Color-variable fabric

A fabric and color technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve problems such as mixed visual effects, and achieve the effects of good elasticity, reduced weaving difficulty and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

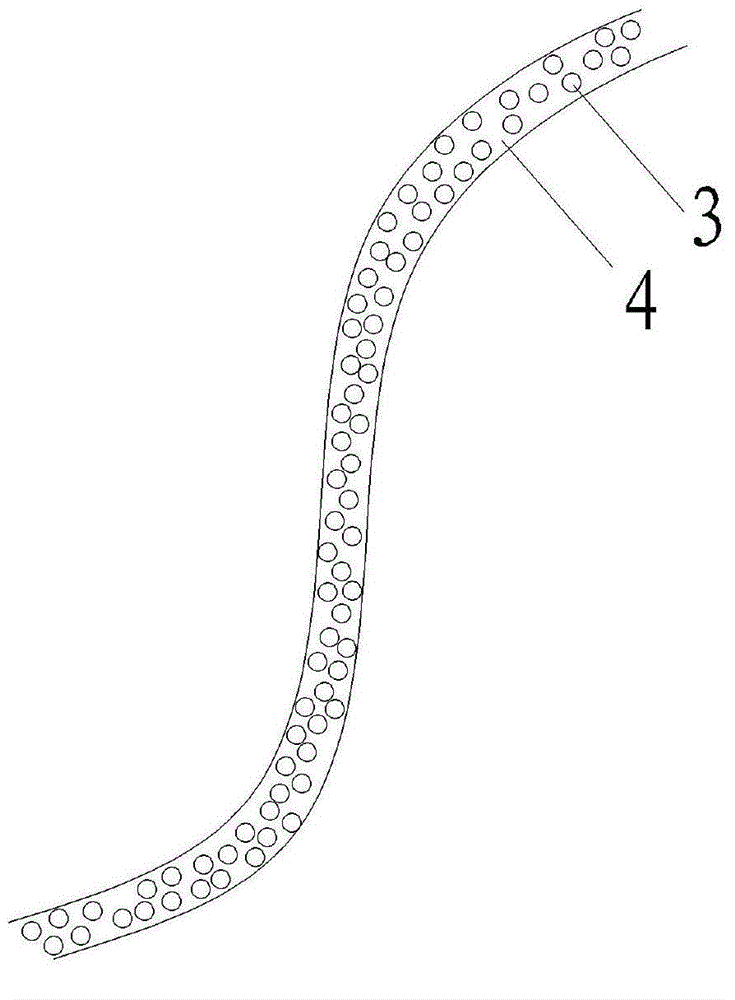

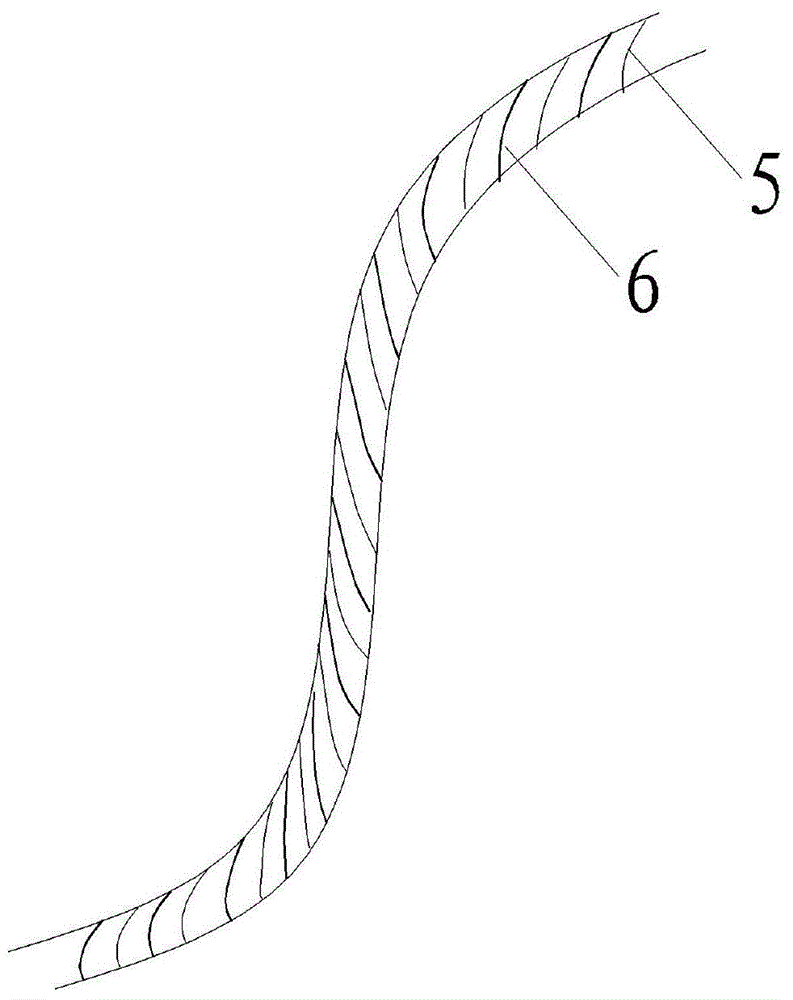

[0029] Such as Figure 2-3 As shown, a color-changing fabric, including warp and weft, the warp is a photosensitive color-changing polypropylene fiber with a fineness of 1.0dtex×5, which is obtained by adding 2.5% of photosensitive materials into polypropylene raw materials for melt spinning, The weft thread is a modified polypropylene fiber with a fineness of 1.3dtex×4, which contains 20% uniform air cells, the color of the warp thread and the weft thread is the same as red, the density of the warp thread is 45 / cm, and the density of the weft thread is 35 / cm.

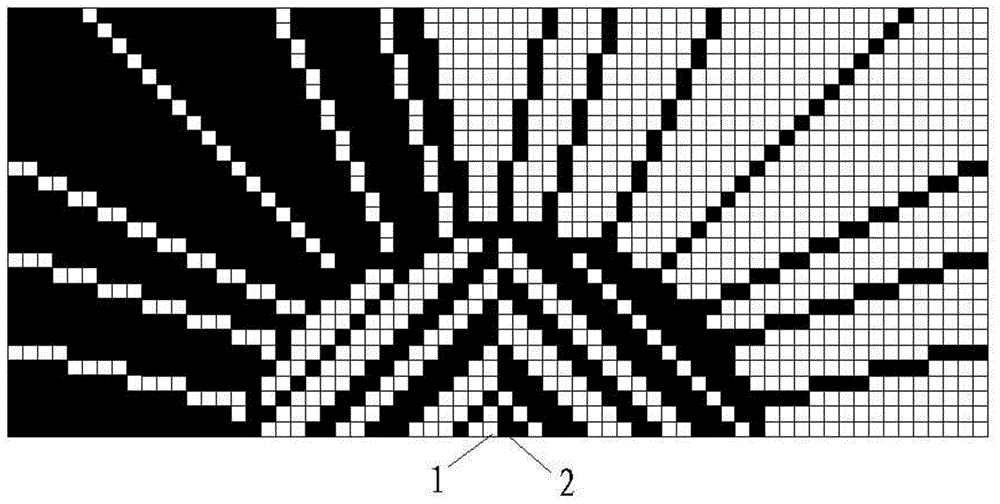

[0030] Such as figure 1 As shown, the warp and weft are woven with changing twill weave, and the changing twill weave is composed of sharp twill weave, slow twill weave, semicircular curve twill weave and broken twill weave, and the sharp twill weave is the basic twill weave. Basic, Sj=2,3,4, slow twill weave is the basic twill weave, Sw=2,3,4, broken twill weave is sharp twill weave, gentle twill weave, curved twil...

Embodiment 2

[0032] Such as Figure 2-3 As shown, a color-changing fabric, including warp and weft, the warp is a photosensitive color-changing polypropylene fiber with a denier of 1.2dtex×5, and the fiber is obtained by adding 3% photosensitive material into the polypropylene raw material for melt spinning, The weft is a modified polypropylene fiber with a fineness of 1.5dtex×4, which contains 25% uniform air cells. The colors of the warp and weft are different, red and blue, and the density of the warp is 50 / cm. The density is 40 / cm.

Embodiment 3

[0034] Such as Figure 2-3 As shown, a color-changing fabric, including warp and weft, the warp is a photosensitive color-changing polypropylene fiber with a fineness of 1.1dtex×5, which is obtained by adding 2.7% of photosensitive materials into polypropylene raw materials for melt spinning, The weft thread is a modified polypropylene fiber with a fineness of 1.4dtex×4, which contains 22% uniform air cells, the color of the warp thread and the weft thread is the same as blue, the density of the warp thread is 47 pieces / cm, and the density of the weft thread is 37 root / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com