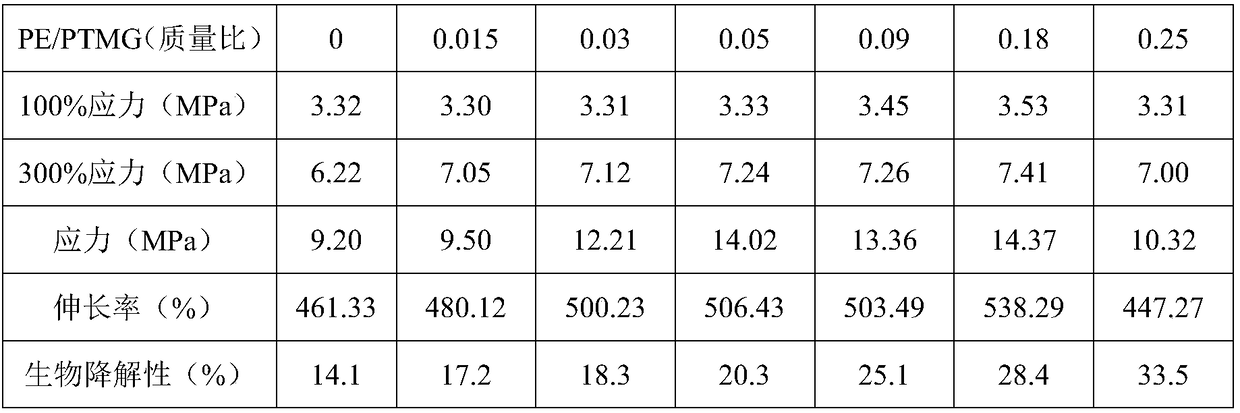

High-performance polyurethane for biological easily degradable spandex and preparation method of high-performance polyurethane

ActiveCN109338504AHigh strengthBiodegradableMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolyesterUltimate tensile strength

The invention discloses high-performance polyurethane for biological easily degradable spandex and a preparation method of the high-performance polyurethane. The high-performance polyurethane is prepared by synthesizing biological easily degradable polyether polyol, polyether polyol, 4,4-diphenylmethane diisocyanate, a chain extender and a functional aid for spandex, wherein the biological easilydegradable polyether polyol accounts for 1-50% of the polyether polyol in the high-performance polyurethane for the biological easily degradable spandex; the biological easily degradable polyether polyol, the polyether polyol and the 4,4-diphenylmethane diisocyanate are subjected to a copolymerization reaction to generate a high-performance prepolymer, and high-performance spandex spinning stosteis prepared through a chain extension reaction. The polyurethane for the spandex prepared with the method has the characteristics of biological easy degradation, high strength, high modus and the like.

Owner:ZHEJIANG HUAFENG SPANDEX

Preparation method of protective sole material

InactiveCN102850633ASimple preparation processReduce manufacturing costSolesWaxTemperature resistance

The invention discloses a preparation method of a protective sole material, which comprises the following steps: adding 100-105 parts by mass of HDPE (high-density polyethylene), 70-80 parts by mass of PP (polypropylene) powder, 16-22 parts by mass of PET (polyethylene terephthalate), 8-9 parts by mass of PE (polyethylene) wax, 3-6 parts by mass of lead stearate, 6-8 parts by mass of sodium benzoate, 3-6 parts by mass of spherical silicon dioxide and 7-8 parts by mass of PA 6 (polyamide 6) into a high-speed mixing machine, and mixing for 10 minutes; and adding the mixture into a double screw extruder, and carrying out melt grafting for 3 hours to obtain the sole material. The method disclosed by the invention has the advantages of simple preparation technique and low production cost; and the protective sole material has the advantages of high elasticity, favorable electric insulativity, high temperature resistance and light weight, and is comfortable.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

Wear-resistant anti-static sole material

InactiveCN102850760ADoes not affect elasticityImprove antistatic performanceSolesWear resistantHardness

The invention discloses a wear-resistant anti-static sole material, which is made from the following raw materials by weight: 75-78 parts of polycarbonate, 40-45 parts of fluorine silica gel, 30-35 parts of polyetheretherketone, 20-22 parts of methylpropanediol, 8-9 parts of aniline, 7-9 parts of acetone, 5-9 parts of white carbon black, 20-24 parts of rice bran, and 30-32 parts of lubricating oil. Under the premise of not influencing the due elasticity, hardness and other properties, the sole material provided in the invention has greatly improved antistatic property and wear resistance, and is suitable for industrialized production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

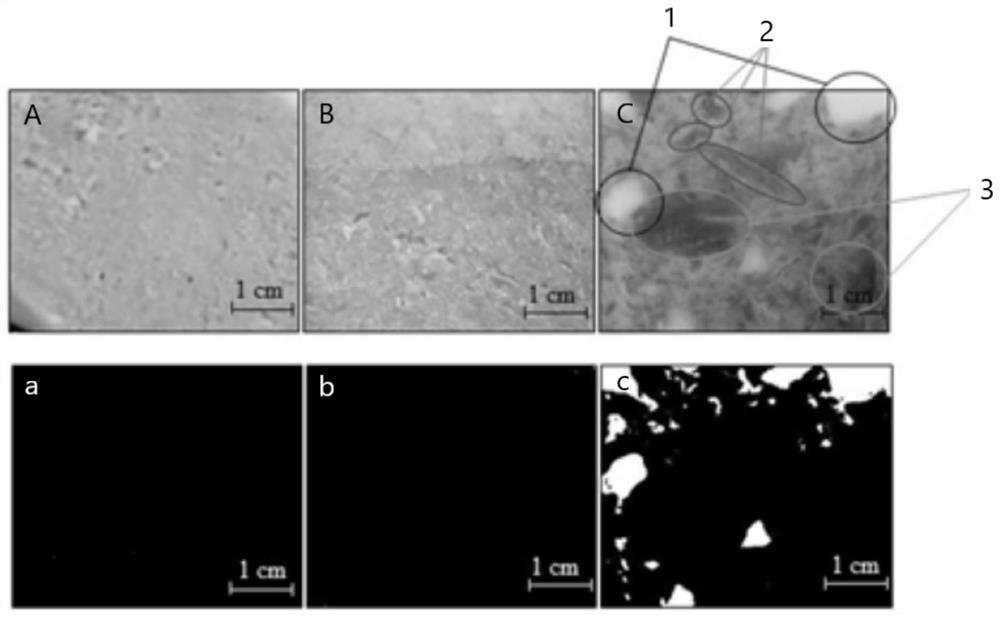

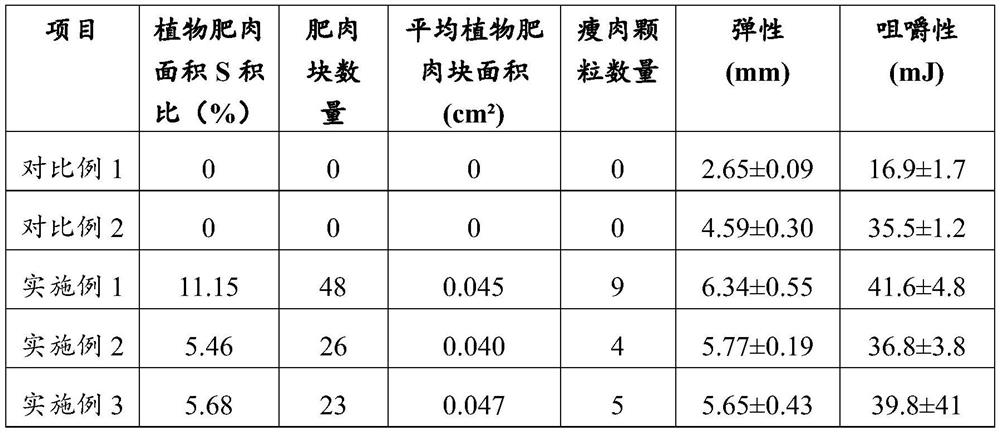

Plant-based meat product and prepared food

PendingCN113995048ADoes not affect elasticityDoes not affect chewabilityProteins working-up by texturisingLipidic food ingredientsBiotechnologyTissue protein

The invention relates to the technical field of food processing, particularly discloses a plant-based meat product, and also discloses a food prepared from the plant-based meat product. The plant-based meat product provided by the invention contains plant-based lean meat granules, fat meat granules and shredded meat, and the fat meat granules are embedded into the meat product, so that the greasy feeling of the meat product is improved, filamentous tissue proteins are respectively used as the plant shredded meat and the shredded meat granules in the meat product, a better meat fiber feeling is provided, and the quality of the plant-based meat product is integrally improved. The plant-based meat product provided by the invention has elasticity and meat fiber feeling and is good in overall chewiness, and the layering sense of taste is improved.

Owner:植物肉(杭州)健康科技有限公司

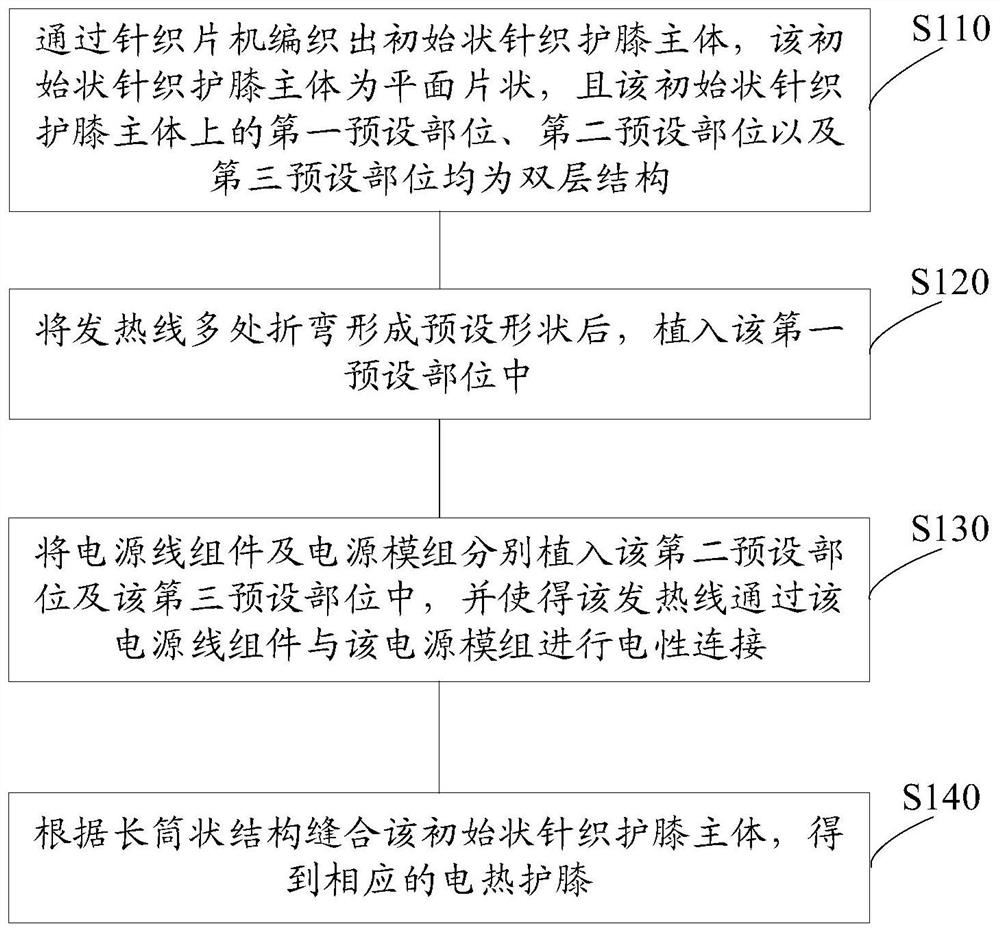

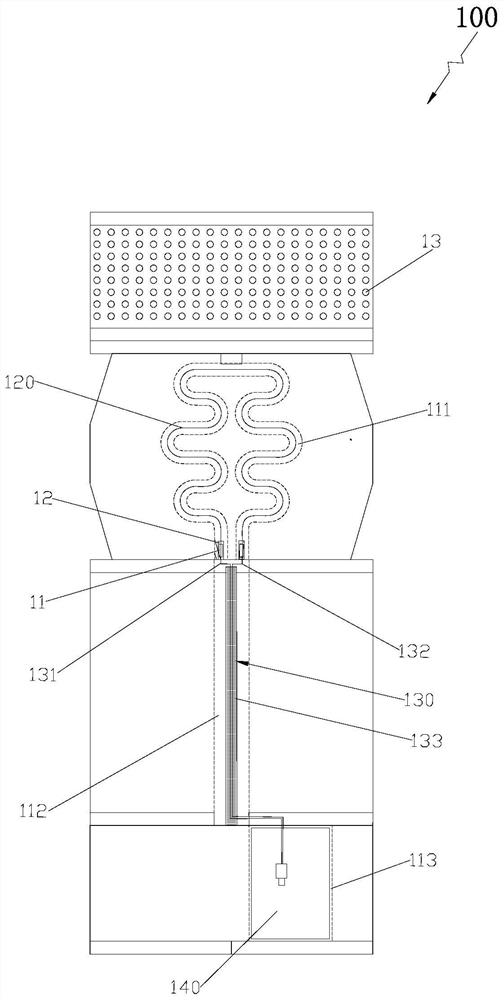

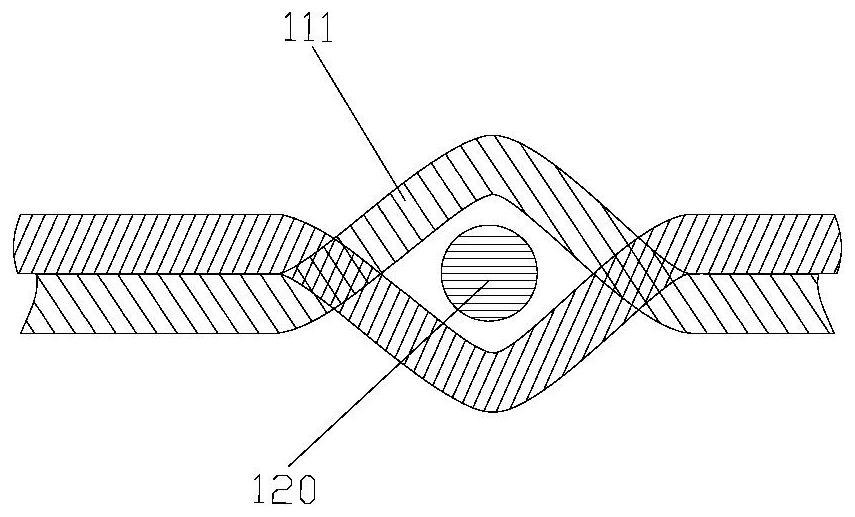

Manufacturing process of electric heating kneecap

InactiveCN112315051ABeautiful craftsmanshipRealize the heating functionGarment special featuresHeating element materialsProcess engineeringBandage

The invention provides a manufacturing process of an electric heating kneecap, and belongs to the technical field of electric heating products. The process comprises the following steps: knitting an initial knitted kneecap main body in a plane sheet shape by using a sheet knitting machine, and the first preset part, the second preset part and the third preset part on the initial knitted kneecap main body are of double-layer structures; bending a plurality of parts of the heating wire to form a preset shape, and implanting the heating wire into a first preset part; respectively implanting the power line assembly and the power supply module into the second preset part and the third preset part, and enabling the heating line to be electrically connected with the power supply module through the power line assembly; and sewing the initial knitted kneecap main body according to the long cylindrical structure to obtain the corresponding electric heating kneecap. According to the technical scheme, the technical problem that an existing electric heating kneecap is poor in wearing experience due to the fact that the existing electric heating kneecap only can adopt a bandage type sheet structure through heating of the heating sheet can be effectively solved.

Owner:深圳市嘉良合科技有限公司

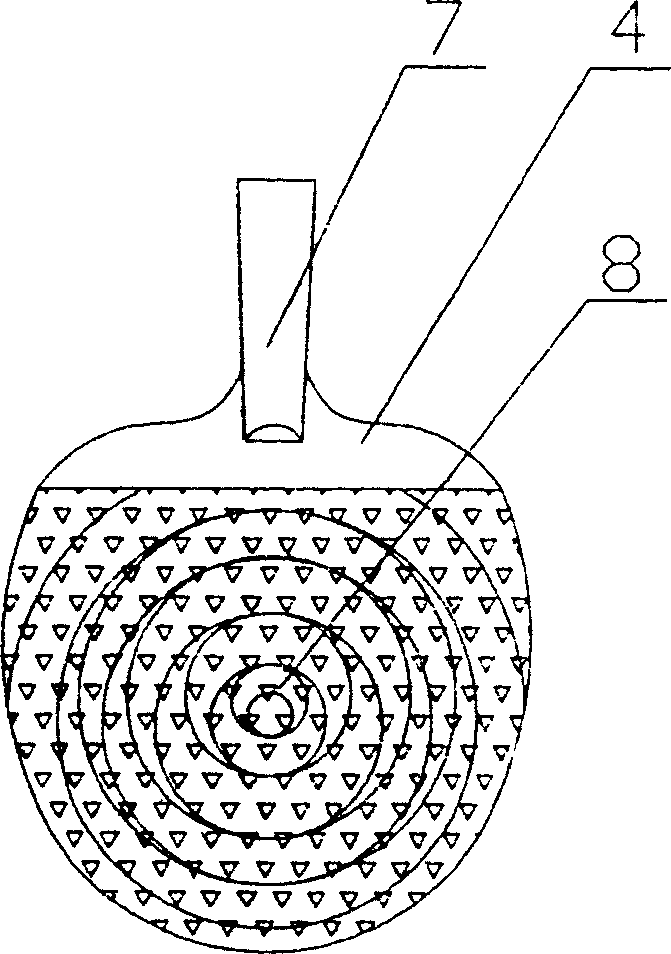

Table tennis bat with perspective image on surface and manufacturing process thereof

InactiveCN1669607ADoes not affect elasticityImprove printing qualityRacket sportsColor imageMicrochiroptera

The invention belongs to the field of physical training apparatus, relates to a kind of table tennis bat whose surface can penetrate images and its manufacturing technique. The invention comprises a bat baseboard, a bat handgrip, a elasticity inlay at the bat baseboard. There are transparent colloidal particle inlay rubber, image thin layer or transparent rubber, image thin layer and colloidal particle inlay in the elasticity inlay. Producing transparent image rubber by extruding or high frequency or ejection forming method, and formed indirectly stick to the middle elasticity inlay or directly stick to the bat baseboard. The invention can make the inner color images be seen from the exterior, the bat surface design connotation abundant, the image stereo, and increase the attractive power of the bat itself but do not affect the surface elasticity of the table tennis bat.

Owner:李建飞

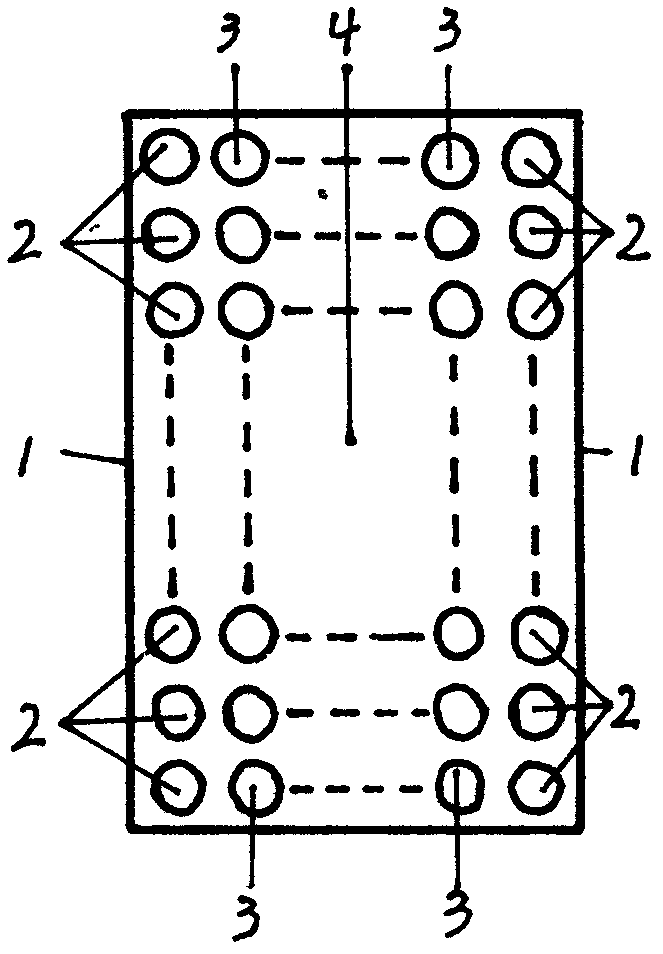

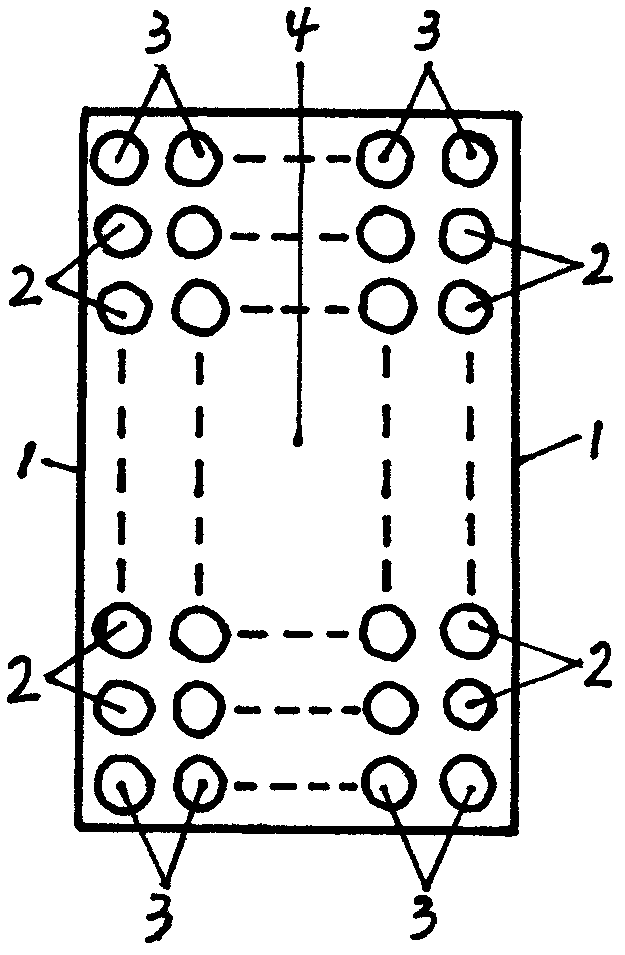

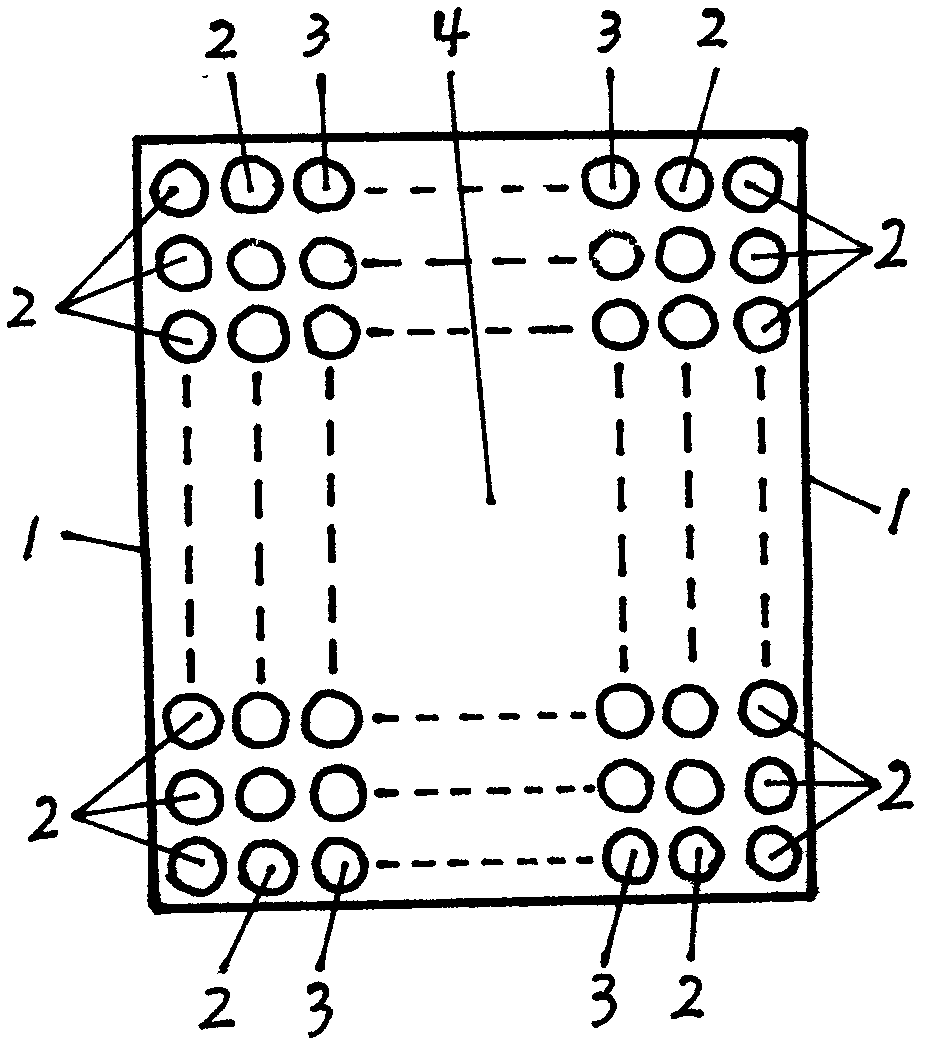

Single-phase power socket

InactiveCN102544837ADoes not affect elasticityGood electrical contactSecuring/insulating coupling contact membersElectricityEngineering

The invention relates to a single-phase power socket, which comprises two copper contacts, an outer cover and a bottom board. Two springs are connected to copper plates on two sides of the middle of each copper contact respectively, the two copper contacts are connected with the bottom board through a screw, and the outer cover is fixed on the bottom board through the screw. The single-phase power socket has the advantages of fine electrical contact, less proneness to heating, and long service life as elasticity of the springs is unaffected in long-term use.

Owner:范益明

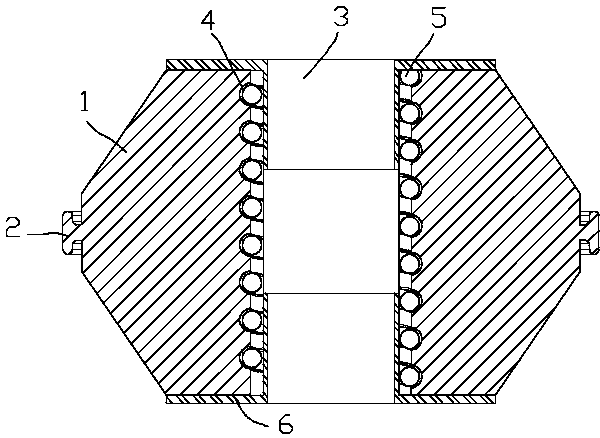

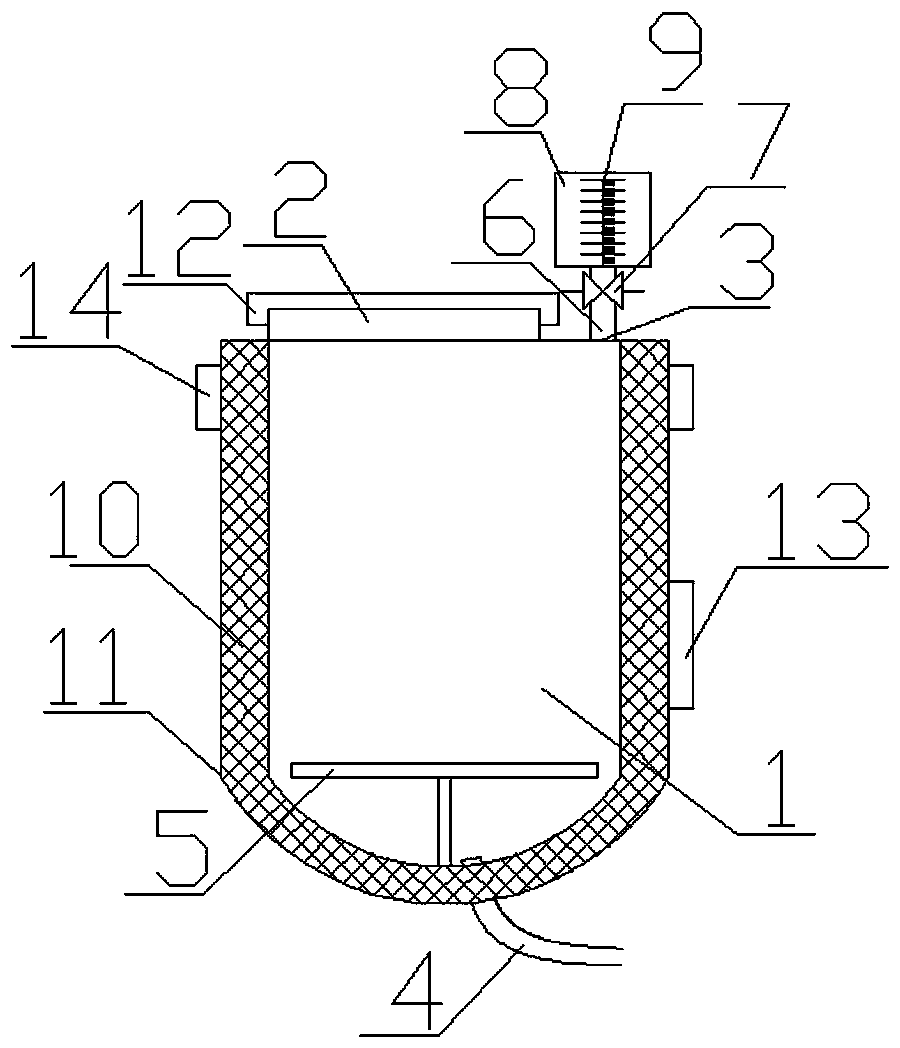

Dyeing device of elastic fabric and dyeing method using dyeing device

InactiveCN108385297AAccurate ingredientsEasy to dyeTextile treatment machine arrangementsDyeing processFiberCarbon fibers

The invention discloses a dyeing device of an elastic fabric and a method thereof and relates to the field of dyeing of fabrics. The dyeing device comprises a dyeing jar and a carbon fiber heating sheet, wherein a stirring device is arranged inside the dyeing jar; a feeding opening is formed in the upper side of the dyeing jar; a liquid inlet is formed in the side of the upper part of the dyeing jar; a liquid inlet pipe is arranged above the liquid inlet; a measuring cylinder is arranged above the liquid inlet pipe; volume scales are arranged on the surface of the measuring cylinder; the carbon fiber heating sheet is arranged at the exterior of the dyeing jar; a shell is arranged at the exterior of the carbon fiber heating sheet. The method comprises the following steps: firstly adding a dye I into the dyeing jar and then uniformly stirring, then adding a dye II into the dyeing jar, stirring and increasing the temperature to 70 DEG C, then putting a fabric to be dyed into the dyeing jar and soaking for 30 minutes, continuously increasing the temperature of the dyes to 100 DEG C and then naturally cooling in the soaking process, then taking the soaked fabric out and drying the fabric, finally rinsing the dried fabric with water and then naturally drying the fabric in the sun. Through the dyeing device and the method thereof, the surface color of the dyed fabric is more uniform;meanwhile, the elasticity of the elastic fabric is also not influenced.

Owner:张家港普坤毛纺织染有限公司

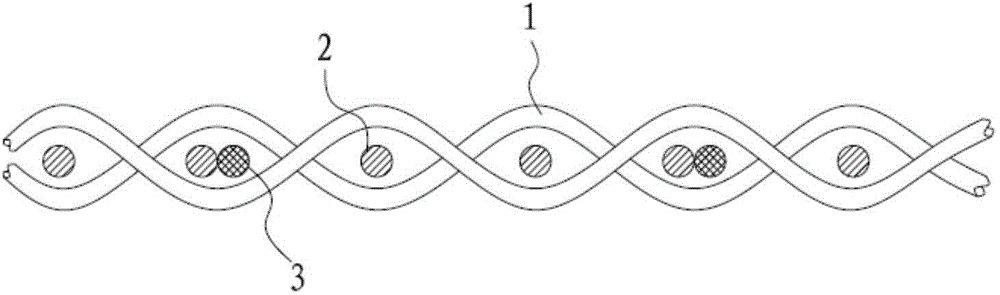

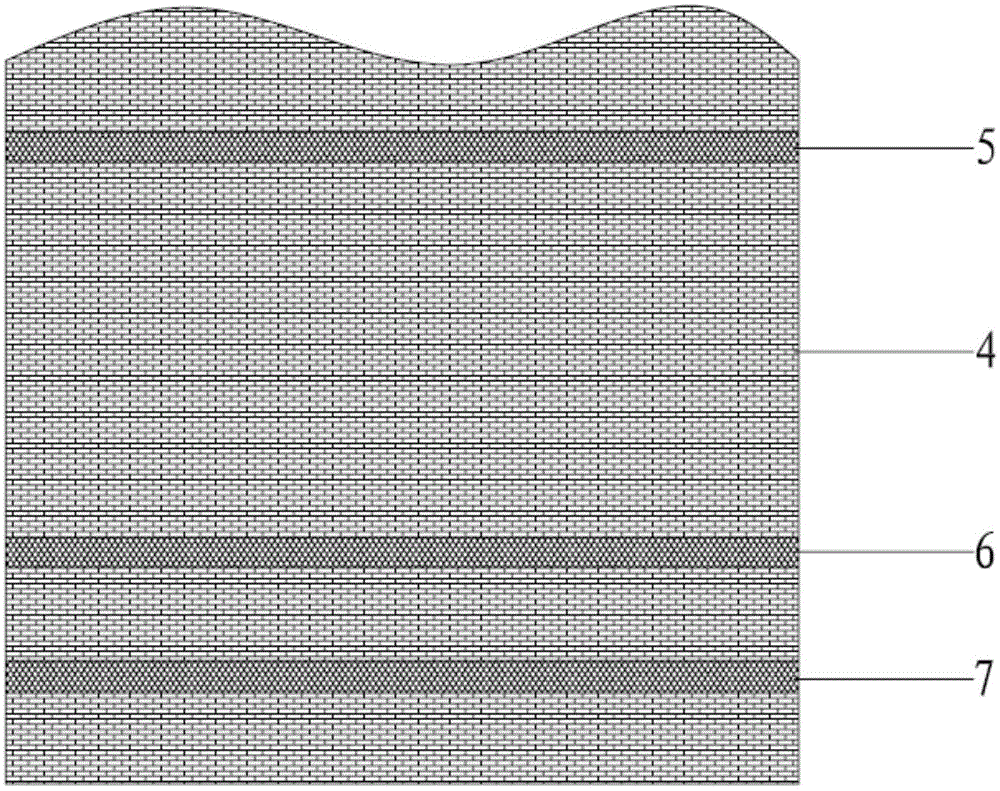

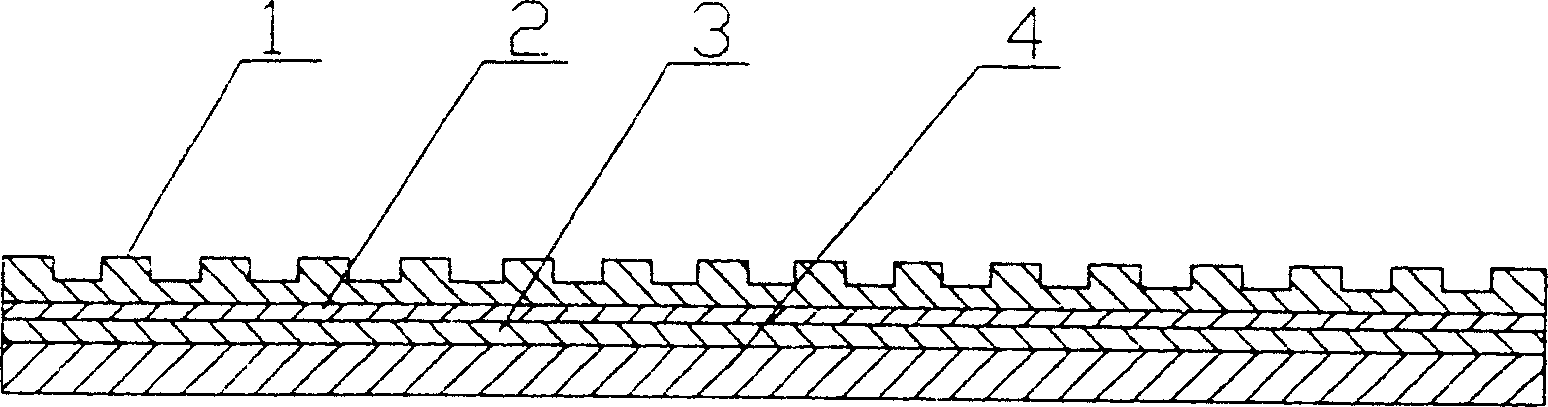

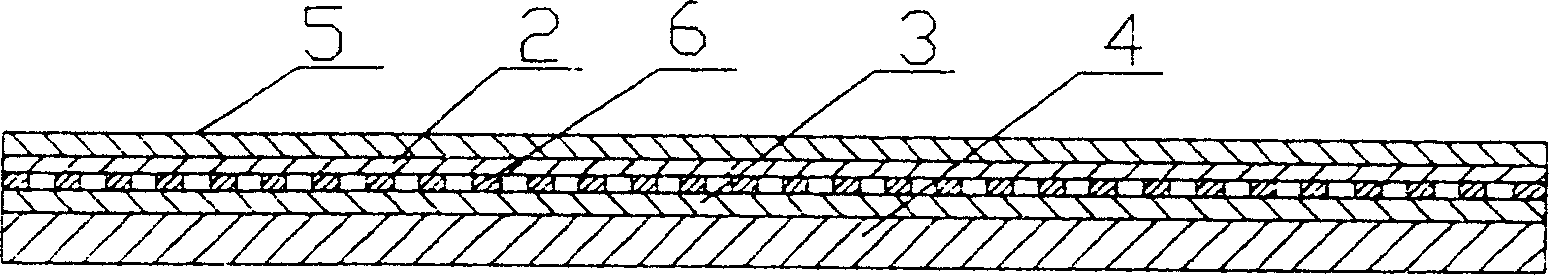

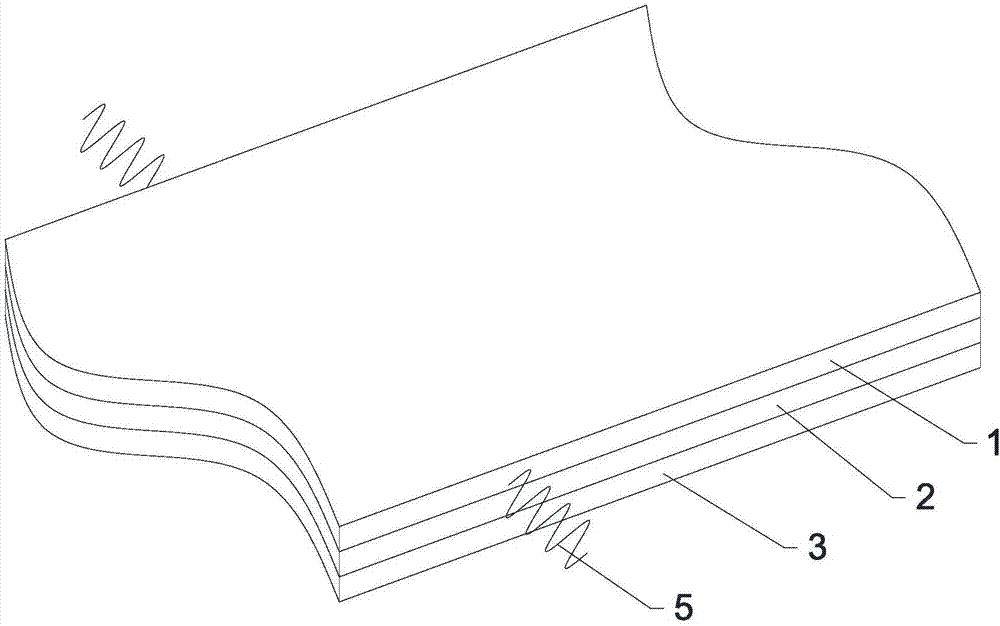

Anti-radiation fabric and preparation method thereof

InactiveCN107234845AImprove textureImprove shielding effectFibre typesSynthetic resin layered productsYarnSilver plate

The invention discloses an anti-radiation fabric, which comprises a surface layer, a middle layer and a lining layer, wherein the surface layer, the middle layer and the lining layer are fixedly connected with each other through a plurality of spiral connecting layers; the spiral connecting layers enter from one side of the anti-radiation fabric and exit from the other side; the upper ends of the spiral connecting layers are connected with the surface layer; the spiral connecting layers pass through the middle layer, and then the lower ends of the spiral connecting layers are connected with the lining layer; the lining layer is weaved from silver nylon multifilament; the middle layer is made from mulberry silks; the surface layer is made from the blended yarns of the regenerated cellulose fiber and the silver nylon multifilament; and the connecting layers are made from silver-plated yarns. According to the invention, the shielding function for electromagnetic waves is enhanced, the shielding effect is excellent and the spiral connecting layers have no influence on the elasticity, texture and hand feeling of the cloth.

Owner:NANCHANG JOYNCLEON CLOTHING

Wear-resistant sole material and preparation method thereof

InactiveCN102336938ADoes not affect elasticityDoes not affect resilienceSolesOrganosiliconCarbon black

The invention discloses a wear-resistant sole material and a preparation method thereof. The wear-resistant sole material comprises the following components in part by weight: 108 parts of thermoplastic styrene-butadiene rubber, 20 parts of white carbon black, 22 parts of diethylene glycol, 36 parts of polystyrene, 42 parts of naphthenic oil, 18 parts of magnesium oxide, 11 parts of calcium-zinc salt and 18 parts of organosilicon foam stabilizer. The preparation method for the wear-resistant sole material comprises the following steps of: mixing the raw materials in the ratio and banburying in a banbury; granulating the mixture subjected to banburying by using a granulator to obtain granules; and cooling the granules in a water tank, and drying at room temperature. The material greatly improves the wear resistance of a sole on the premise of not influencing due elasticity, recoverability, portability and other properties of the sole, and is nontoxic and pollution-free, safe and environment-friendly.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

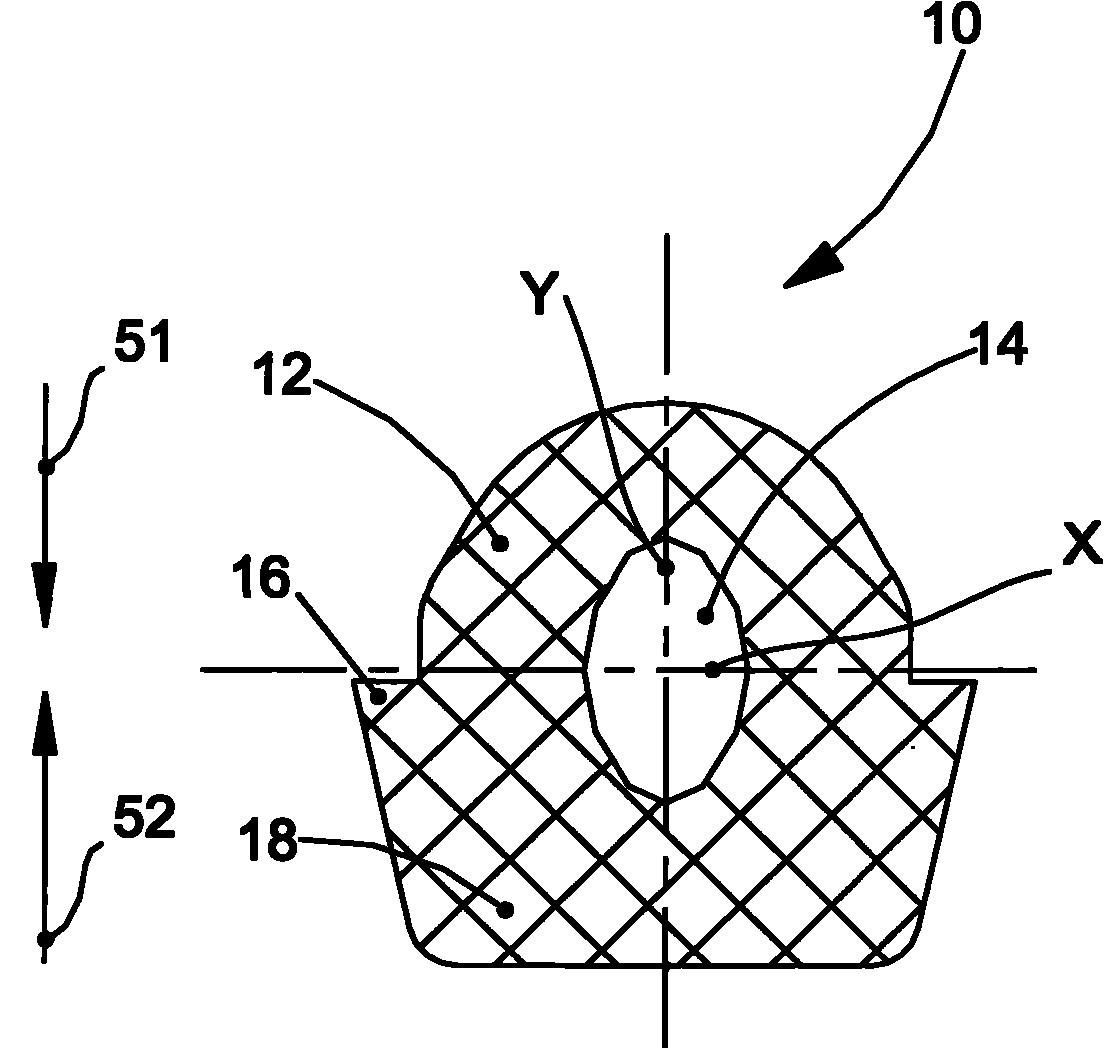

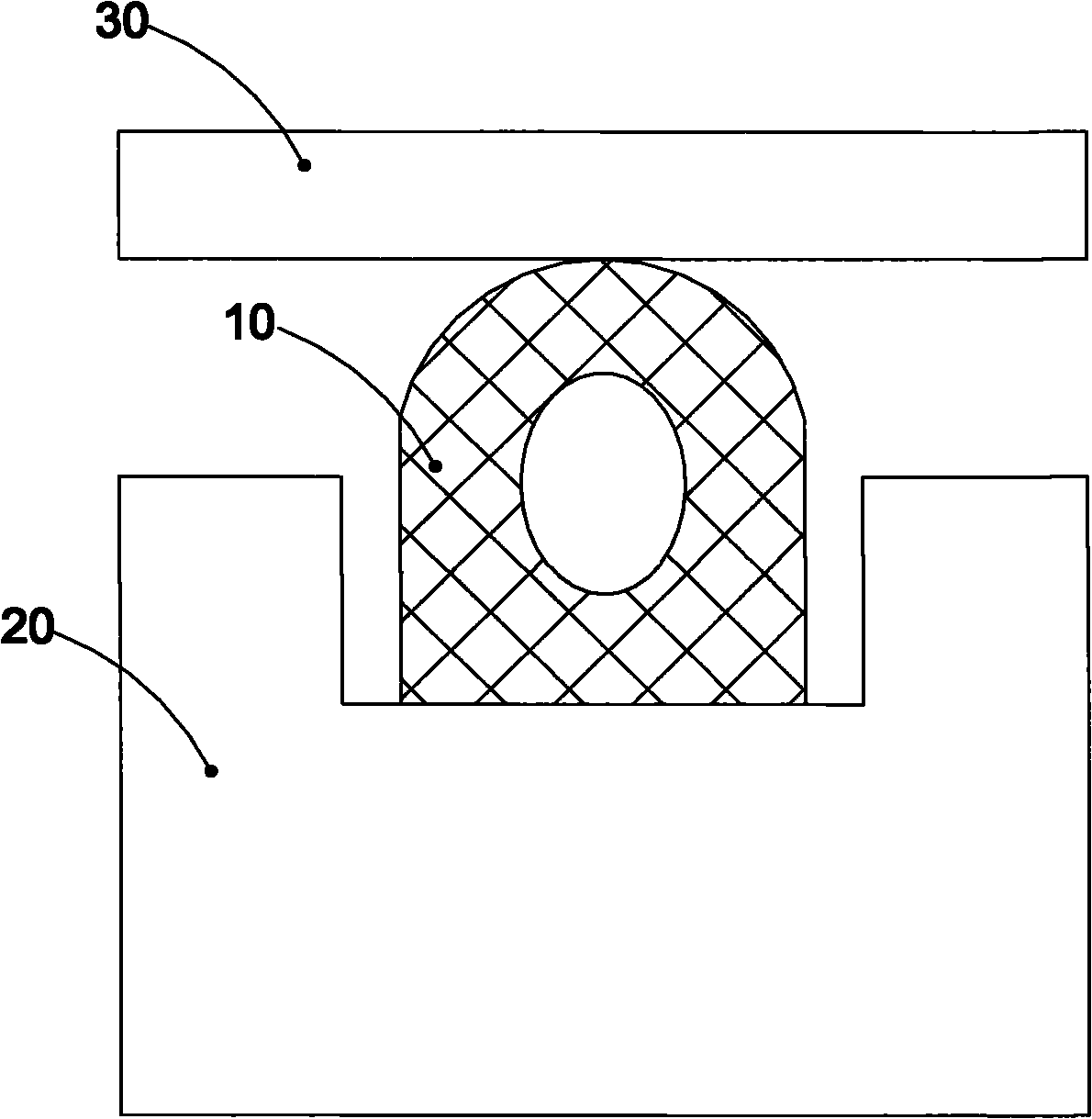

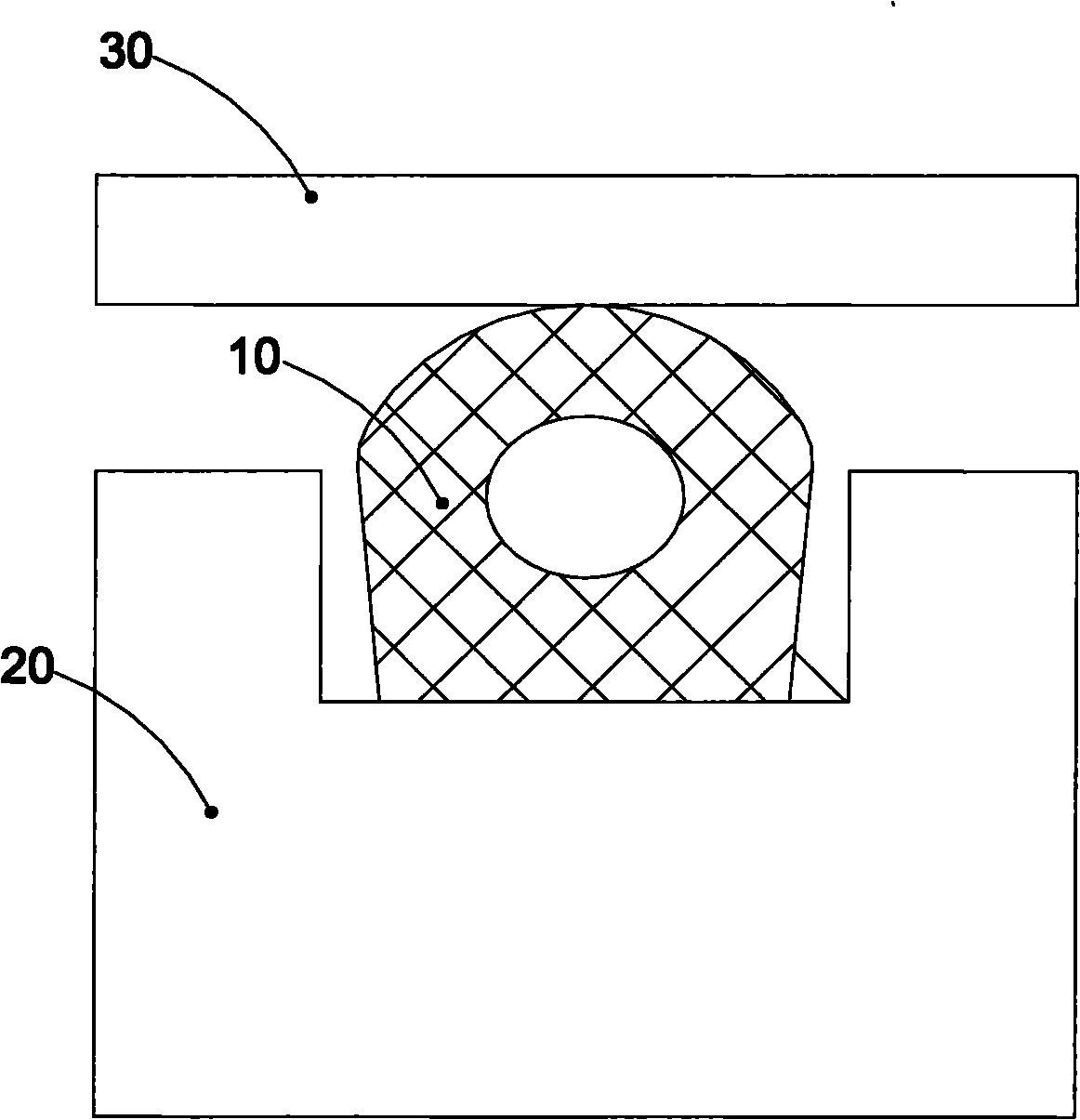

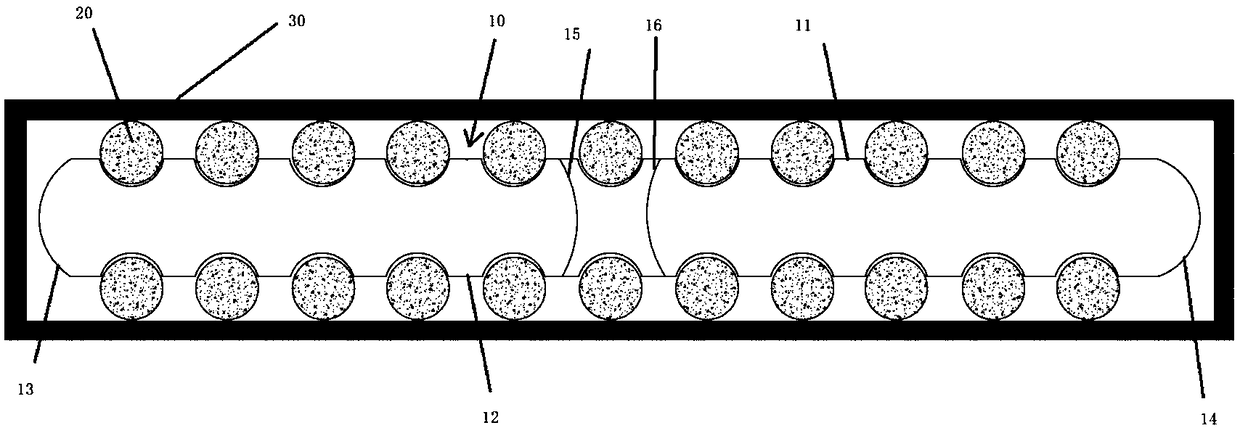

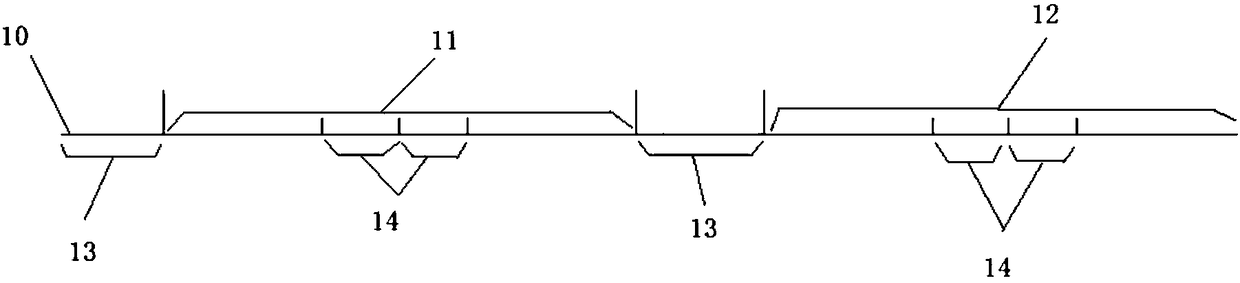

Sealing gasket bar for automobile lamp and preparation method

InactiveCN108177294AWith structural strengthElasticGas-tight/water-tight arrangementsThermoplastic polyurethaneToughness

The invention relates to a sealing gasket bar for an automobile lamp and a preparation method. The sealing gasket bar comprises an annular steel ring (10) with the outer surface being provided with aplurality of evenly-distributed hemispherical concave points, thermoplastic polyurethane elastic particles (20) fixed to the corresponding concave points, and a teflon shell (30) wrapping the particles (20). The sealing gasket bar has ultrahigh airtightness, elasticity and external toughness.

Owner:JIANGSU YUANYANG CAR LAMP

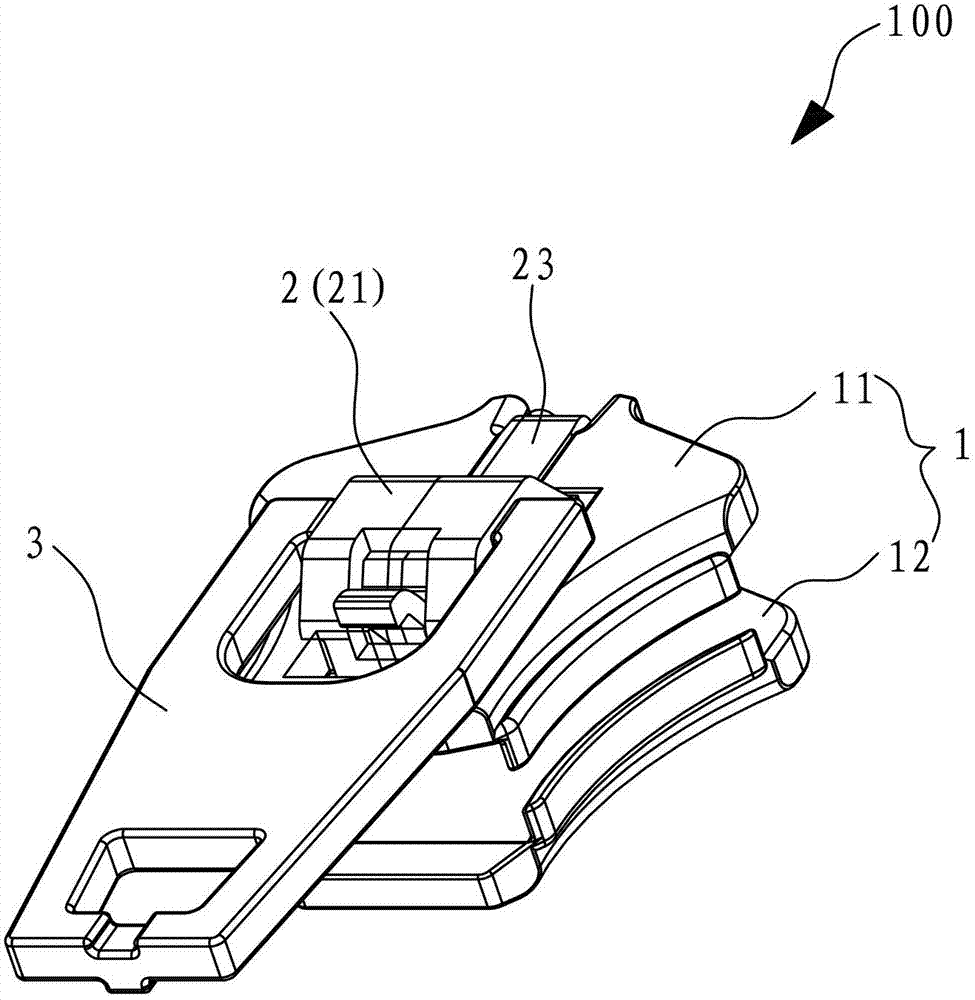

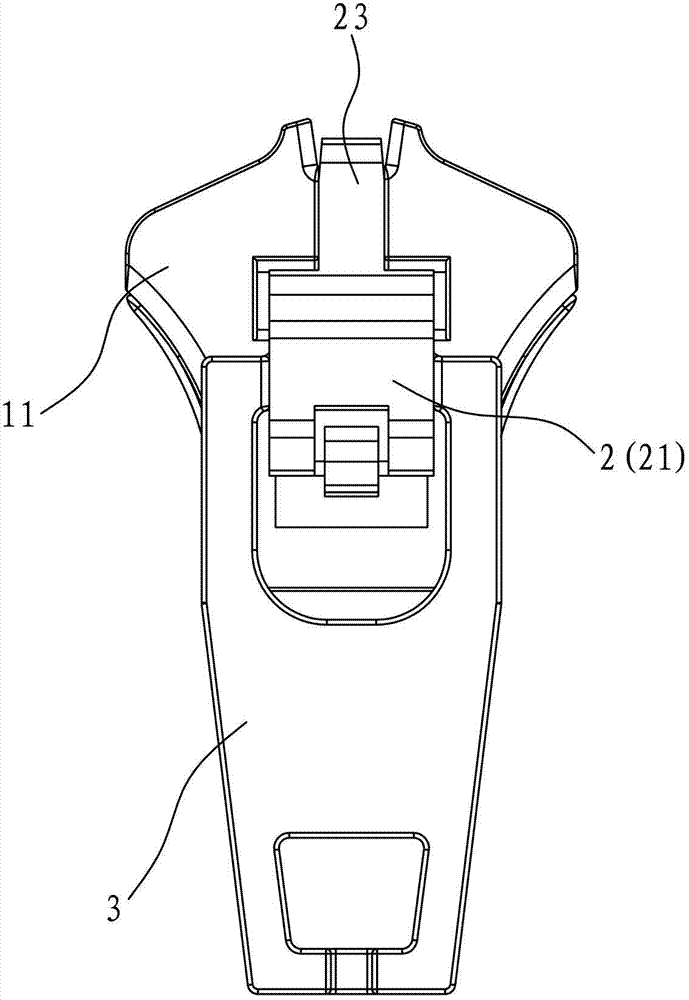

Planar pull head

ActiveCN102771962AEliminate hand scratchingReduce the inconvenience of clogging the trouser lineSlide fastenersEngineering

The invention discloses a planar pull head which comprises a pull head body, an elastic piece and a pull piece; the pull head body is provided with an upper fin, a lower fin and a guide column; the elastic piece is provided with a central base part, a locking pawl which is arranged on the rear end of the central base part and a front end part which is arranged on the front end of the central base part; the pull piece is provided with a handle and an eccentric shaft, and the eccentric shaft can be arranged in a space formed by the central base part and the upper fin and is hidden by the central base part; the planar pull head is characterized in that the elastic piece also comprises a supporting pawl which is arranged on the front end of the central base part; a T-shaped sink is arranged on the upper fin, i.e. a horizontal groove and a vertical groove are arranged; the front end part is contained in the vertical groove of the T-shaped sink, so that the upper surface of the front end part is level with or lower than the surface of the upper fin; and the supporting pawl is inlaid into the horizontal groove and is collided with the groove wall of the horizontal groove. According to the planar pull head, the problems that wires are clamped, the hands of a user are injured, the elastic force of the elastic piece easily loses effect and the like in daily use can be solved, and the planar pull head has the advantages of simplicity in structure, convenience in processing and assembly and the like.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

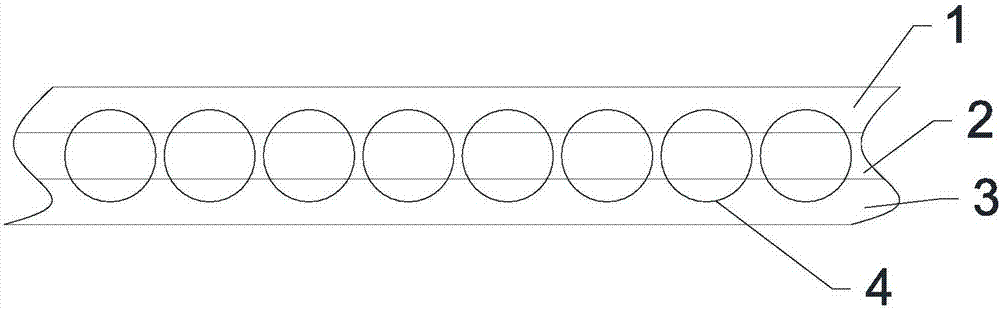

Spring mattress with edge being not easy to collapse

InactiveCN102871417ADoes not affect elasticityNo collapse phenomenonStuffed mattressesSpring mattressesEngineeringMechanical engineering

Owner:江苏君梦美床垫有限公司

Antistatic sole material

InactiveCN102875997ADoes not affect elasticityDoes not affect hardnessSolesPolycarbonatePolypropylene

The invention discloses antistatic sole material which comprises the following materials by weight: 50-70 parts of polypropylene, 110-120 parts of polycarbonate, 30-40 parts of chlorosulfonated polyethylene rubber, 20-24 parts of diethylene glycol, 12-15 parts of triethanolamine, 8-9 parts of carbon black, 11-13 parts of dibutyl ether, 12-14 parts of sulfur, and 20-30 parts of white oil. Under the premise of uninfluenced elasticity, hardness and other performances of sole, the sole material has greatly improved antistatic property, and is suitable for industrialized production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com