Belt for safety belt and mfg. method thereof

A manufacturing method and technology of seat belts, applied in the structure of seat belts, seat belts/slings, textiles and papermaking, etc., can solve problems such as increasing the strength of filaments or fibers, increasing the speed of line production, etc., to achieve increased strength , high tensile strength, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

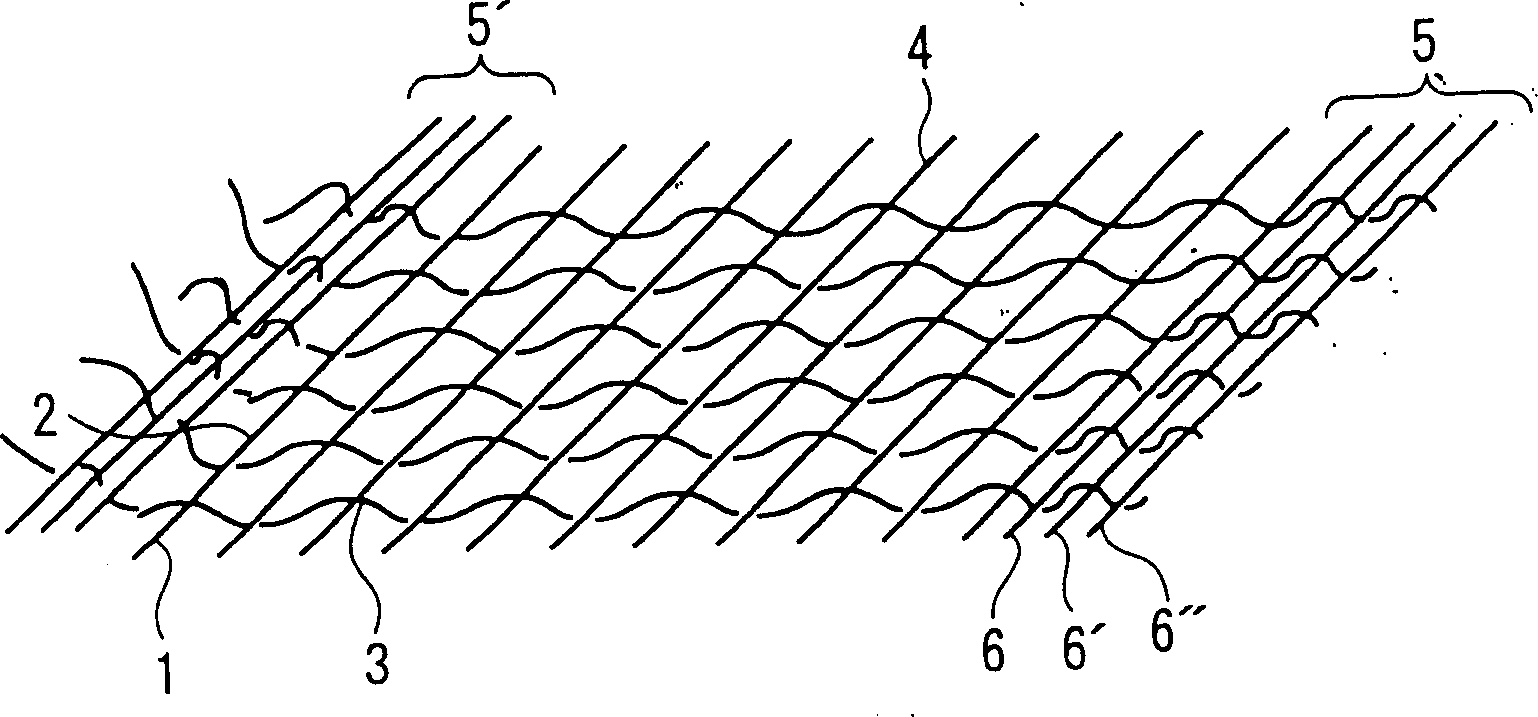

[0076] 200 polyester multifilament threads with 1500 denier per 288 filaments (with a single thread fineness of 5.2 denier) and a strength of 10.5 g / d were used as polyester multifilament threads of small single thread fineness and used in the present invention The warp of the belt 1.

[0077] By using a bobbin as disclosed in Japanese Patent No. 2,630,567, the twisting process is performed so as to give various numbers of twists respectively to the same warp mentioned above, and the twisting operation is performed simultaneously, and each twisted thread is supplied to a Knitting machines are used as warp threads for weaving.

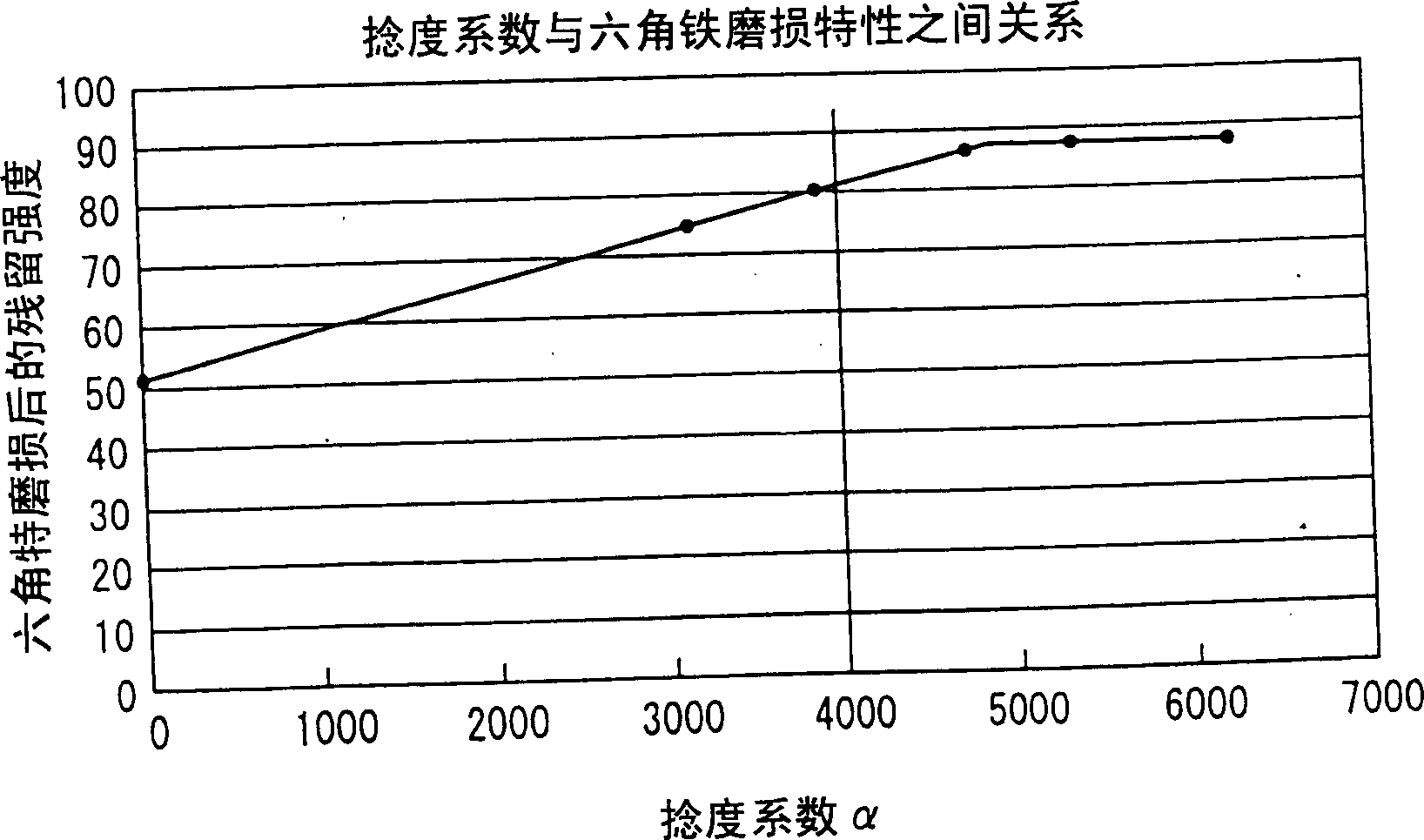

[0078] With the above operation, with a weft density of 20 wefts / 3cm (weft coefficient: 182), 750 denier polyester multifilament yarns were supplied as wefts 3 to the upper warp of the same knitting machine as described above, thus forming a weft with a thick weft density. Denim webbing. Finally, these tapes were subjected to dyeing processing and res...

example 2

[0081] A polyester multifilament thread with 288 filaments of 1500 denier (with a single thread fineness of 6.6 denier) and a tenacity of 10.8 g / d was used as the polyester multifilament thread with a small single thread fineness and as the warp thread 1 of the tape of the present invention.

[0082] By using a spool as disclosed in Japanese Patent No. 2,630,567, a twisting process is performed so as to give a twisting number of 120 t / m to warp yarns, and at the same time the twisting operation is performed, and the twisted threads are supplied to a knitting machine as warp yarns for weave.

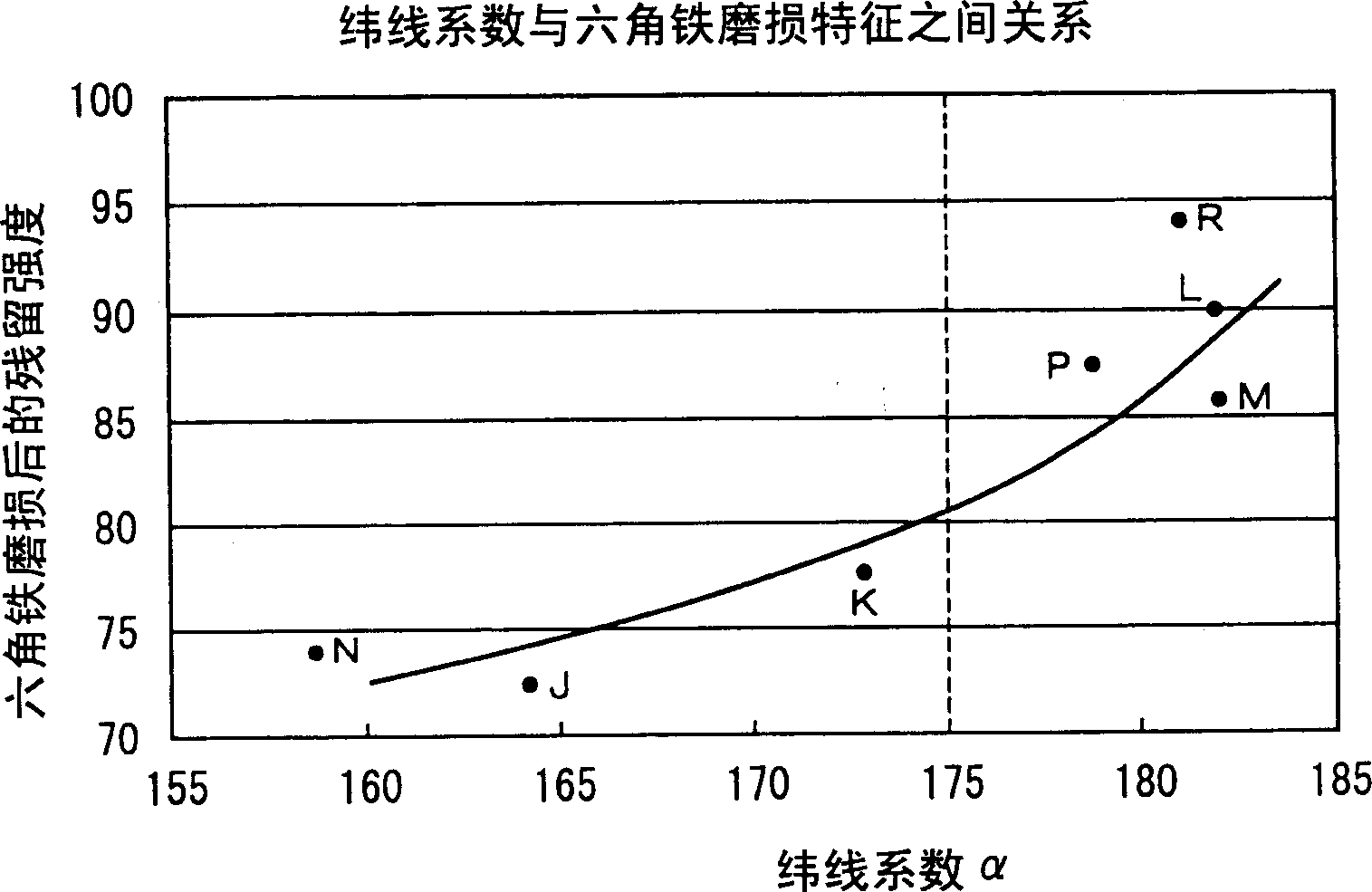

[0083]In the knitting operation, the knitting machine forms the denim webbing using the warp 1 and the weft 3 described above, and when the denim is produced by the knitting machine, as shown in Table 2, by changing the number of wefts, the kind of wefts, and the wefts With different fineness and density, a variety of thick belts J to R are formed.

[0084] Some straps are dyed only, and...

example 3

[0090] In addition to the warp construction of the tape shown in Example D of the invention, a set of 16 polyester multifilament threads, each having 500 denier and 48 filaments and twisted at about 120 t / m, and a set of 16 Polyester multifilament yarns, each having 250 denier and 24 filaments and twisted at about 120 t / m, are respectively inserted into one end 5 of the belt 4 as warp yarns 6 therein, and the above-mentioned same multifilament yarn groups are respectively The other end 5' of the strap 4 is inserted as a warp thread 6 therein.

[0091] Then, if Figure 4 As shown, these warp yarns and appropriate weft yarns are woven into a tape in a predetermined weaving structure so that the shape of both ends of the tape can exhibit a substantially round shape and have a soft feeling.

[0092] In another embodiment, in addition to the warp profile of the tape shown in Example D of the present invention, a set of 32 polyester multifilament threads, each with 500 denier and 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com