Fabric and curtain interwoven with hot-melt yarn

A hot-melt and hot-melt technology, applied in the field of curtains and fabrics interwoven with hot-melt filaments, can solve the problems of inability to achieve natural folding, affect the flatness of the curtains, increase the difficulty of curling, etc., achieve a good feel, and promote a tight structure. , Improve the effect of folding to the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

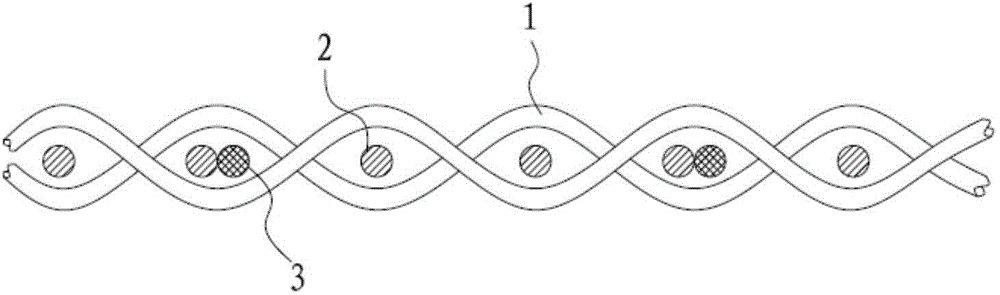

[0036] Such as figure 1 The fabric shown is a plain weave structure, including interwoven warp yarns 1 and weft yarns 2, and a thermal fuse 3 is arranged in the middle of the weft yarn 2. One is a thermal fuse 3 and the other is a non-thermal fuse.

[0037] Wherein, the non-thermofusible yarn is used as a side yarn, and after the thermal fuse 3 is melted, it is interwoven with the warp yarn 1 to maintain the structure of the fabric.

[0038] If the fabric is twill weave or other structures, the warp 1 opening is equivalent to the interweaving position of the weft. At this time, there are more than two wefts in the warp 1 opening, and one of the wefts should be a thermal fuse 3.

[0039] At the same time, in another embodiment, according to the purposes of the fabric, the thermal fuses 3 are arranged at intervals in the warp yarns, that is to say, the weft openings in which the thermal fuses 3 are inserted are also provided with side wires, and the side wires After the therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com