Stiff and smooth, non-deforming and non-pilling tatting air layer fabric and manufacturing method thereof

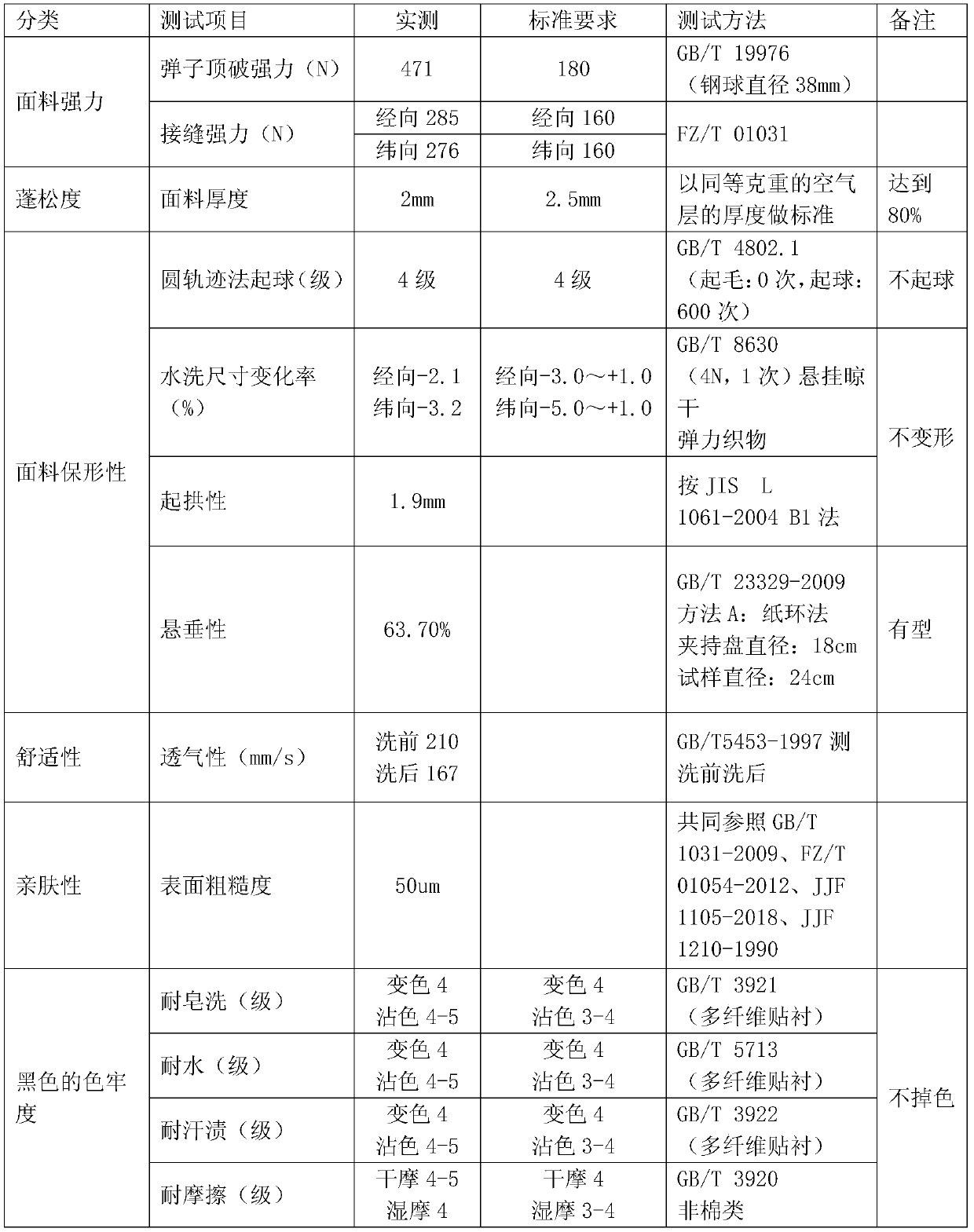

An air-layered and stiff technology, applied in the field of woven air-layered fabrics, can solve the problems of easy pilling and poor compound fastness of polar non-puffed surface, and achieve soft hand feeling, good color fastness and fastness. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

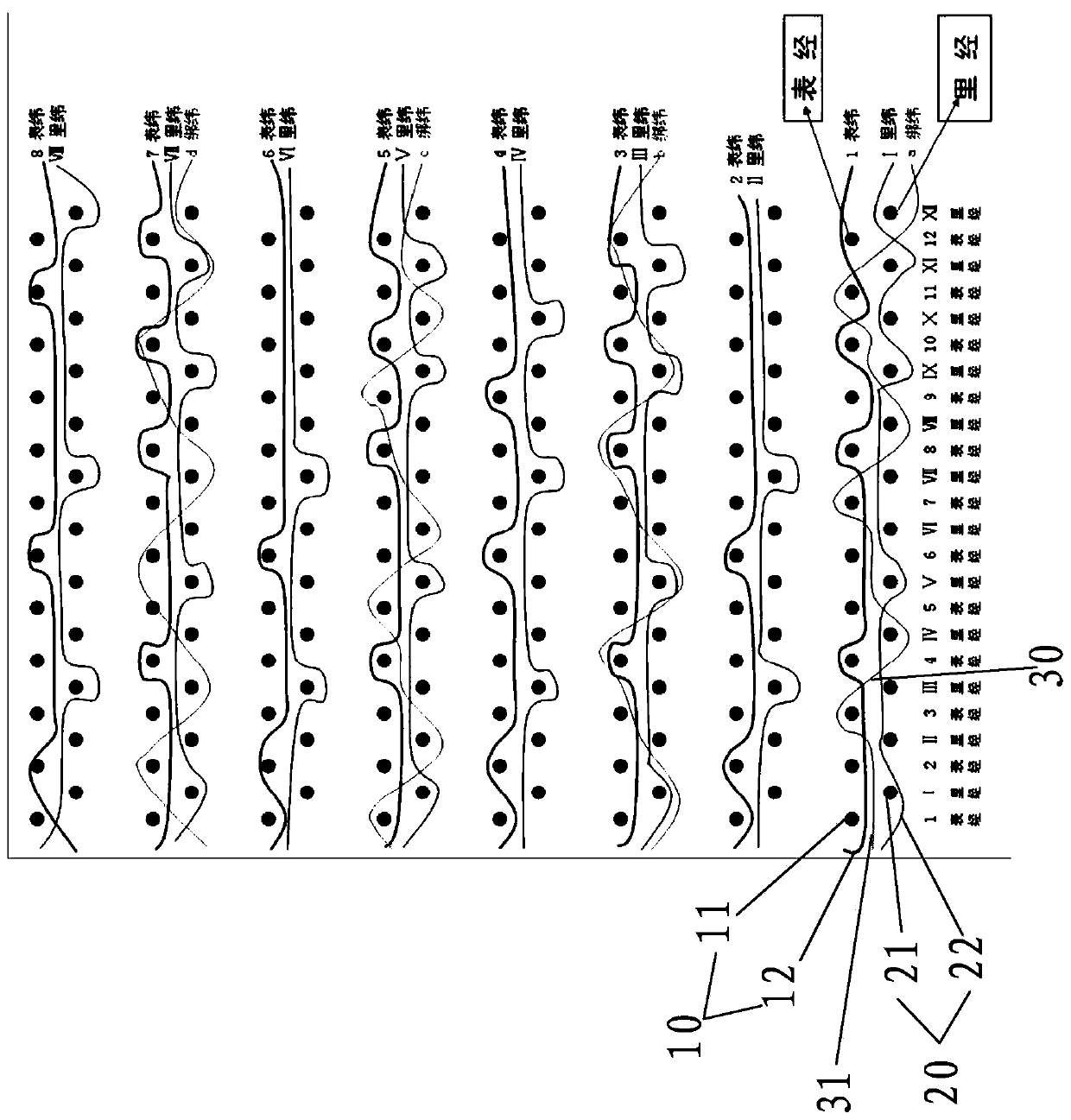

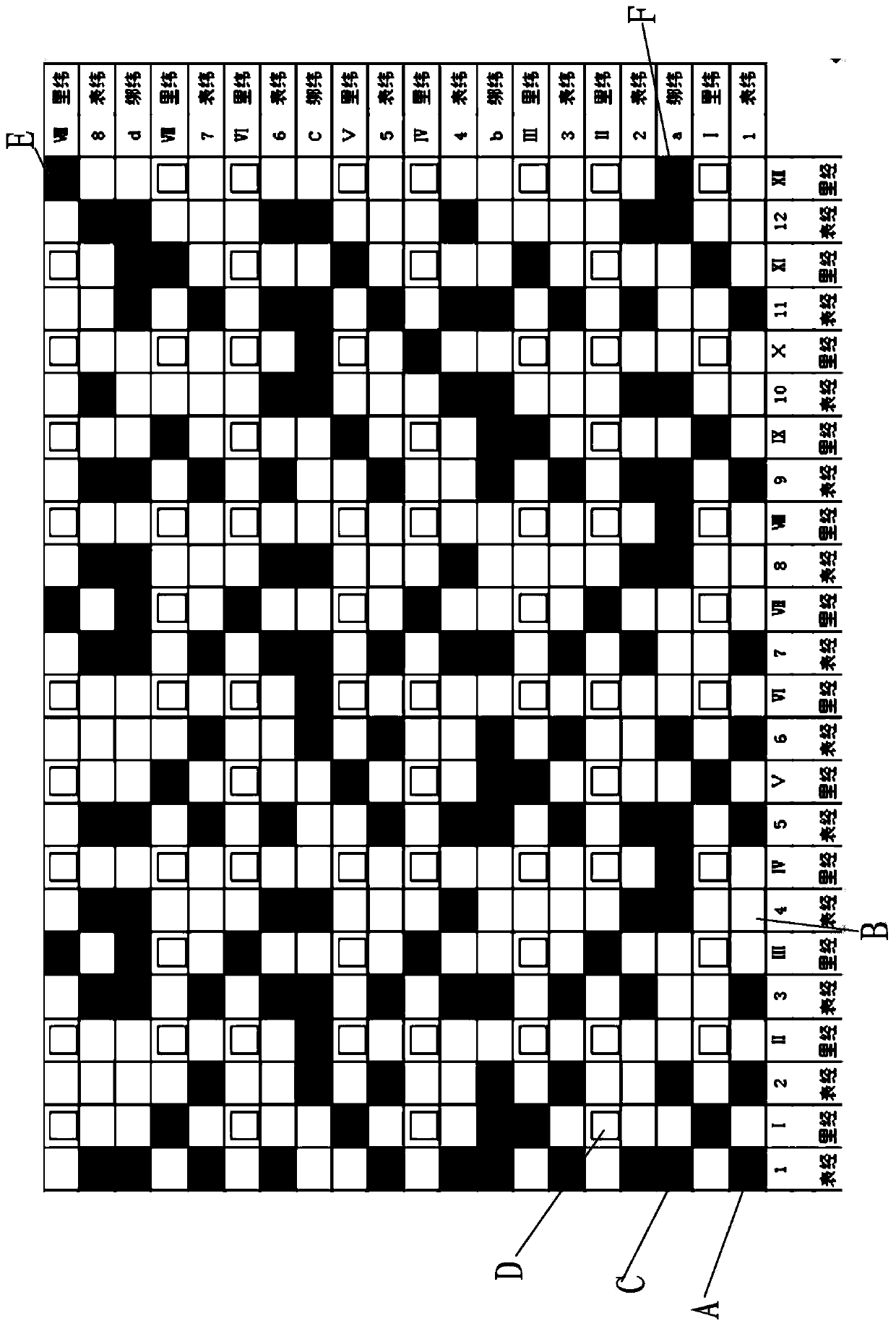

[0029] refer to Figure 1 to Figure 2 , to better represent the interweaving points of the yarns, figure 2 , the interweaving points are represented by color blocks or boxes of different depths, among which the A-type square is the interweaving point of the surface longitude 11 and the surface weft 12, and the surface longitude 11 floats on it; the E-type square, the inner longitude 21 and the inner weft 22 The interweaving point of the inner warp floats on the top; the C type square, the interweaving point of the surface warp 11 and the binding weft 31, the surface warp 11 floats on the top, the F type square, the 31 interweaving point of the inner warp 21 and the binding weft 31, the inner warp 21 floats above; surface latitude 12: interior latitude 22: tie weft 31=2:2:1; B type square: surface latitude floating p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com