Patents

Literature

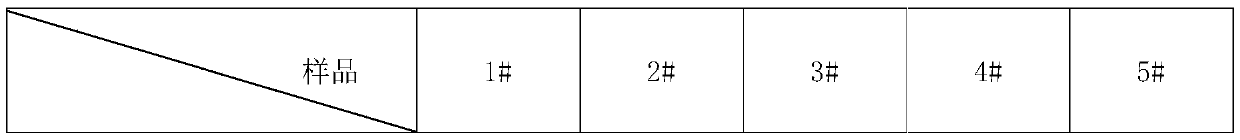

50results about How to "Avoid hair loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

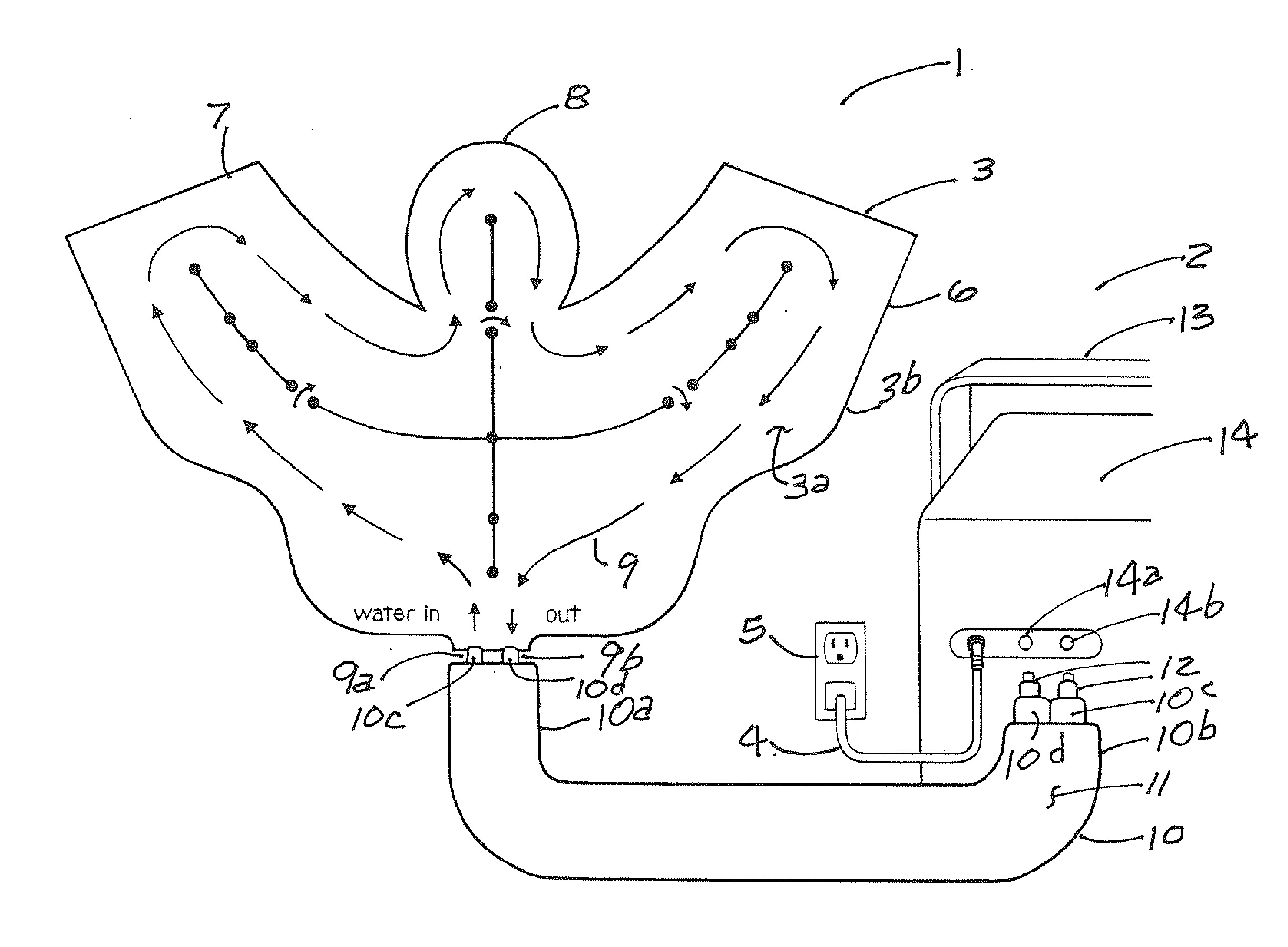

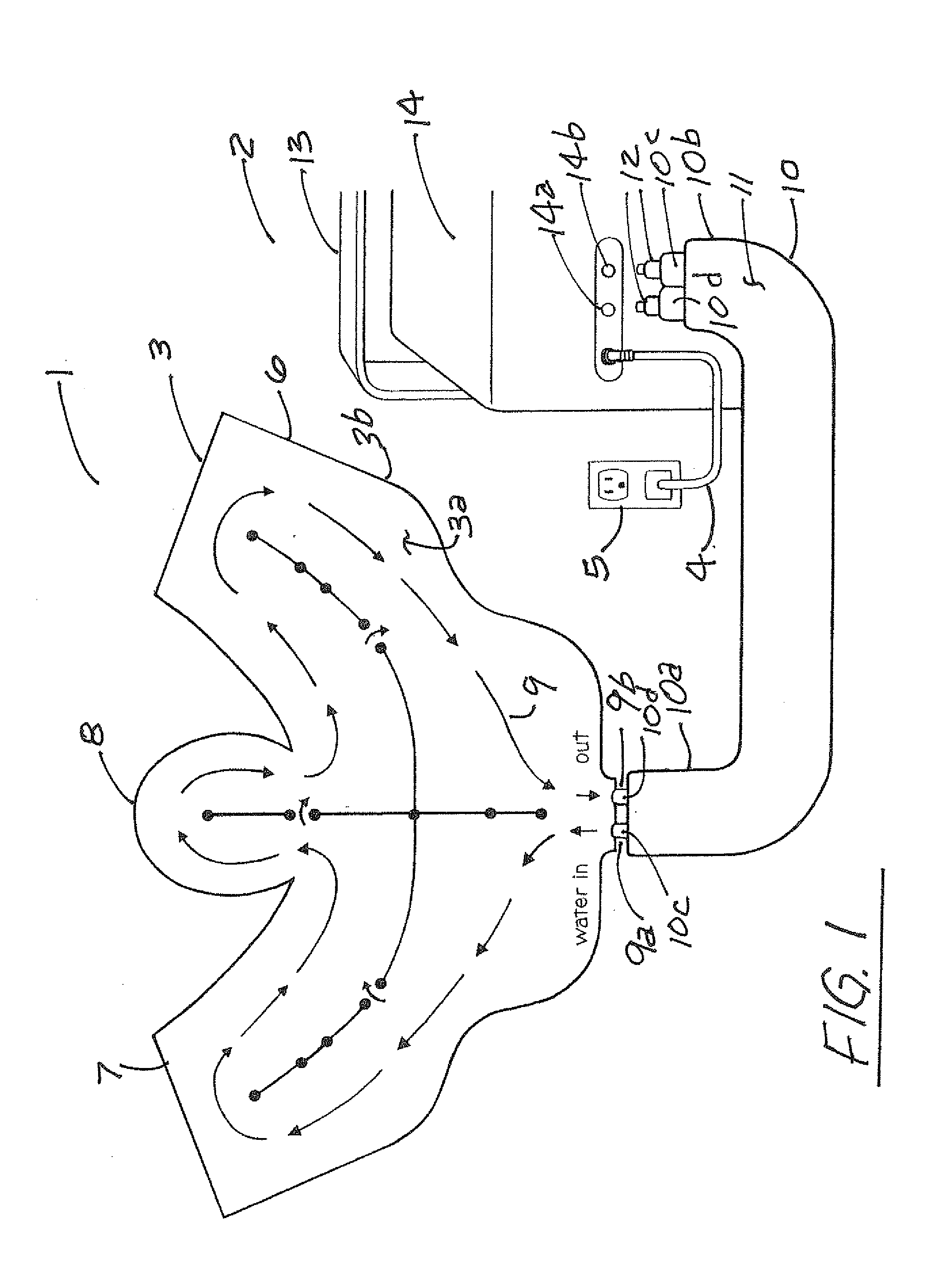

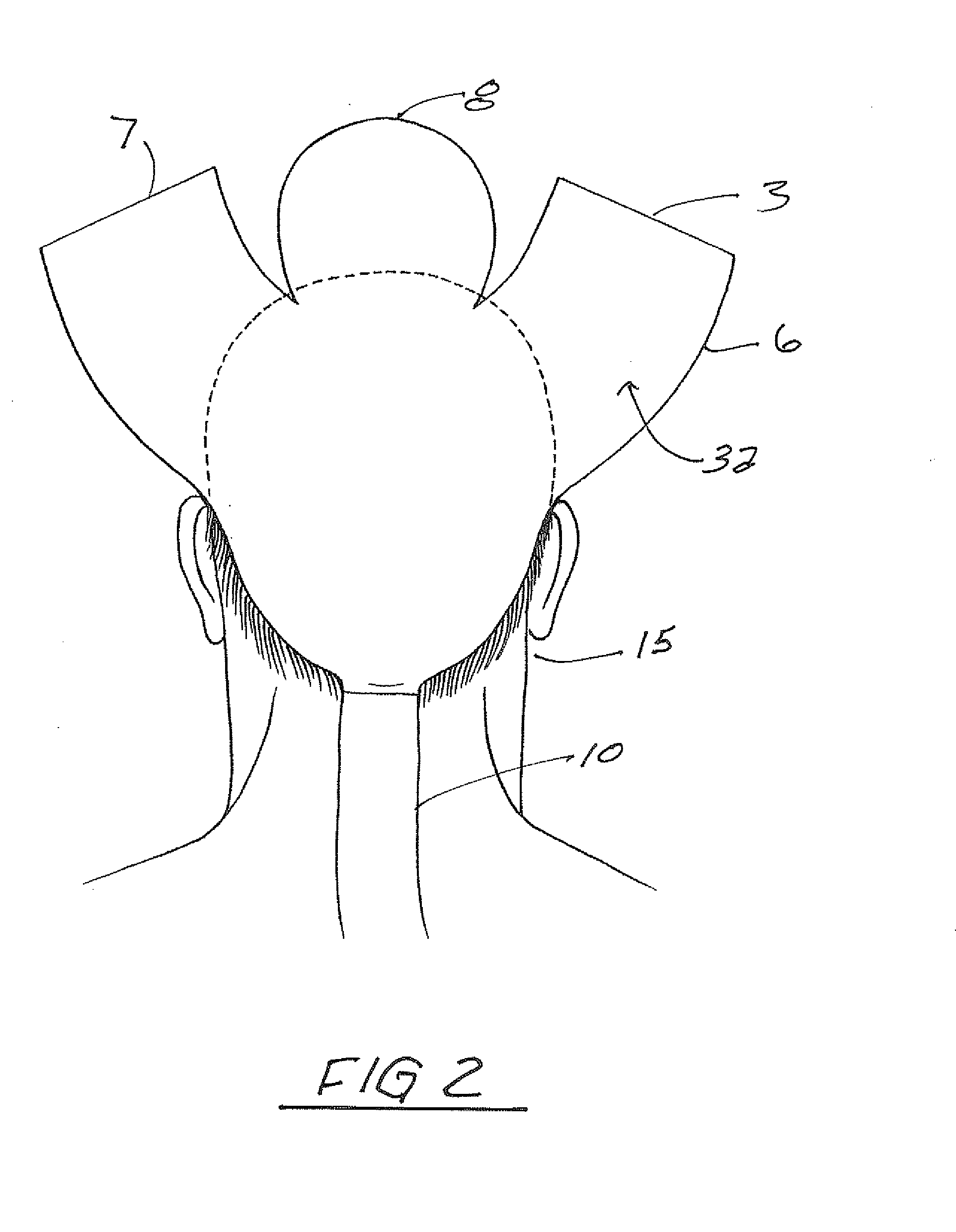

System and method for avoiding hairloss during chemotherapy

InactiveUS20140046410A1Avoid hair lossInexpensive and convenientTherapeutic coolingTherapeutic heatingIce waterScalp cooling

A system and method for scalp cooling to avoid hair loss in patients undergoing chemotherapy with a cooling bonnet, a recirculating ice-water system with ice water circulation hoses, a reservoir, a circulating pump and a power supply, and the method having the steps of providing a cooling bonnet with a recirculating ice water system and chilling the cooling bonnet; placing the chilled cooling bonnet on the patient's head at least 30 minutes before undergoing chemotherapy; during chemotherapy; and retaining the chilled cooling bonnet on the patient's head for at least 90 minutes after chemotherapy with the recirculating ice water system powered by a conventional electrical power supply or by a vehicle power supply such as a 12Volt connection like a cigarette lighter as need may be

Owner:WYATT DAVID

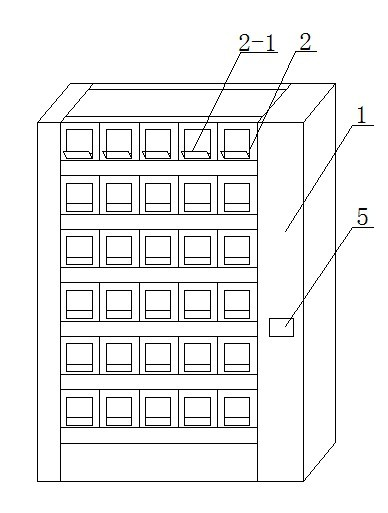

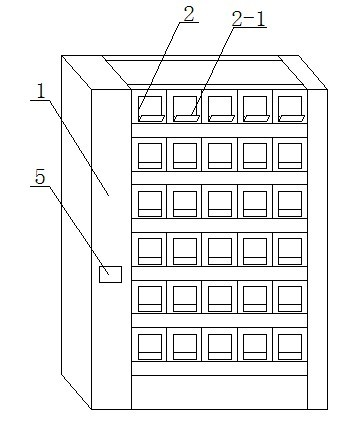

An intelligent cache medicine distribution cabinet

InactiveCN102283508AImprove work efficiencyAvoid confusionChestsDressing tablesLED displayDisplay device

The invention discloses an intelligent cache medicine dispensing cabinet, which comprises a cabinet body, a data reading and identifying device, and a control device, wherein the data reading and identifying device and the controlling device are all located on the cabinet body; the cabinet body is arranged from top to bottom Set more than two storage layers, each storage layer is equipped with a number of independent cabinets, each cabinet is connected front and back, the front end of the cabinet is provided with a front door, the rear end of the cabinet is provided with a rear door, the front door and the Electric control locks are arranged on the back box doors; bar-shaped LED displays or liquid crystal displays can also be set at the positions below the front box doors and the back box doors to display relevant prescription information. The data reading and identifying device is connected with the control device, and transmits the relevant access prescription information to the control device. Or display to indicate the location of storage and withdrawal of medicines. The device of the present invention saves the time for patients to take medicine through the medicine buffer system, and effectively prevents mistakes in dispensing medicine.

Owner:JIANGSU XUNJIE HARNESS TECH

Fox fur nutrition enhancer

InactiveCN1961715AImprove itchingKeep the glossMetabolism disorderAnimal feeding stuffPantothenic acidInositol

The invention relates to a nutrition reinforcing agent for fox fur, wherein each 100g of the product comprises soybean powder 25-40g, fish meal 15-25g, seaweed powder 5-10g, soybean lecithin 3-8g, linoleic acid 1-5g, poly-unsaturated fatty acid OMEGA3 or OMEGA6 2-6g, pantothenic acid 20-80mg, nicotinic acid 10-50mg, bursine 200-800mg, inositol 20-60mg, riboflavin 10-50mg, folic acid 5-15mg, ferrous methionate 120-200mg, zinc methionate 150-250mg, copper methionate 20-50mg, selenium methionate 5-20mg and and balancing maize flour.

Owner:SHANGHAI JIAO TONG UNIV

High concentration glycerol-type minoxidil tincture and preparation method thereof

InactiveCN102349913AIncrease concentrationSolve Oxidation ProblemsOrganic active ingredientsOrganic non-active ingredientsHigh concentrationArginine

The invention relates to a high concentration glycerol-type minoxidil tincture for treating alopecia and a preparation method thereof. The high concentration glycerol-type minoxidil tincture of the invention comprises components of minoxidil, alcohol, glycerol, water-soluble azone, acids, ethylene diamine tetraacetic acid, arginine, cystine and water. Traditional propylene glycol is substituted by glycerol and water-soluble azone, so as to realize a minoxidil concentration of 5-15%, solve allergic problem caused by propylene glycol and realize a high minoxidil dissolving concentration; amino acids are added in the components to increase hair growing speed; when necessary, the arginine and / or sodium hydroxide is added with a pH buffer solution to stabilize a scalp pH at an optimum pH andavoid discomfort and hair shedding caused by pH change along with application of the hair grower. The invention employs a minoxidil step-by-step dissolving method with a short dissolving time to solve a problem of minoxidil oxidation during dissolving in a traditional technology.

Owner:刘国辉

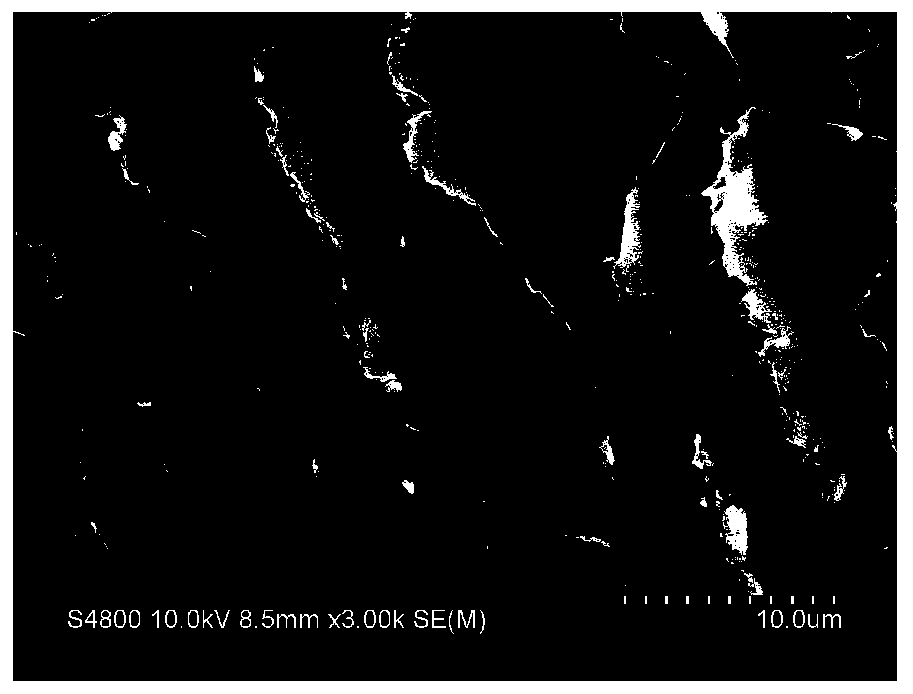

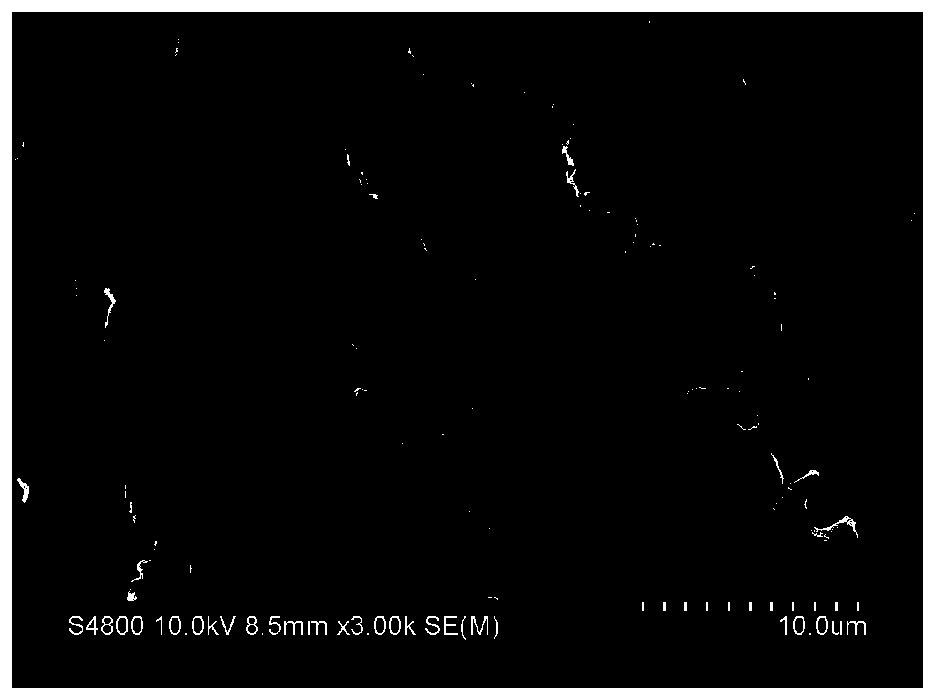

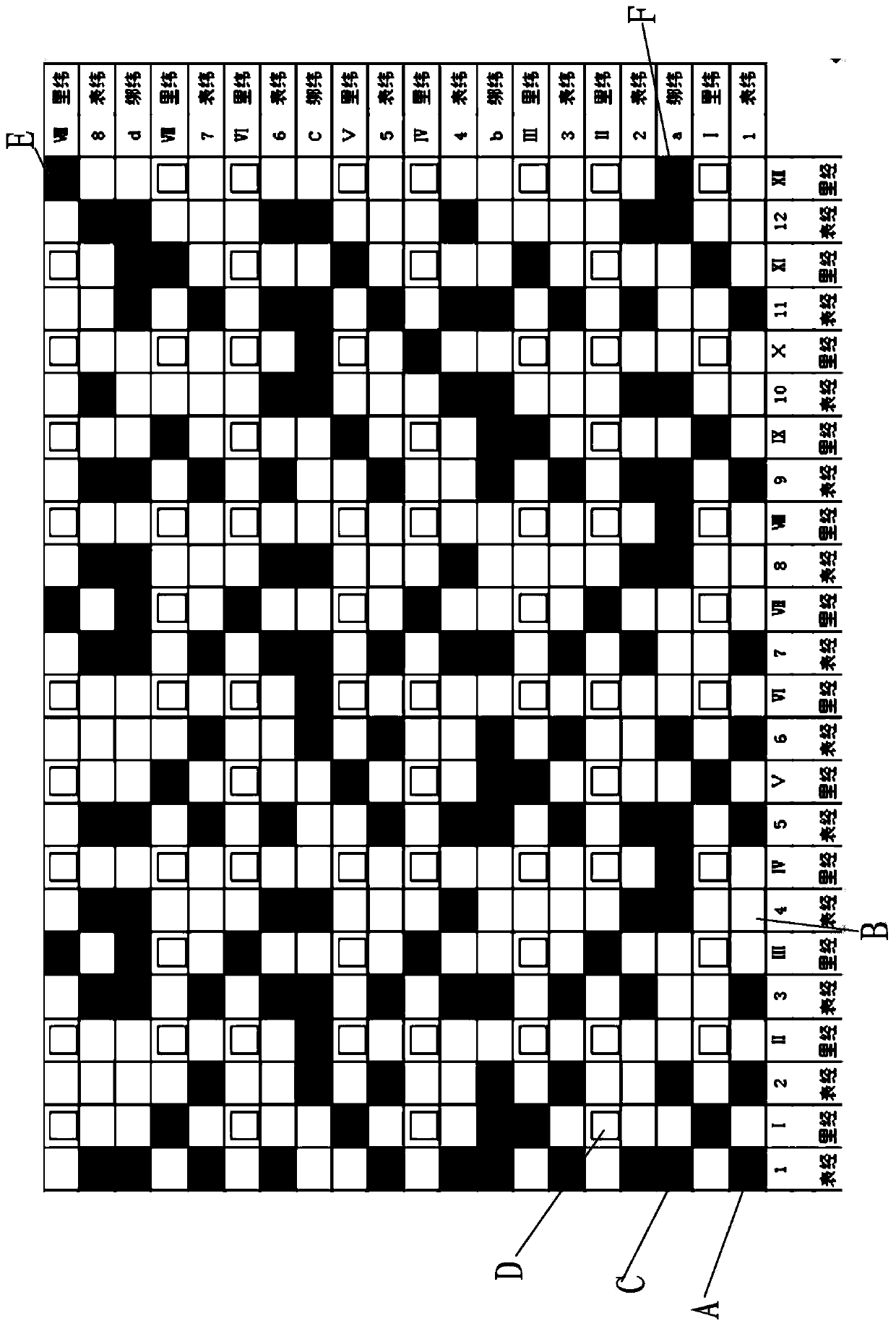

Conductive blended textile

The invention discloses conductive blended textile, which comprises yarns knitted. The yarns are blended by wool fibers, cony hair fibers, conductive fibers and cotton fibers or other fibers, wherein the wool fibers and the cony hair fibers account for 65% to 93% of the yarns, the conductive fibers account for 2% to 6% of the yarns, and the cotton fibers or other fibers accounts for 1% to 33%. The cony hair fibers are made by blending cony hairs and chemical fibers, the content of the cony hairs ranges from 60% to 98%, and the content of the chemical fibers ranges from 2% to 40%. By the above technical scheme, quality of the textile is improved by combining the advantages of the wool fibers and the cony hair fibers and comfortableness thereof is improved. Besides, the conductive blended textile is fine in anti-wrinkle performance, high in humidity and heat adjustability and fine in heat retention, and meanwhile, slipping of fibers is avoided, static electricity is eliminated, and strength of the conductive blended textile is guaranteed.

Owner:常熟市佳懿针纺织品有限公司

Sweater fleece falling prevention technology

InactiveCN103343434AAvoid hair lossPrevent pillingHeating/cooling textile fabricsDyeing processEngineeringSizing

The invention discloses a sweater fleece falling prevention technology. The technology comprises processes of raw material selecting, dyeing, fleece finishing and sizing. The fleece finishing process with sanding, fleecing, carding, ironing and shearing is carried out after dyeing, so that produced sweater fleeces are soft and comfortable and can be prevented from falling and piling, and moreover, the sweater cannot easily deform after being washed and has high warm-keeping performance.

Owner:罗志焯

Shampoo with hair growth and hair caring effects

InactiveCN110403882AHair RestorationPrevent atrophyCosmetic preparationsHair cosmeticsHair follicleHair growth

The invention discloses a shampoo with hair growth and hair caring effects. The shampoo comprises, by mass percentage, 0.35% to 1.4% of a hair restorer, 0.94% to 2.9% of a moisturizer, 0.25% to 2.01%of a nutrient agent, 13% of a surfactant, 5.15% to 5.56% of an auxiliary agent, and the balance of deionized water. The hair restorer includes caffeine, a biota orientalis extract, a ginkgo biloba extract and olive oil, and the weight ratio of caffeine, the biota orientalis extract, the ginkgo biloba extract and olive oil is 1 to 5:0. 5 to 1:1 to 2:2 to 6. The shampoo can repair the hair follicleand activate an active period of the hair follicle, can also provide the nutrient substances needed for hair growth, promotes hair growth, repairs damaged hair, and has the functions of hair growth and hair caring.

Owner:FOSHAN UNIVERSITY +2

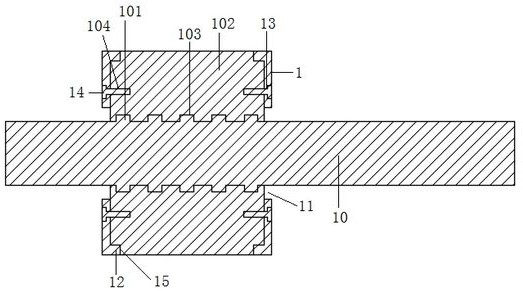

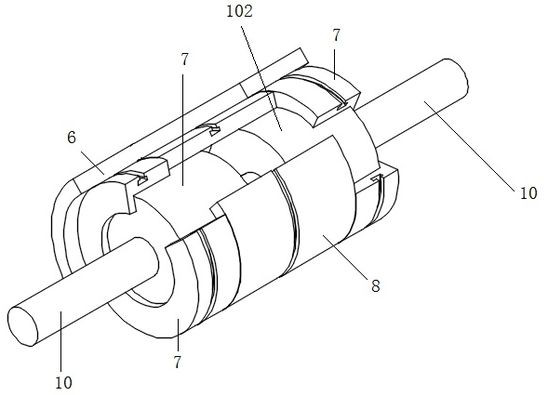

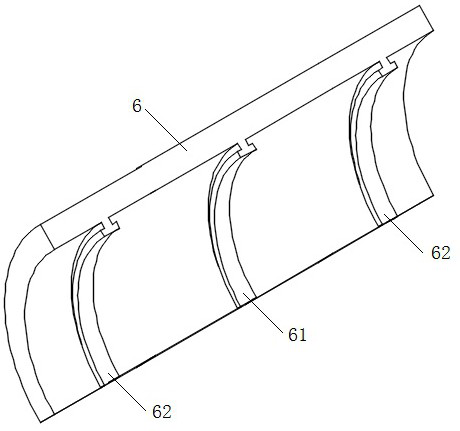

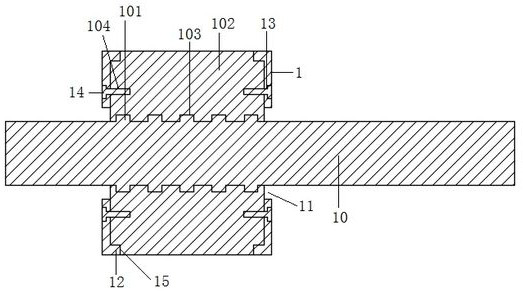

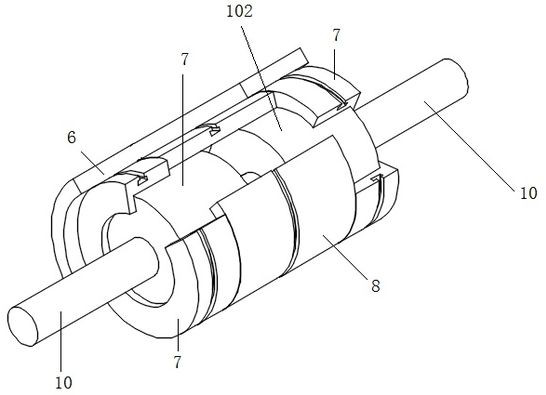

5G communication cable and mounting structure thereof

ActiveCN111710465AEasy to connect and fixConvenient truncationCoupling device detailsInsulated cablesFastenerElectric cables

The invention discloses a 5G communication cable and an installation structure thereof, and relates to the technical field of 5G communication cables and installation thereof. The cable comprises a cable body, and a connector is arranged at the end of the cable body. The joint comprises two fixing blocks which are symmetrically arranged on the peripheral side of the cable body, and mounting ringsare arranged at the two end parts of each fixing block respectively. A plurality of limiting rings are arranged on the outer side face of the cable body at equal intervals in the length direction of the cable body, and arc-shaped grooves matched with the limiting rings are formed in the inner side walls of the fixing blocks. Through the arrangement of the wrapping sleeve, the annular cutting partand the metal layer, the cable body can be conveniently cut off at any position, and the joint can be conveniently installed. Meanwhile, the connecting assembly is composed of the base plate, the first fastener and the cable sleeve, so that the joint of the two cable bodies is conveniently connected and fixed, and the phenomenon that the joint of the two cable bodies is disengaged due to the weight of the cable or construction dragging of the cable is avoided.

Owner:新雅电线电缆(深圳)有限公司

Hair growth shampoo

InactiveCN103655218AAvoid hair lossPromote fur growthCosmetic preparationsHair cosmeticsIrritationNutrient

The invention discloses a hair growth shampoo, which is composed of a surfactant, a foam booster, a conditioner, an anti-dandruff agent, an essence, a corrosion remover, water and sialic acid, wherein the sialic acid is added to shampoo matrix. The shampoo disclosed by the invention can provide sufficient nutrients for hair development and growth of people and fur-bearing animals, prevents the phenomena such as depilation, hair slip and the like, is small in irritation, has the functions of breeding, relieving itching and removing scurf, and is the shampoo integrated with the functions of cleaning the hair and protecting the hair.

Owner:WUXI CIMA SCI

Preparation method of forage for turkey

The invention provides a preparation method of a forage for turkey, consisting of soybean powder, grass powder, sweet potato powder, antarctic krill powder, bitter gourd powder, milk powder, wheat bran powder, krill powder, towel gourd powder, lysimachia sikokiana powder, bamboo leaf powder, salt, blood worm powder, towel gourd leaf powder, liquorice powder, soybean sprout powder, Chinese-date powder, malt powder and pericarpium citri reticulatae powder, wherein the percentage is weight percentage. The bred turkey is quick in growth and development, robust and attractive in body type, large in size, healthy in body, and low in morbidity. The defects that the turkey is easy to fall off feathers, less in pecking, gloomy and lackluster in hair color, slow in growth and development, small in size, light in weight, loosened in feathers, less in activity level, easy to infect various infectious diseases, and easy to die caused by the nutritional deficiency in some breeding households and large-size breeding grounds can be effectively overcome.

Owner:刘学顺

Forage for black-bone chicken

InactiveCN102461754ARich in contentGood preventive and curative effectAnimal feeding stuffBody typeActivity level

The invention provides a forage for black-bone chicken, consisting of bamboo leaf powder, jowar powder, bean cake powder, ginger powder, soybean leaf powder, growth hormone powder for the black-bone chicken, winter peach powder, sesame powder, garlic powder, red flower powder, bean leaf beetle powder, asparagus fern powder, apple leaf powder, malt powder, mineral substance addition agent, jasmine leaf powder, peach tree leaf powder, isatis root powder, clove powder and salt, wherein the percentage is weight percentage. The bred black-bone chicken are quick in growth and development, robust and attractive in body type, large in size, healthy in body, and low in morbidity. The defects that the black-bone chicken are easy to fall off feathers, less in pecking, gloomy and lackluster in hair color, slow in growth and development, small in size, light in weight, loosened in feathers, low in tweeting frequency, less in activity level, easy to infect various infectious diseases, and easy to die caused by the nutritional deficiency in some breeding households and large-size breeding grounds can be effectively overcome.

Owner:刘学顺

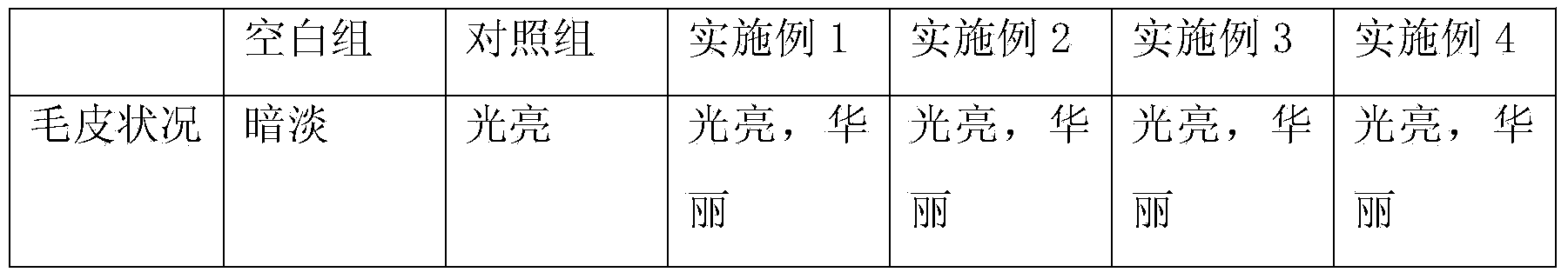

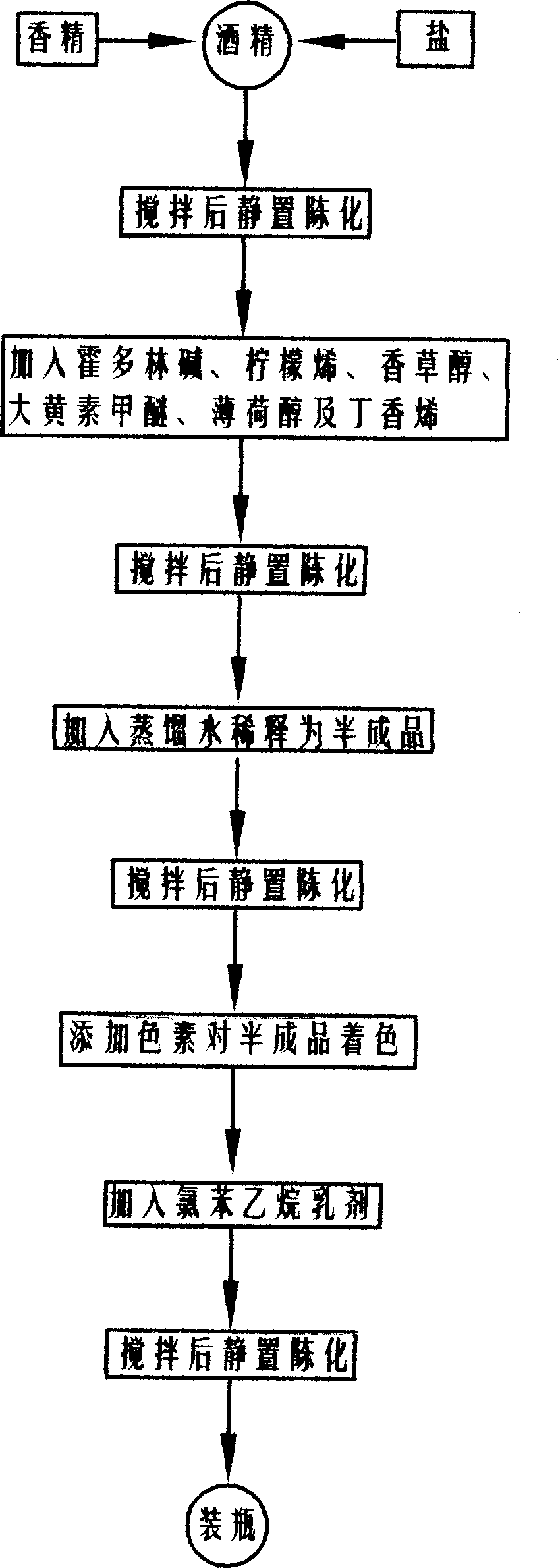

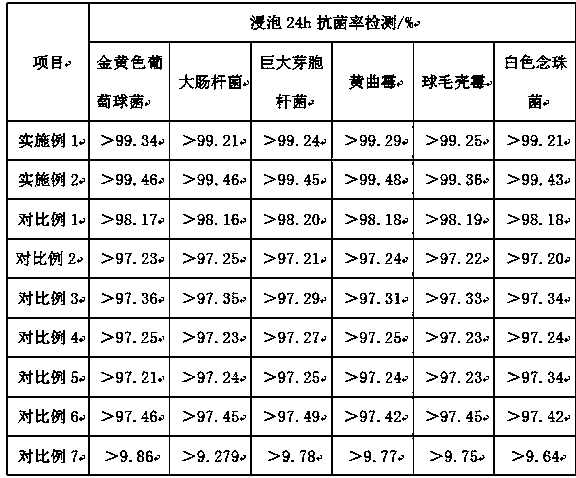

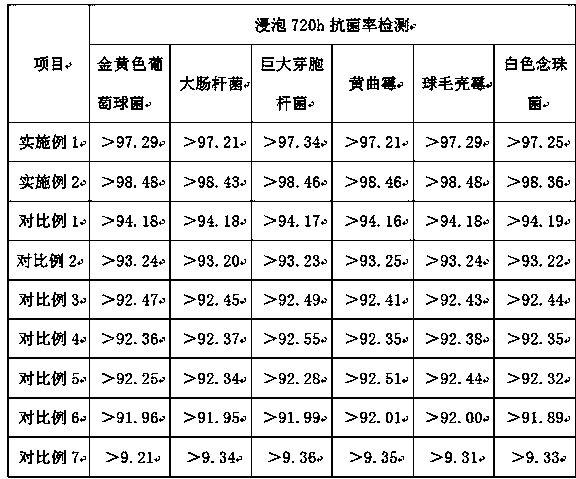

Prepn process of perfume specially for pets to eliminate bad smell, repel parasite and prevent unhairing

InactiveCN1739481AAvoid hair lossPositive use effectCosmetic preparationsToilet preparationsMentholAlcohol

The preparation process of perfume specially for pets to eliminate bad smell, repel parasite and prevent unhairing includes the following steps: dissolving salt in 0.5-2.5 % and essence in 2.5-20 % in 50-75 % concentration alcohol solution at -10 to +50 deg.c via stirring for 5-30 min and ageing for 1-90 min; adding hordorine in 0.5-8 %, limonene in 0.5-8 %, anillic alcohol in 0.5-8 %, ararobinol, menthol in 0.5-8 % and caryophyllene in 0.5-8 %, stirring for 5-30 min, and ageing for 1-90 min; adding distilled water to dilute the mixed solution to 10-80 % concentration semi-product; adding proper amount of pigment and chlorophenothane in 1-5 %, stirring for 5-30 min, and ageing for 1-90 min; and final filtering and bottling.

Owner:邹菲

Antibacterial and mildew-proof pillow towel fabric

InactiveCN108842468AHair conditionerImprove sleep qualityBiochemical fibre treatmentVegetal fibresPolyesterTextile technology

The invention mainly relates to the technical field of textile, and discloses an antibacterial and mildew-proof pillow towel fabric. The fabric is prepared from the following raw materials: cotton fiber, polyester fiber, bamboo fiber, mulberry fiber, aloe fiber, soybean fiber, bamboo charcoal fiber and polycrystalline alumina fiber. The fabric is high in stiffness, easy to clean, heat-insulating,antibacterial and mildew-proof. The polyester fiber, the bamboo charcoal fiber and the polycrystalline alumina fiber are blended, stiffness and adsorption performance of pillow towels are increased, and mould breeding is avoided; meanwhile, by addition of the polycrystalline alumina fiber, sunscreen capability of the pillow towels can be enhanced, aging of the pillow towels is delayed, cleaning capability of the pillow towels is enhanced, and the pillow towels are easy to clean, loose and comfortable; strength of the pillow towels is improved, pilling and aging caused by washing and solarization are delayed, and the service life of the pillow towels is prolonged.

Owner:安徽玉然经编科技有限公司

Method for preparing feed for sunbirds

The invention relates to a method for preparing a feed for sunbirds. The feed comprises the following components in percent by weight: mung bean flour, potato flour, saury meal, wheat bran, nereis meal, carrot meal, bone meal, soybean protein powder, tenebrio molitor meal, fresh escargot meal, milk powder, mineral additives, mixed inorganic salts, licorice powder, anise powder, ginkgo powder, wolfberry powder and cod liver oil. The feed has low preparation cost, readily-available components, a simple formula and a good sunbird feeding effect and is easy to prepare. The sunbirds fed by the feed can grow quickly, are large, robust and graceful, have colorful feather and are not susceptible to diseases.

Owner:郑月玲

Preparation method of lark fodder

InactiveCN101606625ALow pollution ratePhysically fitAnimal feeding stuffAccessory food factorsCod liver oilAnimal science

The invention relates to a preparation method of lark fodder. The lark fodder comprises the following raw materials in percentage by weight: 18-22 percent of peas, 3-9 percent of sorghum, 15-19 percent of dried hen egg yoke, 4-6 percent of millet, 7-9 percent of silkworm chrysalis, 6-8 percent of carrot meal, 2-4 percent of fishbone meal, 8-10 percent of bean cake protein powder, 6-8 percent of fresh red worm meal, 2-4 percent of fresh freshwater shrimp meal, 4-6 percent of milk powder, 1-3 percent of cod-liver oil, 0.5-1.5 percent of terramycin, 0.5-1.5 percent of pinellia powder, 0.5-1.5 percent of honeysuckle flowers, 1-3 percent of peach kernel, 0.5-1.5 percent of rhizoma anemarrhenae and 1-3 percent of vitamin B complex. The preparation method of the lark fodder comprises the following steps: putting the raw materials according to a certain proportion in a stirrer to stir for 130 minutes; taking out and putting in a pulverizer to pulverize into powder; then, taking out and putting in a drier to dry; taking out and putting in a loop-mold bulking machine to bulk; taking out and transferring to a loop-mold hard granulator to produce into precipitate hard granulated fodder; screening by a 10-mesh screen so that the weight of each granule is 0.02-0.03g; and sealing and packaging according to the needed weight.

Owner:张成华

Flocking process

The invention provides a flocking process and relates to the technical field of textiles. The flocking process provided by the invention comprises the following steps of a, printing glue on a fabric base through a silk screen board with predetermined patterns, so that the fabric base with glue patterns is obtained; b, carrying out electrostatic flocking on the glue patterns through electrostatic flocking equipment; c, sucking away excess flock on the surface of the glue through an exhaust fan; d, carrying out cold spray blowing treatment on the flock adhering to the surface of the fabric base;e, roasting and shaping the flock adhering to the fabric base through an oven; and f, sucking away the flock falling onto the fabric base again. By means of the flocking process, the technical problem that flock is liable to fall from fabric produced according to an existing electrostatic flocking process in the using process is solved.

Owner:DONGGUAN HONGYU PLASTIC CO LTD

Composition for preventing hair-loss or stimulating hair growth

InactiveCN103079536APrevent curingGrow fastOrganic active ingredientsCosmetic preparationsPhospholipidHair growth

The present invention relates to a composition for preventing hair-loss or stimulating hair growth and containing phospholipids as an active ingredient. More particularly, the present invention relates to a composition for preventing hair-loss or stimulating hair growth and containing, as an active ingredient, phospholipids extracted from animals.

Owner:BIOPID CORP

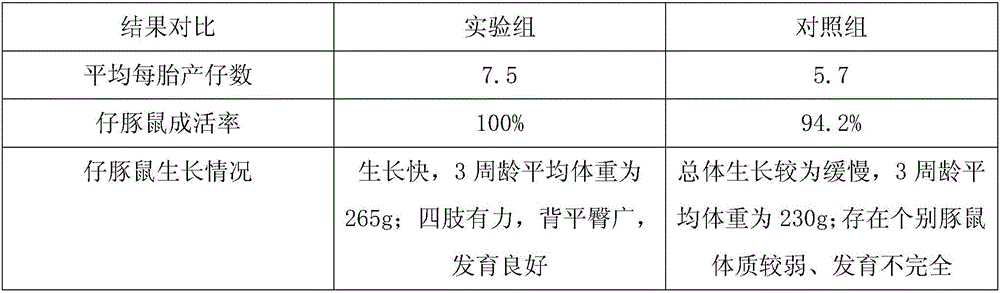

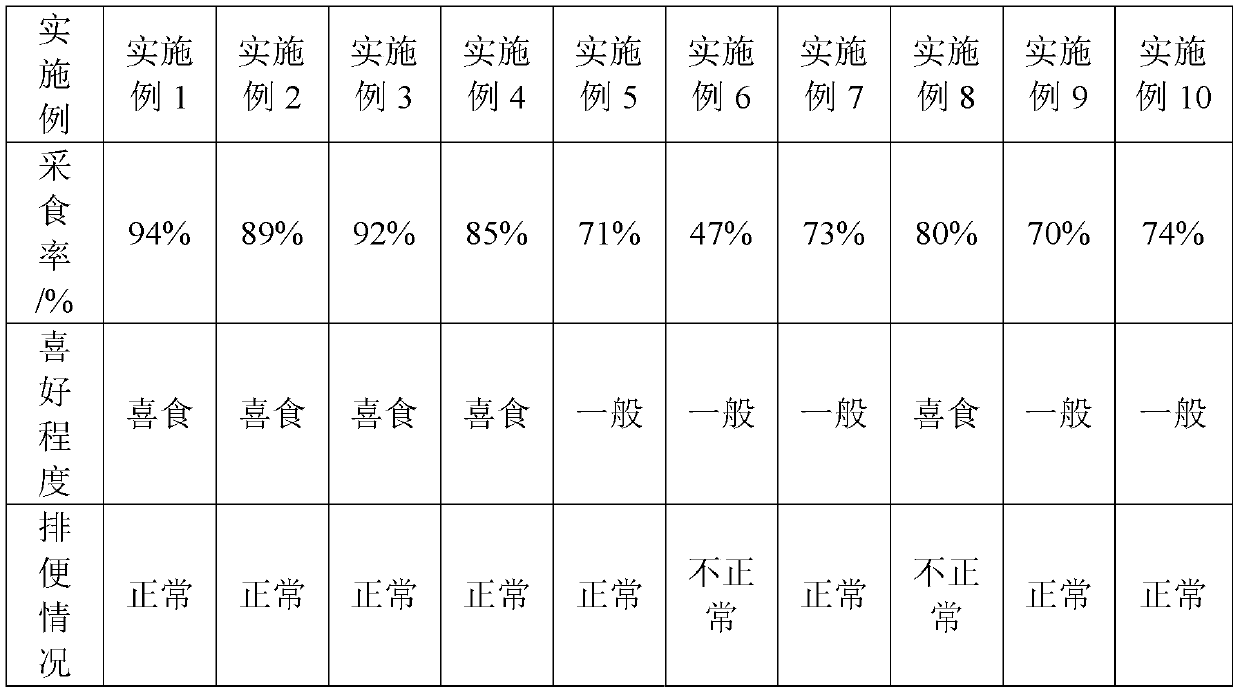

Guinea pig breeding method

InactiveCN106376519AImprove individual qualityImprove pregnancy rateAnimal feeding stuffAccessory food factorsAnimal sciencePorpoise

The invention belongs to the breeding technical field, and specifically discloses a guinea pig breeding method comprising the following steps: 1, species selection: selecting excellent individuals with strong arms and legs, flat back and wide ass and well grown genitals from a batch of guinea pigs of 3-month-old, and using same to serve as male and female guinea pig species; 2, breeding: using culture forage to feed the guinea pigs at the following quantity and frequency: 140-180g / time / pig, and 2times / day; 3, hybridization: allowing pubescent male and female guinea pigs to hybridize, breeding newly produced guinea pig babies to 4-month-old, and determining species. The guinea pig breeding method strictly selects species, uses special formula culture forage to feed the guinea pigs, thus improving guinea pig species breeding capability, guinea pig baby survival rate and growth speed.

Owner:广西河池市明达特种养殖专业合作社

Natural dog food composition for protecting skin and brightening hair and preparation method thereof

InactiveCN111280303AImprove immunityVigorousAnimal feeding stuffAccessory food factorsBiotechnologyCastor Seed

The invention relates to the technical field of pet food, in particular to a natural dog food composition capable of protecting skin and brightening hair and a preparation method of the natural dog food composition. The invention discloses a natural dog food composition for protecting skin and brightening hair; the composition at least comprises the following components by weight parts: 5-20 partsof flaxseeds, 5-15 parts of sunflower seeds, 3-7 parts of castor seeds, 3-10 parts of rapeseeds, 8-15 parts of methionine, 5-15 parts of cystine, 1-5 parts of beewax, 0.1-2 parts of tea leaves, 1-5 parts of Chinese wolfberry, 5-15 parts of jujubes, 1-5 parts of laver, 2-8 parts of undaria pinnatifida, 1-5 parts of spinach, 10-20 parts of buckwheat and 15-30 parts of corn. The dog food prepared bythe invention can protect hair follicles and hair of dogs from being damaged, enable the hair of dogs to be smooth and gentle, prevent bifurcation, reduce hair loss, promote fur regeneration, enablethe hair to grow vigorously, brighten the hair color, improve the hair quality, enable the hair to have elasticity, prevent pilling of the hair, reduce the incidence of skin diseases and improve skinallergy and pruritus.

Owner:SHANGHAI NAVARCH PETS PROD CO LTD

Special nutrient for cats

InactiveCN110463844AImproves fur healthStimulate hair regenerationFood processingAnimal feeding stuffOysterWhey protein powder

The present invention provides a special nutrient for cats. The special nutrient comprises the following raw materials in parts by weight: 30-50 parts of whey protein powder, 8-18 parts of soybean meal, 10-22 parts of micro-ecology live micro-organism preparation, 5-11 parts of oyster powder, 10-18 parts of buckwheat flour, 0.6-4 parts of ultra-fine calcium powder, 1-3 parts of medical stones, 2-5parts of rhizoma polygonati, 3-7 parts of asparagus officinalis, 2-4 parts of boehmeria gracilis, 8-17 parts of radix cynanchi bungei, 0.3-2 parts of herba lycopi, 0.3-2 parts of radix dipsaci, 1-4 parts of white atractylodes rhizome and 0.5-3 parts of vitex negundo var. cannabifolia. The special nutrient can comprehensively improve fur health of the cats, stimulates broken hair regeneration, prevents hair loss and hair breakage, prevents hair from splitting, protects hair follicle, improves hair quality, enables clothing hair to be elastic, prevents the hair from balling-up, comprehensivelyenhances immunity, replenishes spleen and stomach, nourishes qi and blood, enables pets to have spirit and the clothing hair to be flourishing, soft, smooth, bright in color and luster, and elastic, can increase the hair quality and brightens hair color.

Owner:深圳前海格林希尔贸易有限公司

Citrus seed feed for preventing unhairing of geese and preparing method thereof

InactiveCN105076784AImprove palatabilityImprove digestibilityFood processingAnimal feeding stuffAnimal scienceFermentation

The invention discloses citrus seed feed for preventing unhairing of geese and a preparing method thereof. The feed is composed of, by weight, 100-120 parts of citrus seeds, 250-320 parts of 40-60% ethyl alcohol, 10-14 parts of rye bran, 3-4 parts of barley flour, 2-3 parts of sugar bean flour, 1-2 parts of maize meal, 2-3 parts of candida utilis fermentation liquor, 1-2 parts of rohdea japonica, 1-2 parts of delphinium grandifloru, 3-4 parts of codonopsis pilosula leaves, 2-3 parts of radish peels, 1-2 parts of lophatherum gracile, 2-4 parts of white sesame seeds, 1-2 parts of mashed tomato, 2-3 parts of fish sauce, 5-7 parts of dehydrated spinach powder, and 0.5-1 part of konjac glucomannan. The feed has a special fermentation aroma, a fresh taste and unique flavor, and is extremely high in palatability and capable of overcoming the nutrition deficiency of geese, preventing the unhairing of geese, promoting the growth and development of geese, promoting the full growth of goose feather, improving the disease resistance of geese, improving the attractiveness of the appearance of geese, and improving the quality of goose down.

Owner:FENGTAI YONGBO WHITE GEESE BREEDING CO LTD

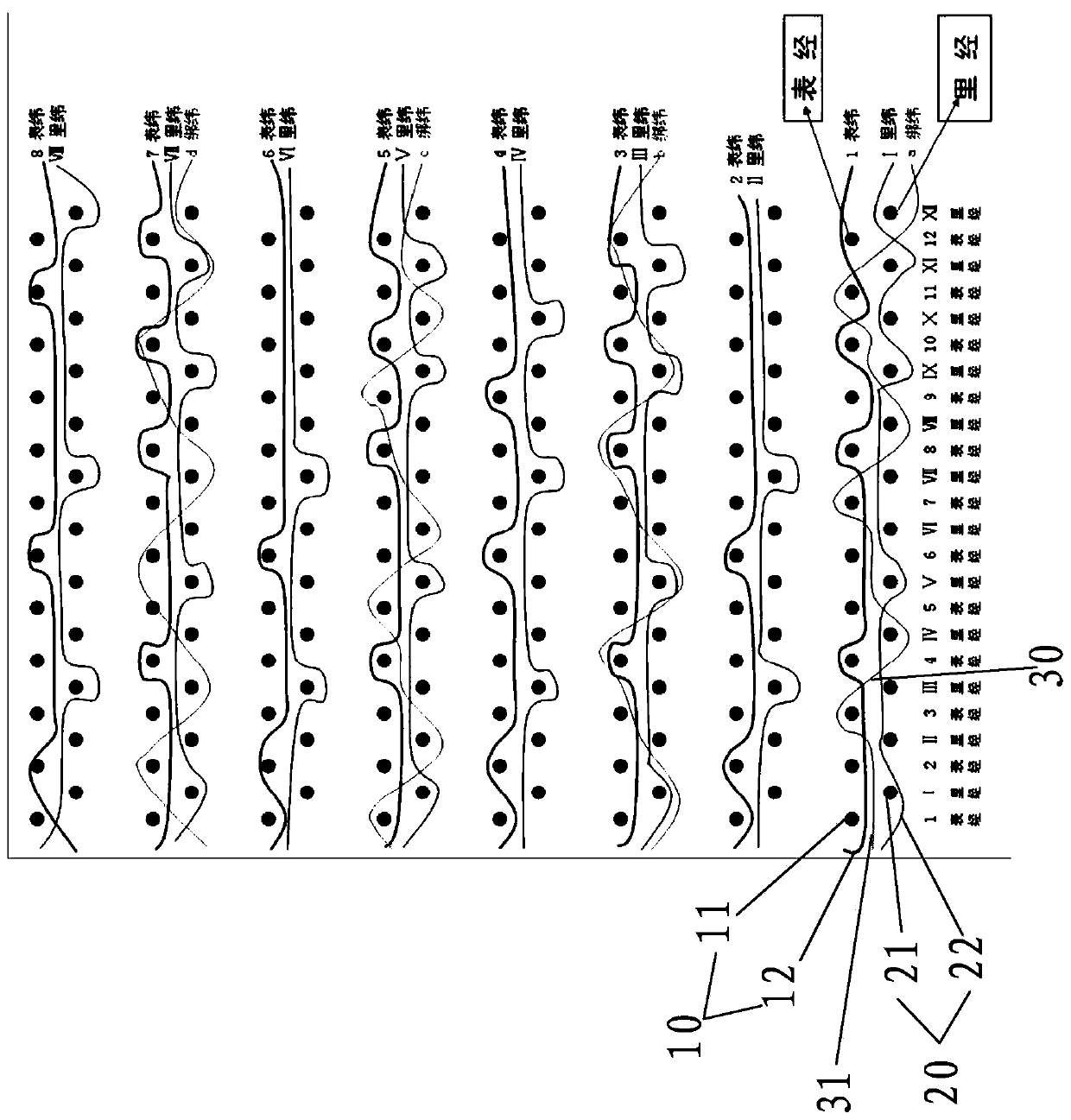

Novel environmental protection composite material runway and weaving process thereof

InactiveCN110016850AImprove structural strengthAvoid breakingGround pavingsWoven fabricsYarnEnvironmental resistance

The invention discloses a novel environmental protection composite material runway and a weaving process thereof, and belongs to the field of runways. The novel environmental protection composite material runway and the weaving process thereof comprise a runway body, a pile yarn layer is arranged on the upper surface of the runway body, the lower surface of the runway body is fixedly coated with anatural latex layer, the lower surface of the natural latex layer is fixedly adhered with a reinforcing fiber block, the outer surface of the reinforcing fiber block is fixedly connected with a connecting fiber strip, the outer surfaces of the reinforcing fiber block and the connecting fiber strip are covered with polyurethane protective layers, the runway body comprises warps, wefts and pile yarn, the warps are connected to the outer surfaces of the wefts in an interlaced weaving mode, the pile yarn is crisscrossed through connection gaps connected to the warps and wefts, a first transitionpart and a second transition part are arranged at the middle position of the pile yarn, using safety is greatly improved, the service life is prolonged, and the environmental protection effect is ensured.

Owner:日照聚润体育工程有限公司

Method for preparing pied magpie fodder

The invention discloses a method for preparing pied magpie fodder. The fodder comprises the following components in percentage by weight: 18 to 22 percent of pea, 3 to 9 percent of sorghum, 15 to 19 percent of egg yolk powder, 4 to 6 percent of millet, 7 to 9 percent of silkworm chrysalis, 6 to 8 percent of carrot meal, 2 to 4 percent of fish bone meal, 8 to 10 percent of bean cake albumen powder, 6 to 8 percent of fresh blood worm powder, 2 to 4 percent of fresh freshwater shrimp meal, 4 to 6 percent of milk powder, 1 to 3 percent of cod-liver oil, 0.5 to 1.5 percent of terramycin, 0.5 to 1.5 percent of pinellia tuber powder, 0.5 to 1.5 percent of honeysuckle, 1 to 3 percent of peach kernel, 0.5 to 1.5 percent of rhizoma anemarrhenae and 1 to 3 percent of composite vitamin B. The method comprises the following steps: putting the powder into a stirrer together according to the proportion and stirring the powder, taking the powder out and then crushing the powder in a crusher, then taking the crushed powder out and drying the powder in a dryer, then stirring the dried powder in the stirrer again, taking the stirred powder out and bulking the powder in a bulking machine, transferring the bulked powder after taking out to a hard granulation machine to produce and precipitate hard granular fodder, then screening the hard granular fodder by using a screen of 10 meshes to obtain granules each of which is 0.02 to 0.03 gram, and sealing and packing the granular fodder according to the required weight.

Owner:张颖

Preparation method of feed for Zuojia pheasant

The invention relates to a preparation method of a feed for Zuojia pheasant, comprising the following components in percent by weight: lean meat powder, yellow mealworm, yellow mealworm powder, sheep blood powder, pig blood powder, rice bran powder, wheat bran powder, soybean protein powder, animal protein powder, honeysuckle powder, dandelion powder, rhizoma anemarrhenae powder, Sichuan fritillary bulb powder, polygonum multiflorum powder, milk powder, cabbage caterpillar powder, shrimp powder, smashed rice grains, amino acid and edible salt. The feed for Zuojia pheasant is low in manufacturing cost, ingredients are available, a formula and a preparation method are simple, a feeding effect is good, fed Zuojia pheasant grow and develop rapidly, body type is robust and beautiful, gross body is huge and healthy, and morbidity of the Zuojia pheasant is low.

Owner:李永

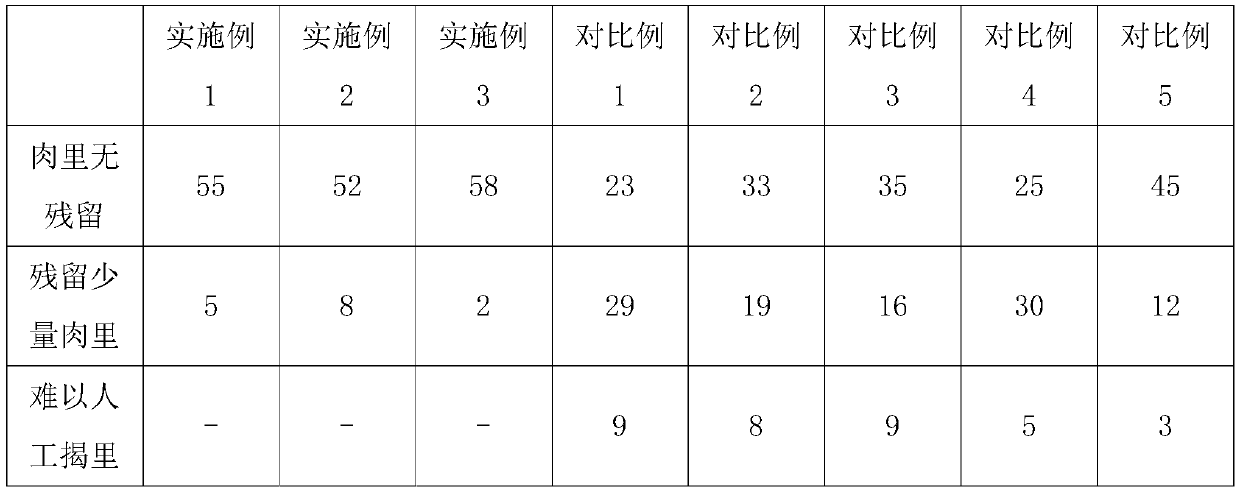

Treatment method for conveniently removing meat on rabbit skin

ActiveCN111549187AAvoid hair lossGuaranteed aestheticsPre-tanning chemical treatmentBiotechnologyAnimal science

The invention discloses a treatment method convenient for removing meat on rabbit skin, and belongs to the technical field of rabbit skin tanning. The treatment method comprises the following steps: S1, soaking rabbit skin at the room temperature, and completely soaking and softening until the skin returns to a fresh skin state; S2, at the room temperature, putting the rabbit skin subjected to a soaking treatment in the step S1 into an acid swelling solution, and soaking for 3 to 8 hours; S3, at the room temperature, putting the rabbit skin subjected to acid swelling soaking in the S2 into a first de-swelling solution, and soaking for 16-20 hours; S4, at a temperature of 30-35 DEG C, putting the rabbit skin treated in the S3 into water, and adding lipase into water; and S5, at the room temperature, putting the rabbit skin treated in the step S4 into a second de-swelling solution, and soaking for one night. According to the method, the meat on rabbit skin can be conveniently removed, the skin plate strength is not obviously lost, the tedious operation of a pure mechanical method or a manual method is reduced, the operation is convenient, and the method is more suitable for industrial production.

Owner:SICHUAN DEHUA LEATHER MFG +2

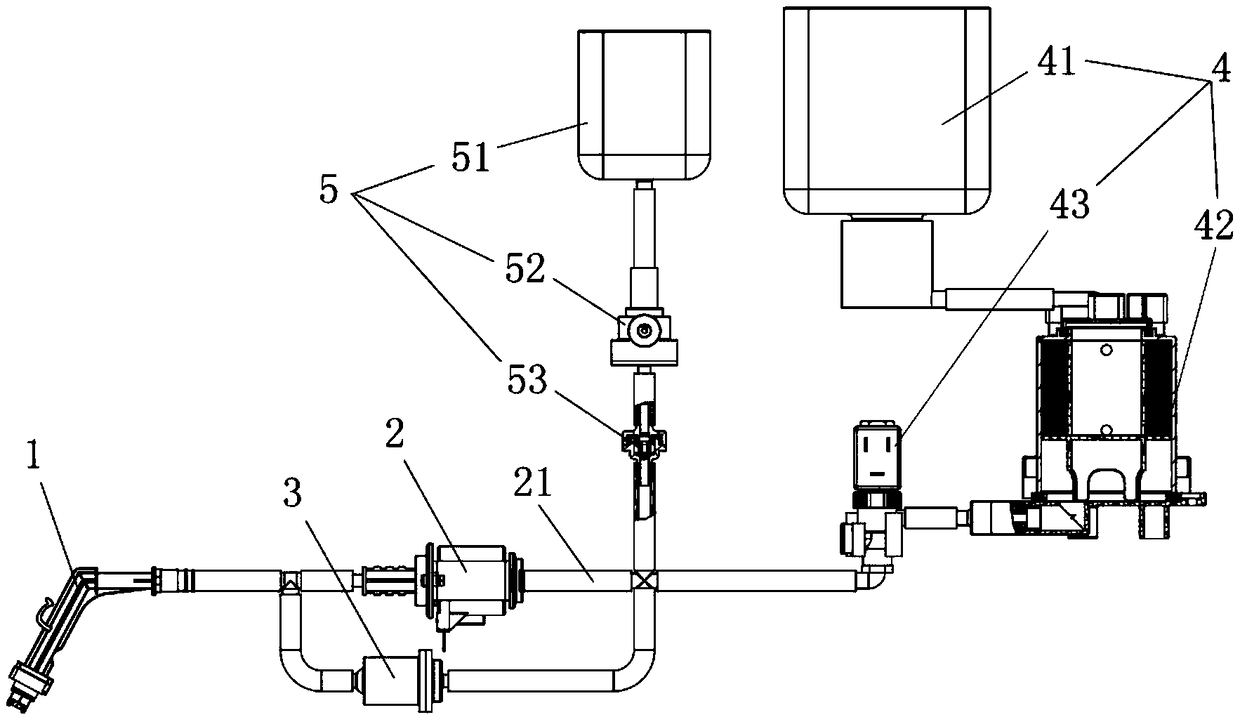

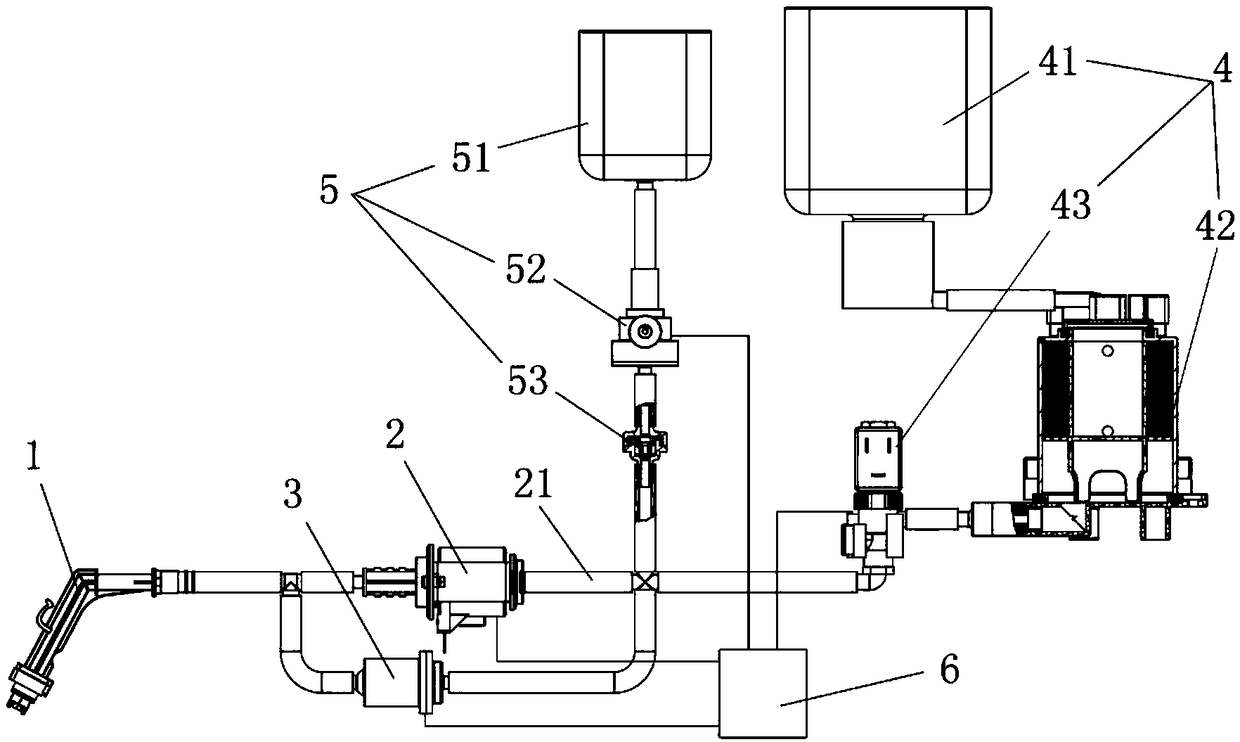

Cleaning system with water purification function

InactiveCN108739481AAvoid hair lossPrecise control of discharge volumeFiltration separationGrooming devicesSuction forceWater filter

The invention discloses a cleaning system with a water purification function. The cleaning system comprises a spray head, a pump, a water purification assembly and a solution assembly, wherein pure water and a solution in the water purification assembly and the solution assembly are mixed before entering the pump; the mixed liquid is conveyed to the spray head to be discharged through the pump; the water purification assembly realizes the purification process under the joint effects of the gravity and the suction force of the pump; the flow rate of the solution assembly can be precisely regulated. After harmful substances in the water are filtered by the water purification assembly, the pure water is conveyed to the spray head and is used for pet cleaning; the pet hair loss can be prevented; the solution in the solution assembly and the pure water filtered by the water purification assembly can be sufficiently mixed before reaching the spray head; the solution discharging quantity of the solution assembly can be precisely regulated and controlled; the cleaning effect can be favorably improved.

Owner:KINGCLEAN ELECTRIC

Stiff and smooth, non-deforming and non-pilling tatting air layer fabric and manufacturing method thereof

The invention provides stiff and smooth, non-deforming and non-pilling tatting air layer fabric. The stiff and smooth, non-deforming and non-pilling tatting air layer fabric comprises a fabric body; the fabric body comprises a surface layer, an inner layer and a middle layer; the surface layer is formed by interweaving surface warps and surface wefts in a tatting mode; the inner layer is formed byinterweaving inner warps and inner wefts in a tatting mode; the middle layer is a binding weft extending in the weft direction; the binding weft is interwoven in the surface layer and the inner layerin an ups and downs mode; the surface warps and the inner warps are first covering yarns; the first covering yarns are yarns which are formed by coating 40D spandex with 75D / 72F terylene; the surfaceweft and the inner wefts are second covering yarns; the second covering yarns are yarns which are formed by coating 40D spandex with 75D / 36F terylene; and the binding weft is 150D / 288F terylene. On the basis of having bulkiness, skin friendliness, air permeability and ductility of knitted silk cloth and air layer, the problem of high possibility of hair slip, deformation, pilling and fading is avoided, so that the tatting air layer is more comfortable and stylish. The invention also provides a manufacturing method of the fabric.

Owner:XTEPCHINA

A kind of 5g communication cable and its installation structure

ActiveCN111710465BConvenient truncationEasy to installCoupling device detailsInsulated cablesStructural engineeringElectric cables

Owner:新雅电线电缆(深圳)有限公司

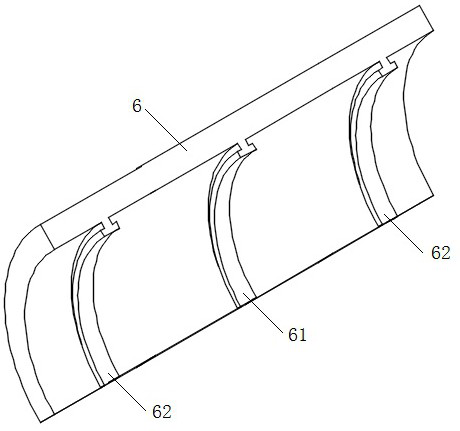

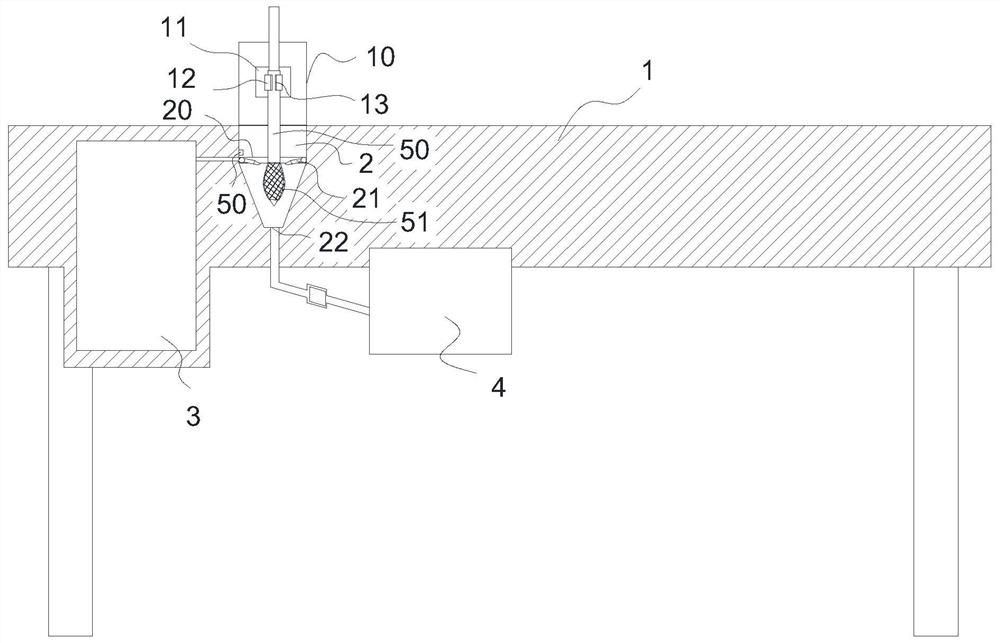

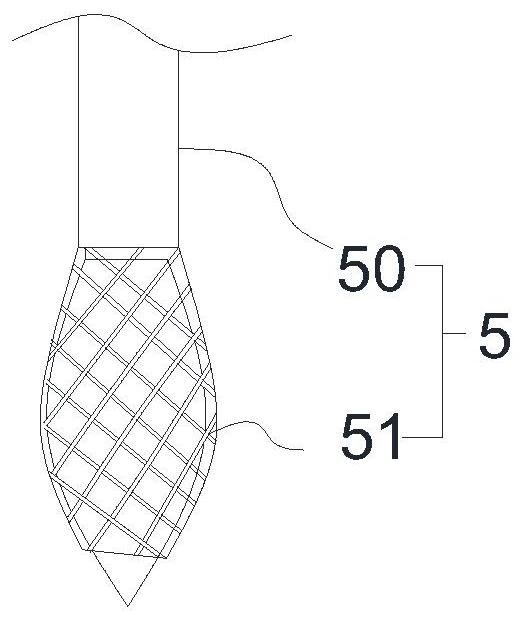

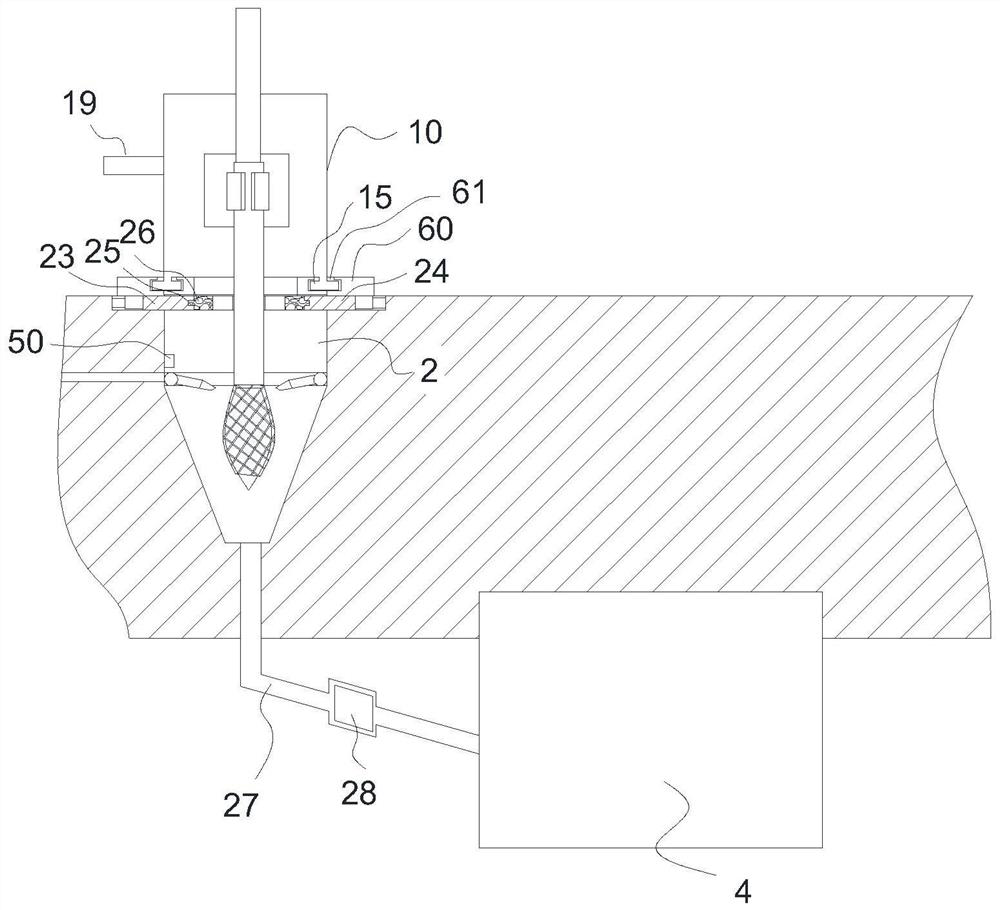

Special drawing table with drawing tool cleaning function and drawing tool cleaning method

ActiveCN113752742AAvoid hair lossAvoid splits, etc.Nib removersDrawing desksWater storage tankWastewater

The invention particularly relates to a special drawing table with a drawing tool cleaning function. The special drawing table comprises a table board, a table body is provided with a writing brush cleaning mechanism, and the writing brush cleaning mechanism comprises a brush holding mechanism arranged on the table top, and a cleaning cavity, a water storage tank, a waste water tank and a micro-control device which are arranged below the table top; the cleaning cavity is formed in the table body corresponding to the lower portion of the brush holding mechanism, the middle lower wall part of the cleaning cavity is of an inverted cone structure, an annular pipe is arranged on the upper wall in the cleaning cavity, 2-4 nozzles which are obliquely arranged downwards are distributed on the inner side of the annular pipe, and the annular pipe is communicated with the water storage tank; a water outlet is formed in the bottom of the cleaning cavity and is connected to the waste water tank; a water level warning sensor is arranged in the cleaning cavity; and the writing brush cleaning mechanism further comprises a net cover, the net cover comprises a hook-and-loop fastener part on the upper portion and a net-shaped part on the lower portion, and the net-shaped part is formed by bonding wefts on the inner side and warps on the outer side. The device is compact in structure, flexible and adjustable in cleaning operation and good in cleaning effect.

Owner:SHAOYANG UNIV

Feed for raising azure-winged magpies

InactiveCN102217703AFast growthLow costAnimal feeding stuffAccessory food factorsAnimal scienceAdditive ingredient

The invention discloses a feed for raising azure-winged magpies. The feed is composed of corn protein powder, soybean protein powder, liquorice powder, freshwater shrimp meal, bran, soybean flour, bean worm meal, fleece-flower root powder, chicken intestine meal, animal protein powder, lotus seed powder, pine nut powder, balsam pear powder, honeysuckle powder, elecampane powder, common anemarrhena powder and safflower powder. By adoption of the scheme, the pollution rate of the feed for raising the azure-winged magpies, prepared according to the prescription is low, the contents of proteins and vitamins in the feed are abundant, and the combination of various nutrient ingredients is reasonable; the requirements of the azure-winged magpies for fat, carbohydrates, crude fibres and mineral substances can be satisfied by the feed; additionally, the natural Chinese medicinal ingredients such as the pine nut powder, the balsam pear powder, the honeysuckle powder, the elecampane powder, the common anemarrhena powder and the safflower powder are contained in the prescription, so that the feed has a good prevention and treatment function to cold, cough, unhairing, skin diseases, rectocele, gastritis, digestive system diseases and the like of the azure-winged magpies.

Owner:王先德

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com