Patents

Literature

90results about How to "Prevent pilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

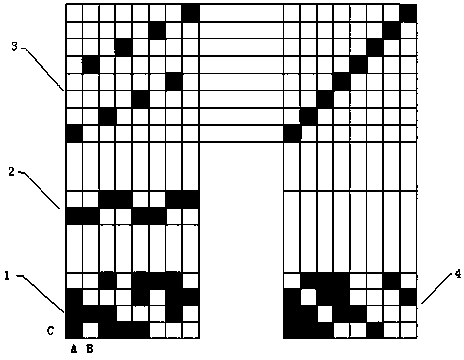

Warp backed weave double cloth weaving process

ActiveCN104278407AEasy to operatePrevent static electricityFibre treatmentMulti-ply fabricsHemp fiberSizing

The invention discloses a warp backed weave double cloth weaving process. The process comprises the following processing steps of spooling, warping, preparing size, sizing, denting, weaving and finishing. According to the process, one side, exposing JC27.8Tex+40D warp yarns, of a fabric formed by processing the JC27.8Tex+40D warp yarns and JC / H(60 / 40)21.6Tex warp yarns serves as an outer layer to ensure the stiffness and smoothness and the style keeping property of clothes, the other side exposing the JC / H(60 / 40)21.6Tex warp yarns serves as an inner layer, hemp fibers have high moisture absorption and moisture exhaust properties, the inner layer of the fabric can timely absorb and exhaust sweat of a human body and water vapor, and the wearing comfort of the clothes is improved.

Owner:JIHUA 3542 TEXTILE CO LTD

Method of staining copper ammonia fiber and tencel interwoven cloth

ActiveCN101016683AFeel goodIncrease elasticityLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonCellulose

The invention relates to a dying method of copper ammonia fiber and silk interwoven cloth, comprising that (1) washing with water, (2) refining, (3) washing with cellulose, (4) dying. And the fur burning process is purpose to remove silk fiber exposed outside the interwoven cloth and the short flannel, eyebrow and foreign material adhered on the face of cloth. The water washing process is purposed to clean the dirt on the face of interwoven cloth. The refining process is purposed to remove the slurry, grease of wrap and the dirt on the face of cloth. The cellulose washing process is purposed to remove the hair generated by fibrosis, to avoid balling. The inventive product has the appearance of silk brocade cloth and improves bacteria resistance function.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Production method of anti-pilling cashmere sweater

The invention discloses a production method of anti-pilling cashmere sweater. The method comprises the following steps that cashmere and milk protein fiber are blended, in the twisting step, the single twist of the cashmere blended yarns is 520-550 twists / m, the twisting direction is the Z-twisting direction, in the double twisting step, the joint stock twist of the cashmere blended yarns is 360-380 twists / m, the twisting direction is the S-twisting direction, the joint stock and single twist ratio is 0.32-0.47, then, the anti-pilling cashmere sweater is obtained through the steps of weaving, sweater forming and tidying, and the cashmere and the milk protein fiber are blended according to a mass ratio being 5:(1-2). The cashmere sweater can not generate pilling after long-time use, meanwhile, a good antibacterial effect can be realized, and the service life of the cashmere sweater is long.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

Wool product for preventing electric radiation and manufacturing technology thereof

PendingCN107237038AGood anti-electron radiation effectPromote absorptionWeft knittingBiochemical treatment with enzymes/microorganismsYarnPolyester

The invention provides a wool product for preventing electric radiation. The wool product comprises 10-20% of wool fiber, 30-40% of modified polyester fiber, 25-35% of silver-coated filament and 15-35% of bamboo pulp fiber, wherein the silver-coated filament is coated with the modified polyester fiber to form core spun yarn, the core spun yarn, the wool fiber and the bamboo pulp fiber are blended to form fabric with a function of preventing the electric radiation. Through the coordination of a manufacturing technology, the wool product which has a high electromagnetic shielding effect, comfortable in handfeel, is suitable for being worn can be obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

Anti-pilling and washable wool knitted trousers material and process for preparing same

InactiveCN106757714AShrinkage stablePrevent pillingWeft knittingHeating/cooling textile fabricsPolyesterPolymer science

The invention discloses an anti-pilling and washable wool knitted trousers material and a process for preparing the same. The anti-pilling and washable wool knitted trousers material is a jacquard double-faced fabric and comprises fabric faces and fabric bottoms. Cotton yarns and wool yarns are patterned to form the fabric faces; wool yarns and polyester filaments are interwoven with one another to form the fabric bottoms; Australian wool silver, acrylic fibers and viscose fibers are blended to obtain the wool yarns. The process includes carrying out dyeing, silver mixing and combing treatment and carrying out spinning by the aid of a spinning frame to obtain single yarns; carrying out automatic winding, doubling and re-twisting and yarn steaming treatment on the single yarns; weaving the wool yarns, the polyester filaments and the cotton yarns to obtain grey fabrics of the jacquard double-faced fabric; carrying out fulling and washing treatment on the grey fabrics of the jacquard double-faced fabric and then drying the grey fabrics of the jacquard double-faced fabric; carrying out water type approval and over-feed treatment, shearing technologies and decatizing on the dried grey fabrics of the jacquard double-faced fabric to obtain the anti-pilling and washable wool knitted trousers material. The anti-pilling and washable wool knitted trousers material and the process have the advantages that the anti-pilling and washable wool knitted trousers material which is a fabric is high in yarn count density, tight in weaving and good in fuzzing and pilling performance and is difficult to shrink after being washed.

Owner:LILANG CHINA

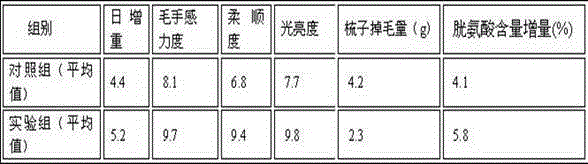

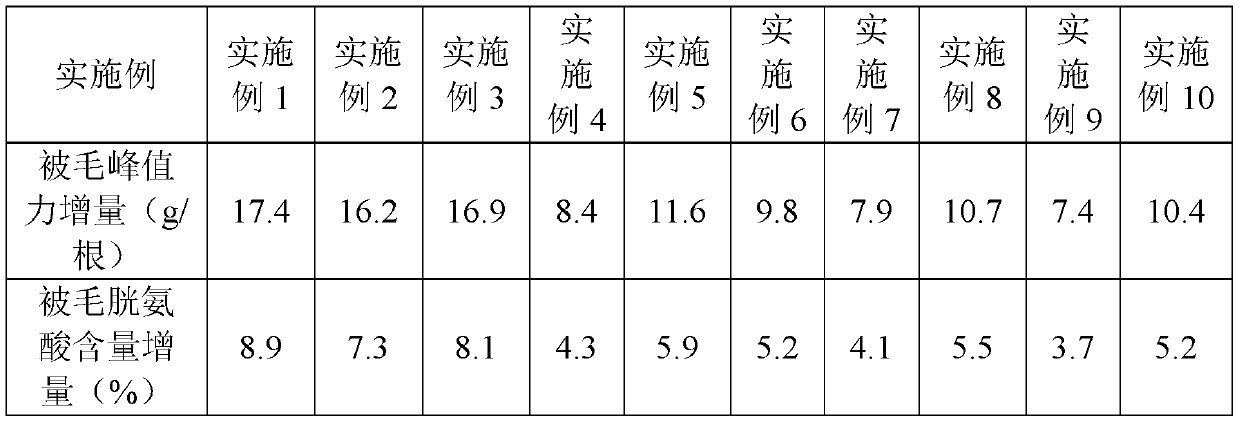

Dog feed additive for improving hair quality and brightening hair color

The invention discloses a dog feed additive for improving the hair quality and brightening the hair color and belongs to the technical field of feed additives. The dog feed additive is characterized by comprising the following components in parts by weight: 100-300g of deep sea fish oil, 50-100g of lecithin, 200-300g of methionine, 0.5-3g of nicotinic acid and the balance being yeast powder based on 1kg of the dog feed additive. The feed additive disclosed by the invention is high in stability, few in components and convenient to produce, and is capable of carrying out especial optimizing in terms of the growth of fur hairs of pet dogs, comprehensively improving the health of the fur hairs of the dogs, protecting hair follicles and hair shafts from being damaged, enabling surface hairs to be bright and smooth, preventing branching, reducing hair slip, promoting regeneration of the fur hairs, enabling the surface hairs to vigorously grow, improving the hair quality, enabling the surface hairs to be elastic, preventing the surface hairs from pilling, brightening the hair color and improving the hair quality, comprehensively improving immunity, and keeping smooth blood flowing, so that the pet dogs can be in a healthy and lively state all the time.

Owner:许伟琦

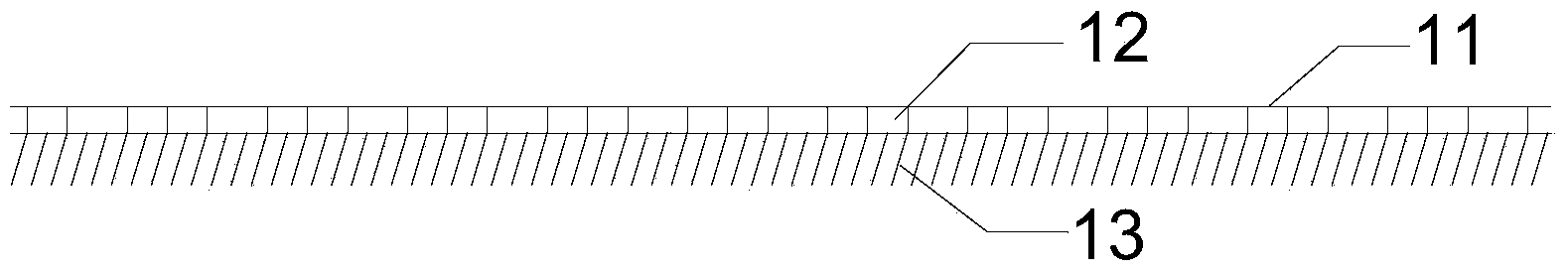

Air layer fabric and production method and application thereof

PendingCN111020837AGood anti-snagImprove pilling performanceWeft knittingHeating/cooling textile fabricsYarnPolyester

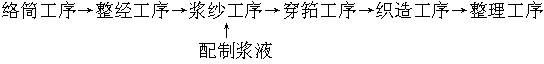

The invention relates to an air layer fabric and a production method and an application thereof. The air layer fabric comprises an outer layer, a secondary outer layer, a middle layer, a secondary inner layer and an inner layer; the outer layer and the inner layer are of a knitted weft flat tissue structure composed of cotton yarns; the secondary outer layer is composed of a first polyester yarn and a coil of the outer layer in a tucking manner; the secondary inner layer is composed of a second polyester yarn and a coil of the inner layer in a tucking mode; and the middle layer is formed by sleeving the first polyester yarn of the secondary outer layer and the second polyester yarn of the secondary inner layer by a third polyester yarn in a tucking manner. The fabric and the clothing provided by the invention have good anti-hooking and pilling performance and the anti-napping performance of the fabric, and is capable of effectively improving the wearability of the fabric.

Owner:台巨纺织(上海)有限公司

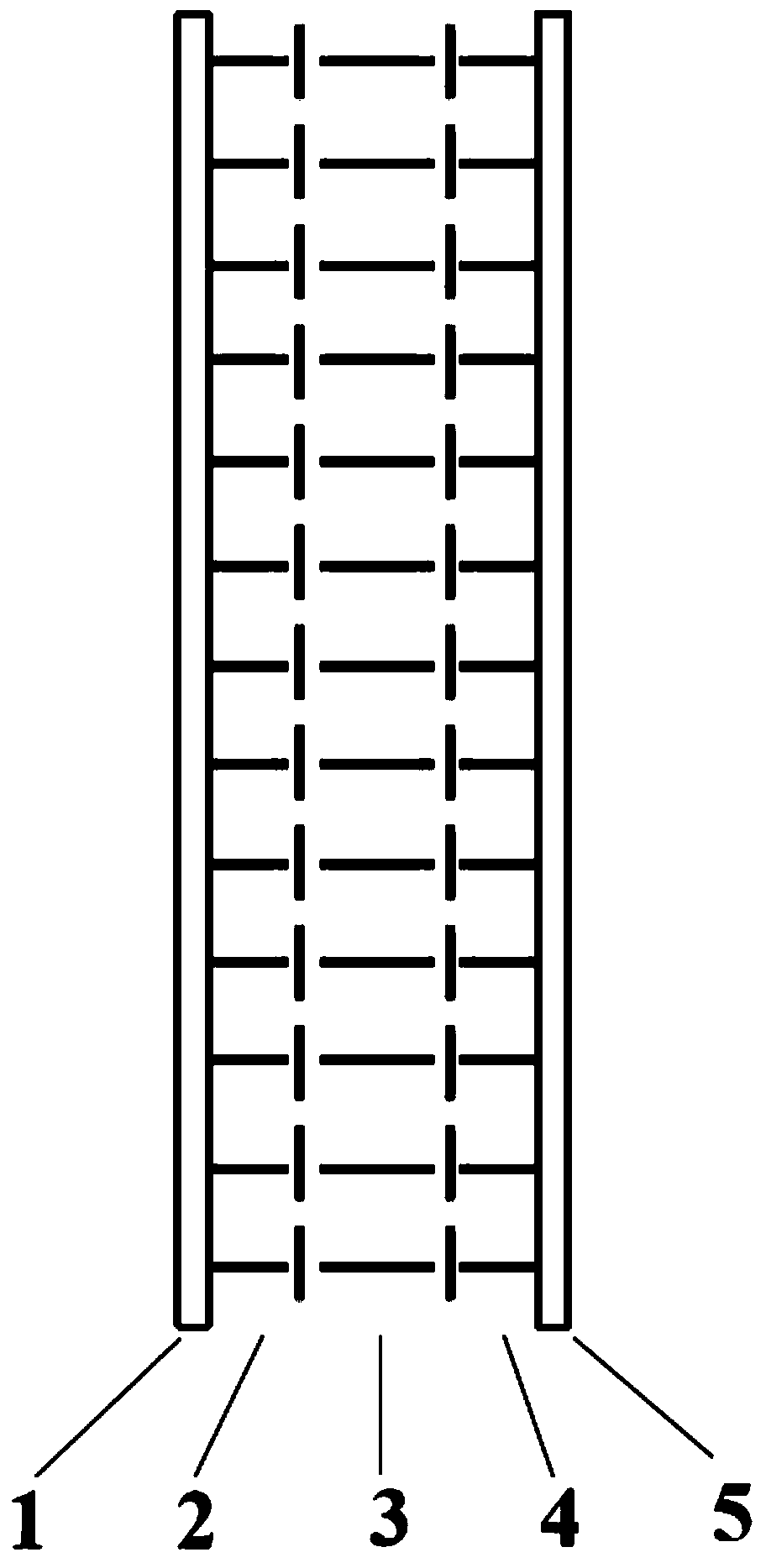

Three-dimensional terry flannelette fabric and manufacturing method thereof

ActiveCN104032464ASimple preparation processEasy to operateWeft knittingHeating/cooling textile fabricsHoneycomb structureEngineering

The invention provides three-dimensional terry flannelette fabric and a manufacturing method thereof. The three-dimensional terry flannelette fabric is woven through a weft knitting single-face multi-needle-passage circular knitting machine, one layer of the fabric is of a honeycomb structure, the other layer of the fabric is of a suede structure, and the two layers are wounded and knotted with each other. According to the fabric, the manufacturing process is simple, operation is easy to carry out, a blank with the two faces of the honeycomb structures is formed through interweaving, terry processing is carried out on terries of one face so that the honeycomb structure can be formed on one face, and the three-dimensional terry flannelette fabric of the suede structure can be formed on the other face; the anti-pilling performance of the three-dimensional terry flannelette fabric is improved through the shearing process, and the filling power of the three-dimensional terry flannelette fabric is increased through the anti-pilling process; when the three-dimensional terry flannelette fabric is used for manufacturing clothes, the face of the honeycomb structure can serve as the outer surface of the clothes, fuzzing and pilling of the clothes are avoided, the face of the suede structure can serve as the inner surface of the clothes, and the fabric is soft, preserves heat and has the windproof function.

Owner:NINGBO DAQIAN TEXTILE

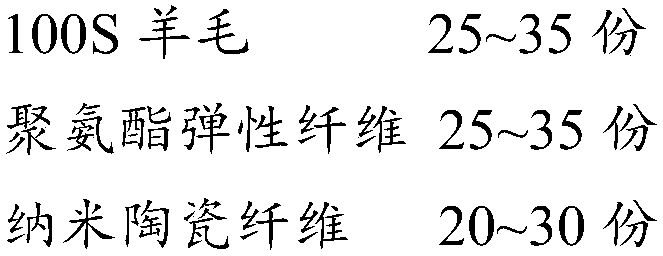

Anti-wrinkling fabric and preparation method thereof

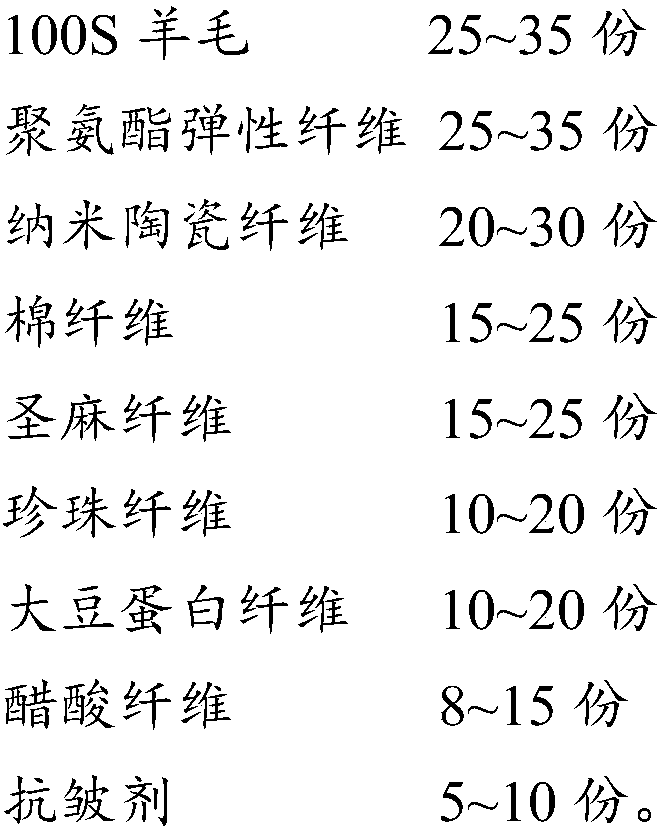

InactiveCN108950807APrevent pillingGood warmth retentionGrip property fibresDyeing processAnti wrinkleCotton fibre

The invention discloses an anti-wrinkling fabric. The anti-wrinkling fabric is prepared from, by weight, 25-35 parts of 100 S wool, 25-35 parts of polyurethane elastic fibers, 20-30 parts of nanometerceramic fiber, 15-25 parts of cotton fibers, 15-25 parts of Shengma fiber, 10-20 parts of pearl fiber, 10-20 parts of soybean fiber, 8-15 parts of cellulose acetate fiber and 5-10 parts of anti-wrinkling agent. According to the anti-wrinkling fabric, warp adopts the 100 S wool, the polyurethane elastic fibers, the nanometer ceramic fiber and the cotton fiber, the warm keeping performance and comfort of the warp are good, weft adopts the Shengma fiber, the pearl fiber, the soybean fiber and the cellulose acetate fiber, the warp and the weft are interweaved and twisted, the texture is thick andsolid, and not only are the warm keeping performance and comfort performance ensured, but also the problem of pilling of the fabric is further solved. Due to the fact that the anti-wrinkling agent isadded and the special preparation method is combined, the fabric has excellent anti-wrinkling performance.

Owner:AOYANG GRP CO LTD

Method for spinning soybean fiber and ES fiber blended yarn by siro spinning

A method for preparing soybean fiber yarn and ES fiber blended yarn by Siro-spinning. It contains 1, adopting Siro-spinning technology, 2, adopting 3-15 % (by weight) of ES fiber and soybean fiber yarn to blend, making ES fiber and soybean fiber yarn to form a number of thermal joint points in joint area by post heat treatment to avoid fuzzing and pilling, the temperature is 80-120 degree centigrade for 2-5 minutes, said produce is finely fixed by the binding action of ES fiber.

Owner:DONGHUA UNIV

Sweater fleece falling prevention technology

InactiveCN103343434AAvoid hair lossPrevent pillingHeating/cooling textile fabricsDyeing processEngineeringSizing

The invention discloses a sweater fleece falling prevention technology. The technology comprises processes of raw material selecting, dyeing, fleece finishing and sizing. The fleece finishing process with sanding, fleecing, carding, ironing and shearing is carried out after dyeing, so that produced sweater fleeces are soft and comfortable and can be prevented from falling and piling, and moreover, the sweater cannot easily deform after being washed and has high warm-keeping performance.

Owner:罗志焯

Antistatic wool anti-shrinking agent and wool processing method with same

The invention provides a wool anti-shrinking agent and a wool processing method with the same. After the wool anti-shrinking agent and the wool processing method are used, the shrinkage rate of a wool fabric can be reduced to about 1%, the phenomenon of pilling caused by bonding generated when wool is washed can be prevented, and the washed wool fabric is bright in color and does not easily turn yellow. According to the formula, the wool anti-shrinking agent is good in water solubility, can achieve a good washing effect at room temperature, is easy to wash, is free from any chemical damage to wool products and does not produce formaldehyde residue; the wool anti-shrinking agent has effective functions of decontamination, static electricity resistance and bacteria and mold prevention for the wool fabric; the wool fabric washed by the wool anti-shrinking agent is soft in texture and has lasting natural faint scent. The antistatic wool anti-shrinking agent is less in dosage when being used for processing the wool fabric, and the content of organic halide with adsorbability in waste water is low; when chloride waste water is treated by a flocculating agent, organic halide with adsorbability in the waste water is reduced by about 90%, and thus the problem that the environment is polluted by the waste water can be solved.

Owner:山东大明消毒科技有限公司

Anti-pilling and perspiring-resistant woolen sweater

InactiveCN103271472APrevent pillingActs as an antiperspirant and deodorizerYarnProtective garmentAromatherapyMaterials science

The invention discloses an anti-pilling and perspiring-resistant woolen sweater. The anti-pilling and perspiring-resistant is formed by blending, by weight, 70-80 parts of merino extrafine wool, 5-10 parts of cashmere, 10-15 parts of soybean fibers, 5-10 parts of acrylic fibers, 5-10 parts of modal fibers and 5-10 parts of combed cotton. Since the diameter of the merino extrafine wool adopted in the anti-pilling and perspiring-resistant woolen sweater is 11.7 microns and is far lower than that of ordinary wool, the merino extrafine wool feels smooth and soft; pilling of the woolen sweater can be prevented by adding the modal fibers; aromatherapy strips arranged on armpit positions of the woolen sweater can have anti-pilling and perspiring-resistant functions.

Owner:TAICANG SHARTEX SHENTAI SWEATER

Anti-fuzzing and anti-pilling polyester sportswear fabric and preparation method thereof

InactiveCN112941699AGood anti-pillingCohesion is smallGrip property fibresAbrasion resistant fibresPolyesterFiber

The invention discloses an anti-fuzzing and anti-pilling polyester sportswear fabric. The polyester sportswear fabric is formed by weaving warp yarns and weft yarns; both the warp yarns and the weft yarns contain anti-fuzzing and anti-pilling polyester fibers; and the anti-fuzzing and anti-pilling polyester fibers are obtained by sequentially modifying polyester fibers with anthocyanin and camphorsulfonic acid. A preparation method of the anti-fuzzing and anti-pilling polyester fibers comprises the following steps of 1, adding the polyester fibers into alkali liquor for soaking and washing to obtain porous polyester fibers; 2, performing grafting treatment on the porous polyester fibers and the anthocyanin to obtain glycosidated porous polyester fibers; and 3, carrying out binding reaction on the glycosidated porous polyester fibers and the camphorsulfonic acid to obtain the anti-fuzzing and anti-pilling polyester fibers. By modifying the polyester fibers, the cohesive force between the polyester fibers and the flexibility of the polyester fibers are increased, so that the polyester fibers are not prone to scratching the surface of the fabric, and the effect of avoiding fuzzing and pilling is achieved.

Owner:宁波共振运动科技有限公司

Textile processing agent for removing pilling and preparation method thereof

ActiveCN106381712AReduce dosageBright colorStain/soil resistant fibresBiochemical treatment with enzymes/microorganismsPolyvinyl alcoholPOLYOXYETHYLENE ETHER

The invention provides a textile processing agent for removing pilling. The textile processing agent comprises the following components in parts by weight: 5 to 10 parts of sodium lauryl polyoxyethylene ether sulfate, 2 to 5 parts of lauryl alcohol polyoxyethylene, 0.5 to 3 part of calcium chloride, 6 to 10 parts of cellulase, 0.1 to 0.8 part of polymethacrylic acid, 0.05 to 0.5 part of polyvinyl alcohol, 0.5 to 1 part of sodium citrate, and 75 to 85 parts of water. The invention belongs to the technical field of washing agents. The provided textile processing agent has excellent comprehensive functions of removing and preventing pilling, removing contaminants, protecting color, improving hand feeling, and preventing static electricity, and is very stable.

Owner:WALCH GUANGZHOU COMMODITY

Pilling-resistant artificial leather

ActiveUS20120156416A1Elegant appearanceGood pilling-resistance without affecting the spinning performanceLayered productsConjugated synthetic polymer artificial filamentsElastomerPolyester

An artificial leather is provided having a raised nap to give an elegant appearance, and further has a good pilling-resistance without affecting the spinning performance. The pilling-resistant artificial leather is a sheet-form object including a microfiber having a monofilament diameter of 0.3 to 10 μm and a polymeric elastomer, and having a raised nap made of the microfiber. The microfiber includes inorganic particles in a proportion of 0.01 to 5% by mass relative to 100% by mass of the microfiber, and a silicone oil in a proportion of 0.001 to 1% by mass relative to 100% by mass of the microfiber. The microfiber contains a polyester microfiber in a proportion of 90% by mass or more thereof.

Owner:TORAY IND INC

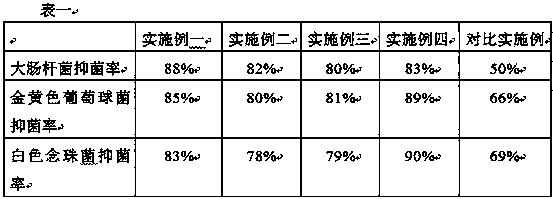

Special antibacterial textile fabric for infants and preparation method thereof

InactiveCN108978185ASolve the problem of not having antibacterial functionImprove antibacterial propertiesBiochemical fibre treatmentAbrasion resistant fibresAntistatic agentProtein fiber

The invention discloses a special antibacterial textile fabric for infants and a preparation method thereof. The antibacterial textile fabric is prepared from the following components in parts by weight: 20 to 30 parts of modal fiber, 5 to 8 parts of viscose fiber, 3 to 6 parts of acetate fiber, 40 to 50 parts of wool fiber, 15 to 20 parts of corn protein fiber, 5 to 10 parts of an antibacterial finishing agent, 3 to 5 parts of an antistatic agent and 2 to 5 parts of an anti-pilling agent. The antibacterial textile fabric provided by the invention has good antibacterial capability, antistaticcapability and anti-pilling capability, can be widely applied to nursing of the infants and has a good market application prospect.

Owner:福建樱幼佳科技有限公司

Special mold-proof caring agent for wool fabric

The invention relates to a special mold-proof caring agent for a wool fabric. The special mold-proof caring agent for the wool fabric is made of the following raw materials in parts by weight: 8-16 parts of polyoxyethylene ether, 2-4 parts of sodium hydroxide, 9-13 parts of stearic acid, 6-12 parts of lanolin alcohol, 13-24 parts of Vaseline, 12-20 parts of titanium isopropylate, 5-11 parts of fatty alcohol-polyoxyethylene ether, 4-8 parts of acrylic resin, 3-5 parts of aluminum oxide, 2-4 parts of polypyrrolidone, 2-4 parts of organic siloxane and 4-7 parts of sodium dodecyl benzene sulfonate. The special mold-proof caring agent for the wool fabric has the beneficial effects that the stain removing performance and mothproof performance are good, the friction of the wool fabric is reduced, the phenomenon of balling-up is prevented and the effect is excellent.

Owner:QINGDAO DONGCHANGRUI TEXTILE

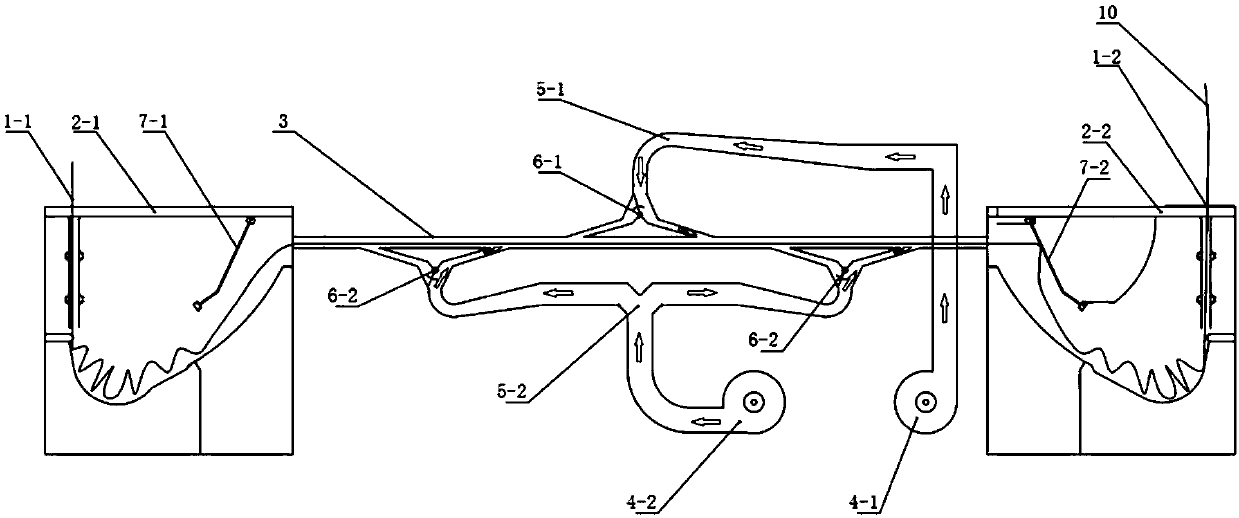

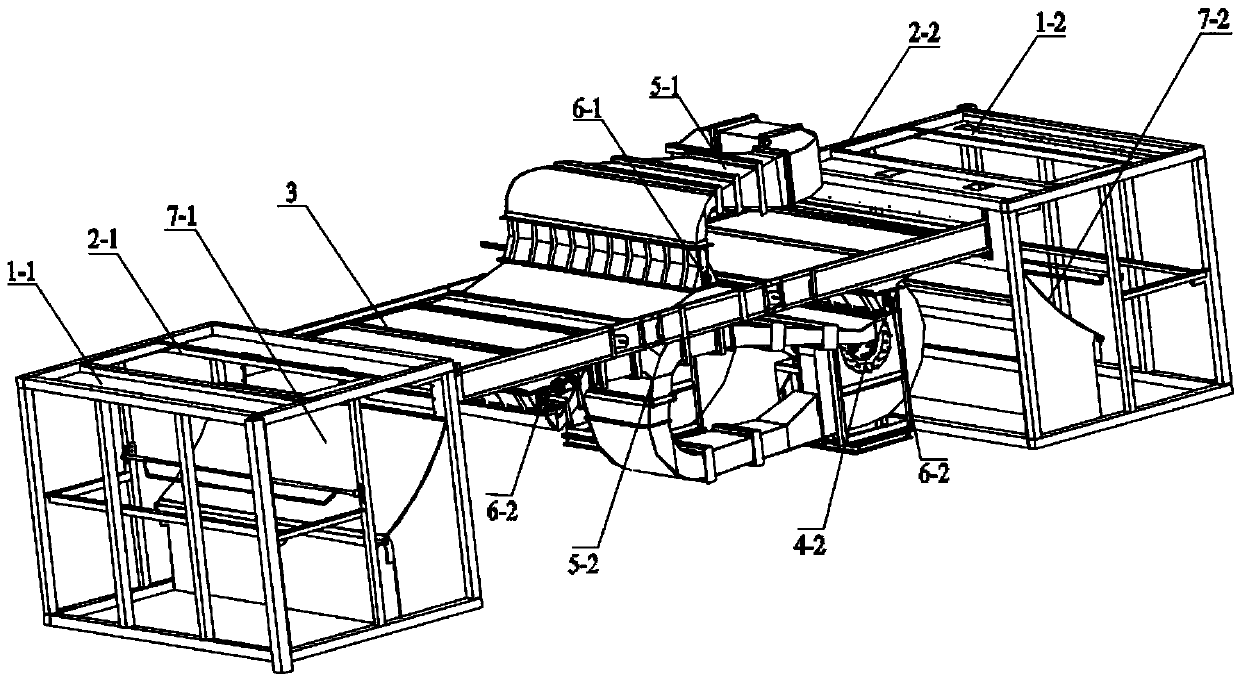

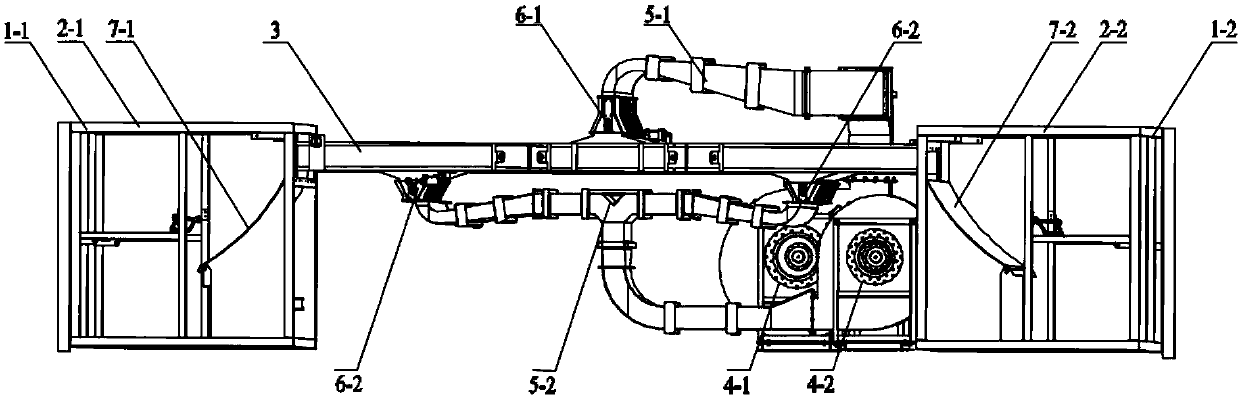

Pneumatic circulation drying system of soft drying machine

InactiveCN109595910AControl flowEfficient slapping effectDrying gas arrangementsDrying chambers/containersReciprocating motionFree state

The invention provides a pneumatic circulation drying system of a soft drying machine. The system comprises a cloth inlet, a first cloth storage box, a cloth outlet, a second cloth storage box, a cloth groove air flue, a main fan and an auxiliary fan, the cloth groove air flue is connected with the first cloth storage box and the second cloth storage box, the main fan and the auxiliary fan are communicated with the cloth groove air flue, the main fan is connected with at least one main air duct, the main air duct is connected with a main air duct reversing valve plate, the main air duct reversing valve plate is connected with a left branch main fan and a right branch main fan of the main fan, the left branch main fan and the right branch main fan are connected with the cloth groove air flue; the auxiliary fan is connected with at least one auxiliary air duct, the auxiliary air duct is connected with an auxiliary air duct reversing valve plate, the auxiliary air duct reversing valve plate is connected with a left branch auxiliary fan and the right branch auxiliary fan of the auxiliary fan, the left branch auxiliary fan and the right branch auxiliary fan are connected with the clothgroove air flue. According to the pneumatic circulation drying system, the reversible air duct structure is arranged, so that the fabric is supported by the upper hot air flow and the lower hot air inthe air duct for left and right reciprocating motion and is beating, so that the fabric can obtain a soft hand feeling, meanwhile, the fabric can obtain an ideal pre-shrinking effect in a tension-free state and a high-temperature state, in addition, due to the fact that the fabric does not rub with any object, the pilling is avoided.

Owner:惠州泰纶纺织机械有限公司

High strength self-cleaning medical bedding

InactiveCN109610063AStrength is good for maintainingImprove comfortMonocomponent protein artificial filamentFibre treatmentAramidCow milk

The invention mainly relates to the technical field of medical instrument processing, and discloses a high strength self-cleaning medical bedding, which is made from the following raw materials: 57-59parts of linen fiber, 41-43 parts of copper ammonia fiber, 30-32 parts of milk fiber, 15-17 parts of Ag-soybean protein fiber, 12-14 parts of modified aramid fiber and 6-8 parts of a surface treatment agent. The invention has the advantages that the high strength self-cleaning medical bedding is soft and comfortable in use and strong in bacterial resistance, has stronger hydrophobicity, preventsstains from entering into the fibers, and is convenient to wash and beneficial to keeping clean; primary blending is performed on the linen fiber, the copper ammonia fiber and the milk fiber, therebyincreasing the comfort degree and the bacterial resistance of the bedding, preventing a patient from breeding germs and mites after living in a hospital and speeding up the wound healing process of the patient; secondary blending is carried after the fiber obtained by the primary blending, the Ag-soybean protein fiber and the modified aramid fiber are mixed, thereby enhancing the strength of the bedding and preventing the bedding from pilling or being damaged due to frequent washing.

Owner:安徽一升医疗设备有限公司

Cashmere fabric anti-pilling finishing liquor containing modified sericin and preparation method of finishing liquor

InactiveCN106592229APrevent pillingDoes not affect the feelBiochemical treatment with enzymes/microorganismsAbrasion resistant fibresEmulsionChemistry

The invention discloses cashmere fabric anti-pilling finishing liquor containing modified sericin and a preparation method of the finishing liquor. The finishing liquor is prepared from, by weight, 24-48 parts of modified sericin, 11-25 parts of SXA-amino silicone elastomer, 12-26 parts of protease, 8-15 parts of sodium chloride, 3-11 parts of keratin, 5-21 parts of polyethylene wax emulsion, 4-16 parts of magnesium sulfate, 4-15 parts of zinc chloride and 3-11 parts of hydrogen peroxide. The cashmere fabric anti-pilling finishing liquor containing modified sericin can form a protective film on the surface of cashmere fabric aiming at the characteristics of the cashmere fabric, and the cashmere fabric is prevented from pilling; the cashmere fabric anti-pilling finishing liquor containing modified sericin does not affect the hand feeling, elasticity, dyeing fastness and gloss of the fabric.

Owner:JIANGSU AIXISHI TECH SERVICE CONSULTATION CO LTD

Pet cat food with effect of beautifying hair quality and hair color of persian cat

InactiveCN106819507AImprove stabilityReasonable and effective combination of componentsAnimal feeding stuffAccessory food factorsPersian catSide effect

The invention provides a pet cat food with an effect of beautifying the hair quality and hair color of a persian cat. The pet cat food is prepared from the following components in parts by weight: 3-8 parts of multi-vitamins, 3-6 parts of microelements, 55-150 parts of carbohydrate, 10-35 parts of animal protein, 15-55 parts of vegetable protein, 2-6 parts of an additive, 1-4 parts of a flavoring agent and 5-15 parts of a Chinese herbal medicine extract. The invention aims at providing the pet cat food with the effect of beautifying the hair quality and hair color of the persian cat, which is fast in absorption, high in bioavailability, few in intestinal residues and small in side effect.

Owner:钱建荣

Wear-resisting blended shell fabric

ActiveCN105369426AImprove wear resistanceIncrease elasticityAbrasion resistant fibresWoven fabricsMohairSurface layer

The invention discloses wear-resisting blended shell fabric. The wear-resisting blended shell fabric comprises a base cloth layer and a surface layer, wherein the base cloth layer is formed by interweaving warp yarn and weft yarn, the warp yarn includes the first warp yarn and the second warp yarn, the weft yarn includes the first weft yarn and the second weft yarn, the first warp yarn is mohair fiber, the first weft yarn is glazed polyester filament yarn, camel fiber is adopted as the second warp yarn, and polyester ramie blended yarn is adopted as the second weft yarn. The surface layer is a composite wear-resisting coating on the upper surface of the base cloth layer. The wear-resisting blended shell fabric integrates characteristics of various kinds of fiber, and the interwoven shell fabric is compact in fiber structure, good in wear resistance, high in elasticity, free of deformation, soft, light and breathable and absorbs moisture; the composite wear-resisting coating is arranged on the surface and capable of resisting friction and preventing pilling and fading, caused by wear, of the base cloth layer.

Owner:TONGXIANG YUXI KNITTING

Novel blended yarn and production process thereof

InactiveCN104862842ALess hairyImprove the defect of poor wrinkle resistanceYarnPolymer scienceCotton fibre

The invention discloses novel blended yarn and a production process thereof. The novel blended yarn is formed by blending cotton fibers with the blending ratio being 50%, bamboo pulp fibers with the blending ratio being 40% and soybean protein fibers with the blending ratio being 10%. The novel blended yarn has the advantages that a compact Siro spinning technology is adopted, raw materials are reasonably mixed, the defect of poor crease resistance of the soybean protein fibers is overcome, the soybean protein fibers are prevented from pilling to a large extent, and the size stability of fabric is improved. The problems that the bamboo pulp fibers are poor in hand feel, skin friendliness and cohesive force are solved. The produced yarn is good in strength, high in evenness, good in breathability, fluffy and soft, and has good skin friendliness and health care functions. The three-blending mode is adopted, the blending ratio can be more accurate, ingredients are even, produced single yarn is high in evenness, the strength of the single yarn is high, the number of cotton neps is small, and the number of yarn faults is small. The yarn variety enables fabric to have good breathability, to be fluffy and soft and to have good skin friendliness and a health care function.

Owner:NANTONG YUEDA KNITTING GARMENT

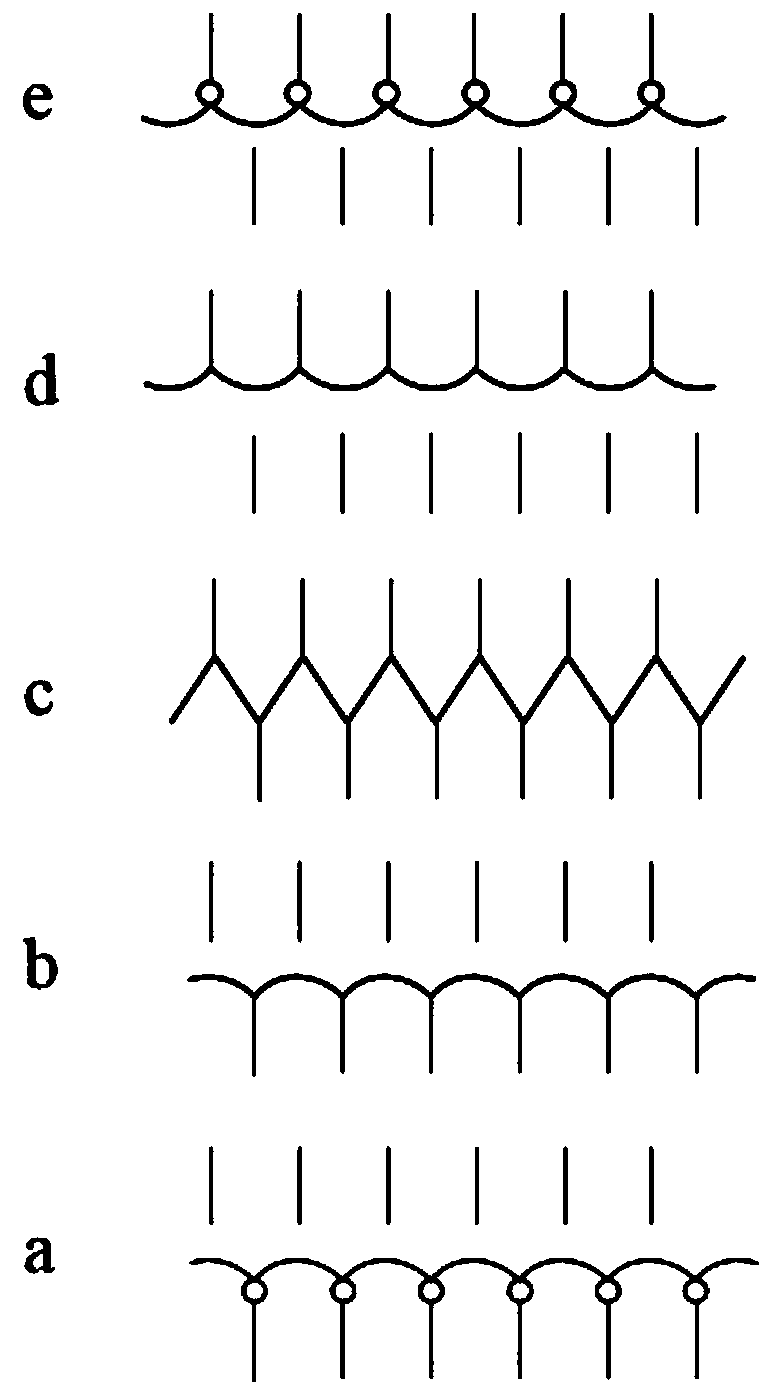

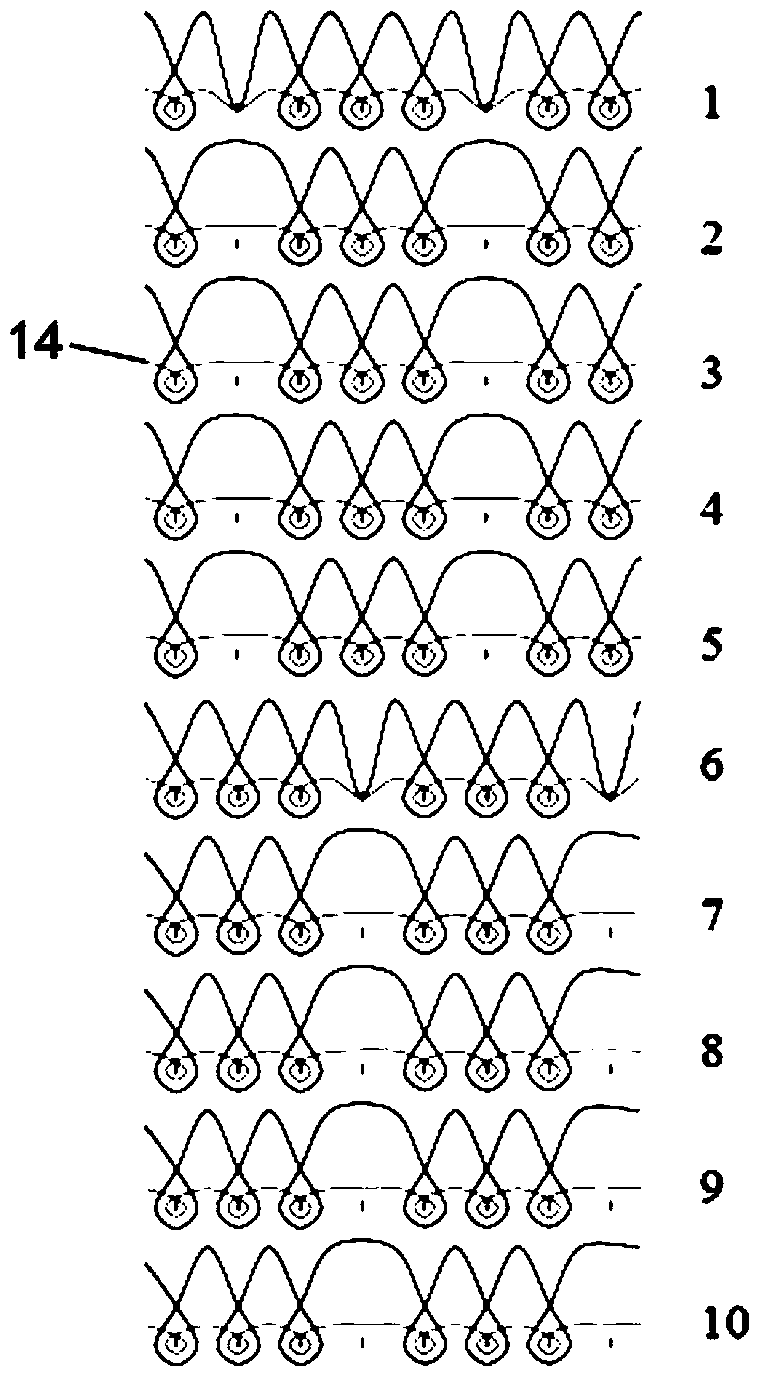

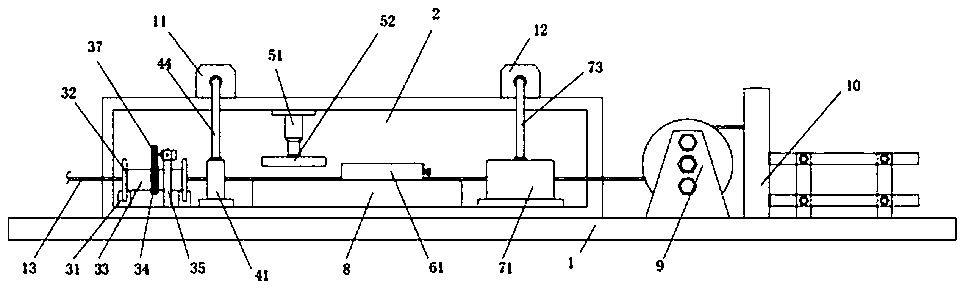

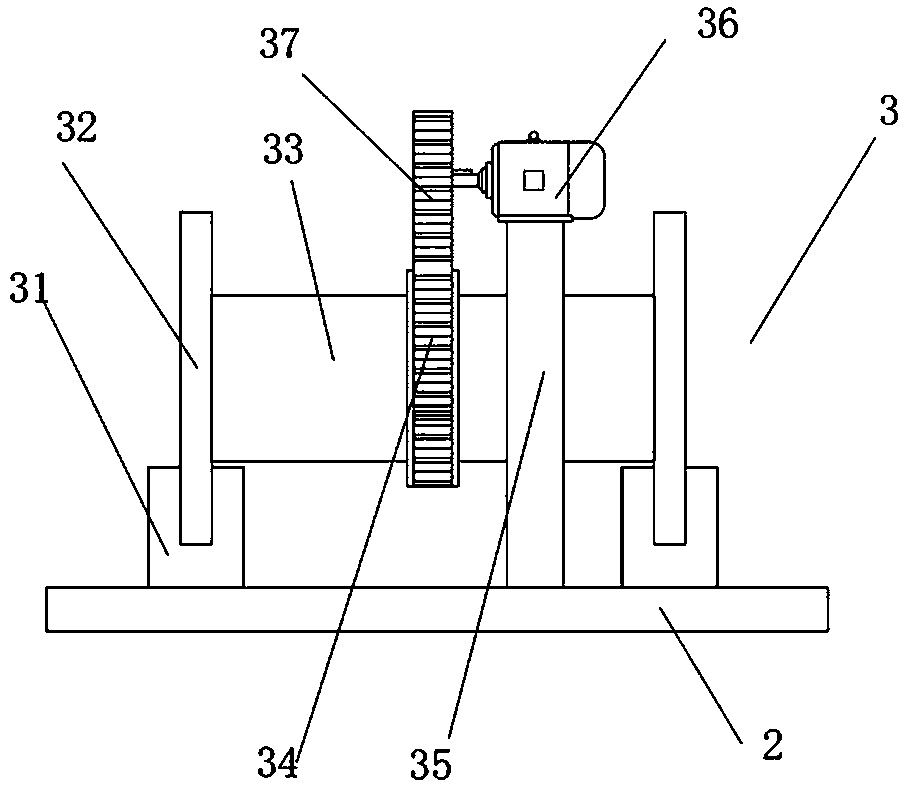

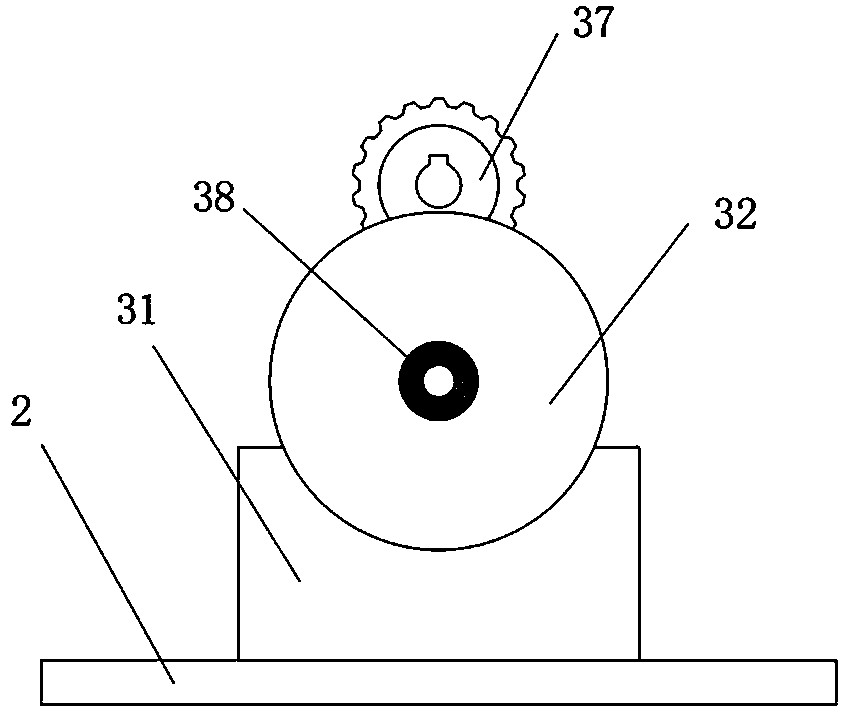

Knitting device for anti-pilling wool textiles

InactiveCN110158218AEfficient removalReduce voidsFibre cleaning/openingTextile treatment by spraying/projectingYarnEngineering

The invention discloses a knitting device for anti-pilling wool textiles. The knitting device comprises a workbench and a traction line, the left side of the top of the workbench is fixedly connectedwith a treatment box, a brushing device is fixedly connected on the left side of the bottom of the inner wall of the treatment box and positioned in the middle, a spraying device is fixedly connectedat a position, close to the right side of the brushing device, of the bottom of the inner wall of the treatment box, a thermosetting device is fixedly connected at a position, corresponding to the left side of a supporting platform, of the top of the inner wall of the treatment box, and the right side of the top of the supporting platform is fixedly connected with a rolling device. By arranging limiting clamping blocks, turnplates and a drum, arranging a fixing ring, a driving motor and a driving gear in a matched manner and arranging a transmission rack on a circular ring and meshed with thedriving gear, the drum is enabled to rotate at a constant speed; by arranging a cleaning brush on the inner wall of the drum, when wool yarn penetrates the drum, dust and impurities on the surface ofthe wool yarn can be removed effectively.

Owner:阜南华翔羊毛衫有限公司

Method for anti-crease finishing of cotton fabric with biopolishing waste liquid

ActiveCN107287895APrevent pillingSmooth appearanceWrinkle resistant fibresVegetal fibresTextile printerCarboxylic acid

The invention relates to a method for anti-crease finishing of a cotton fabric with biopolishing waste liquid, belonging to the technical field of textile printing and dyeing. The method provided by the invention comprises the following steps: (1) subjecting conventional cellulase biopolishing waste liquid to filtering and concentration to allow the concentration of cellulase protein in water to reach 2 to 4 g / L; (2) adding a conventional amount of a polybasic carboxylic acid finishing agent, fully dissolving the polybasic carboxylic acid finishing agent, heating the obtained treatment fluid to a temperature of 95 DEG C and maintaining the temperature for 60 to 80 min; and (3) adding a conventional amount of a catalyst, then carrying out sufficient stirring to dissolve the catalyst, soaking a to-be-treated cotton fabric into the obtained solution and carrying out anti-crease finishing on the fabric by using a conventional baking process. According to the invention, the polybasic carboxylic acid finishing agent is prepared from the biopolishing waste liquid and used for anti-crease finishing of the cotton fabric, so recycling of the waste liquid is realized, and residual cellulase is used for reinforcing anti-crease finishing effect of polybasic carboxylic acid on the cotton fabric.

Owner:QINGDAO UNIV

Radix isatidis extract modified terylene fiber and preparation method thereof

InactiveCN111676696AImprove antibacterial propertiesPrevent pillingBiochemical fibre treatmentAbrasion resistant fibresFiberSODIUM PYRROLIDONE CARBOXYLATE

The invention relates to radix isatidis extract modified terylene fiber and a preparation method thereof. The modified terylene fiber comprises radix isatidis extract, white paeony root extract, sodium pyrrolidone carboxylate, melamine phosphate and triethylamine. The radix isatidis extract, the white paeony root extract, porous nano material and a hydrophilic agent are modified. As the nano porous material has a large specific surface area, the plant extract is packaged in the pore channels of the porous material, the components of the plant extract cannot be damaged, and the performance andthe hydrophilicity of terylene staple fiber are improved. According to the radix isatidis extract modified terylene fiber and the preparation method thereof, the radix isatidis extract is added to improve the antibacterial performance of the terylene staple fiber, the white paeony root extract and the pyrrolidone sodium carboxylate are added to effectively avoid the problem of pilling of the terylene, and the anti-melting performance of the terylene can be effectively improved by adding the melamine phosphate and triethylamine. The preparation method disclosed by the invention can improve themechanical property, air permeability, moisture absorption and melting resistance of the terylene staple fiber, and also can effectively prevent the terylene fiber from pilling.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Natural dog food composition for protecting skin and brightening hair and preparation method thereof

InactiveCN111280303AImprove immunityVigorousAnimal feeding stuffAccessory food factorsBiotechnologyCastor Seed

The invention relates to the technical field of pet food, in particular to a natural dog food composition capable of protecting skin and brightening hair and a preparation method of the natural dog food composition. The invention discloses a natural dog food composition for protecting skin and brightening hair; the composition at least comprises the following components by weight parts: 5-20 partsof flaxseeds, 5-15 parts of sunflower seeds, 3-7 parts of castor seeds, 3-10 parts of rapeseeds, 8-15 parts of methionine, 5-15 parts of cystine, 1-5 parts of beewax, 0.1-2 parts of tea leaves, 1-5 parts of Chinese wolfberry, 5-15 parts of jujubes, 1-5 parts of laver, 2-8 parts of undaria pinnatifida, 1-5 parts of spinach, 10-20 parts of buckwheat and 15-30 parts of corn. The dog food prepared bythe invention can protect hair follicles and hair of dogs from being damaged, enable the hair of dogs to be smooth and gentle, prevent bifurcation, reduce hair loss, promote fur regeneration, enablethe hair to grow vigorously, brighten the hair color, improve the hair quality, enable the hair to have elasticity, prevent pilling of the hair, reduce the incidence of skin diseases and improve skinallergy and pruritus.

Owner:SHANGHAI NAVARCH PETS PROD CO LTD

Special nutrient for cats

InactiveCN110463844AImproves fur healthStimulate hair regenerationFood processingAnimal feeding stuffOysterWhey protein powder

The present invention provides a special nutrient for cats. The special nutrient comprises the following raw materials in parts by weight: 30-50 parts of whey protein powder, 8-18 parts of soybean meal, 10-22 parts of micro-ecology live micro-organism preparation, 5-11 parts of oyster powder, 10-18 parts of buckwheat flour, 0.6-4 parts of ultra-fine calcium powder, 1-3 parts of medical stones, 2-5parts of rhizoma polygonati, 3-7 parts of asparagus officinalis, 2-4 parts of boehmeria gracilis, 8-17 parts of radix cynanchi bungei, 0.3-2 parts of herba lycopi, 0.3-2 parts of radix dipsaci, 1-4 parts of white atractylodes rhizome and 0.5-3 parts of vitex negundo var. cannabifolia. The special nutrient can comprehensively improve fur health of the cats, stimulates broken hair regeneration, prevents hair loss and hair breakage, prevents hair from splitting, protects hair follicle, improves hair quality, enables clothing hair to be elastic, prevents the hair from balling-up, comprehensivelyenhances immunity, replenishes spleen and stomach, nourishes qi and blood, enables pets to have spirit and the clothing hair to be flourishing, soft, smooth, bright in color and luster, and elastic, can increase the hair quality and brightens hair color.

Owner:深圳前海格林希尔贸易有限公司

Modified Dacron mattress fabric with high antibacterial properties

InactiveCN108977976AGood skin affinitySolve the problems of poor air permeability and poor antibacterial effectBed linenFilament/thread formingBreaking strengthPolyester

The invention relates to the technical field of high-performance fibers and composite materials, and discloses a modified Dacron mattress fabric with high antibacterial properties. According to the technical scheme, the modified Dacron mattress fabric has the advantages that modification materials with porous structures are added into Dacron polyester melt to carry out melting modification on theDacron performance, matrix fabrics further can be obtained by means of textile processing, accordingly, bacterial growth environments can be destroyed, the modified Dacron mattress fabric is excellentin antibacterial properties, moisture permeability and moisture conductivity and good in skin friendliness, and the antibacterial properties can be prevented from being deteriorated along with factors such as rubbing and washing; the tensile breaking strength of Dacron fibers further can be improved, the health of human bodies can be protected, and the service lives of mattresses can be prolonged; the problem of defects of existing Dacron materials can be solved by the aid of the prepared modified Dacron mattress fabric, antibacterial effects and the cost are taken into account, development and utilization of composite fiber materials can be improved, the practical significance of the healthcare properties and the physical and mechanical properties of the mattresses can be improved, and the modified Dacron mattress fabric is extremely worthy of being popularized and utilized.

Owner:界首市梦佳怡家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com