Patents

Literature

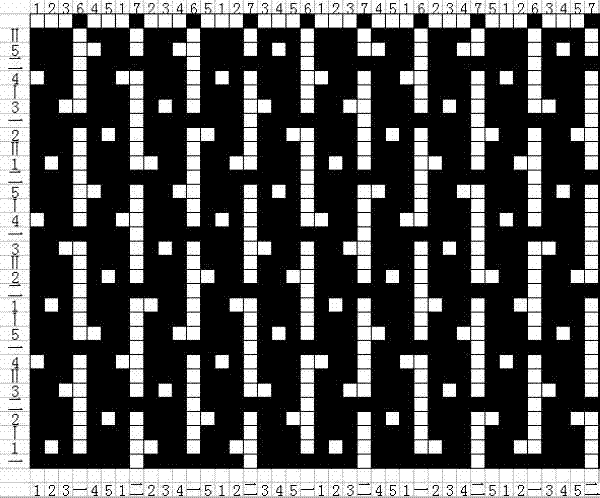

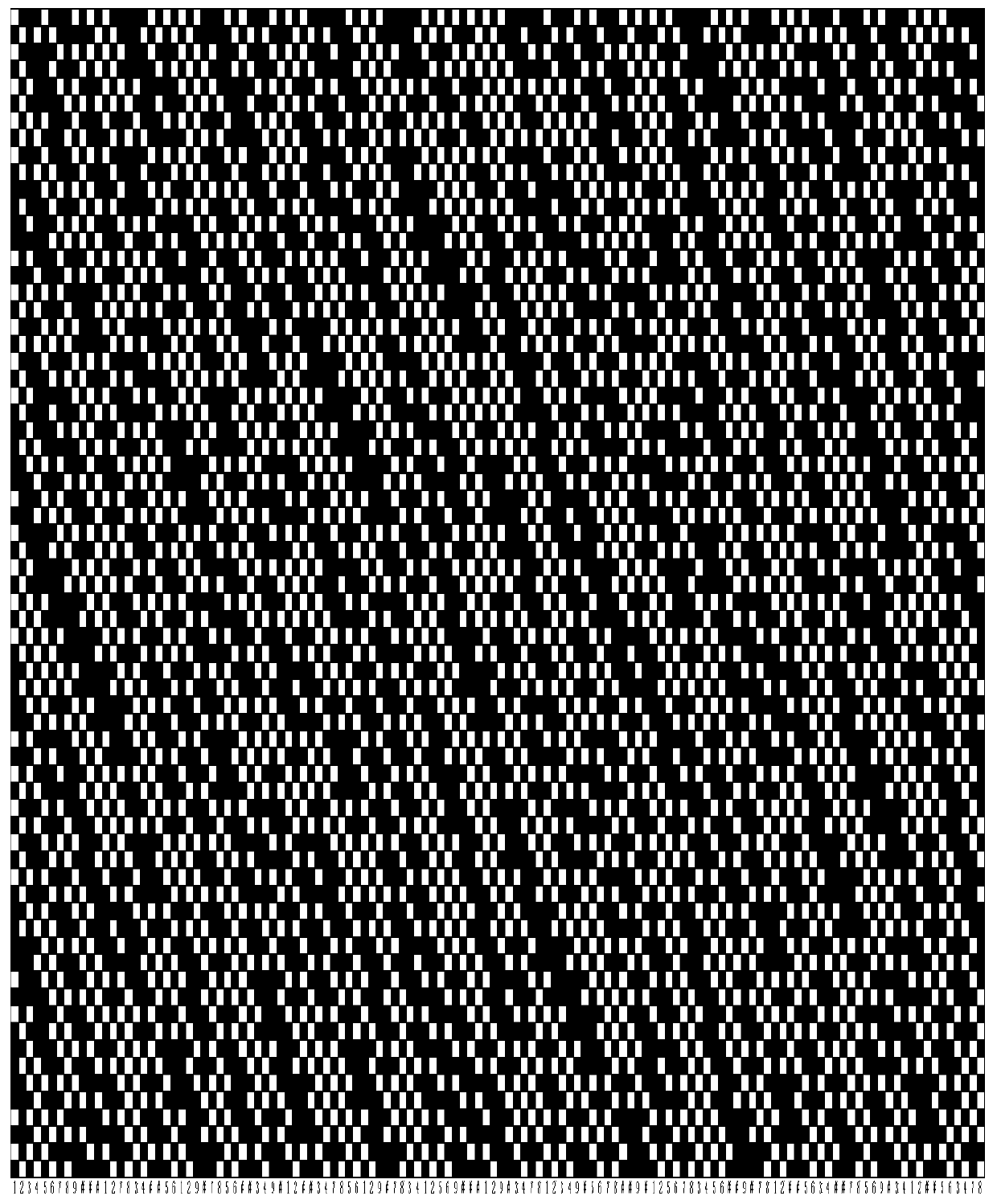

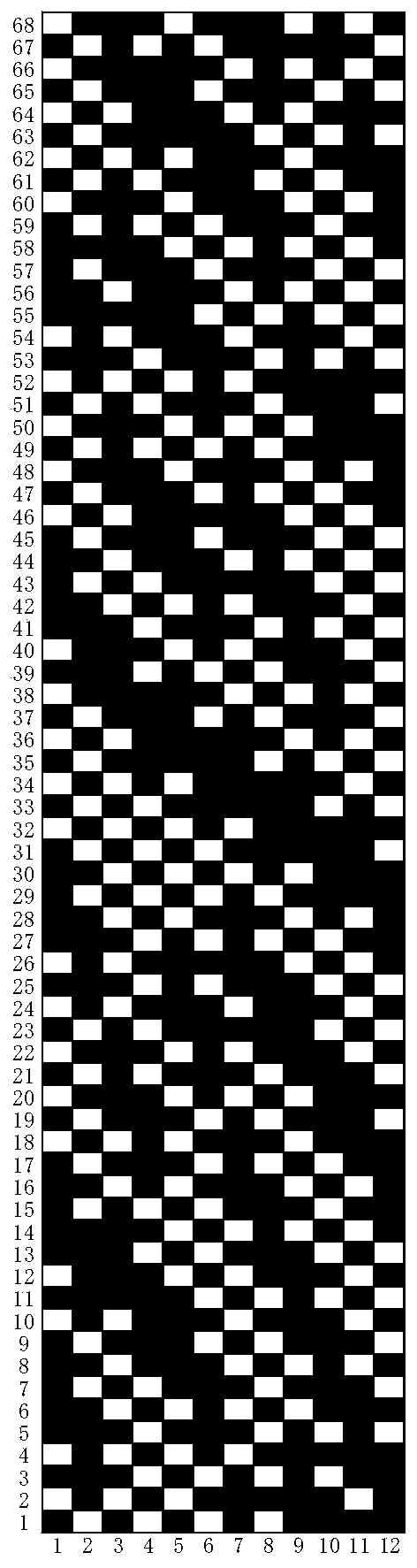

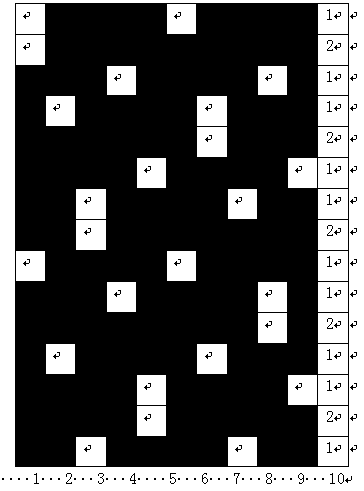

34results about How to "Weaving difficulty is small" patented technology

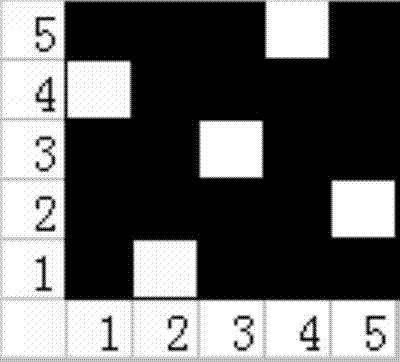

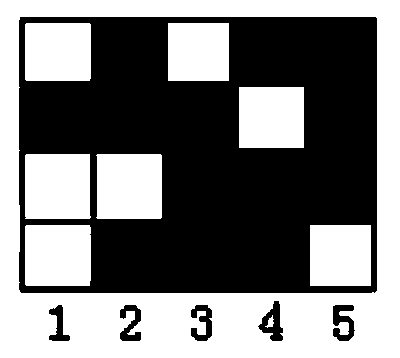

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

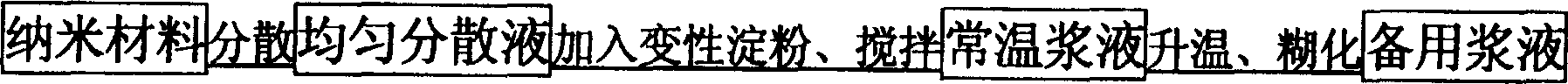

Size composition for textile

A textile size composition is prepared from modified starch (20-90%) and specia nano material (0.05-5%) which is chosen any one of SiO2, TiO2, Al2O3 and ZrO2. Its advantages are high stability, shortdissolving time and high effect of benefiting weaving.

Owner:杭州科瀚盟新材料技术有限公司

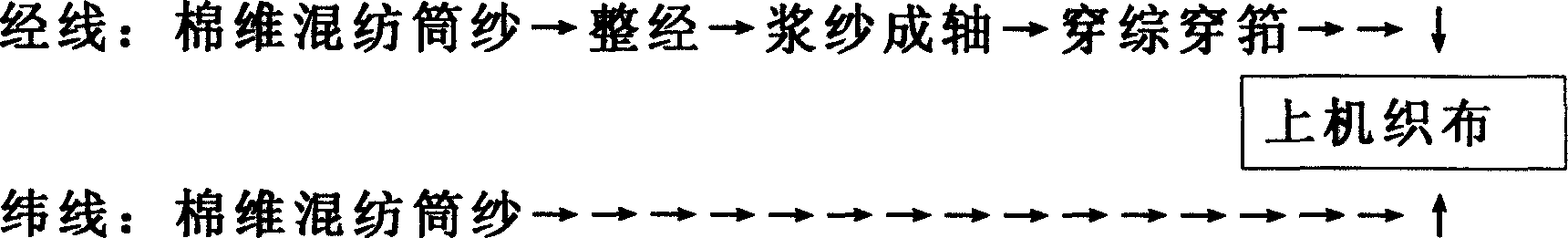

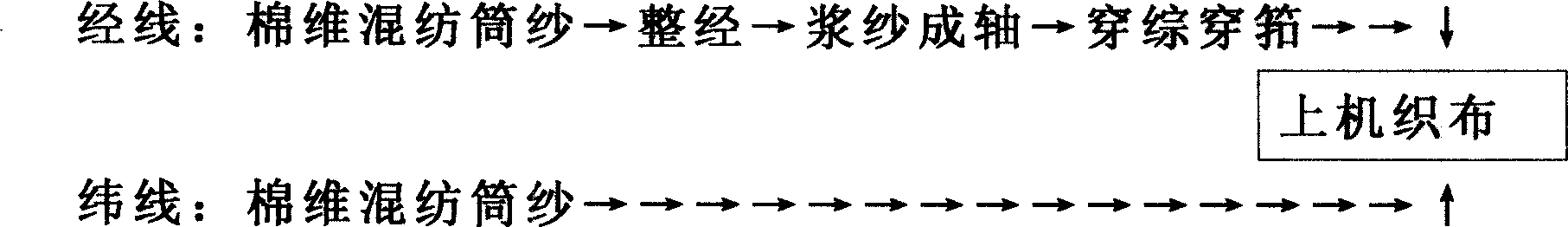

Cotton fiber fabric and manufacture technology thereof

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

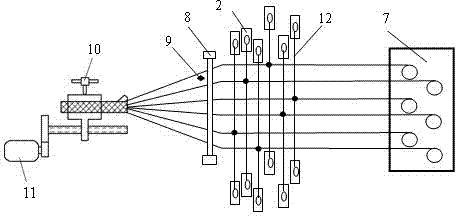

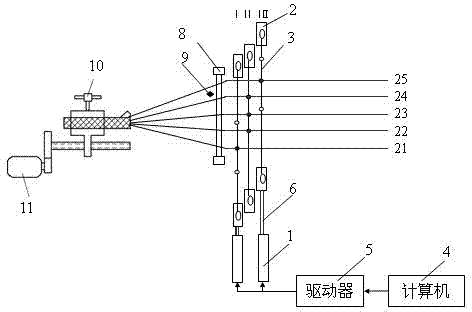

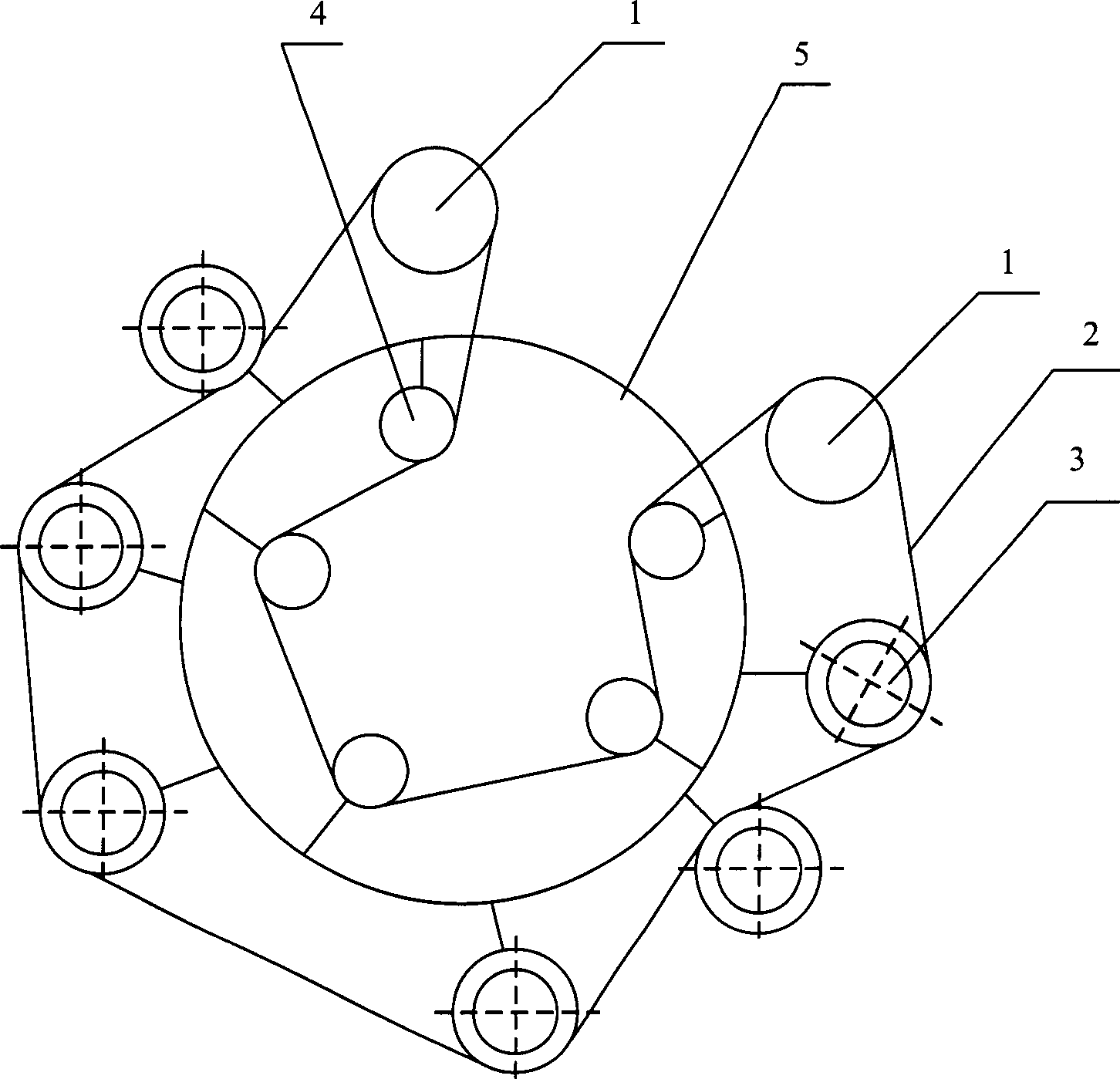

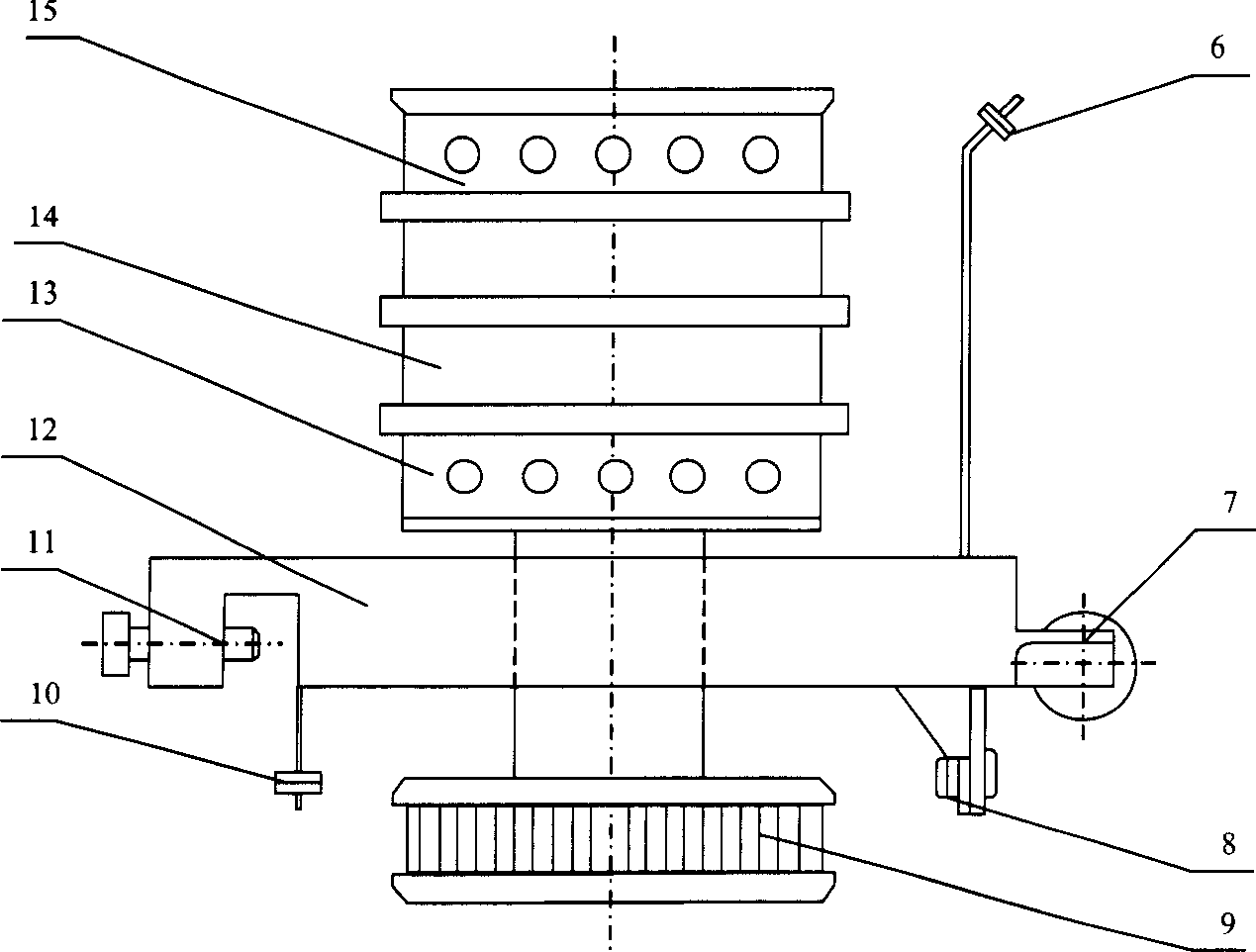

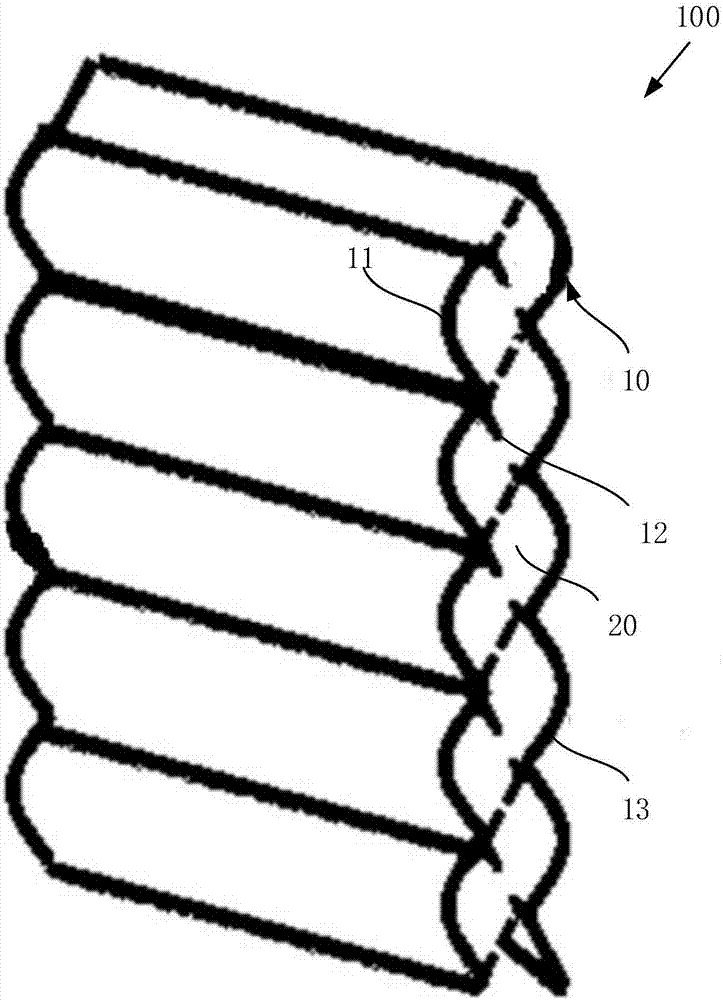

Opening device for stereo loom

InactiveCN102517741AReduce the number of pagesGood for weavingHealdsOther shedding mechanismYarnPalm fiber

The invention provides an opening device for a stereo loom. The opening device contains healed frames and is characterized in that at least one healed frame is connected with multi-hole palm fiber; at least one healed frame is connected with a push rod, which is connected with a servo electric cylinder; and the servo electric cylinder is connected with a driver, which is connected with a computer. By the adoption of the opening device, the number of heddles can be minimized and high-speed and digitalized control is carried out on the motion of the healed frames, thus greatly expanding types and specifications of fabrics and reducing abrasion of palm fiber to warp yarn.

Owner:DONGHUA UNIV

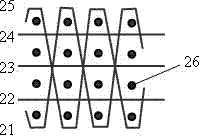

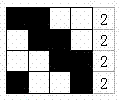

Multi-layer cloth fabric and weaving process thereof

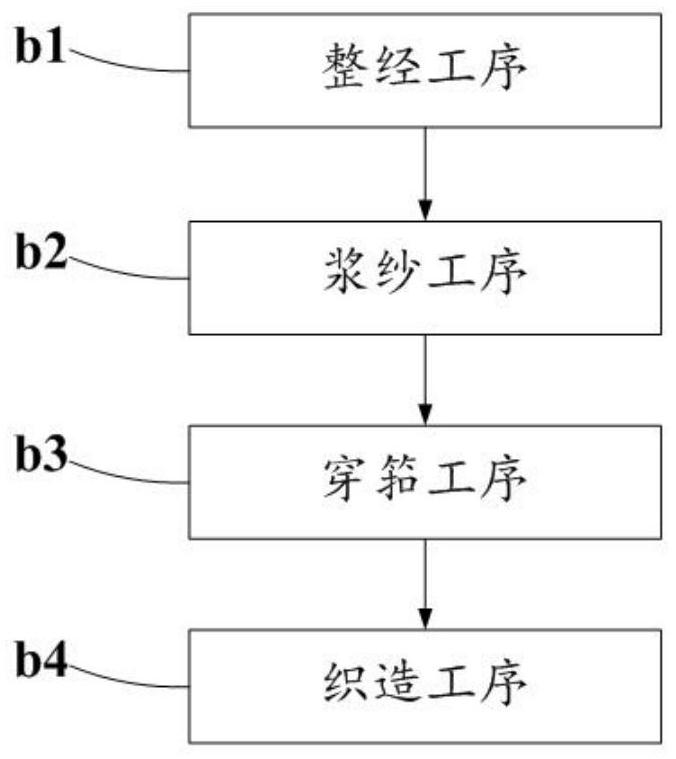

ActiveCN102226305ASimple processWeaving difficulty is smallLoomsMulti-ply fabricsGramFilling materials

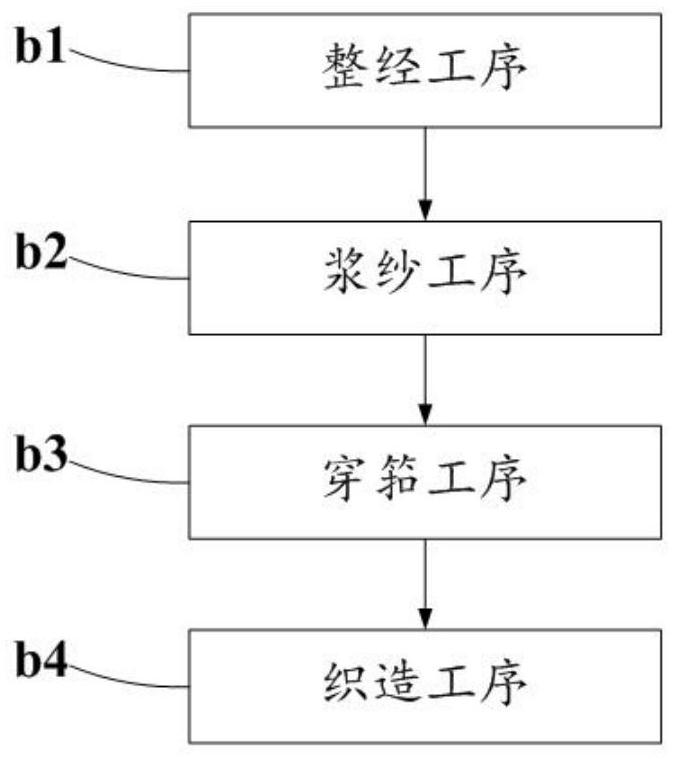

The invention relates to a multi-layer cloth fabric and a weaving process thereof, and the multi-layer cloth fabric comprises a surface-layer fabric, a middle fabric and a bottom-layer fabric, wherein the surface-layer fabric is a plain weave, twill weave or satin weave fabric; the middle fabric is filling material which is not interwoven with warps, and the yarn number can be adjusted according to the needs of gram weight; the bottom-layer fabric is a plain weave or twill weave fabric; and the process comprises the following steps: cheese winding, warping, slashing, denting, weaving and arranging. The middle fabric is not interwoven with the warps, which is equivalent to the situation that the filling material is not included in limit tightness, and the yarn number of the middle fabric can be adjusted for getting the required ideal heavy-weight, thereby solving the problem that ultra-heavy-weight fabric can not be produced by the traditional weaving process; by adopting the process, the gram weight of the broad-width fabric can be above 300g / m<2>; and the weaving process has the characteristics of simple process, small difficulty in weaving and low consumption of spinning devices, and an ultra-heavy-weight textile product can be added for the field of textiles.

Owner:JIHUA 3542 TEXTILE CO LTD

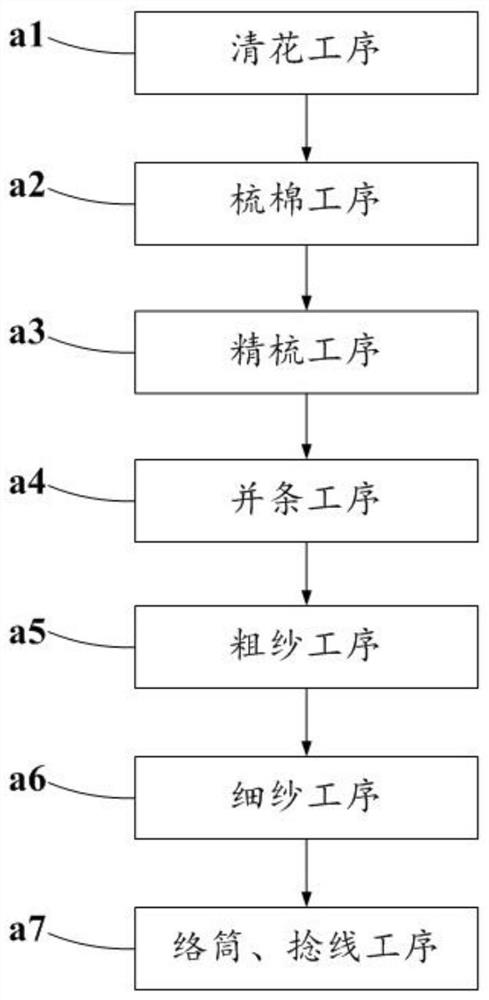

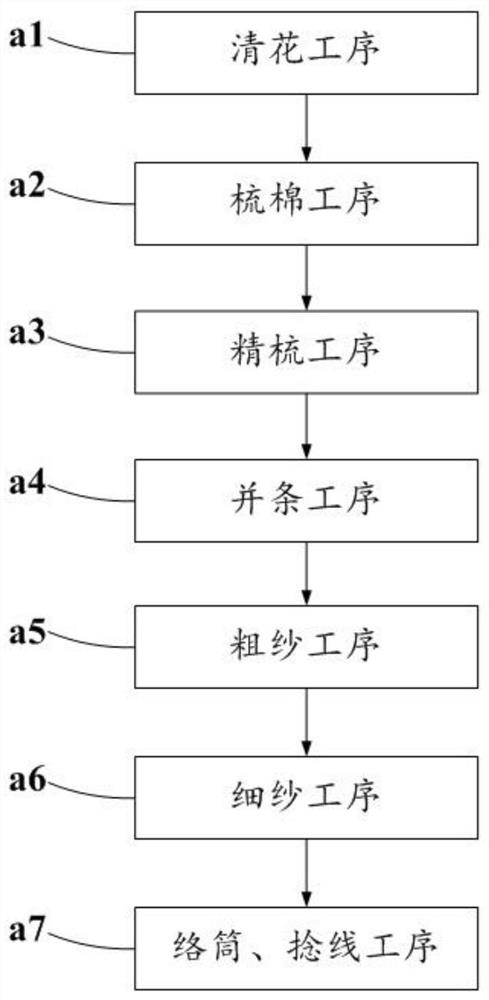

Linen blend yarn and producing method thereof

InactiveCN1609299AImprove spinnabilityWeaving difficulty is smallDry-cleaning apparatus for textilesYarnYarnEngineering

The present invention is blended hemp yarn and its production process, and aims at providing blended hemp yarn with high quality. The blended hemp yarn consists of blended flax fiber and soluble vinylon in the ratio of 50-60 to 40-50. The production process of the blended hemp yarn includes first mixing the above said materials and the subsequent conventional spinning process. After desizing, the blended hemp yarn is treated in water with penetrant inside the dye jigger and washed first in water at 100 deg.c and then in cold water.

Owner:薛冬梅

Warp different fabric and weaving process thereof

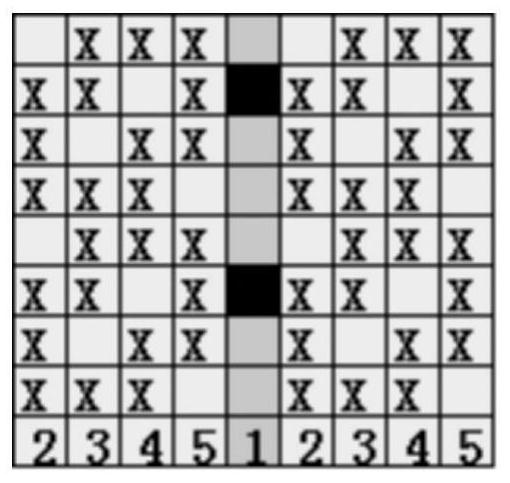

The invention discloses a warp different fabric made of special warps and a weaving process thereof. Conventional warp yarns of the fabric are polyester, refined cotton and vinylon blended yarns; the special warps are two-for-one twisting yarns with 75-denier polyester network yarns and double twisting yarns with 18-denier grey conductive metal wires; the process comprises a spooling process, a warping process, a sizing process, a denting process, a weaving process and a trimming process; during the warping process, arrangement of the special yarns is required to guarantee uniformly winding on a warping shaft, the warping tension is controlled, and stretched warps are avoided; during the denting process, the special yarns adopt ultra-thin droppers to avoid unhalt when the warps are broken; the special yarns are weaved in the front area to guarantee a small opening technology; a yarn separator is used to separate the yarns to avoid adhesion and breaking; a reverse weaving process is adopted to guarantee the special yarns arranged in the front of the fabric and convenient inspection. The weaving process of the warp different fabric has the advantages of enabling the warp different fabric made of special warp yarns to be weaved in a conventional air jet loom, being simple in technology and small in weaving difficulty, well guaranteeing fabric quality and increasing one functional weaving product for the weaving field.

Owner:JIHUA 3542 TEXTILE CO LTD

Processing method for silk georgette knitted fabric

The invention relates the real silk handing method, especially the real silk georgette knitted fabric handing method. The method comprises the following steps: twist range of real silk yarn between 2700-3000 twist / meter, adopting the same twist and reverse direction of twist to make the two yarns become one inlet wire, every yarn passing the hard twist yarn conveying appliance installed on knitting frame. The hard twist real silk is still at equilibrium state, overcoming the problem of producing unwinding when hard twist real silk entering into yarn-sinking opening from spindle. The yarn possesses the good air permeability, drapability and elasticity, and the added value of real silk products is improved after refining, dyeing and collating. The method has simple technology, easy operation and low cost. The product possesses the high quality, elasticity and georgette crepe effect.

Owner:JIANGSU HUAJIA SILK +1

Production process for high-moisture-absorption polyester down-proof fabric used for home textiles

ActiveCN107099908AGood flexibilityImprove compactnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterFiber

The invention relates to a production process for a high-moisture-absorption polyester down-proof fabric used for home textiles. The production process includes the following steps that weaving is conducted, wherein polyester DTY silk serves as warp yarn, sea-island fibers serve as weft yarn, and weaving is conducted on a water-jet loom; the sea-island fibers refer to PET, the island refers to COPET, the on-loom warp density is 137-200 per inch, the weft density is 100-200 per inch, and a gray fabric is formed by weaving; one side of the fabric is brushed; refining and splitting are conducted, the brushed fabric is fed into an overflow dyeing machine, splitting is conducted in the overflow dyeing machine, and the softness and compactness of the fabric are improved; water washing and plastification are conducted, fluffing and setting are conducted, the fabric obtained after water washing and plastification is subjected to pad-roll processing with a polyester bulking agent before passing through a setting machine, and a finished fabric product is formed after being subjected to setting through the setting machine. The process does not require the high-count and high-density weaving process required by a traditional down-proof fabric, so that the gray fabric weaving production difficulty is low, at the same time, the disadvantages that the coated down-proof fabric production process requires coating operation and thus causes long production process, hard hand feeling and easy-to-fall-off coatings are overcome, and therefore the production process is more suitable for the down-proof fabric used for the home textiles.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Imitation chiffon fabric and weaving process

The invention provides an imitation chiffon fabric and a weaving process. The imitation chiffon fabric is formed by changing the structure of the fabric. The fabric is woven from tencel fiber / cotton blended yarns in the blending ratio of 55 / 45, and the yarn count is 80s; the warp and weft density of the fabric is 133*108 / 10cm, and the cloth width is 65''. The weaving process comprises the steps of spooling, warping, sizing, denting, weaving and finishing. The purpose of the invention is to design a new fabric structure, and conventional yarns are adopted to avoid the case of weaving the chiffon cloth by changing the degree and the direction of twist of the yarns in the traditional process; the weaving process of the imitation chiffon fabric has the characteristics of simple process, weaving difficulty and low consumption of special textile parts; as a result, a textile product of chiffon cloth can be added to the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

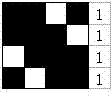

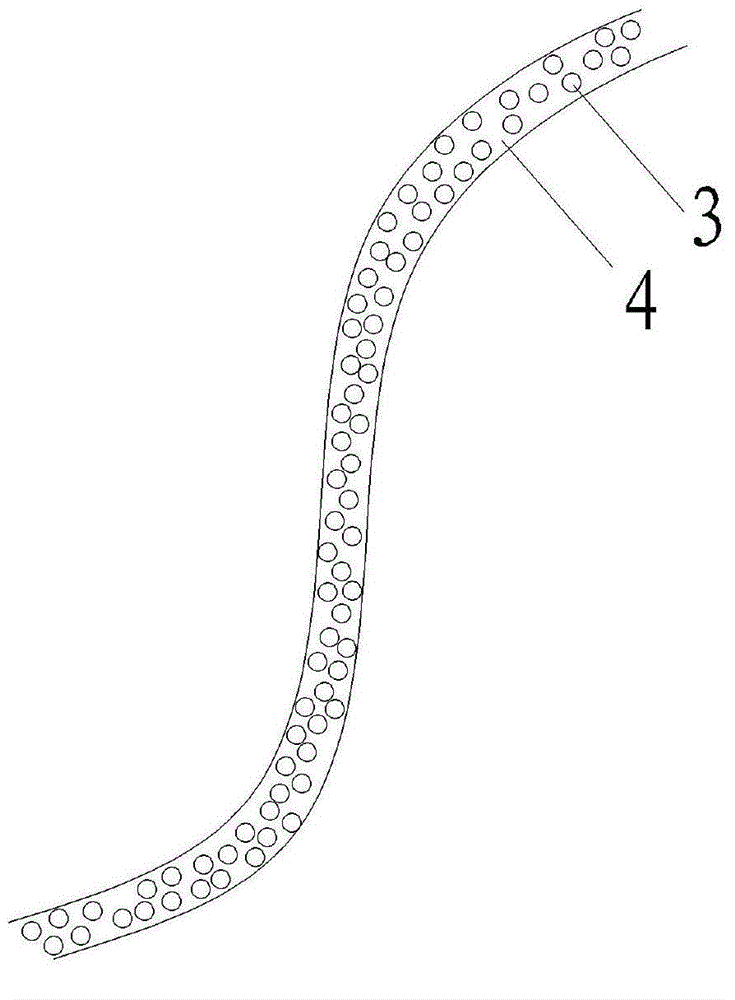

Embedded fabric and weaving process thereof

InactiveCN104514063AReduce consumptionSolve the problem of being unable to produce embeddedMulti-ply fabricsLiquid/gas/vapor yarns/filaments treatmentFiberMoisture absorption

The invention provides an embedded fabric and a weaving process thereof. The embedded fabric comprises a 3 / 1 surface fabric, a 2 / 2 medium fabric and a 1 / 3 inner fabric. The process comprises the steps of spooling; beaming; slashing; denting; weaving; finishing. According to the embedded fabric and the weaving process, the inner fabric is woven according to the process requirement; twill strips are formed on the fabric surface and are connected to form the embedded fabric; the types of embedded yarns can be adjusted; low-elastic yarns can be embedded to improve the comfort, conductive yarns can be embedded to prevent static, and breathable fiber yarns can be embedded to improve the capacity of moisture absorption and sweat releasing; therefore, the corresponding functions can be achieved, and the problem that the embedded weaving cannot be performed in the traditional weaving process can be solved; embedded fabric has the characteristics of being simple in process, small in difficult at weaving and little in consumption of special weaving devices; an embedded fabric type textile product is added for the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

Method for producing checked fabric

The invention relates to a method for producing a checked fabric, which sequentially comprises the following steps of: selecting F terylene silk threads with different thickness and gloss as warp threada and weft threads; warping in batch; pulping yarn in batch; reeding on parallel shafts in areas; twisting twice and forming an upper area and a lower area; and carrying out after-treatment processing. The invention replaces nylon with terylene as fabrics of middle and high grade feather garment and a leisure sportswear, can produce a checked pattern by a simple and convenient weaving process, achieve the aims of feather prevention and smooth hand feeling by an after-treatment oil press feather preventing coating and reduce the cost of blank cloth and is popular in the market.

Owner:SUZHOU CINC TEXTILE TECH RP

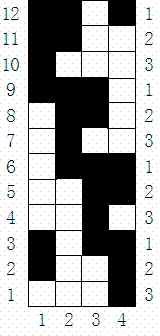

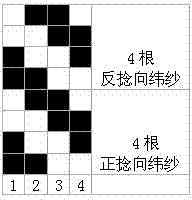

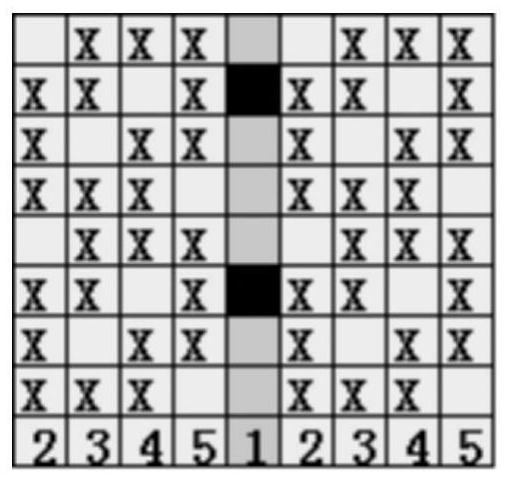

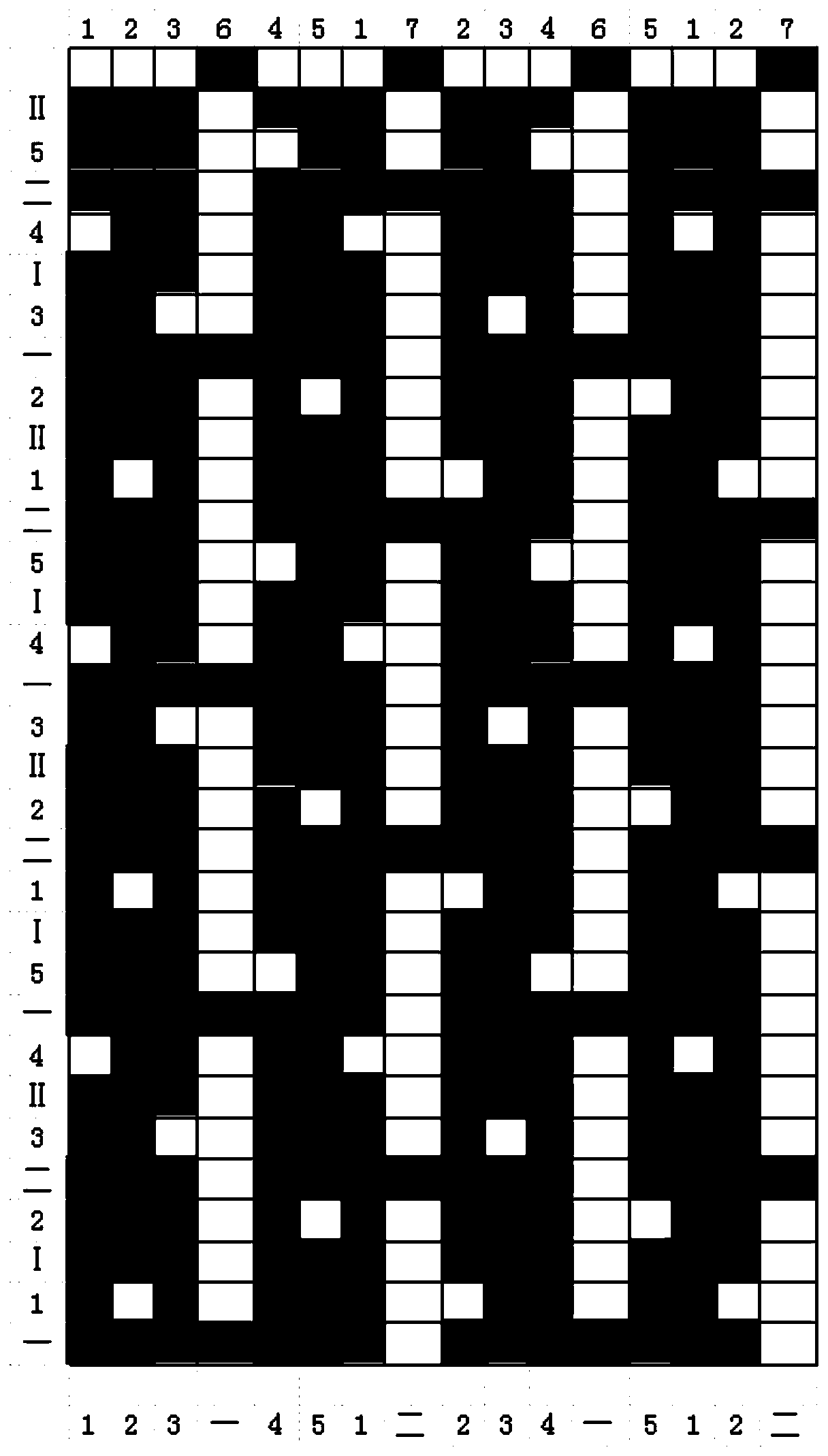

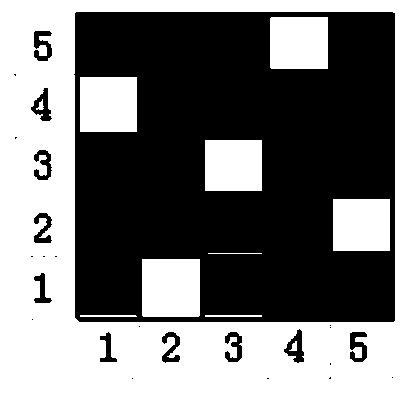

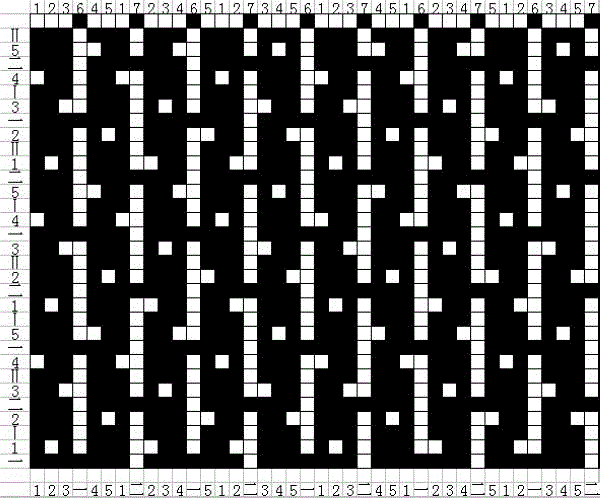

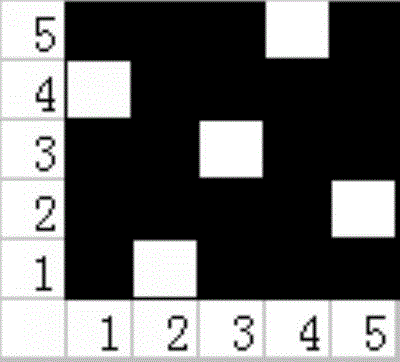

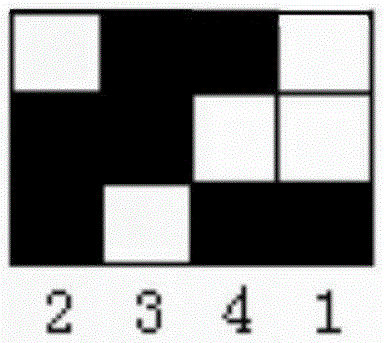

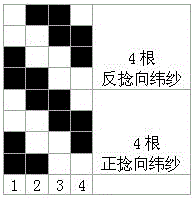

Positive and negative twisting fabric with different diameter and different weft and weaving process thereof

ActiveCN104514066ASolve the problem of not being able to produce such fabricsEasy to distinguishLoomsWoven fabricsYarnEngineering

The invention discloses a positive and negative twisting fabric with different diameter and different weft and weaving process thereof and relates to the spinning production technical field. The warp of the fabric has positive twisting direction and negative twisting direction and the weft has positive twisting direction and negative twisting direction; the ratio of the yarn of positive twisting direction and the yarn of negative twisting direction of the fabric is 1: 1, the fabric organization is 2 / 2 left cross grain; the weaving process comprises the following steps: spooling, beaming, slashing, denting, weaving and trimming. According to the rational combination of the fabric weave, the fabric has the effect of dark grain, and the problem that the conventional textile device cannot produce the fabric can be solved, the ratio and component of two types of yarn can be adjusted according to the demand of the fabric use, and different fabric weave can be designed for realizing different fabric style.

Owner:JIHUA 3542 TEXTILE CO LTD

Bark crepe fabric and weaving process thereof

The invention relates to a bark crepe fabric. Yarns of the bark crepe fabric are prepared by blending tencel and modal, wherein a blending ratio of the tencel to the modal is 65:35; the yarn count ofthe bark crepe fabric is 55S, the thread count of the fabric is 120*105 yarns / inch, the cloth width is 67 inches, and the weave of the bark cockled fabric is prepared by compounding 1 / 1 plain weave and 5 / 1 twill weave. The invention further relates to a preparation process of the fabric. The preparation process sequentially comprises the following steps: spooling, beaming, slashing, denting, weaving and finishing. The fabric made by the weaving method has the advantages of being excellent in drapability, soft, bright in texture and special in texture, is simple in production process and low inproduction cost, and can be widely applied to the technical field of textile production weaving.

Owner:WUHAN LEWEI E COMMERCE CO LTD

Weaving method for positive and negative twisting nylon elastic double-layer cloth

InactiveCN105506833ASimple processWeaving difficulty is smallMulti-ply fabricsResilient fabricsEngineeringTextile

The invention discloses a weaving method for positive and negative twisting nylon elastic double-layer cloth. The method for producing the positive and negative twisting nylon elastic double-layer cloth comprises the following processes: rewinding, warping, slashing, reed stringing, weaving and finishing; the problems that the conventional elastic cloth fabric is single in pattern and is light and thin are solved; the positive and negative twisting nylon elastic double-layer cloth is woven by utilizing a common weaving machine; the weaving method is simple in process and low in weaving difficult; special equipment consumption for weaving is low; a new textile is added.

Owner:JIHUA 3542 TEXTILE CO LTD

Textile fabric and application thereof

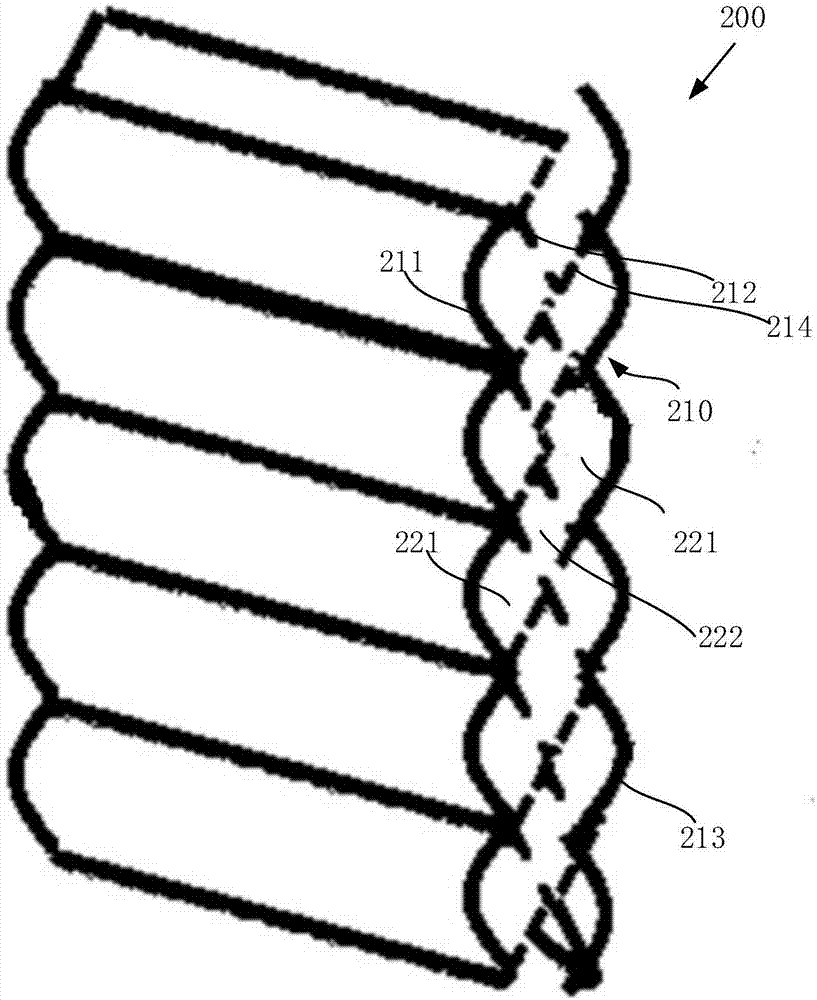

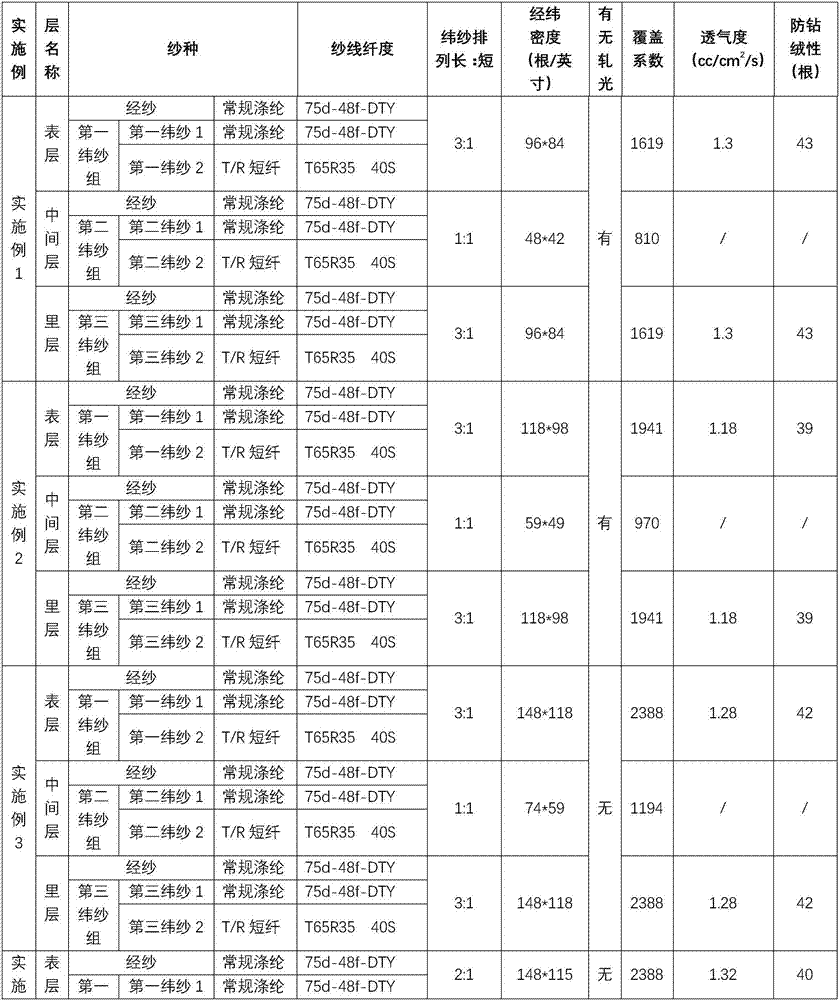

InactiveCN107083602AWon't moveReduce workloadOrnamental textile articlesMulti-ply fabricsSurface layerEngineering

The invention provides a direct filling type textile fabric and application of the textile fabric, and the textile fabric is good in downproofness and air permeability, is environment-friendly, and reduces the problems of unevenness, wrinkles, filling bars and the like. The textile fabric is woven from a plurality of warps and a plurality of groups of wefts, and is characterized by comprising a surface layer part, a plurality of filling cavities, and long filament yarns and staple fiber yarns in a plurality of warps and various groups of wefts, wherein the surface layer part is provided with a plurality of layers, the layers are respectively a surface layer, at least one middle layer and a lining layer sequentially arranged from outside to inside; the filling cavity is formed in a way that the surface layer and the lining layer are bound with the middle layers alternately, and at least part of the filling cavity is located between the surface layer and the middle layers or between the middle layers and the lining layer, the various groups of wefts respectively correspond to the surface layer, the middle layers and the lining layer one by one, the various groups of wefts are respectively used for weaving wefts of the corresponding surface layer, the lining layer and the middle layers, each warp shuttles from outside to inside and is used for weaving wraps of the surface layer, the lining layer and the middle layers, as well as filament yarn and staple fibre yarn in warps and groups of wefts, and the coverage coefficient of the textile fabric is more than or equal to 1600.

Owner:浙江懿纱纺织科技有限公司

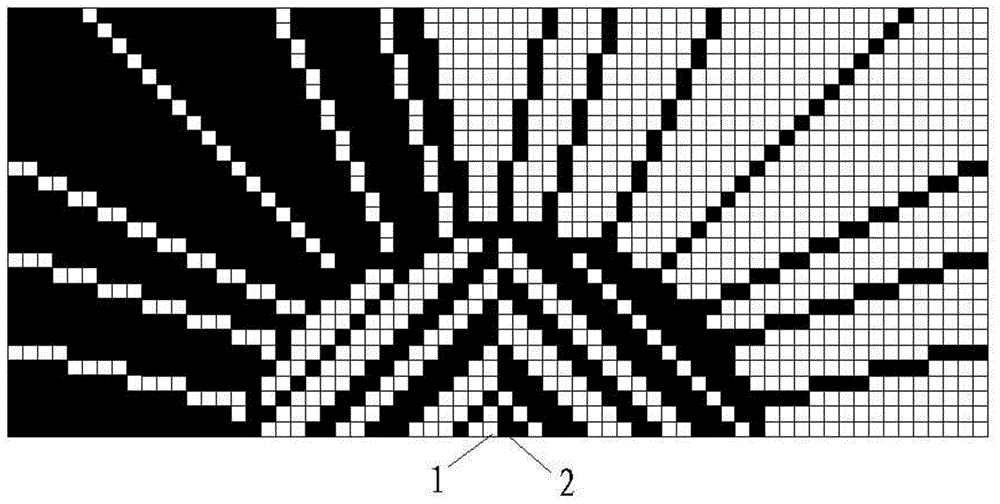

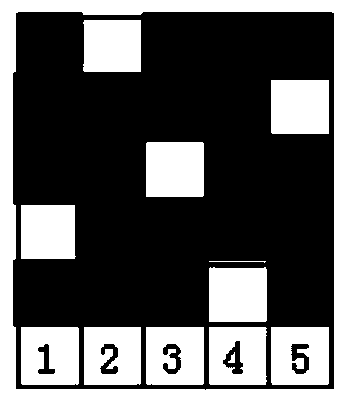

Color-variable fabric

InactiveCN104831448ACotton feels soft and comfortableWeaving difficulty is smallWoven fabricsProtective garmentWeft yarnIntensity change

The invention provides a color-variable fabric which employs two special fibers and changeable twill structure to jointly obtain color-variable effect. Warp yarns employ mekralon containing photosensitive color variable materials, and weft yarns employ mekralon containing uniform bubbles. The structure employs a composite structure combining steep twill, reclining twill, curved twill and broken twill, and the warp yarns and weft yarns are woven according to the composite structure. The color-variable fabric fabricated in such a method can change colors as light angles and intensity change, and is gorgeously in a random way. The color-variable fabric is soft, light, warm, durable and practical.

Owner:SUZHOU WILDER IND & TRADE

Tencel satin fabric and production method thereof

InactiveCN111041648ASimple processWeaving difficulty is smallWoven fabricsVegetal fibresPolymer sciencePolymer chemistry

The invention discloses a Tencel satin fabric. The Tencel satin fabric is a five-piece three-fly satin fabric composed of warp yarns and weft yarns, and the warp yarns and the weft yarns are both 9.8tex; and the Tencel satin fabric has the warp density of 714-716.5 pieces / 10 cm, the weft density of 512 pieces / 10 cm and the width of 269-270 cm. The high-count Tencel warp yarns are warped, sized and reeded and woven together with the weft yarns to produce a high-warp-density Tencel satin fabric, and the required ideal fabric can be obtained by adjusting the number of the warp yarns, the numberof the weft yarns, the warp density and the weft density for the requirement of a cloth cover style; and the production method of the Tencel satin fabric provided by the invention has the advantages of simple process and small weaving difficulty, the quality of the Tencel fabric is improved, and a green and comfortable textile product is added to the field of textiles.

Owner:JIHUA 3509 TEXTILE

Sizing composition for textile

A textile size composition is prepared from modified starch (20-90%) and specia nano material (0.05-5%) which is chosen any one of SiO2, TiO2, Al2O3 and ZrO2. Its advantages are high stability, short dissolving time and high effect of benefiting weaving.

Owner:杭州科瀚盟新材料技术有限公司

High-count high-density fabric with warps and wefts both made of 80-count pure Tencel and weaving technique thereof

InactiveCN110344157ALight in massQuality improvementAuxillary apparatusWoven fabricsTextile technologyMechanical engineering

The invention discloses a high-count high-density fabric with warps and wefts both made of 80-count pure Tencel and a weaving technique thereof and relates to the technical field of textiles. Both thewarps and wefts of the high-count high-density fabric are 80-count Tencel; when warpwise density is 230 per inch and weftwise density is 195 per inch, fabric wave is satin weave. The specific weavingtechnique comprises the steps of (1) spooling; (2) warping; (3) sizing; (4) reeding; (5) weaving; and (6) finishing. The sizing process is adjusted reasonably; after sizing, a size film is complete,tough and effective; the requirements on weaving is met at the premise of ensuring sizing quality. The reasonable parameters of the weaving technique are designed herein; the technique with low tension, high rear beam, early opening and late weft insertion is utilized; elastic supporting is employed, so that the quality of the high-count high-density fabric is guaranteed. The technical problems oflike products produced at present are solved. The high-count high-density fabric and the weaving technique thereof have the advantages that the weaving technique is simple and weaving difficulty is low.

Owner:JIHUA 3542 TEXTILE CO LTD

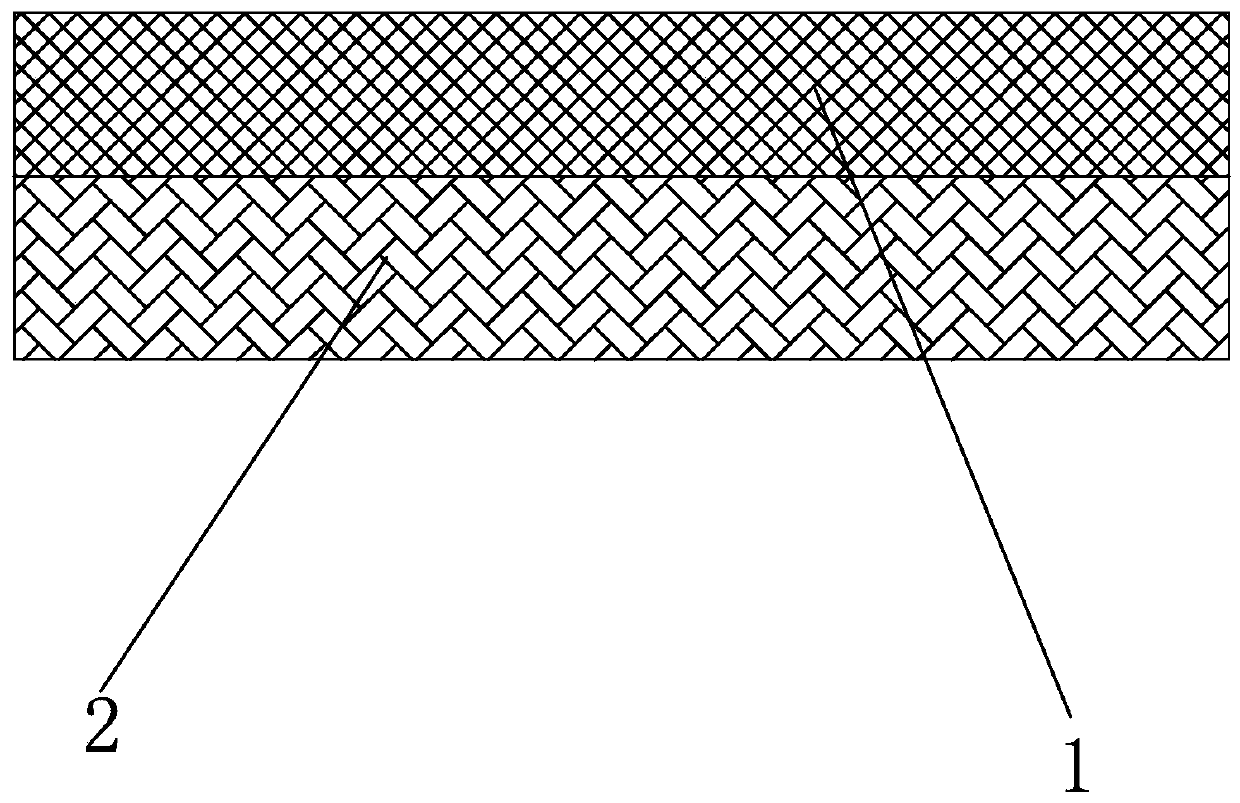

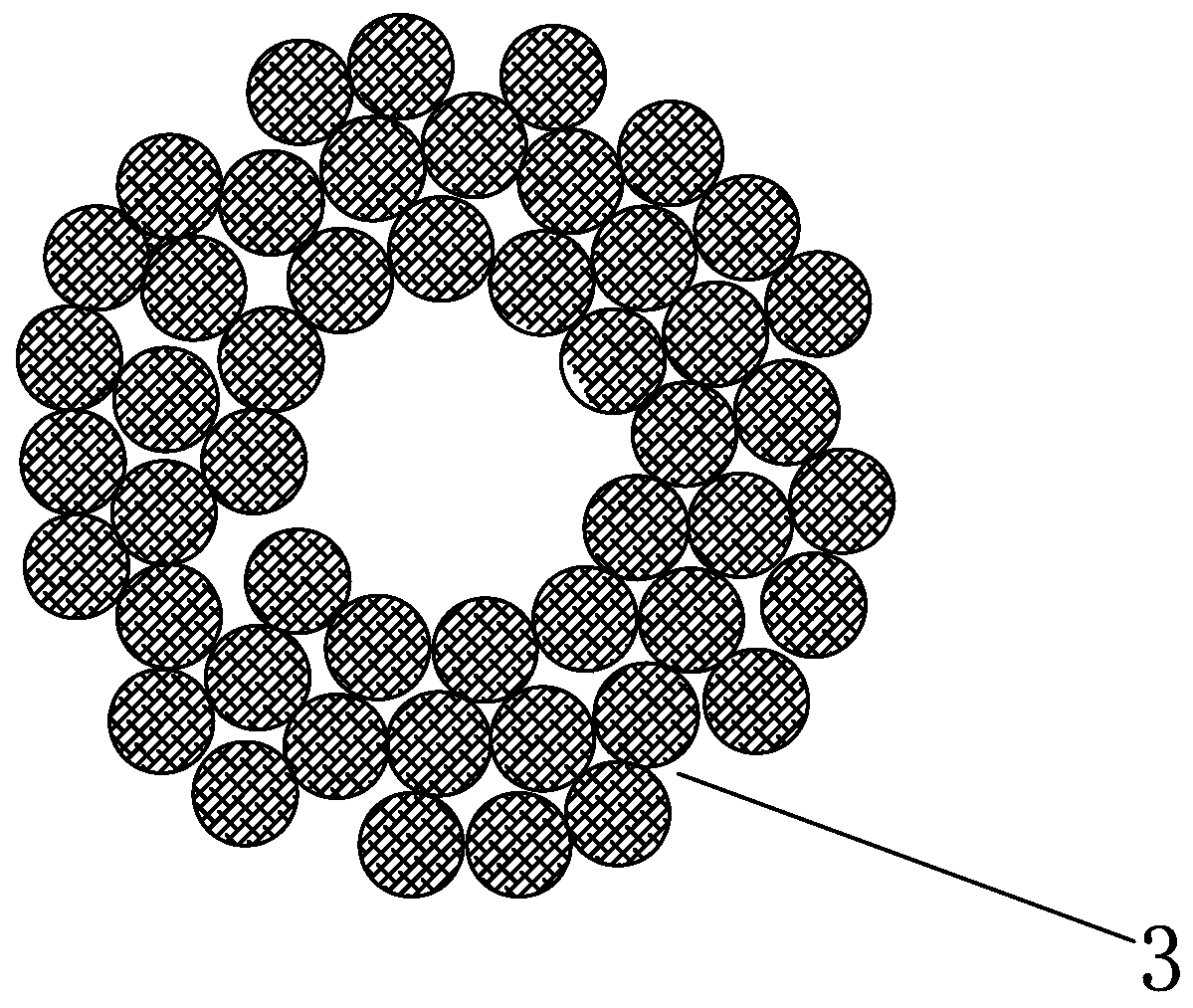

Dual-filament twin wire, fabric prepared from dual-filament twin wire and production methods of dual-filament twin wire and fabric

ActiveCN111793866AImprove yarn strengthHigh-strength yarn strengthWoven fabricsYarnYarnPolymer science

The invention discloses a dual-filament twin wire, fabric prepared from the dual-filament twin wire and production methods of the dual-filament twin wire and the fabric. The dual-filament twin wire isa twin wire of a core-spun fasciated yarn prepared from two polyamide filaments and a cotton fiber, wherein a cotton-polyamide mass ratio is 1 to (0.9-1.1), and the count number of the core-spun fasciated yarn is 32; the strength of the core-spun fasciated yarn is greater than 650 cN / tex, and the strength of the dual-filament twin wire is greater than 1400 cN / tex. The core-spun fasciated yarn oftwo high-strength polyamide filaments and long stapled cotton is adopted, and the dual-filament twin wire prepared from the core-spun fasciated yarn is high in strength and is low in production difficulty. A fabric product made by the dual-filament twin wire disclosed by the invention has the characteristics of being high in strength, resistant to wear and anti-static, is resistant to balling-up,is good in moisture absorption performance and gas permeability, is soft in hand feeling, can be used for manufacturing a military garment material, disruptive-pattern serial products, and the like, and is wide in market prospect. The production method for the fabric has the characteristics of being low in weaving difficulty and simple in production process.

Owner:JIHUA 3509 TEXTILE

A kind of production technology of acetate fiber blended fabric

ActiveCN103924361BLittle strengthHigh strengthPattern makingHeating/cooling textile fabricsPolymer scienceEngineering

The invention discloses a production process of acetate fiber blended fabric. The acetate fiber blended fabric has a base fabric and pile warp, the base fabric has a plain weave structure, the pile warp has a W-shaped weave structure, and the bottom warp adopts 32S / 2 all-cotton yarn. The pile warp adopts 120D~150D double-strand acetate filament fiber, and the weft yarn adopts 21S / 1 cotton yarn. The twist of the cashmere warp is 120-200 twists / m, and the pile height of the cashmere warp is 6-10mm. The production process of the acetate fiber blended fabric has the following steps: 1) warping; 2) weaving; 3) washing; 4) dyeing; 5) aftertreatment; 6) embossing; 7) shaping. Acetate fiber can effectively prevent static electricity, but the yarn strength of acetate fiber is low and easy to break. The present invention adopts acetate fiber with suitable parameters to be blended with cotton yarn to form acetate fiber blended fabric, which not only reduces the weaving difficulty, but also enhances the strength of the fabric, and Still can effectively prevent the generation of static electricity.

Owner:JIANGSU AOYANG TEXTILE IND +1

Filled fabric and weaving process thereof

InactiveCN110359153ASolve the problem of not being able to produce ultra-heavy fabricsReduce consumptionMulti-ply fabricsSizingPlain weave

The invention discloses filled fabric and a weaving process thereof and relates to the technical field of spinning. The filled fabric comprises surface fabric, middle fabric and bottom fabric, whereinthe surface fabric is satin fabric, the middle fabric is filler and is not interwoven with warps, and the bottom fabric is plain weave fabric. The weaving process specifically includes the steps of firstly, spooling; secondly, warping; thirdly, sizing; fourthly, reeding; fifthly, weaving; sixthly, finishing. The weaving process has the advantages that the middle fabric is not interwoven with thewarps, the filer is not included in extreme tightness, ideal thickness and weight can be obtained by regulating the yarn number of the middle fabric during weaving, the difficulty that super-thick andsuper-heavy fabric cannot be produced by a traditional weaving process is solved, and the weaving process is simple in process, low in weaving difficulty, low in special spinning equipment consumption, promising in market application prospect and suitable for being widely popularized.

Owner:JIHUA 3542 TEXTILE CO LTD

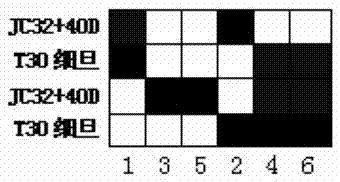

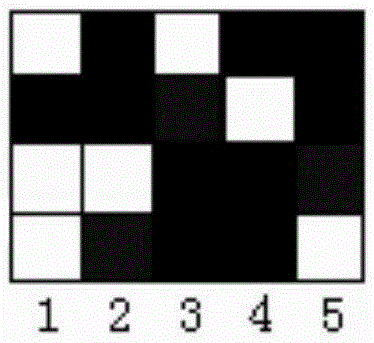

Elastic dobby fabric with different warp and different weft and its weaving process

ActiveCN103774318BPrevent static electricityPrevent pillingSolvent-treatmentAuxillary apparatusYarnPolyester

The invention discloses warp and weft different elastic mini Jacquard fabric and a weaving process thereof. Warps of the fabric are pure cotton yarns and pure polyester yarns; wefts of the fabric are the pure cotton yarns and elastic yarns; the technological process comprises spooling, warping, warp sizing, denting, weaving and trimming; during the warp sizing, the pure cotton yarns and the pure polyester yarns can performed sizing, dye which can be washed out is added to the pure cotton serous fluid to perform dying, and antistatic agent is added to the pure polyester serous fluid; during denting, the pure polyester yarns are weaved in the front area to guarantee a small opening technology in weaving and reduce up and down friction and a selvage structure is in a double-tank side weaving method; during weaving, a yarn separator is used to separate the yarns, the pure cotton yarns are arranged on the upper layer of the yarn separator, the pure polyester yarns are arranged on the lower layer of the yarn separator, and identification is convenient and error is not easy to occur during weaving. The weaving process of the warp and weft different elastic mini Jacquard fabric has the advantages of enabling the warp and weft different elastic mini Jacquard fabric to be weaved in a conventional air jet loom, being simple in technology and small in weaving difficulty, well guaranteeing fabric quality and increasing one functional weaving product for the weaving field.

Owner:JIHUA 3542 TEXTILE CO LTD

Vortex-spun high-count high-density fabric and production method thereof

PendingCN110592769ASimple production methodReduce manufacturing costMulti-ply fabricsLiquid/gas/vapor yarns/filaments treatmentHigh densitySurface layer

The invention discloses a vortex-spun high-count high-density fabric and a production method thereof. The vortex-spun high-count high-density fabric comprises a fabric body; the fabric body is of a double-layer plain weave structure and comprises a surface-layer shell fabric and an inner-layer shell fabric; surface warps and surface wefts of the surface-layer shell fabric are both DTY 50D / 72F differential fine denier yarns, and inner warps and inner wefts of the inner-layer shell fabric are pure cotton twisted yarns; each of the pure cotton twisted yarns is formed by twisting and stranding twosingle hollow combed cotton yarns; a combined tying mode is adopted for the surface-layer shell fabric and the inner-layer shell fabric, tying units are two adjacent warp and weft tying nodes and aremutually restricted, and each tying unit is composed of a warp tying node and a weft tying node which are adjacent. The surface-layer shell fabric of the vortex-spun high-count high-density fabric has a silk-like effect, is smooth in touch feeling, fine, bright and clean, good in staining resistance and air permeability, stiff and smooth and resistant to crease, and the inner-layer shell fabric is soft and comfortable in touch feeling, not prone to pilling, good in skin friendliness, good in moisture absorption and warm-keeping effects and comfortable to wear.

Owner:WUJIANG JINGYI SPECIAL FIBER

Double-filament double-strand thread, fabric made of the double-filament double-strand thread, and production method thereof

ActiveCN111793866BImprove yarn strengthHigh-strength yarn strengthWoven fabricsYarnPolymer scienceCotton fibre

Owner:JIHUA 3509 TEXTILE

Multi-layer fabric and its weaving process

ActiveCN102226305BReduce consumptionSolve the problem of not being able to produce ultra-heavy fabricsLoomsMulti-ply fabricsSurface layerGram

Owner:JIHUA 3542 TEXTILE CO LTD

Cotton fiber fabric and manufacture technology thereof

InactiveCN100365182CIncreased coverage factorImprove fluffinessWoven fabricsYarnYarnTextile technology

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

Different warp fabric and its weaving process

A kind of different warp fabric with special warp yarn and its weaving process, the conventional warp yarn of the fabric warp yarn is polyester, fine cotton, dimension blended yarn, and the special warp yarn is the two-fold twisted yarn of polyester network yarn 75D and gray conductive metal wire 18D; the process flow is : Winding process → warping process → sizing process → reeding process → weaving process → finishing process: In the warping process, the arrangement of special yarns should ensure that they are evenly wound on the warping beam, and the warping tension should be controlled. Avoid warp tightness, during the reeding process, use ultra-thin warp droppers for special yarns to avoid non-stop warp breaks. The head adopts the reverse weaving process to ensure that the special yarn is on the front side of the cloth for easy inspection. The invention can weave special warp fabrics with special warps on conventional air-jet looms, has the advantages of simple process, low weaving difficulty, ensures the quality of such fabrics, and can add a functional textile product to the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

Production method of high-elasticity chiffon-like fabric

The invention discloses a production method of a high-elasticity chiffon-like fabric. The method comprises the following steps of warping polyester fibers to obtain warp yarns, and twisting polyesterfibers and spandex fibers to obtain weft yarns; sequentially carrying out warping, slashing, re-beaming and harness wire opening threading on the warp yarns, and then loading the warp yarns on a textile machine fiber shaft; dividing the weft yarns into two groups, enabling one group to be directly loaded on the textile machine fiber shaft, and enabling the other group to be loaded on the textile machine fiber shaft after two-for-one twisting; and setting process parameters of the textile machine, and orthogonally consolidating the warp yarns and the weft yarns to form the high-elasticity chiffon-like fabric. The method has the characteristics of simple process, low weaving difficulty and low consumption of special textile equipment.

Owner:吴江市双盈化纺实业有限公司

Direct and reverse twist different warp and different weft fabrics and its weaving technology

ActiveCN104514066BSolve the problem of not being able to produce such fabricsEasy to distinguishLoomsWoven fabricsYarnAdditive ingredient

The invention relates to a fabric with different warps and wefts with positive and negative twists and a weaving process thereof, relating to the technical field of textile production. The warp yarn of the fabric is two kinds of twist directions of forward twist and reverse twist, and the weft yarn is two kinds of twist directions of normal twist and reverse twist; the ratio of the forward twist yarn and the reverse twist yarn of the fabric is 1:1, and the fabric structure is 2 / 2 left twill; its weaving process includes the following steps: winding process→warping process→sizing process→reeding process→weaving process→finishing process. The invention enables the fabric itself to have the effect of a dark pattern through the reasonable matching of the fabric structure, and solves the problem that conventional textile equipment cannot produce such fabrics. According to the needs of the fabric use, the ratio and composition of the two yarns can be adjusted. Different fabric weaves can also be designed to achieve different fabric styles.

Owner:JIHUA 3542 TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com