Narrow fabric needle loom for producing a strip-shaped tissue, and corresponding strip-shaped tissue

A technology for looms and strips, applied in looms, fabrics, small looms, etc., can solve problems such as low productivity and difficulty in fabricating strips, improve physical properties, and eliminate the risk of injury and/or human injury , the effect of preventing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

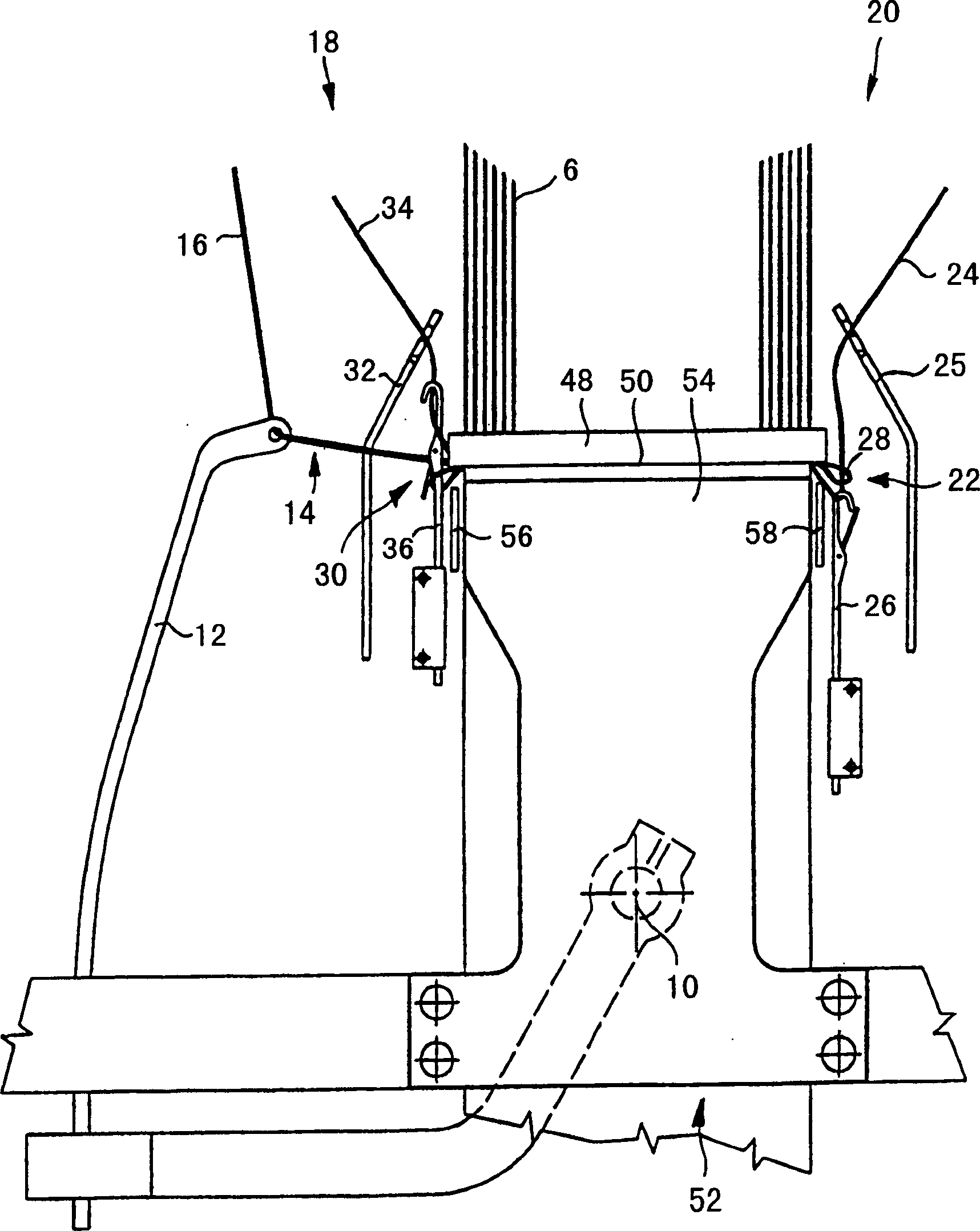

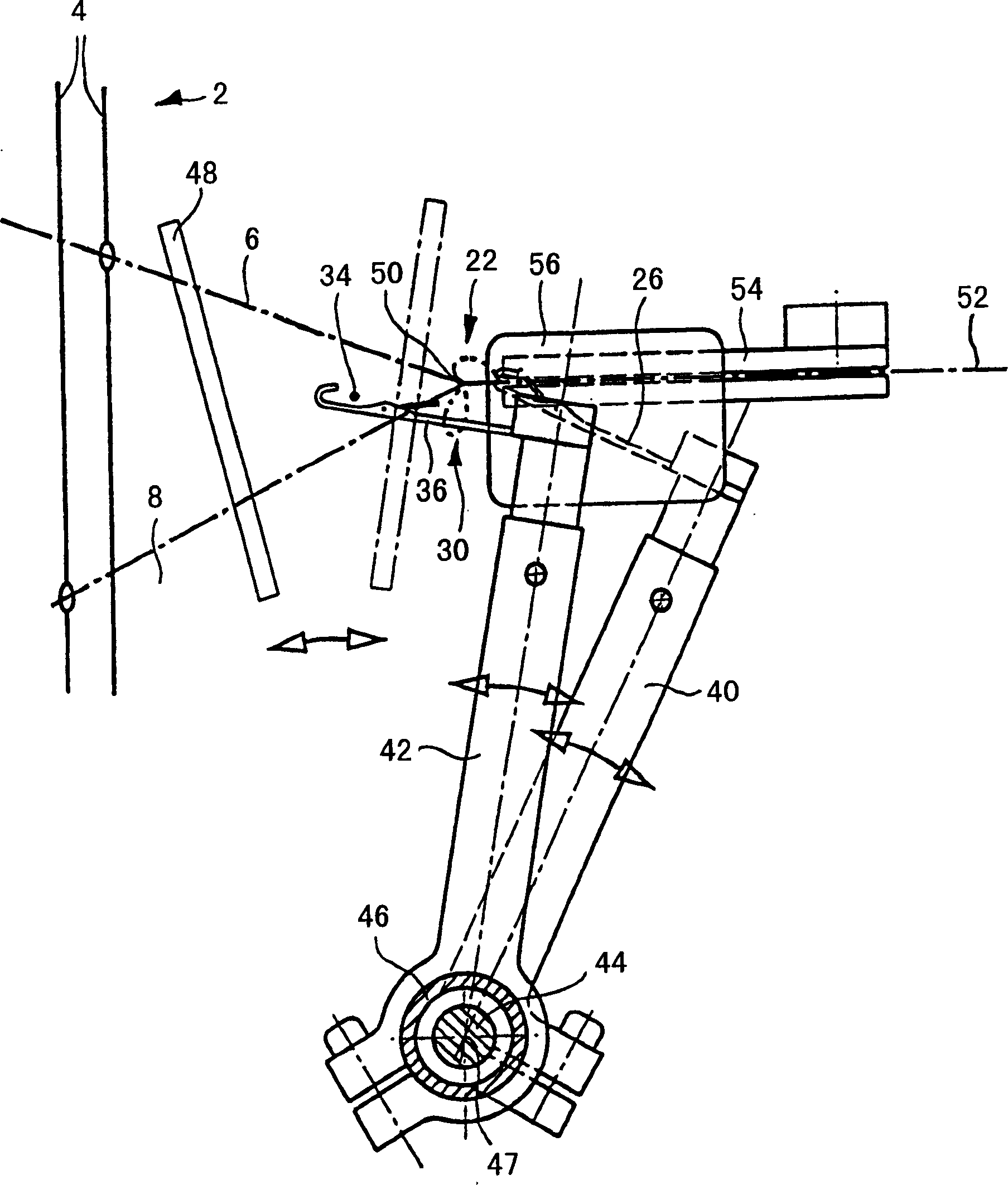

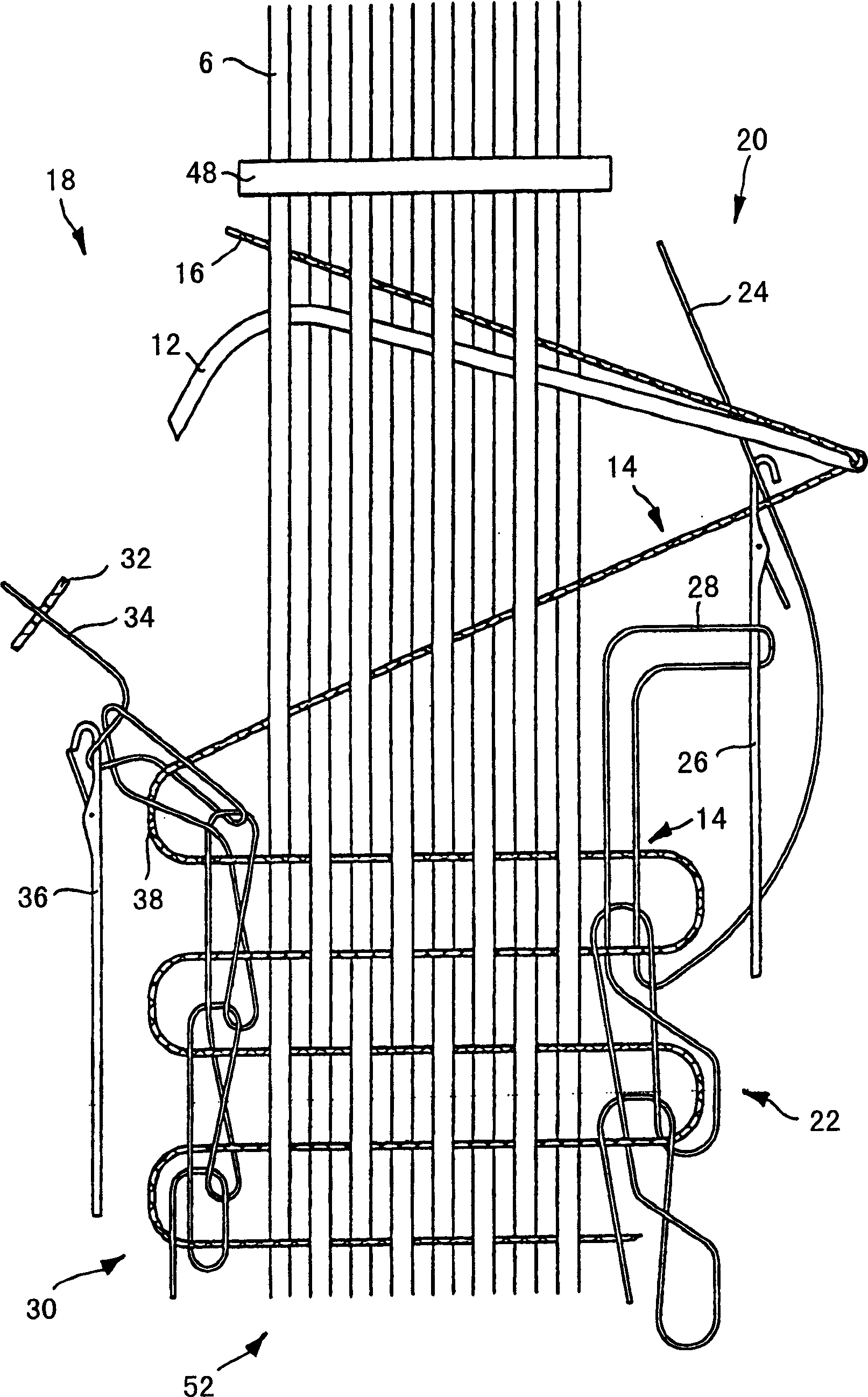

[0017] figure 1 , 2 The weaving area of the ribbon loom is shown schematically, wherein only the essential parts of the invention are shown. A shedding device 2 comprises pattern-controlled healds 4 which open warp threads 6 to form a shed 8 according to a pattern program. A weft picker 12 rotatable about an axis 10 introduces weft loops 14 of a multifilament or monofilament weft thread 16 into the shed 8 on the picking side 18 . The weft insertion needles 12 and thus the weft loops 14 protrude from the shed 8 on the delivery side 20 and are connected there by a knitting part 22 .

[0018] exist Figure 1-Figure 3 In the example of , the knitting part is formed by a multifilament connecting yarn 24 supplied by a yarn guide 25 , which is drawn through the weft loop 14 by the first knitting needle 26 and passed through the loop formed by the connecting yarn 24 28 is connected to itself. This connection system is described as Muller Braiding System II on page 86 of KIPP, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com