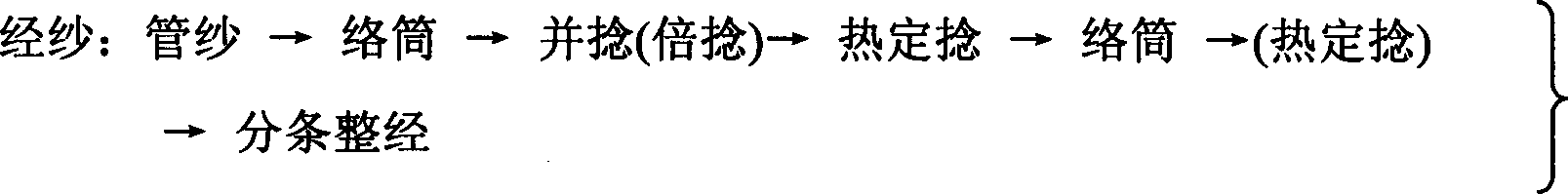

Patents

Literature

145results about "Resilient fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

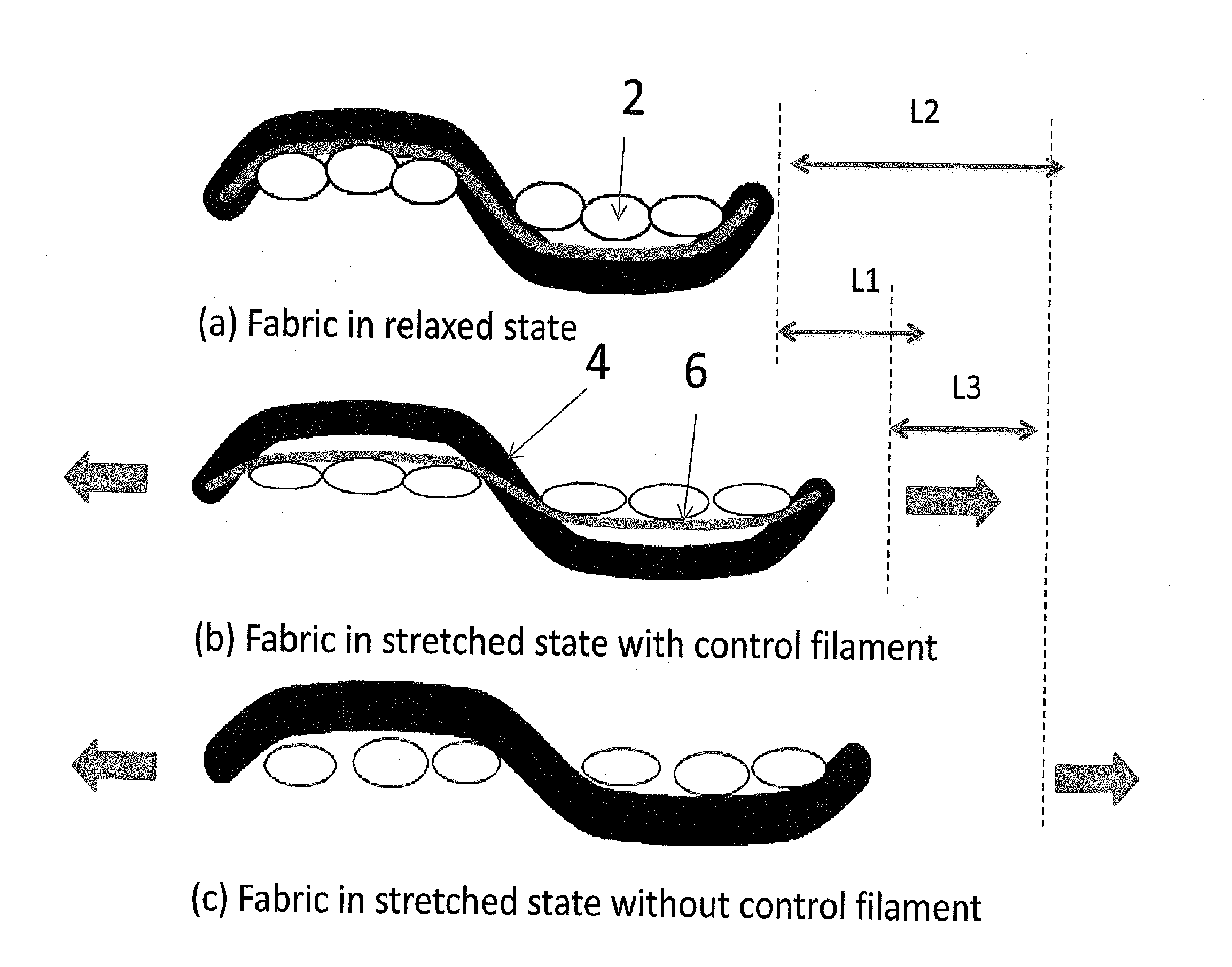

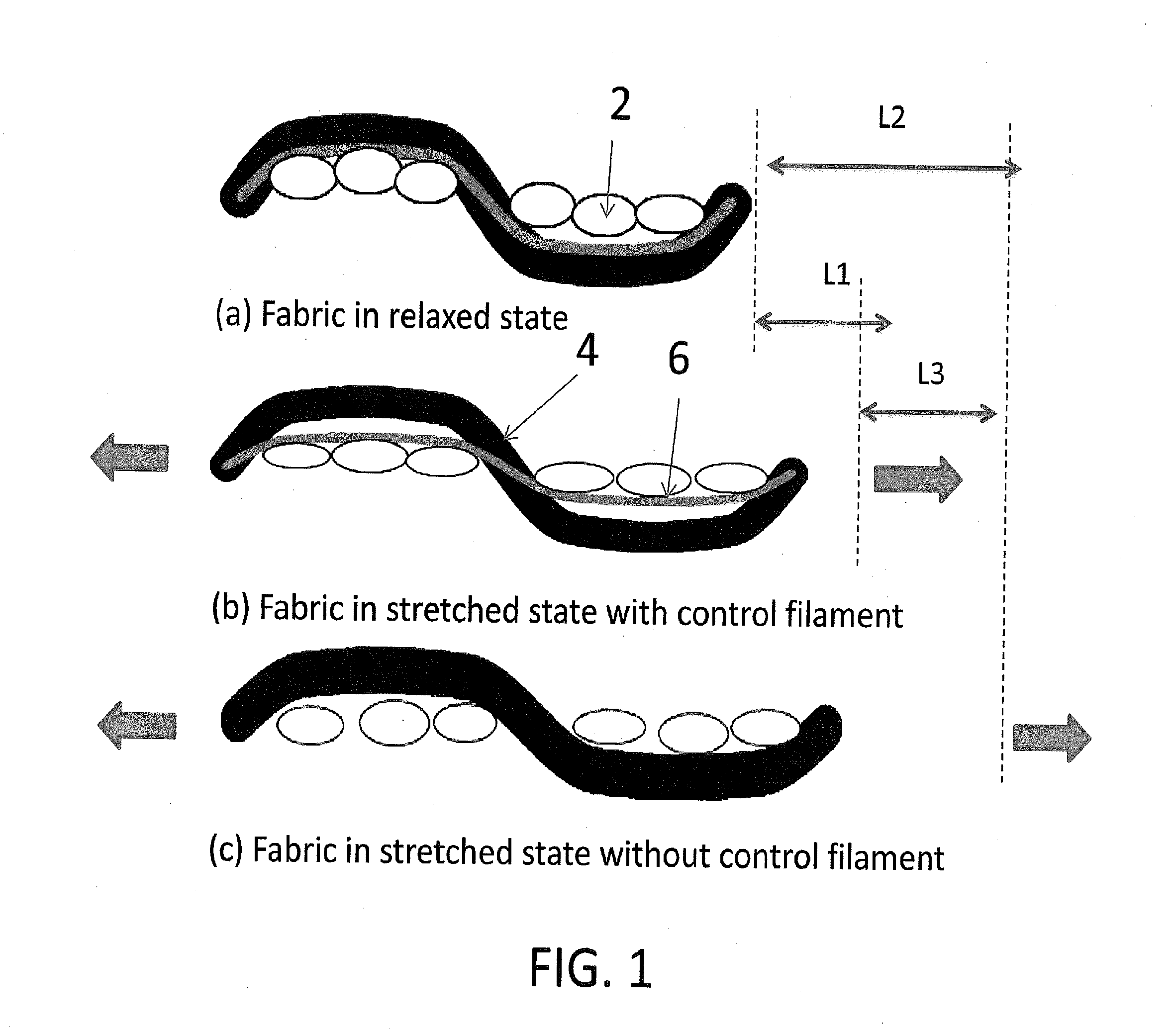

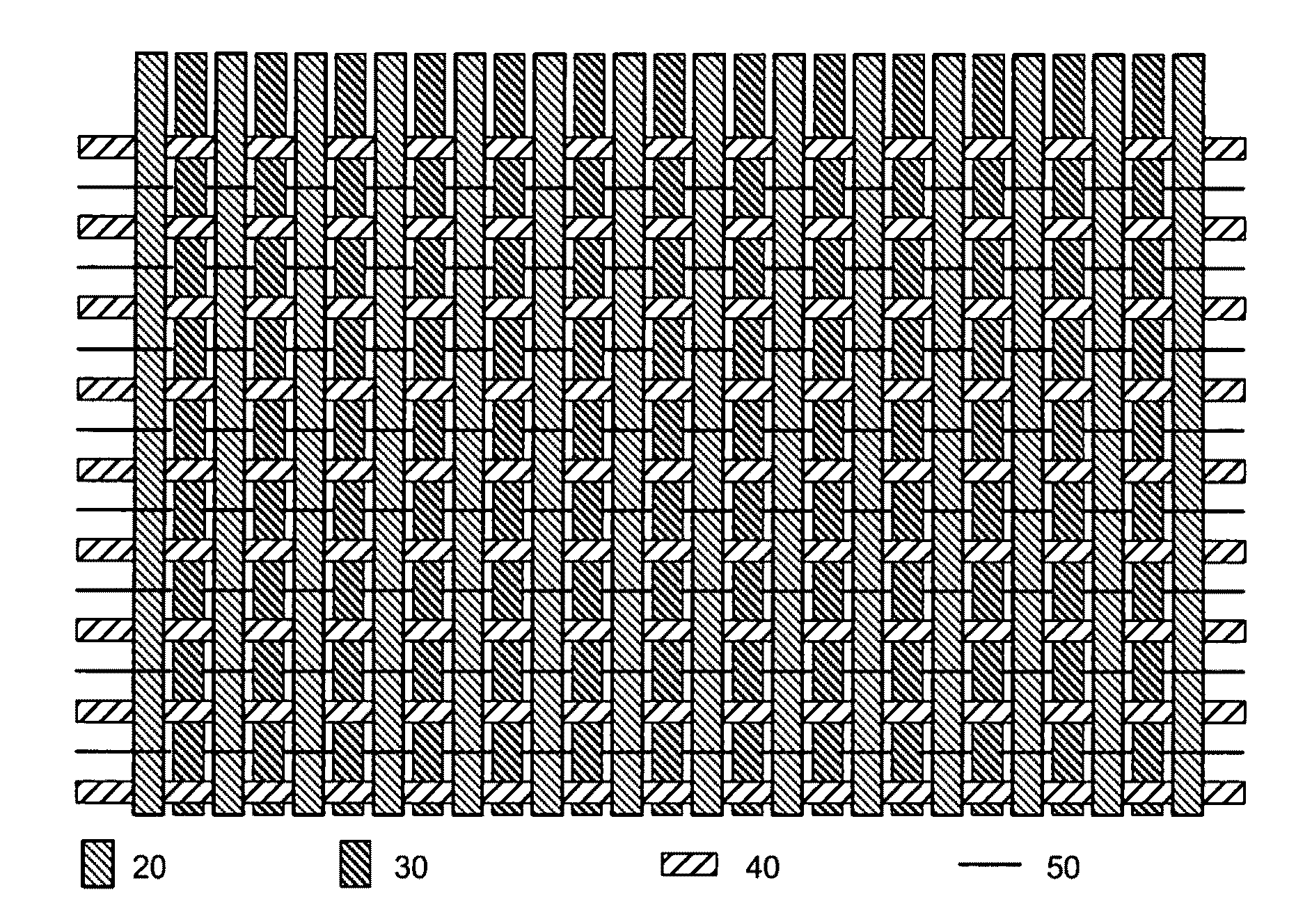

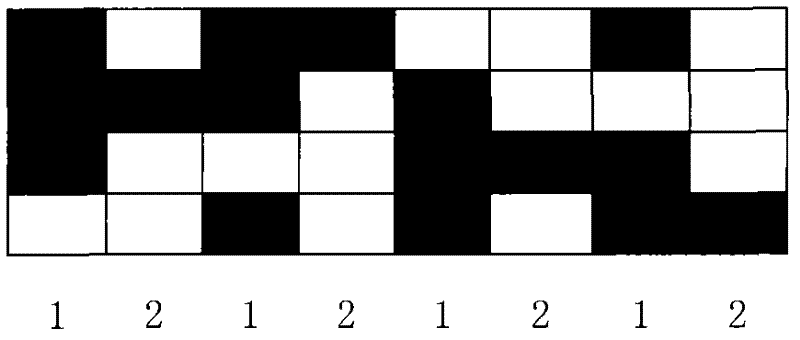

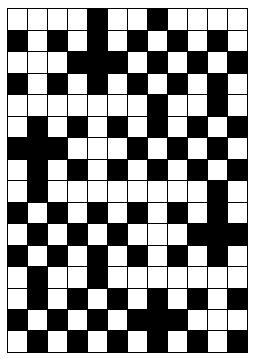

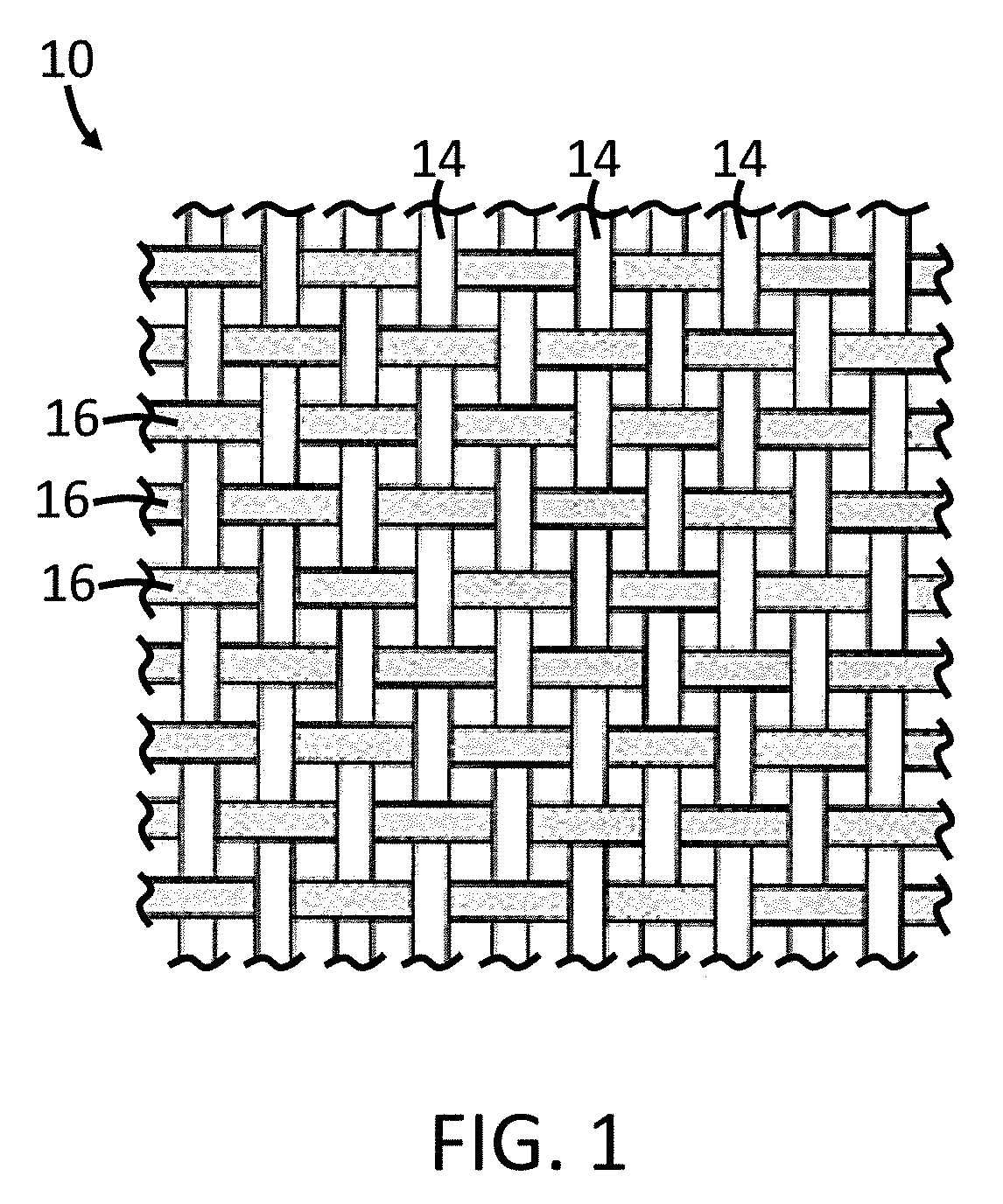

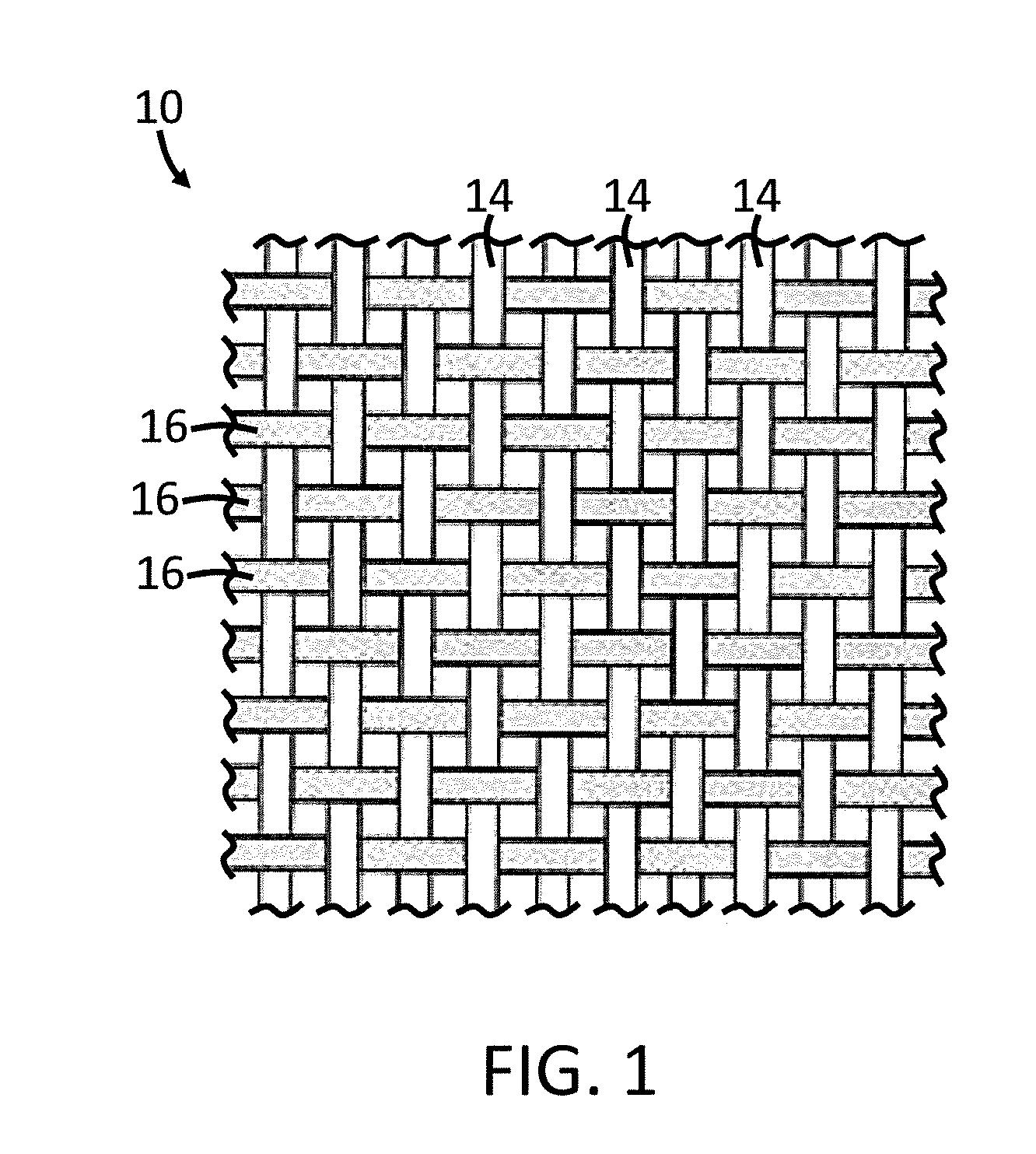

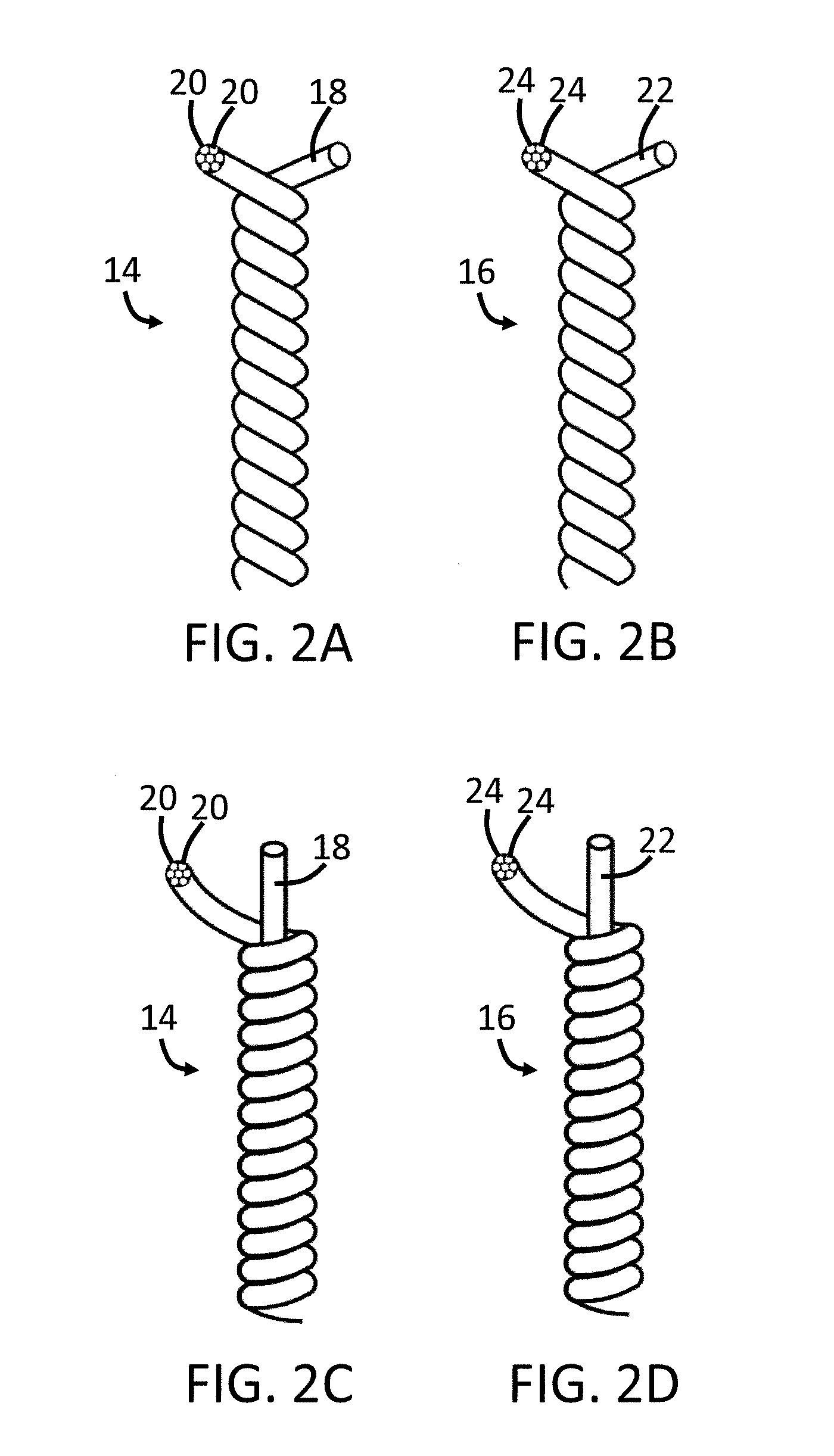

Stretch wovens with a control yarn system

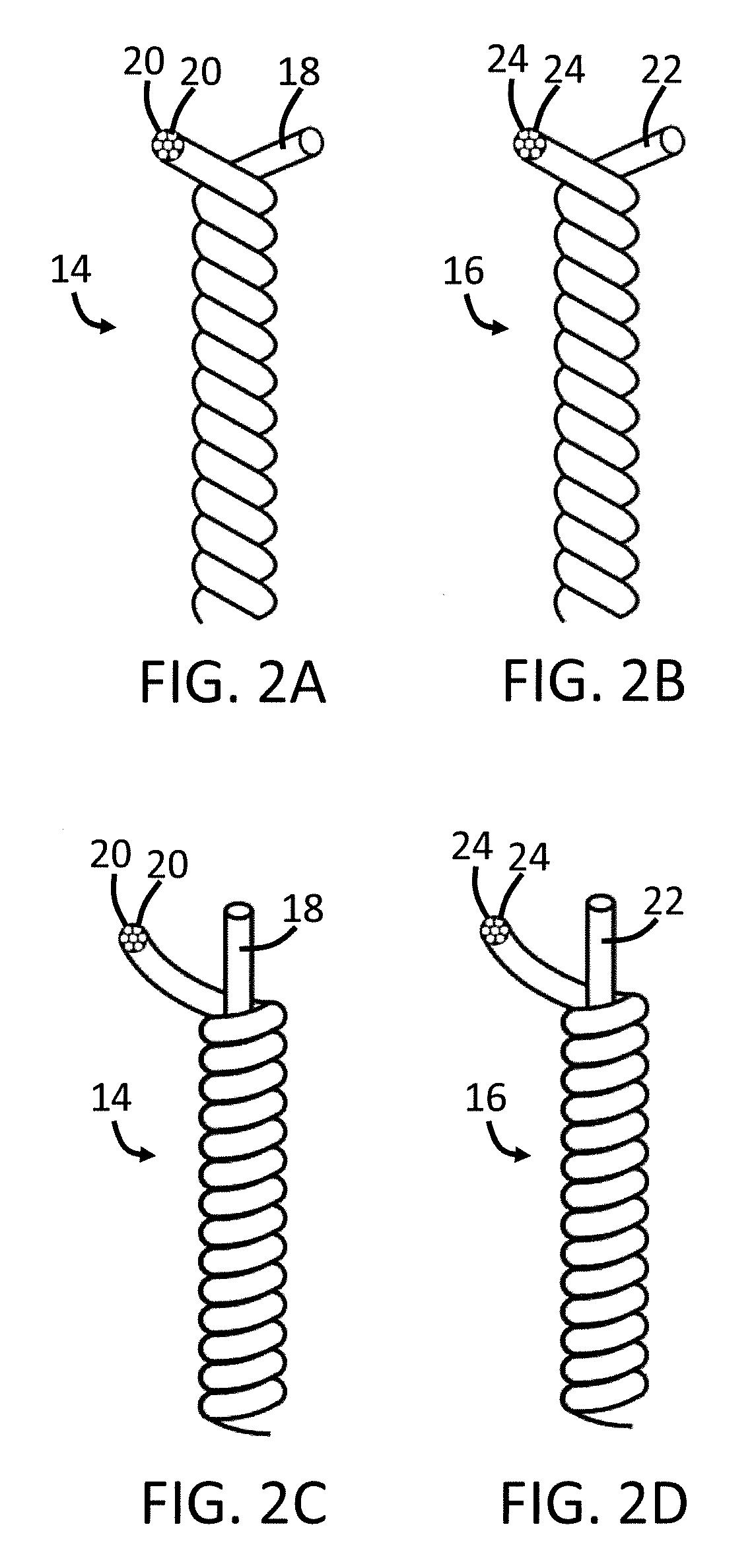

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

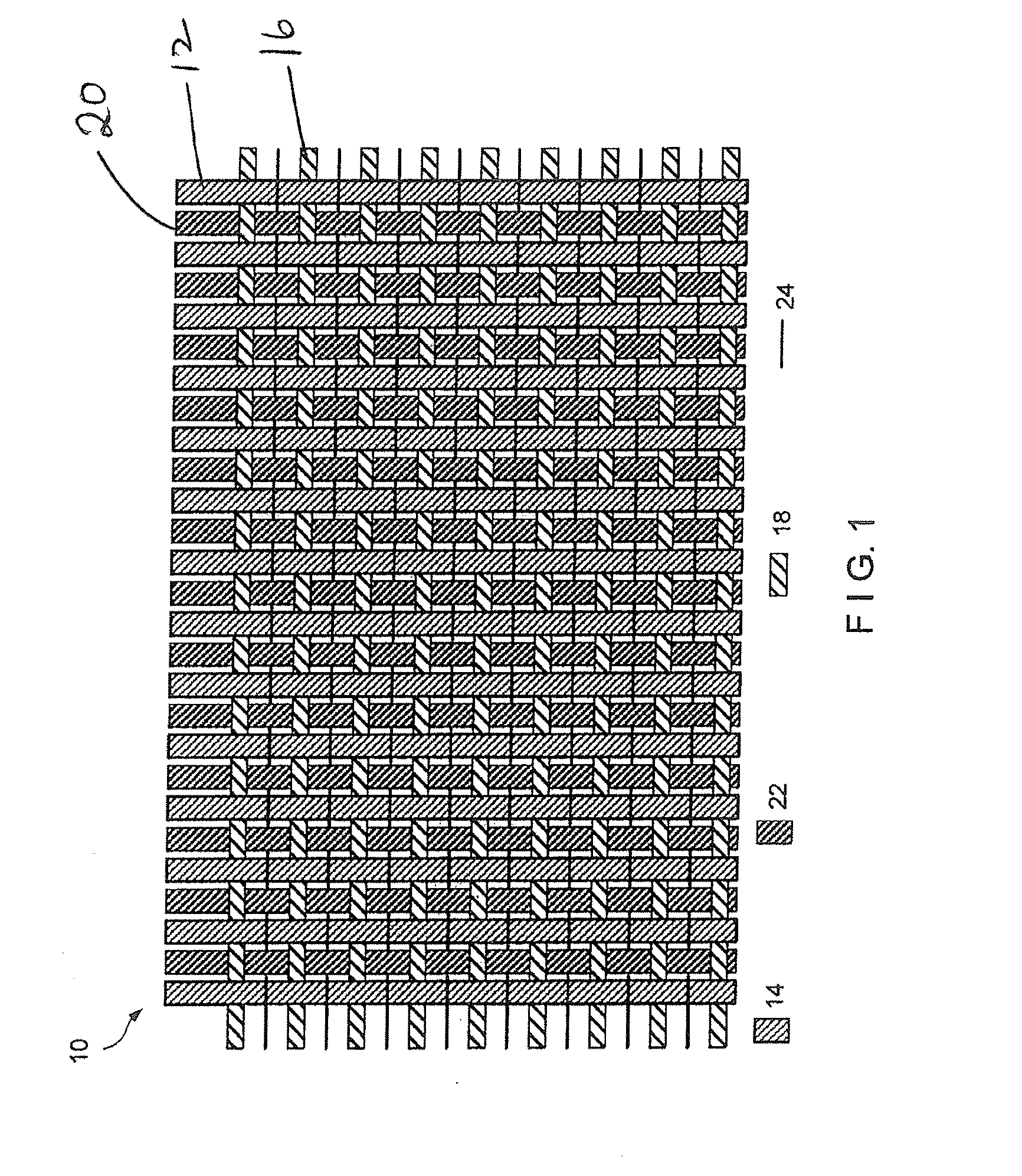

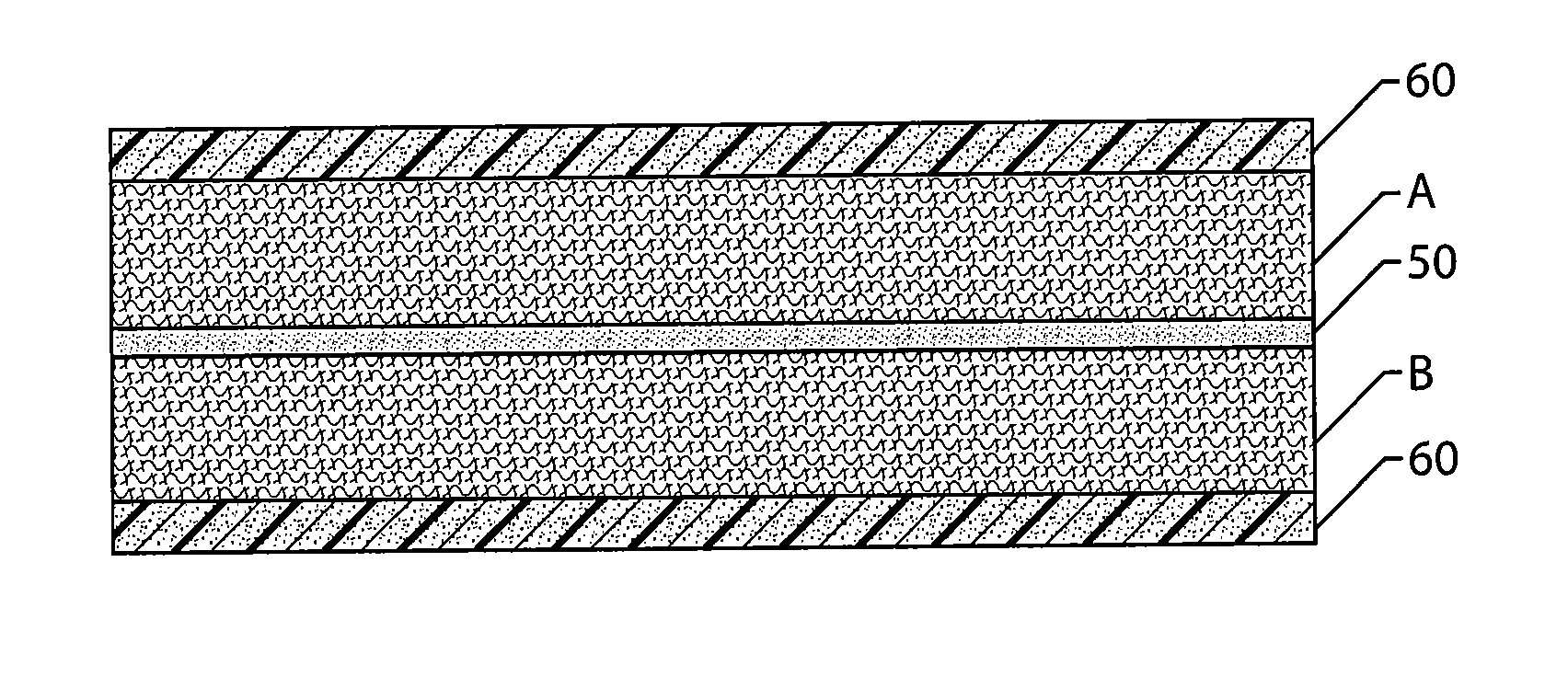

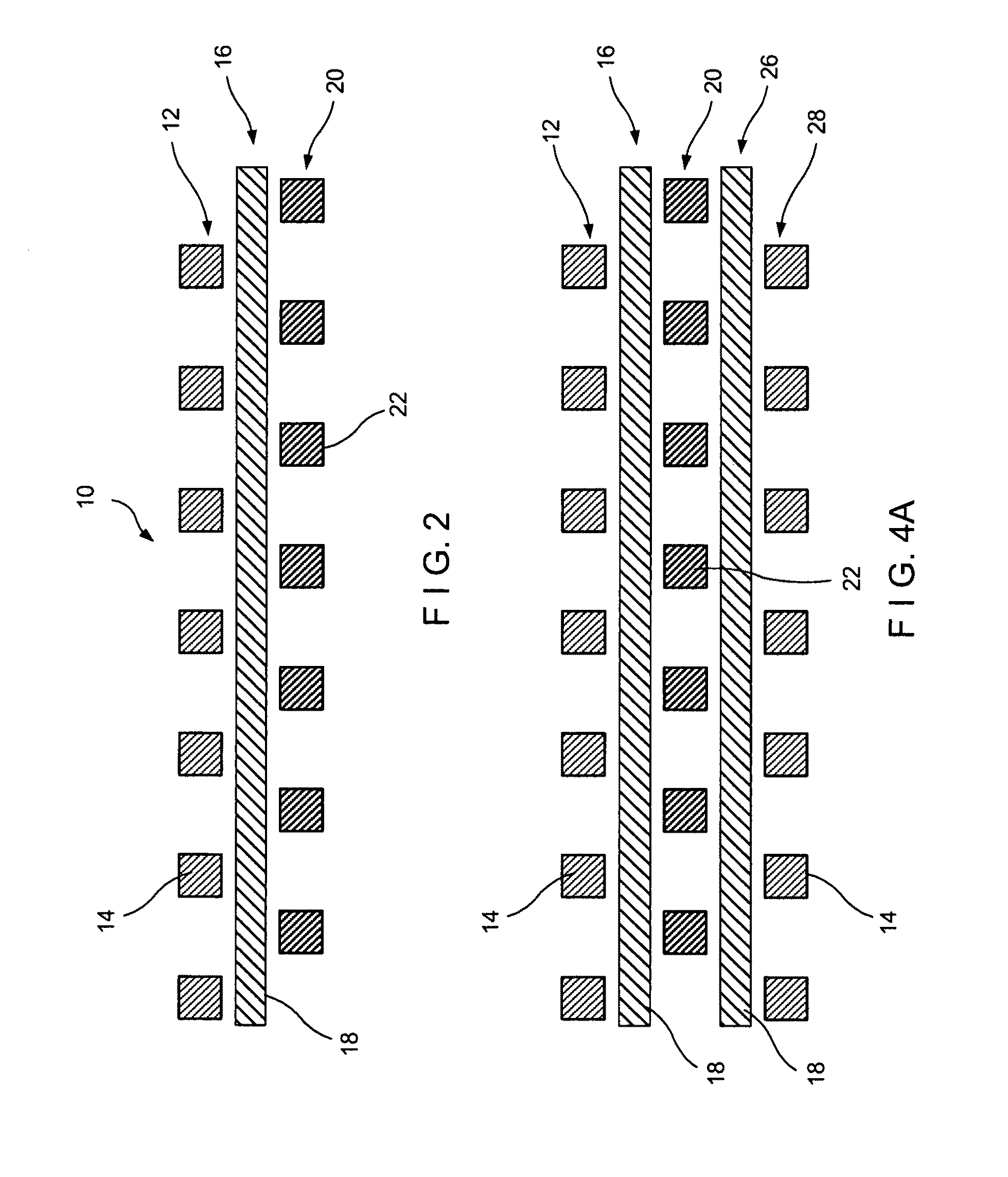

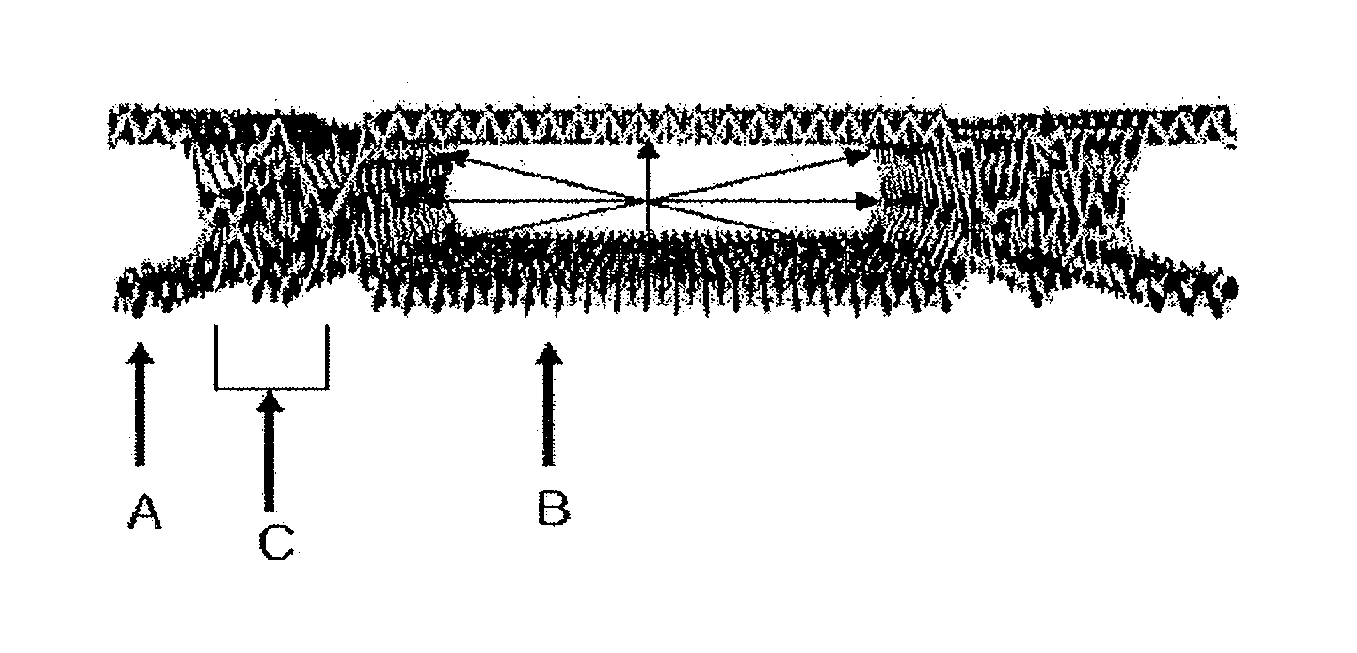

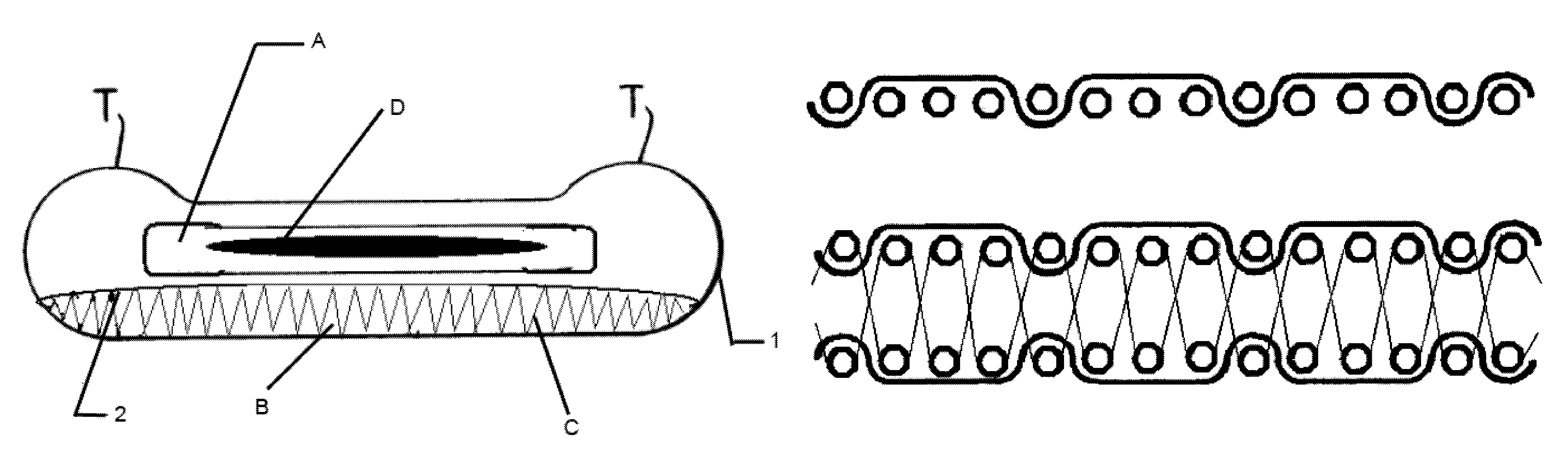

Flame Resistant Spacer Fabric

InactiveUS20080299854A1Light weightSufficient protectionSynthetic resin layered productsWarp knittingFiberBiomedical engineering

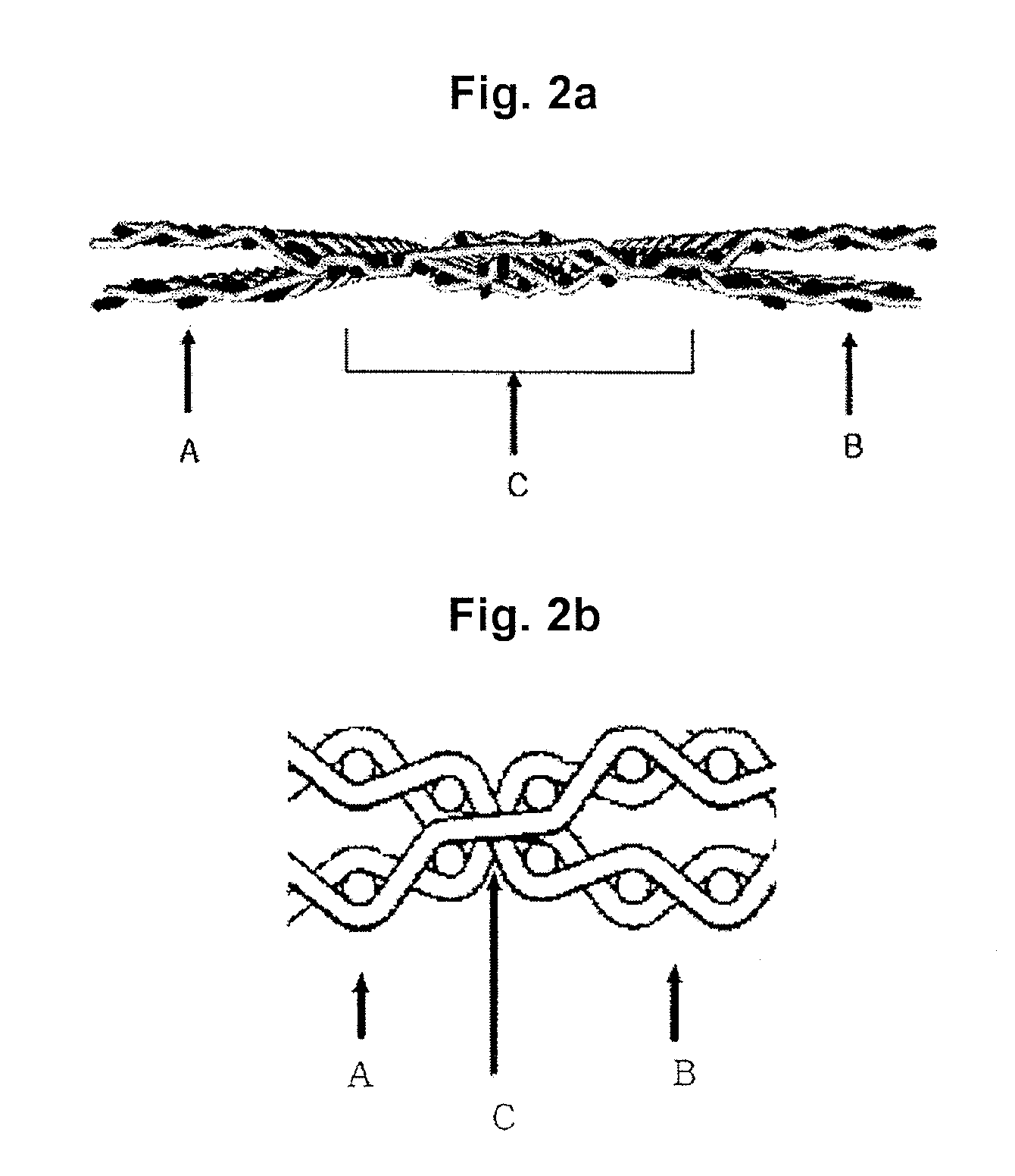

The present invention provides a heat resistant spacer fabric comprising a first and second fabric layers that are formed of a flame resistant material arranged in opposing face-to-face relation and are spaced apart from each other. The first and second fabric layers are interconnected to each other with one or more spacer fibers that interconnect the first and second fabric layers and define a space therebetween. The spacer fibers comprise at least one core fiber having one or more wrap fibers of a flame resistant material wrapped thereabout. The wrap fibers protect the core fibers from direct contact with heat and flame. If the spacer fabric is exposed to heat / flame, the flame resistant wrap fibers help to prevent any melted material of the core fibers from flowing out of the spacer fabric. The spacer fabric can be used in protective garments such as coats, gloves, pants, cover-alls, suits, etc.

Owner:SSM IND

Elastic fabric and elastic face material

An elastic fabric useable for covering pillows, seats, mattresses and the like is disclosed. The fabric is formed from elastic yarns having a breaking elongation greater than 60%, a rate of elastic recovery after 15% elongation of more than 90% and a stress at 10% elongation greater than 150 N / 5 cm and less than 600 N / 5 cm oriented in a direction parallel to the elastic yarn, and a rate of hysteresis loss between 20% and 45%. The fabric may be woven or knitted and provides a stable, comfortable feeling for sitting or reclining and deforms when supporting weight but returns readily to its undeformed shape.

Owner:TB KAWASHIMA CO LTD

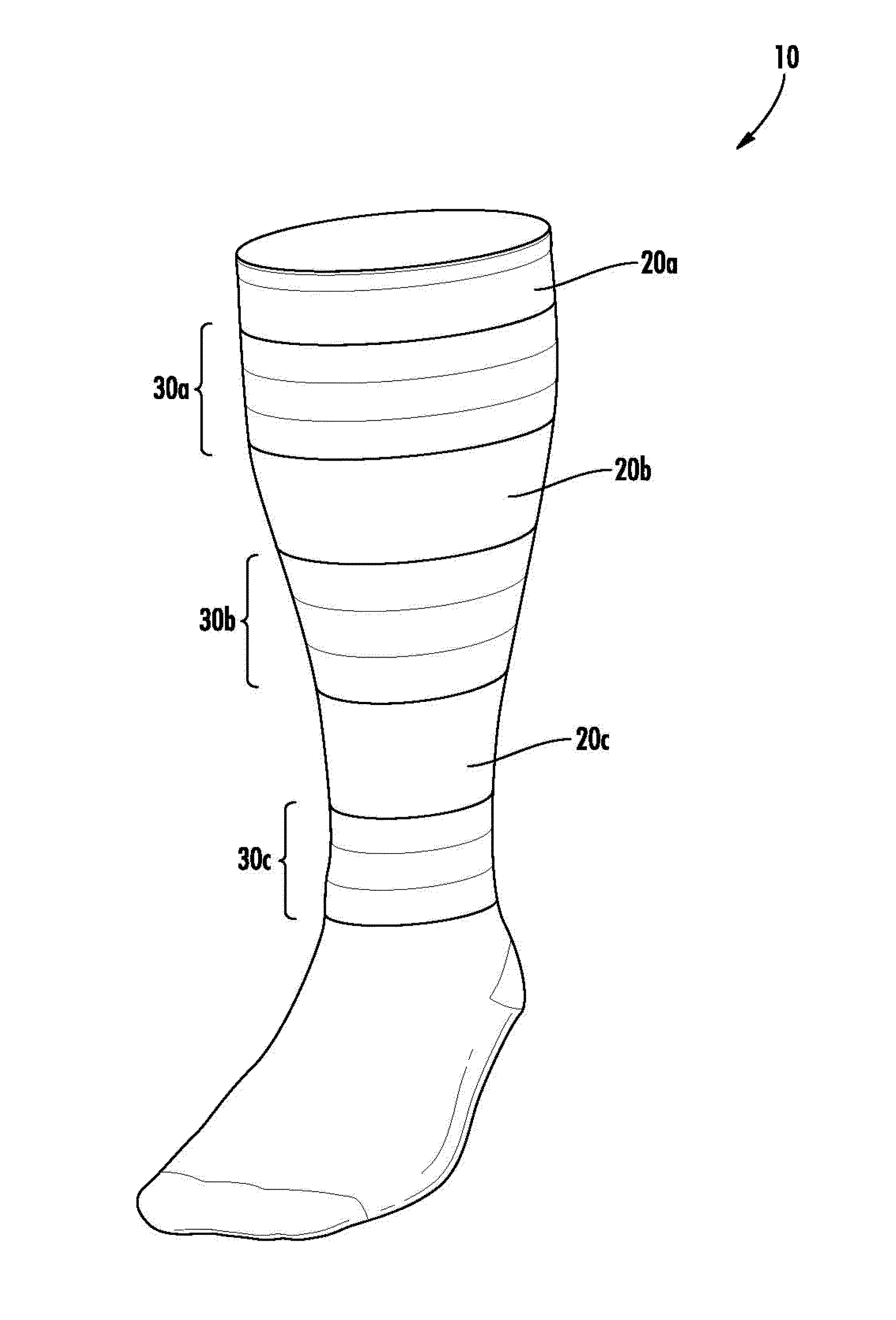

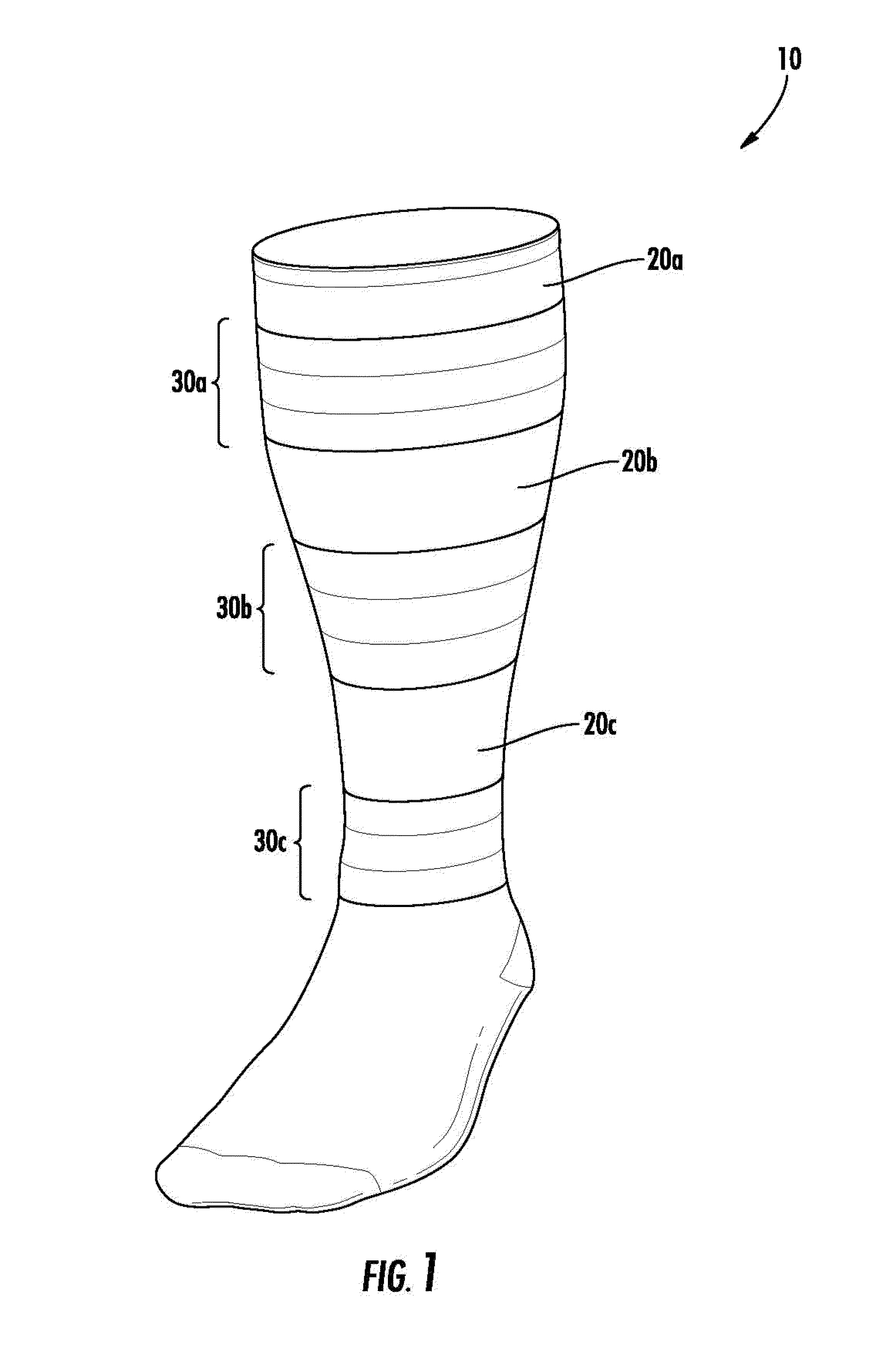

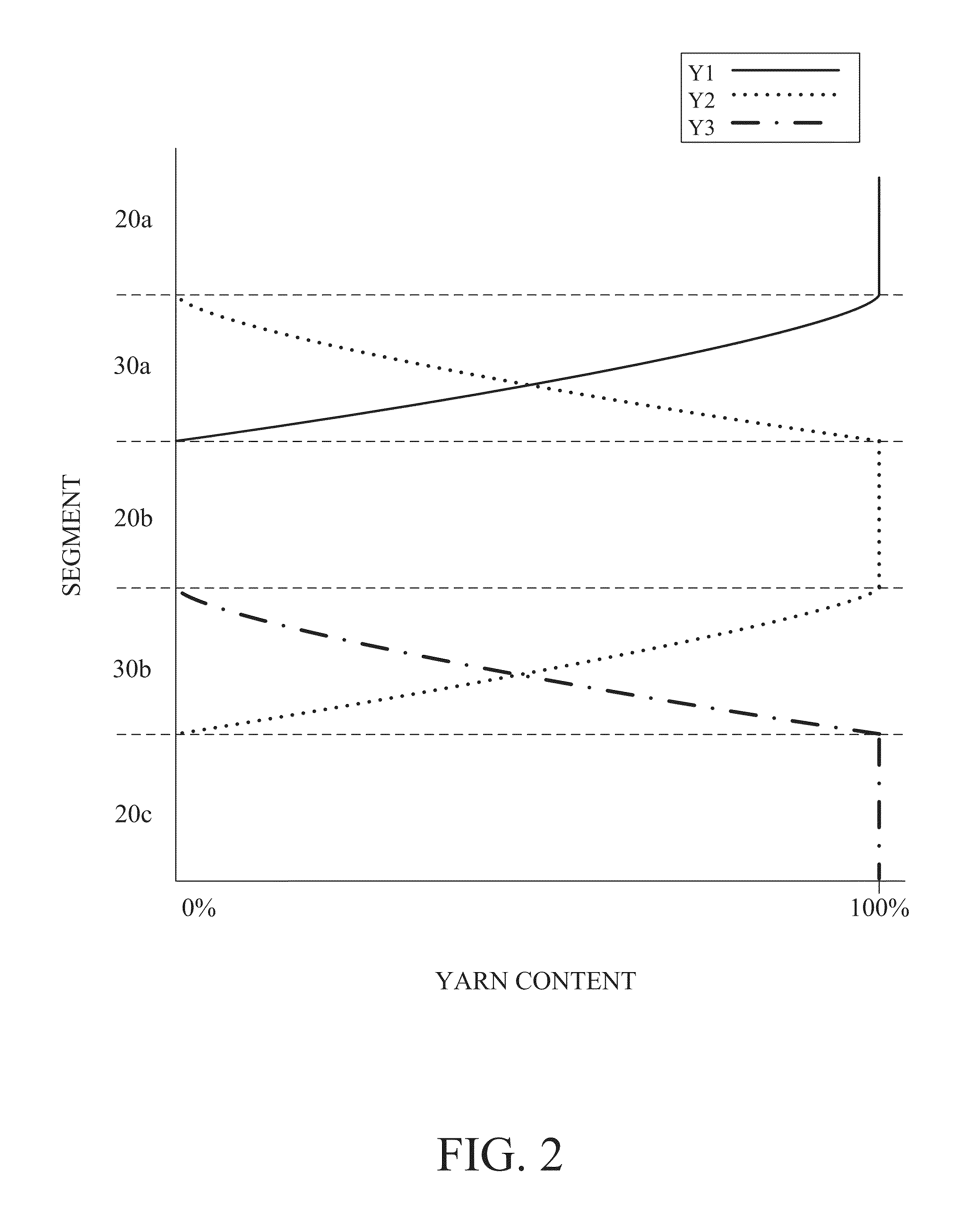

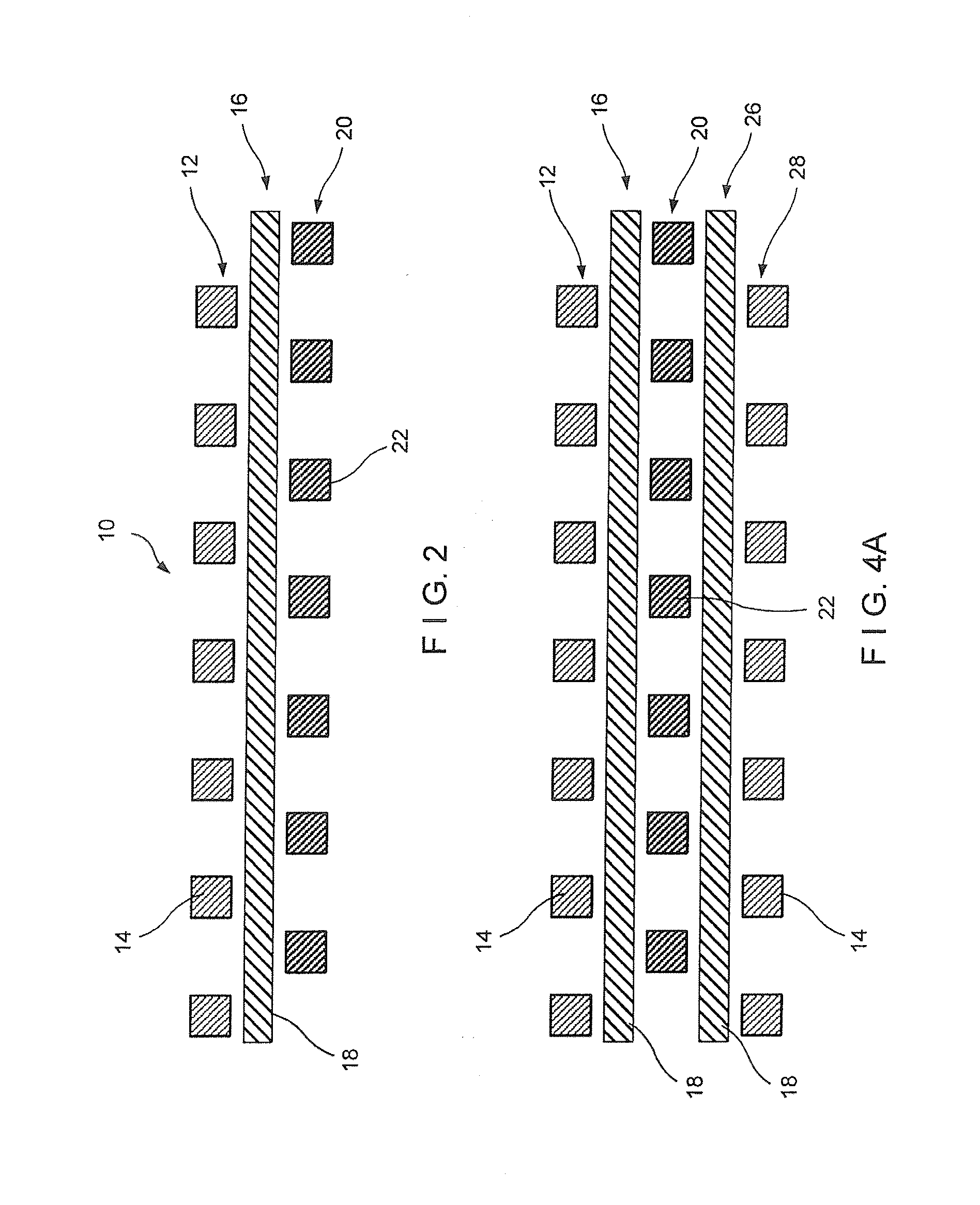

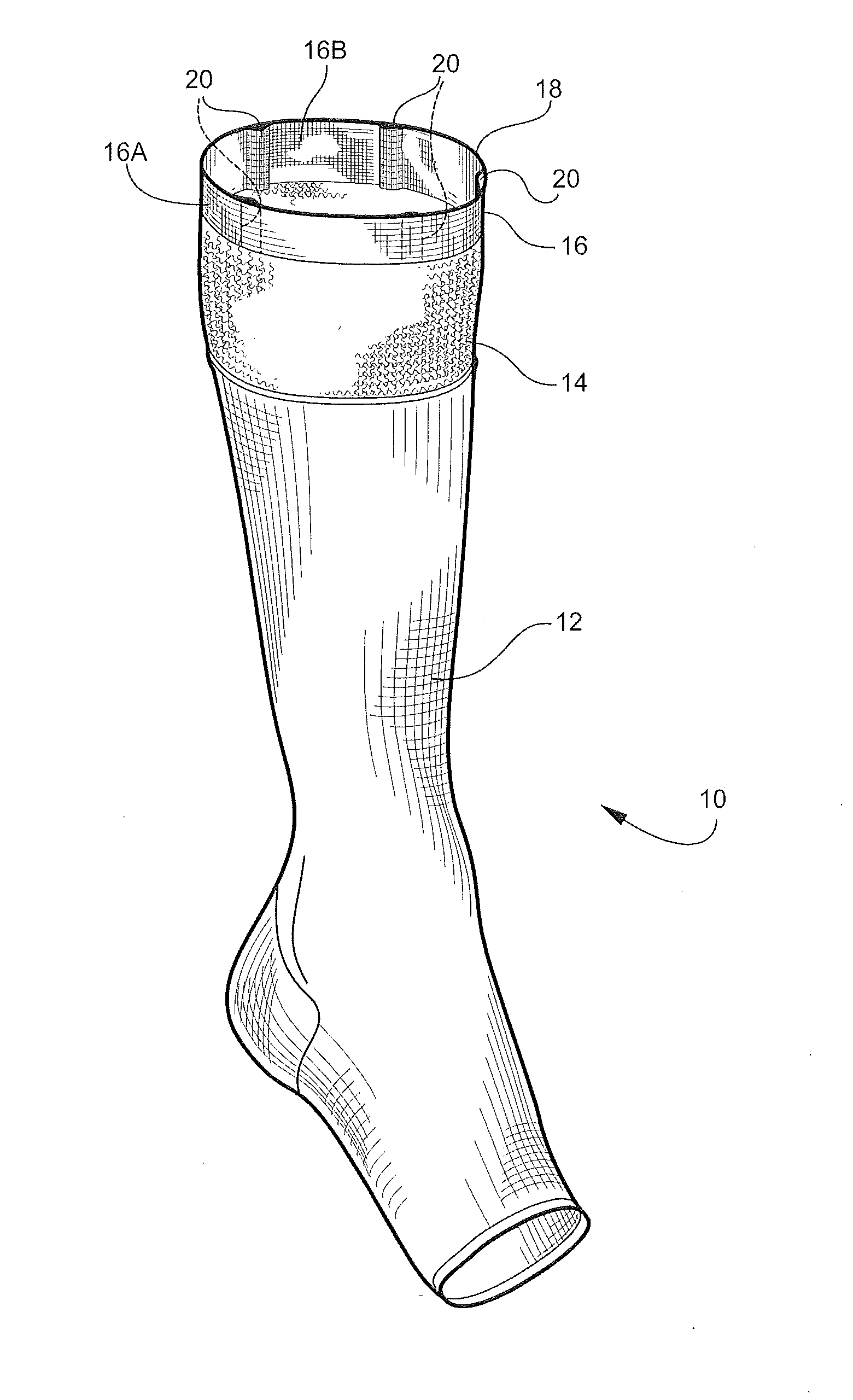

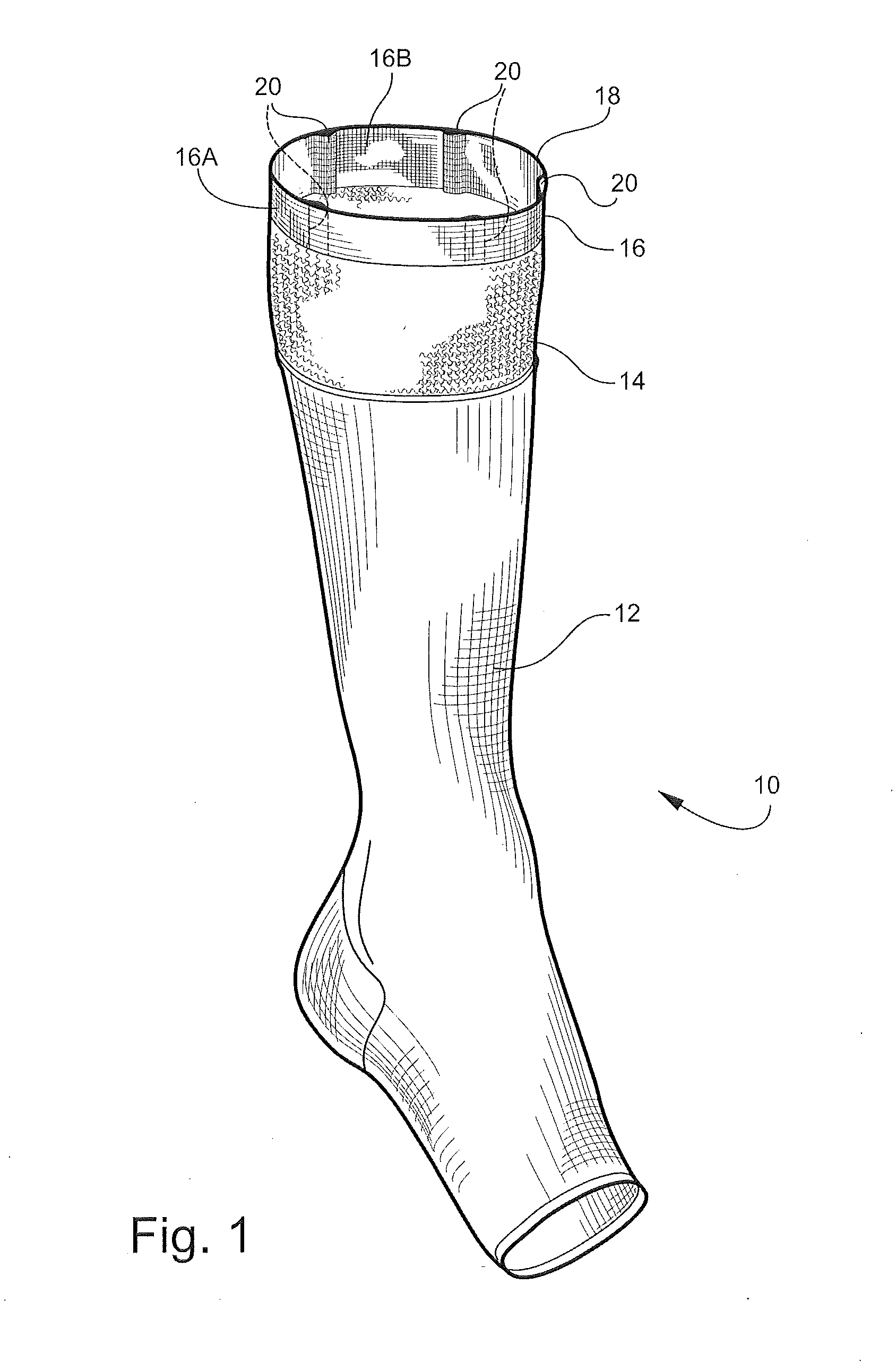

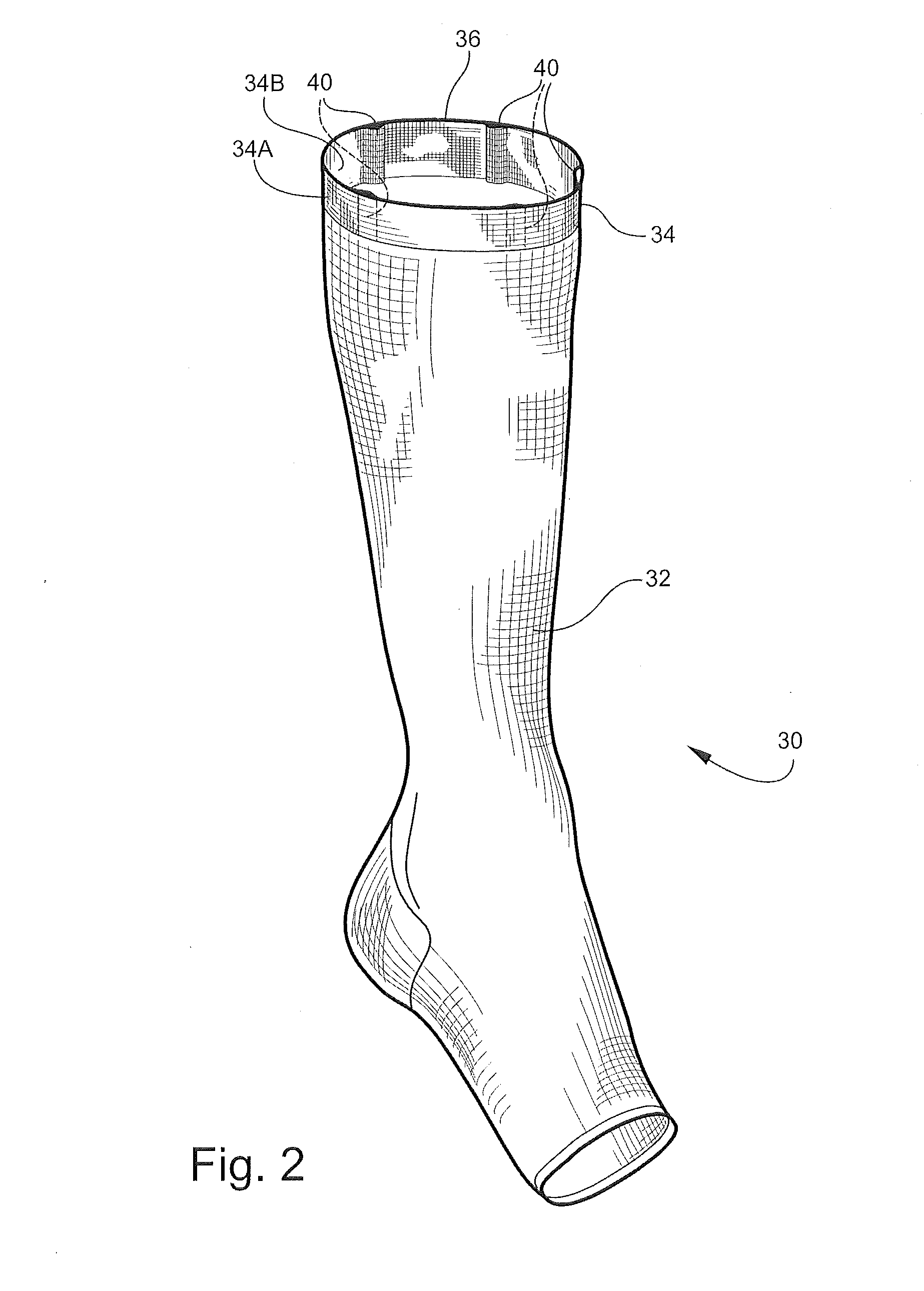

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

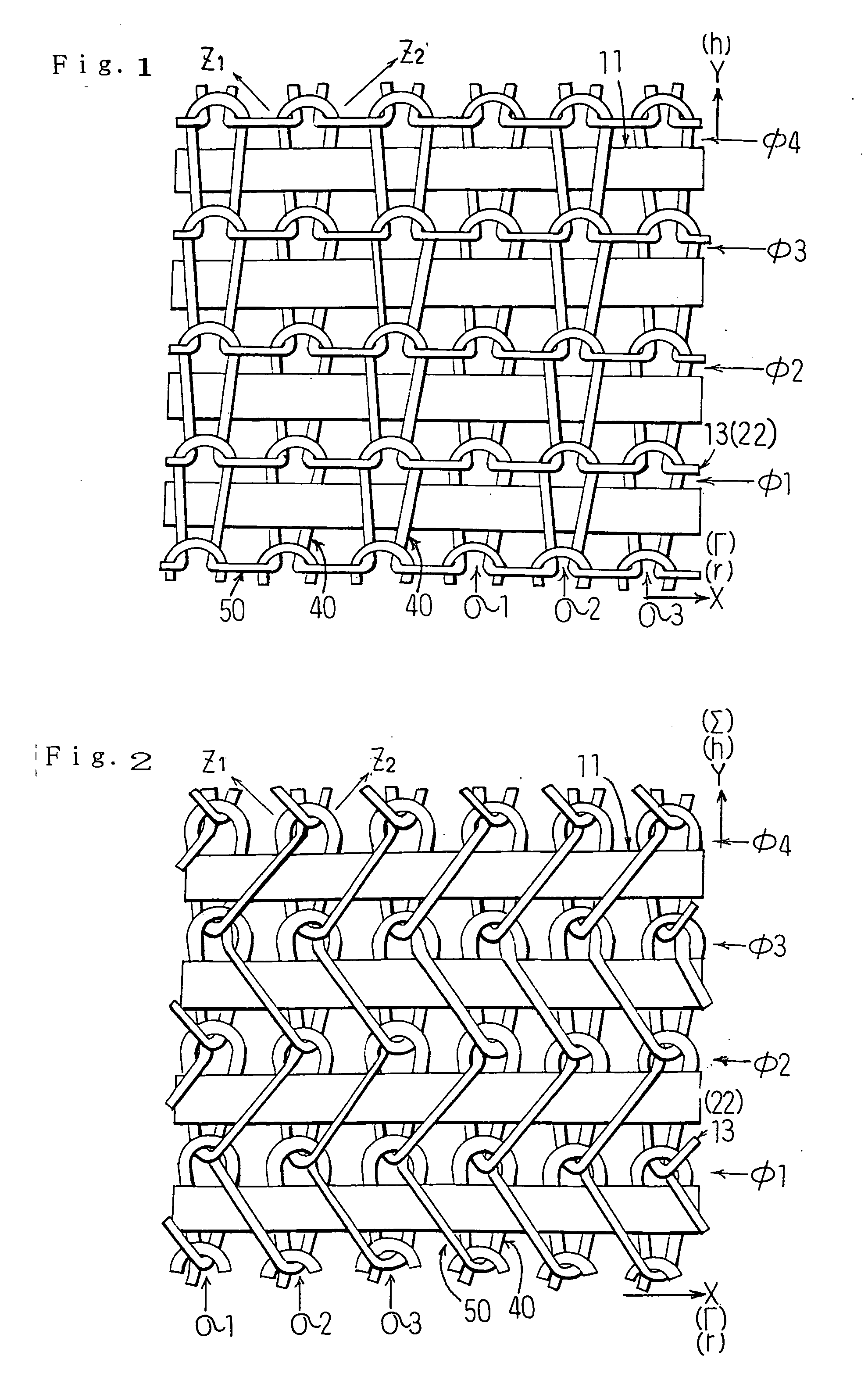

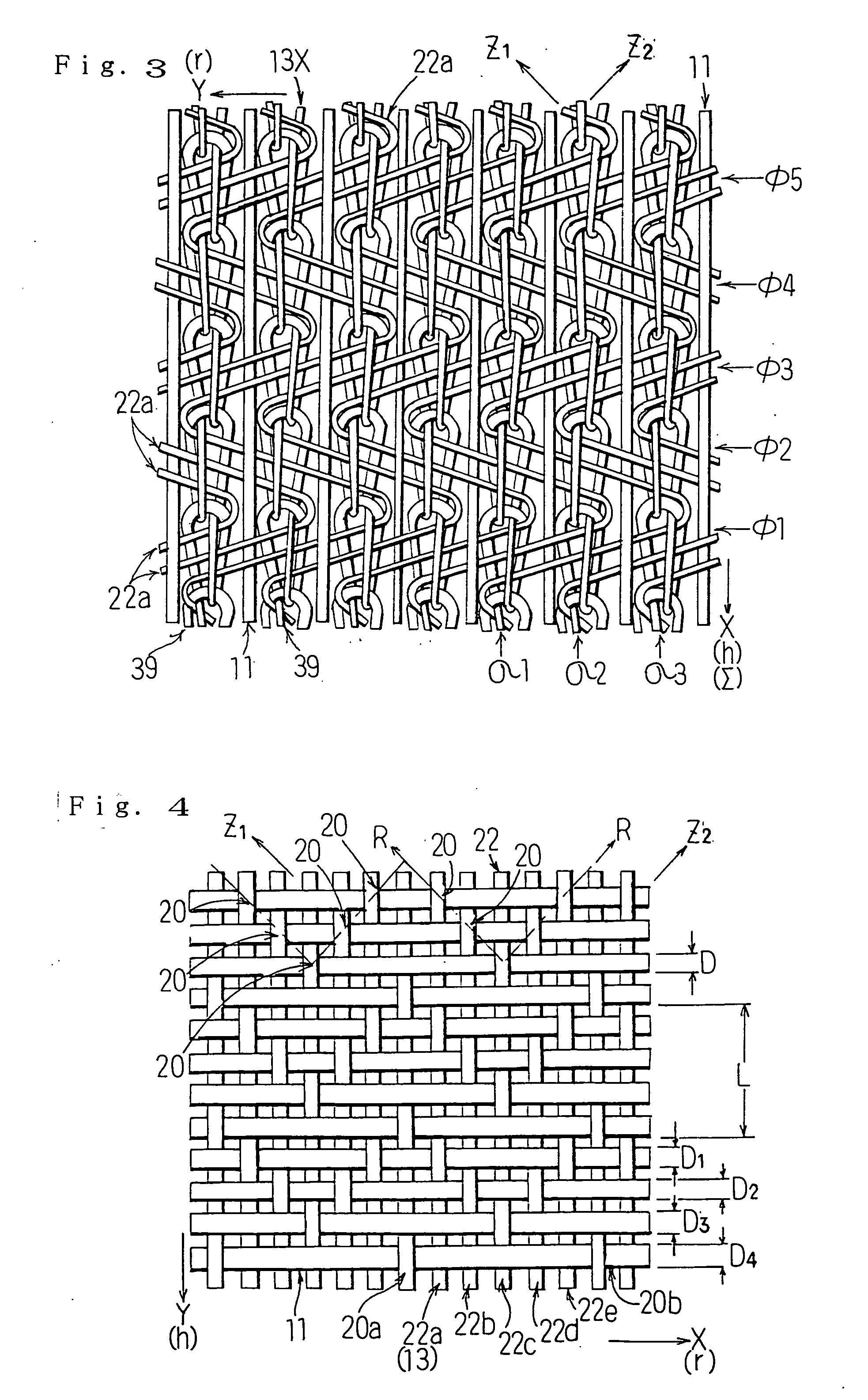

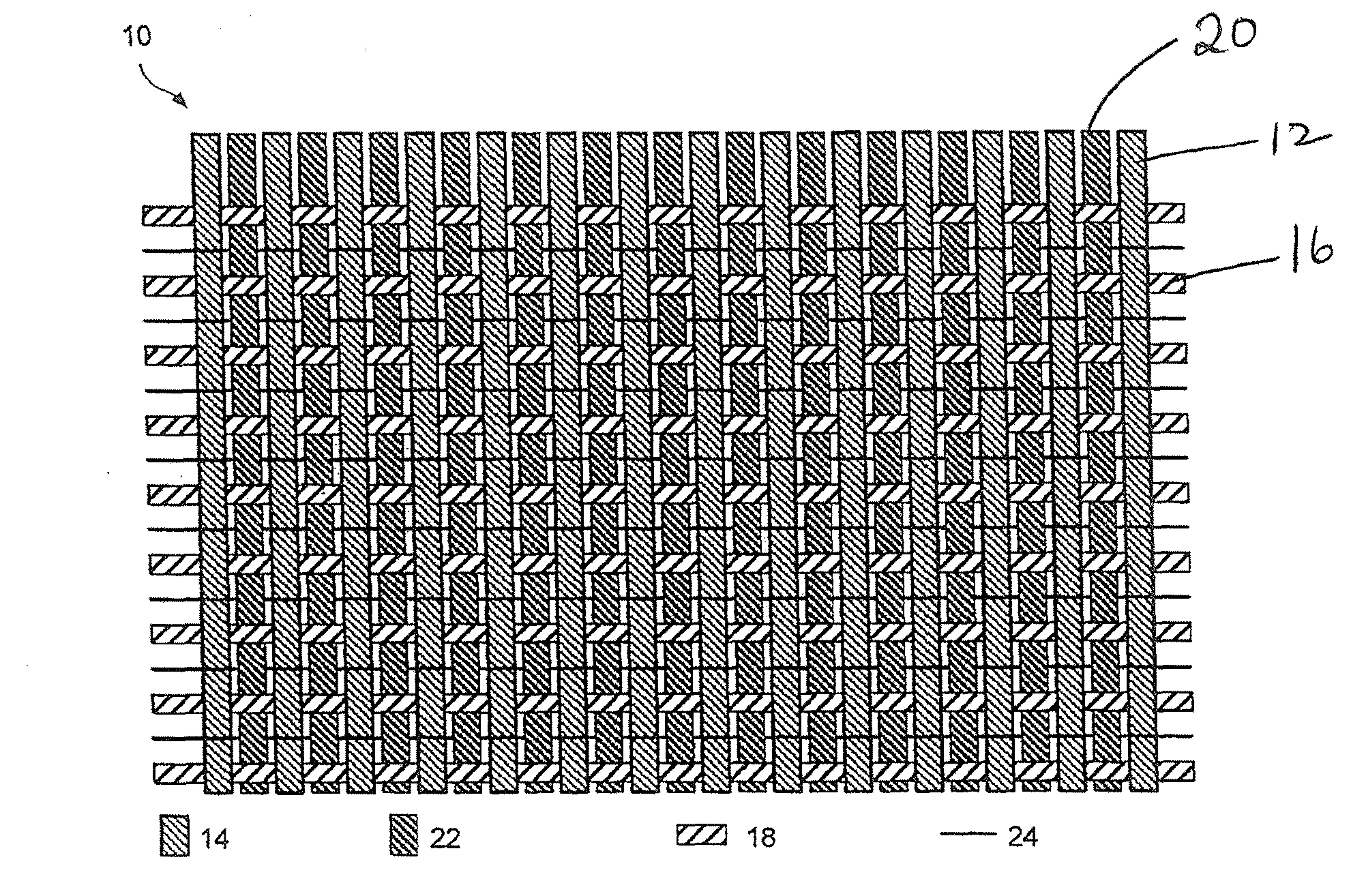

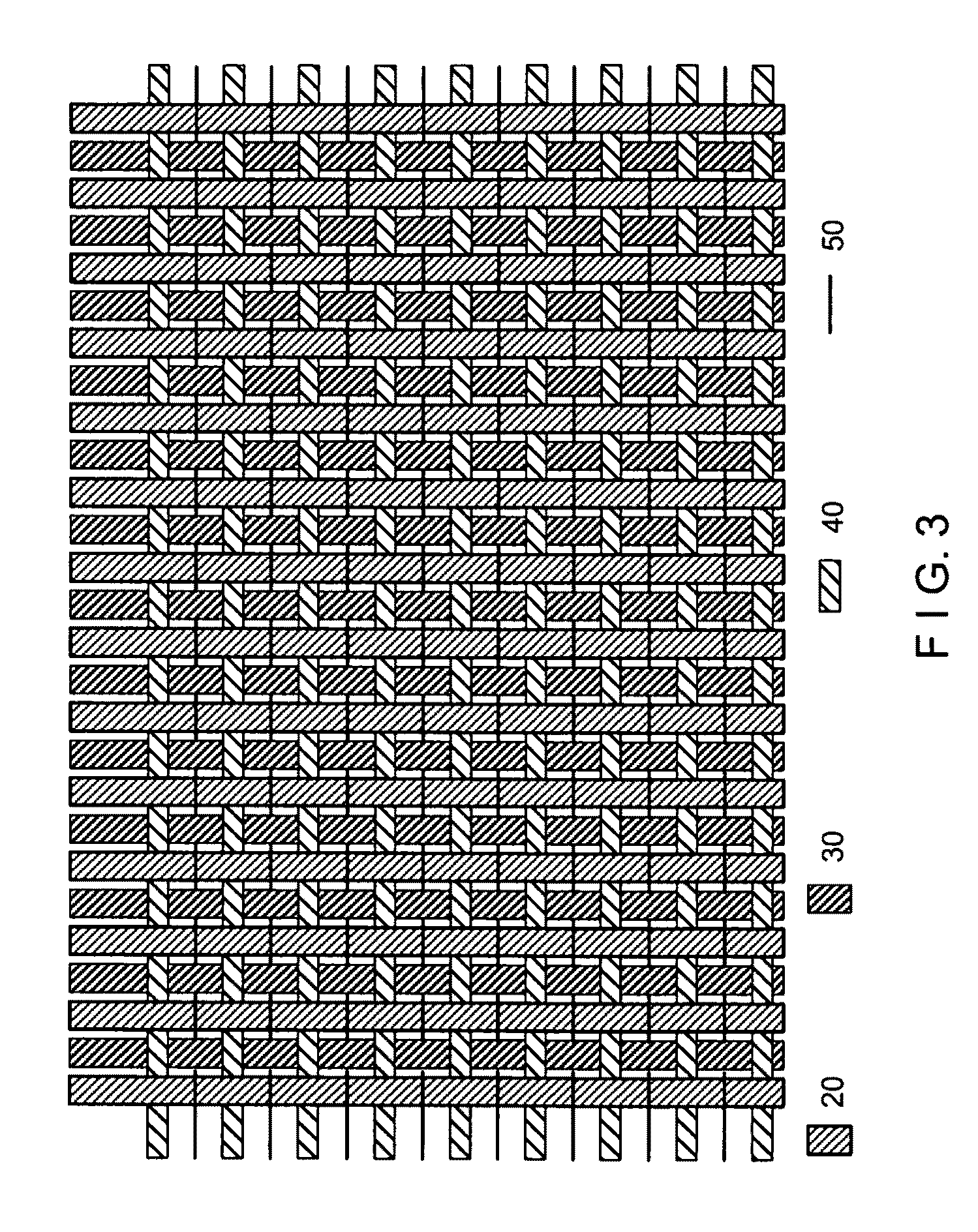

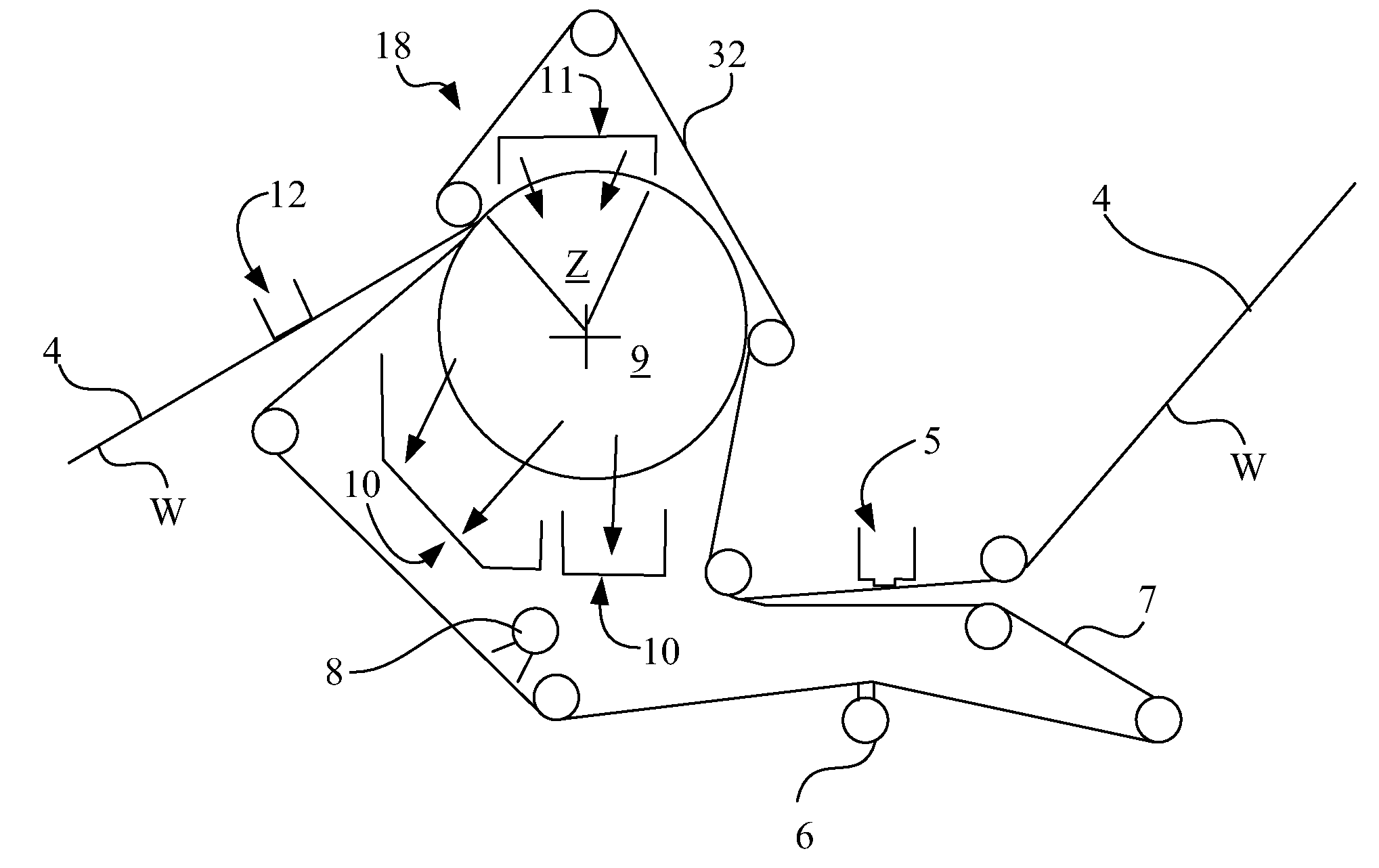

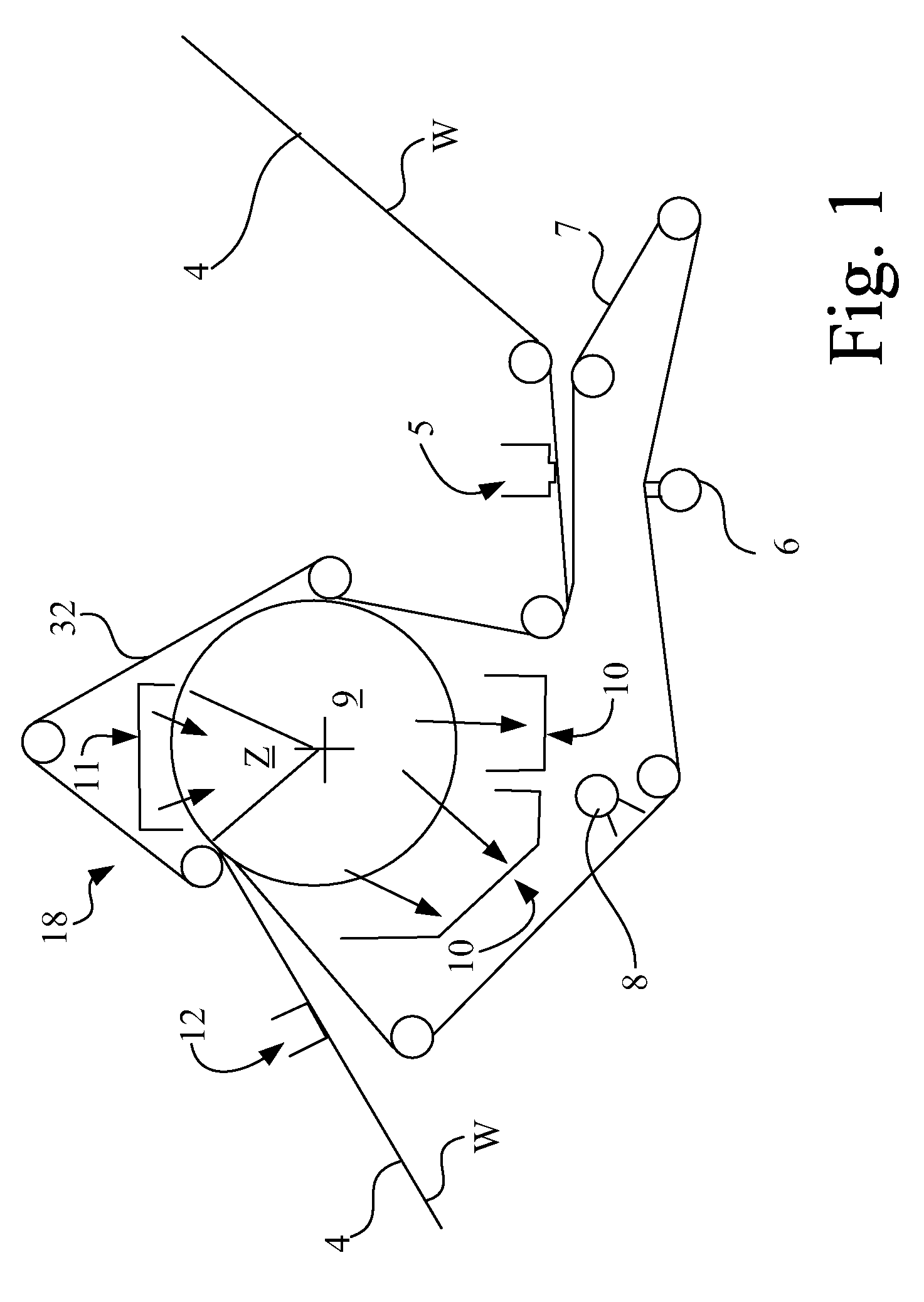

Ultra-Resilient Fabric

A structure for use in industrial fabrics such as paper machine clothing and engineered fabrics is disclosed. The structure includes axially and radially elastic hollow members, and relatively inelastic yarns in various patterns. The structure has a high degree of both compressibility under an applied normal load and excellent recovery (resiliency or spring back) upon removal of that load.

Owner:ALBANY INT CORP

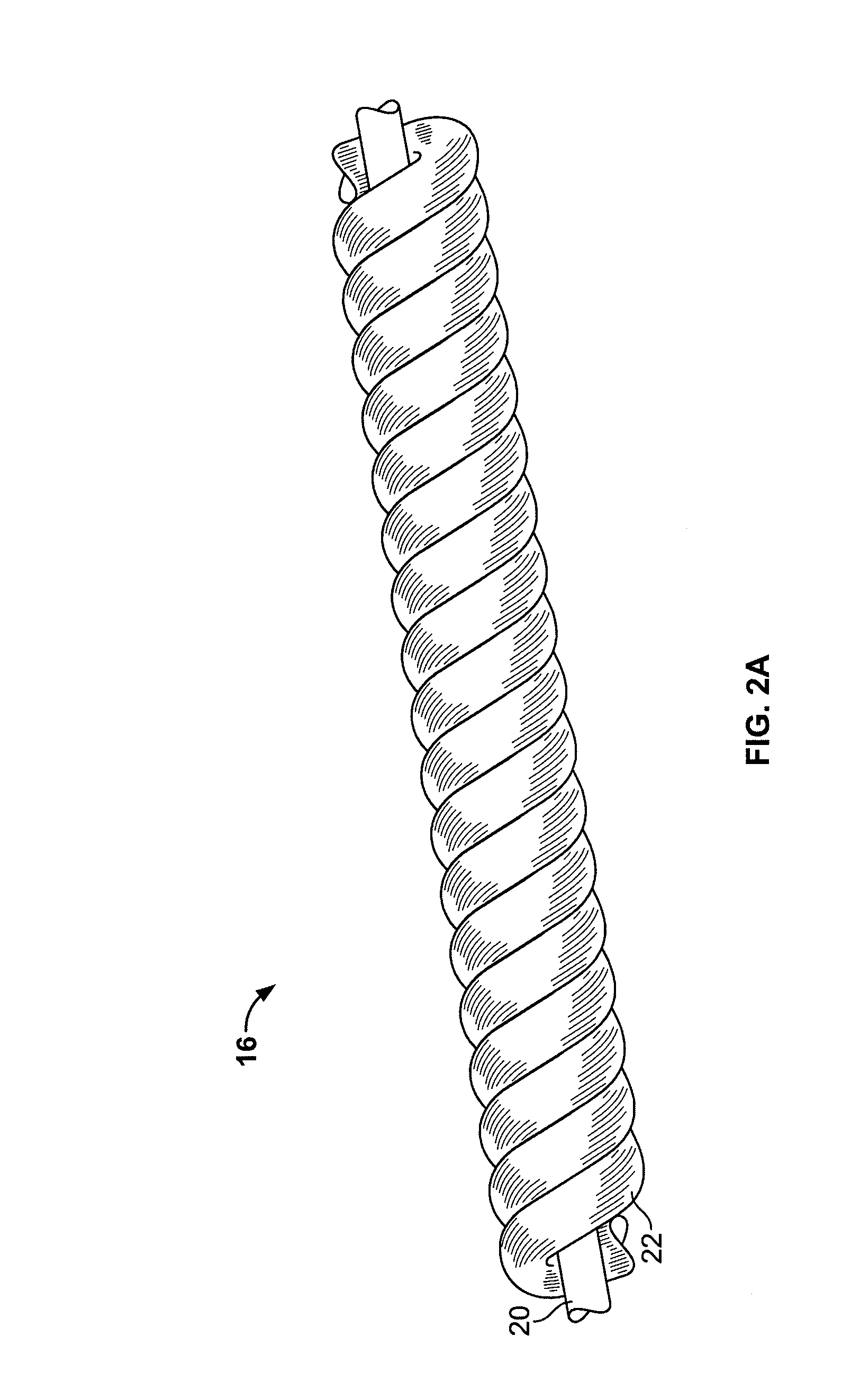

Color change compression fabrics and garments

A color change compression fabric and / or garment can include an elastic material having one color in an unstretched condition that changes to a different color in a stretched condition. The different, stretched color corresponds to a predetermined amount of stretch applied to the material, which in turn can correspond to a predetermined amount of compressive pressure. The compression fabric may include a covering yarn having a first color and wrapped a number of turns about an elastic yarn having a second color different than the first color. When the fabric is stretched, the turns of the covering yarn move apart from each other to expose the second color of the elastic yarn underneath. A particular amount of fabric stretch can provide a unique color profile of a combination of the first and second colors, and the unique color profile preferably corresponds to a certain amount of compressive pressure.

Owner:CAROLON

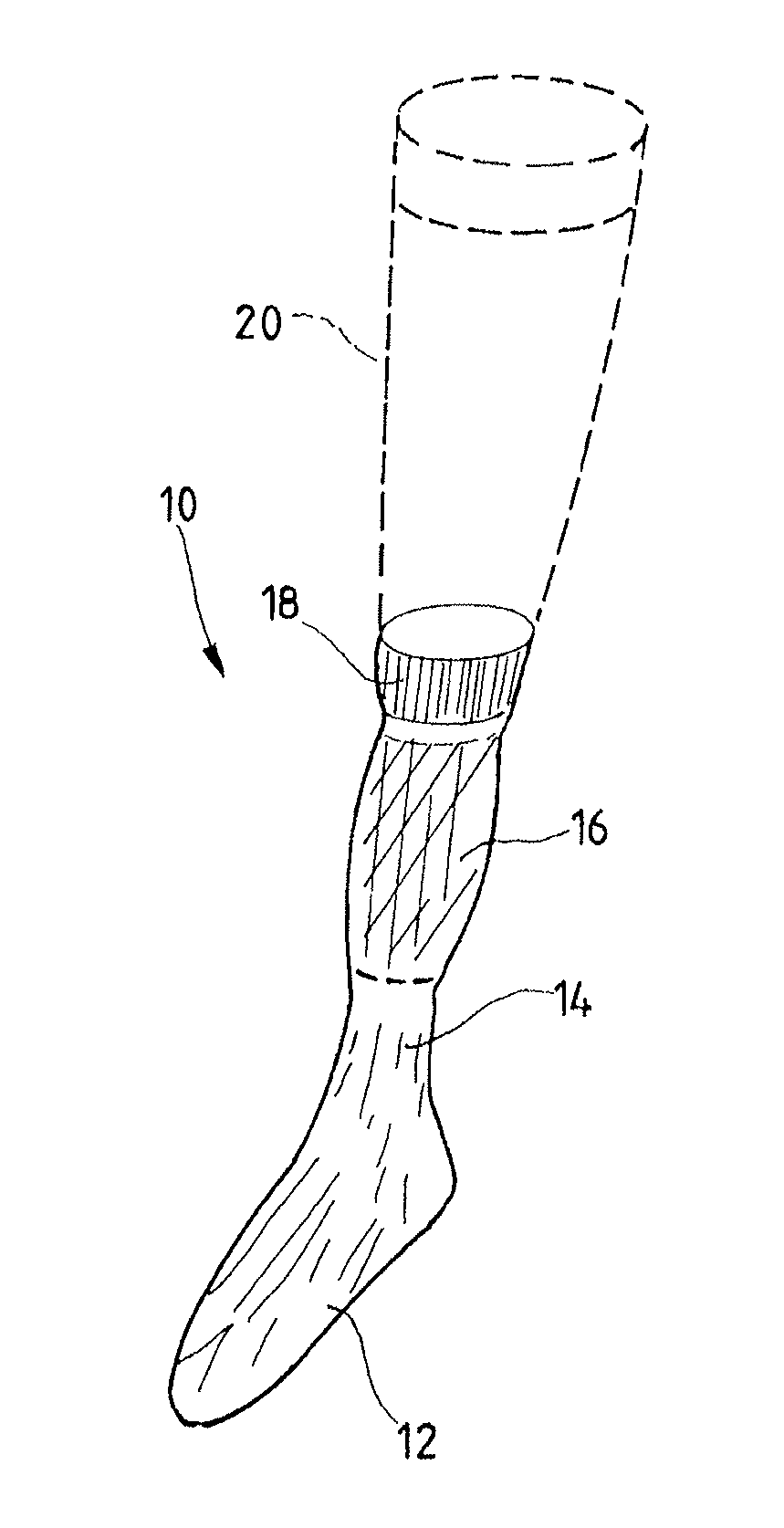

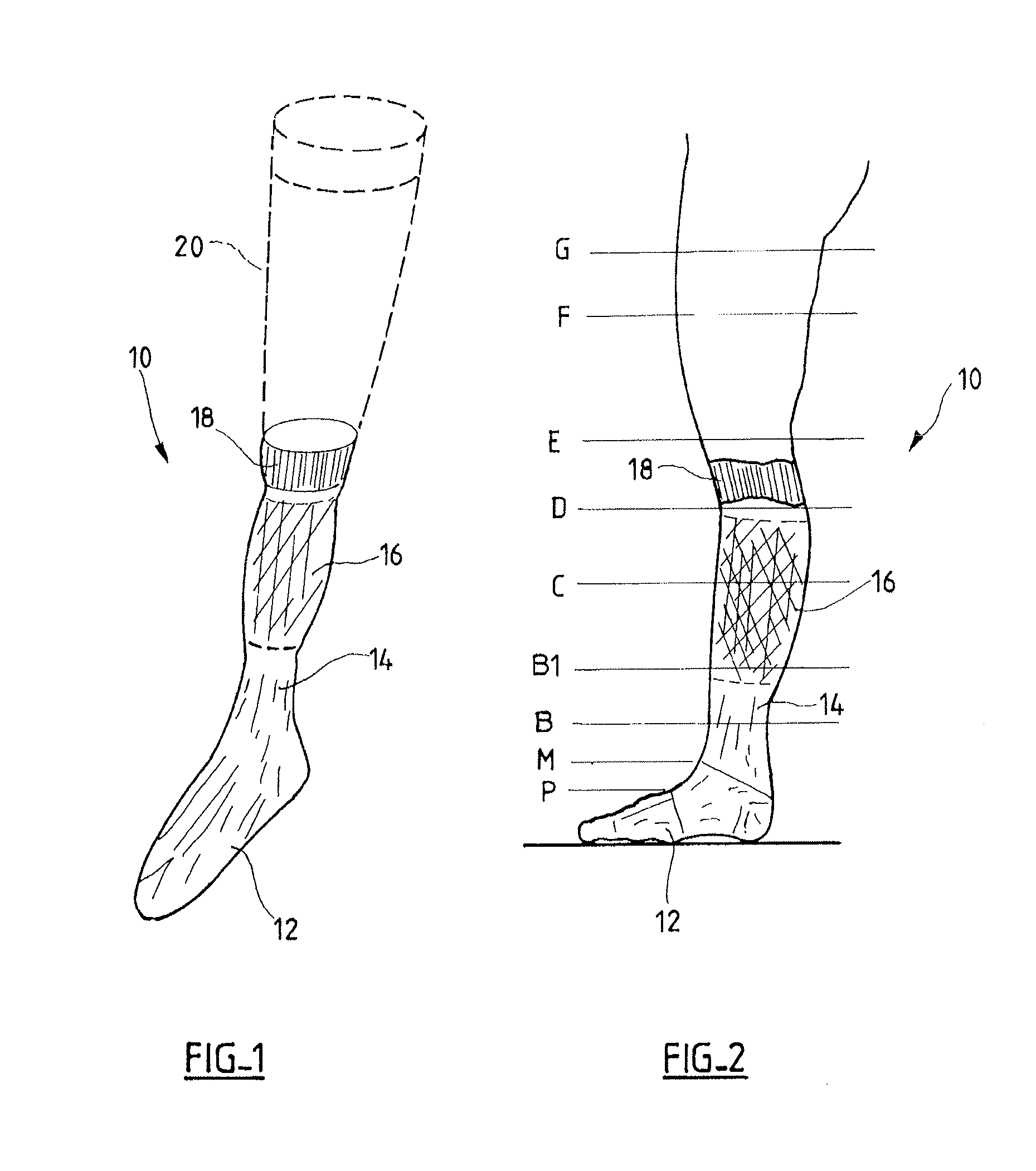

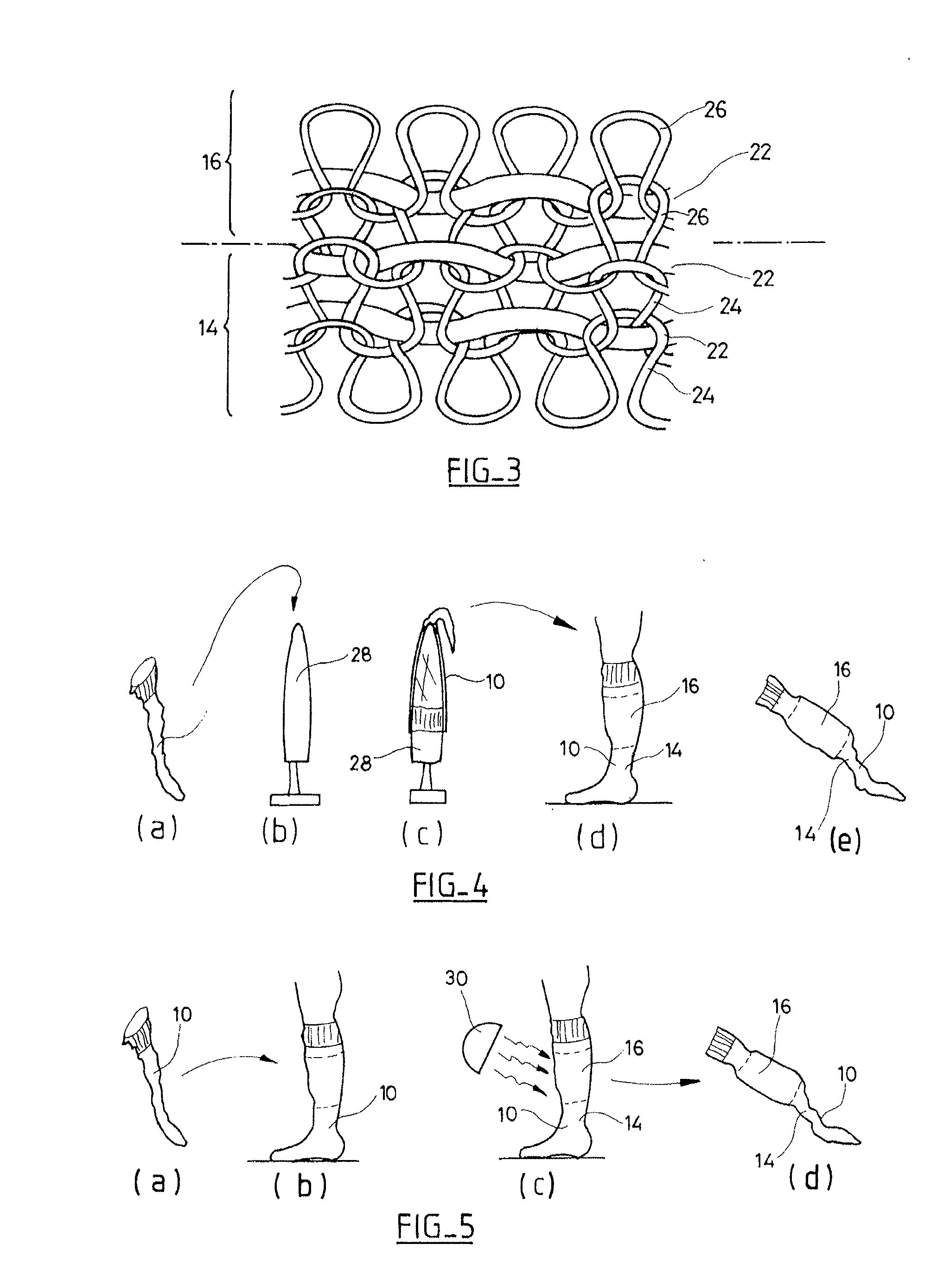

Made-to-measure orthosis for compression/containment, for reinforcing the musculo-aponeurotic pump of the calf

InactiveUS20120116282A1Easy to installReduce rigidityFinger bandagesBreast bandagesYarnDistal portion

Owner:INNOTHERA TOPIC INT

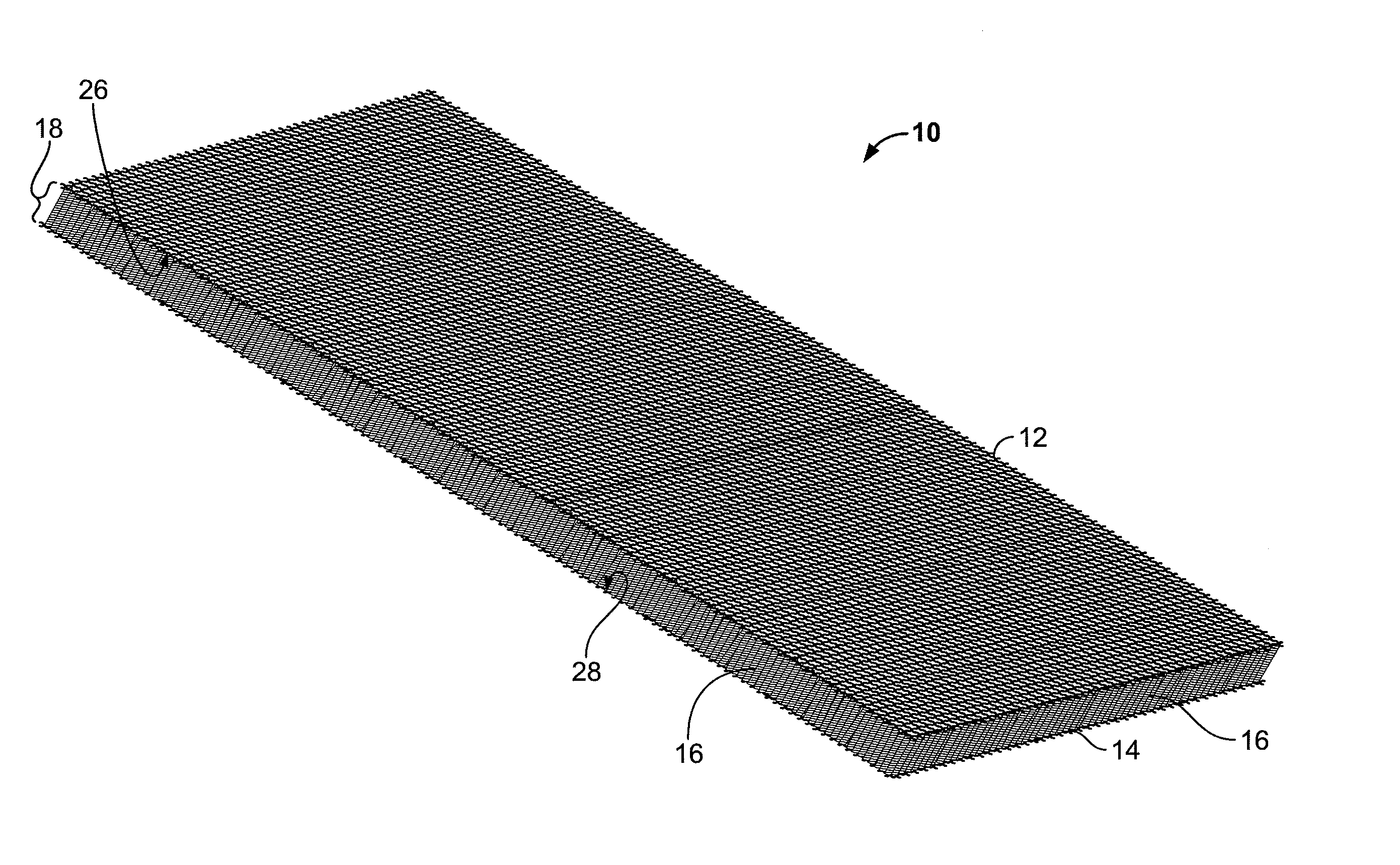

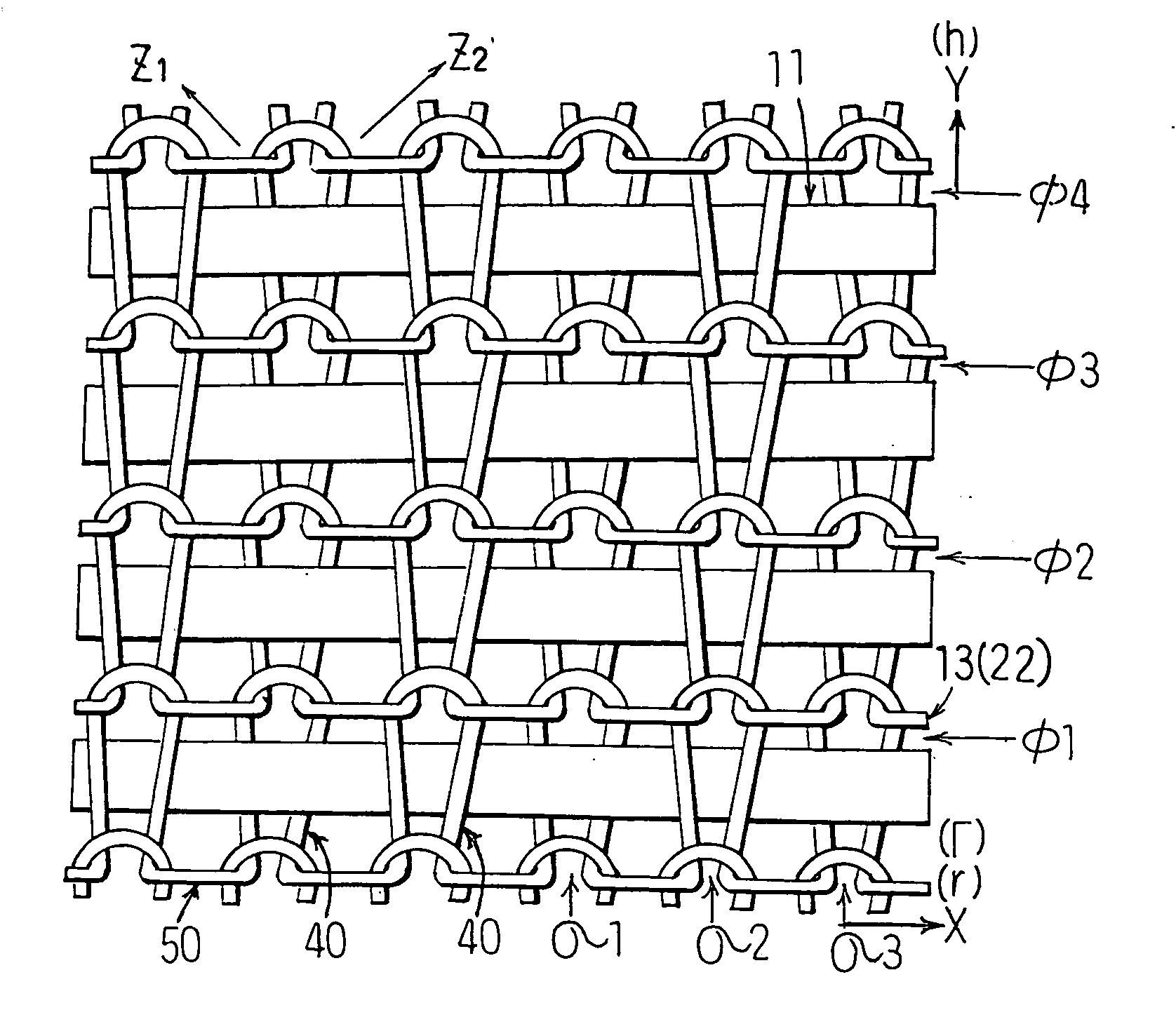

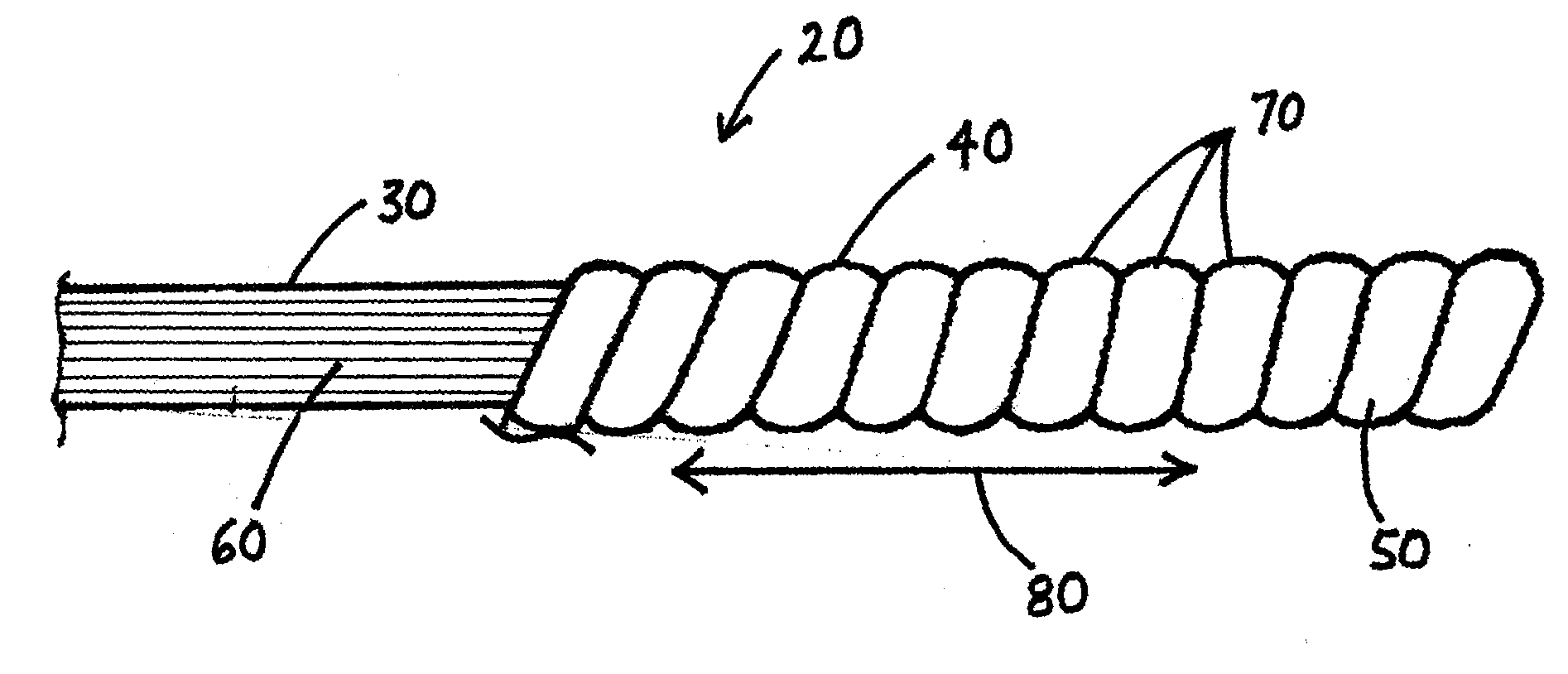

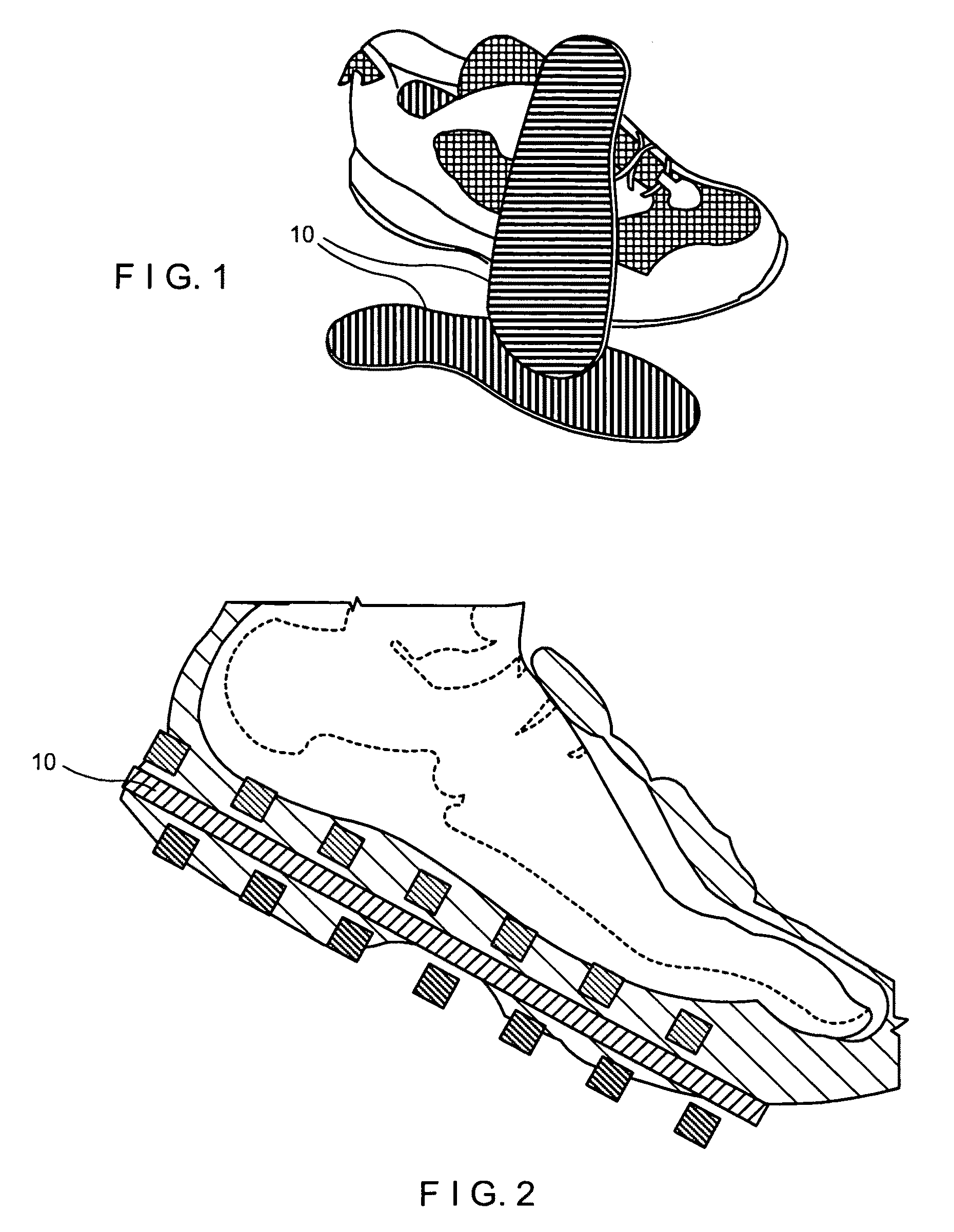

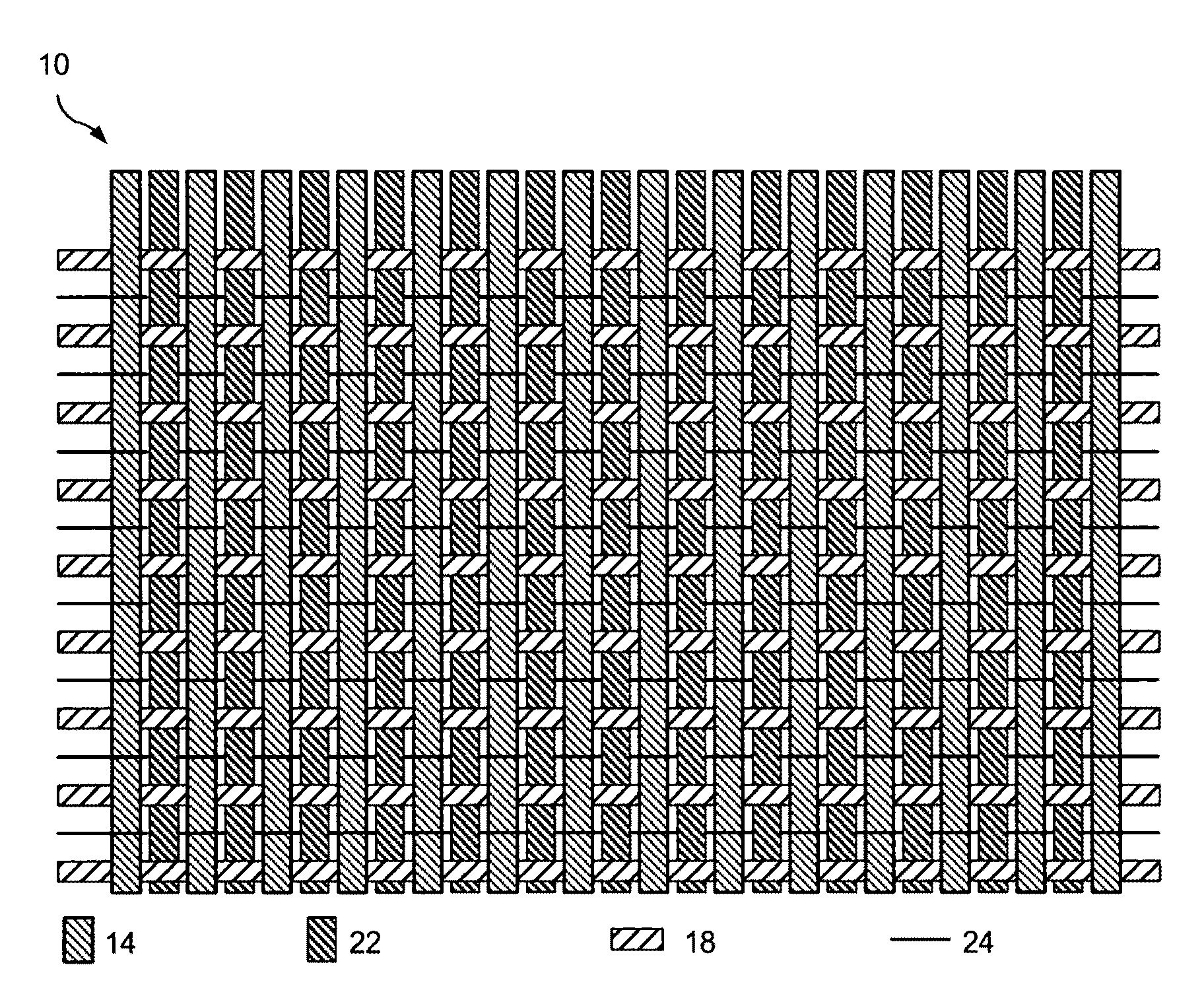

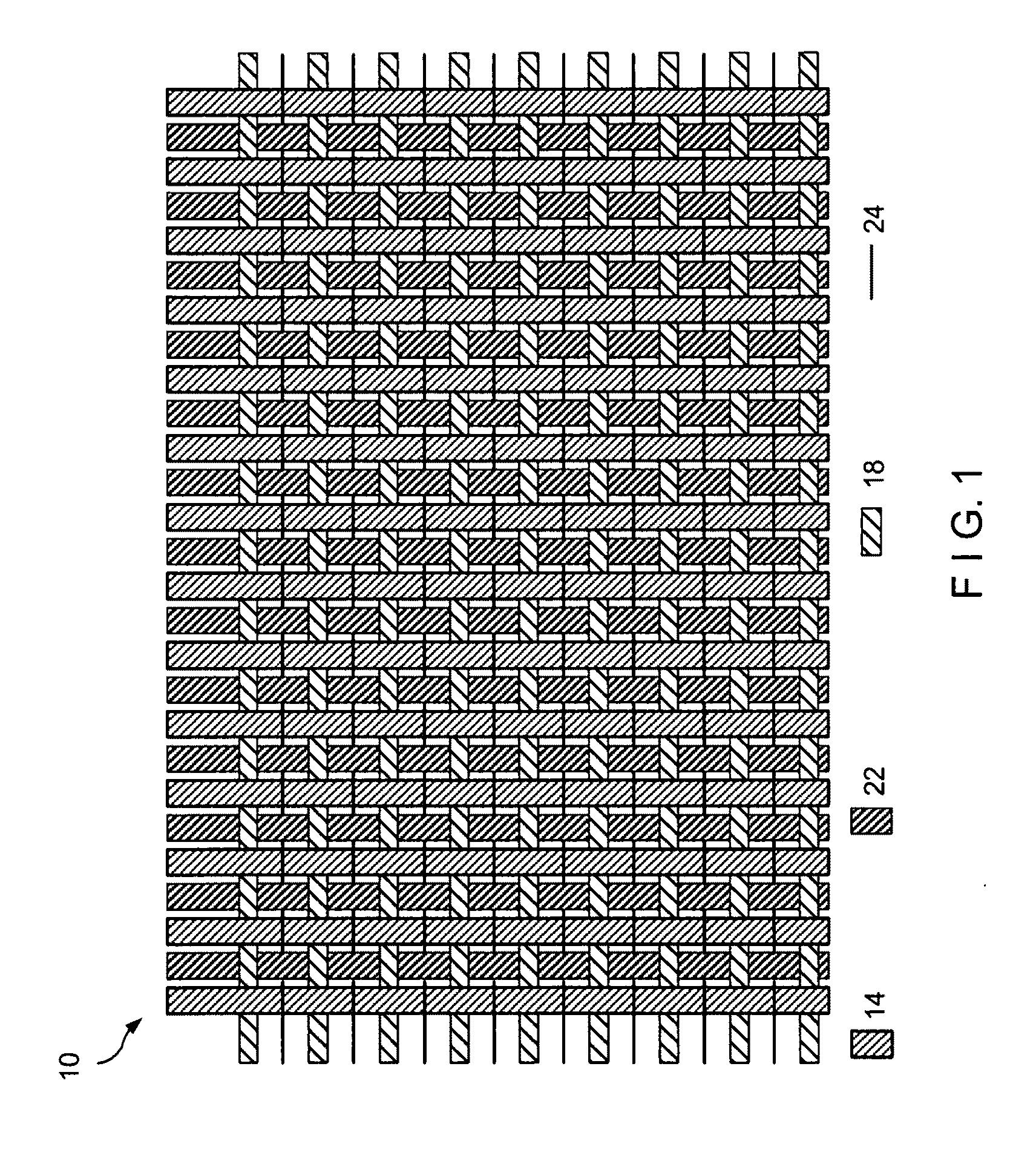

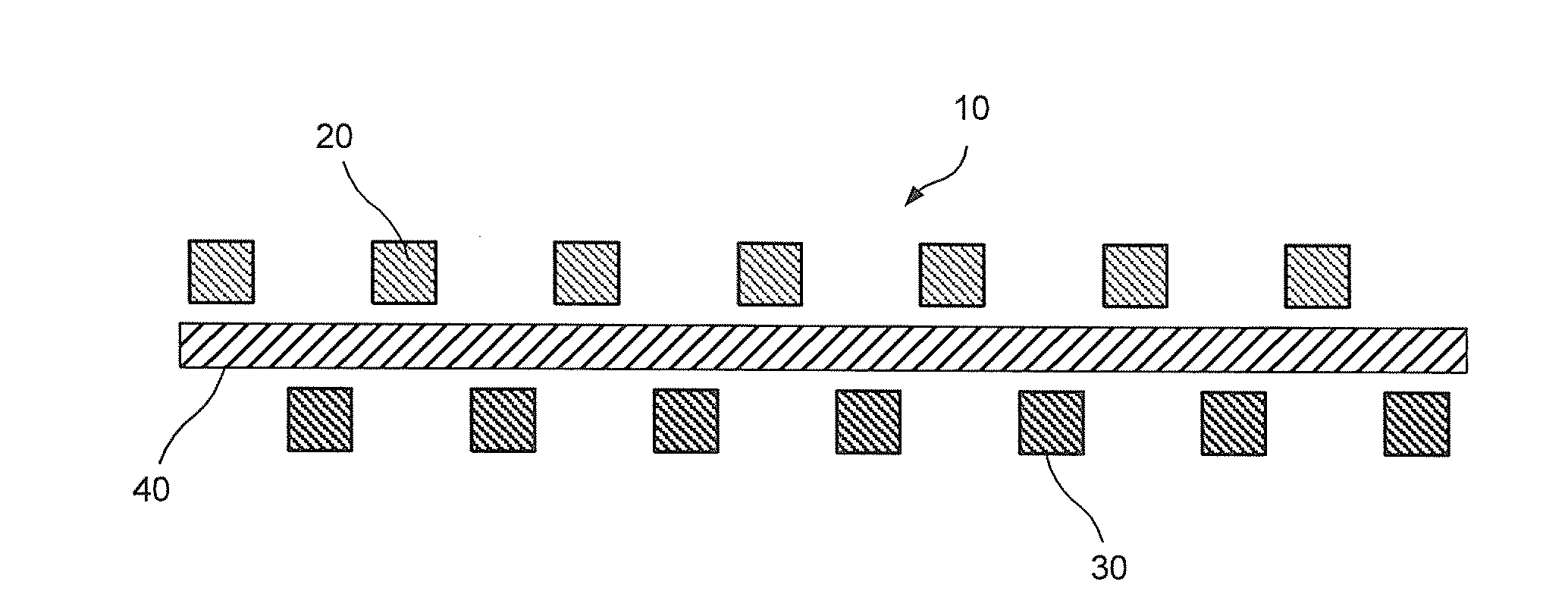

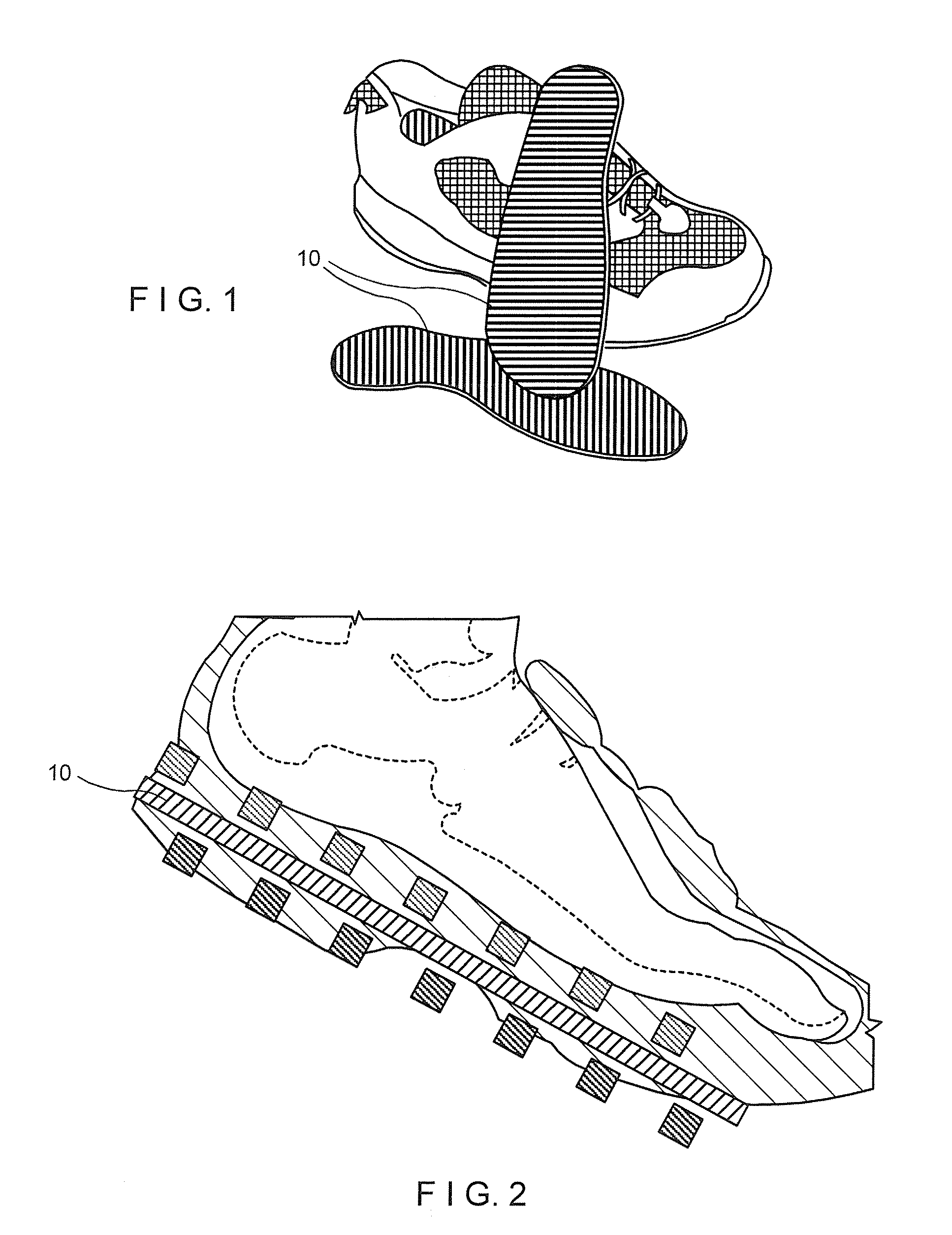

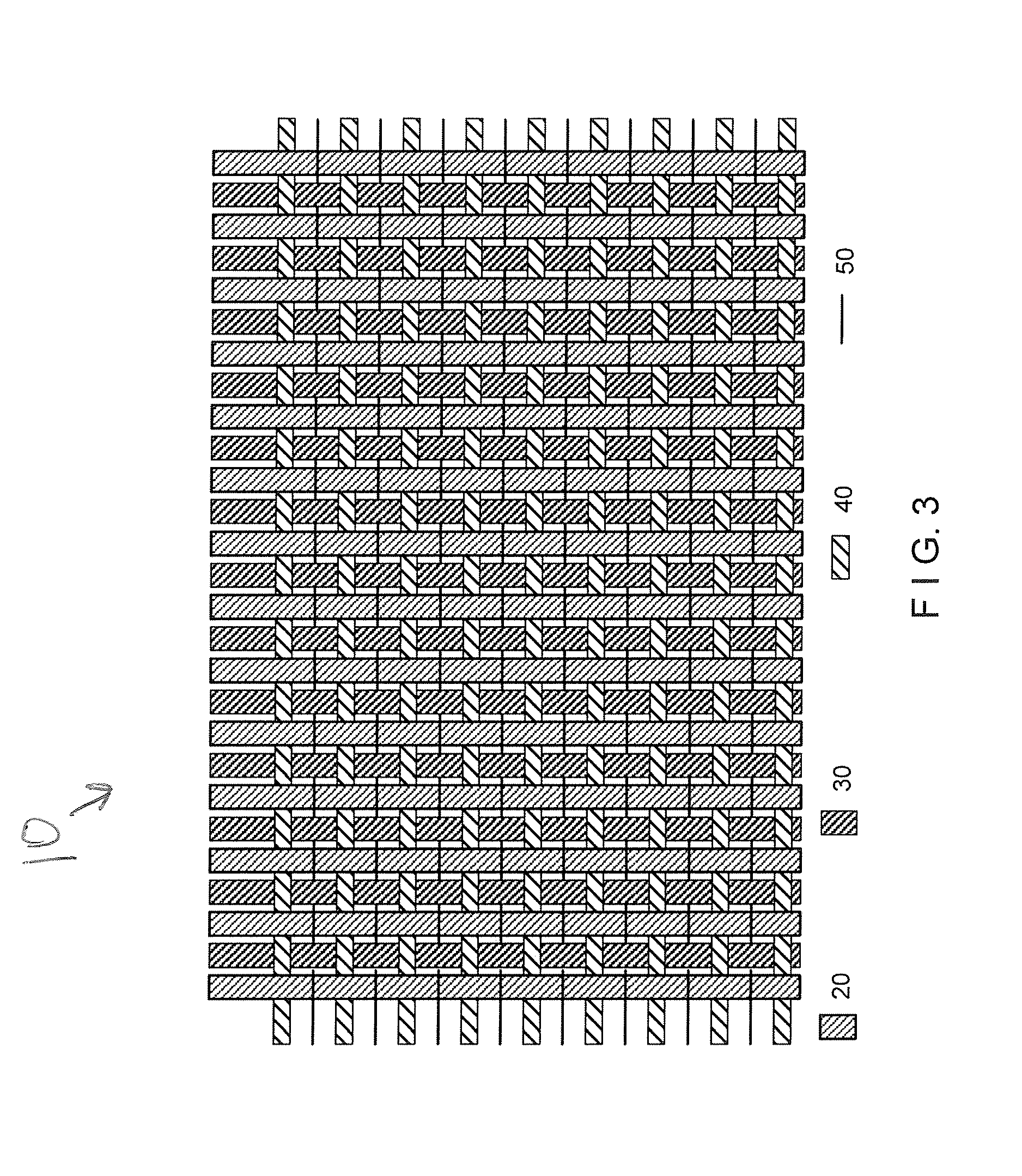

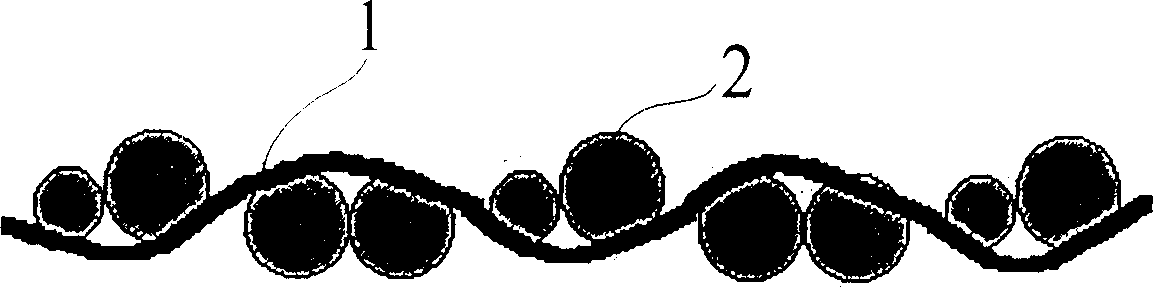

Ultra-Resilient Pad

ActiveUS20090181590A1Elastic behaviorHigh through thickness recoverySolesLayered productsYarnNormal load

A structure for use in a compressible resilient pad. The structure contains both axially elastomeric yarns and relatively inelastic yarns in various patterns. The structure has a high degree of both compressibility under an applied normal load and excellent recovery (resiliency or spring back) upon removal of that load.

Owner:ALBANY INT CORP

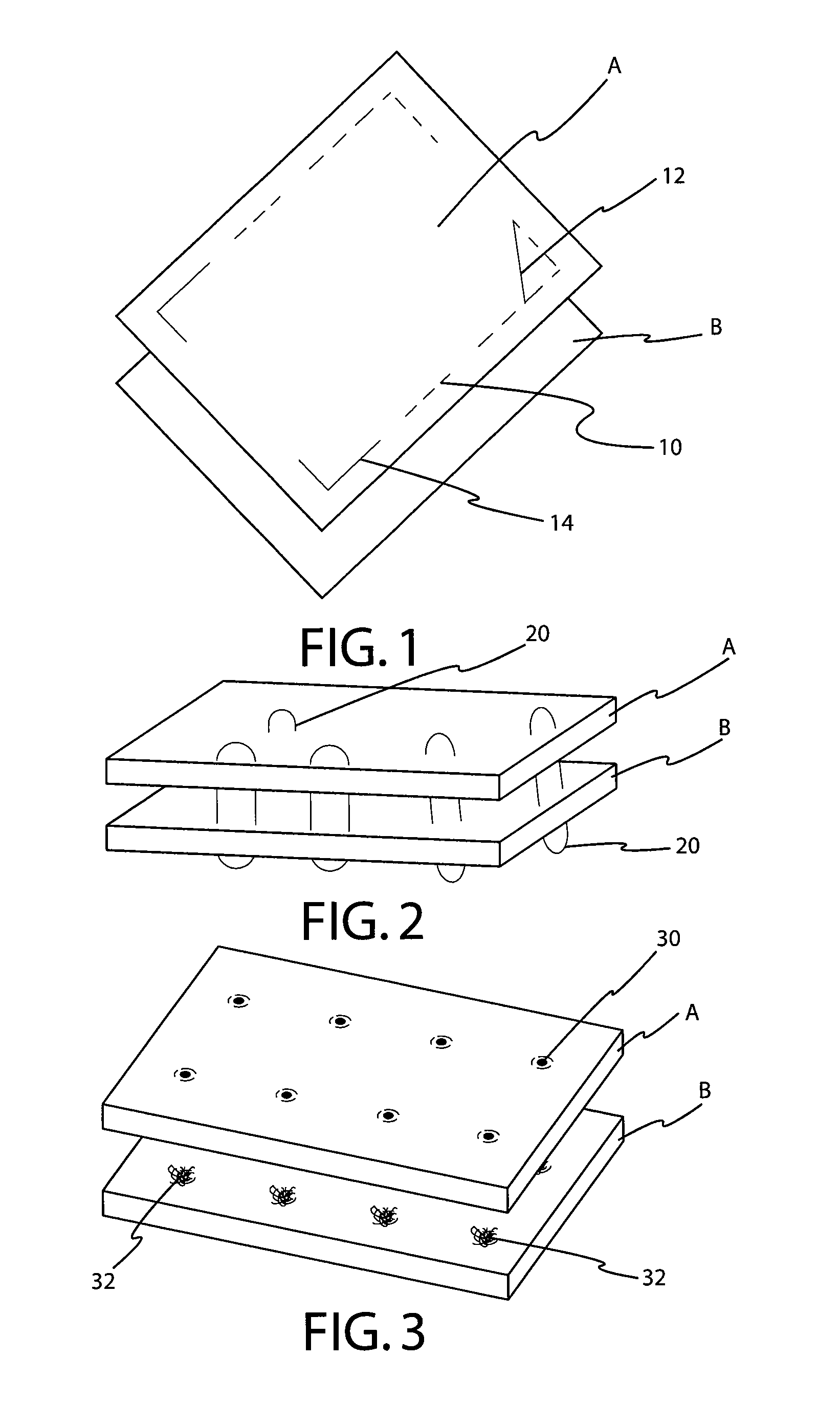

Impact dissipating fabric

InactiveUS20130090029A1Equal, if not better, levels of protectionsThinner and lighter and flexibleOrnamental textile articlesProtective equipmentFiberEngineering

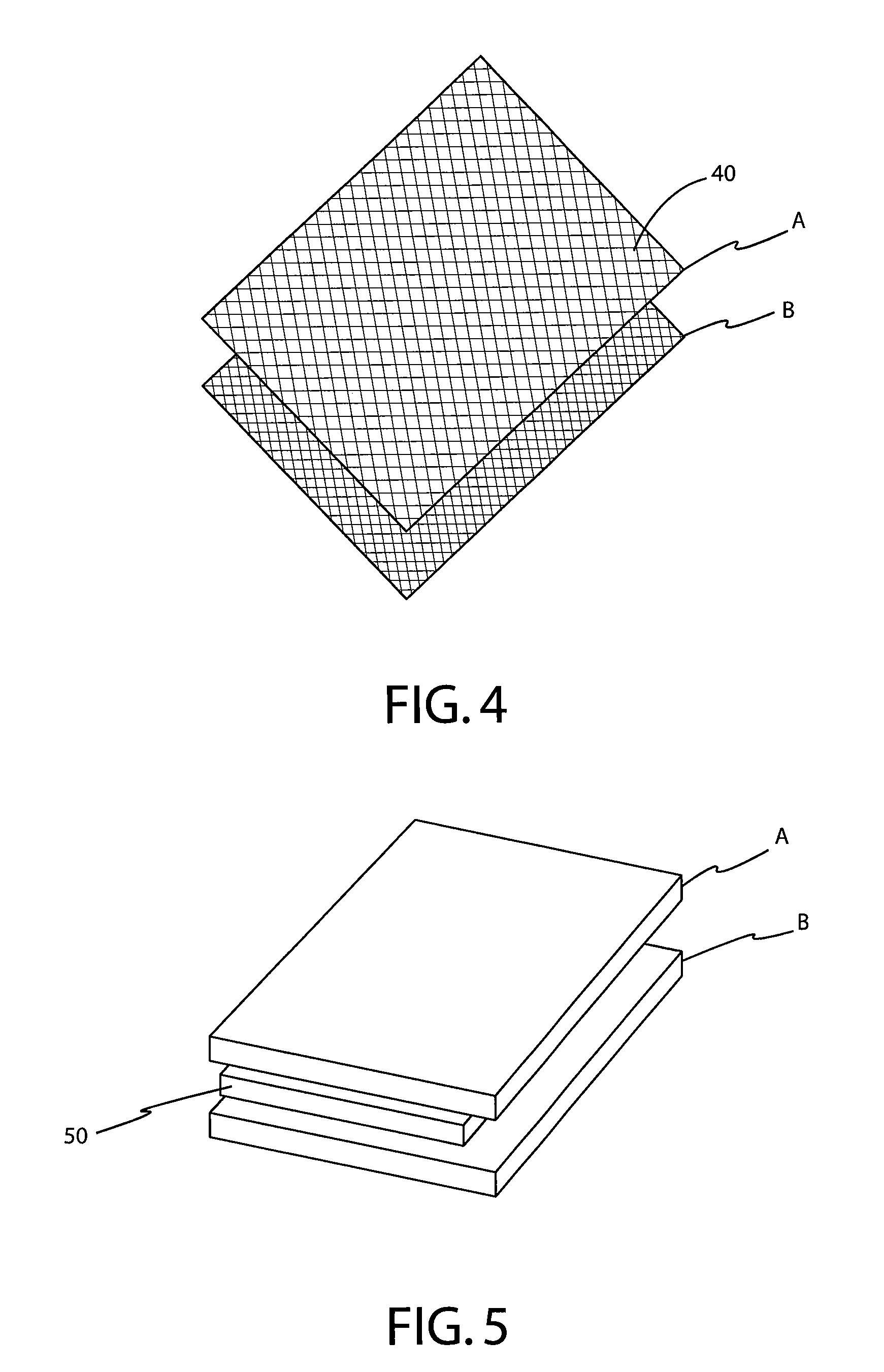

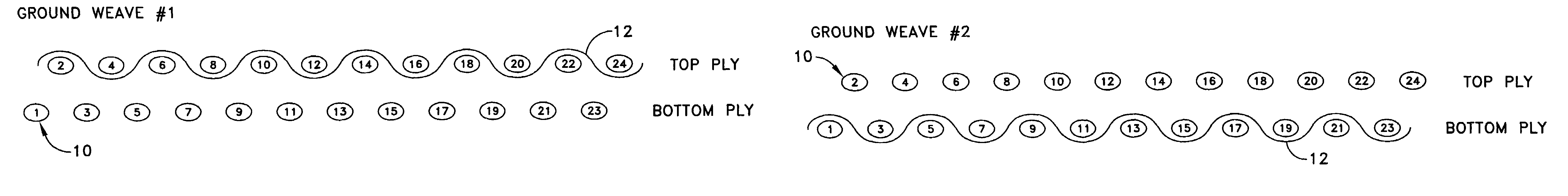

A first impact dissipating fabric system includes a first fabric layer formed using a first weave pattern, and a second fabric layer formed using a second weave pattern different from the first wave pattern. A second impact dissipating fabric system includes a first fabric layer formed with fibers having a first denier, and a second fabric layer formed with fibers having a second denier different from the first denier. A third impact dissipating fabric includes a first fabric layer formed using a first weave pattern from fibers having a first denier, and a second fabric layer formed using a second weave from fibers having a second denier. The first weave and the second weave are different types of weaves and / or the first denier and the second denier are different from one another. In each system, the first and second fabric layers are disposed on one another and coupled together.

Owner:MATSCITECHNO LICENSING

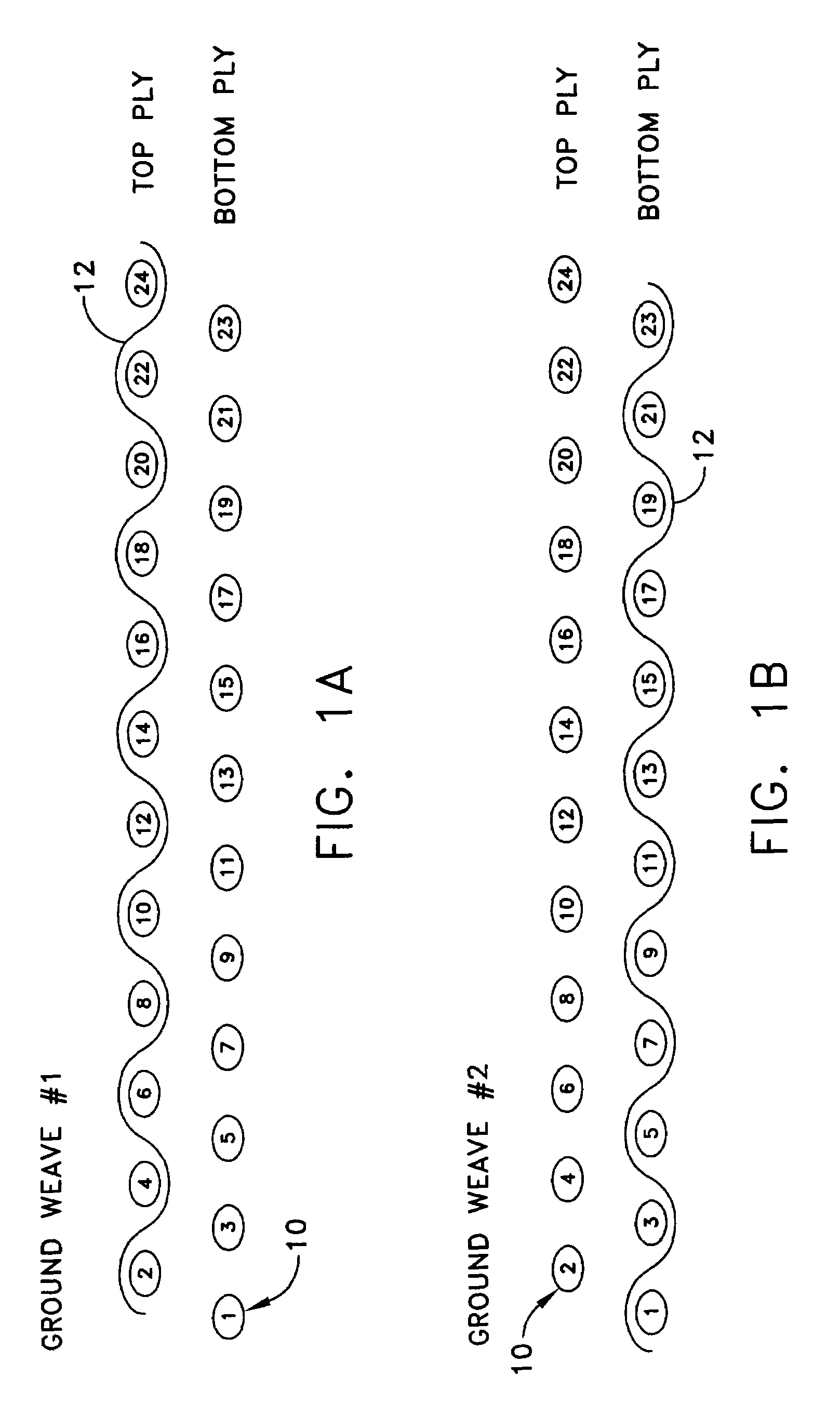

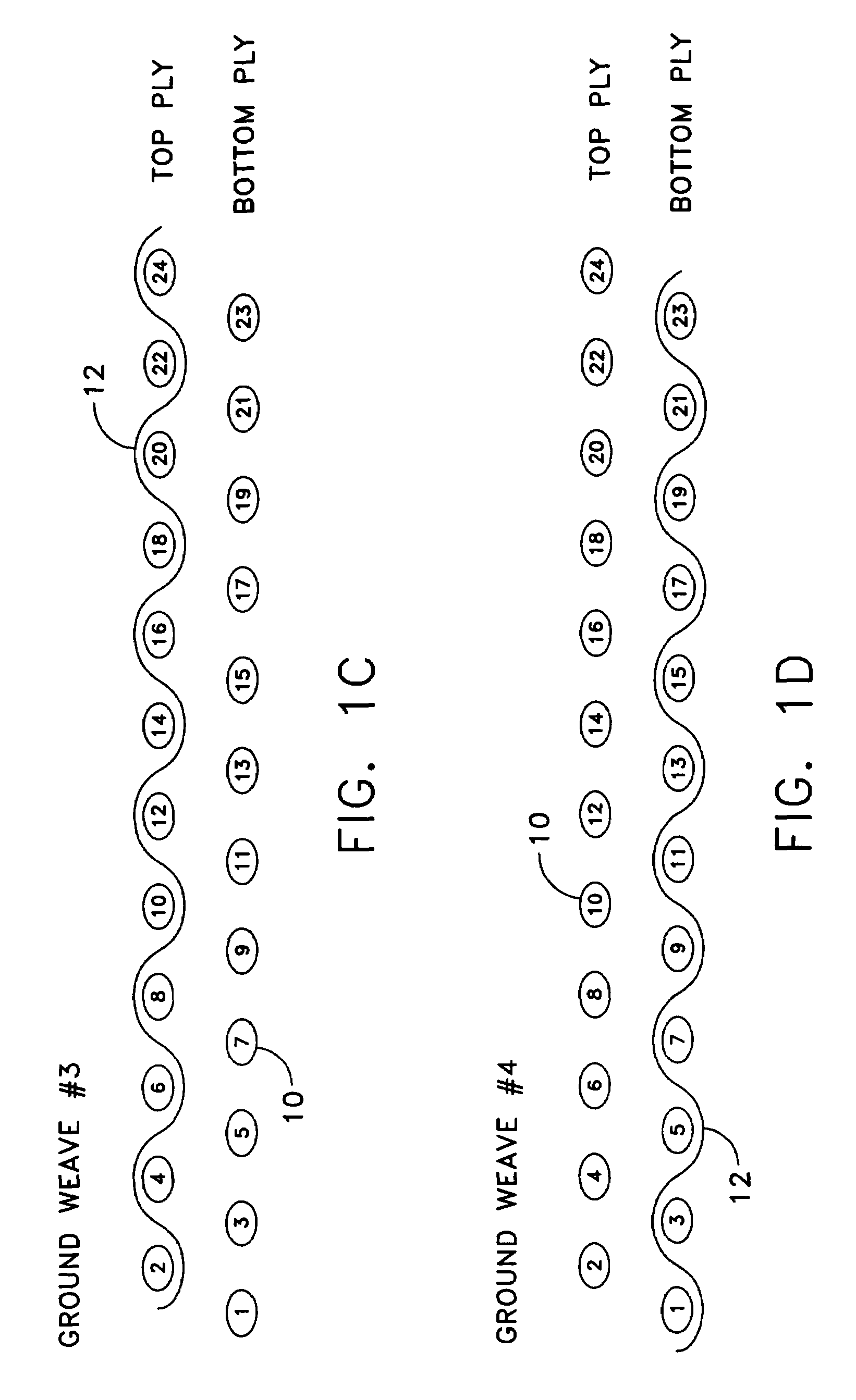

Moldable webbing

A woven fabric that is characterized by retaining its shape once formed and that includes monofilament filling yarns that are disposed in at least two separate plies, ground yarns that weave alternatively over and under respective monofilament yarns, stuffer yarns that extend in the direction between monofilament filling yarns of respective plies and binder yarns that extend between monofilament filling yarns of respective plies. A method forms a woven fabric into a permanent shape.

Owner:MURDOCK WEBBING

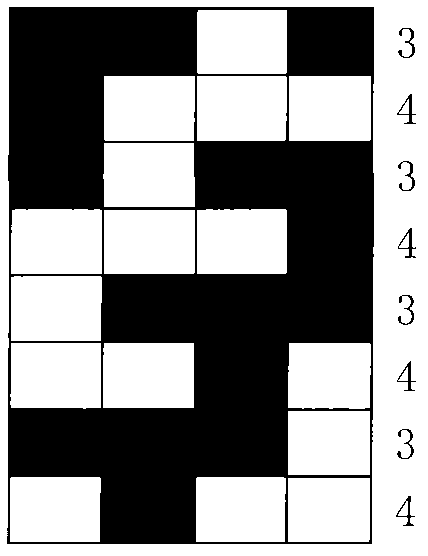

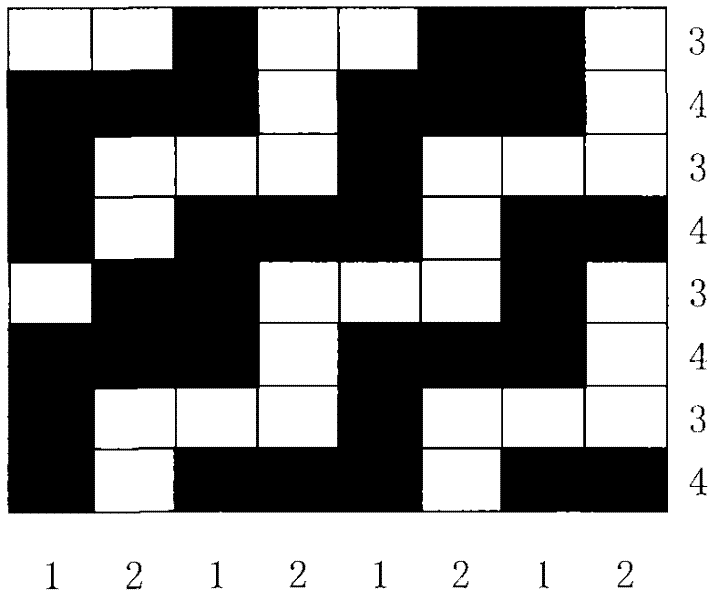

Method for selecting warp, abb, fabric texture and cloth gauge of stretch cotton fabric

The invention discloses the selection method of binding yarn, textile weave and thread count. The selection of binding yarn comprises: 1 the selection of yarn: twist yarn: 30S / 2 combed cotton yarn, weft yarn: 20S / 2 combed cotton; 2 the selection of twist and direction of twist: in twist yarn single thread being Z twist; ply yarn being hard twist yarn intervallic ranging by Z / ZíóZ / S. The selection of textile weave and thread count comprises: 1 the textile weave being loose structure calico weave, twist yarn radial arrangement being SZZSSZZ......ZZSSZZS, two twistings which have the same direction kinking with each other; 2 fabric density warp rate being 185.5strip / 10cm, the weft density being 78.6strip / 10cm; 3 using the breadth shuttle loom to get the breadth fabric, then cutting it to fixing dimension bandage. There are 3-4mm gap between crossing warps.

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD

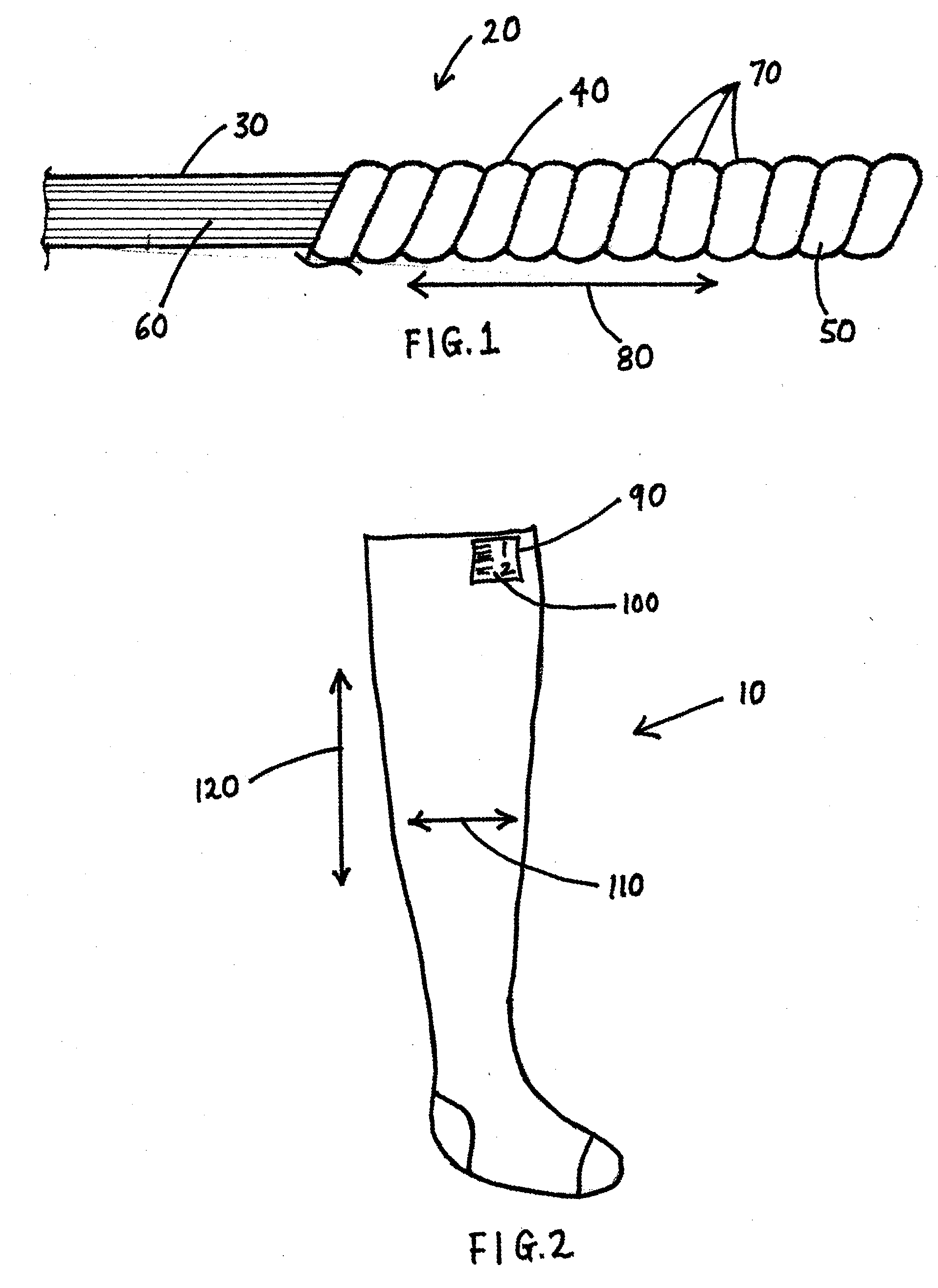

Therapeutic medical compression garment and method

ActiveUS20160038346A1Inhibit wearWelt becomes stableShrinkingNon-adhesive dressingsEngineeringBiomedical engineering

A therapeutic medical garment including a knitted welt proximate one end thereof with a surface adapted for residing against the wearer's skin. The garment includes a ground yarn and a plurality of raised, skin-engaging stabilizer elements, such as elongate bars extending in spaced-apart relation around an inner surface of the welt and along a longitudinal axis of the garment to reduce a tendency of the welt to roll over on itself.

Owner:BSN MEDICAL INC

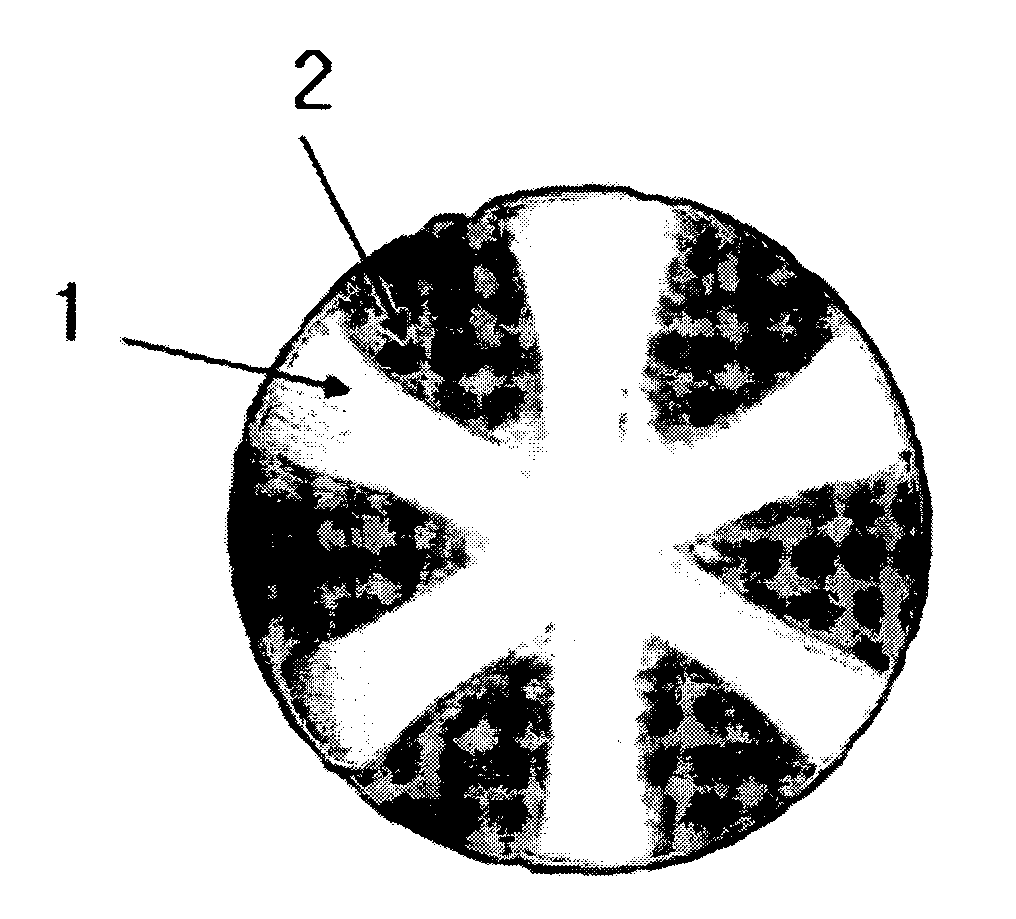

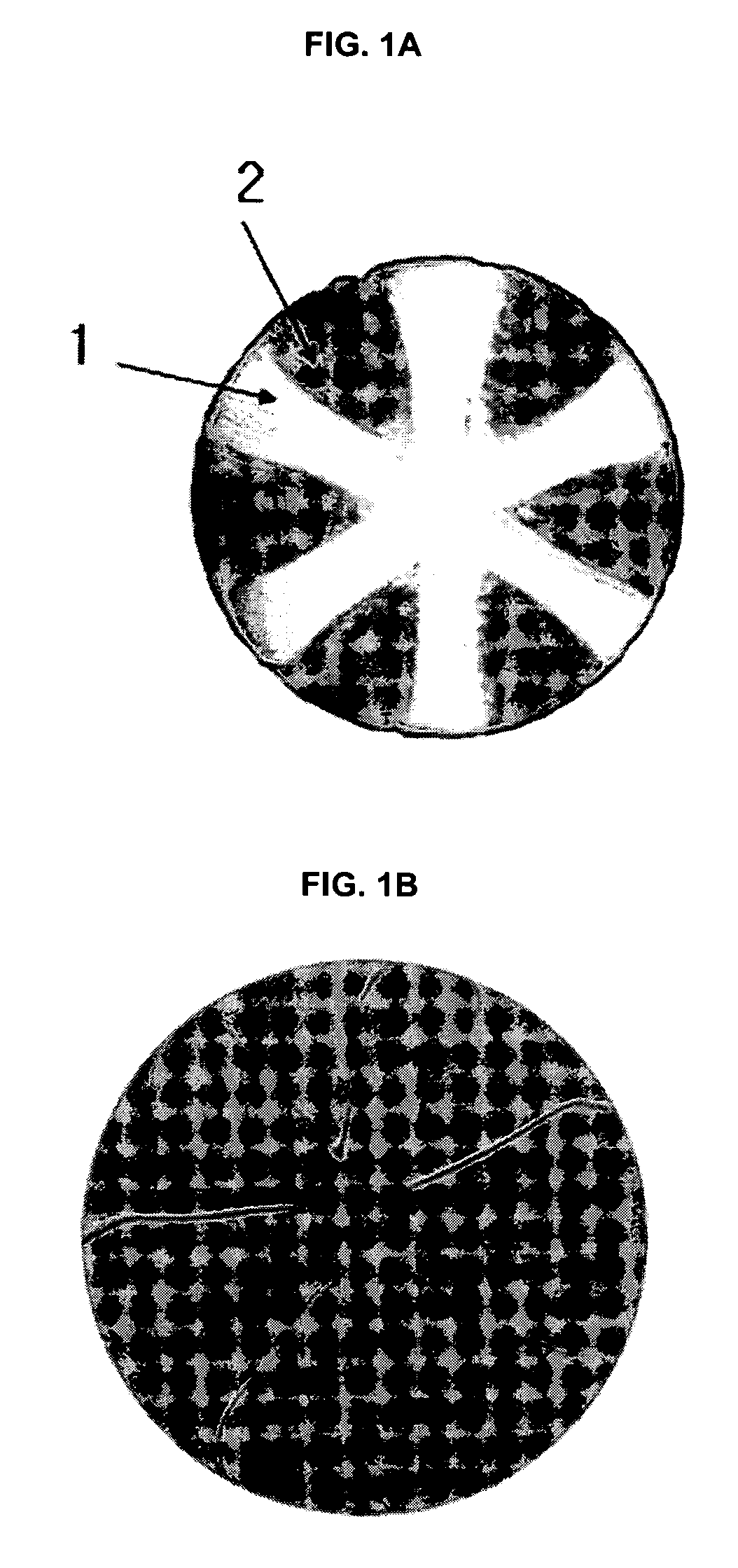

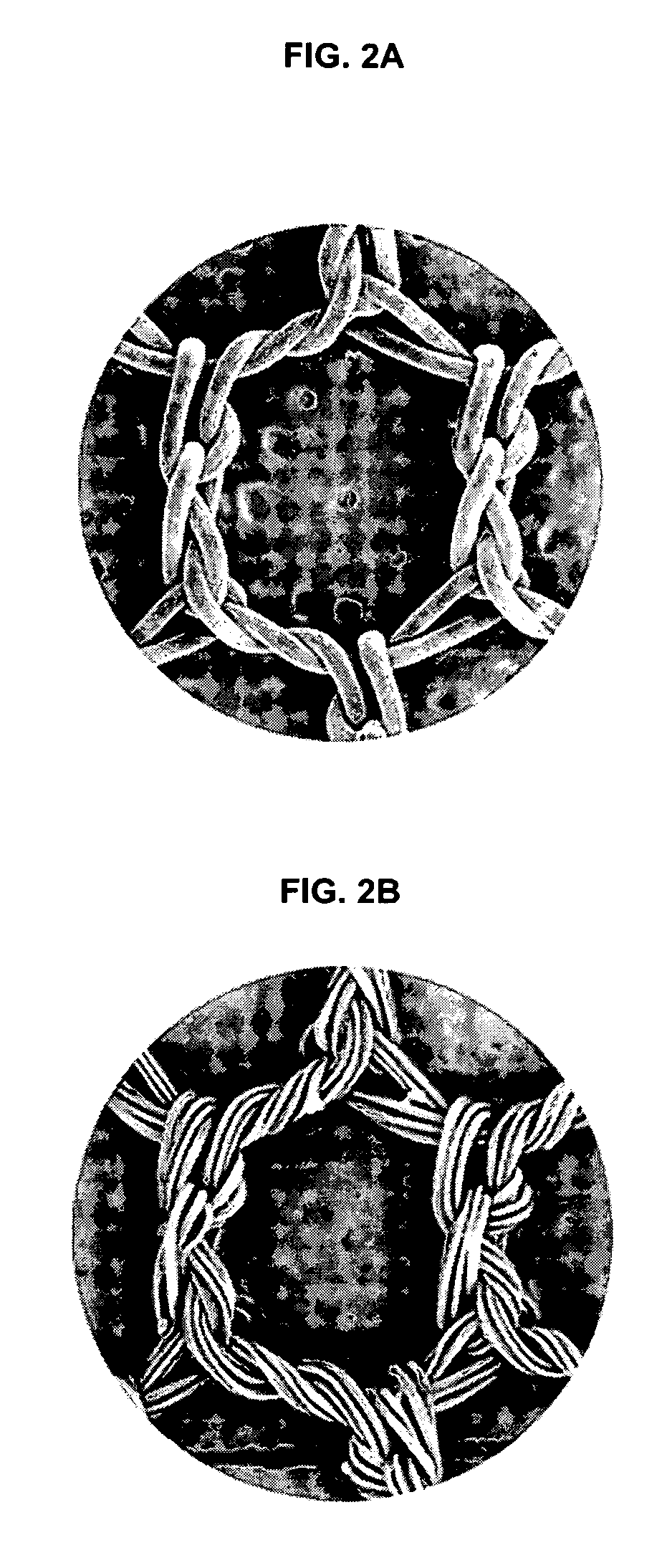

Monofilament, Surgical Mesh Having Improved Flexibility and Biocompatibility, and Process for Preparing the Same

InactiveUS20070219568A1Improved flexibility and biocompatibilityAnti-incontinence devicesWarp knittingMedicinePliability

The present invention relates to a monofilament with a segmented pie structure formed by conjugated spinning of degradable polymers and non-degradable polymers, a hernia mesh having improved flexibility and biocompatibility, and a preparation method thereof. More specifically, the hernia mesh of the present invention having improved flexibility and biocompatibility is prepared using the monofilament obtained by conjugated spinning of degradable polymers and non-degradable polymers into a segmented pie form, to control it to be gradually degraded in the body, whereby the stiffness of the early stage is removed, and thereby the foreign body sensation is also removed.

Owner:SAMYANG BIOPHARMLS CORP

Wrinkle-resistant elastic polyester-cotton fabric and production method thereof

The invention discloses winkle-resistant elastic polyester-cotton fabric and a production method thereof. The warp yarn of the fabric is formed by arranging polyester filament yarns A and all-cotton yarns or polyester-cotton yarns in a ratio of 1 to 1, and a weft yarn is formed by arranging elastic yarns B and polyester-cotton covered yarns in a ratio of 1 to 1; the fabric has a waft backed weave, a weft backed weave or a double weave; and the winkle resistance of the fabric in warp and weft directions can reach above 3 level, the elastic elongation in a weft direction can reach over 12 percent, and the elastic recovery is over 85 percent. Cotton yarns and the polyester filament yarns are arranged appropriately, an appropriate organizational structure is adopted, only common dyeing and finishing processing of cotton fabric is performed, and any pollution to environment can be avoided.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

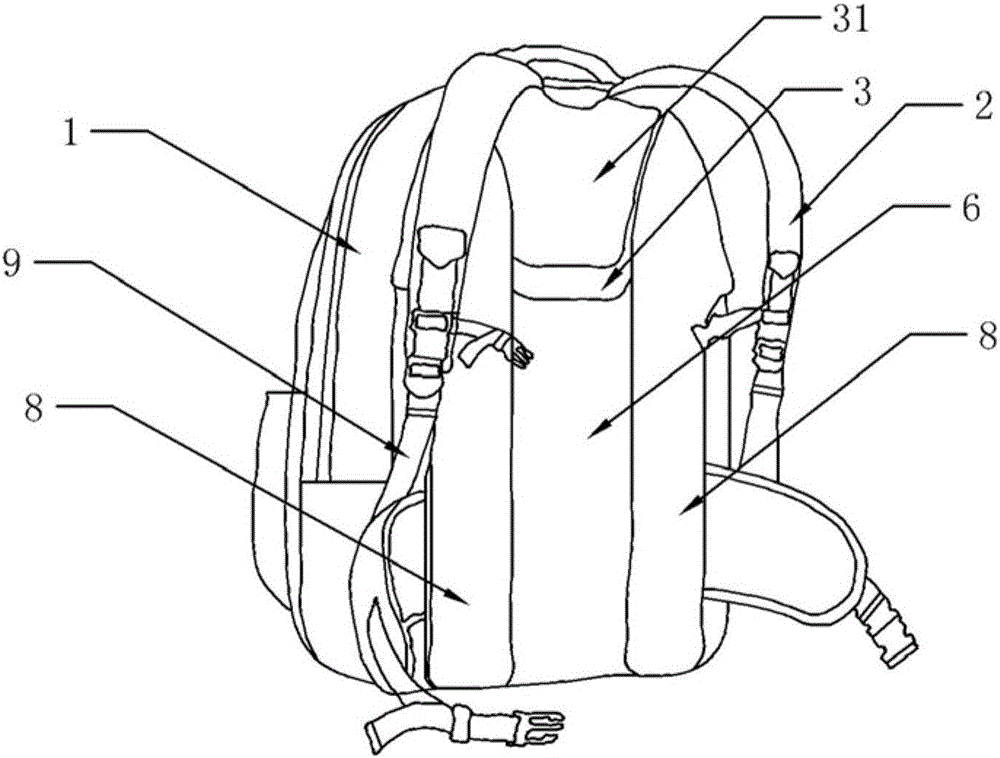

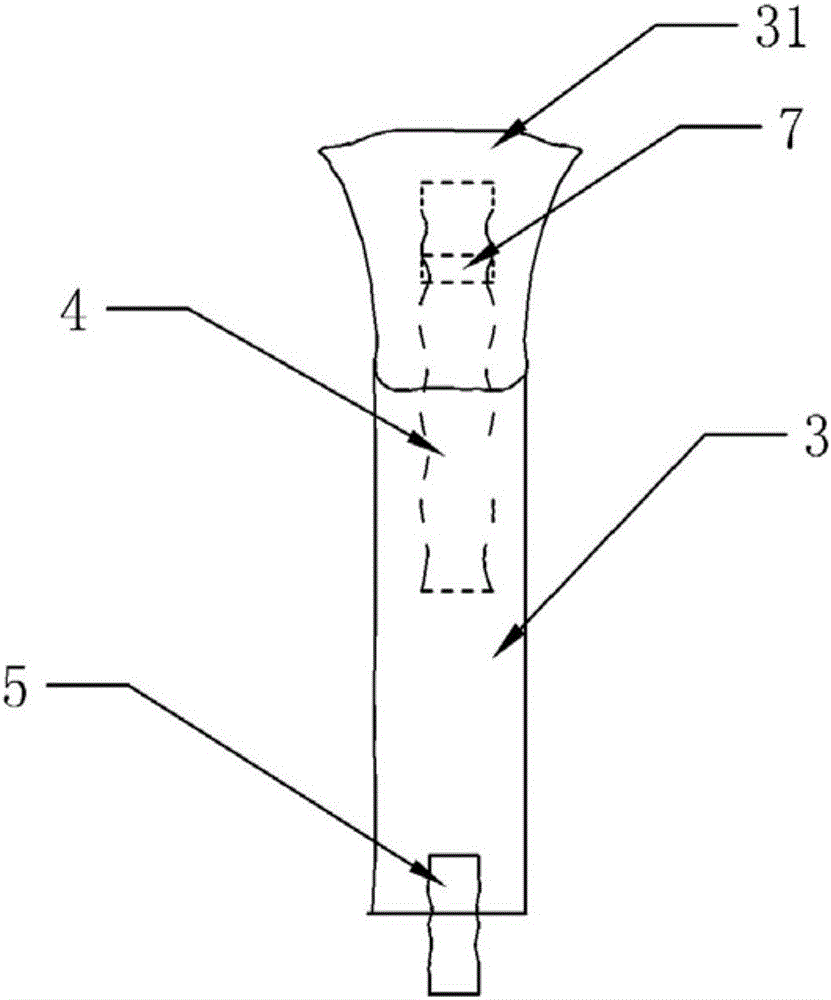

Antigravity backpack

ActiveCN105747477AImprove comfortReduce loadTravelling sacksOther accessoriesUser needsVertical vibration

The invention discloses an antigravity backpack.The antigravity backpack comprises a pack body and two shoulder straps.A supporting plate is arranged on the back face of the pack body.A pressure reduction plate is arranged on the back face of the supporting plate.The upper ends of the shoulder straps are connected with the upper end of the back face of the pressure reduction plate.The lower ends of the shoulder straps are connected with the lower end of the back face of the pack body.A first elastic belt and a length fixing belt are arranged between the pressure reduction plate and the supporting plate.According to the antigravity backpack, due to the existence of the pressure reduction plate, the first elastic belt and the length fixing belt, when a user uses the backpack, vertical vibration is generated by the backpack, the buffering effect is provided for the user, the feeling of pressure caused by load transmission on the shoulders of the user can be well relieved, strength which the user needs to give is reduced by means of resilience force generated by means of the elastic belt, loads of the shoulders are reduced, the user seems to place himself in the antigravity space, and the user can walk easily and save labor.

Owner:吴栢涛

Polyester-nylon-woven elastic fabric and producing method thereof

InactiveCN103374776AGood deep dyeing effectHigh color fastnessDyeing processResilient fabricsPolyesterEngineering

The invention discloses a polyester-nylon-woven elastic fabric and a producing method thereof. The elastic fabric is deep dyed, warp yarns are nylon fibers, weft yarns are polyester bicomponent elastic fibers, and an L value ranges from 10 to 18. One bath dyeing is adopted, the pH value of the dyeing bath is adjusted twice, deep dyeing effect of the finished product is optimized well, and incidence of dyeing defects is reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

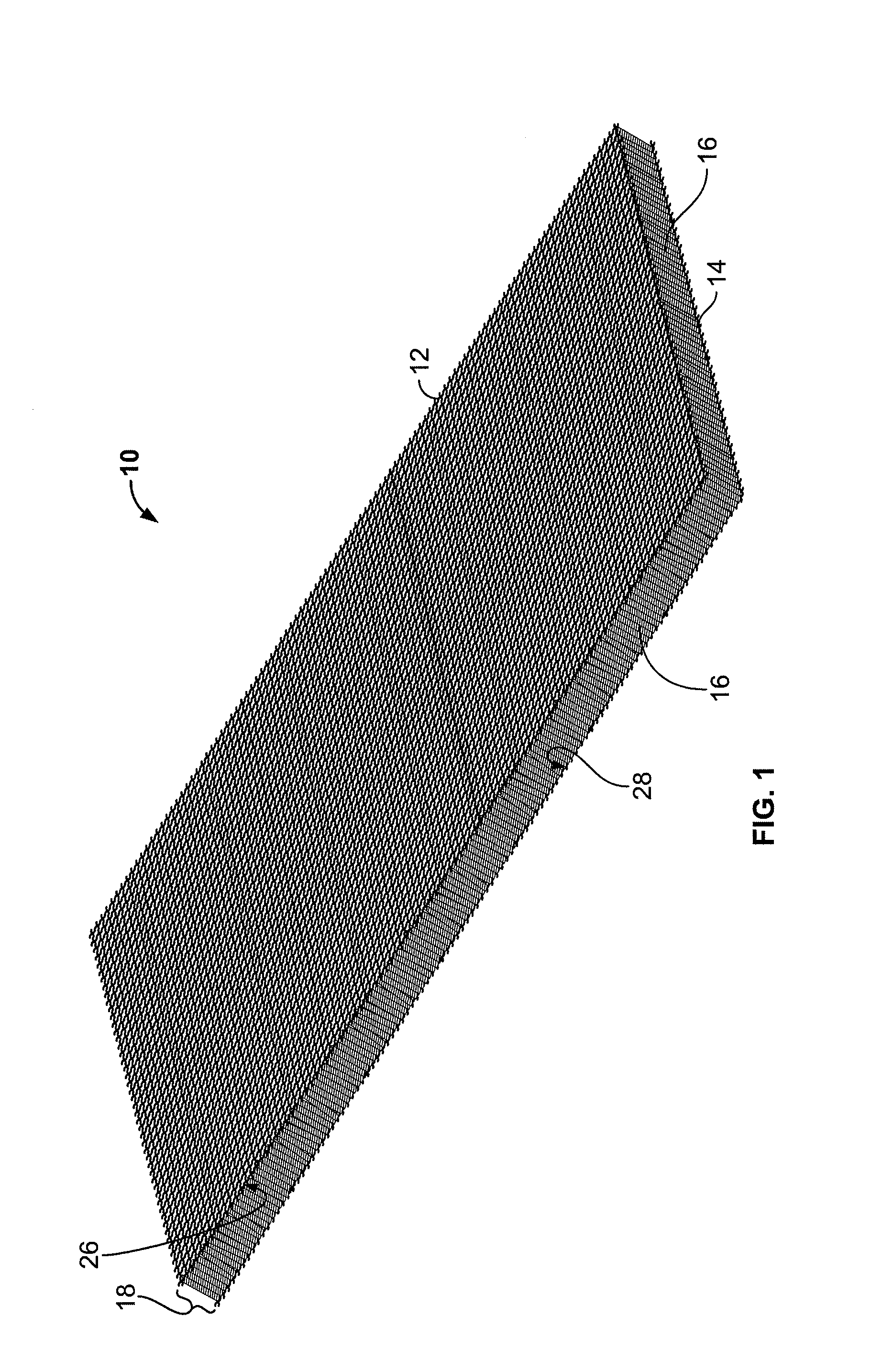

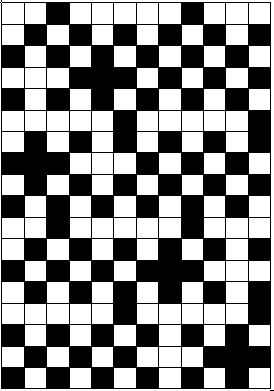

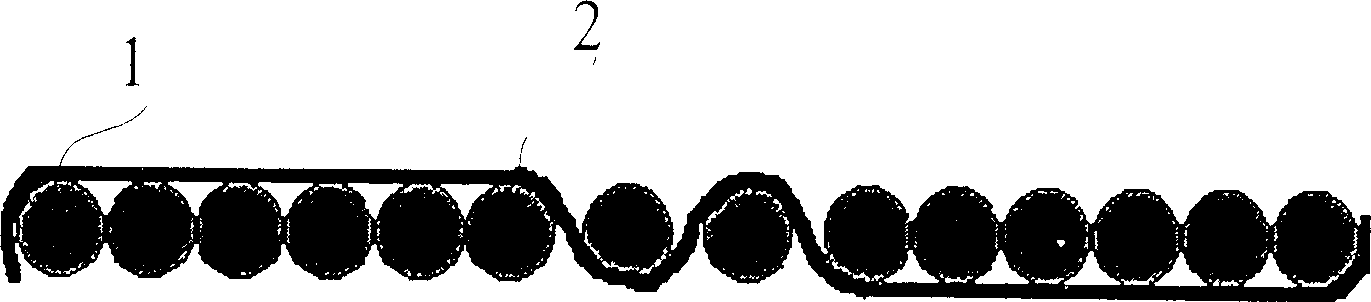

Ultra-Resilient Fabric

A structure for use in industrial fabrics such as paper machine clothing and engineered fabrics. The structure contains both axially elastomeric yarns and relatively inelastic yarns in various patterns. The structure has a high degree of both compressibility under an applied normal load and excellent recovery (resiliency or spring back) upon removal of that load.

Owner:ALBANY INT CORP

Thin and light elastic women wear fabric and method for preparing fabric

A thin and light elastic women wear fabric is prepared by weaving warp yarn and weft yarn, and is characterized in that the warp yarn is formed by covering 40 D cotton elastic yarn and 20 D network yarn; the cotton elastic yarn is composed of twelve fibers; the weft yarn is four-color woof; the first weft yarn is 150 D black dacron low-elasticity network yarn; the second weft yarn is 150 D cation dacron low-elasticity network yarn; the third weft yarn is 32 British teams of combing pure cotton yarn; and the fourth weft yarn is 80 D silvery bright yarn. The invention further discloses a method for preparing the fabric. Compared with the prior art, the invention has the following advantages: the warp yarn combines the cotton with the polyurethane fiber; the weft yarn uses four raw materials; the fabric is colored and has different raw material properties, and has the advantages of colorful color, smooth handle, good rebound resilience, good color fastness, strong hygroscopicity, good service, and the like.

Owner:正凯纺织有限公司

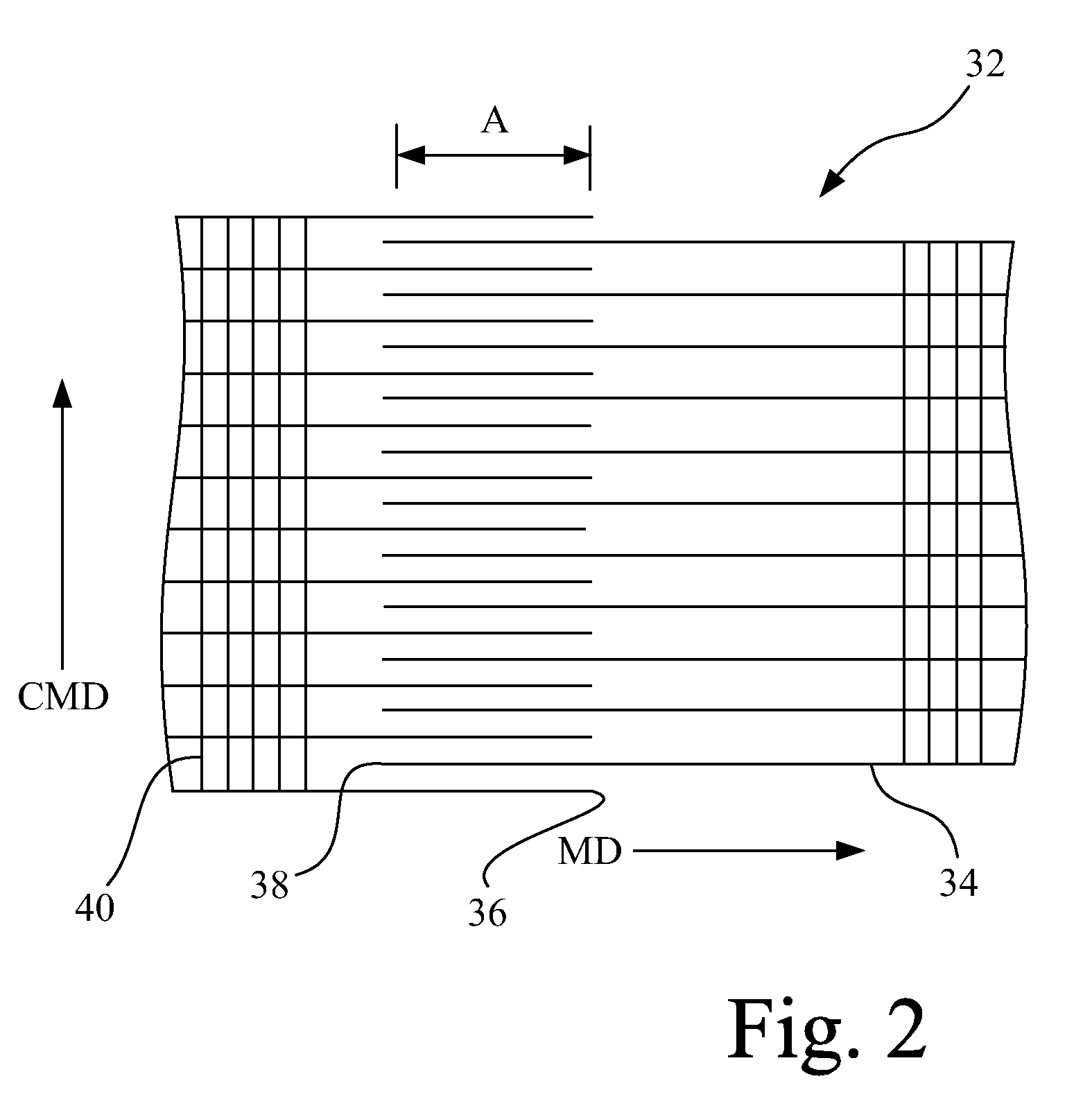

Low tensile creep belt

An endless fabric belt subjected to a substantial running tension. The belt has an endless woven fabric formed from a plurality of MD (machine direction) ultra high molecular weight polymer strands approaching zero creep at high tensile loads. A plurality of CMD (cross machine direction) strands are interwoven with the MD strands. The plurality of MD strands have first and second ends spliced to one another to form an endless belt, the splices forming a significant linear MD overlap of about 30 cm with each other.

Owner:VOITH PATENT GMBH

Ultra-Resilient Pad

ActiveUS20100112275A1Elastic behaviorHigh through thickness recoverySolesProtective equipmentYarnNormal load

A structure for use as a compressible ultra-resilient pad is disclosed. The structure includes axially and radially elastic hollow members and relatively inelastic yarns in various patterns. The structure has a high degree of both compressibility under an applied normal load and excellent recovery (resiliency or spring back) upon removal of that load.

Owner:ALBANY INT CORP

Inflatable fabrics and an air-bag

InactiveUS20100253047A1Superior internal pressure maintaining propertyIncreased durabilityUmbrellasPaper/cardboard articlesEngineeringAirbag

Disclosed is a inflatable double-layered fabric. The fabric includes an inflating part having gas inflatability, a non-inflating part supporting the inflating part, and a co-woven part constituting a boundary between the inflating part and the non-inflating part, wherein the inflating part is composed of two separated fabric layers, and the weave of the co-woven part is set up at a nk+1 pixel from the width or length end of the double-layered fabric (where, k is 2 or 3, and n is 0 or a positive number) when dividing the double-layered fabric into a plurality of pixels, an airbag including the same, and a method of preparing the airbag.

Owner:KOLON IND INC

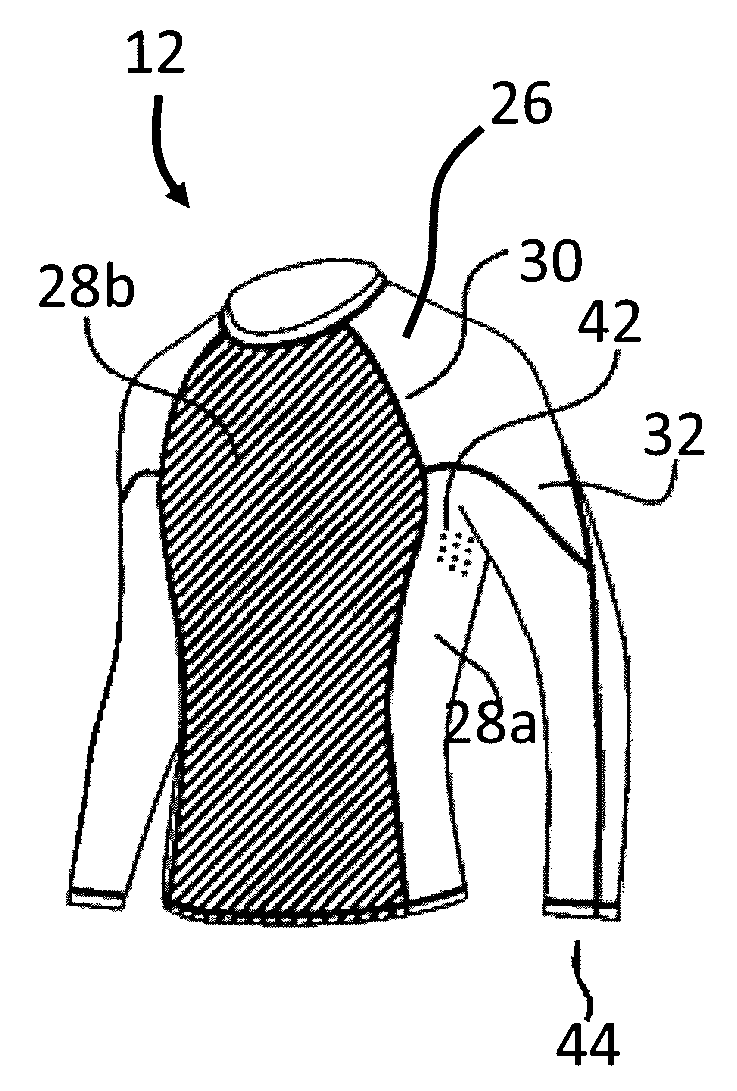

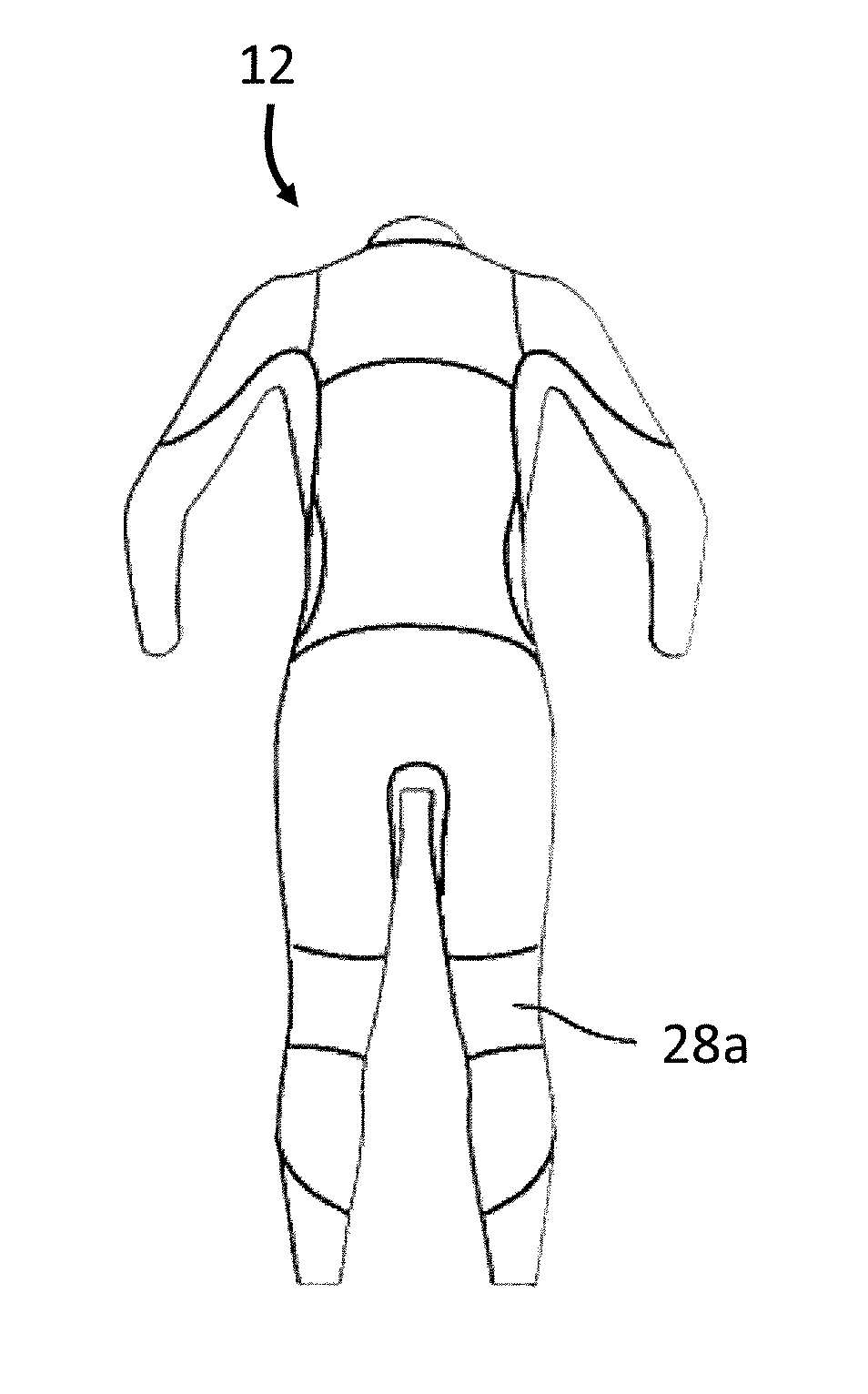

Textile, garment including the textile, and methods for manufacturing the textile and the garment

Owner:XEFCO PTY LTD

Fine-coarse combined light elastic wool and production technology thereof

The invention discloses fine-coarse combined light elastic wool and a production technology thereof. The elastic wool is plain-weave cloth; the wrap yarns in the plain-weave cloth are 42 / 2 half-fine spun yarns, and the weft yarns in the plain-weave cloth are 20 / 1 coarse spun yarns and 16 / 1 spandex core spun yarns, wherein the coarse spun yarns and the spandex core spun yarns are arranged in a proportion of 1:1. The production technology comprises the following steps of: preparing the wrap yarn raw materials of wool fiber, polyester fiber and modal fiber and the weft yarn raw materials of wool fiber, polyester fiber and modal fiber for spinning the fine-coarse combined light elastic wool; dyeing all fibers; spinning the wrap half-fine spun yarn, weft coarse spun yarn and elastic core spun yarn; and performing weaving and after-finishing to obtain a finished product. The fine-coarse combined light elastic wool disclosed by the invention has relatively high elasticity, excellent resilience and soft hand feeling, is comfortable to wear, and is suitable for making high-grade clothes.

Owner:慕昕纺织(淮安)有限公司

Elastic water-proof damp/air permeable cloth

InactiveCN1721596AElasticImprove ductilityWarping machinesHeating/cooling textile fabricsEngineeringCotton material

This invention relates to a cloth with elasticity and water and humidity proof materials, wherein the beaming engineer comprises the following steps: voile weaving; beaming, fetching, warp tying; sizing, fetching, merging, weaving tying. The weaving engineer comprises the steps of weaving tying, passing, running, dropper pinning machine, and setting weaving parameters, crude cloth. The whole dying process comprises the following steps: desizing; defining; pre-shaping; dying; drying; after shaping process or crude cloth shaping; desizing; defining; dying; drying; after shaping or crude cloth; desizing defining; pre-shaping; drying; testing in middle; shaping; final testing and packing.

Owner:MAGICTEX APPAREL CORP

Polymeric binders having specific peel and cure properties and useful in making creped webs

InactiveUS8012285B2High degree of softness and absorbencyReduce productionShrinkingNon-fibrous pulp additionFiberEmulsion polymerization

This invention is directed to alkylphenol ethoxylate (APE)-free polymer binders formed by aqueous free radical emulsion polymerization and having specific peel and cure properties. The APE-free polymeric binders have a peel value, when adhered to a heated metal surface, of 35% to 200% of the peel value shown by a standard APE-based polymer binder control and exhibit a cure profile such that at least 55% cure is achieved within 30 seconds at a temperature required for cure, and a wet tensile strength at 30-seconds of cure of at least 1000 g / 5 cm. Wet tensile strength is used as a measure of cure. Binders having the peel and cure properties described herein can be considered for use in crepe processes, especially DRC processes.

Owner:WACKER CHEM CORP

Textile, Garment Including The Textile, And Methods For Manufacturing The Textile And The Garment

ActiveUS20160040325A1High elastic stretchabilityImprove adhesionCrochetingInspecting textilesEngineeringE-textiles

Owner:XEFCO PTY LTD

Elastic healthy underwear shell fabric

InactiveCN102429326AFully elasticGood skin affinityResilient fabricsYarnSingle filamentBamboo charcoal

The invention discloses elastic healthy underwear shell fabric, comprising warps and abbs interweaved. The warps comprise bamboo charcoal fiber, polyster fiber and polyurethane fiber filaments. The polyurethane fiber filaments are polyurethane fiber composite filaments consisting of three single filaments. The proportion of the bamboo charcoal fiber, the polyster fiber and the polyurethane fiber filaments is 15-35:25-55:30-40. By above manner, the invention which is adequately elastic has the healthy functions of negative ions, far infrared ray, deodorization and the like and is highly affinitive with the skin, healthy and comfortable as the underwear shell fabric.

Owner:JIANGSU BOOULUN HOME TEXTILE

Mark-free wire fabric straps

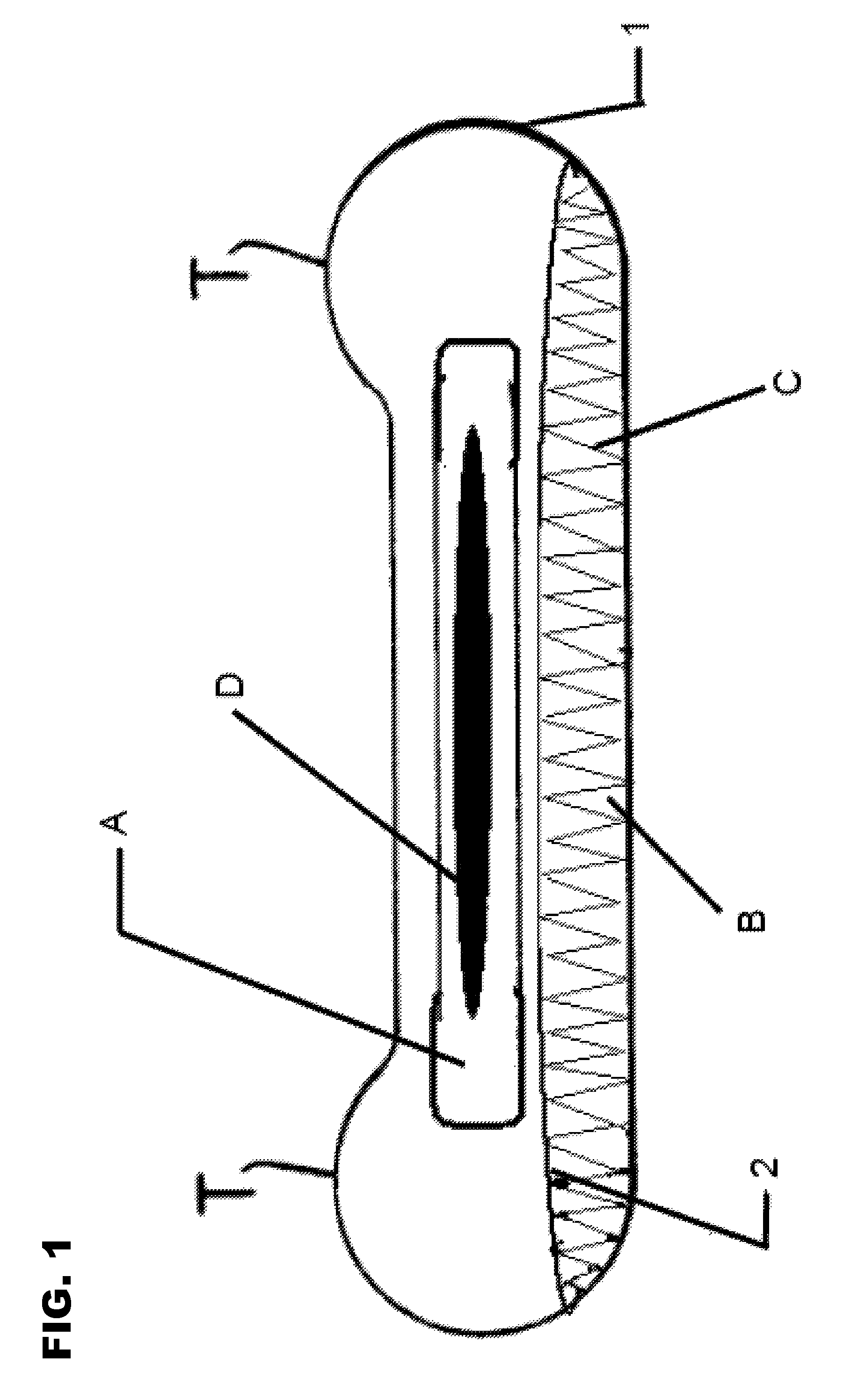

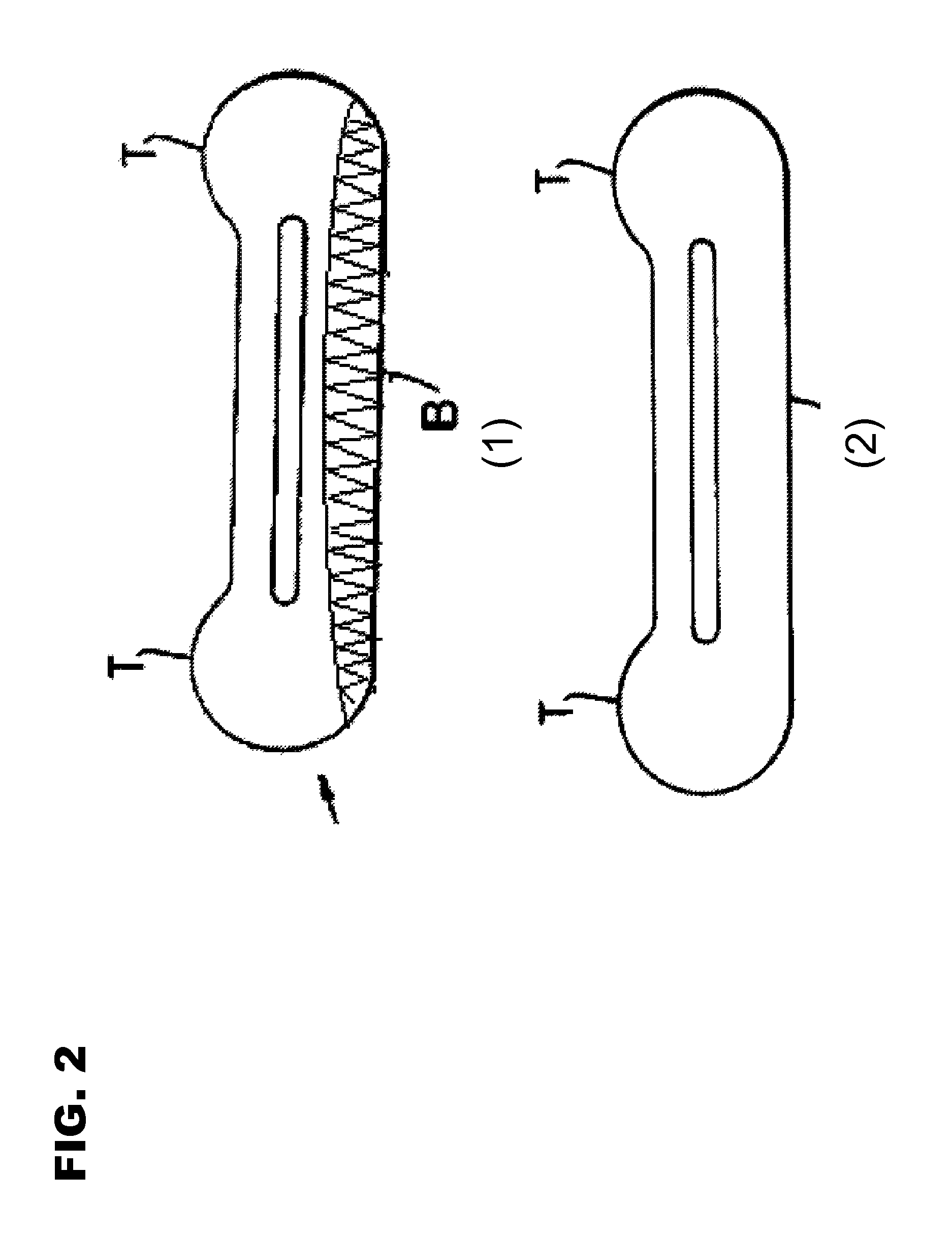

InactiveUS8317568B2Not causing significant pressing feel on the skinSimple structureOrnamental textile articlesBrassieresEngineeringVisual appearance

A mark-free fabric strap wire casing. The casing is provided with a cushion B which is composed of erect fine hairs C for relieving the stress generated by the bra wire on skin. With simple structure, the present invention which is used as the casing for the wire used in female underwear can be manufactured with high production efficiency and suitable for the production automation. Because the fabric strap itself is provided with a cushion composed of erect fine hairs, it has a softer feel when in contact with skin and relieves the pressure feel generated by the wire within the underwear on skin. It reduces the wire impression mark left under the breasts after wearing it. The wire can be embedded without causing much embossment, thereby enchaining visual appearance of the underwear article.

Owner:NEW HORIZON ELASTIC FABRIC

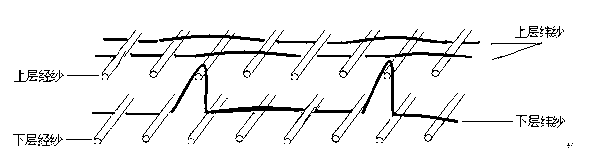

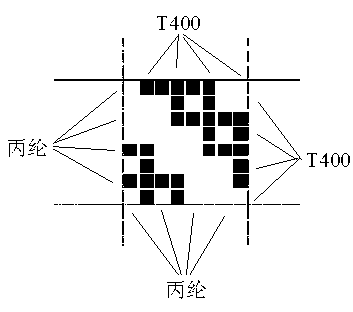

Production method of polyester/polypropylene double-layer woven sportswear fabric

ActiveCN102936779AReduce weightHigh strengthMulti-ply fabricsResilient fabricsPolyesterThermal insulation

The invention discloses a production method of a polyester / polypropylene double-layer woven sportswear fabric. The method comprises the steps of raw material selection, silk dressing, silk sizing, re-beaming, drafting and weaving; and good elastic shrinkage is obtained by subsequent processes such as dyeing and the like, thus many special clearances can be generated between two layers of fiber to realize a thermal insulation effect. When a user taking exercise is in a sweating state, due to the ultrafine-denier special-shaped section of polypropylene microfiber and the unique dog bone-shaped section of the polyester T400, the capillary effect of the fiber clearances is ensured, and the sweat is quickly transferred and diffused from the inner layer to the outer layer so as to dissipate heat; when the exercise is over and the sweating stops, a static air layer is formed in the fiber; and thus, the polyester / polypropylene double-layer woven sportswear fabric is very suitable for the winter sportswear.

Owner:DANYANG DANSHENG TEXTILE

Stretchable high-density woven fabric

A stretchable high density woven fabric showing a cover factor of from 1,800 to 2,540 and stretchability in terms of a stretch ratio of from 5 to 20% in the warp or weft direction and having a poly(trimethylene terephthalate) fiber at least in the direction in which the woven fabric shows stretchability. The high density woven fabric shows good stretchability and water resistance (water pressure resistance), produces less rustling when contacted with woven fabrics, and provides an excellent soft and comfortable feeling, and it is therefore appropriate for sportswear, outerwear, and the like.

Owner:ASAHI KASEI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com