Fabric construction capable of preventing selvedge curling

A technology for hemming and fabrics, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of increased processing costs, forced shutdown of machines, damage to machinery and equipment, etc., to reduce the cost of quality loss and solve the problem of hemming , Eliminate the effect of fabric curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

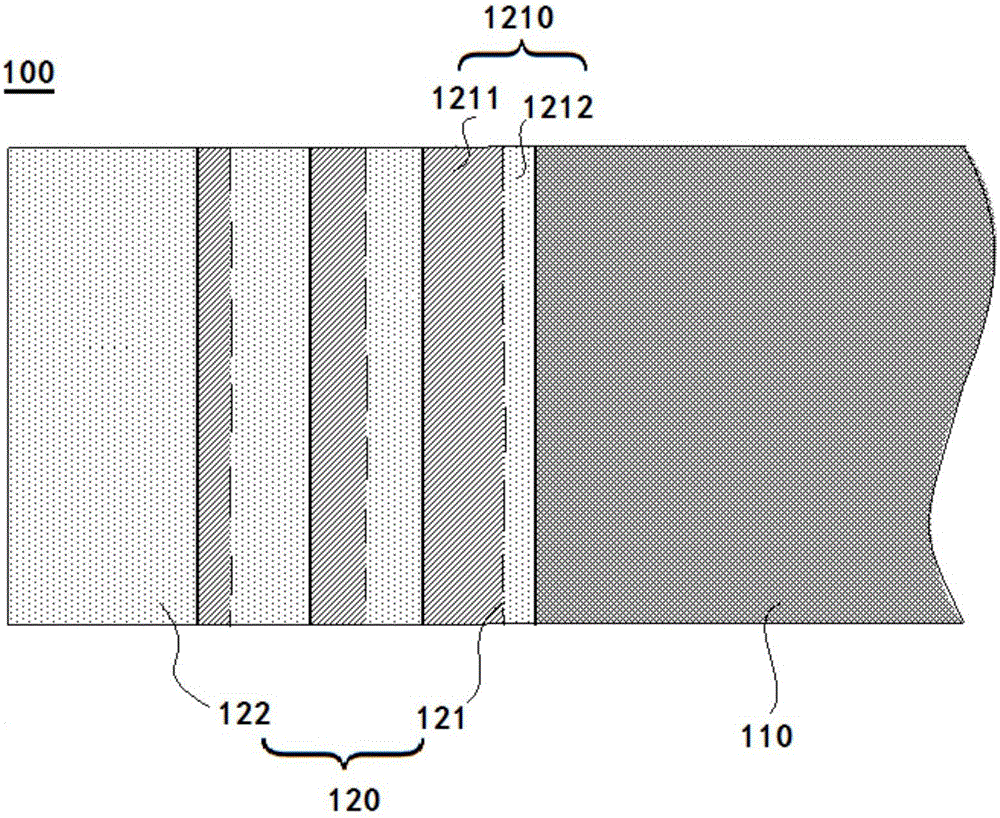

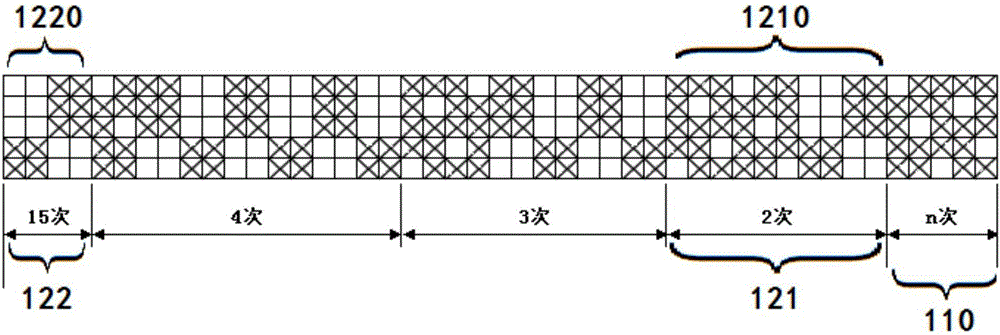

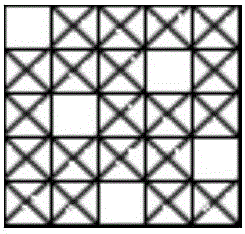

[0033] refer to figure 1 and figure 2 , the fabric structure 100 for preventing curling in Embodiment 1 includes a cloth body 110 and a cloth edge 120, and the cloth body 110 only includes one kind of weave, that is, the first cloth body weave.

[0034] Wherein, the selvedge 120 is disposed on the edge of the cloth body 110 . The selvedge 120 has a plurality of sequentially connected stress transition regions 121 , each stress transition region 121 has at least one stress transition unit 1210 and each stress transition unit 1210 in the stress transition region 121 with a plurality of stress transition units 1210 is repeatedly arranged. Each stress transition unit 1210 has a variety of selvage weaves with different degrees of curl stress balance, including a first selvage weave 1211 that curls in the same direction as the first fabric weave.

[0035] Each stress transition unit 1210 further includes at least one second selvage weave 1212 with a more balanced crimping stress ...

Embodiment 2

[0061] refer to Figure 5 The fabric structure 100 for preventing curling in Embodiment 2, the difference between Embodiment 2 and Embodiment 1 is that the cloth body 110 includes two kinds of weaves, specifically, the cloth body 110 includes the first cloth body weave, and also includes another an organization.

[0062] The cloth body 110 is 1 / 1 plain weave and 5 / 3 warp satin weave arranged in narrow strips at intervals, specifically 10 1 / 1 plain weave inserts 2 reeds + 4 5 / 3 warp satin weave inserts 4 reeds , satin weave is a tissue with uneven curling stress, easy to curl, plain weave is a tissue with relatively balanced curling stress, not easy to curl. If the cloth body 110 is made of elastic cloth with large weft shrinkage, it is also easy to curl.

[0063] Among them, the first fabric weave is a weave with relatively uneven curl stress, that is, 5 / 3 warp satin weave; the other weave is 1 / 1 plain weave, such as Figure 6 shown. It can be understood that when the degr...

Embodiment 3

[0072] refer to Figure 7 and Figure 8 The fabric structure 200 for preventing curling in Embodiment 3 includes a fabric body 210 and a fabric edge 220, and the fabric body 210 includes two kinds of fabrics in which the curling is reversed. Specifically, the fabric body 210 includes a first fabric body fabric and another A body tissue.

[0073] Wherein, the selvedge 220 is disposed on the edge of the cloth body 210 . The selvedge 220 has a plurality of sequentially connected stress transition regions 221 , each stress transition region 221 has at least one stress transition unit 2210 and each stress transition unit 2210 in the stress transition region 221 with a plurality of stress transition units 2210 is repeatedly arranged. Each stress transition unit 2210 has a variety of selvage weaves with different degrees of curl stress balance, including a third selvage weave 2211 that curls in the same direction as the first fabric weave.

[0074]Each stress transition unit 2210 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com