Patents

Literature

105results about "Selvedges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and weaving loom for producing a leno ground fabric

Owner:LINDAUER DORNIER GMBH

Method and weaving loom for producing a leno ground fabric

Owner:LINDAUER DORNIER GMBH

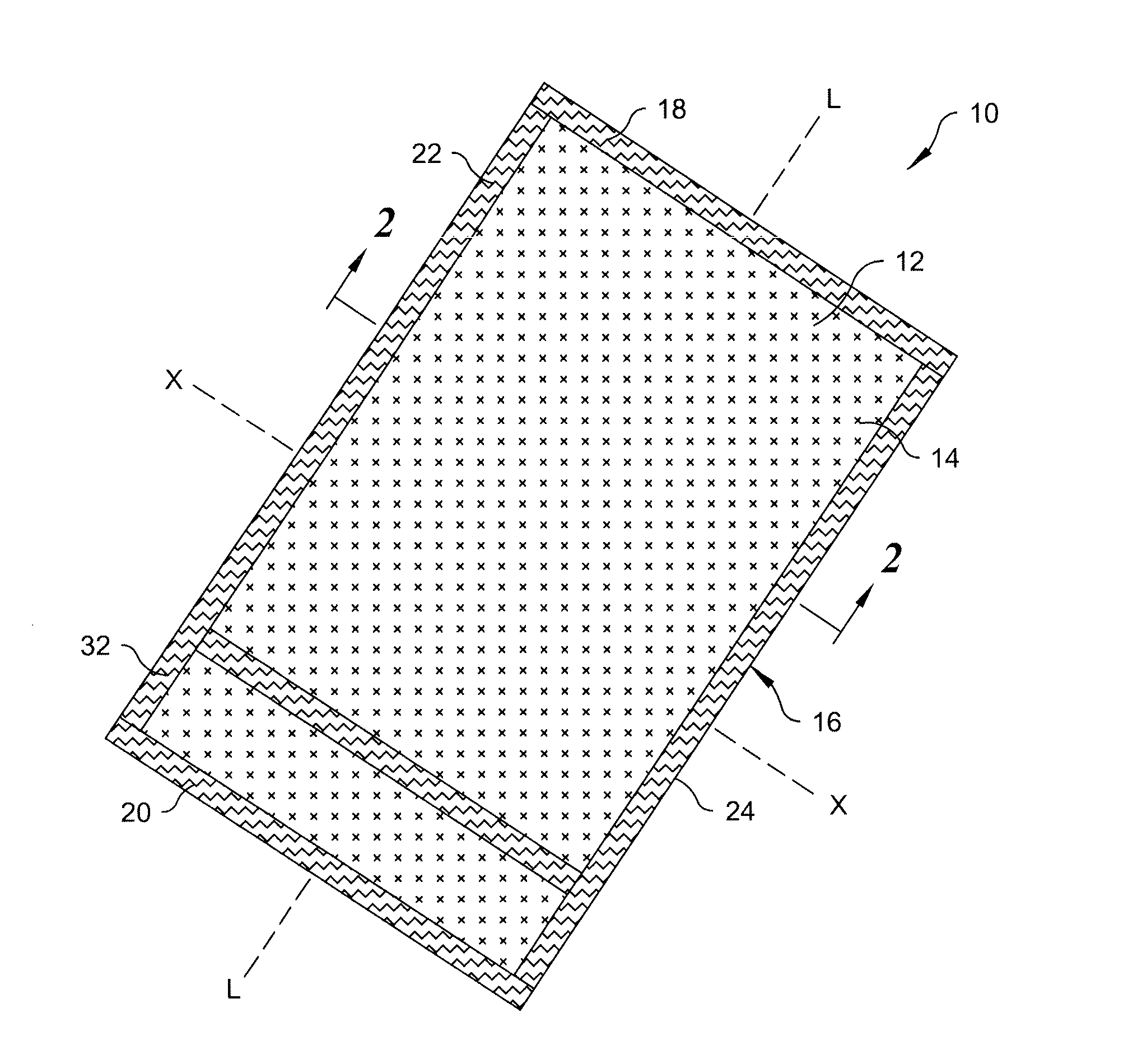

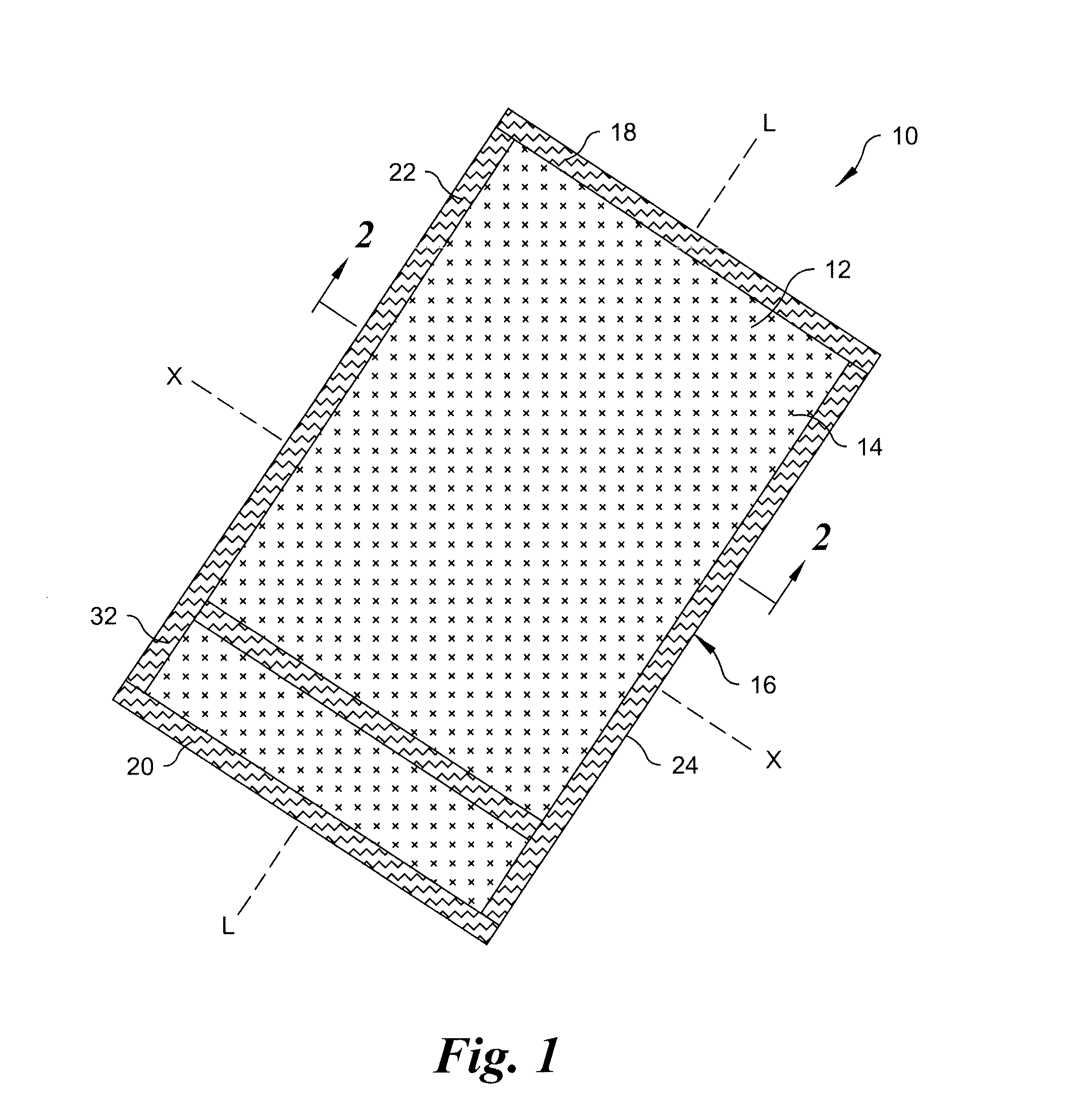

Woven polyester fabric for airbags

ActiveUS7375042B2Pedestrian/occupant safety arrangementSynthetic resin layered productsThermal creepEngineering

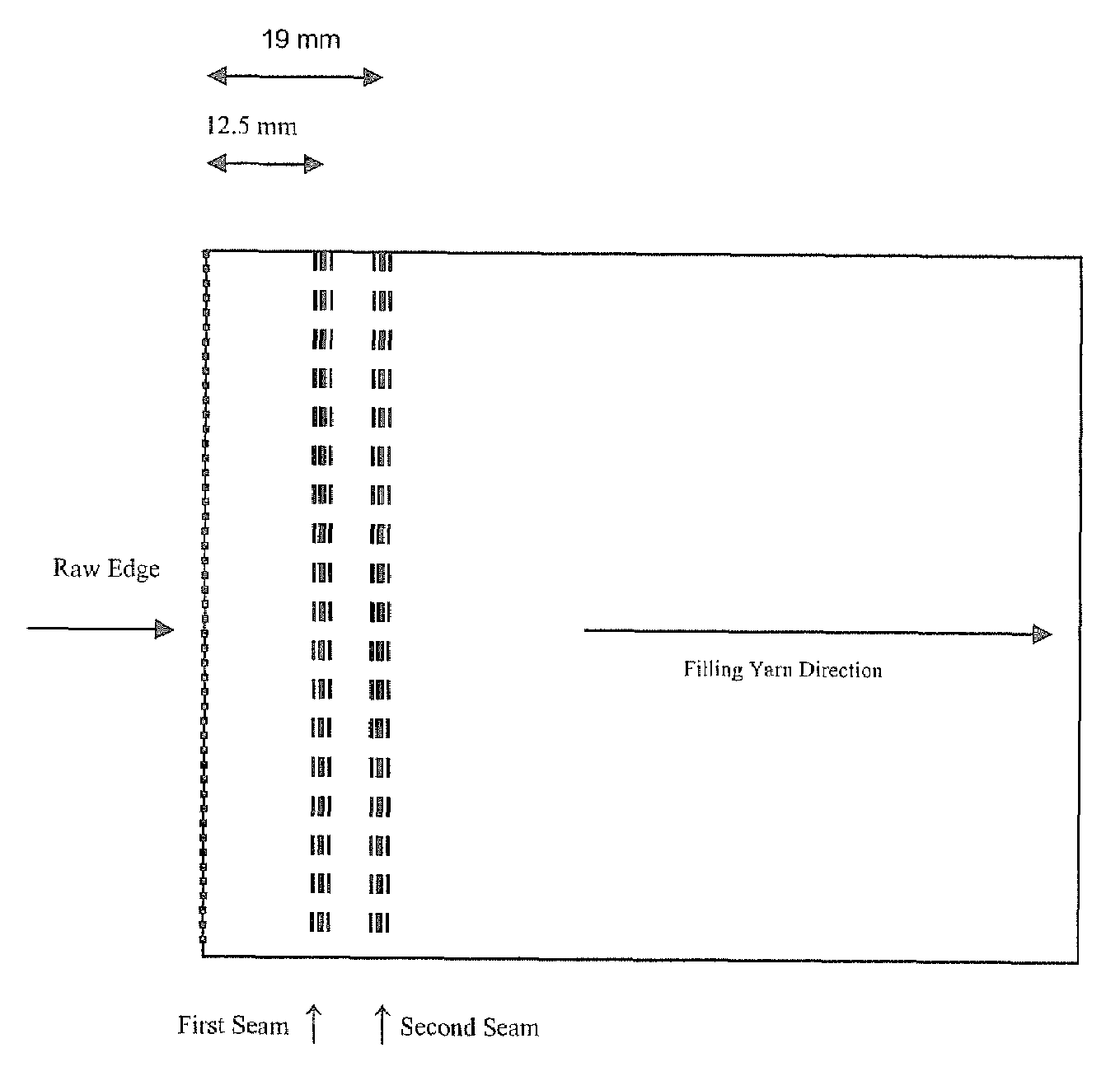

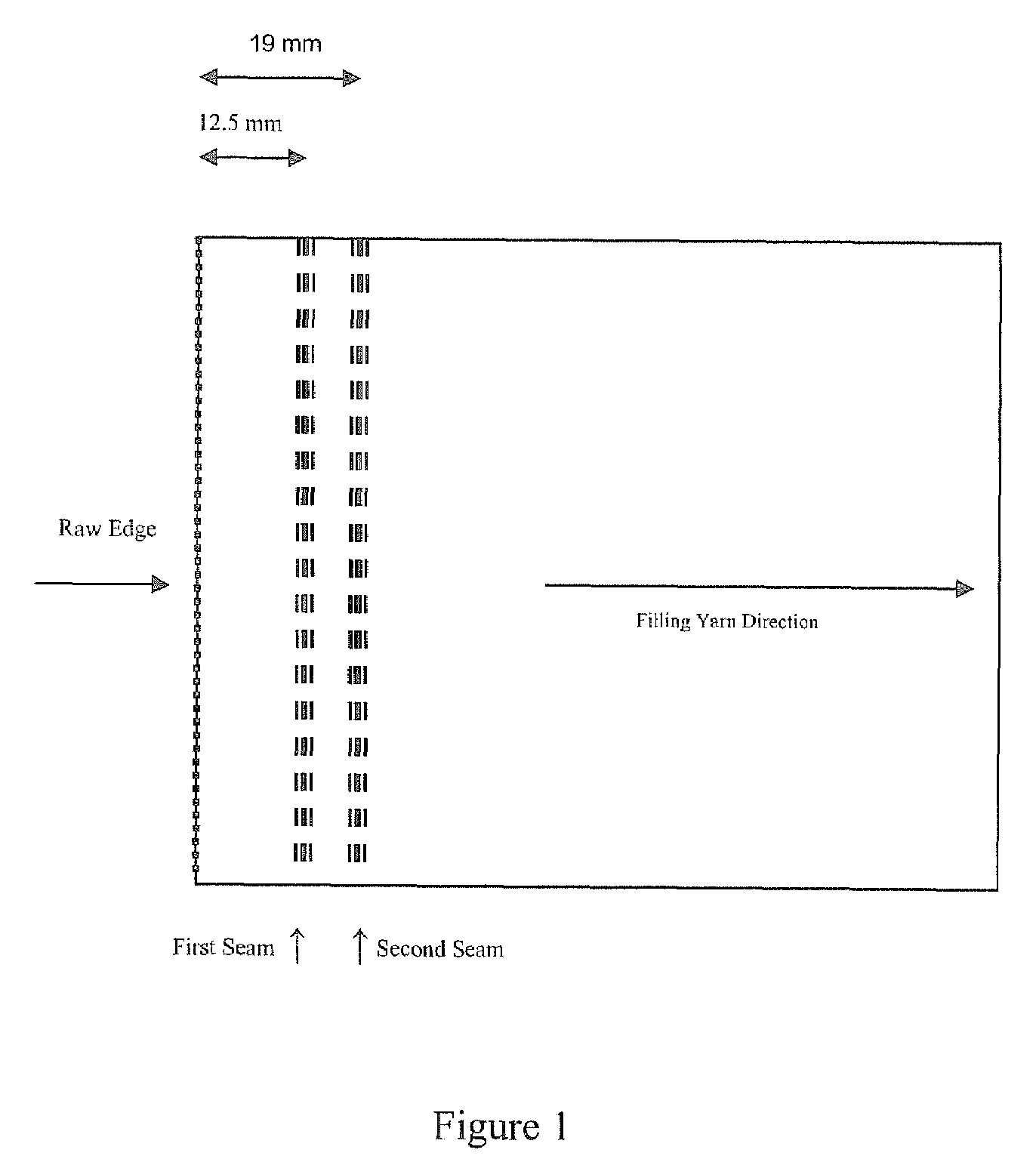

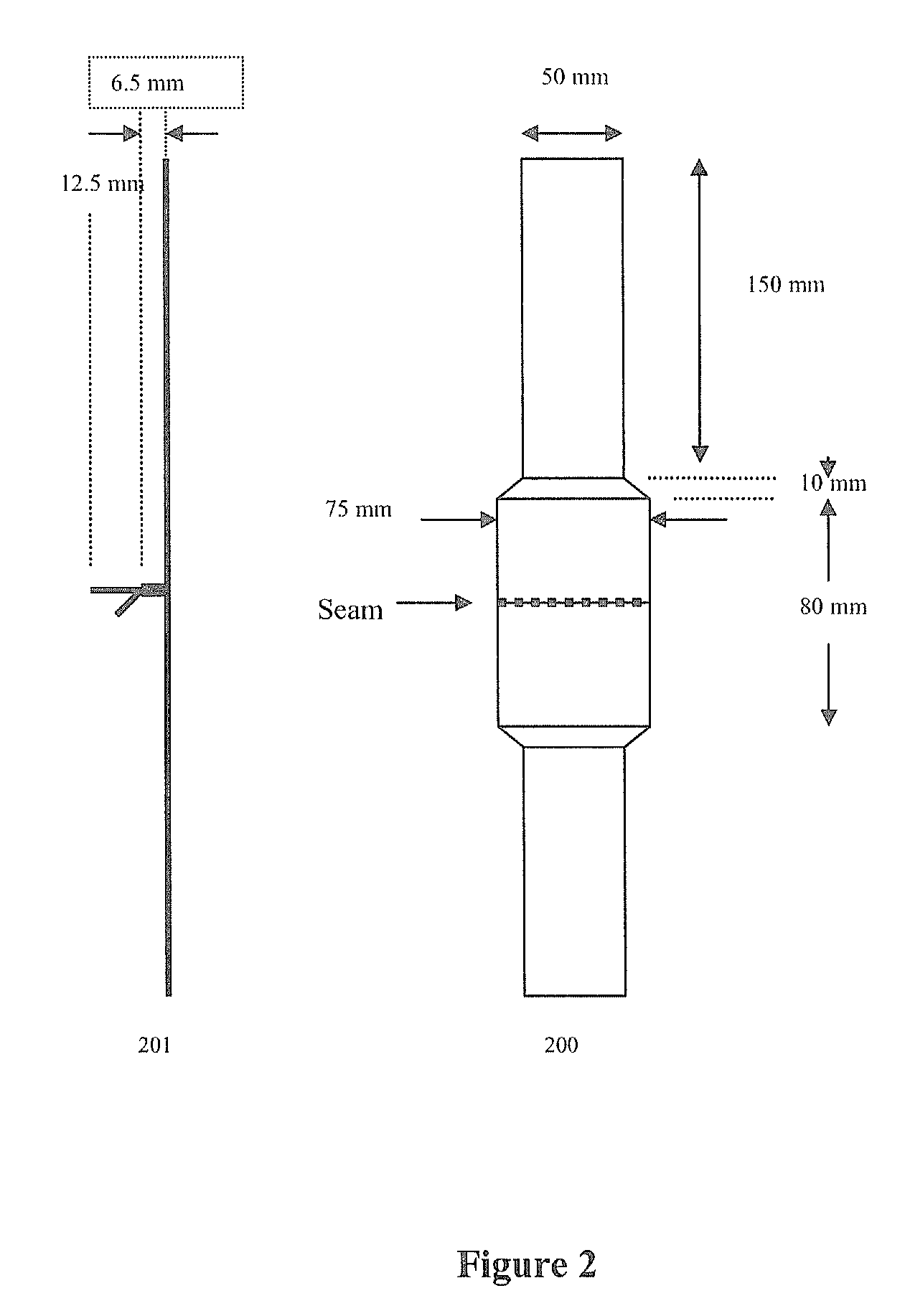

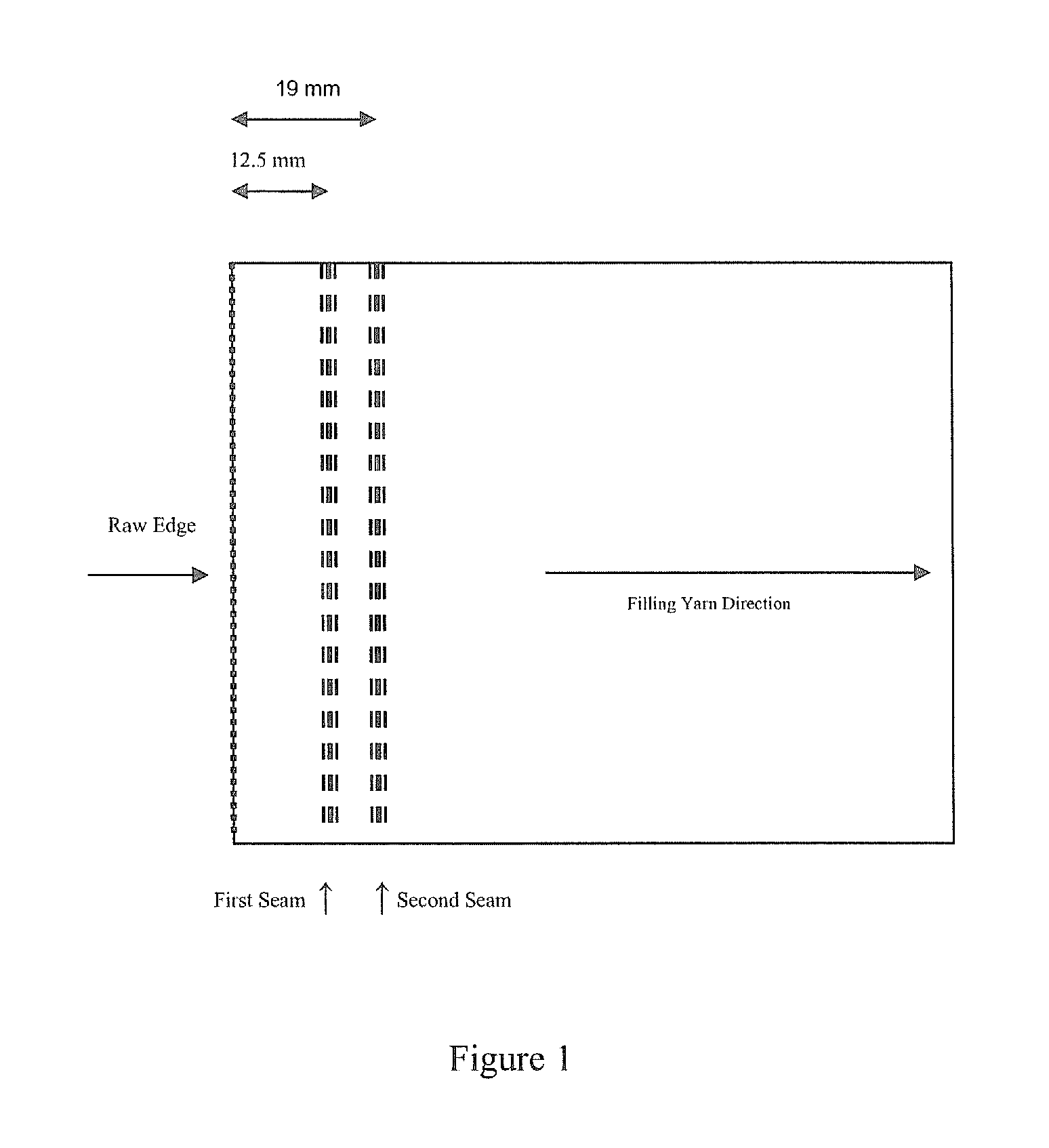

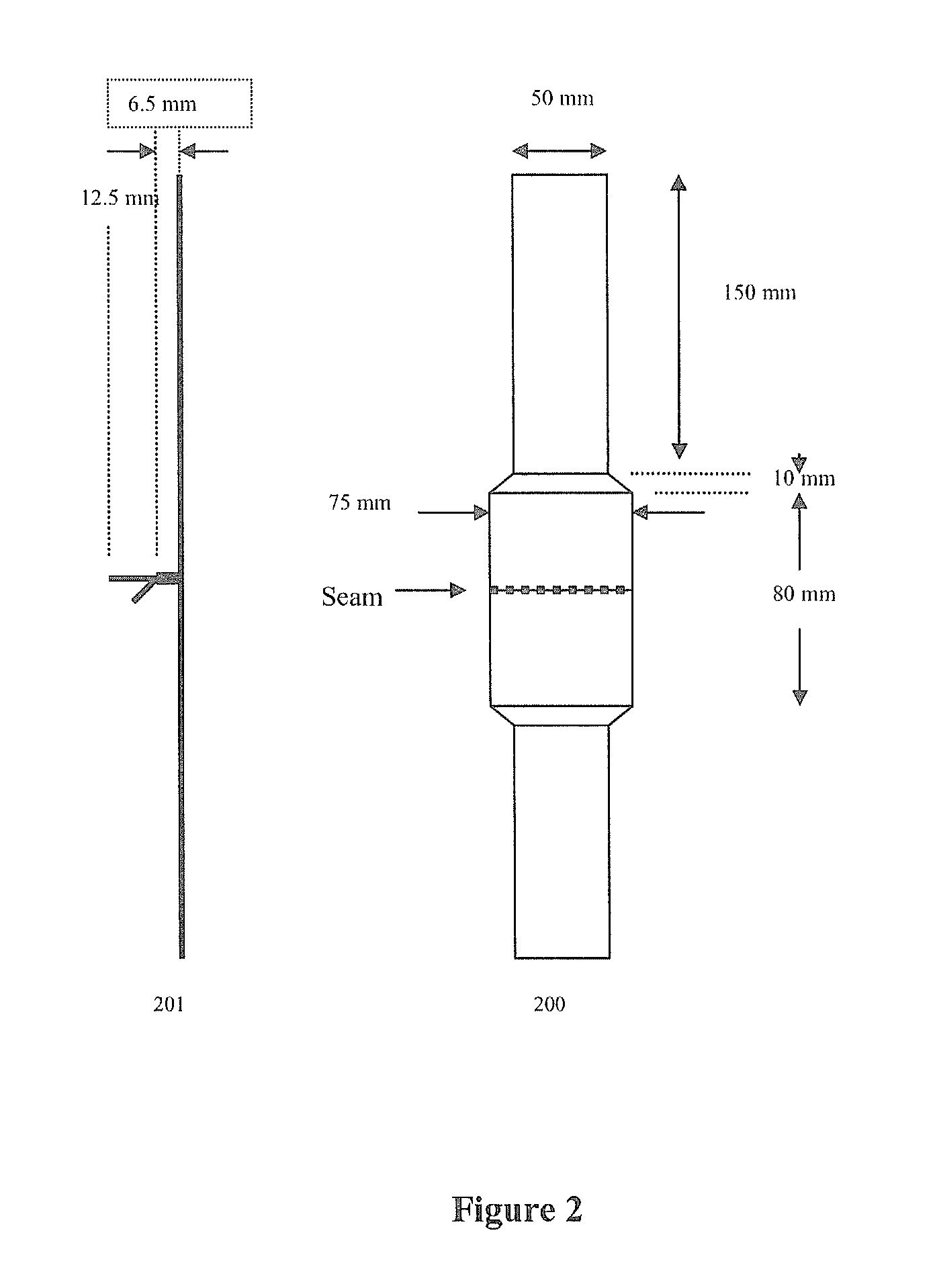

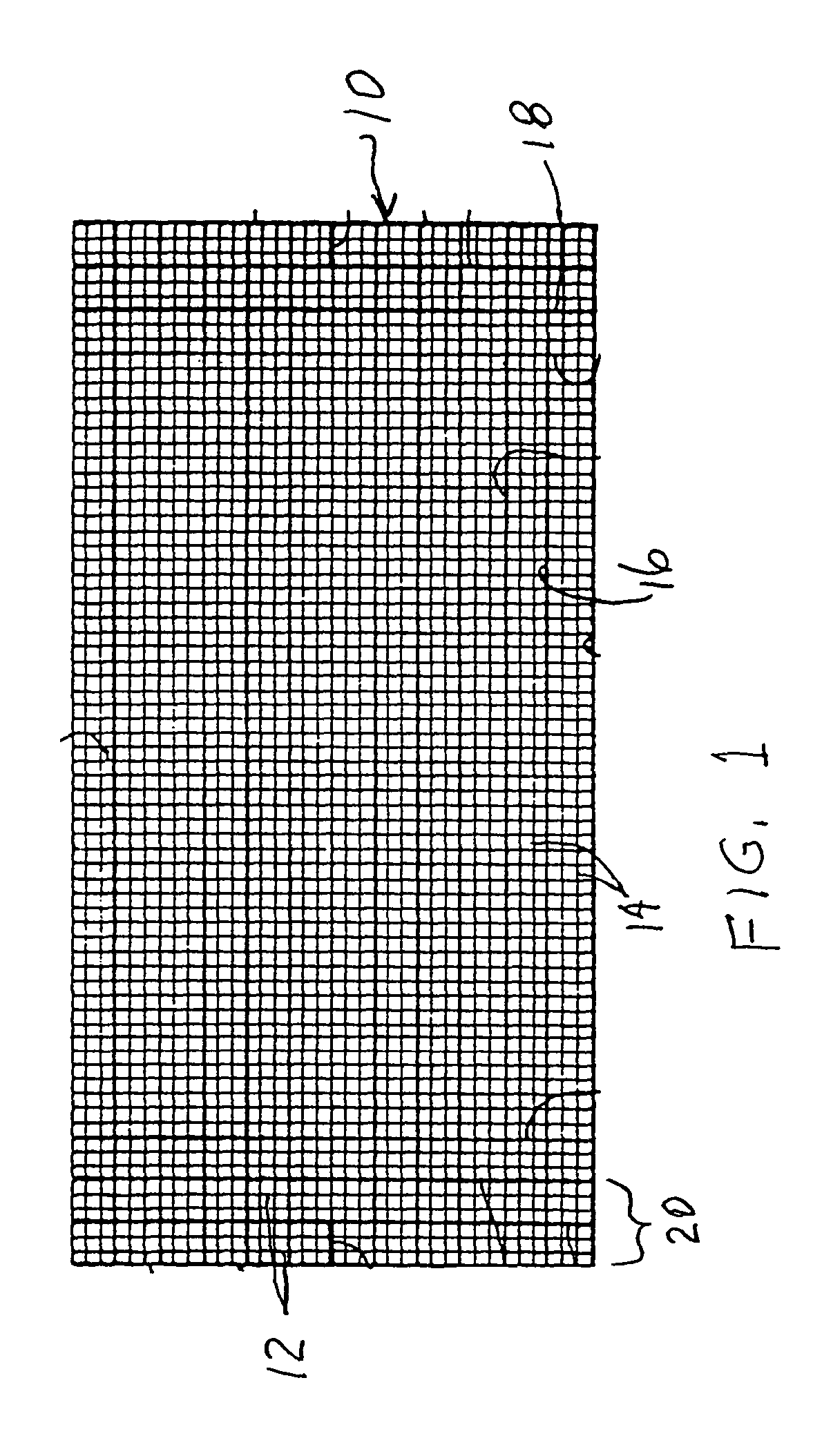

The present invention relates to a woven polyester fabric for use in airbags. The present invention includes a woven fabric using a polyester filament yarn, wherein the polyester filament yarn has a tenacity of about 65 cN / tex or greater and an Instantaneous Thermal Creep (ITC) at 100° C. of about 0.5% or less. Additional embodiments of the present invention include an airbag made from the woven polyester fabric. Woven fabrics of the present invention can reduce the extent of seam combing during a hot module deployment of an airbag.

Owner:INV PERFORMANCE MATERIALS LLC

Woven polyester fabric for airbags

ActiveUS20080014816A1Pedestrian/occupant safety arrangementSynthetic resin layered productsThermal creepEngineering

The present invention relates to a woven polyester fabric for use in airbags. The present invention includes a woven fabric using a polyester filament yarn, wherein the polyester filament yarn has a tenacity of about 65 cN / tex or greater and an Instantaneous Thermal Creep (ITC) at 100° C. of about 0.5% or less. Additional embodiments of the present invention include an airbag made from the woven polyester fabric. Woven fabrics of the present invention can reduce the extent of seam combing during a hot module deployment of an airbag.

Owner:INV PERFORMANCE MATERIALS LLC

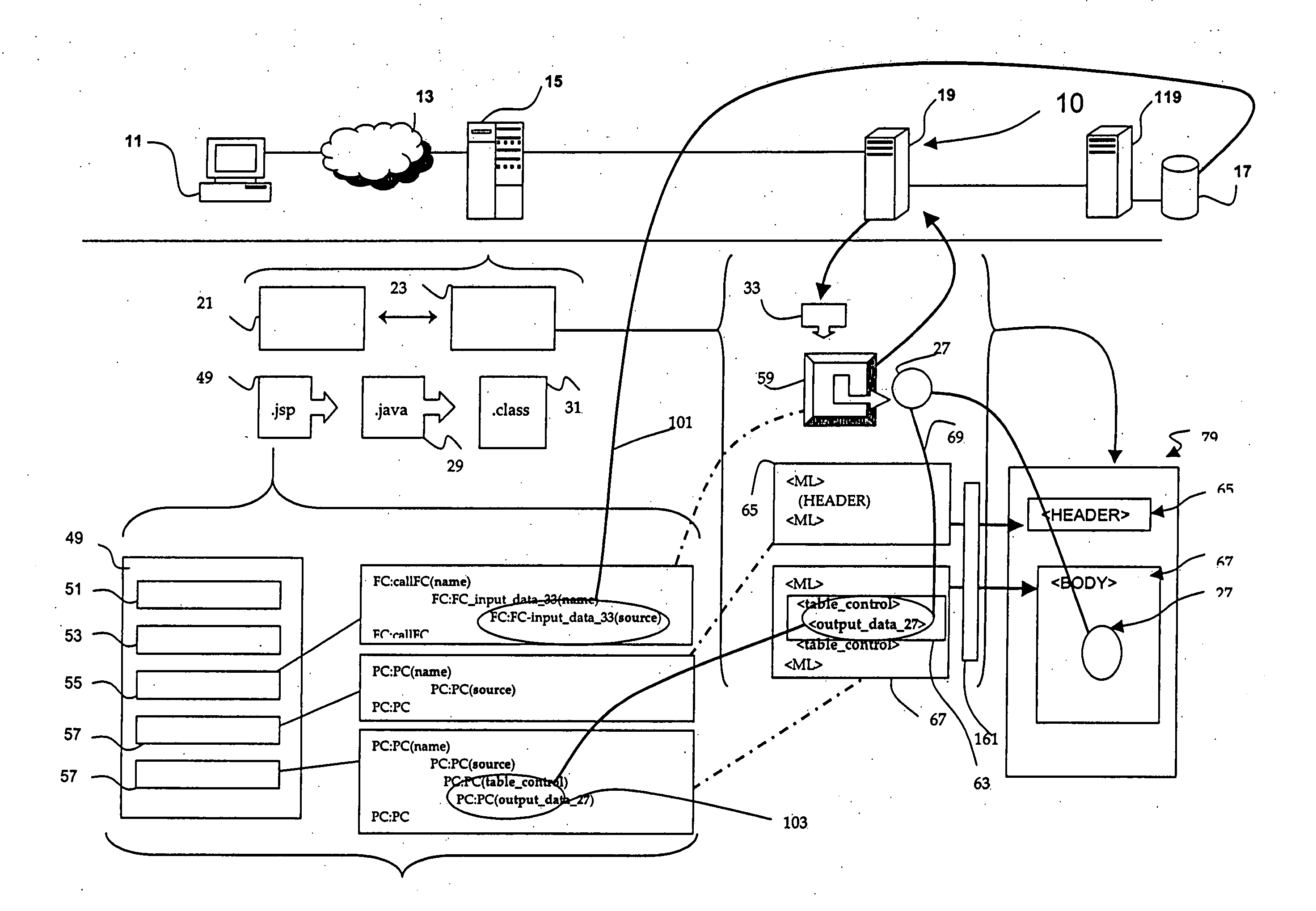

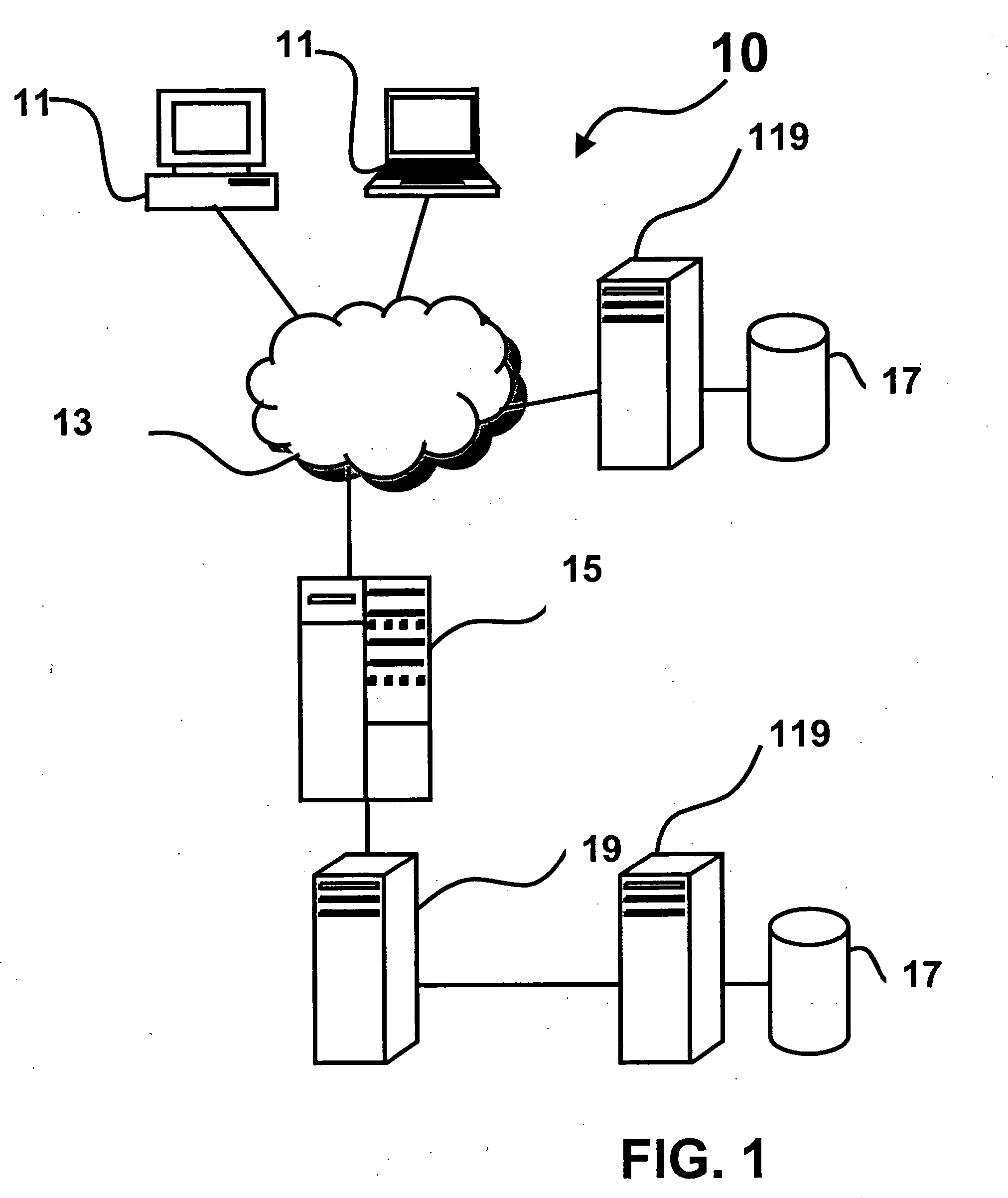

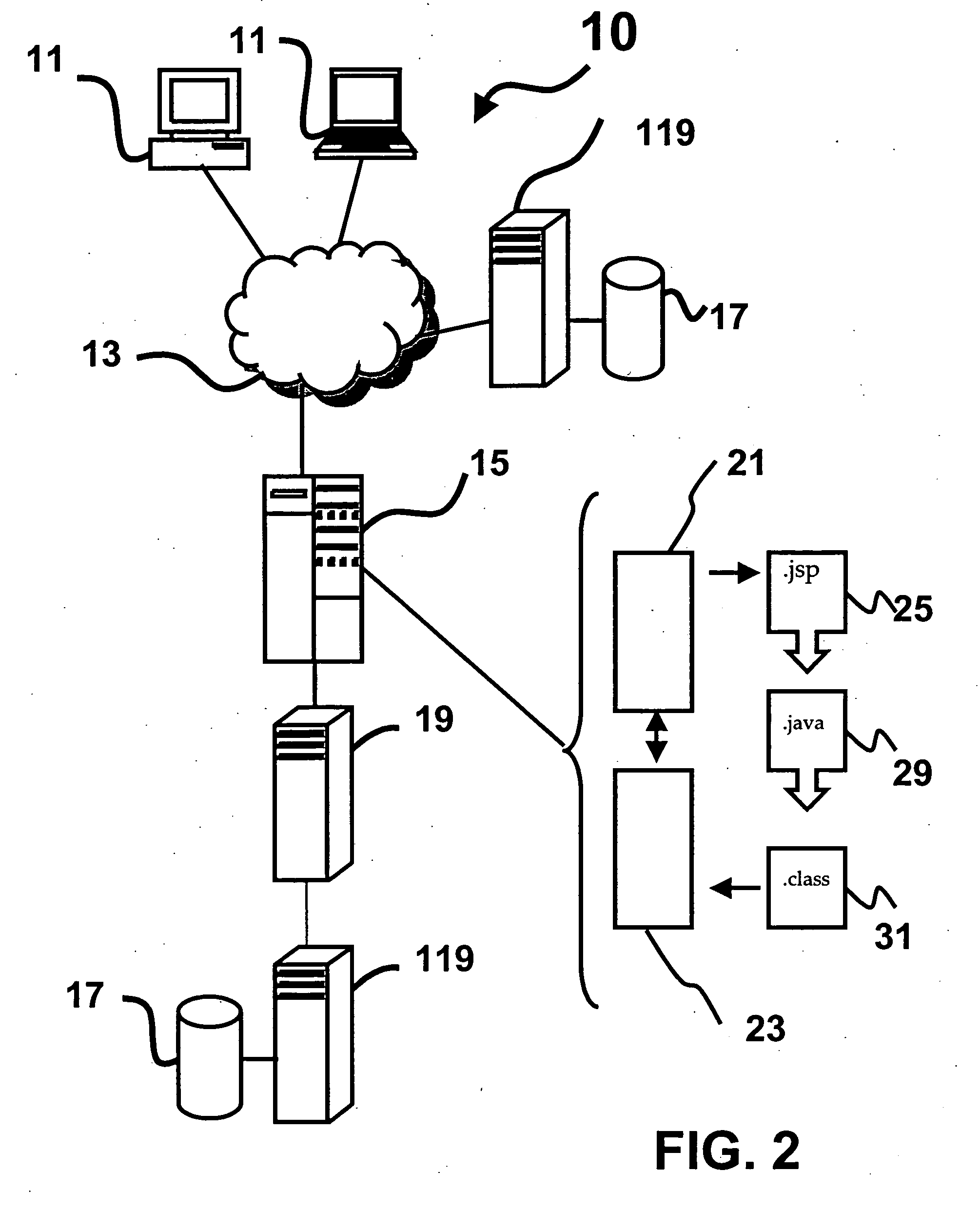

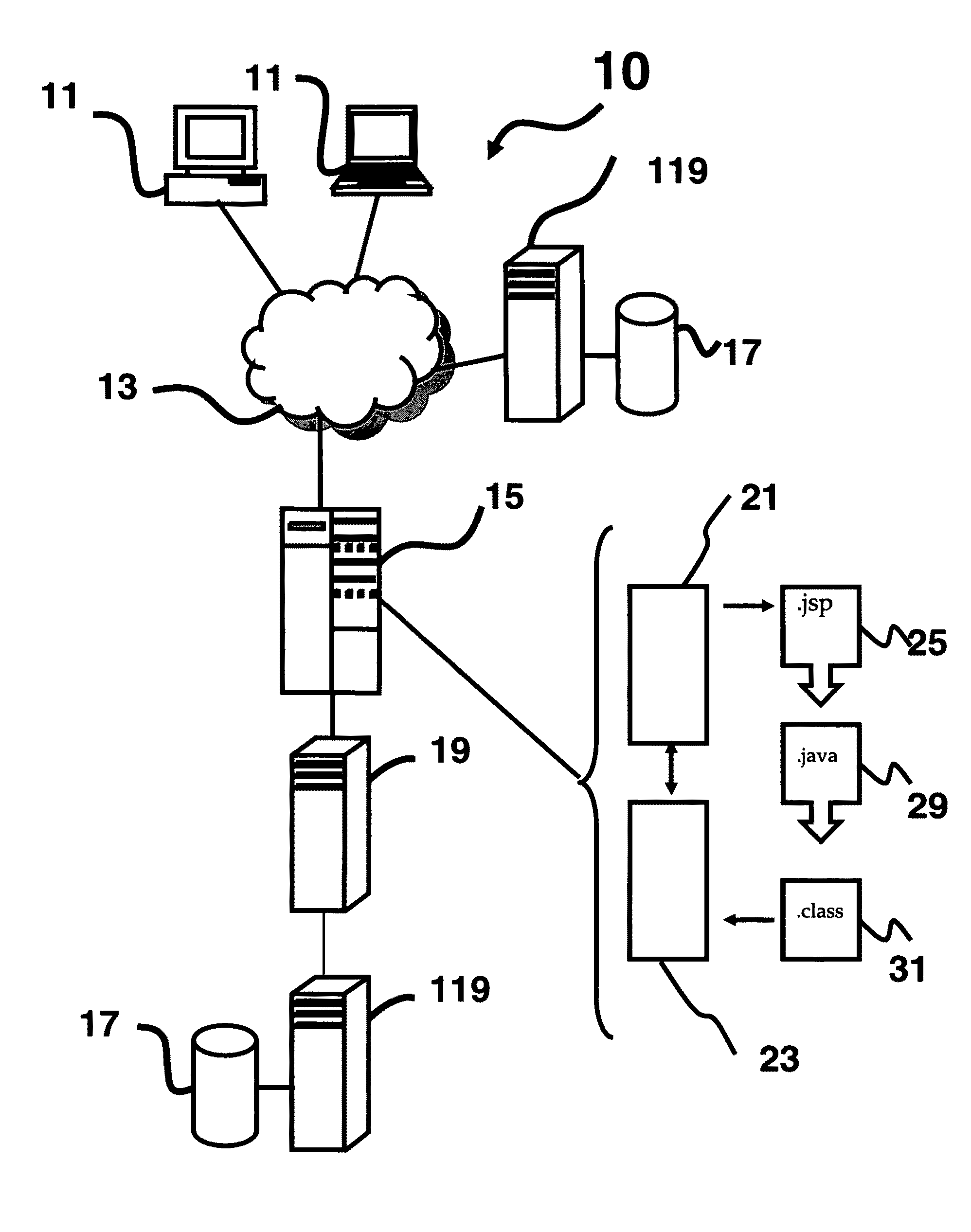

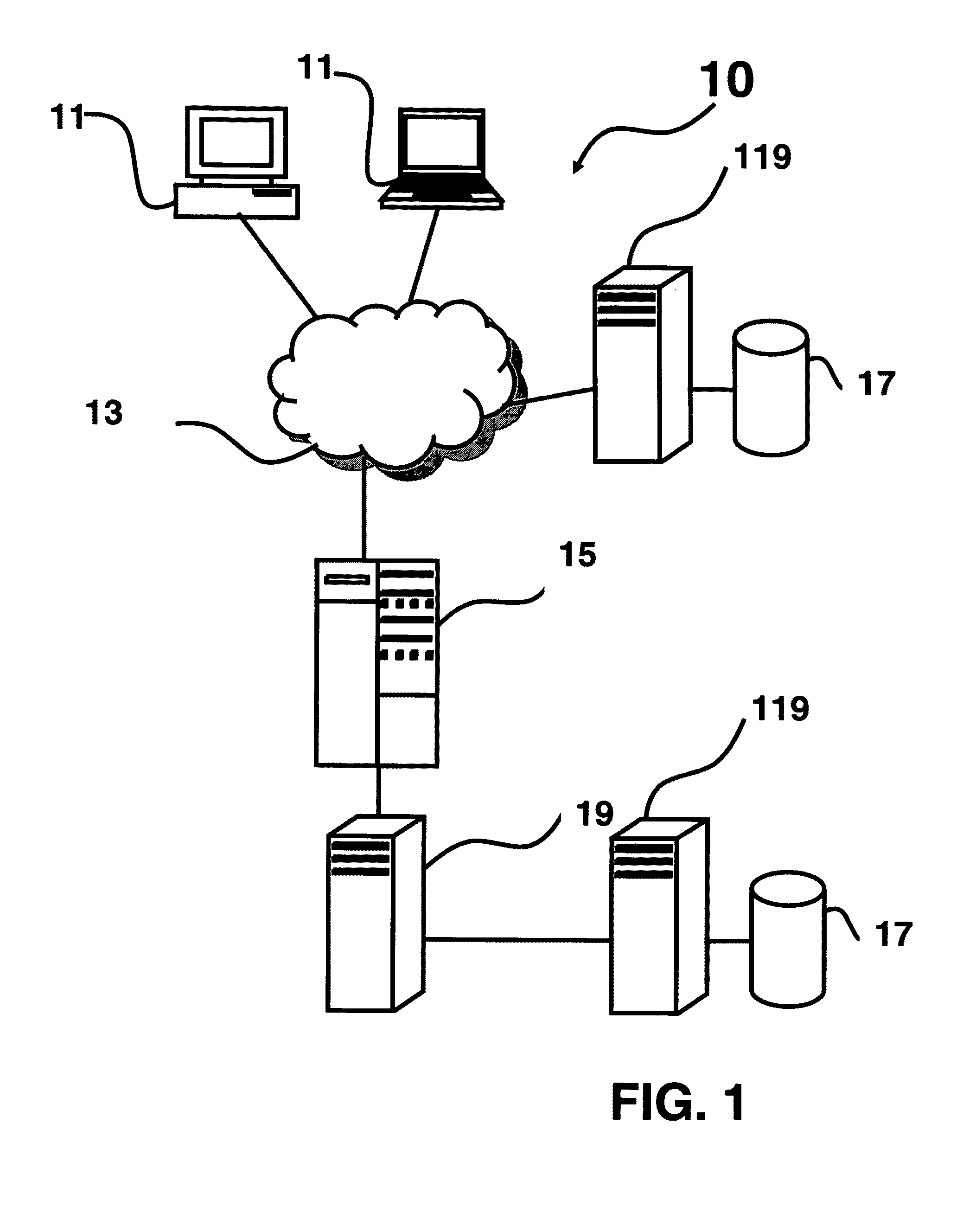

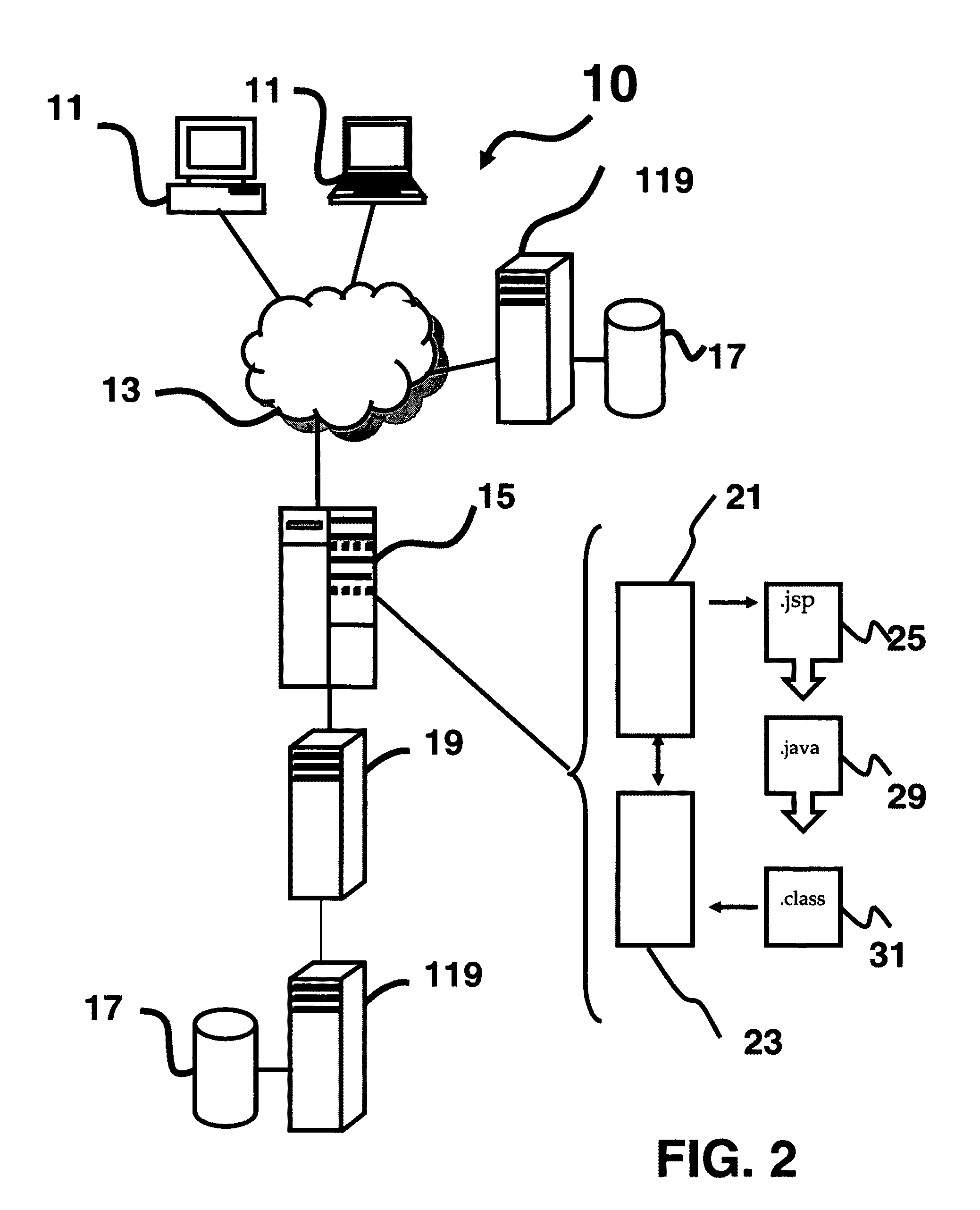

Method and system for creating and providing a multi-tier networked service

InactiveUS20050138650A1Special service provision for substationData processing applicationsApplication serverWeb service

A multi-tier application for interaction with a user interface, such as a browser on a PC or PDA. The application comprises a presentation tier (such as a web server with a JSP / servlet engine) and a business logic tier (such as an application server) to manipulate data for subsequent presentation on the user interface. A direction module has a plurality of coupled directions, including a function direction to direct a corresponding functional component to perform a data processing function using the business logic tier and provide a data processing output, and a presentation direction to direct a corresponding presentation component to incorporate the data processing output, when applicable, into a presentation template to produce a presentation element for the user interface. The function component and presentation component are independent and separate from each other, the connection being the function component produces the data and the presentation component consumes the output data. The presentation component is an abstract representation of a general kind of presentation element, each specific presentation element having its layout and format (such as markup language) stored in a different presentation template, and the reference to a specific presentation template for the presentation component can be determined at processing time in the presentation tier.

Owner:EMERGIS INC

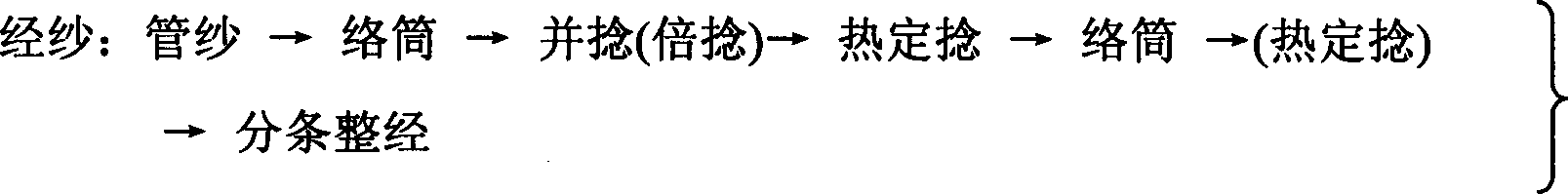

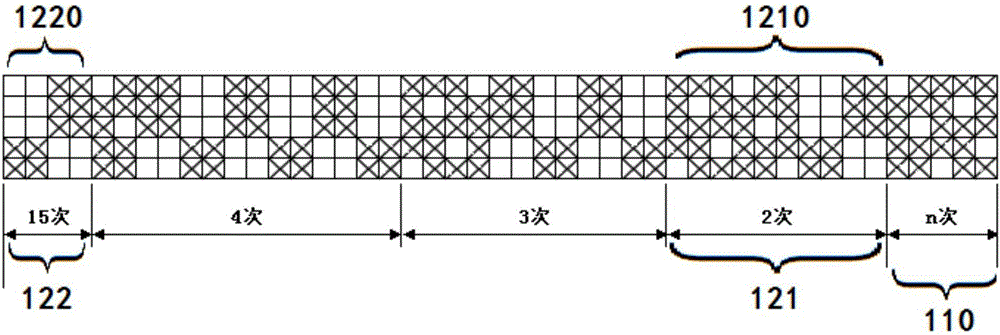

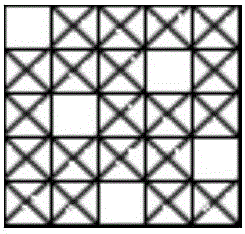

Method for selecting warp, abb, fabric texture and cloth gauge of stretch cotton fabric

The invention discloses the selection method of binding yarn, textile weave and thread count. The selection of binding yarn comprises: 1 the selection of yarn: twist yarn: 30S / 2 combed cotton yarn, weft yarn: 20S / 2 combed cotton; 2 the selection of twist and direction of twist: in twist yarn single thread being Z twist; ply yarn being hard twist yarn intervallic ranging by Z / ZíóZ / S. The selection of textile weave and thread count comprises: 1 the textile weave being loose structure calico weave, twist yarn radial arrangement being SZZSSZZ......ZZSSZZS, two twistings which have the same direction kinking with each other; 2 fabric density warp rate being 185.5strip / 10cm, the weft density being 78.6strip / 10cm; 3 using the breadth shuttle loom to get the breadth fabric, then cutting it to fixing dimension bandage. There are 3-4mm gap between crossing warps.

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD

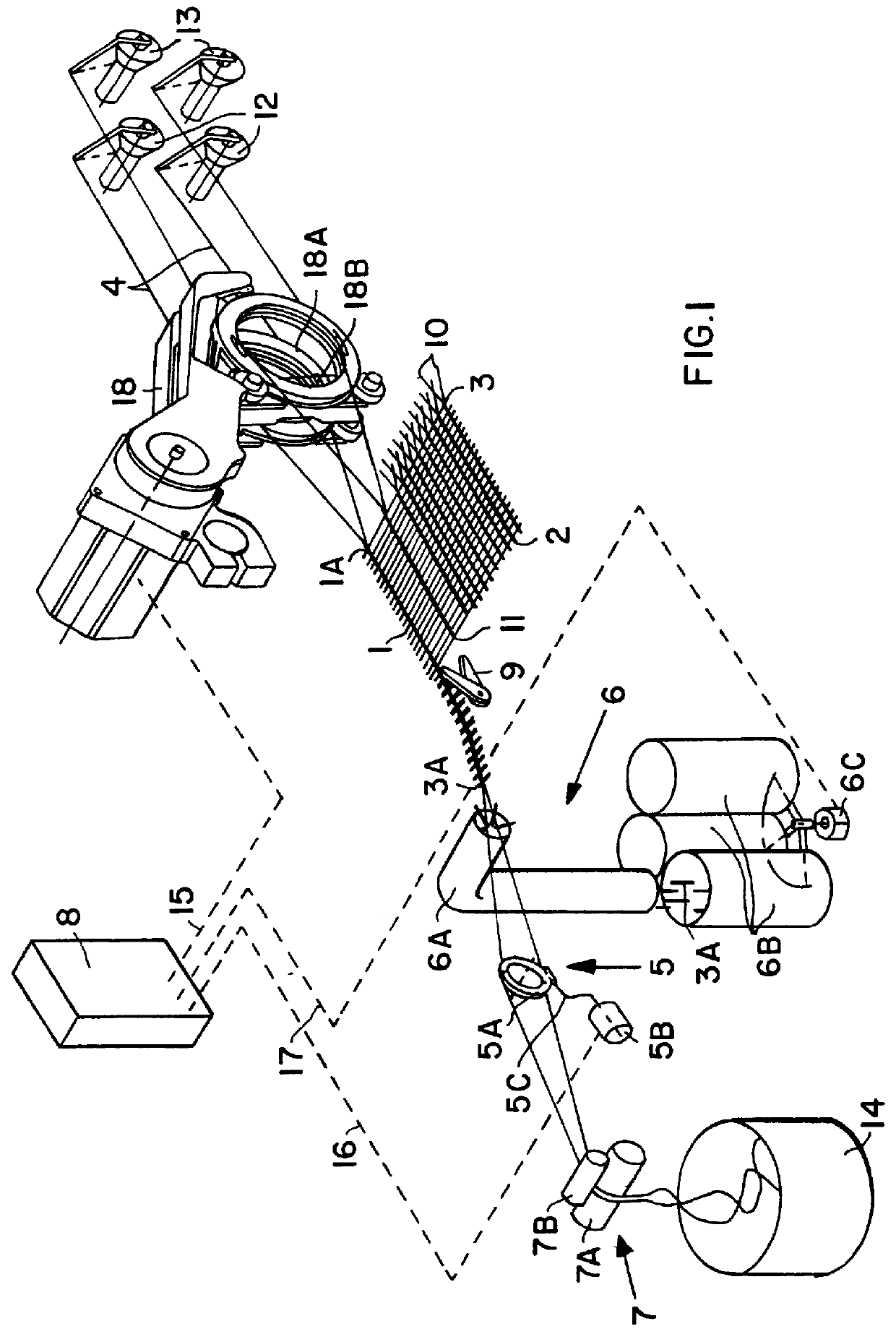

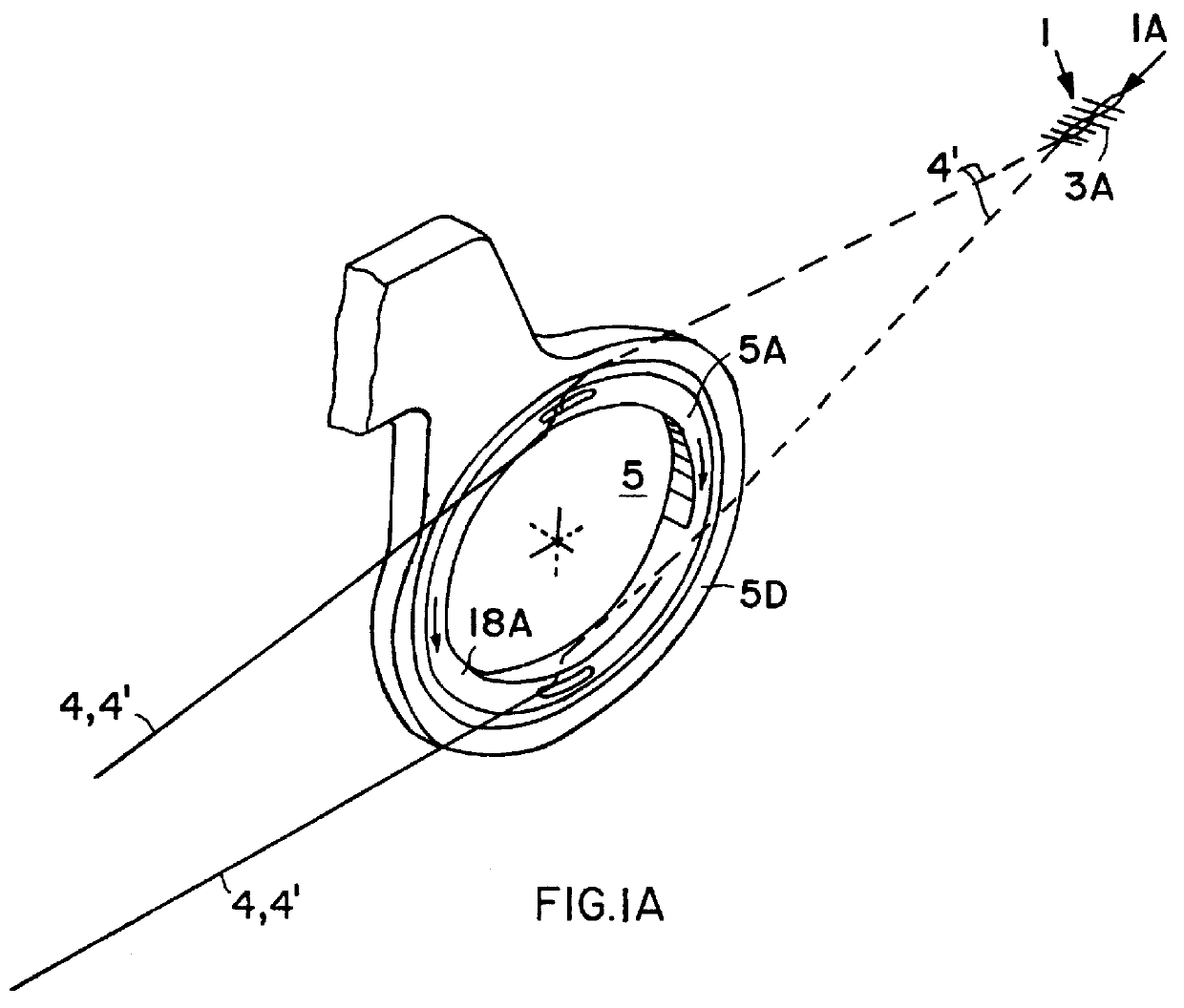

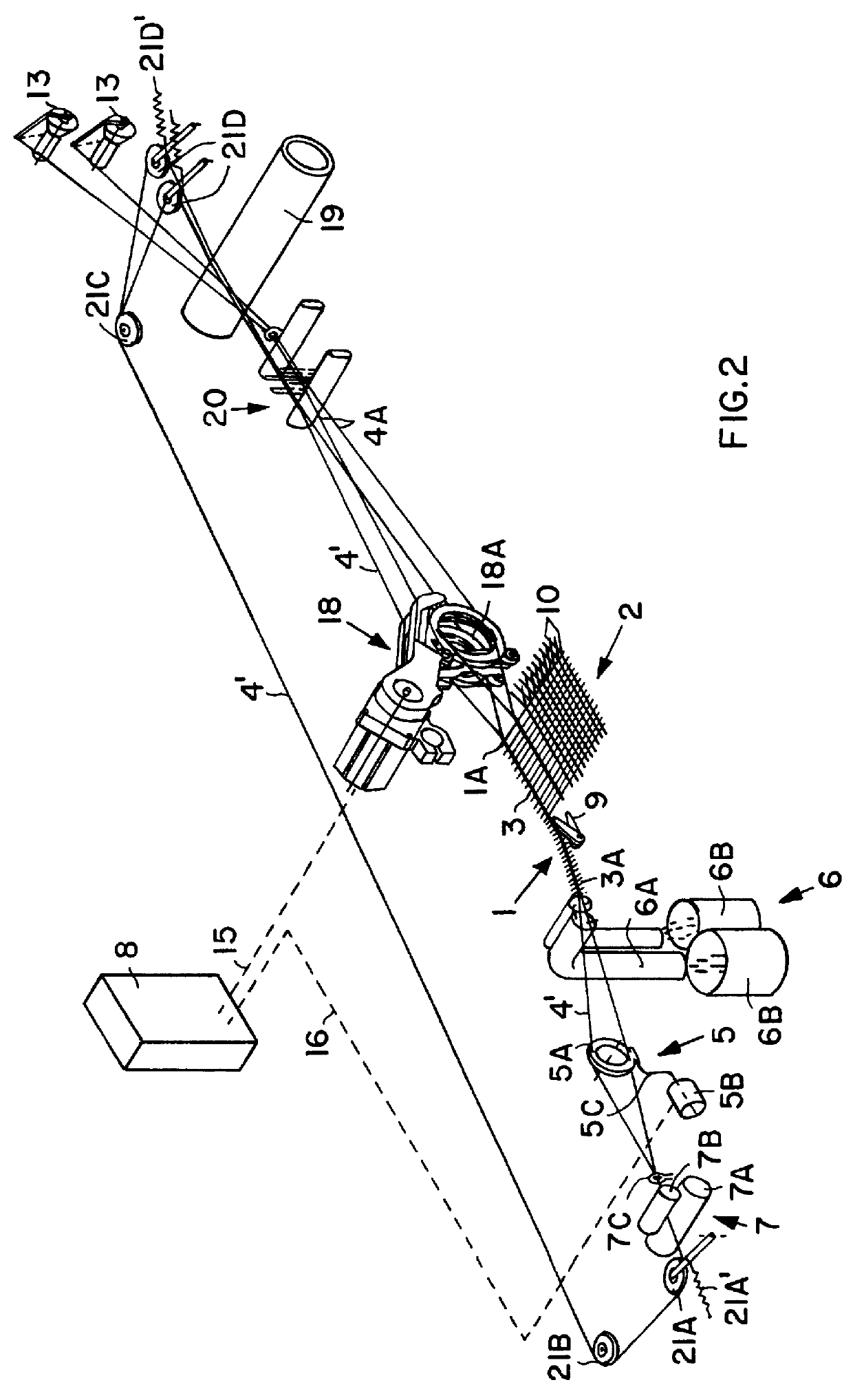

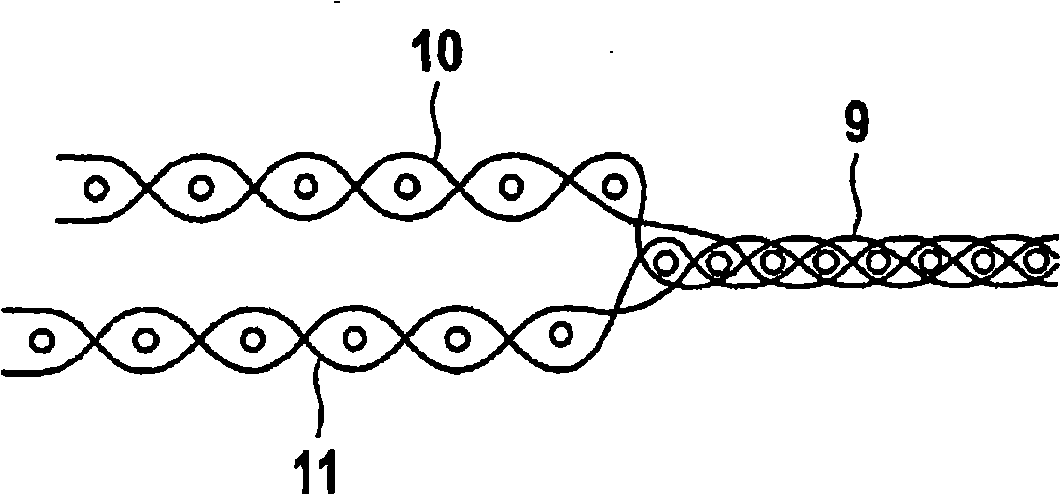

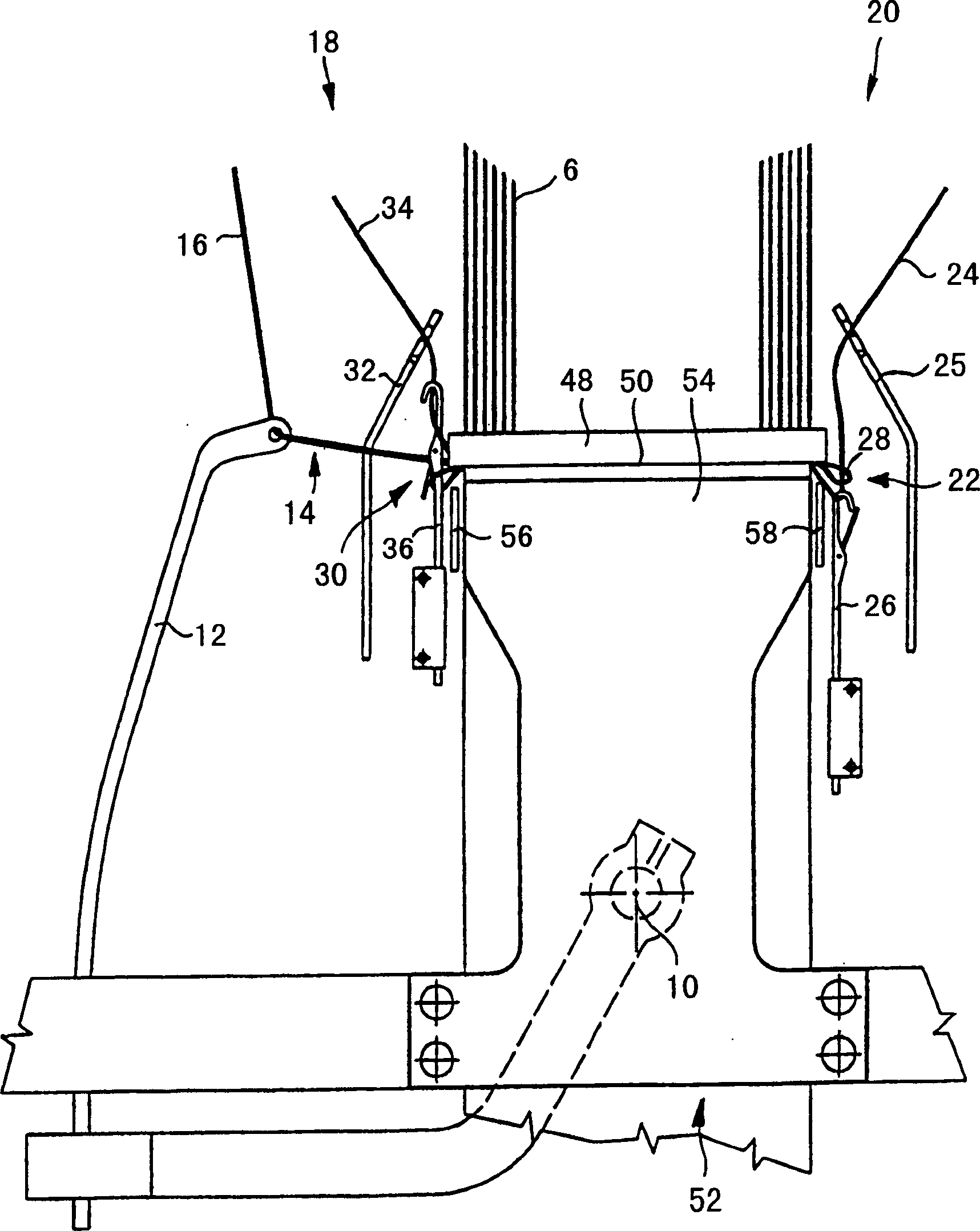

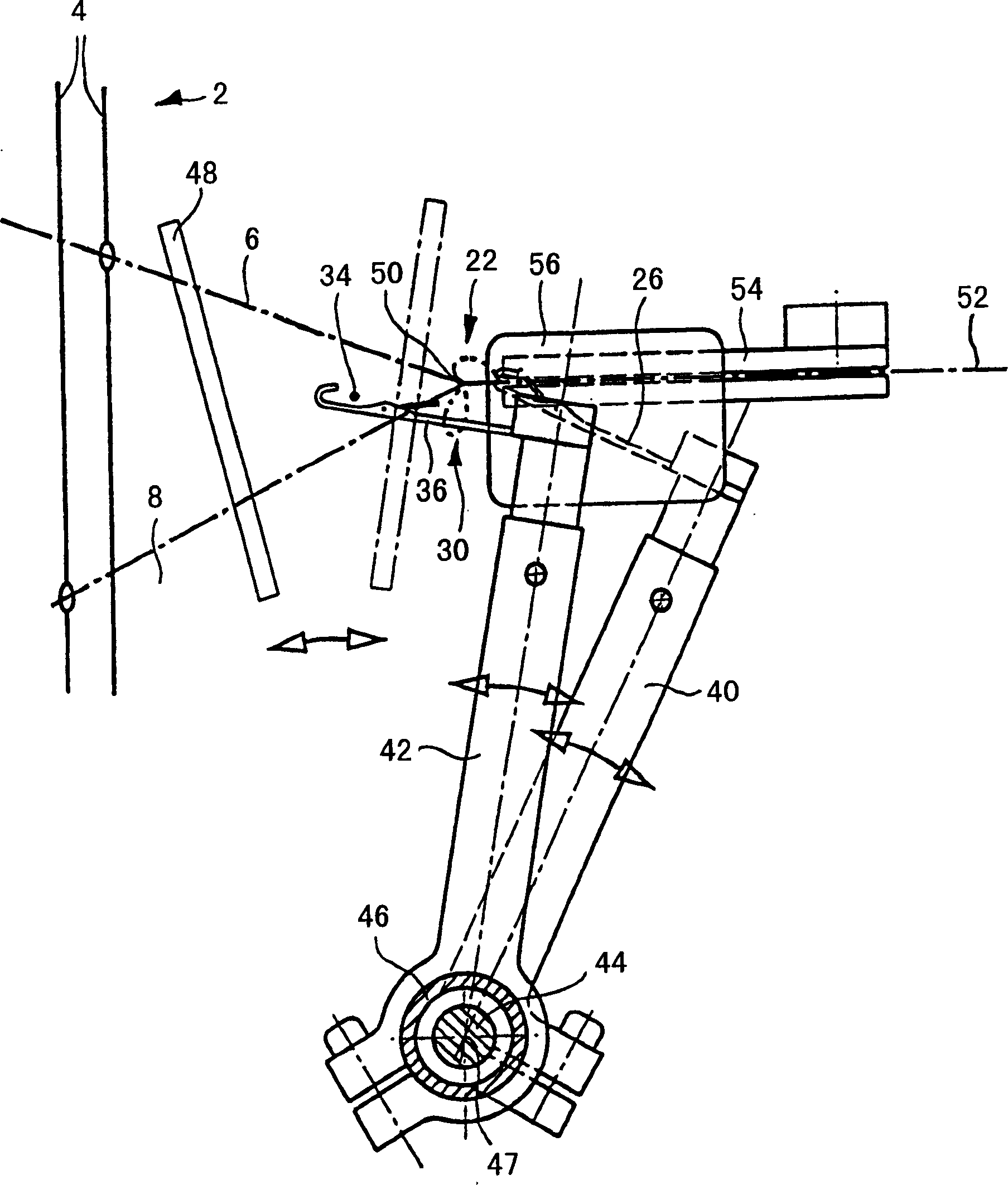

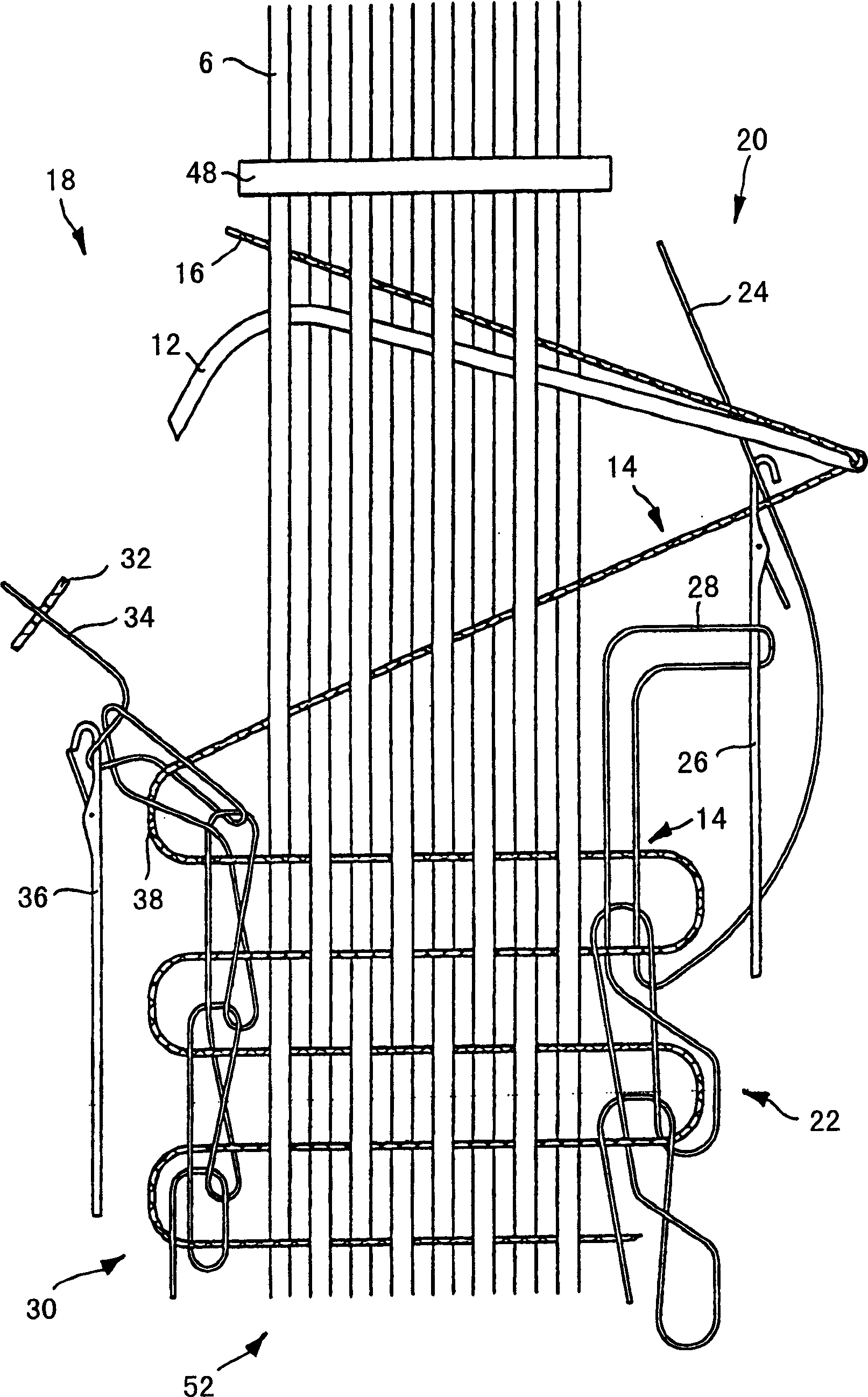

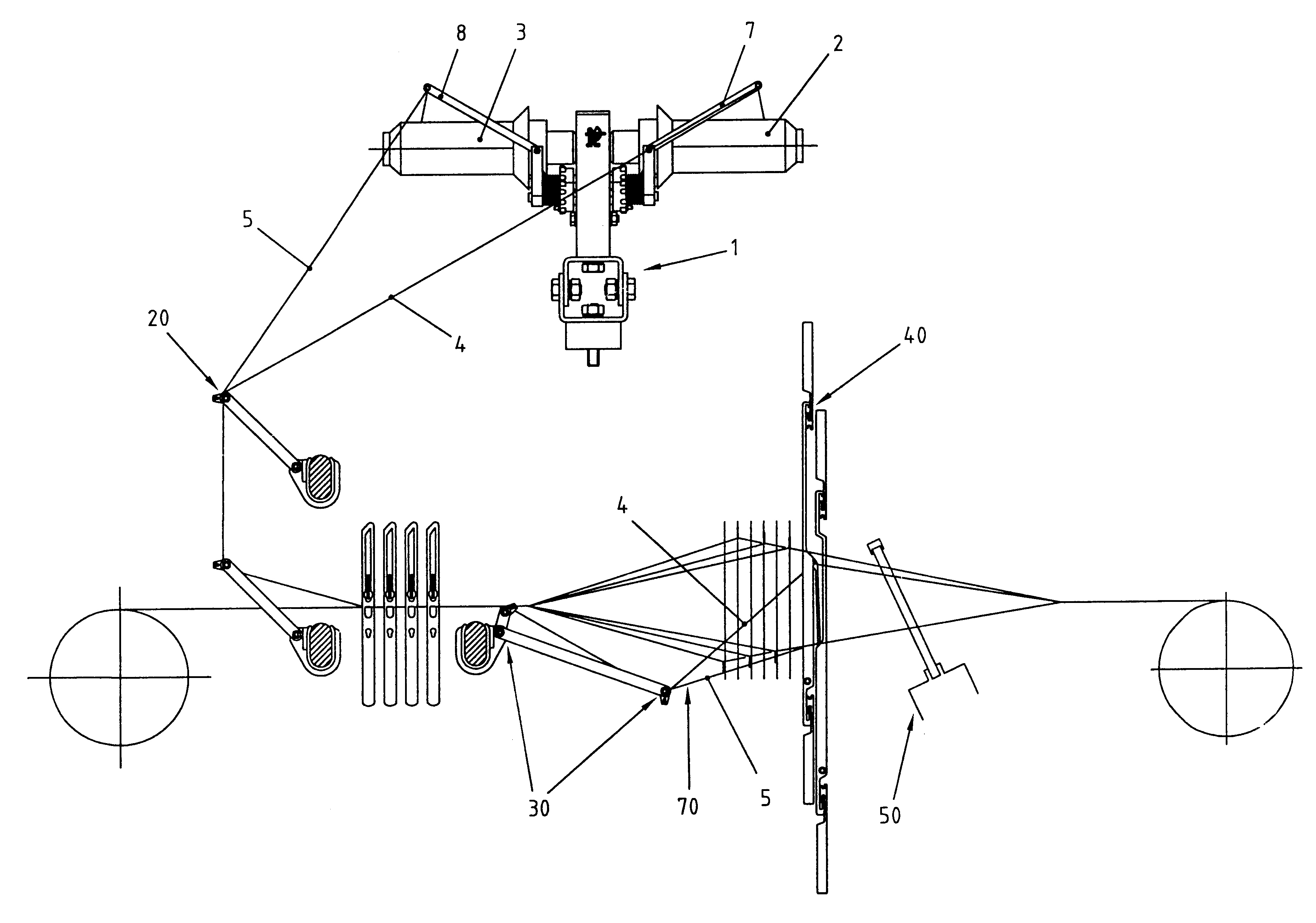

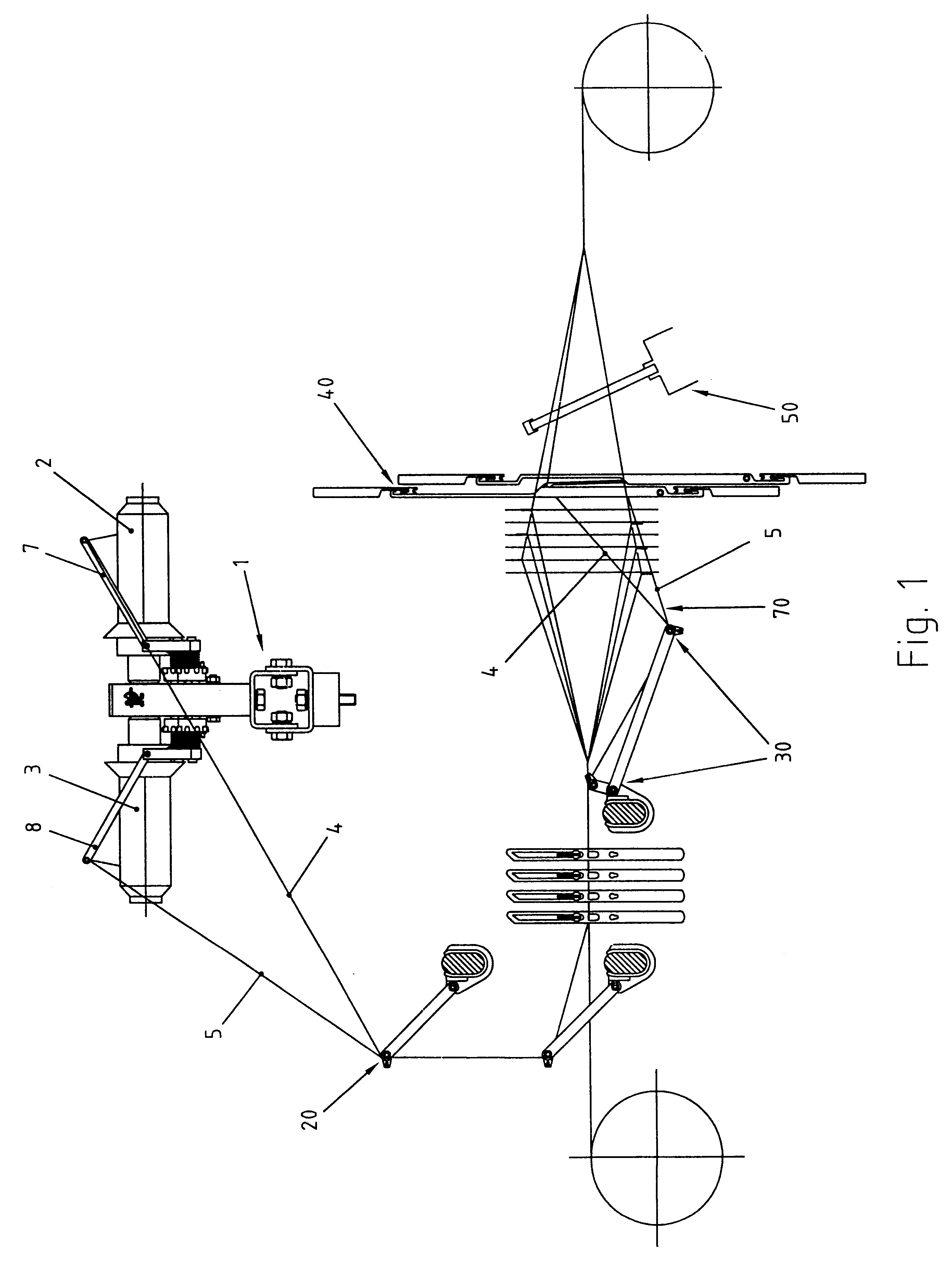

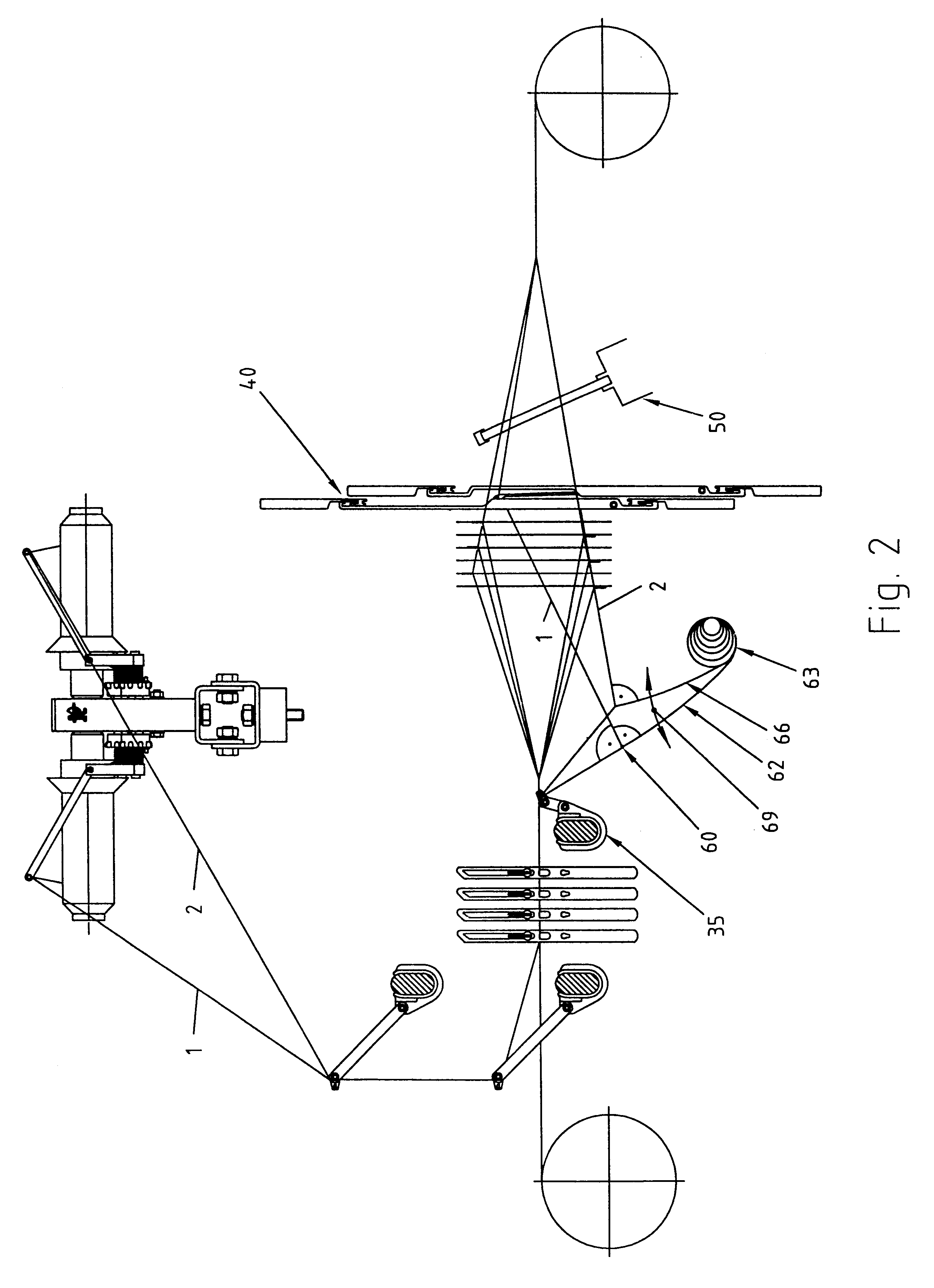

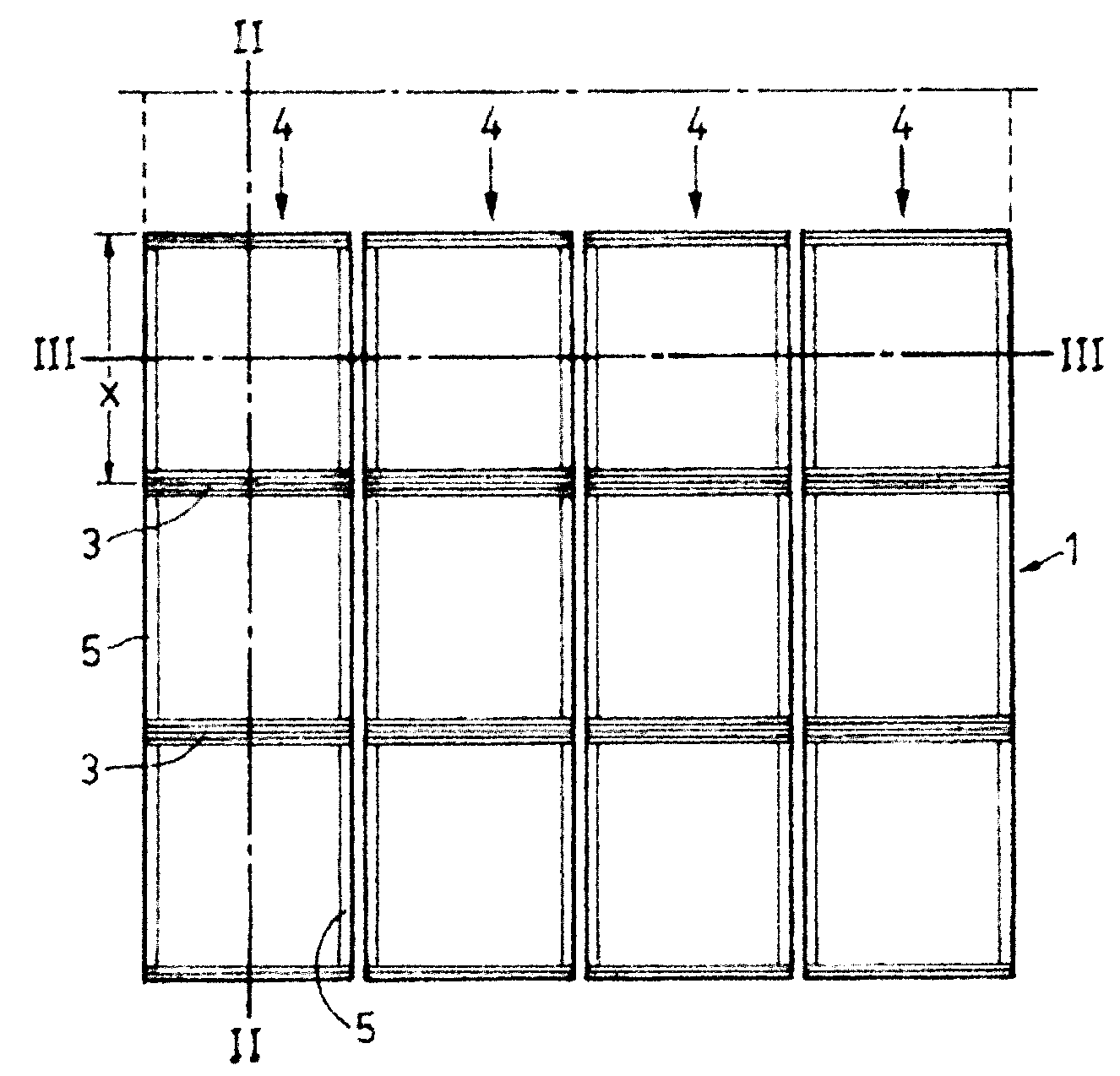

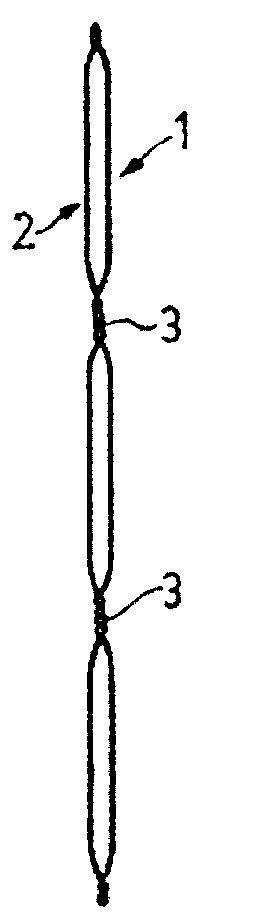

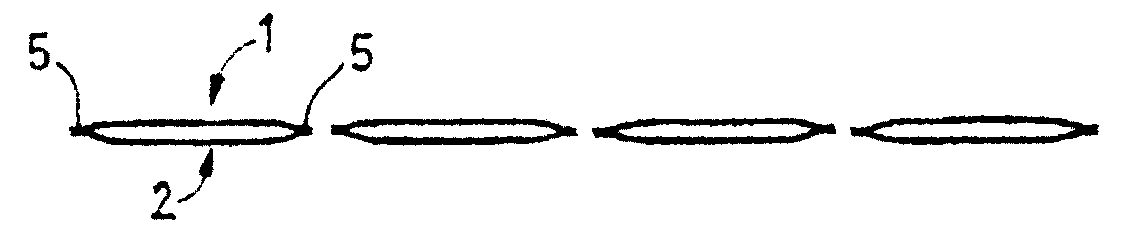

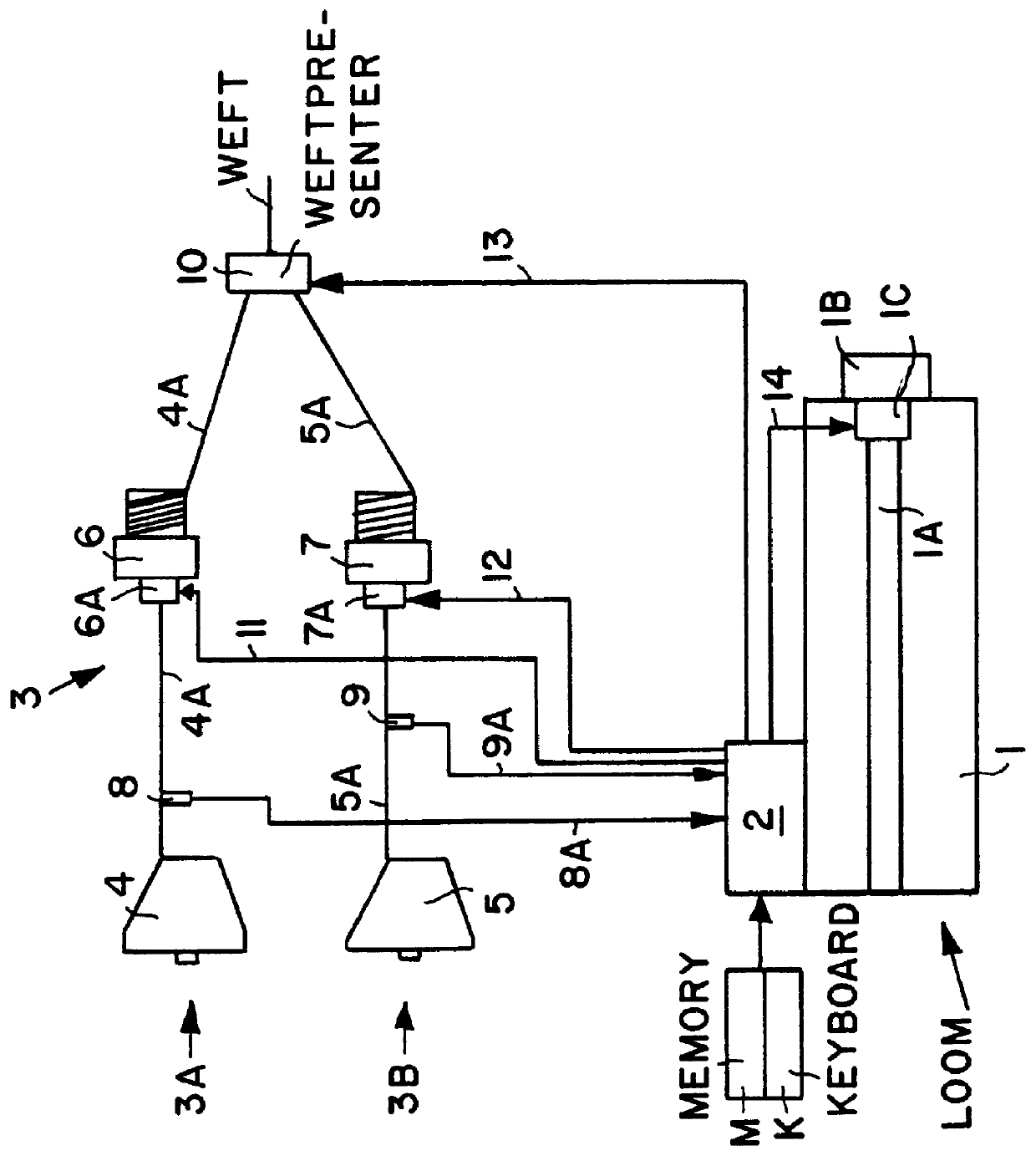

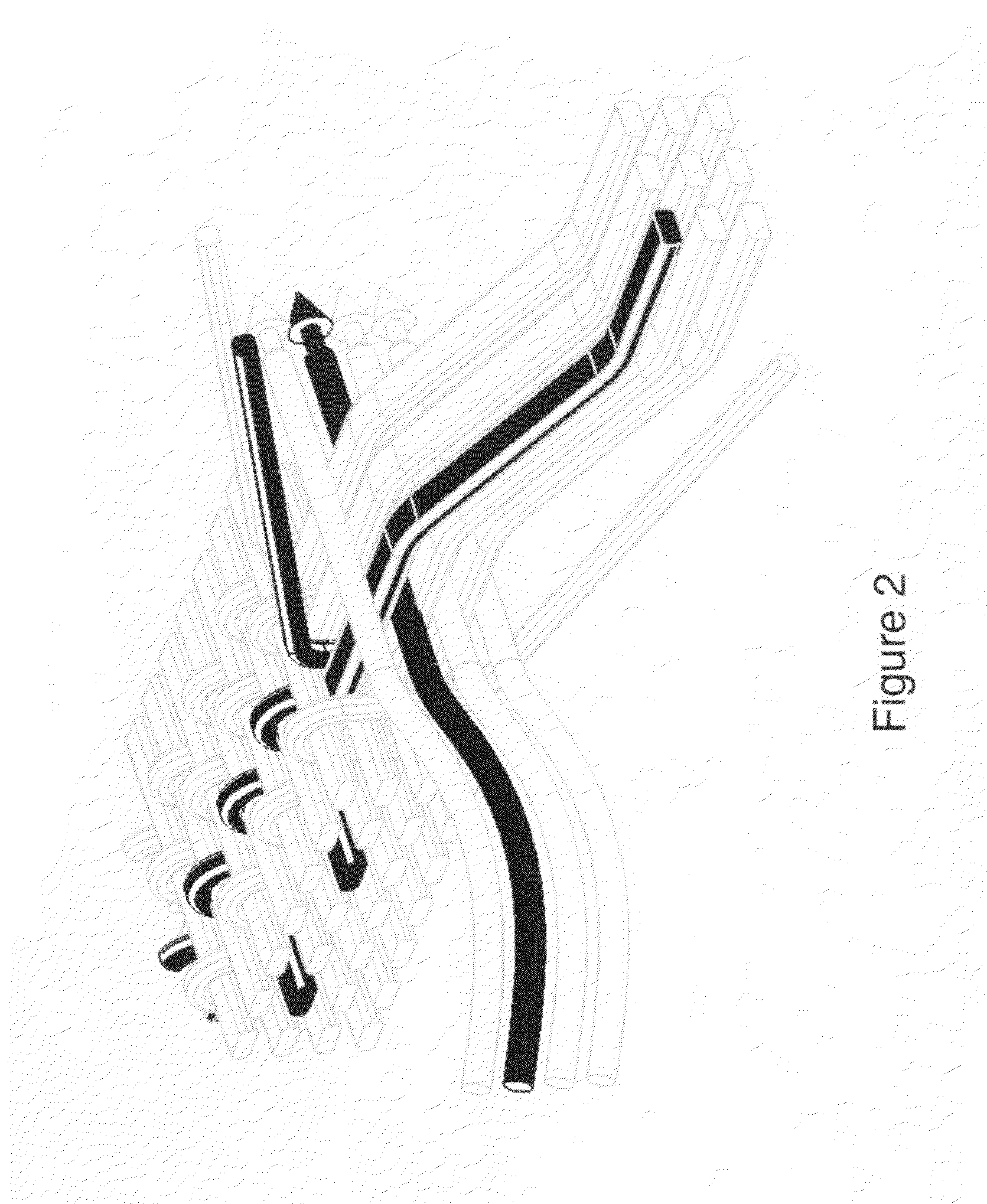

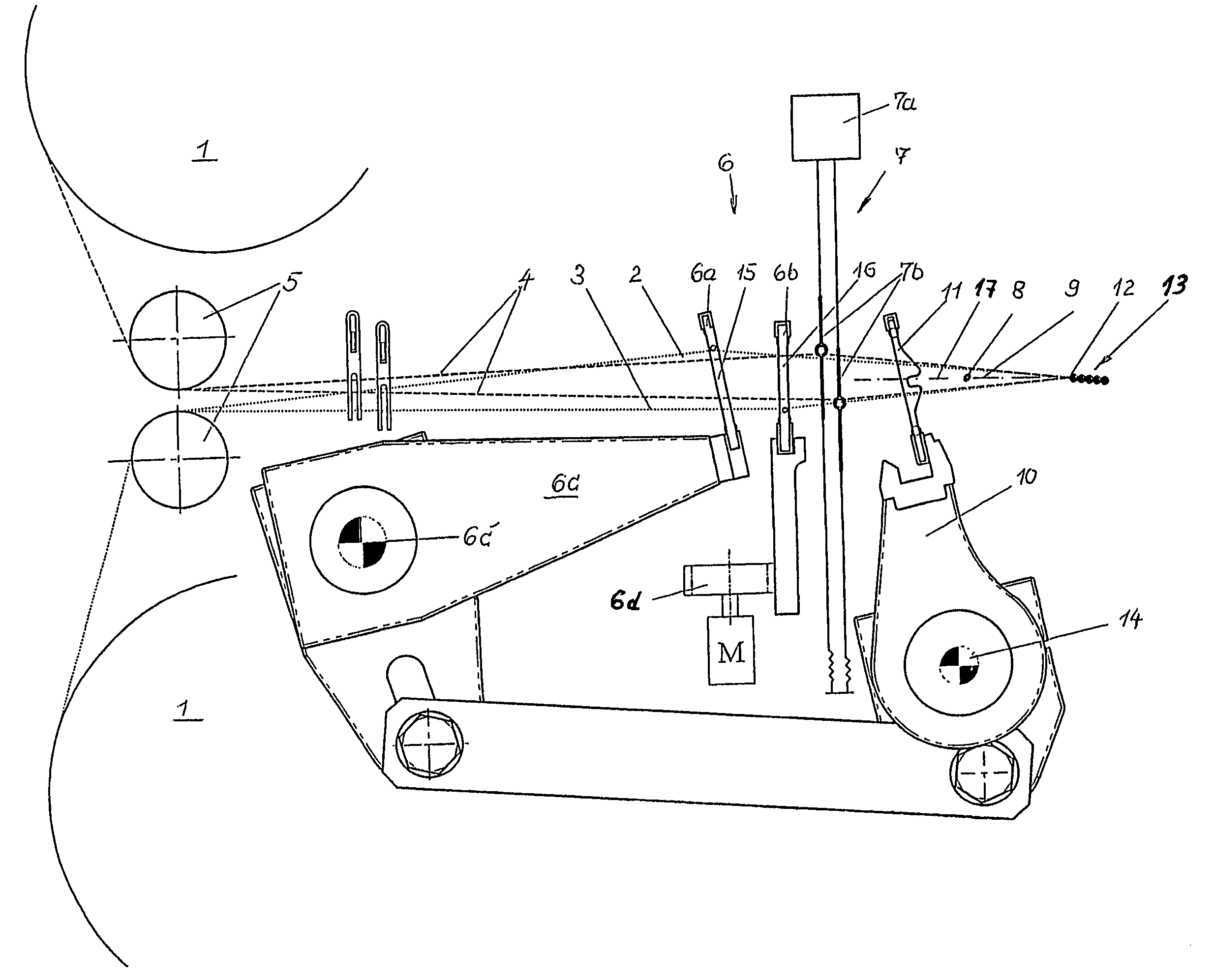

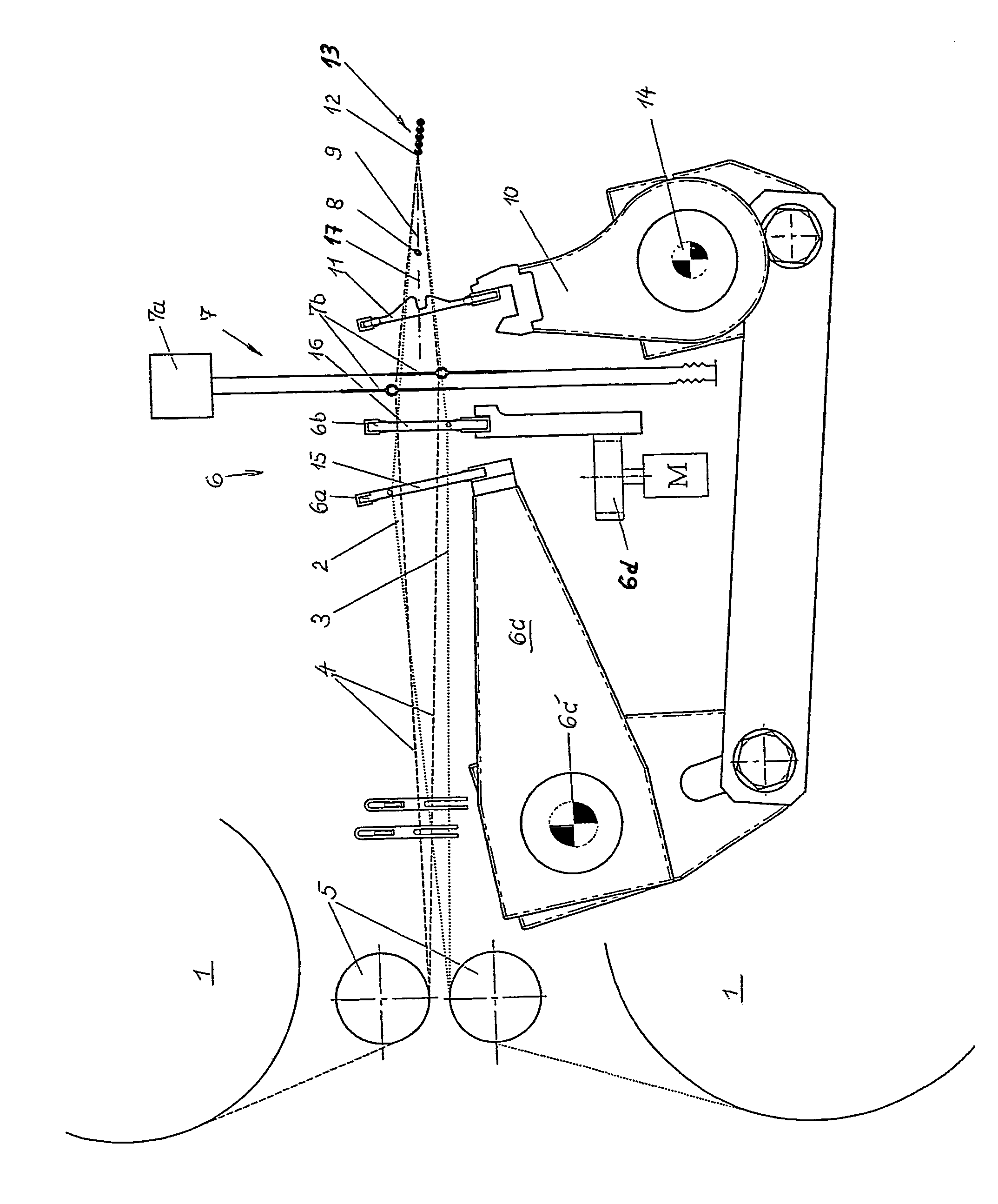

Separating weft thread waste of a single uncontaminated material from untwisted leno binding threads in trimmed catch selvages

A method and an apparatus serve to process a catch selvage that has been trimmed from a web being woven on a loom, so as to separate weft thread ends and leno threads from the catch selvage to produce a type-pure weft thread waste and a type-pure leno thread waste or reusable leno threads. The term "type-pure" refers to a waste material containing a single uncontaminated type or color of thread material, e.g. wool vs. synthetic or blue vs. red. After the catch selvage (1) has been trimmed from the edge (11) of the woven web (2), the leno threads (4, 4') are untwisted from each other by being rotated by an untwisting apparatus (5) in a direction opposite the binding twist applied by the leno device (18). Thereby, the full leno binding (1A) is completely unbound and opened, so as to release the weft thread ends (3A), which are then sucked into a proper one of weft waste collection containers (6B) by a suction pipe (6A), so that only a single type-pure and / or color of weft thread end is collected in each container (6B). The unbound leno threads (4) are collected as a type-pure waste or are rewound on spools to be reused. Alternatively, by using endless closed-loop leno threads (4'), the leno threads (4') are continuously recirculated back to the leno device (18), without intermediately being wound onto spools.

Owner:LINDAUER DORNIER GMBH

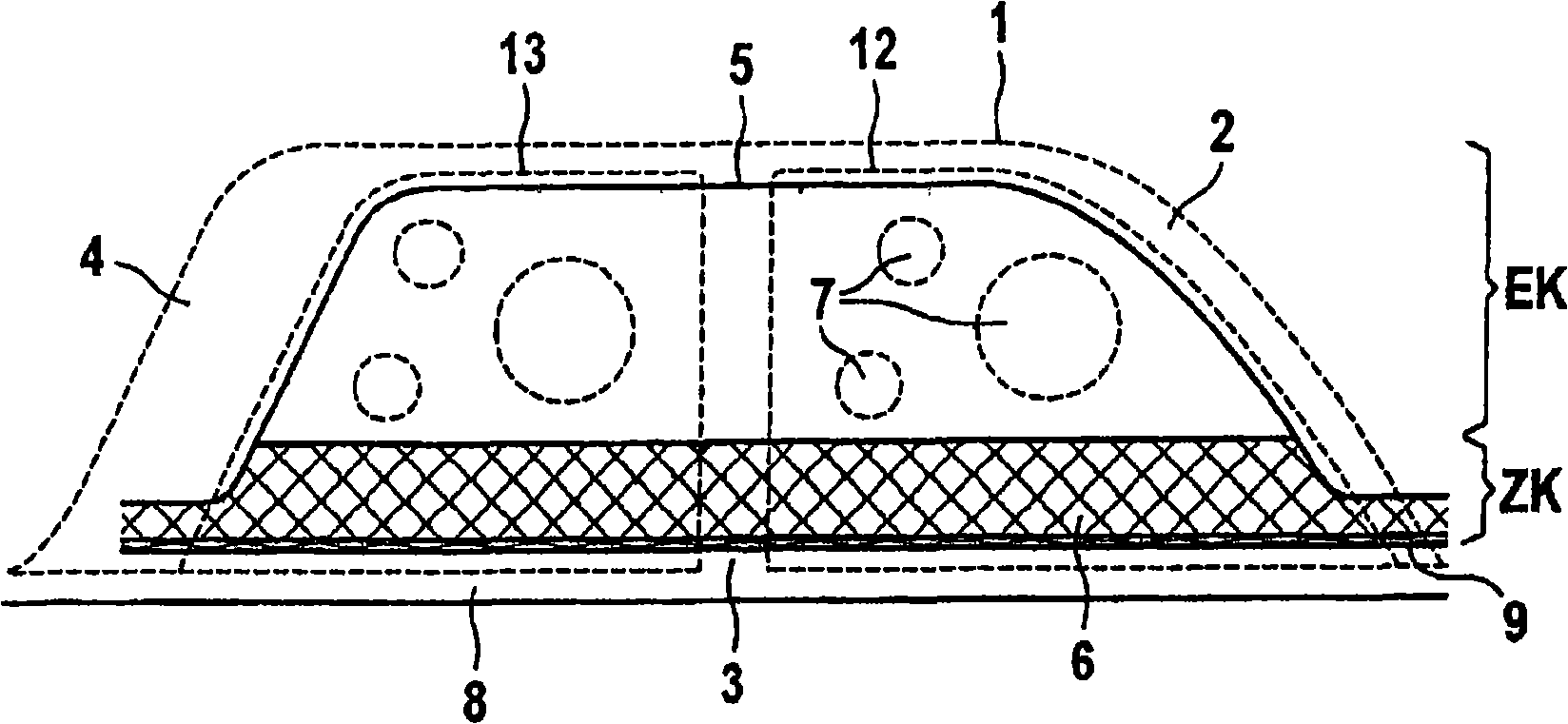

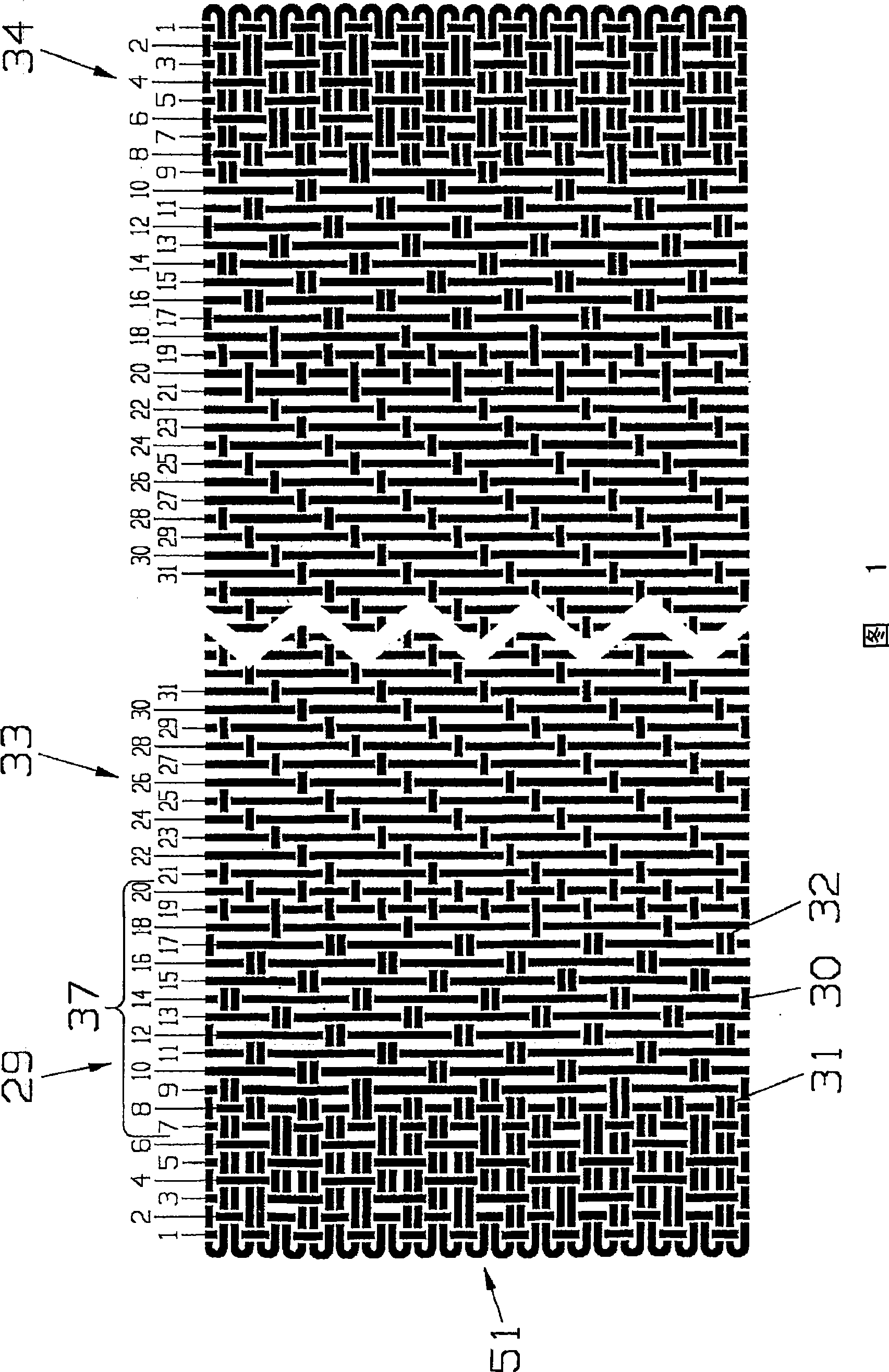

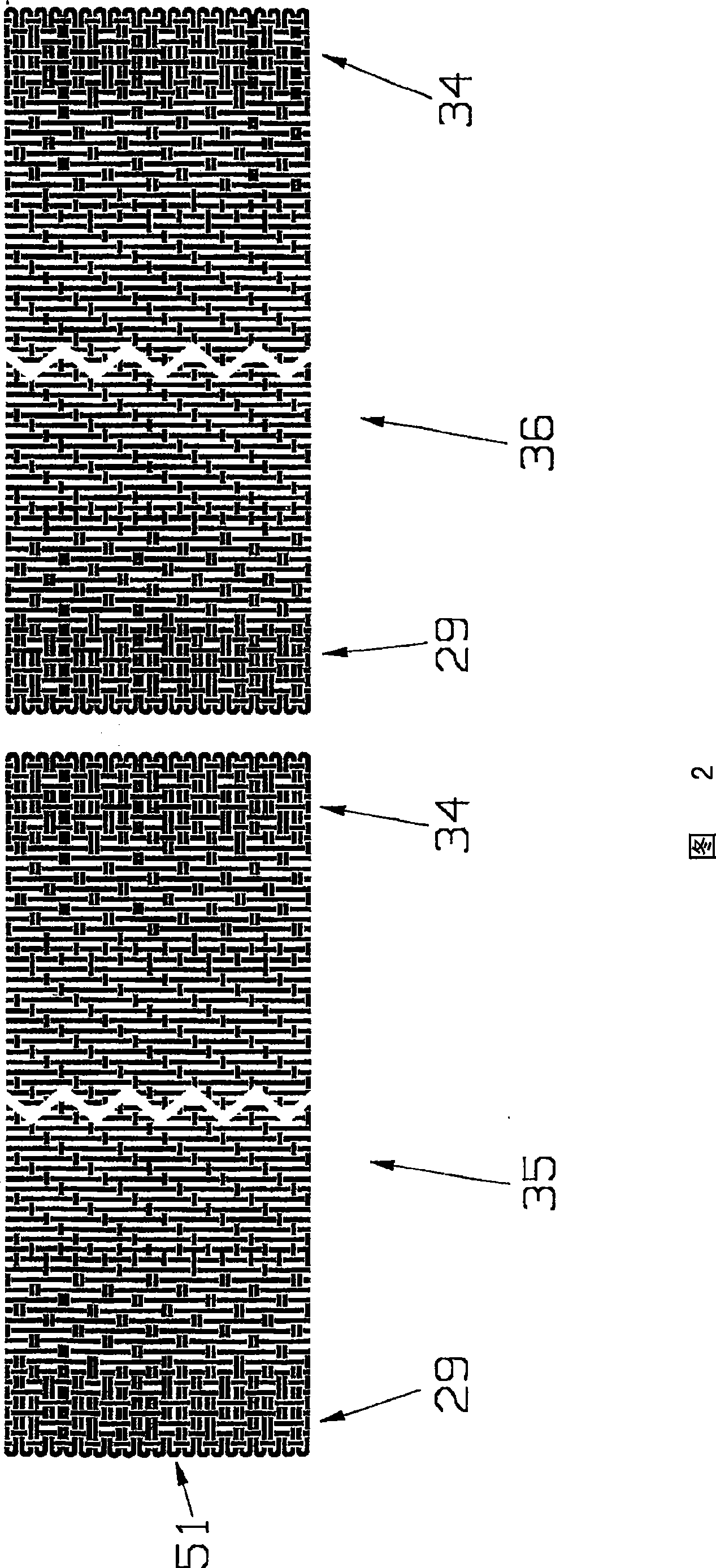

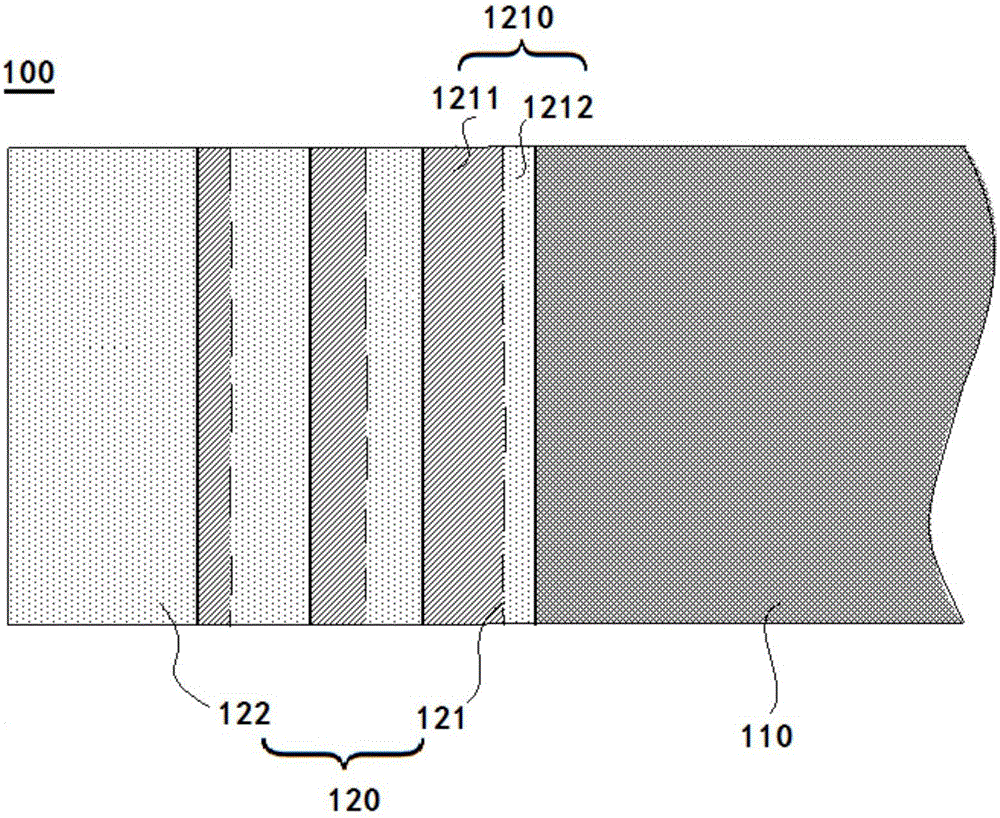

Airbag and method for manufacturing a fabric for an airbag

InactiveCN101356081AReduce material costsReduce manufacturing costPedestrian/occupant safety arrangementSelvedgesWoven fabricWeft yarn

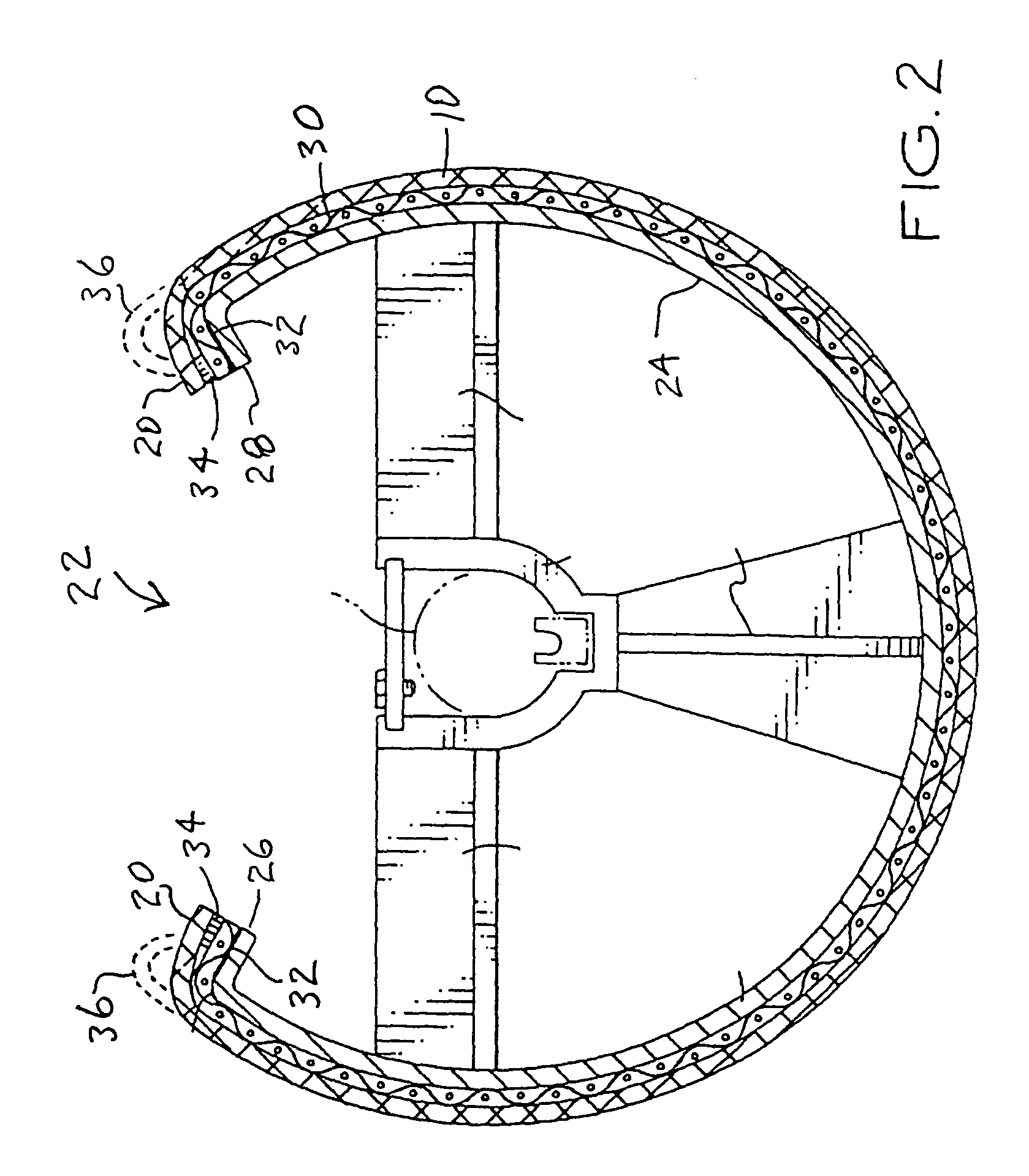

Method for manufacturing a woven fabric for an airbag for passenger restraint systems for motor vehicles, characterized via the steps of preparing a group of warp yarns composed of warp yarns (24, 26) of different yarn qualities, having first warp yarns (24) and having second warp yarns (26) which are arranged in selected regions (ZK) of the group of warp yarns and are made of hybrid yarn which has first filaments (61) and second filaments (62), weaving the fabric with at least one weft yarn quality, and thermal, mechanical or chemical treatment of the fabric in such a way that the second filaments lose their filament structure, become an amorphous mass and connect the first filaments to one another.

Owner:GLOBAL SAFETY TEXTILES

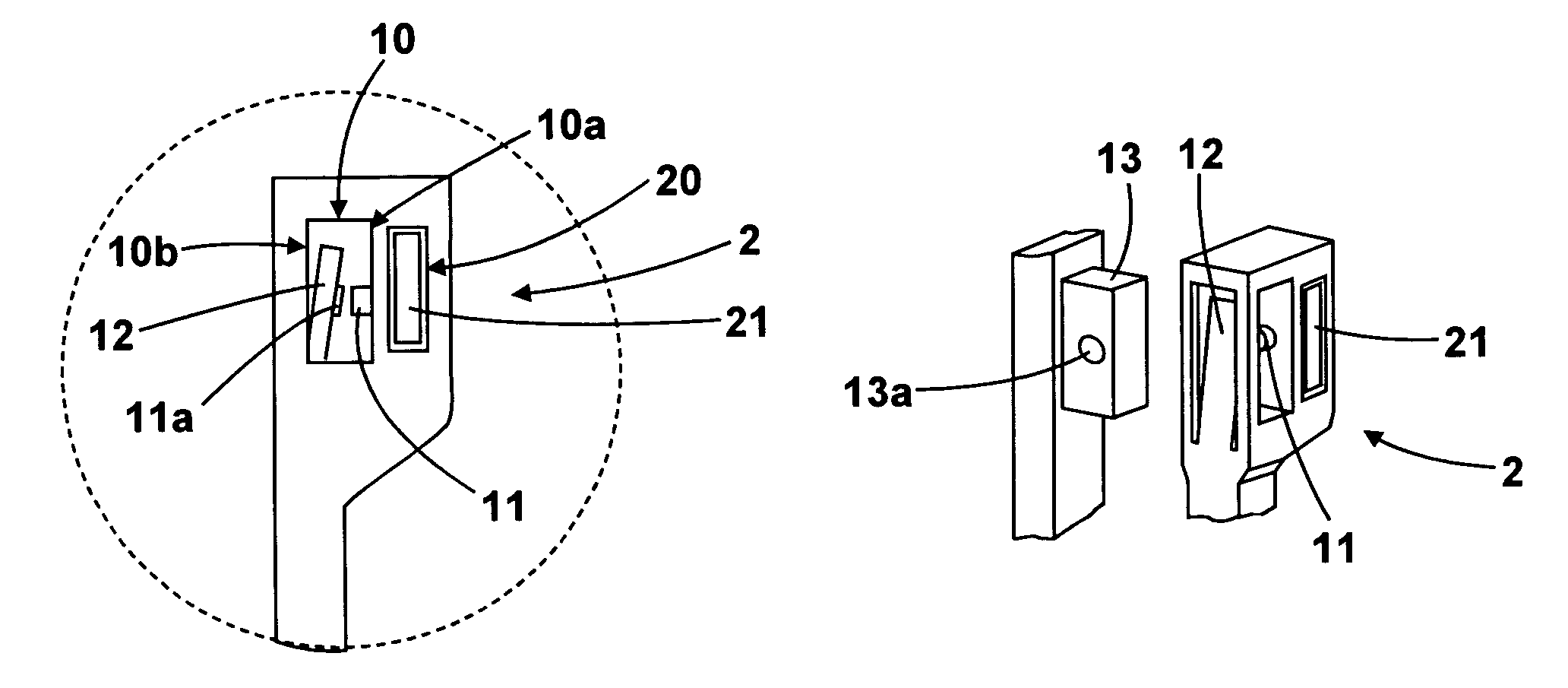

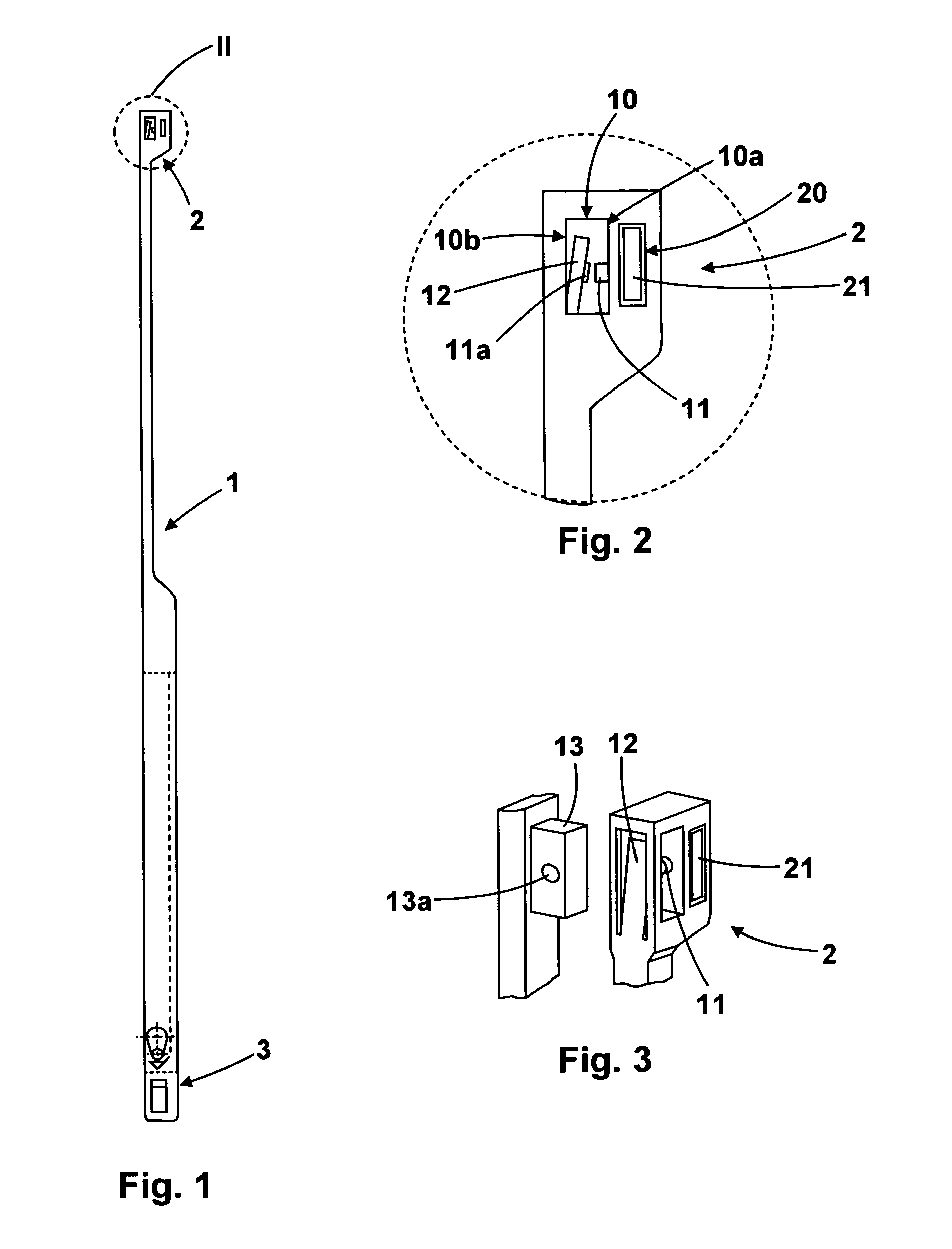

Heddle, especially lifting heddle

The subject matter of the invention is a heddle (1), more specifically a lifting heddle as part of a leno selvedge device, the heddle comprising a head portion and a base portion with a closed or an open eyelet for mounting to a heddle frame or to a heddle ridge bar (13), the head portion and / or base portion (2, 3) being adapted to be secured stationarily to the heddle frame or the heddle ridge bar (13), with the head portion (2) and / or the base portion (3) being adapted to be interlockingly and non-slidably fixed to the heddle frame or to the heddle ridge bar (13) by means of a detent system (11, 12, 13a).

Owner:GEBR KLOCKER

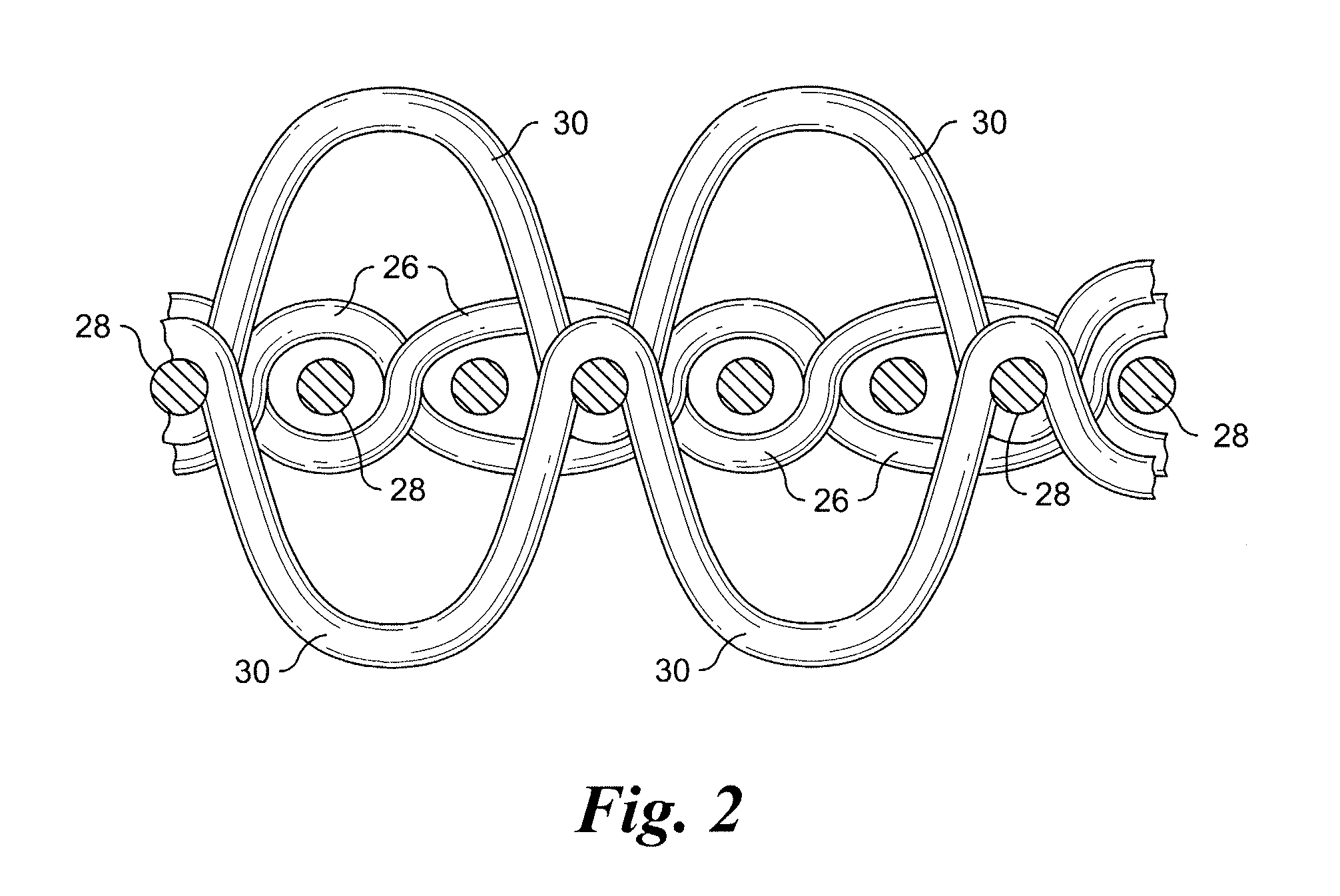

Webbing belt

Belts and methods of their manufacturing are provided. In one aspect, belts are manufactured by the steps of weaving the belt from a plurality of warp yarns and at least one weft yarn, the belt having a central region and two opposed edges. The warp yarns in the central region have a predetermined shrinkage characteristic. The belts also have at least one edge region between the central region and an edge of the belt has a predetermined number of warp yarns, each having a lesser shrinkage characteristic than the warp yarns of the central region. The method further includes the steps of passing the weft yarn across the warp yarns to effect a weaving in the central region of the belt. Further in the edge region, looping the weft yarn, on each pass, around a selected warp yarn, so that on a plurality of successive passes the weft yarn is looped around each of the warp yarns in the edge region. Subsequently, the yarns in the belt are shrunk.

Owner:AUTOLIV DEV AB

Narrow fabric needle loom for producing a strip-shaped tissue, and corresponding strip-shaped tissue

InactiveCN1422342AGood lookingGood physical propertiesSmallware loomsSelvedgesRotational axisDevice form

The invention relates to a narrow fabric needle loom, comprising a shedding device forming a shed, and a weft insertion needle (12) for at least one weft loop (14). A knitting needle (26) is provided on the discharge end (20) of the shed facing away from the feed end (18) of the weft insertion needle (12) and secures the weft loops (14) by meshing (22). A second knitting needle (36) that meshes (30) the loops is provided on the feed end (18) of the weft insertion needle (12). The knitting needles for the feed end (18) and the discharge end (20) are mounted so that they can be swiveled about the same rotational axis (47).

Owner:TEXTILMA AG

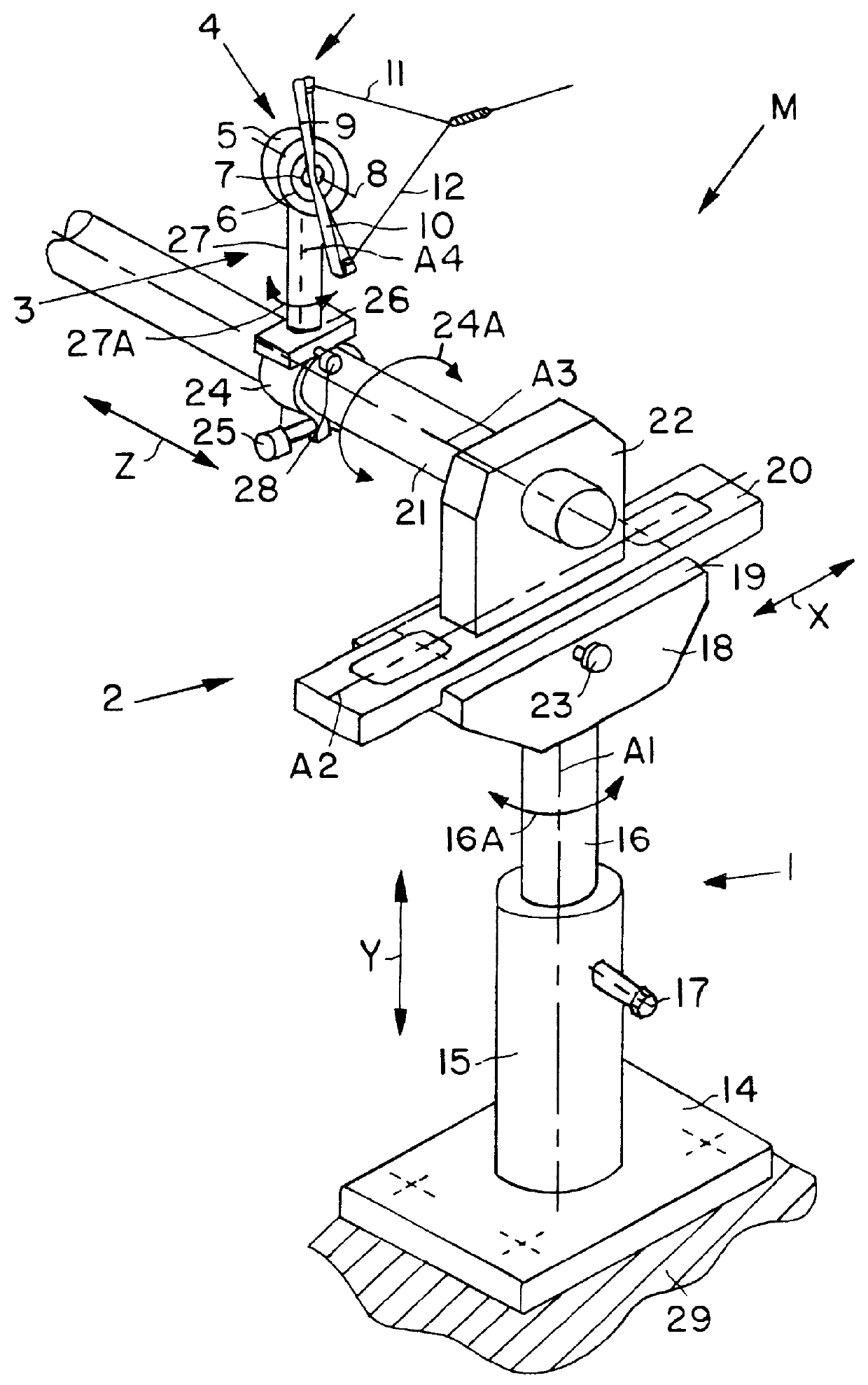

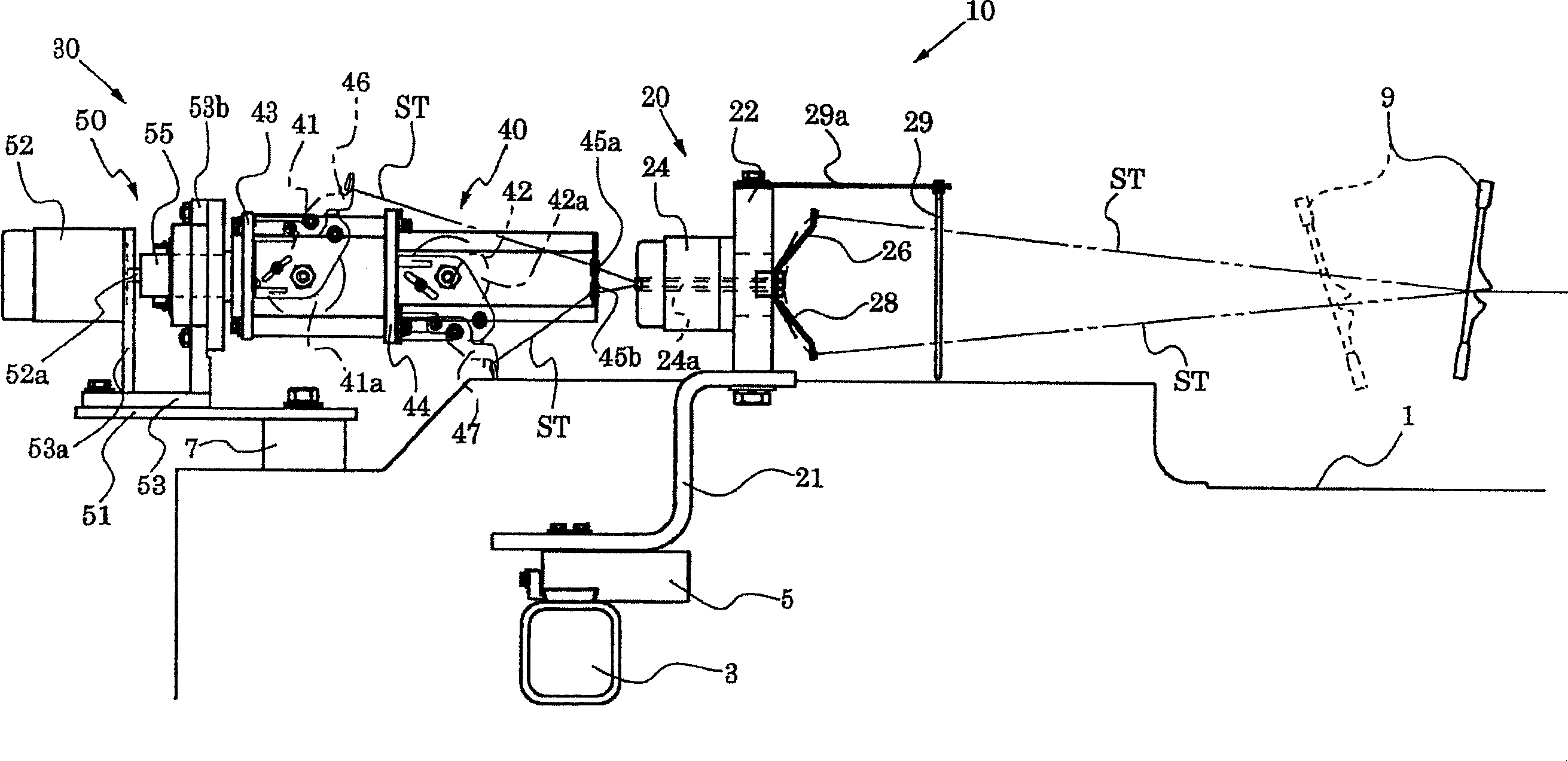

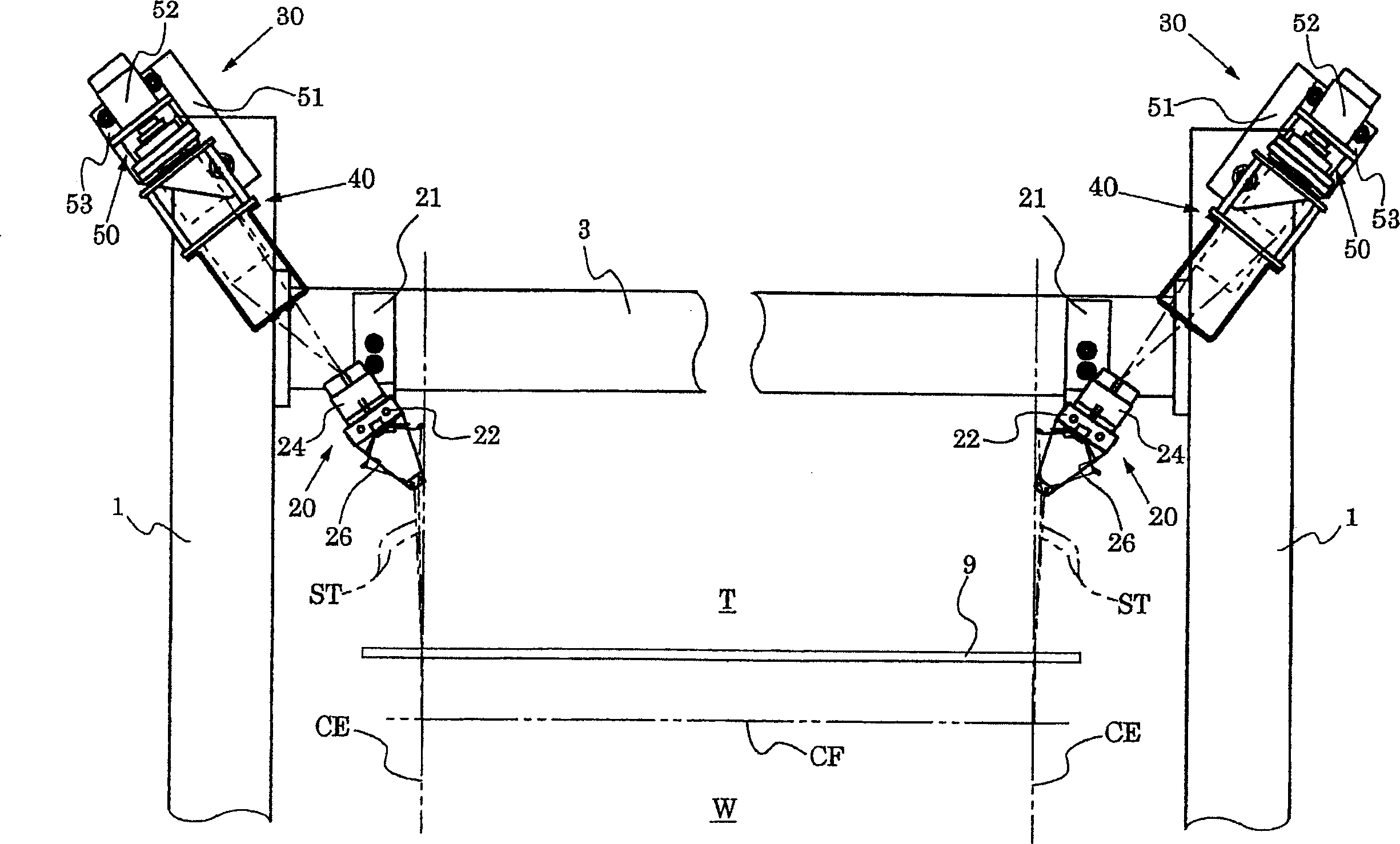

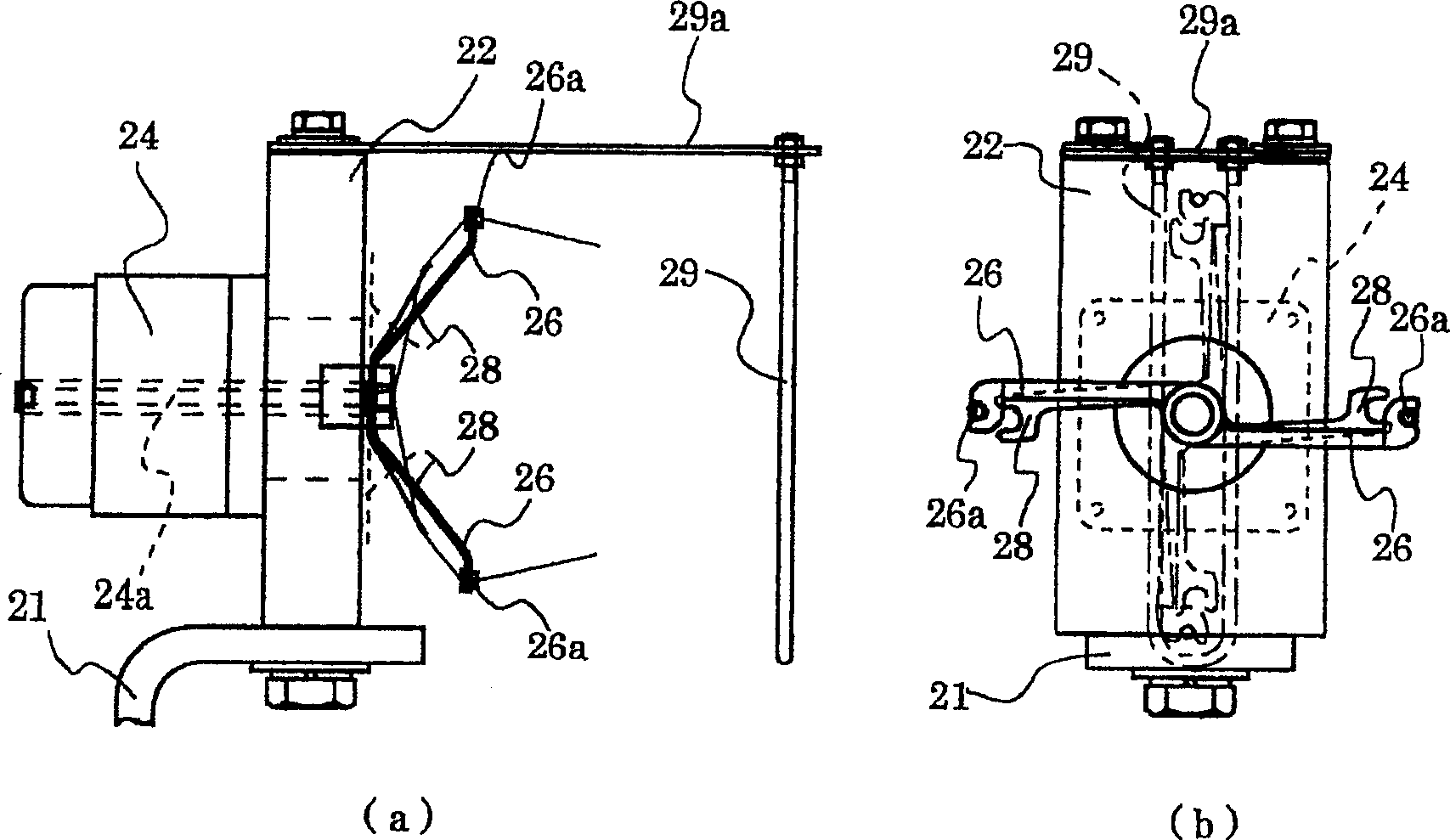

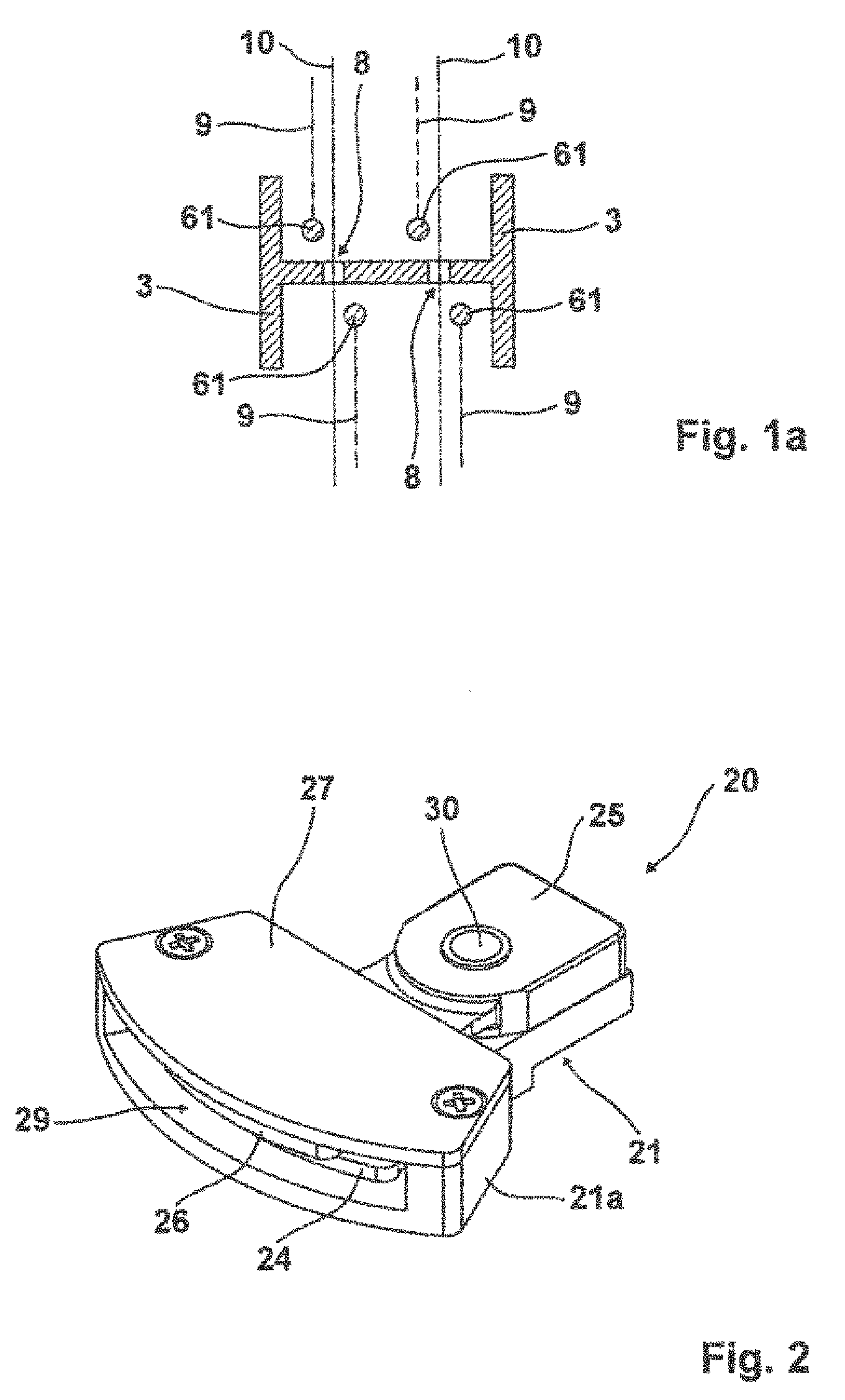

Mounting and positioning apparatus for a leno selvage former

A leno selvage former is supported by a mounting for position adjustments in the three directions of a three-dimensional rectangular coordinate system and preferably also for an angular position adjustment about at least one rotational axis. For this purpose the mounting has three sections. A first section carries a second section which carries a third section. The first section is, for example adjustable in the Y-direction, while the second section is adjustable in the X-direction and the third section is adjustable in the Z-direction of the rectangular coordinate system. At least one of the three sections is preferably also angularly adjustable. At least one lock such as a screw is provided for locking-in an adjusted position.

Owner:LINDAUER DORNIER GMBH

Belt for safety belt and mfg. method thereof

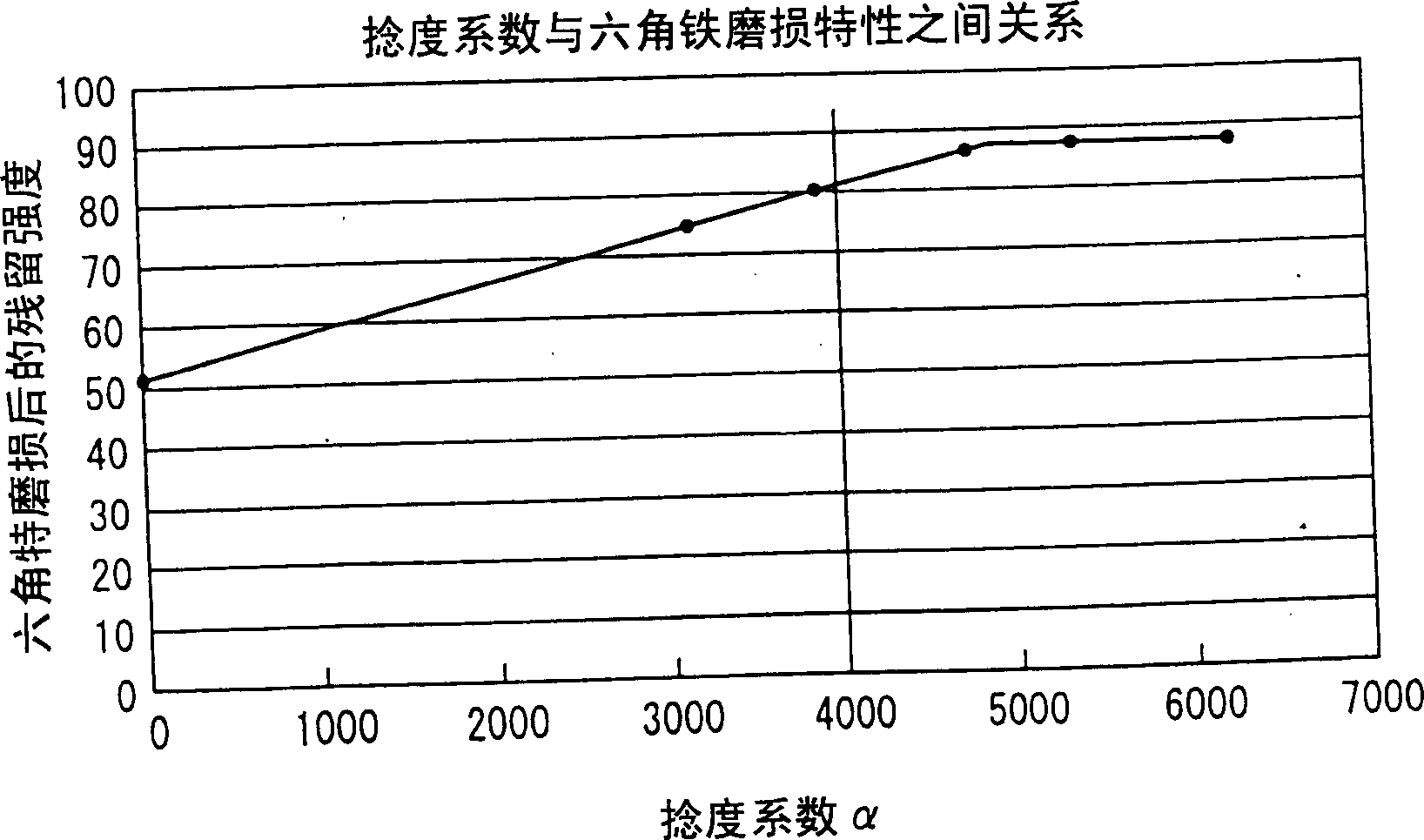

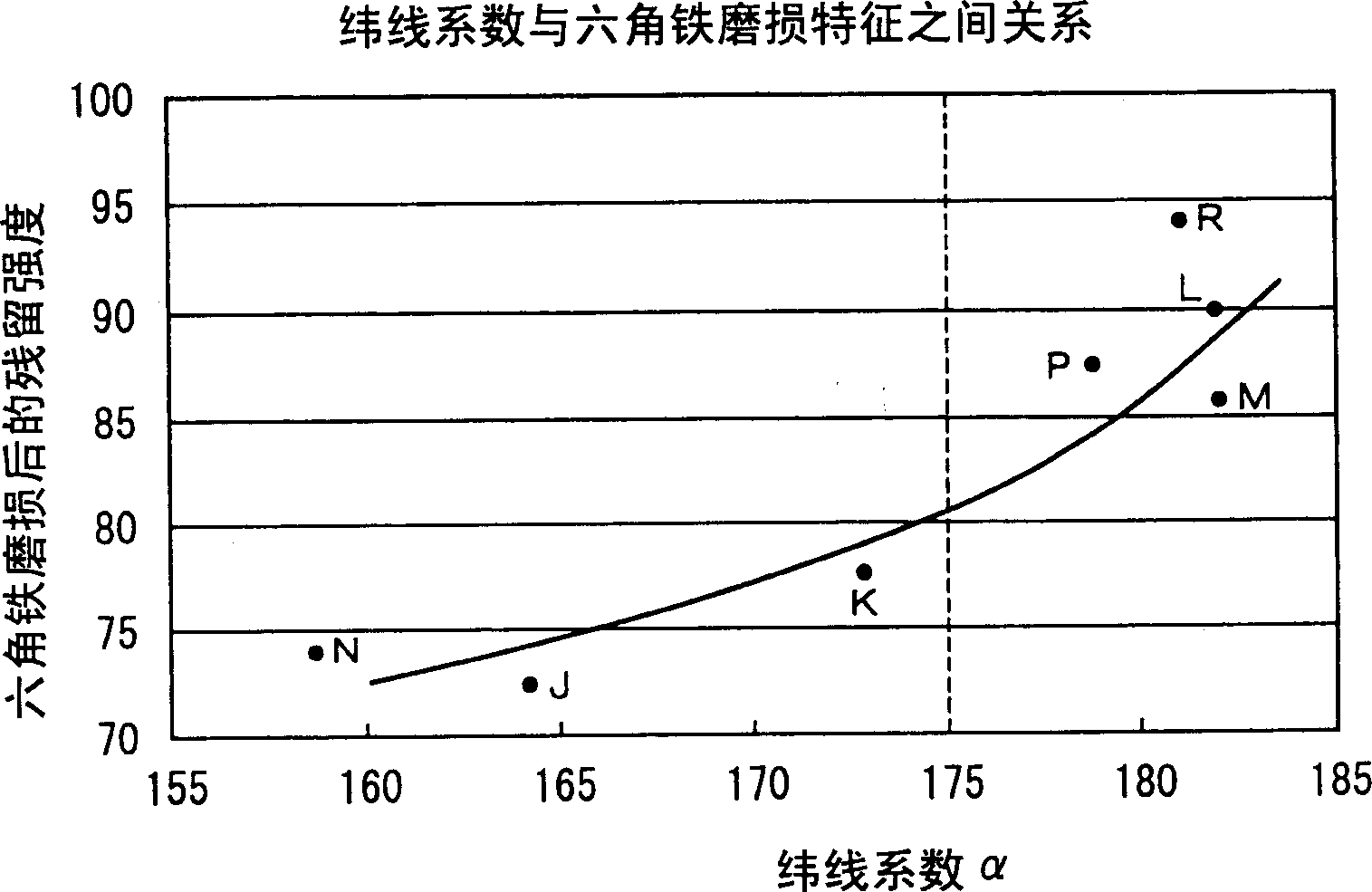

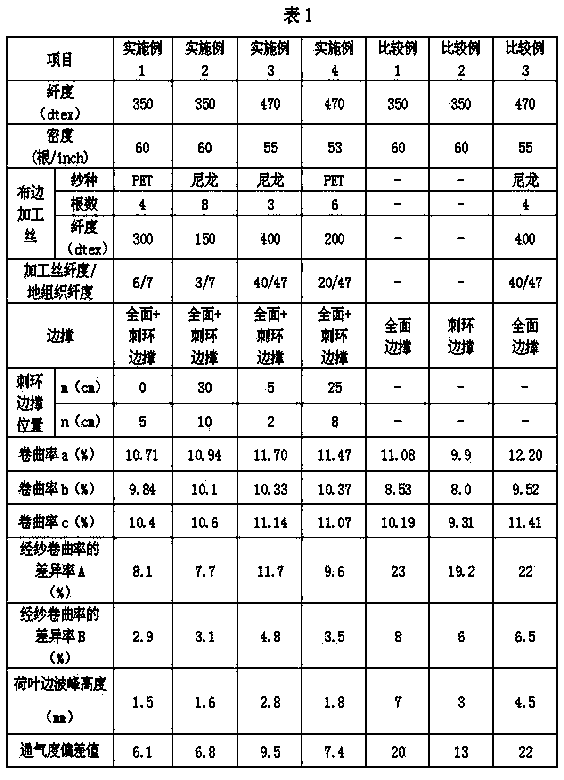

InactiveCN1427104ANo damage to abrasion resistanceHigh strengthWeft knittingSafety beltsPolyesterSingle fiber

In a thin and light webbing having a high strength per warp yarn unit, maintaining abrasion resistance, and using as a warp yarn a very strong polyester multifilament yarn for a seat belt made by fine single-yarn fibers, the warp yarn is obtained by performing a twisting process of a high degree of twist on a polyester multifilament yarn made of fine single-yarn fibers so as to be highly bound. The polyester multifilament yarn of fine single-fibers is woven at the maximum stretch ratio in a yarn making process to obtain very-strong polyester fiber for a seat belt. A multifilament yarn and / or a monofilament yarn of polyester is / are used as weft yarns. By making the weft yarns and warp yarns cross each other so as to be woven in a belt like configuration, a webbing having a very high strength per unit of warp yarns, using low-cost base yarns, and maintaining abrasion resistance is obtained.

Owner:KIKUCHI KOGYO

Fabric for safety air bag and production method of fabric

ActiveCN104278392ALow utilization efficiencyGood fixation effectPedestrian/occupant safety arrangementSelvedgesAirbag deploymentMechanical engineering

Owner:TORAY IND INC

Doup end tension regulating device for a selvedge former

Owner:GEBR KLOCKER

Making method of nine-striped car child seat safety woven belt

InactiveCN103088588AHigh strengthImprove wear resistanceFibre treatmentSelvedgesNon toxicityWear resistance

The invention relates to a making method of a nine-striped car child seat safety woven belt. The method mainly comprises the following steps: warping warps on a special device in a specific tension environment, respectively putting warped beams on a special weaving machine, weaving, and carrying out a dyeing and finishing operation on a special dyeing and finishing device under a specific technological condition to obtain the nine-striped car child seat safety woven belt. Compared with car child seat safety woven belts made in the prior art, the nine-striped car child seat safety woven belt made through adopting the making method has the advantages of high strength, good abrasion resistance, moderate elongation rate, high light resistance, non-toxicity, good flame resistance, good edge self-lock thread running resistance and the like, so the nine-striped car child seat safety woven belt provides a high safety guarantee for babies and children in motor vehicles.

Owner:SHANGHAI ACE WEBBING

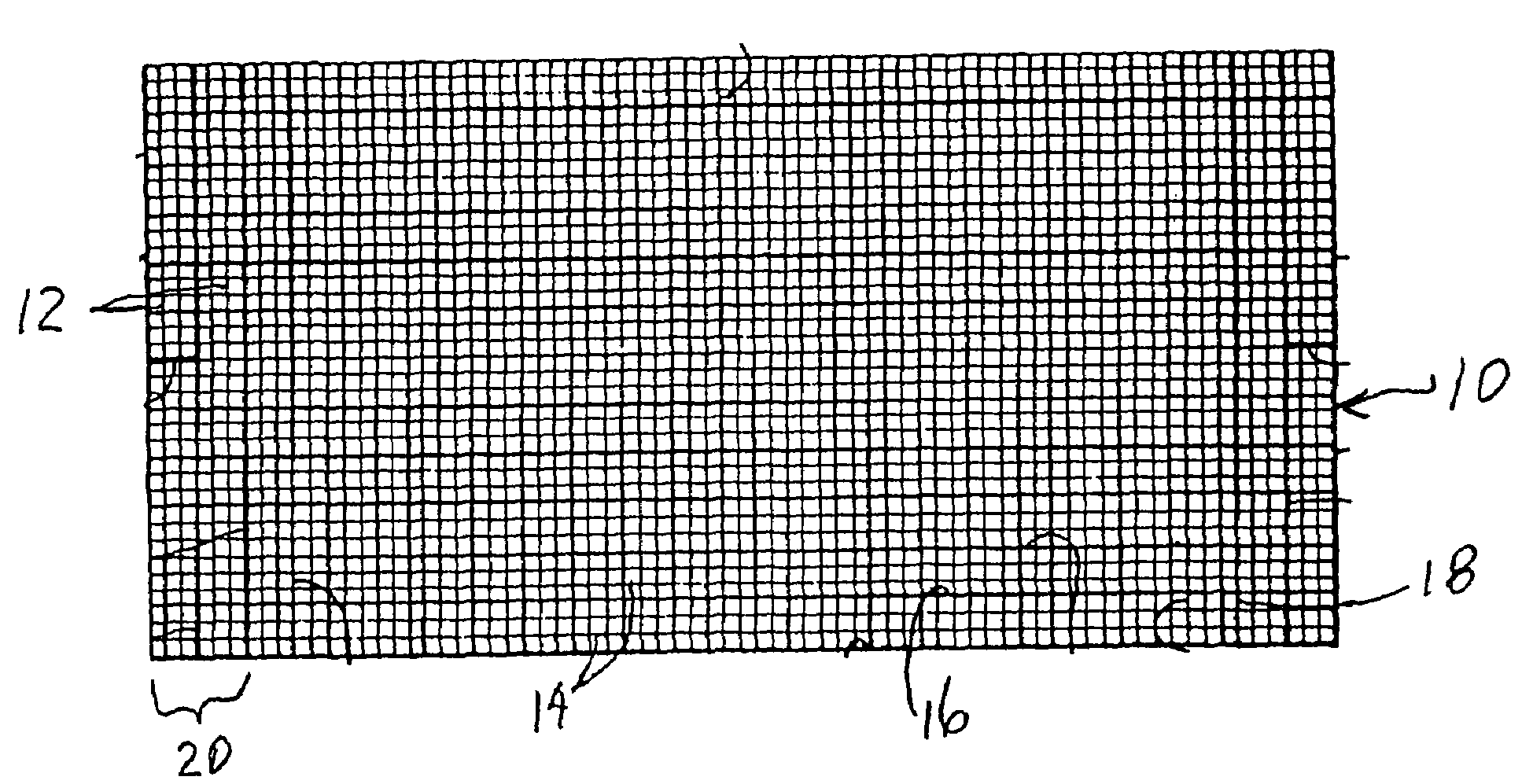

Fabric strap with soft side edges

InactiveUS20140174586A1Simple manufacturing processFacilitate industrial automationSelvedgesYarnDaily wear

The present invention relates to an integrally woven fabric strap having a soft edge on one or both longitudinal sides. The soft edge of the strap comprises spandex covered warp yarns which are thinner than the counterpart warps in the main body of the strap and also has a less dense weaving pattern for reducing weft exposure on the edge warp. Both these technical features contribute to the effect of softness and smoothness of the side edges. With the soft edge, the strap of this invention can find various applications in the underwear industry, as it causes no discomfort despite it is in close contact with the skin and has frequent movement causing frictions thereon during the course of daily wearing.

Owner:NEW HORIZON ELASTIC FABRIC

Woven towel

A woven towel includes a ground fabric having a set of warp yarns woven together with a set of weft yarns and a plurality of pile yarns interlaced with the ground fabric. The warp yarns and weft yarns are polyester vortex spun fibers or polyester air-jet spun yarns. The pile yarns are cotton spun yarns or cotton / polyester blended spun yarns. The warp yarns, the weft yarns and the pile yarns are woven together in a terry weave.

Owner:LINEN HLDG

Method, fabrics and machines for producing seamless bags and similar items

The invention relates to a method, fabrics and machines for producing seamless bags and similar items. The method is characterised in that a weaving loom is used to weave two independent stacked fabrics which are joined transversely at pre-determined distances by interlinking warp threads using weft threads. Simultaneously, independent bands with corresponding selvages along the longitudinal edges thereof are formed in the warp direction in the weaving loom and, subsequently, said bands are fully or partially punched in order to form the bag or similar item. According to the invention, the area between the transverse and longitudinal selvages of one the fabrics to be used includes connecting zones with floating warp threads and connecting zones with floating weft threads. The machine includes means for pulling, tightening and aligning the fabric and means for cutting same in a curved or angular transverse manner.

Owner:马科斯・瓜施・帕比尔

Method and system for creating and providing a multi-tier networked service

InactiveUS20090144759A1Special service provision for substationData processing applicationsApplication serverWeb service

A multi-tier application for interaction with a user interface, such as a browser on a PC or PDA. The application comprises a presentation tier (such as a web server with a JSP / servlet engine) and a business logic tier (such as an application server) to manipulate data for subsequent presentation on the user interface. A direction module has a plurality of coupled directions, including a function direction to direct a corresponding functional component to perform a data processing function using the business logic tier and provide a data processing output, and a presentation direction to direct a corresponding presentation component to incorporate the data processing output, when applicable, into a presentation template to produce a presentation element for the user interface. The function component and presentation component are independent and separate from each other, the connection being the function component produces the data and the presentation component consumes the output data. The presentation component is an abstract representation of a general kind of presentation element, each specific presentation element having its layout and format (such as markup language) stored in a different presentation template, and the reference to a specific presentation template for the presentation component can be determined at processing time in the presentation tier.

Owner:EMERGIS INC

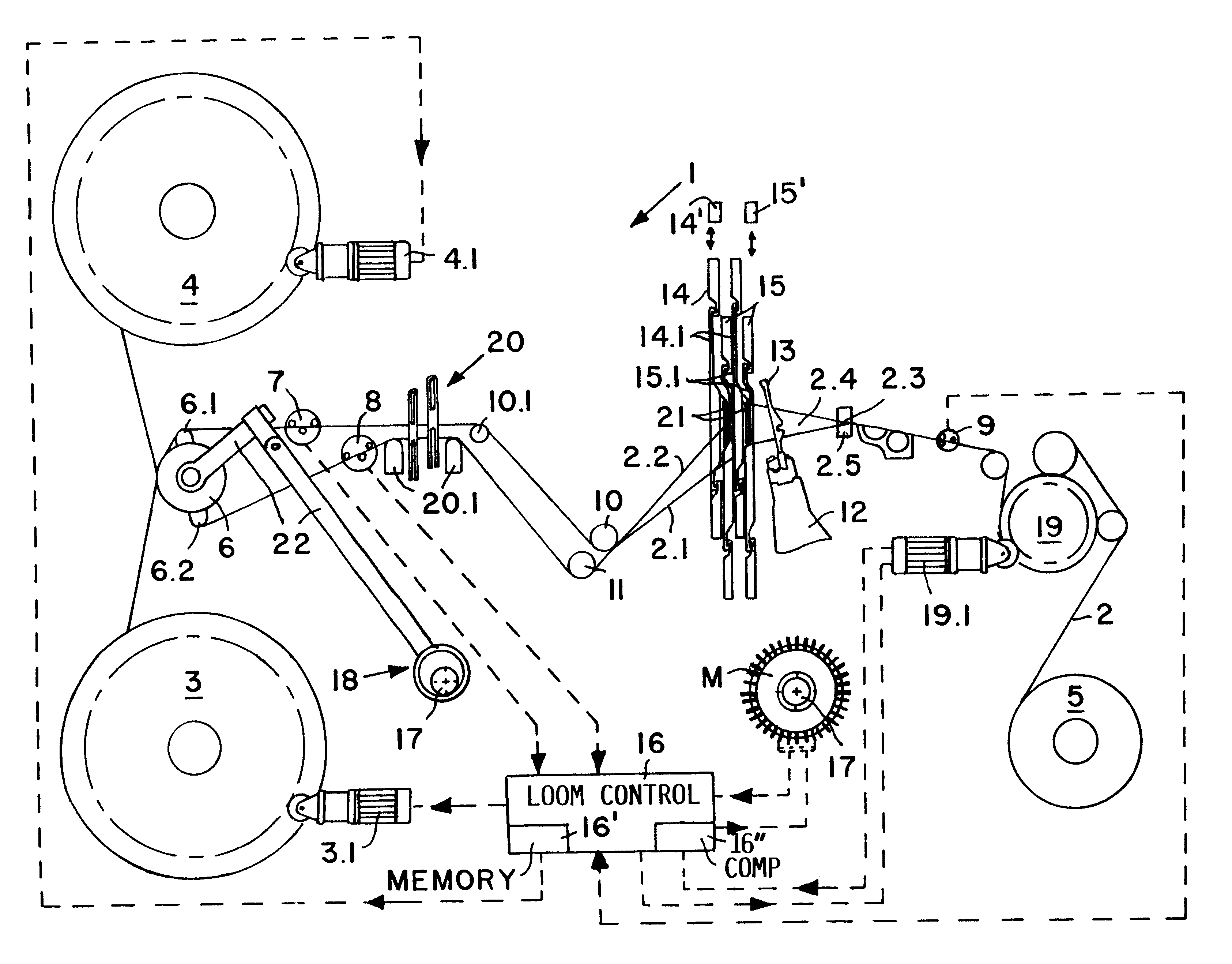

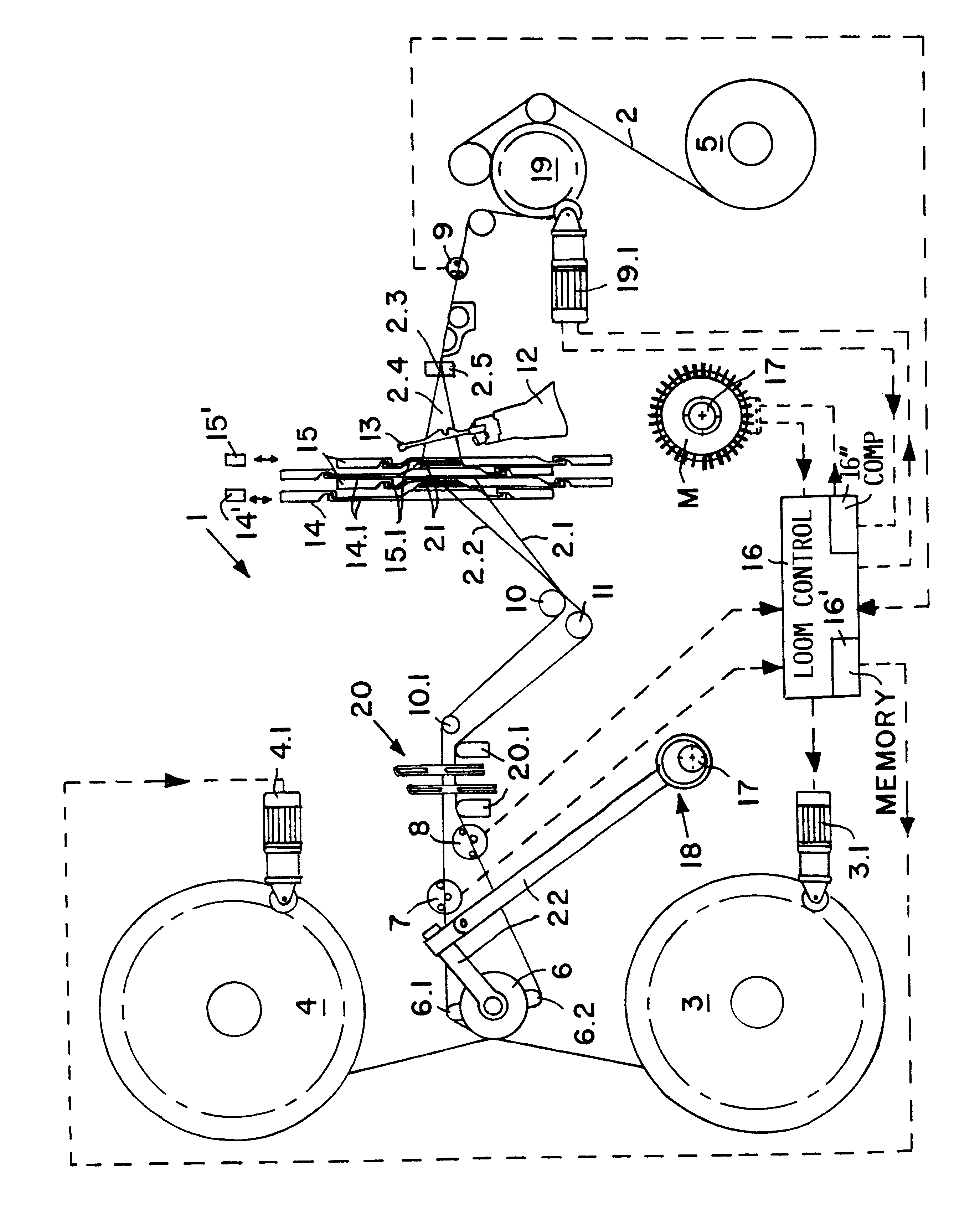

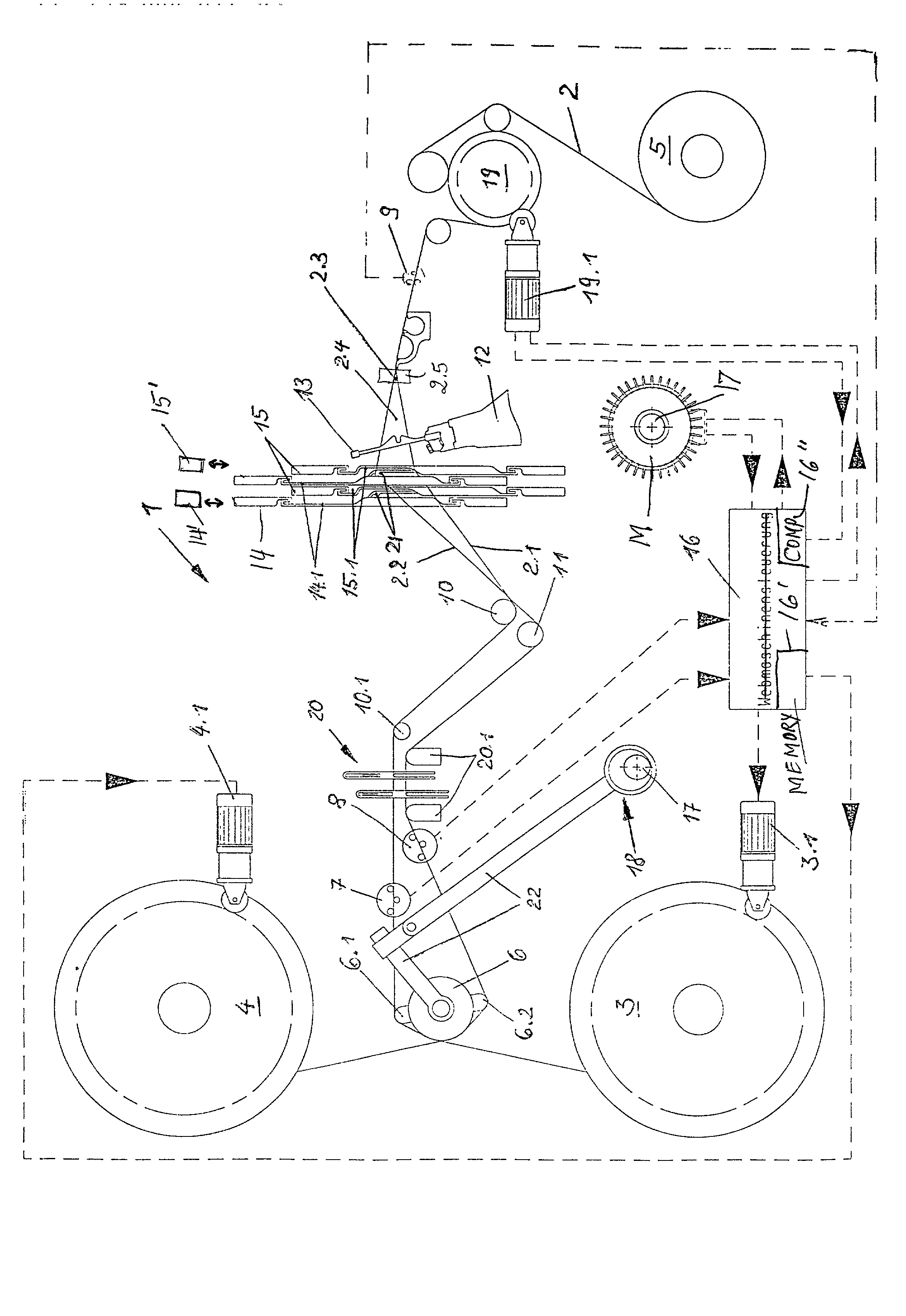

Method and apparatus for temporarily activating a brake in a weaving loom

The brake components of a clutch brake combination in an automatic high speed loom are periodically cleaned to avoid delays in the brake action that occur following a prolonged loom operation without a stopping. The stopping signal is either derived from randomly occurring events or criteria such as a weft breakage or similar criteria on the one hand, or when a criterium stored in the memory or program of the loom control occurs. The respective control signal is generated in response to whichever criterium occurs first.

Owner:LINDAUER DORNIER GMBH

Selvage device in loom

A selvage device in a loom has a rotary member provided with guides for guiding selvage yarns, and rotates the rotary member to move the selvage yarns in a shedding motion. The selvage device includes a selvage shedding mechanism having the rotary member and a designated driving motor that rotates the rotary member unidirectionally in an intermittent fashion; and a selvage feeding mechanism disposed upstream of the selvage shedding mechanism in a traveling direction of the selvage yarns. The selvage feeding mechanism includes a guide unit having a pair of guide portions for guiding the selvage yarns respectively fed from a pair of yarn feeders; and a rotating unit supporting the guide unit and rotated continuously in the same rotational direction as the rotary member. The guide portions revolve in response to the rotation of the rotating unit, such that sections of the selvage yarns extending from the yarn feeders to the corresponding guide portions revolve without intercrossing each other.

Owner:TSUDAKOMA KOGYO KK

Tissue with an insert edge and use of said tissue

The invention relates to a tissue, in particular a jeans tissue, comprising a basic tissue (140) and a tucked selvedge (135). The terminal sections (138) of the weft threads (137) are folded over at the edge (147) of the tissue and then resupplied into the tissue. The ends (139) of the terminal sections of the weft threads (138) can be dispersed over a zone a and become a visual bore. A field (144) having alphanumeric signs, logos or at least one colour is woven into the tucked selvedge (135). The field (144) serves for publicity purposes and renders the ends (139) of the terminal sections of the weft threads (138) largely or completely invisible by covering the ends (139) on the upper and inner side of the tissue according to weave technology or present the same colour as the warp threads (109 to 117) in the region of the field (144).

Owner:LINDAUER DORNIER GMBH

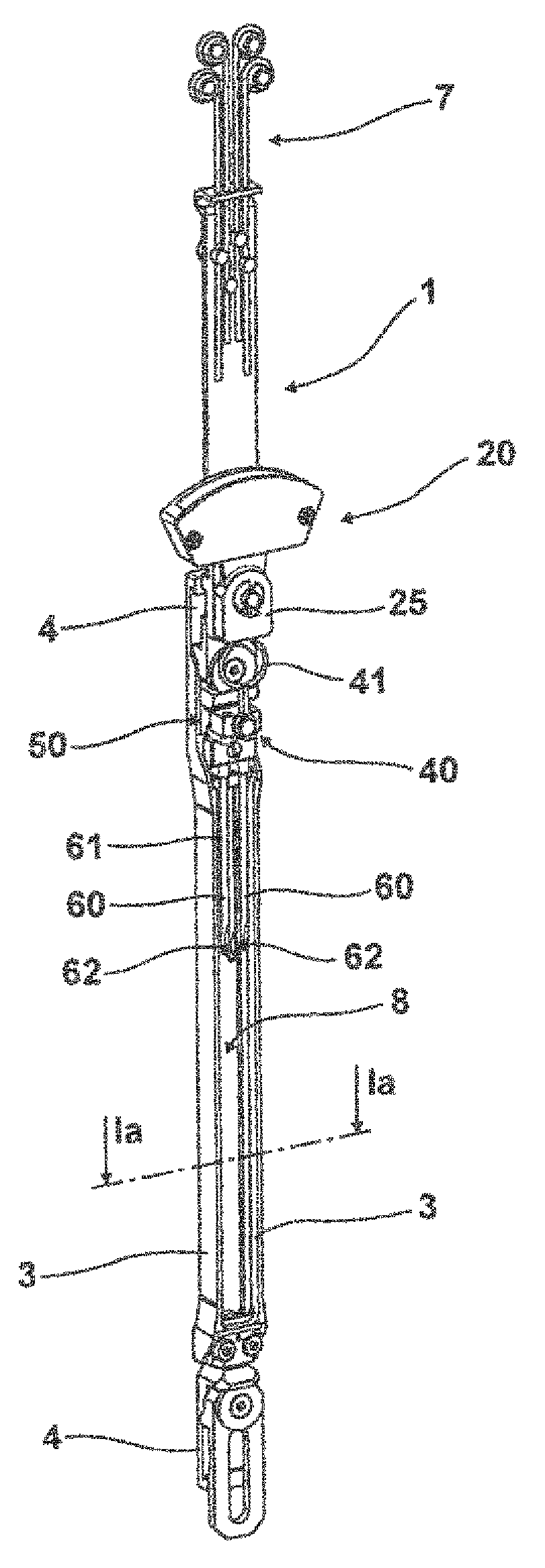

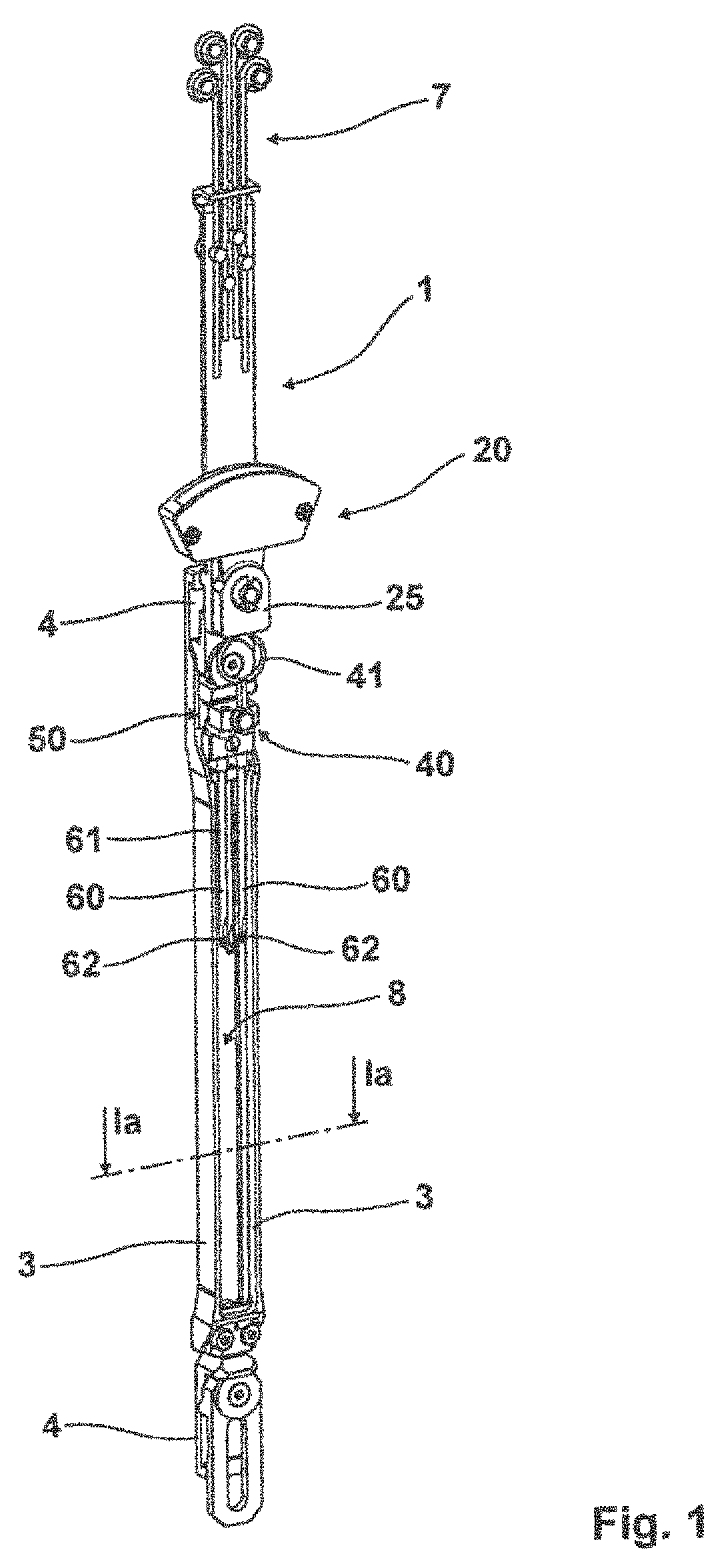

Selvedge-forming device with independent control and eccentric drive system

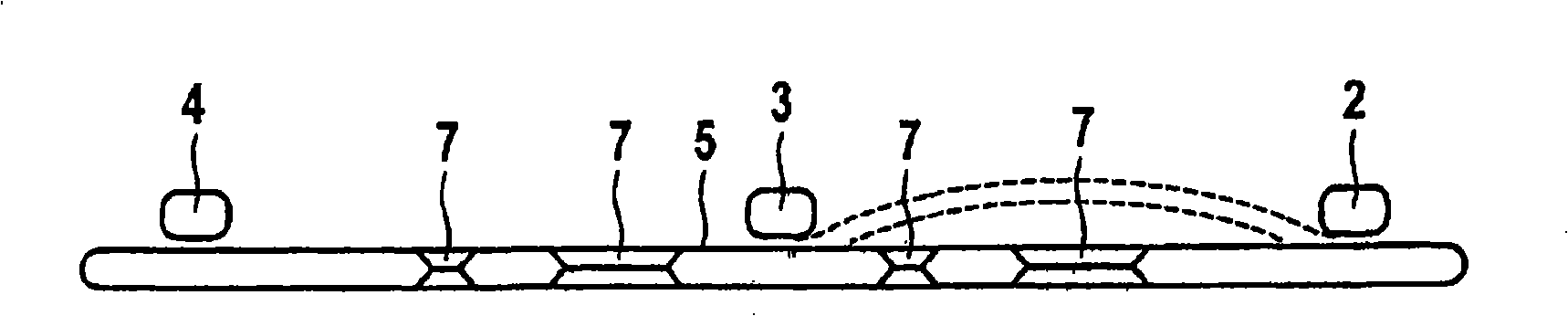

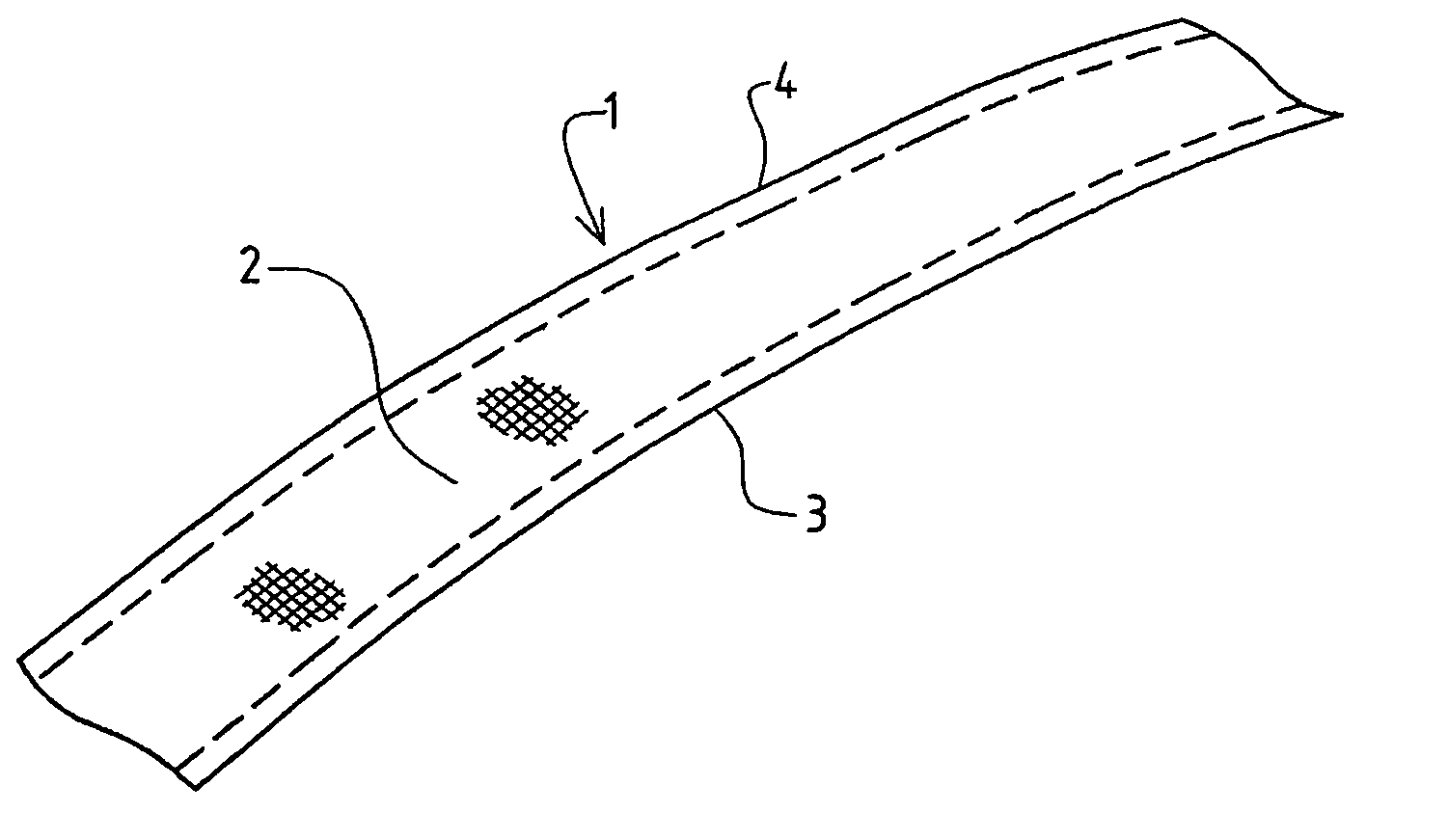

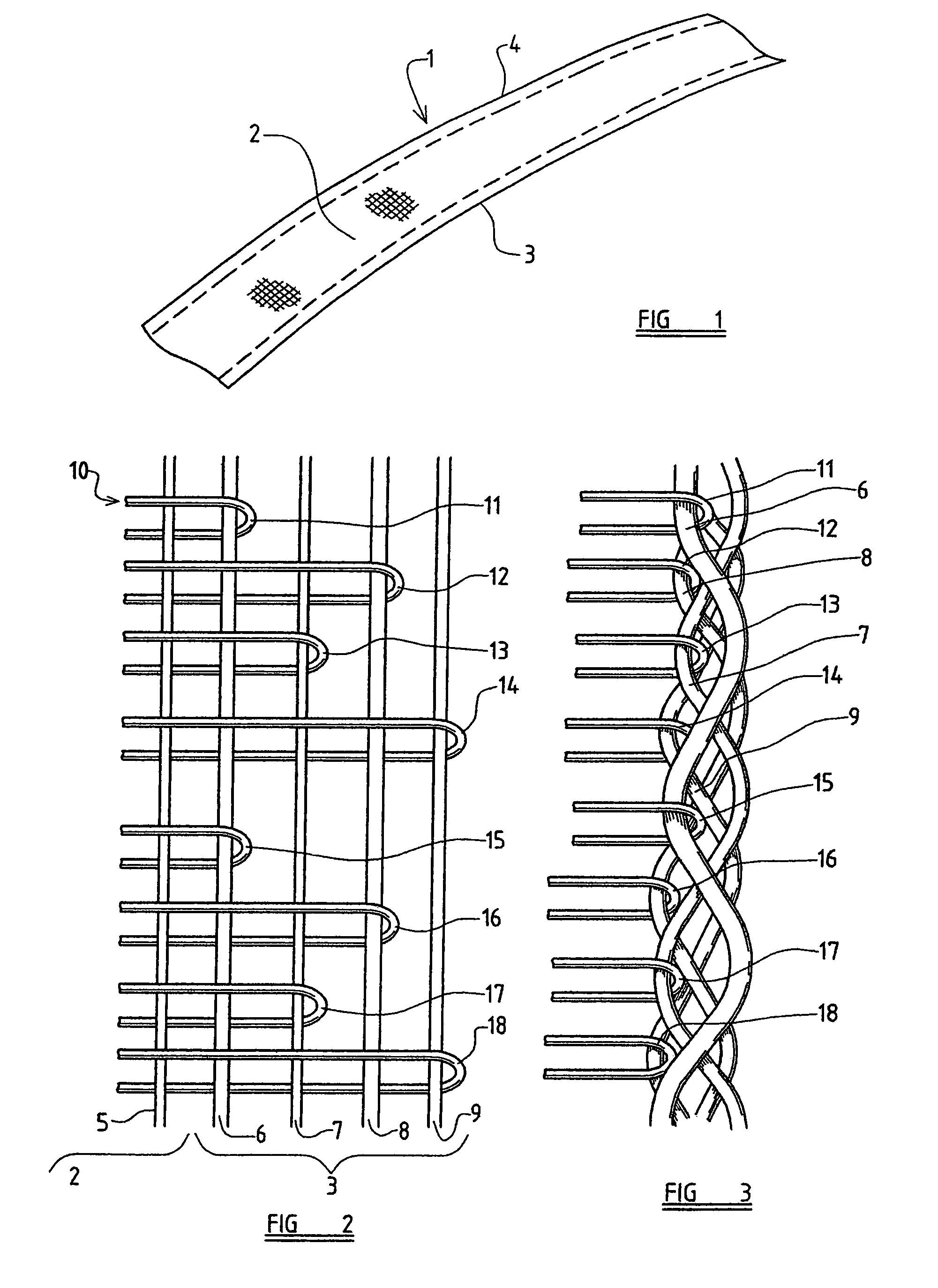

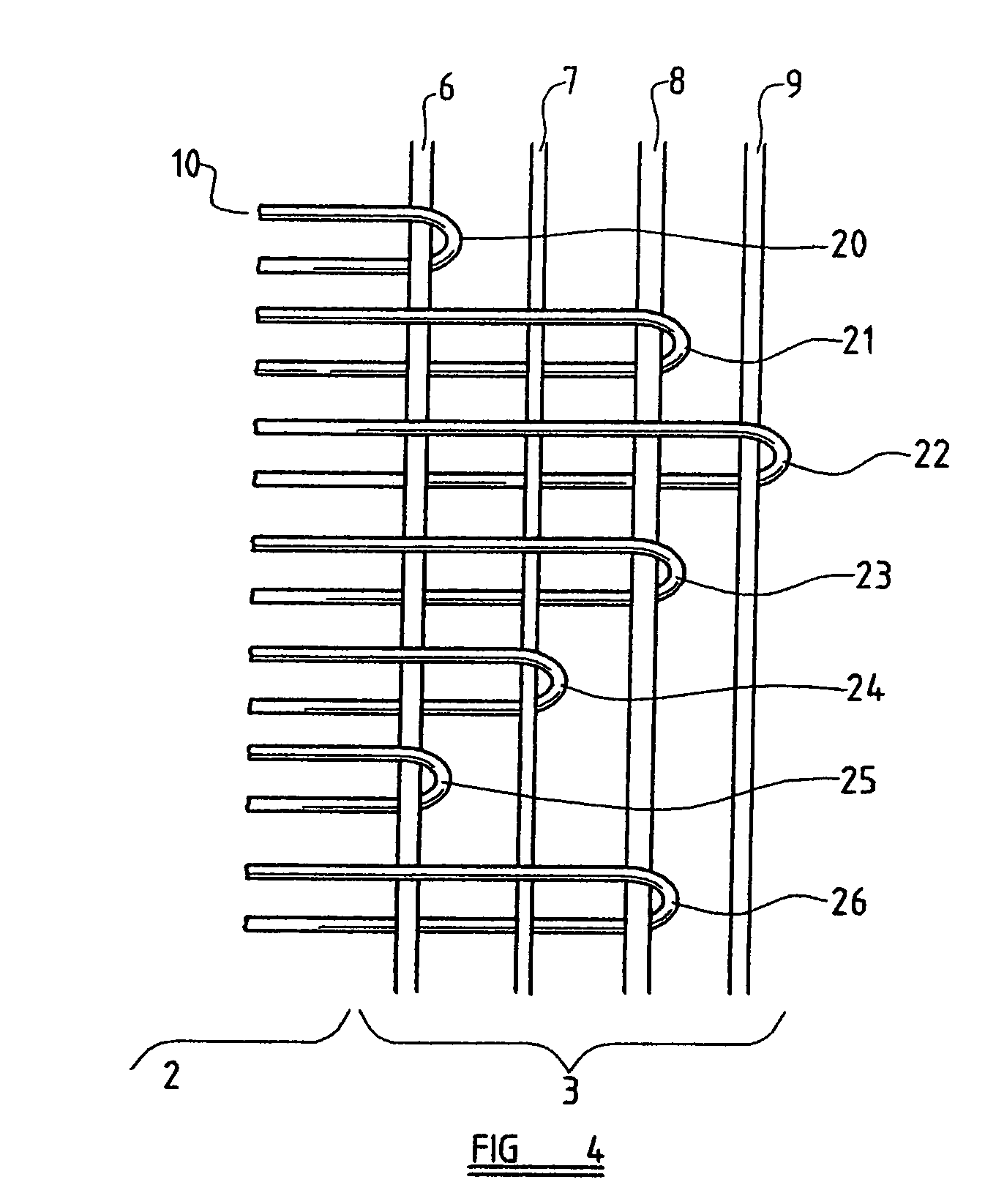

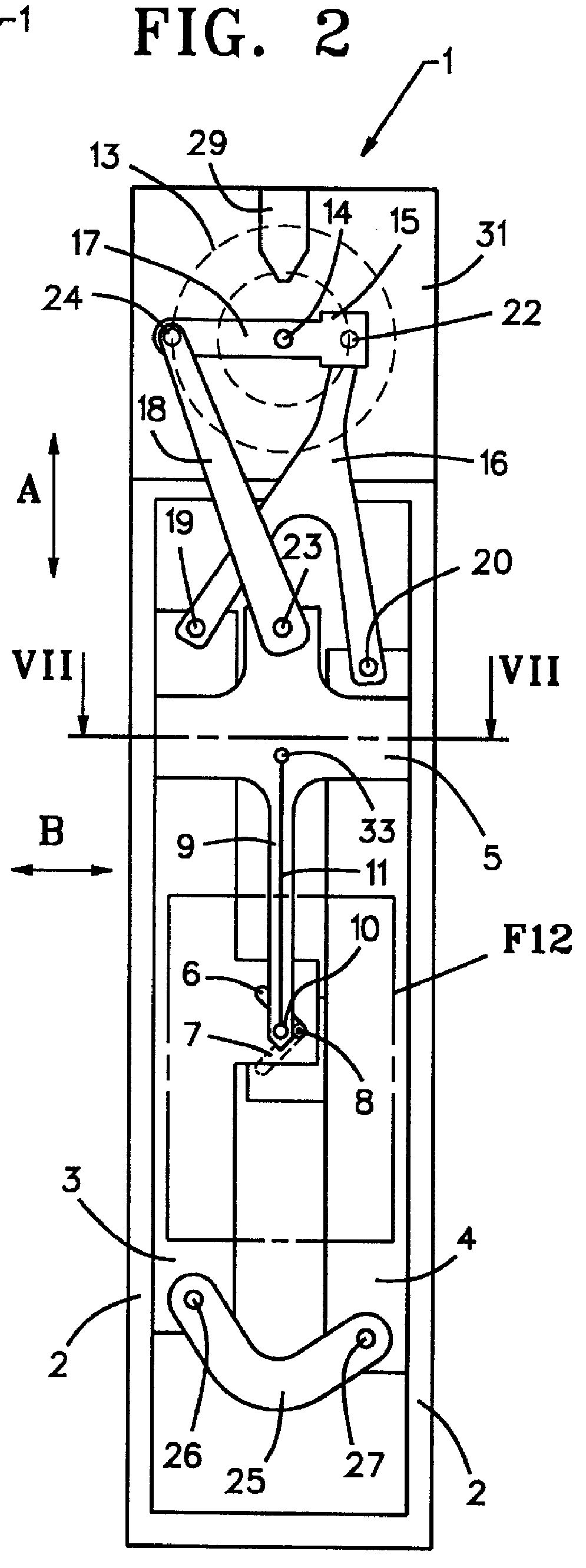

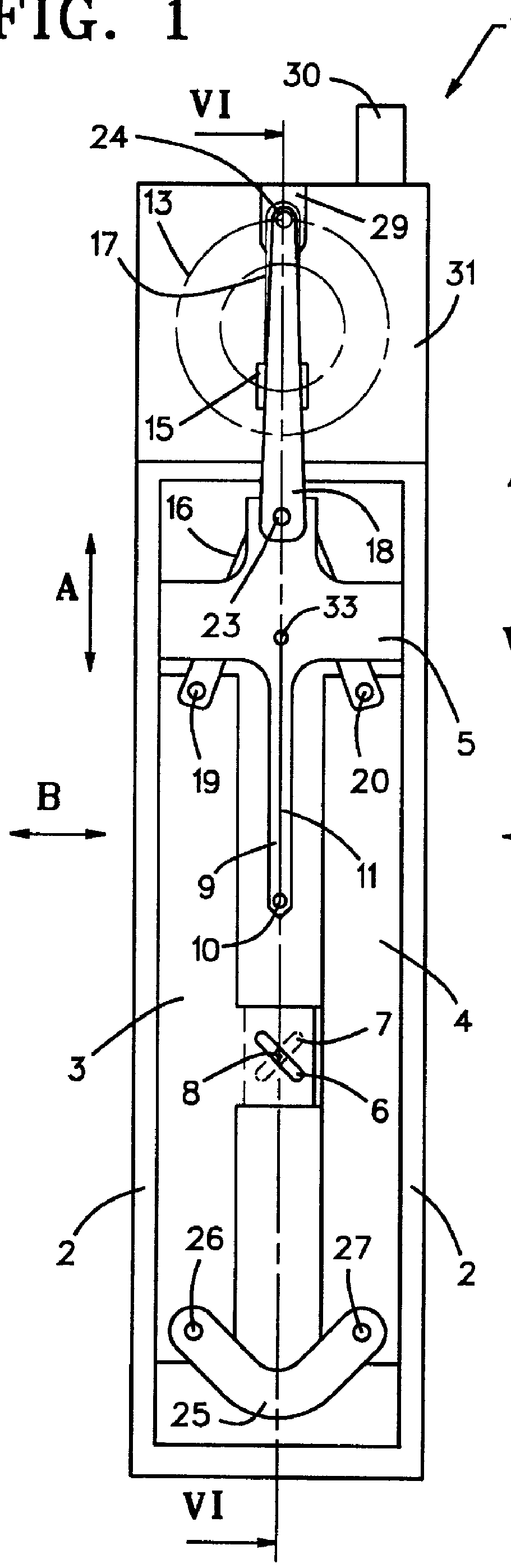

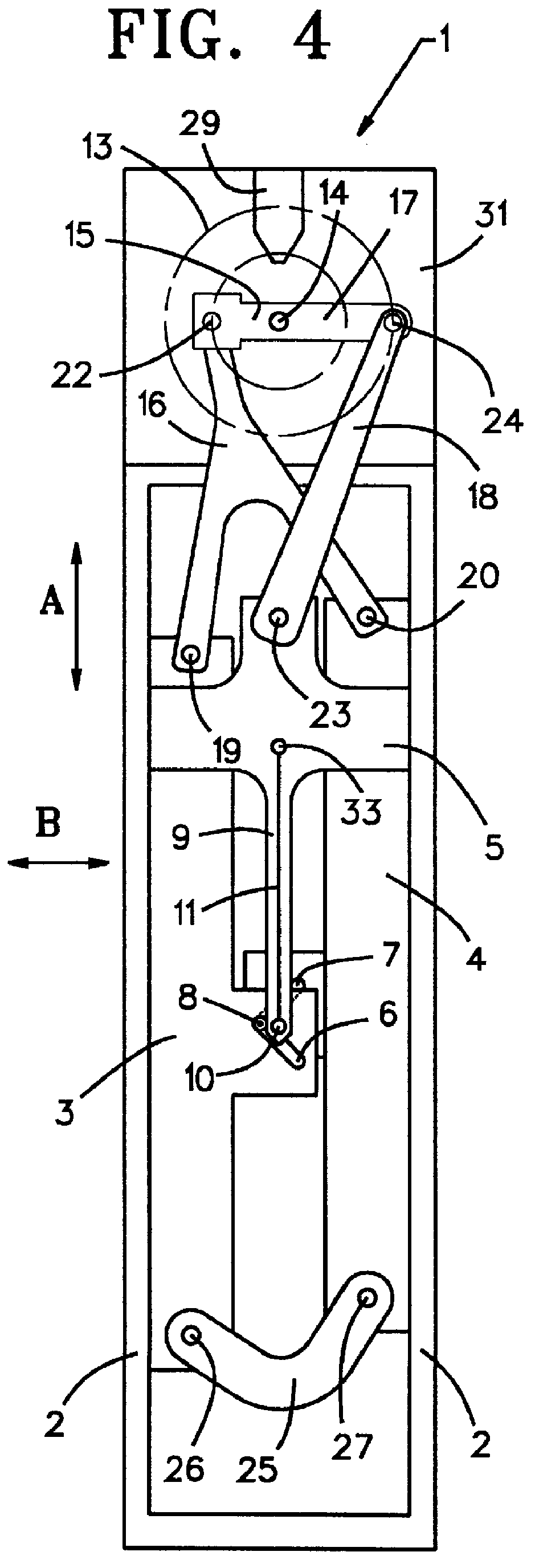

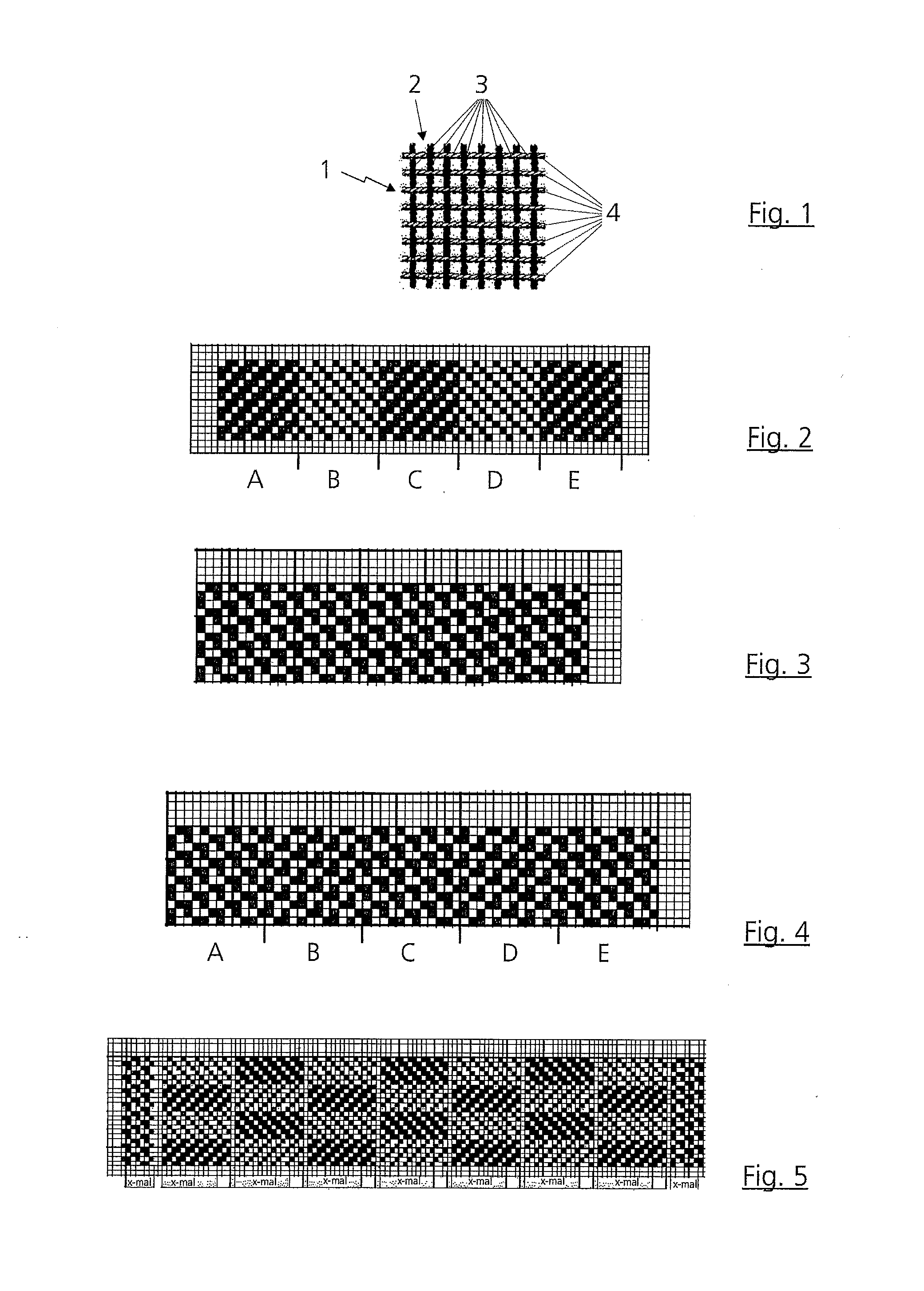

PCT No. PCT / EP97 / 00495 Sec. 371 Date Nov. 20, 1998 Sec. 102(e) Date Nov. 20, 1998 PCT Filed Feb. 4, 1997 PCT Pub. No. WO97 / 29232 PCT Pub. Date Aug. 14, 1997A selvage-forming device (1) for a loom includes yarn guide structures (2, 3, 5) to guide at least two selvage yarns (8, 11) that are alternating raised and lowered to form a selvage shed (12). These yarn guide structures are powered through the intermediary of eccentrics driven by their own independently controlled drive (13) and an eccentric drive coupling-bracket (16) that creates a motion by which one selvage yarn (8) is additionally shifted transversely to form mutually crossing interlacings.

Owner:PICANOL NV

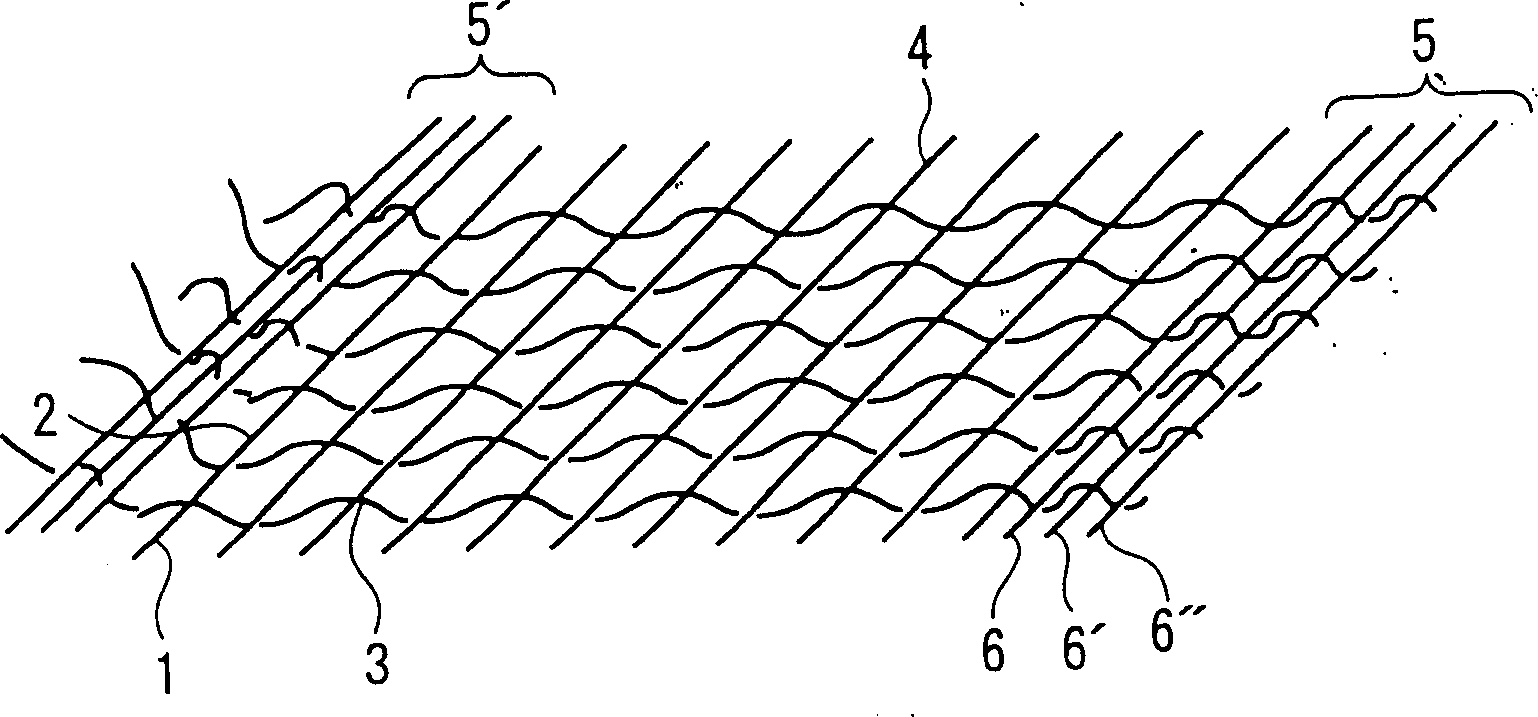

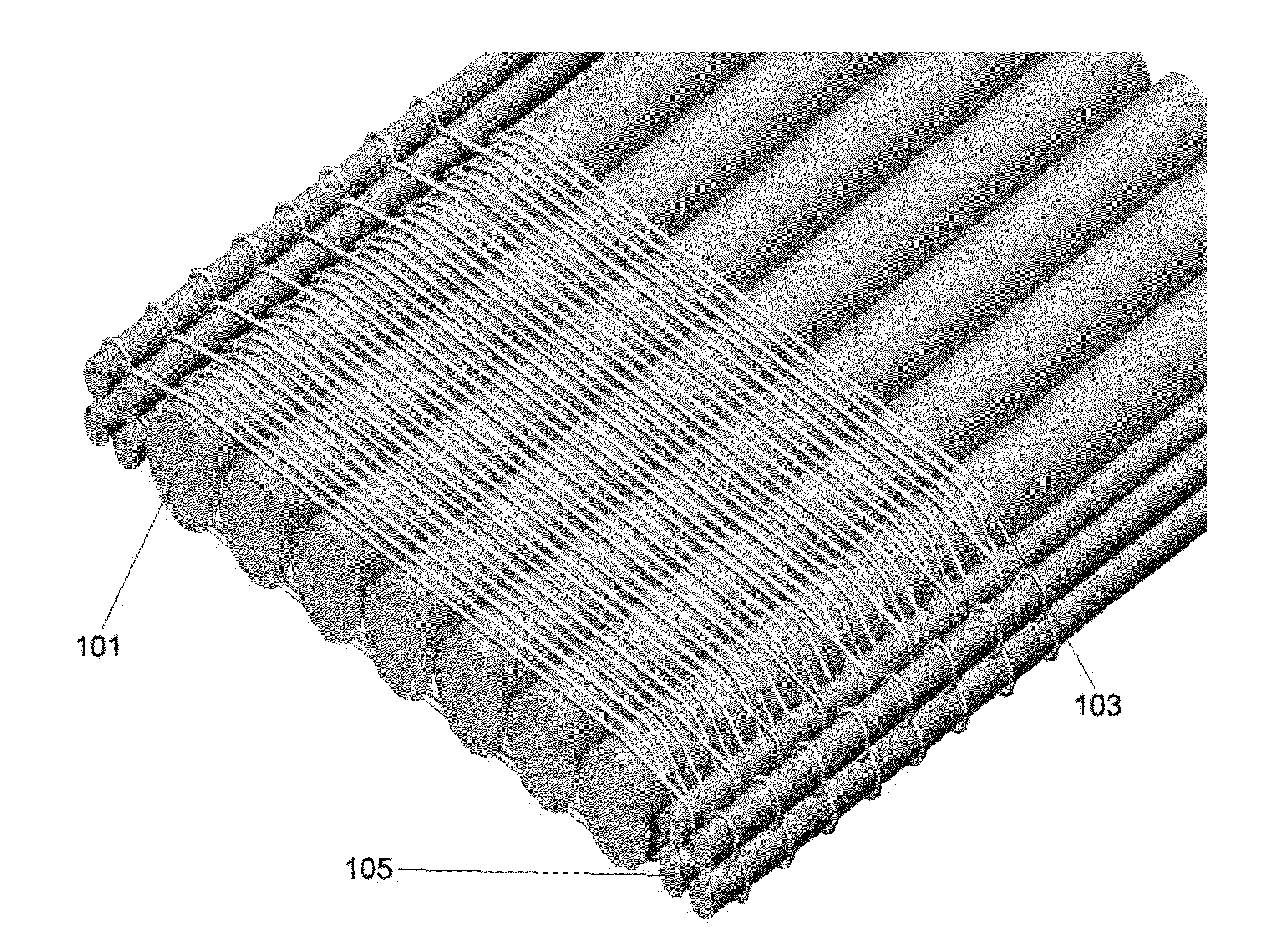

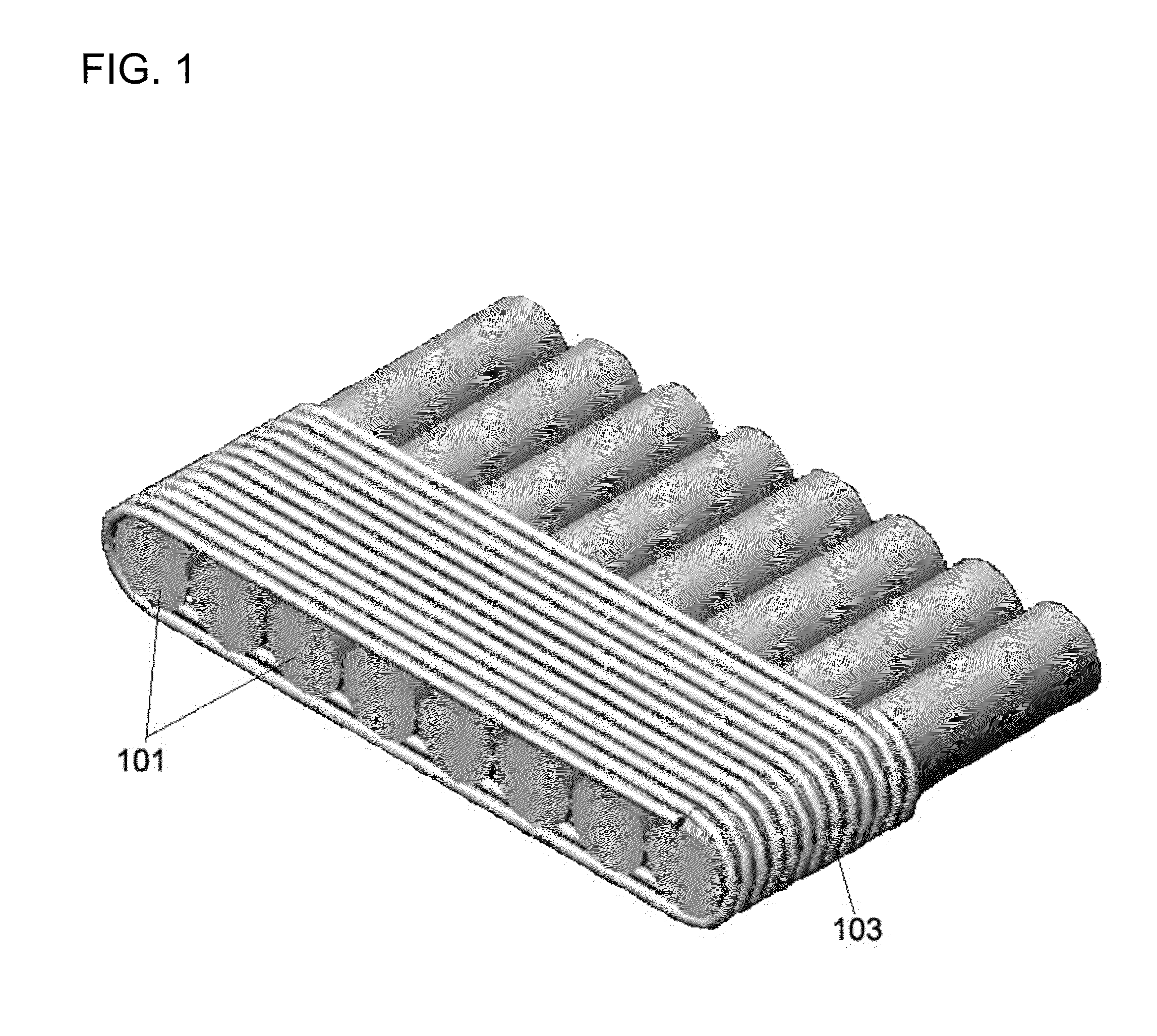

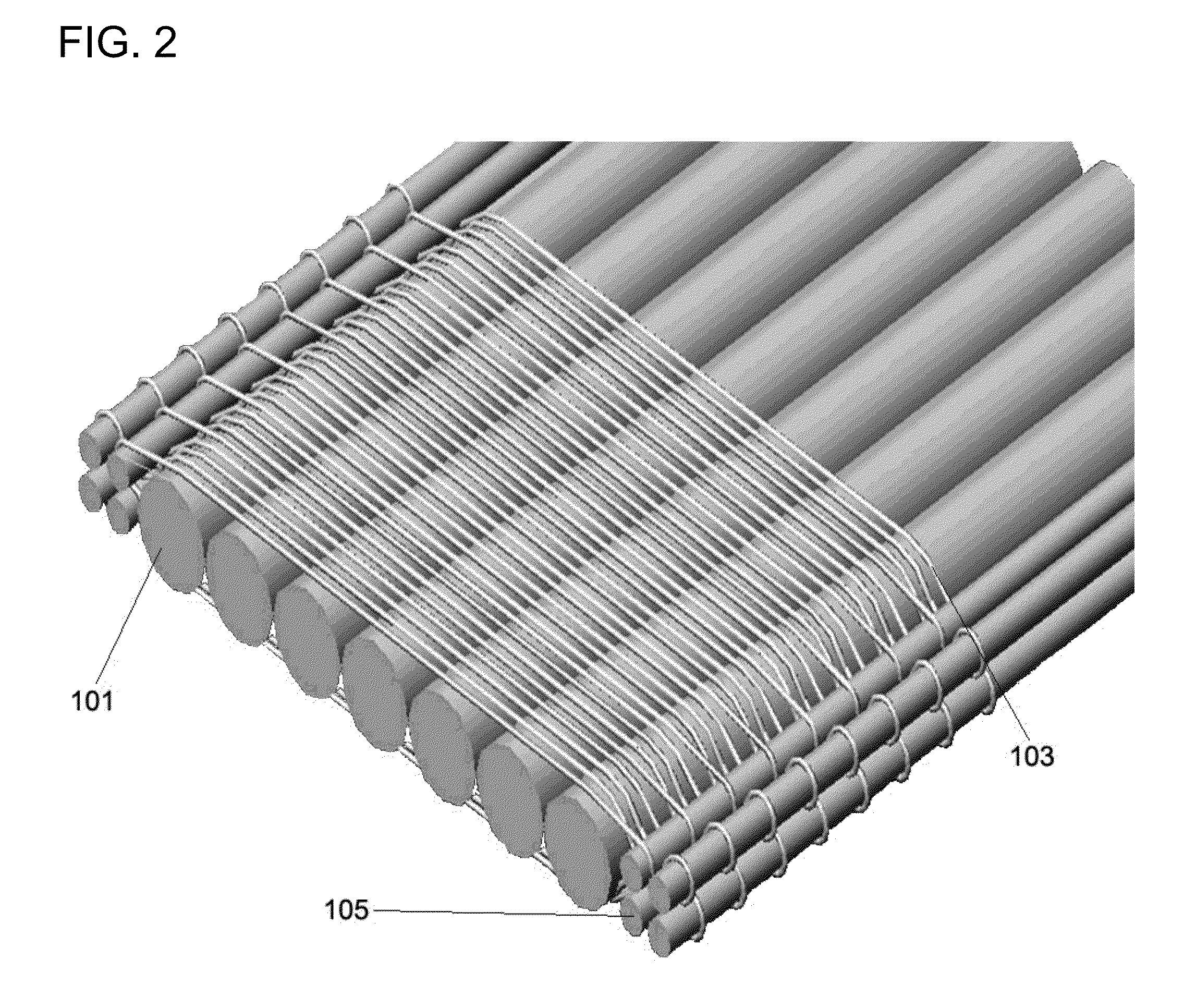

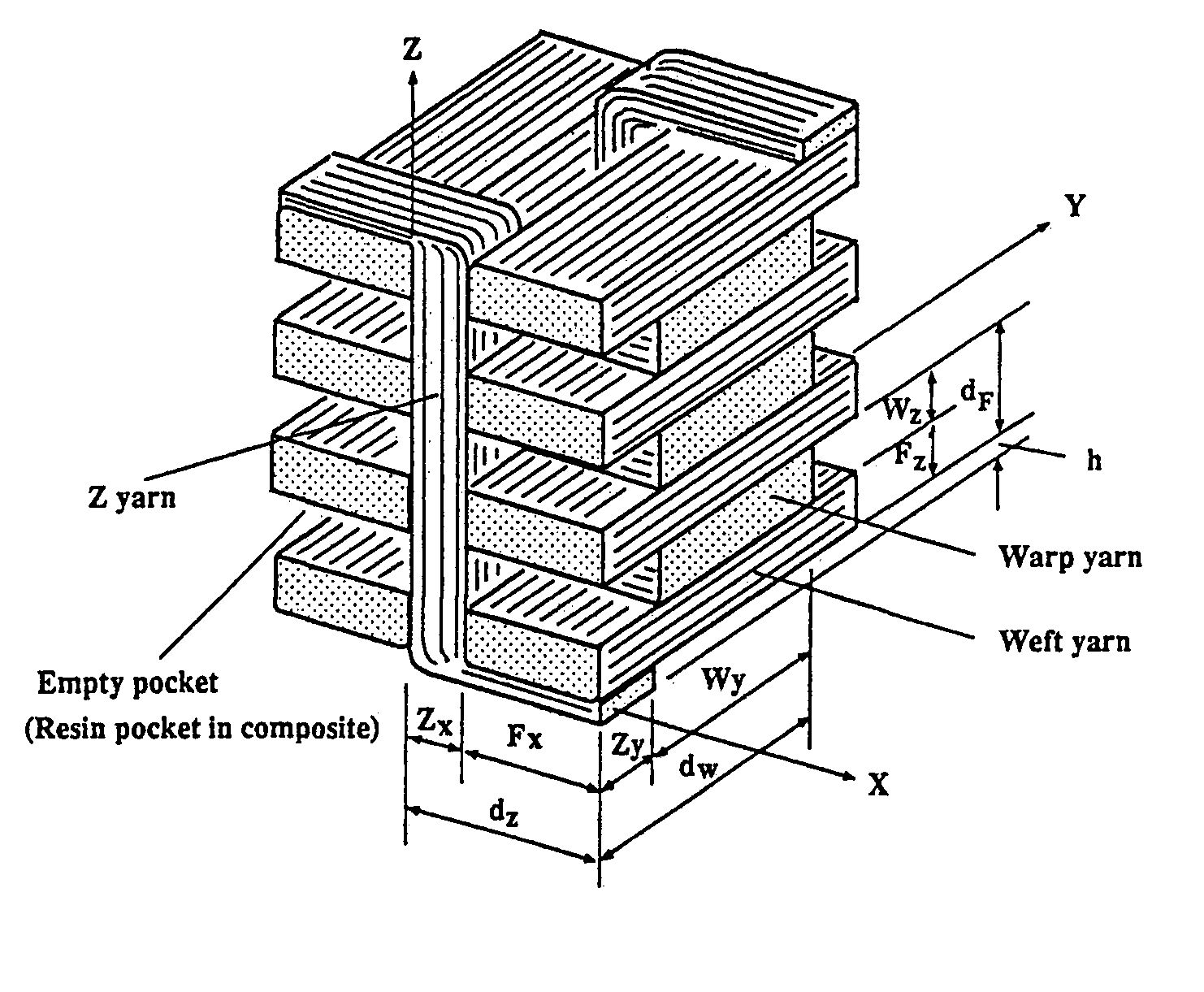

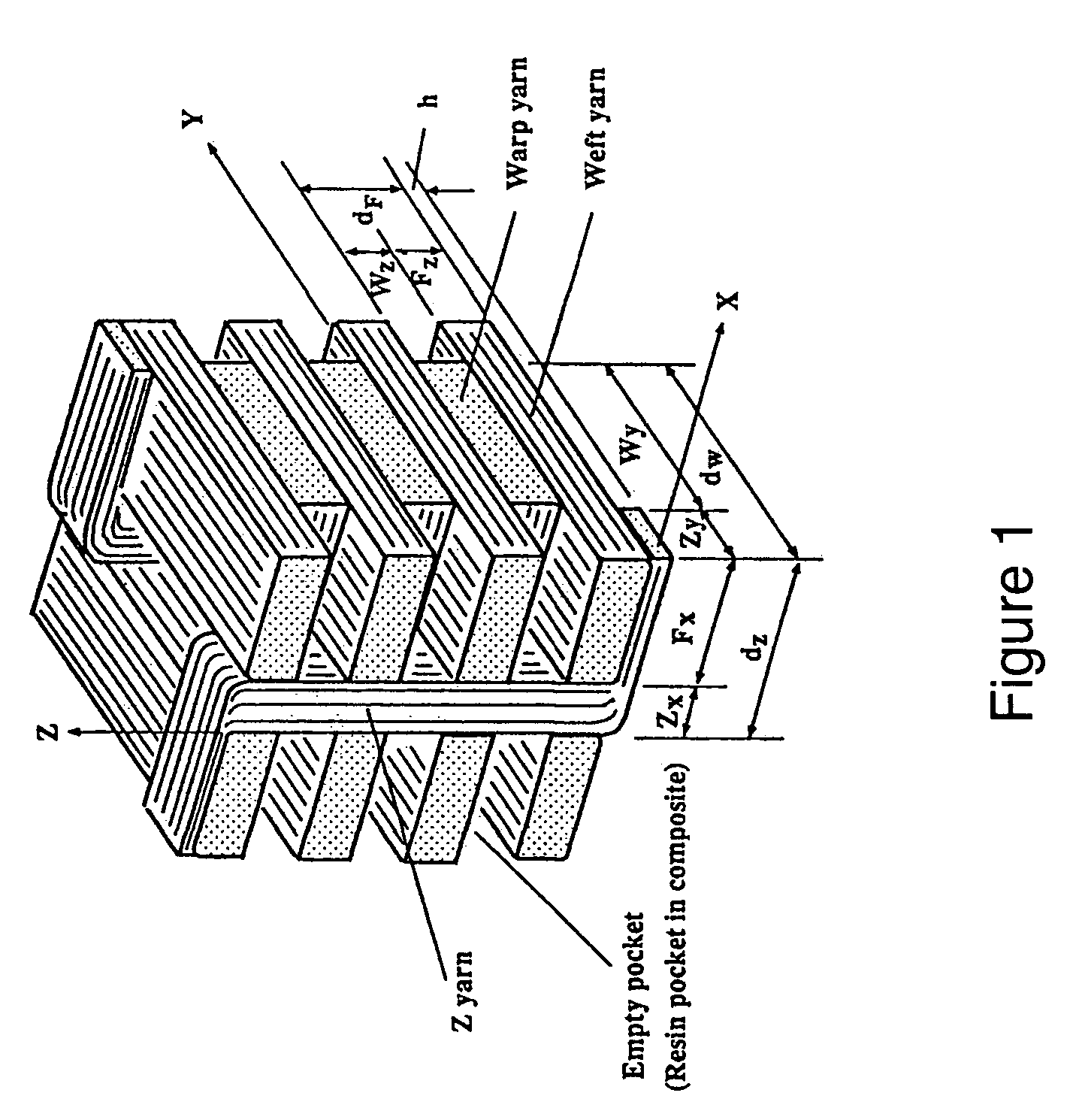

3-D woven fabric and methods for thick preforms

Fabric and methods of forming thick 3-D woven preforms wherein substantially orthogonal yarn systems are manipulated in each direction to provide predetermined thickness and cross-sectional shapes.

Owner:3TEX

Printing press cylinder flexible jacket covering

A flexible jacket covering for a printing press transfer cylinder having a low density selvage for attaching one edge of the jacket to a hook and loop attachment strip on the transfer cylinder. The covering is cut from fabric woven on a shuttleless loom. The fabric has a reduced density selvage formed by reducing the density of warp threads in the selvage is no more than the warp thread density in the body of the covering fabric and preferably to about half the warp thread density in the body of the fabric.

Owner:PRINTING RES

Seat-belt strap for a seat-belt system

ActiveUS20140232165A1Easy to useSafety beltsPedestrian/occupant safety arrangementSeat beltEngineering

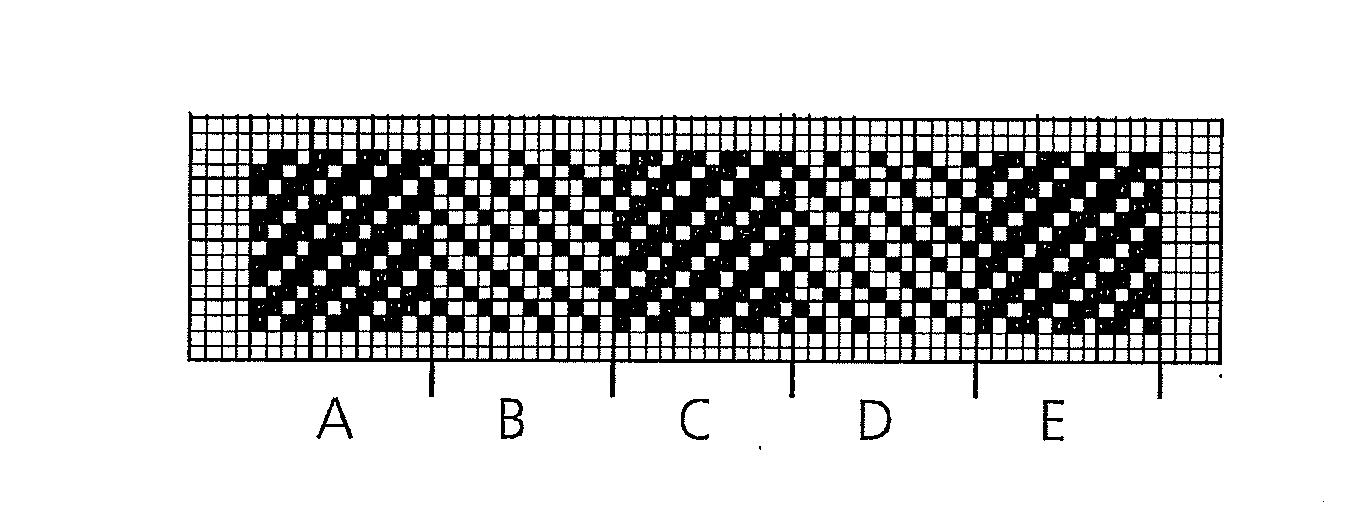

A seat-belt strap for a seat-belt system in a motor vehicle has a woven fabric consisting of warp threads and weft threads. The seat-belt strap is woven alternately with a 1 / 2 twill weave and a 2 / 1 twill weave across at least part of its width.

Owner:CARL STAHL GMBH & CO KG

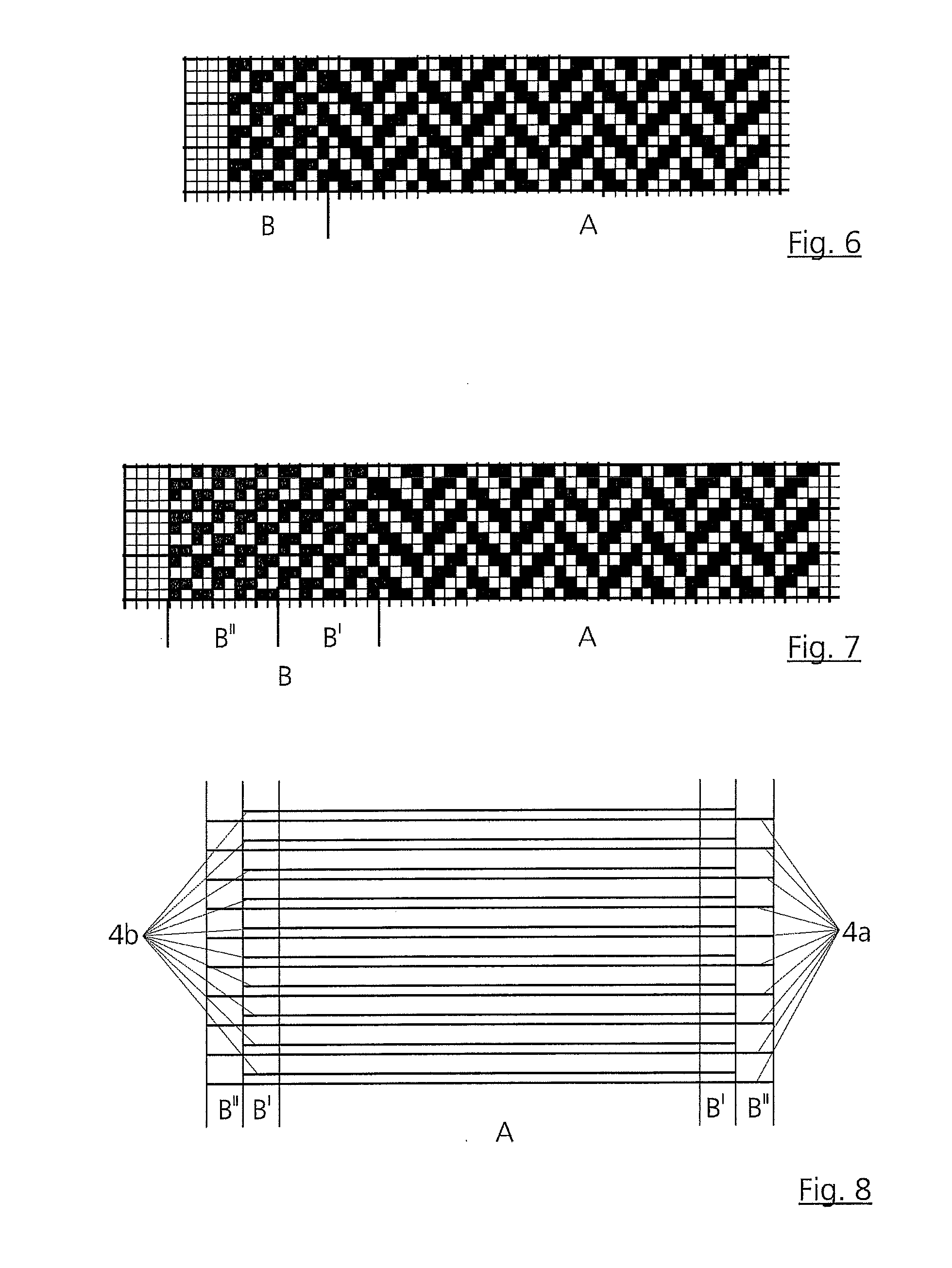

Power loom, particularly an air jet power loom, for the production of a leno fabric with integral patterning

A loom, especially an air jet loom for producing a leno cloth with integrated patterning includes a weaving reed and first and second shed forming devices. The first shed forming device includes a pivotable reed as a first guide arrangement for guiding and shedding leno warp threads, and an upright reed as a second guide arrangement for guiding and shedding ground warp threads, to form leno bindings. The second shed forming device includes a third guide arrangement for guiding and shedding patterning warp threads, to form pattern bindings. The third guide arrangement is arranged between the first shed forming device and the weaving reed.

Owner:LINDAUER DORNIER GMBH

Fabric construction capable of preventing selvedge curling

ActiveCN105063846AClever construction methodSimple construction methodSelvedgesEngineeringMultiple stress

The invention relates to a fabric construction capable of preventing selvedge curling. The fabric construction comprises a cloth body and selvedge arranged at the edges of the cloth body, and the cloth body comprises at least a first cloth body weave. The selvedge is provided with multiple stress transition areas which are sequentially connected; each stress transition area comprises at least one stress transition unit, and all the stress transition units in the stress transition area with the stress transition units are repeatedly arranged, each stress transition unit is provided with multiple selvedge weaves of which the curling stress balance degree is different and at least one selvedge weave curled in the same direction as the first cloth body weaves, and all the selvedge weaves are distributed according to the width law. According to the fabric construction capable of preventing selvedge curling, the stress transition areas of the selvedge are designed from the cloth body to the selvedge to form a curling stress gradual releasing area, the curling stress of the cloth body can be effectively guided to be released gradually, edge curling of a fabric can be prevented from being brought at the junction of the cloth body and the selvedge due to sudden changes of the weaves, and therefore fabric selvedge curling can be significantly improved or eliminated to enable the selvedge to be flat.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Device to form a leno selvedge

Owner:GEBR KLOCKER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com