Embedded fabric and weaving process thereof

An embedded, fabric technology, applied in the direction of fabrics, multi-strand fabrics, textiles and papermaking, can solve the problem of inability to produce embedded fabrics, and achieve the effect of enhancing moisture absorption and perspiration, simple process and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embedded fabric of the present invention is composed of a surface fabric, a middle fabric and an inner fabric, and the arrangement of the surface fabric, the middle fabric and the inner fabric in the warp direction is adjusted as 1 table: 1 middle: 1 bottom according to actual needs. In order to meet the needs of the fabric style, adjust the weft number of the lower fabric according to the thickness, so as to obtain the desired ideal weight.

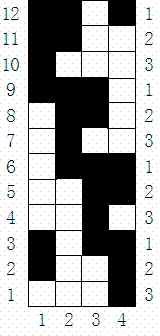

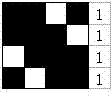

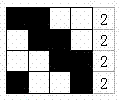

[0024] Example: such as figure 1 , 2 , Shown in 3, 4, surface fabric of the present invention is designed as 3 / 1 twill weave, middle weave is 2 / 2, and bottom fabric is designed as 1 / 3 twill weave. figure 1 The number above is the corresponding threading method.

[0025] The embedded yarns of the embedded fabric are low elastic yarns, conductive yarns and air-conditioning fiber yarns.

[0026] The weaving process of the present invention comprises the following steps:

[0027] (1) Winding process: Murata automatic winding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com