Patents

Literature

156results about "Smallware looms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

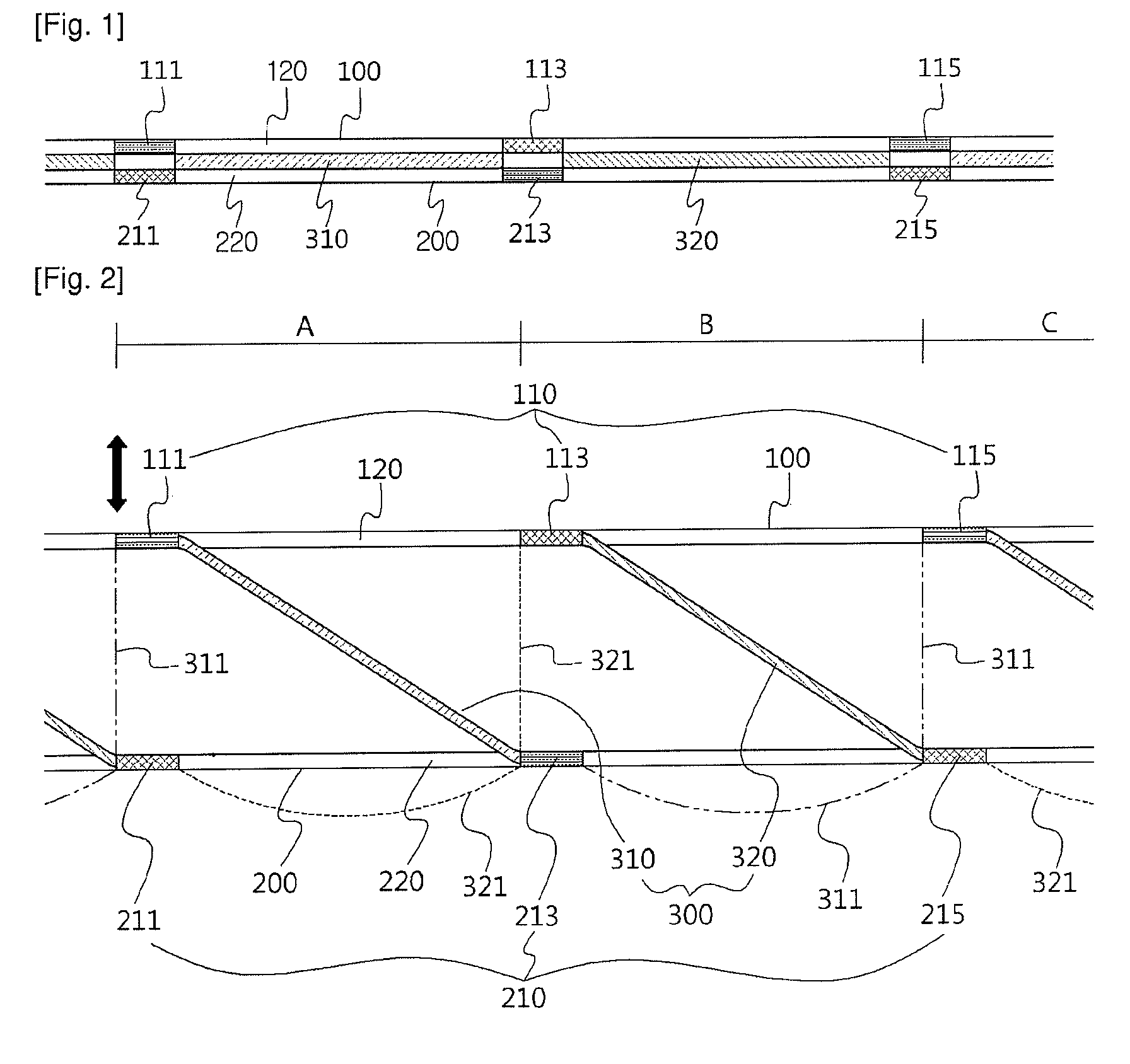

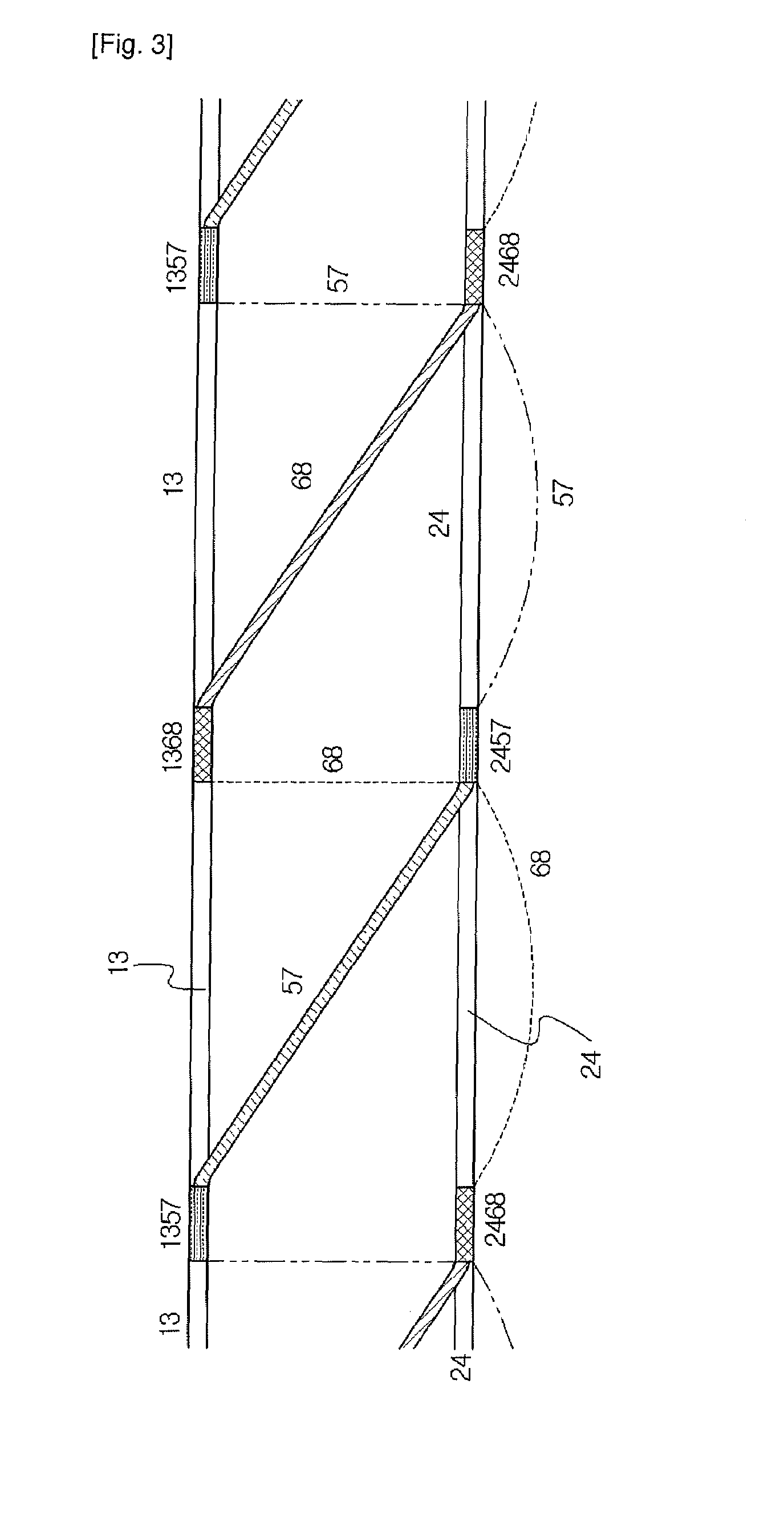

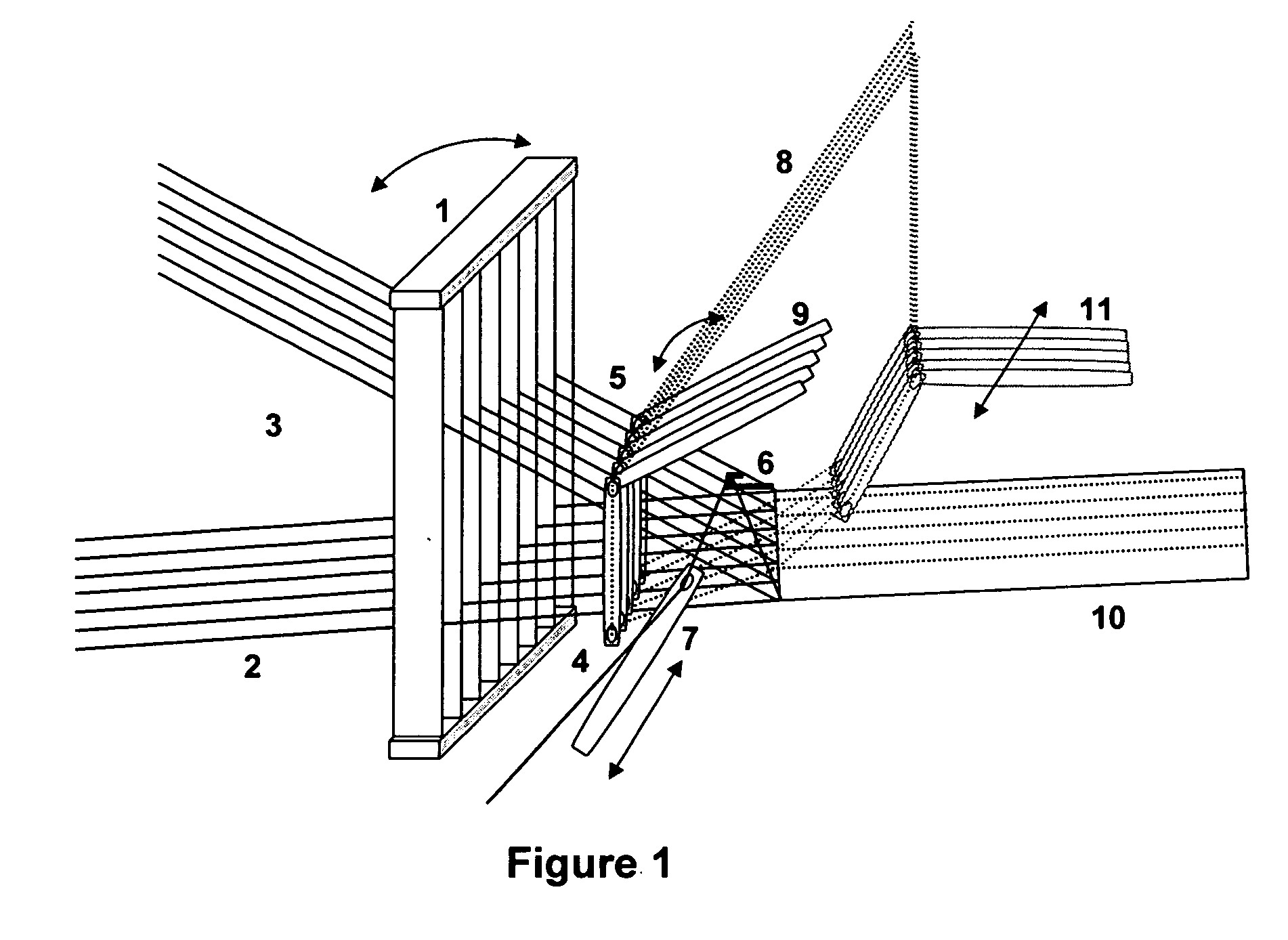

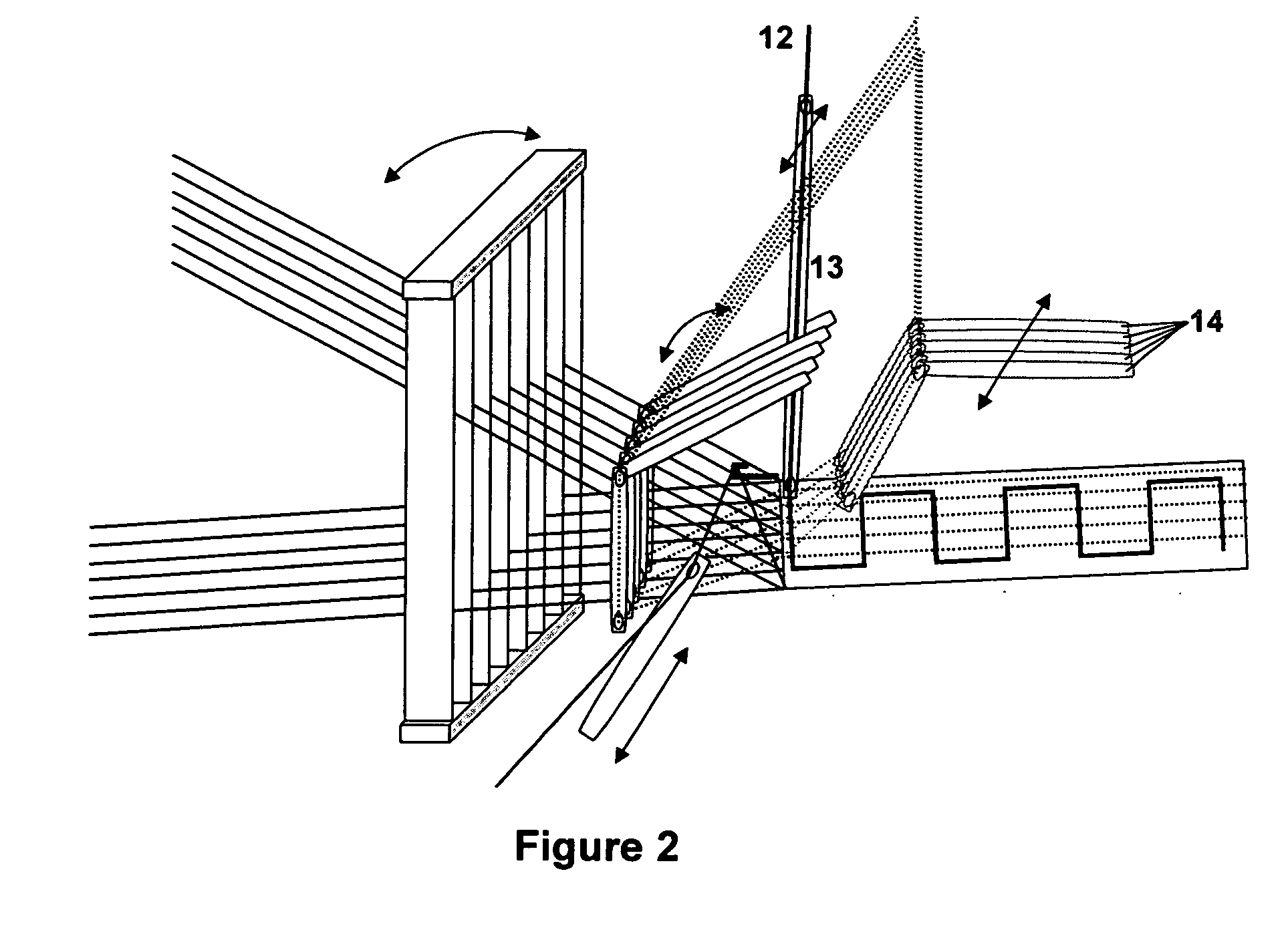

Method for Weaving Closed Structures with Intersecting Walls

ActiveUS20090149100A1Shorten manufacturing timeLow costSmallware loomsOrnamental textile articlesShell moldingTransfer molding

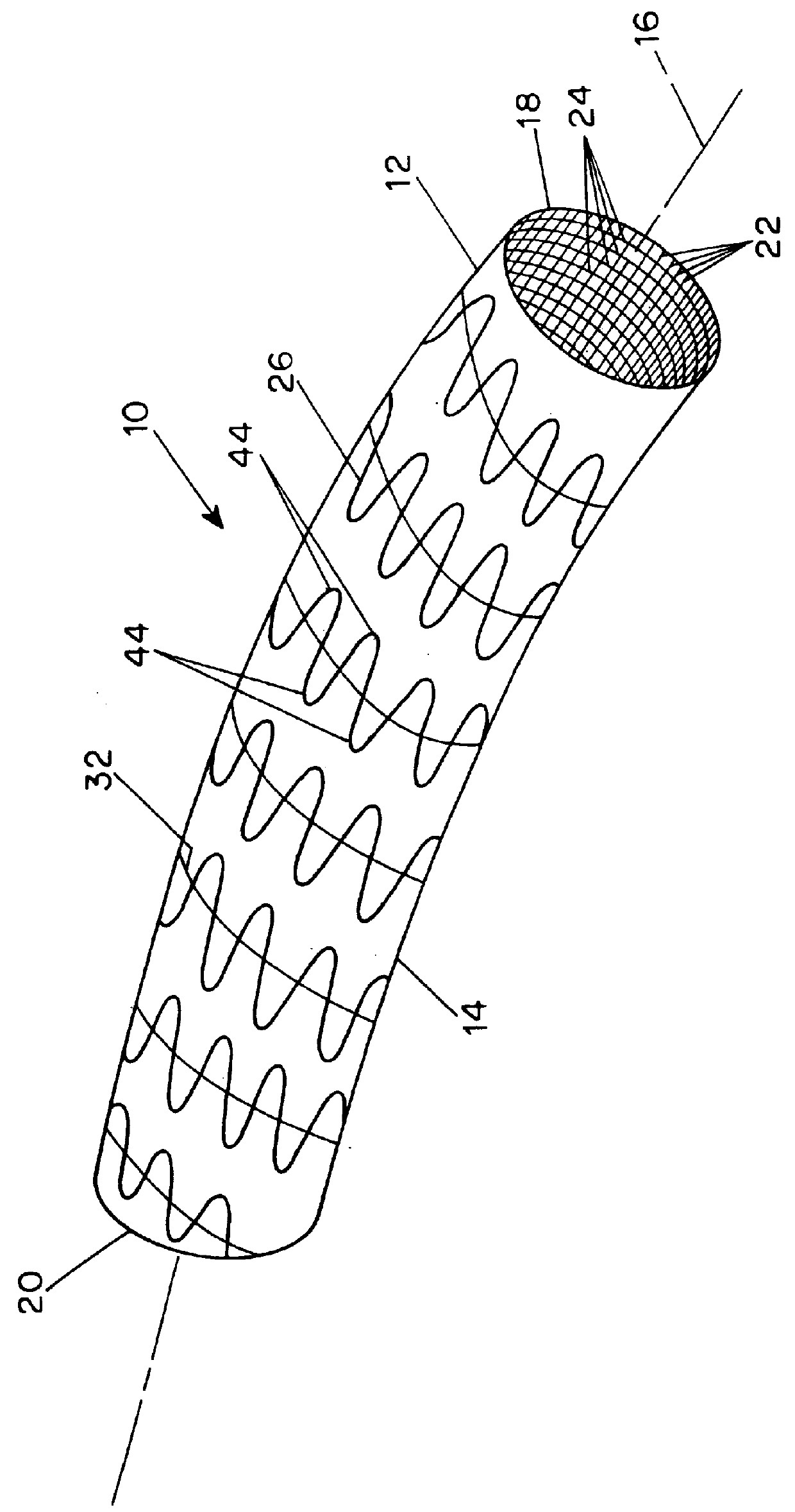

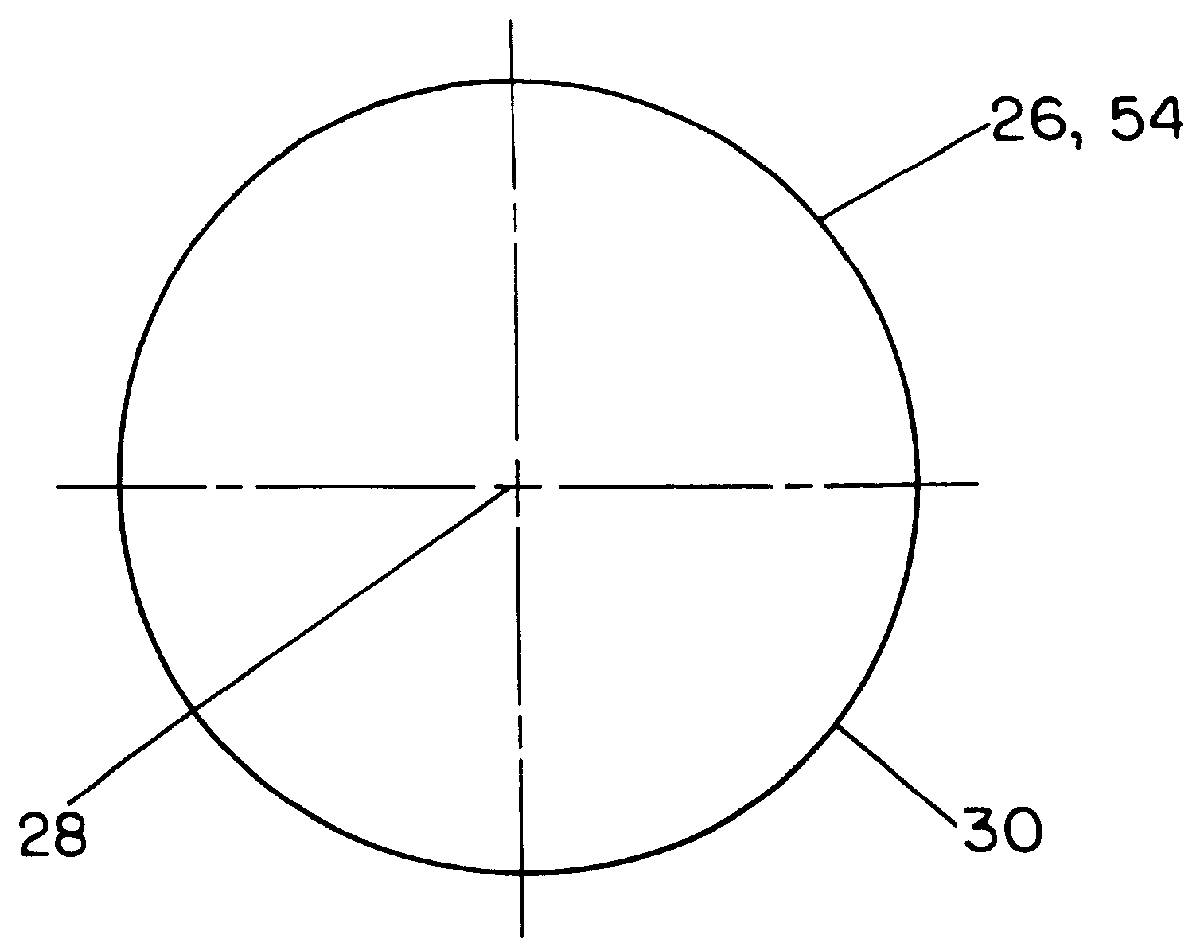

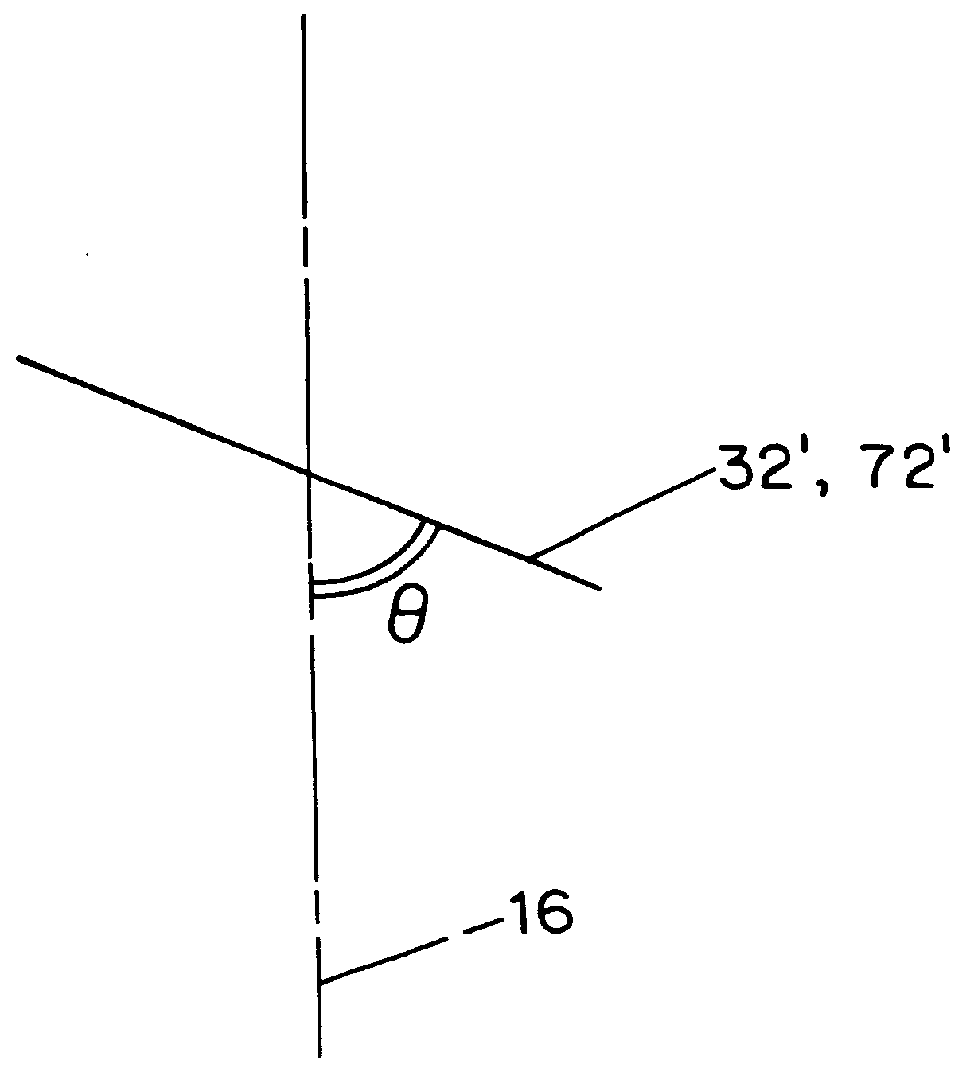

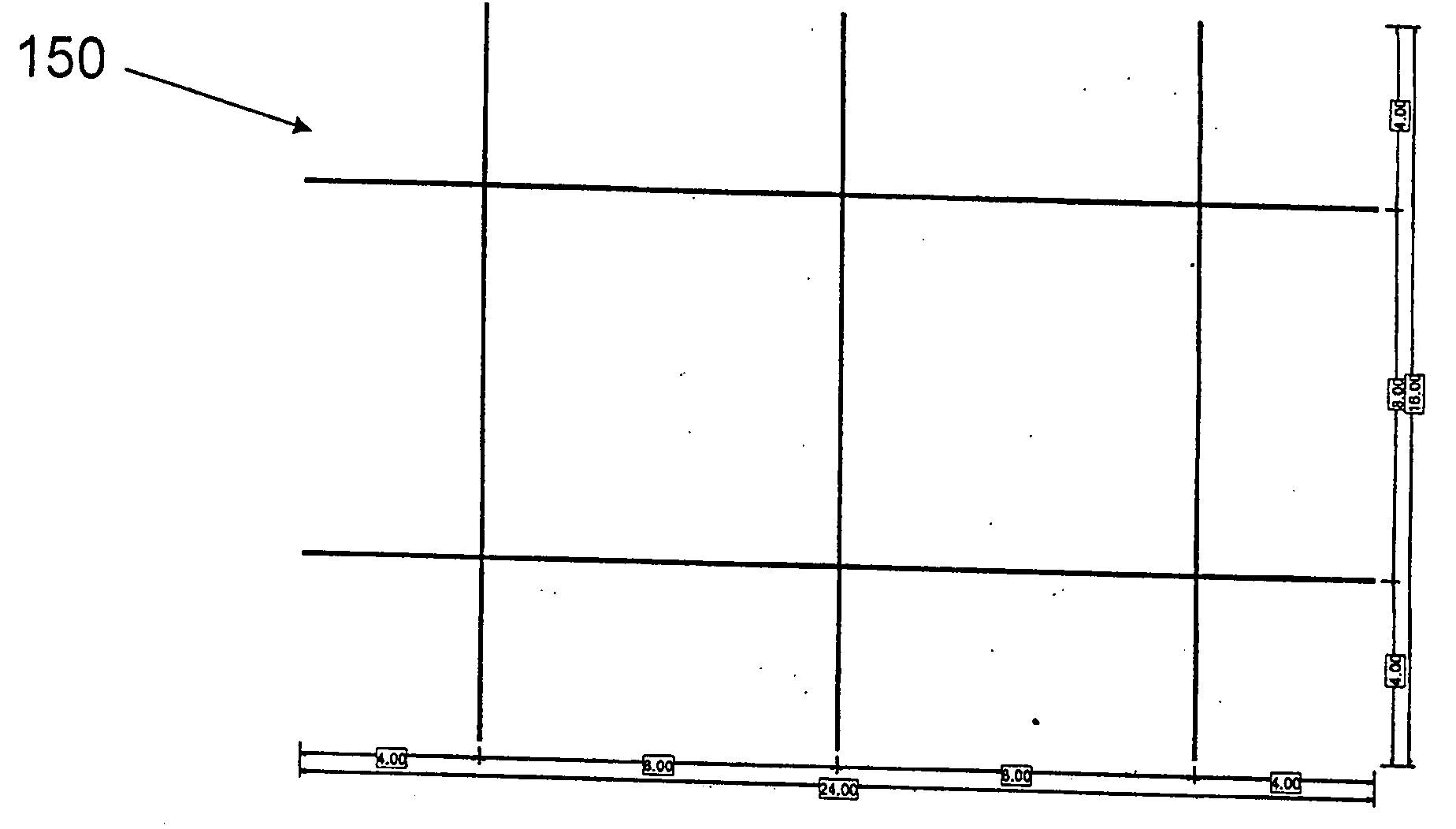

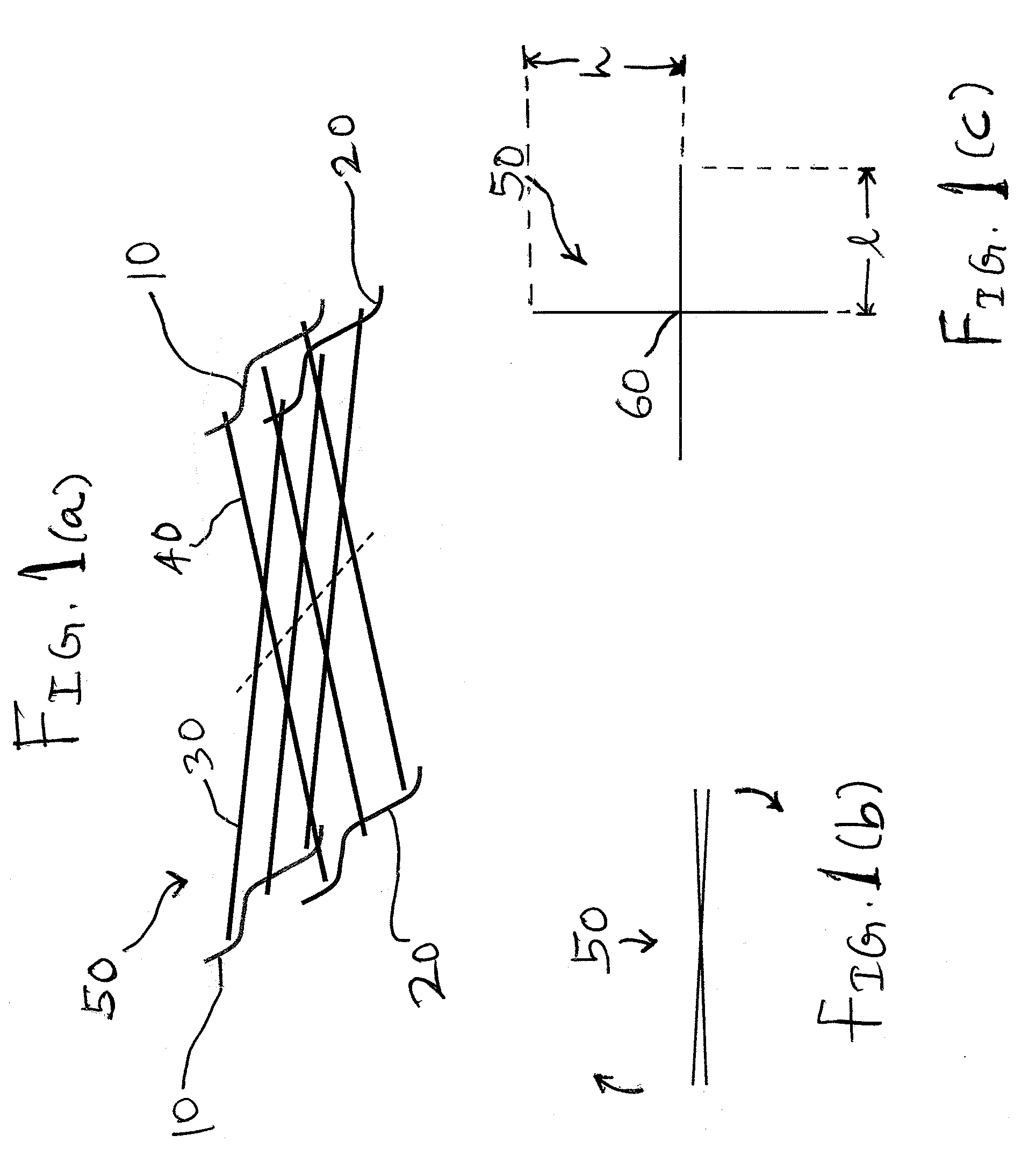

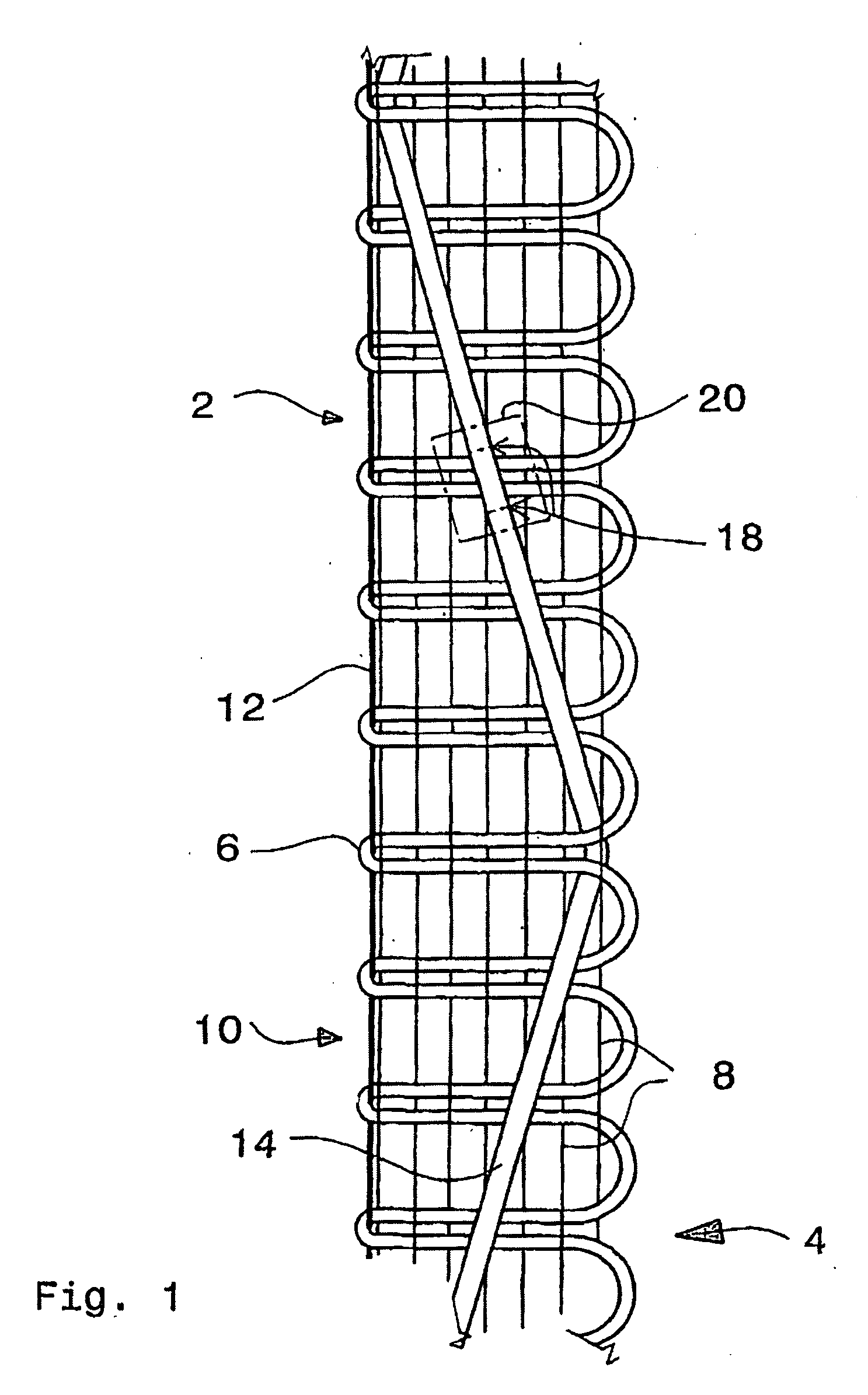

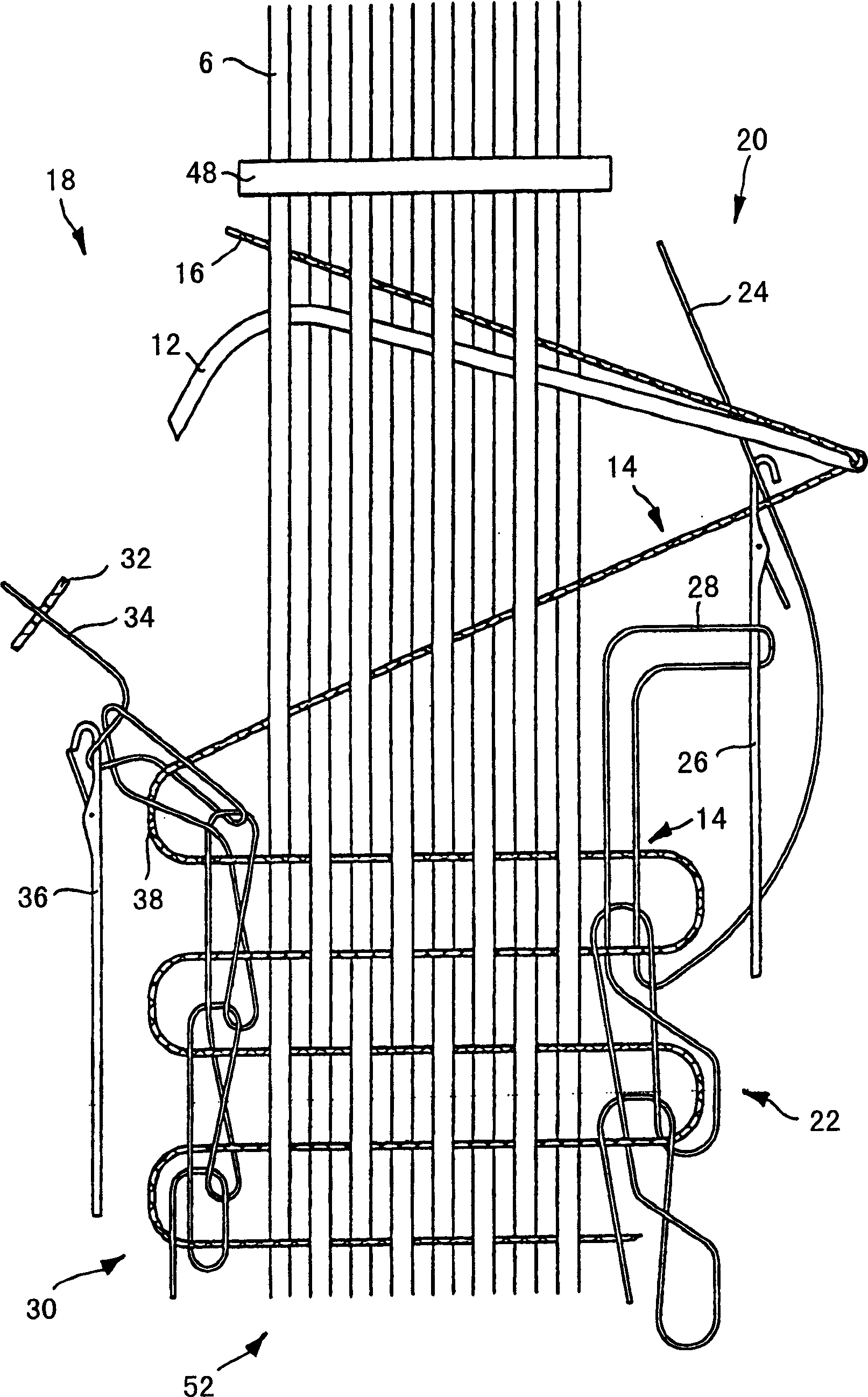

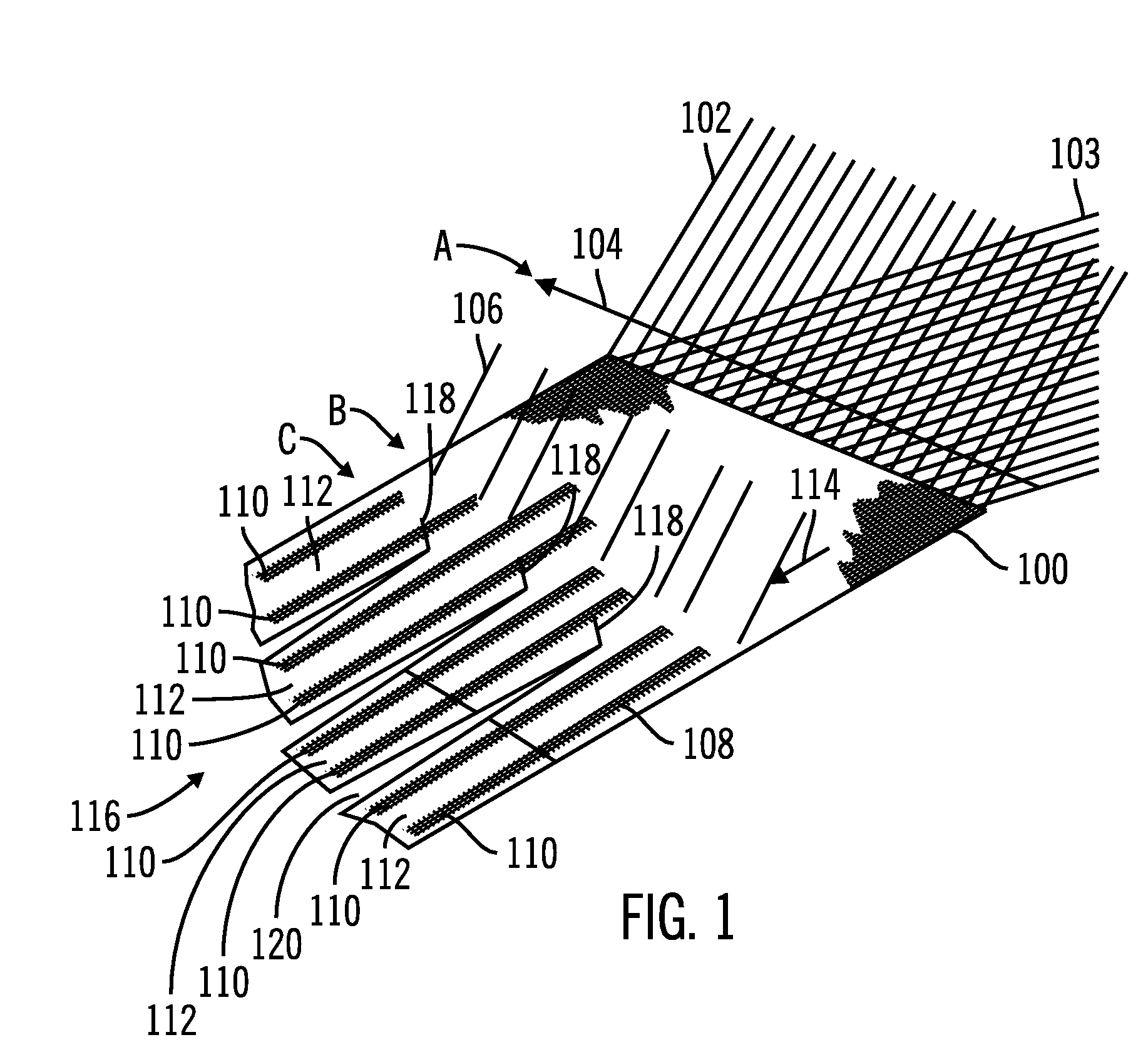

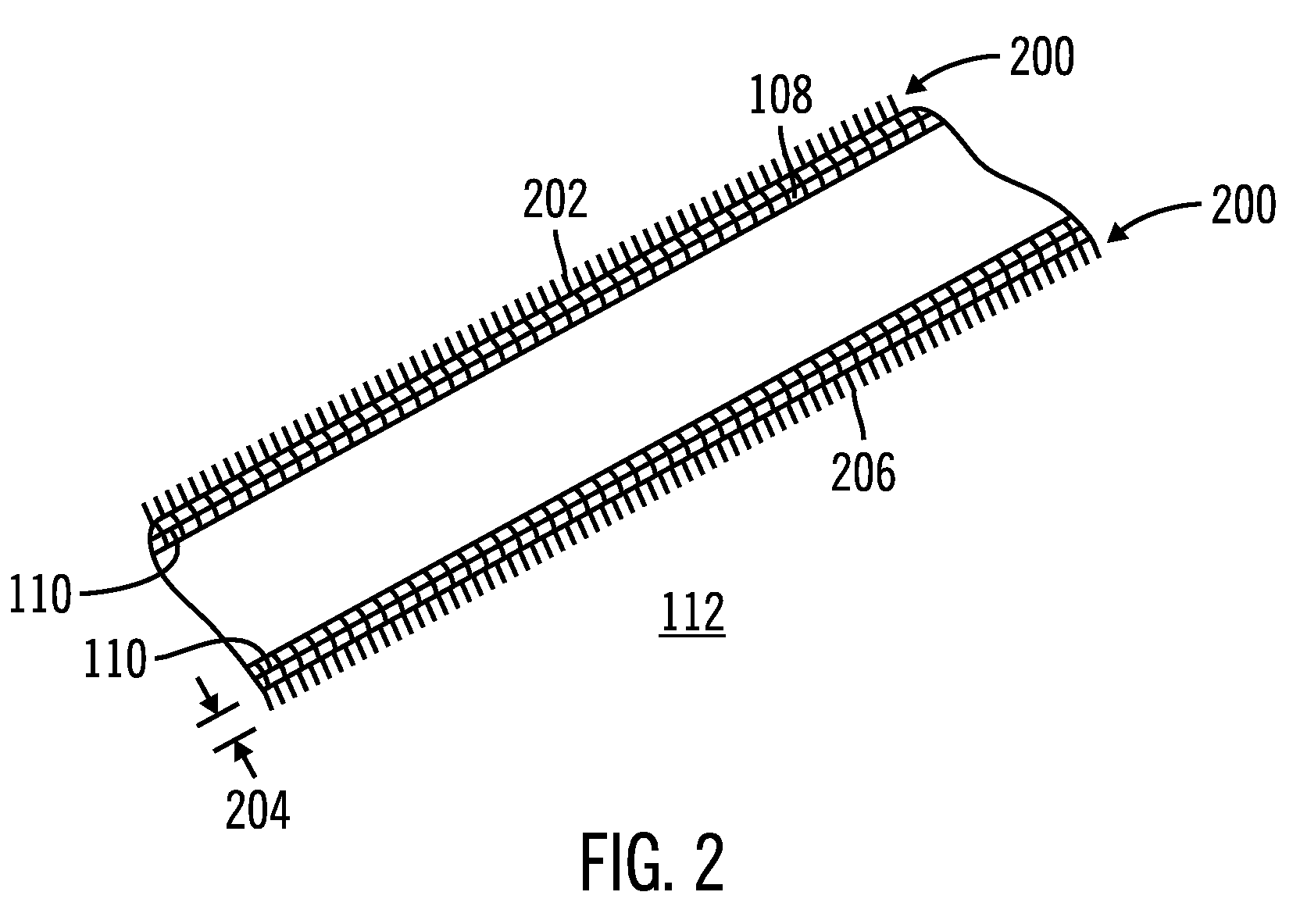

The present invention generally relates to a woven preform for reinforced composite materials and a method of making thereof. Specifically, the present invention is a method of machine weaving fiber preforms for polymer matrix composites that consist of closed perimeters with multiple intersecting members in their interiors. More specifically, the invention is a woven preform and a method of forming thereof with closed cells at the outer edges with continuous hoop reinforcement in each cell of the preform. The woven preform is woven flat in both the warp and weft directions, and then unfolded to achieve the final shape of the structure, and can be processed into composite structural components using known methods such as resin transfer molding or chemical vapor infiltration. Thus, complicated shapes of all sizes can be woven on a conventional loom using the instant method.

Owner:ALBANY ENGINEERED COMPOSITES

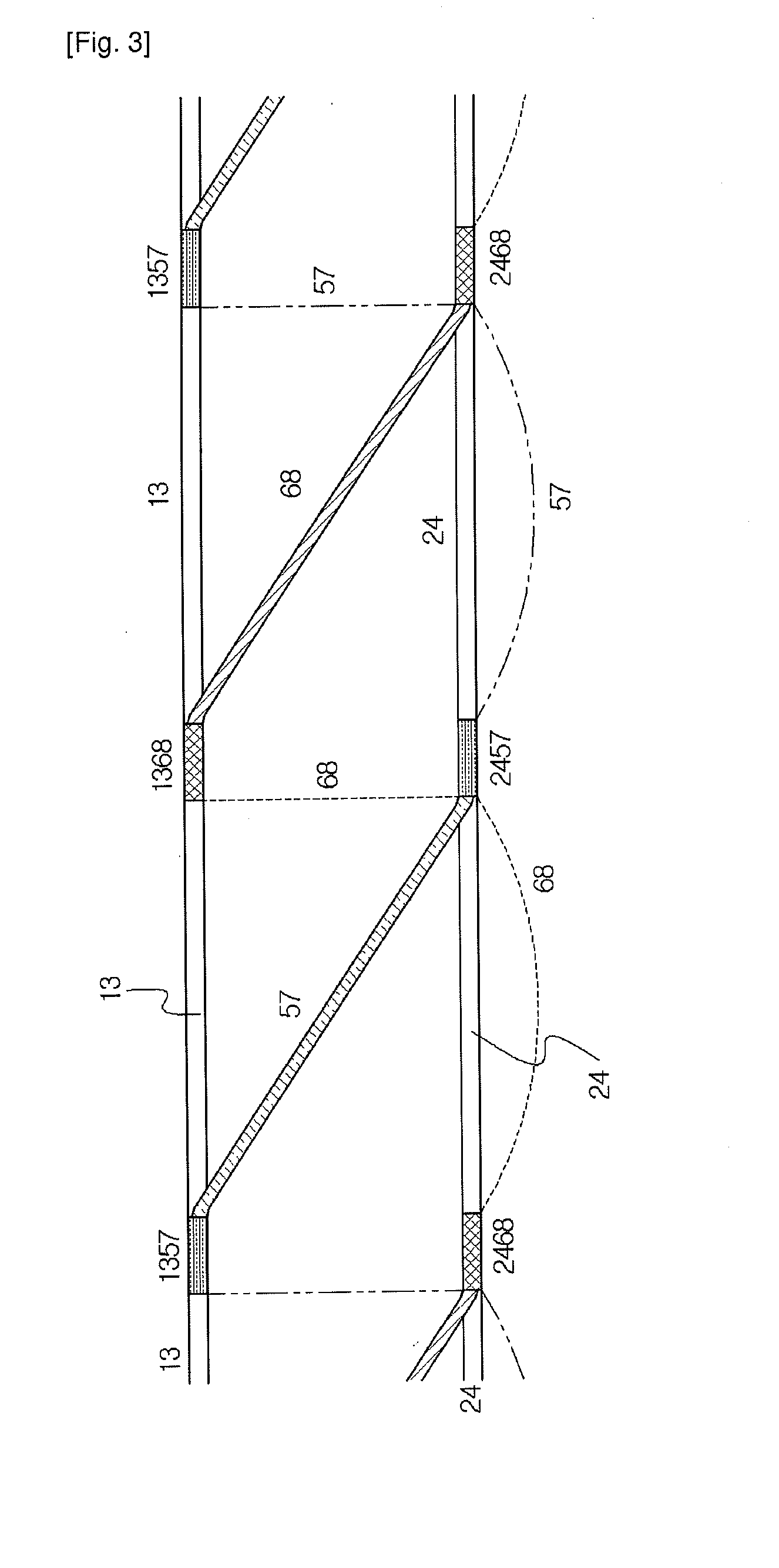

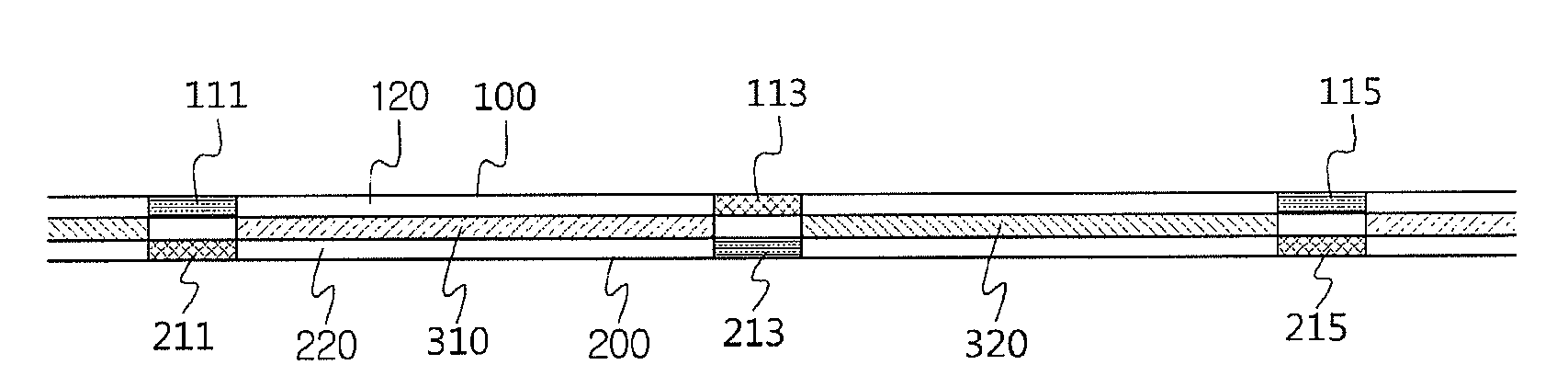

3D fabric and preparing thereof

ActiveUS20090288731A1Maintain shape stabilityMaintain inherent flexibilitySmallware loomsOrnamental textile articlesSurface layerRepeat pattern

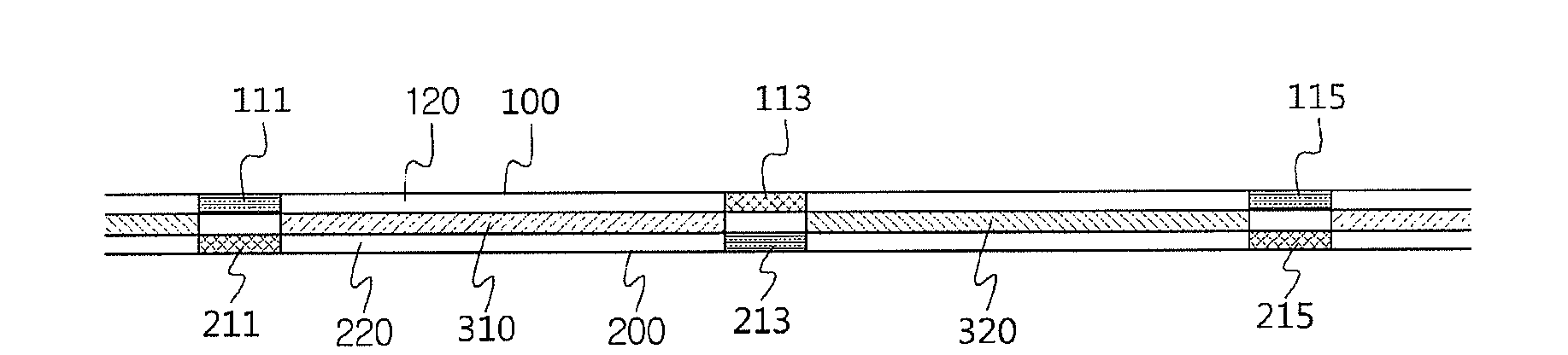

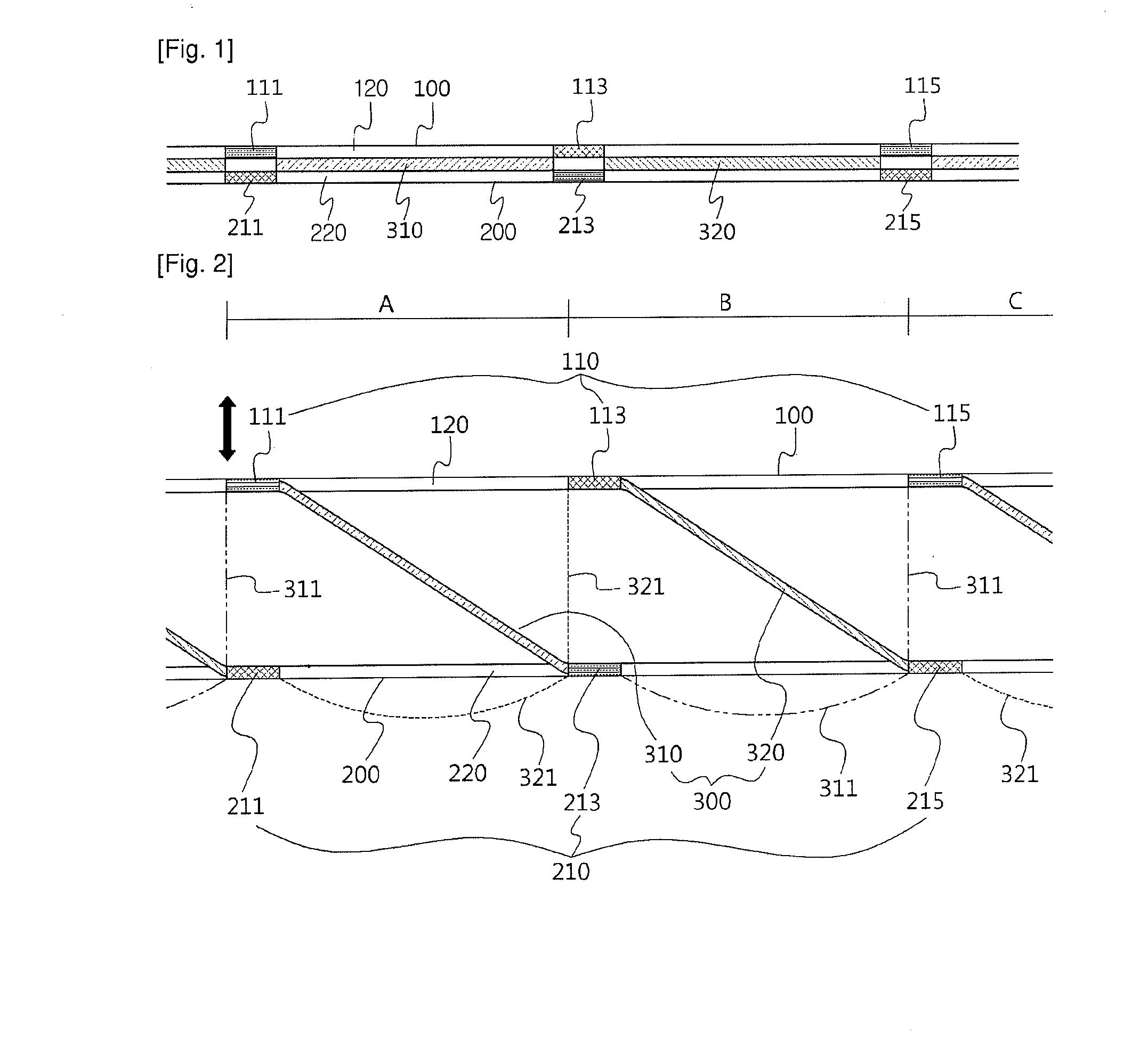

A three-dimensional multilayer fabric is provided. The fabric comprises a surface layer, a backing layer, and an intermediate layer connecting the surface layer and the backing layer. The surface layer includes sequential unstitched surface portions and sequential stitched surface portions formed in an alternating and repeating pattern. The unstitched surface portions of the surface layer are essentially composed of surface warp threads only, and the stitched surface portions of the surface layer are composed of the surface warp threads and intermediate warp threads. The backing layer includes sequential unstitched backing portions and sequential stitched backing portions formed in an alternating and repeating pattern. The unstitched backing portions of the backing layer are essentially composed of backing warp threads only, and the stitched backing portions of the backing layer are composed of the backing warp threads and the intermediate warp threads. The intermediate warp threads are woven without interlacing with weft threads on the surfaces of the unstitched backing portions. The intermediate layer includes sequential intermediate portions composed of the intermediate warp threads only. Each of the intermediate portions consists of a first intermediate portion and a second intermediate portion connected to the stitched surface portions and the stitched backing portions in an alternating and repeating pattern. The connecting warp threads of the intermediate layer exposed to the outside of the backing layer are sheared. Further provided is a method for the production of the fabric.

Owner:YOUIL

3D fabric and preparing thereof

ActiveUS7694696B2Efficiency sometimes variesMaintain shape stabilitySmallware loomsOrnamental textile articlesSurface layerRepeat pattern

A three-dimensional multilayer fabric is provided. The fabric comprises a surface layer, a backing layer, and an intermediate layer connecting the surface layer and the backing layer. The surface layer includes sequential unstitched surface portions and sequential stitched surface portions formed in an alternating and repeating pattern. The unstitched surface portions of the surface layer are essentially composed of surface warp threads only, and the stitched surface portions of the surface layer are composed of the surface warp threads and intermediate warp threads. The backing layer includes sequential unstitched backing portions and sequential stitched backing portions formed in an alternating and repeating pattern. The unstitched backing portions of the backing layer are essentially composed of backing warp threads only, and the stitched backing portions of the backing layer are composed of the backing warp threads and the intermediate warp threads. The intermediate warp threads are woven without interlacing with weft threads on the surfaces of the unstitched backing portions. The intermediate layer includes sequential intermediate portions composed of the intermediate warp threads only. Each of the intermediate portions consists of a first intermediate portion and a second intermediate portion connected to the stitched surface portions and the stitched backing portions in an alternating and repeating pattern. The connecting warp threads of the intermediate layer exposed to the outside of the backing layer are sheared. Further provided is a method for the production of the fabric.

Owner:YOUIL

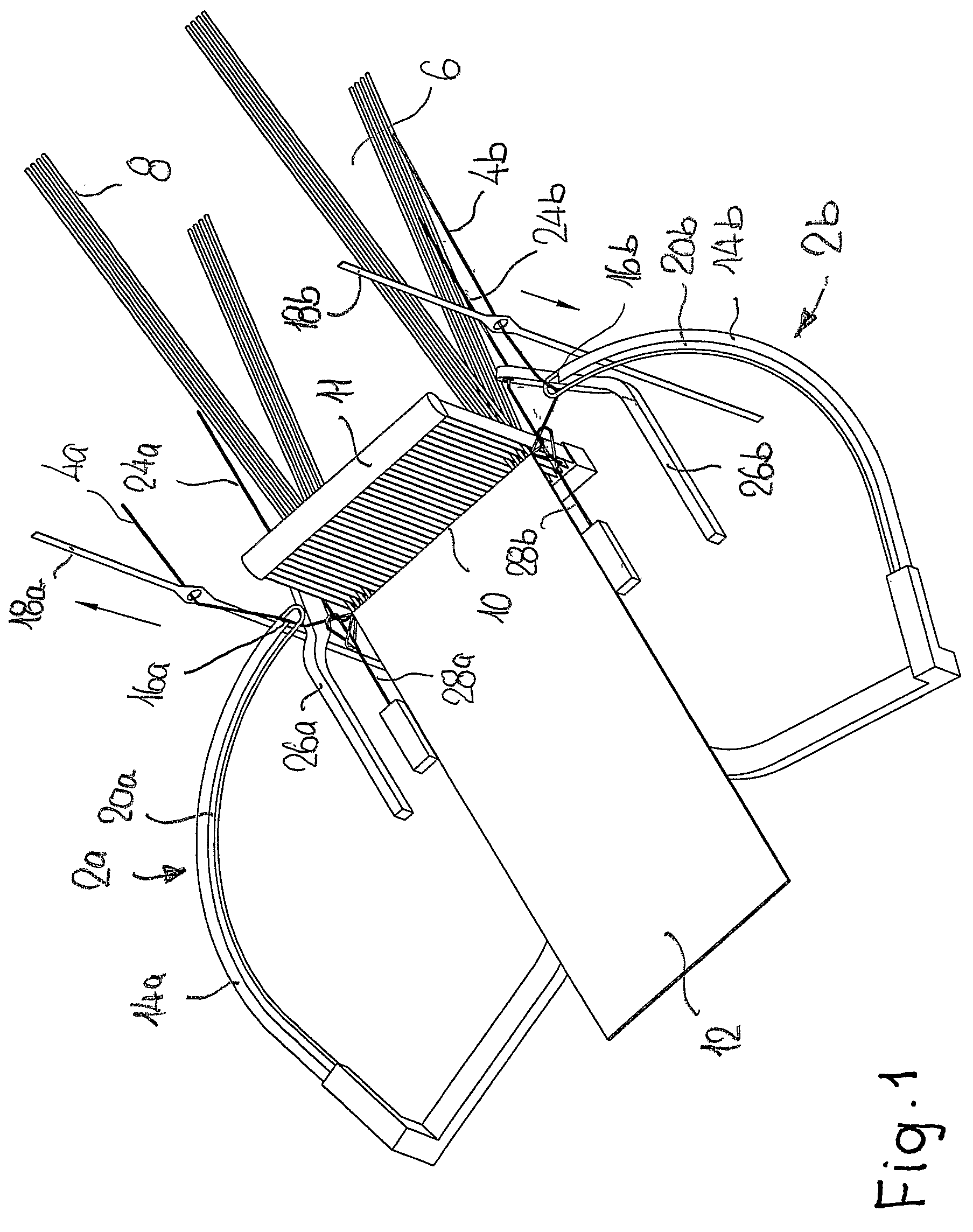

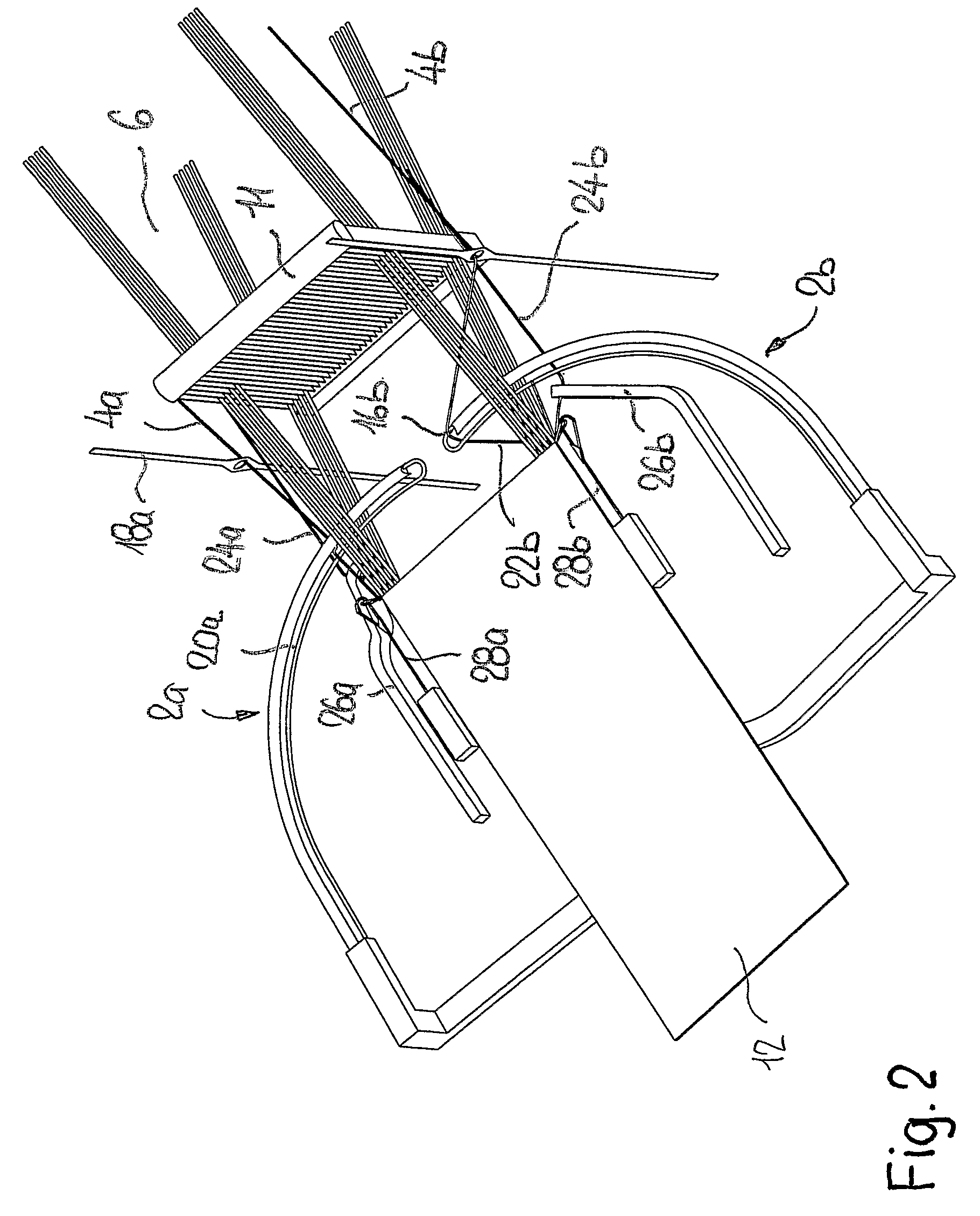

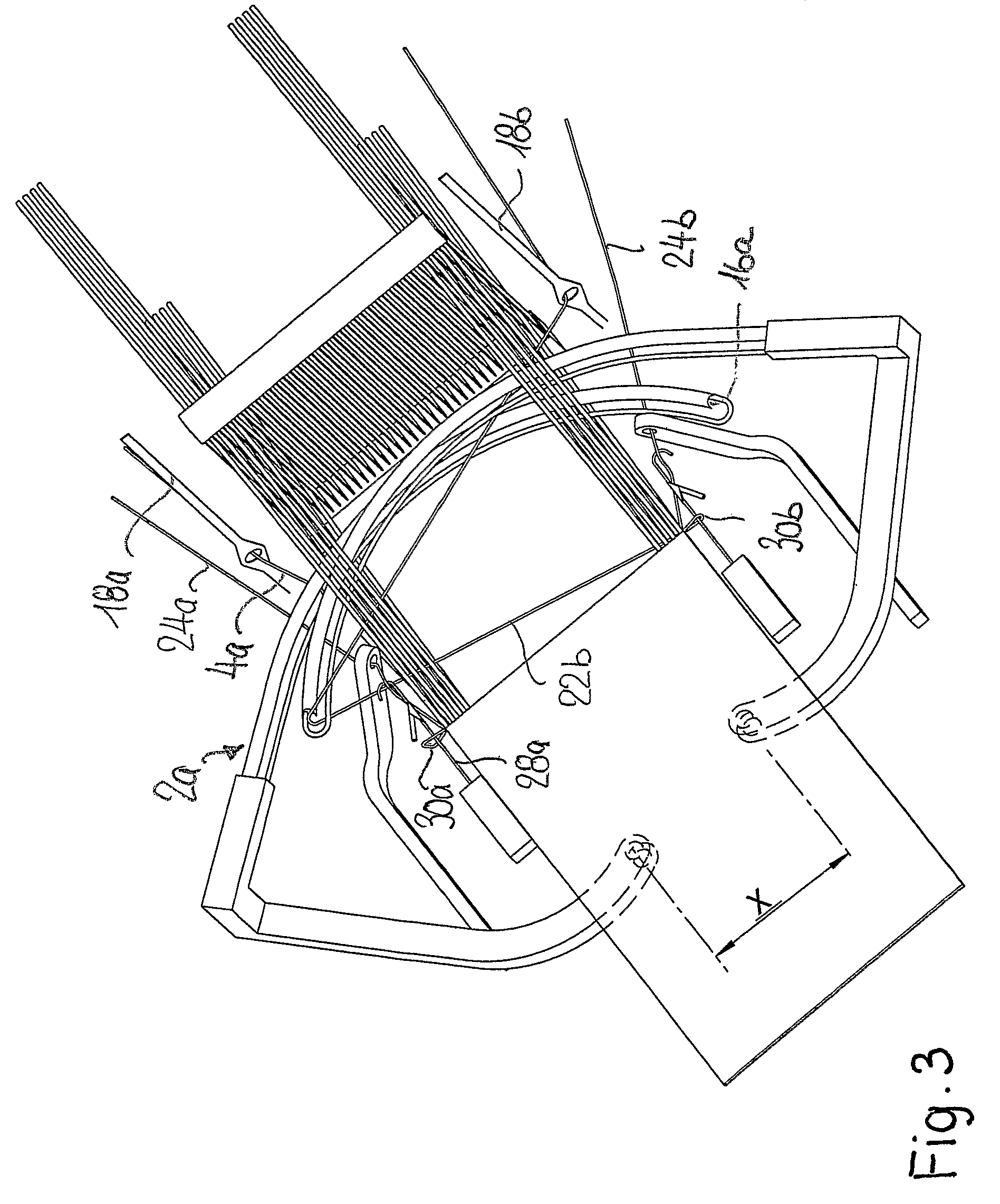

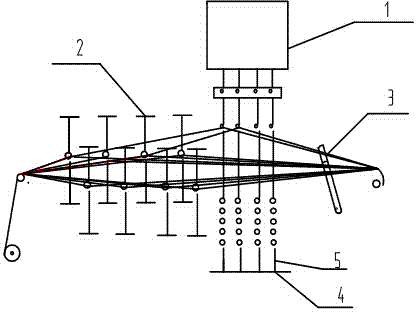

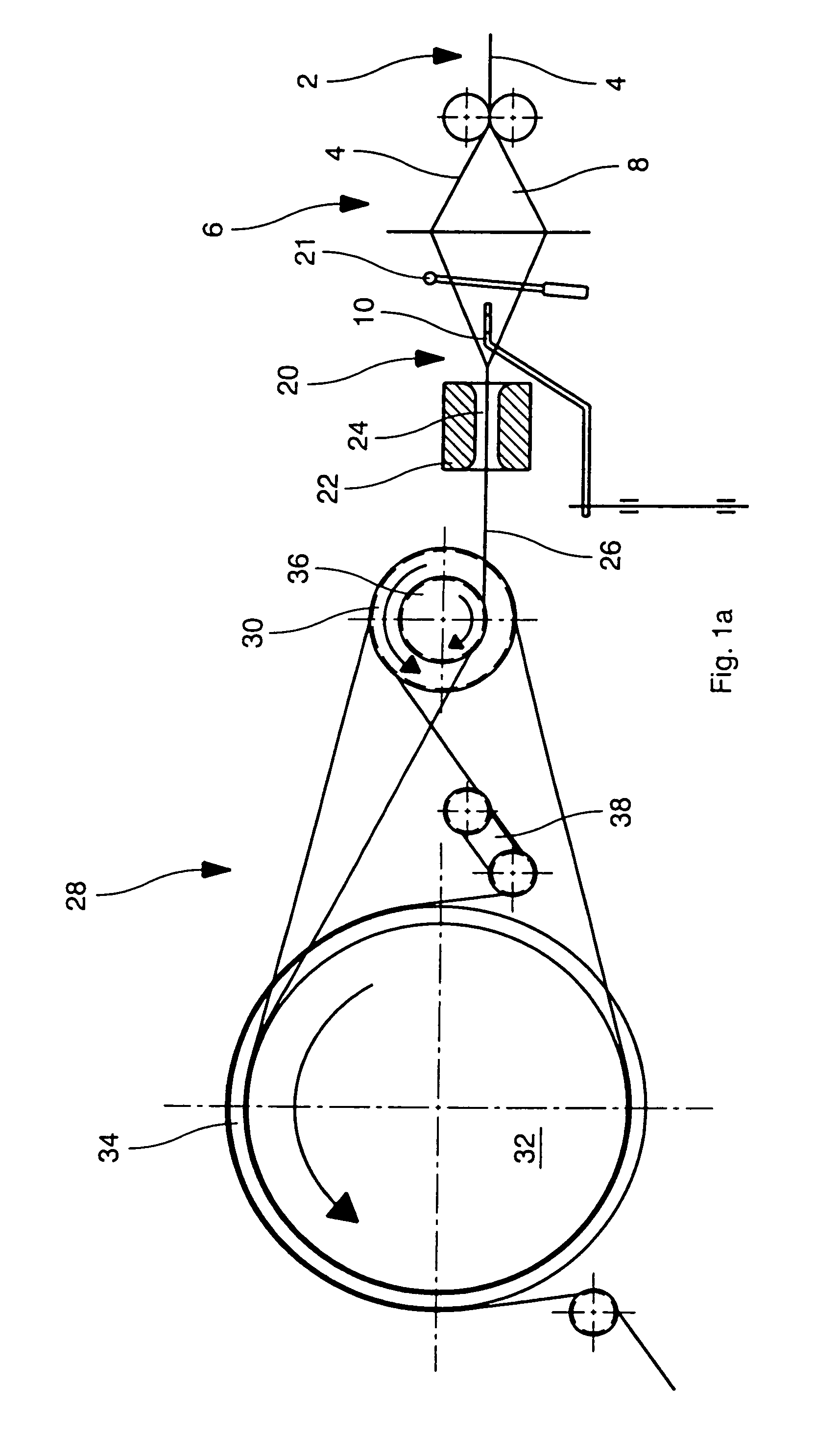

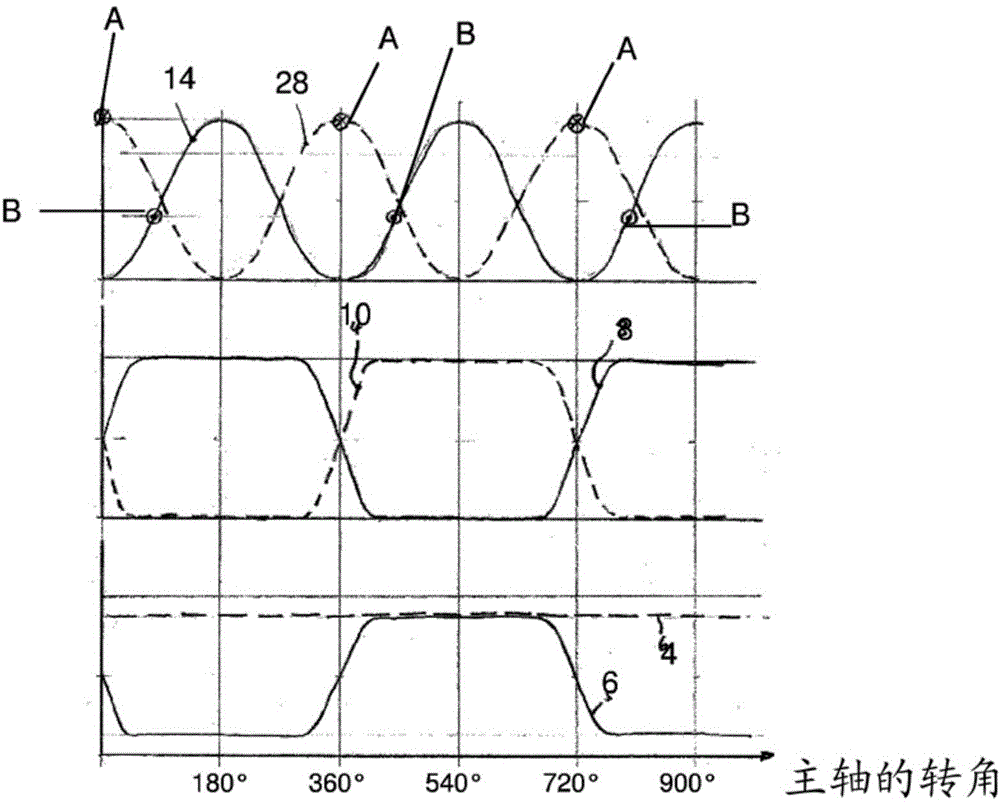

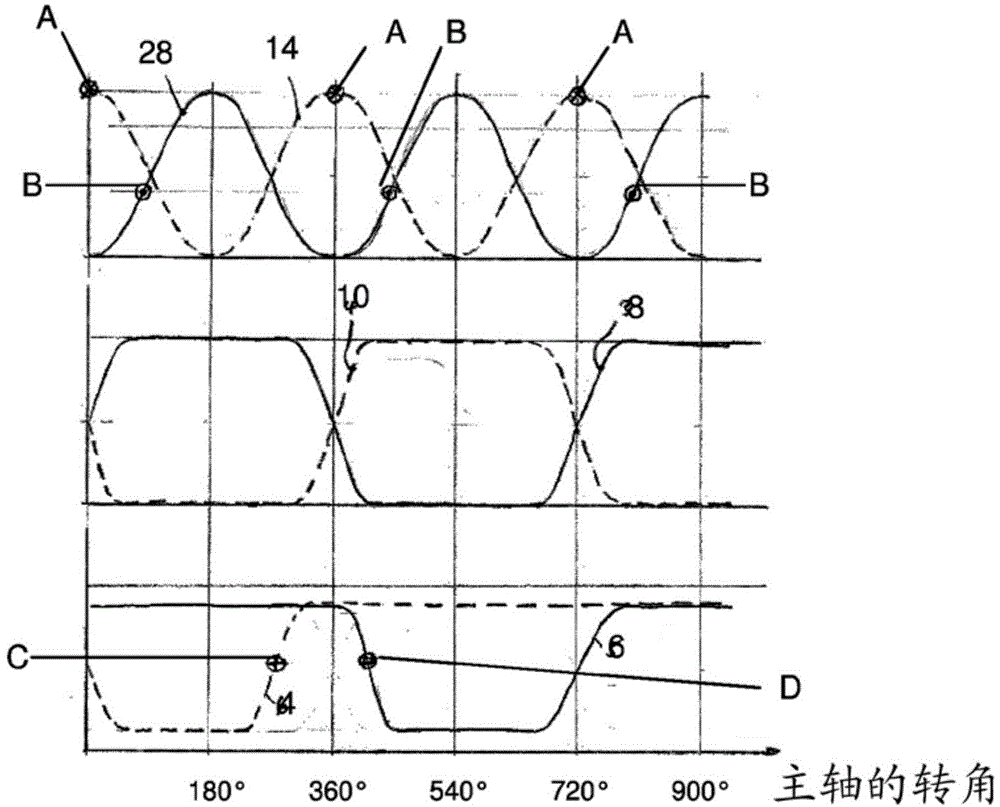

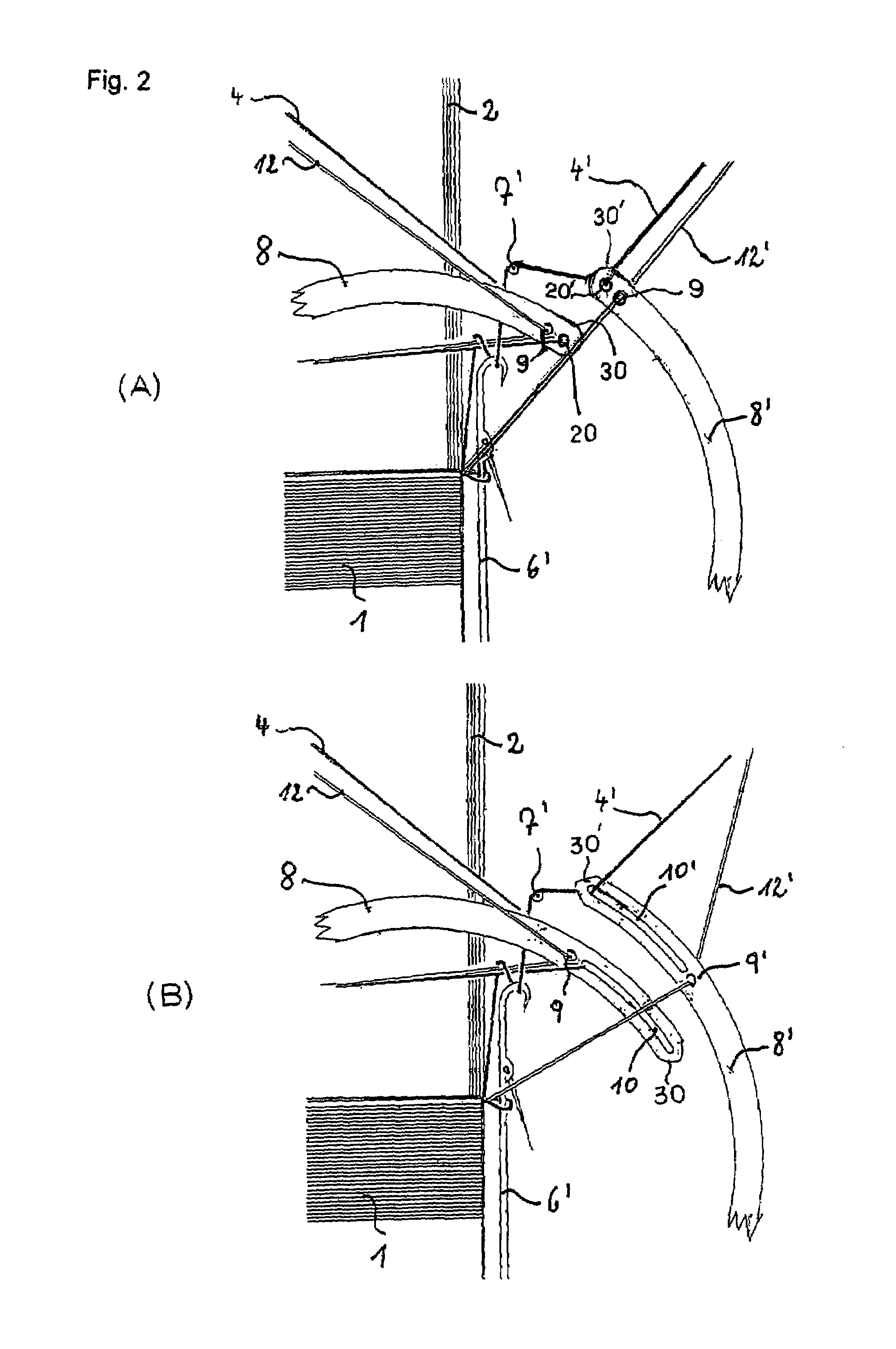

Method and needle webbing loom in order to weave a ribbon

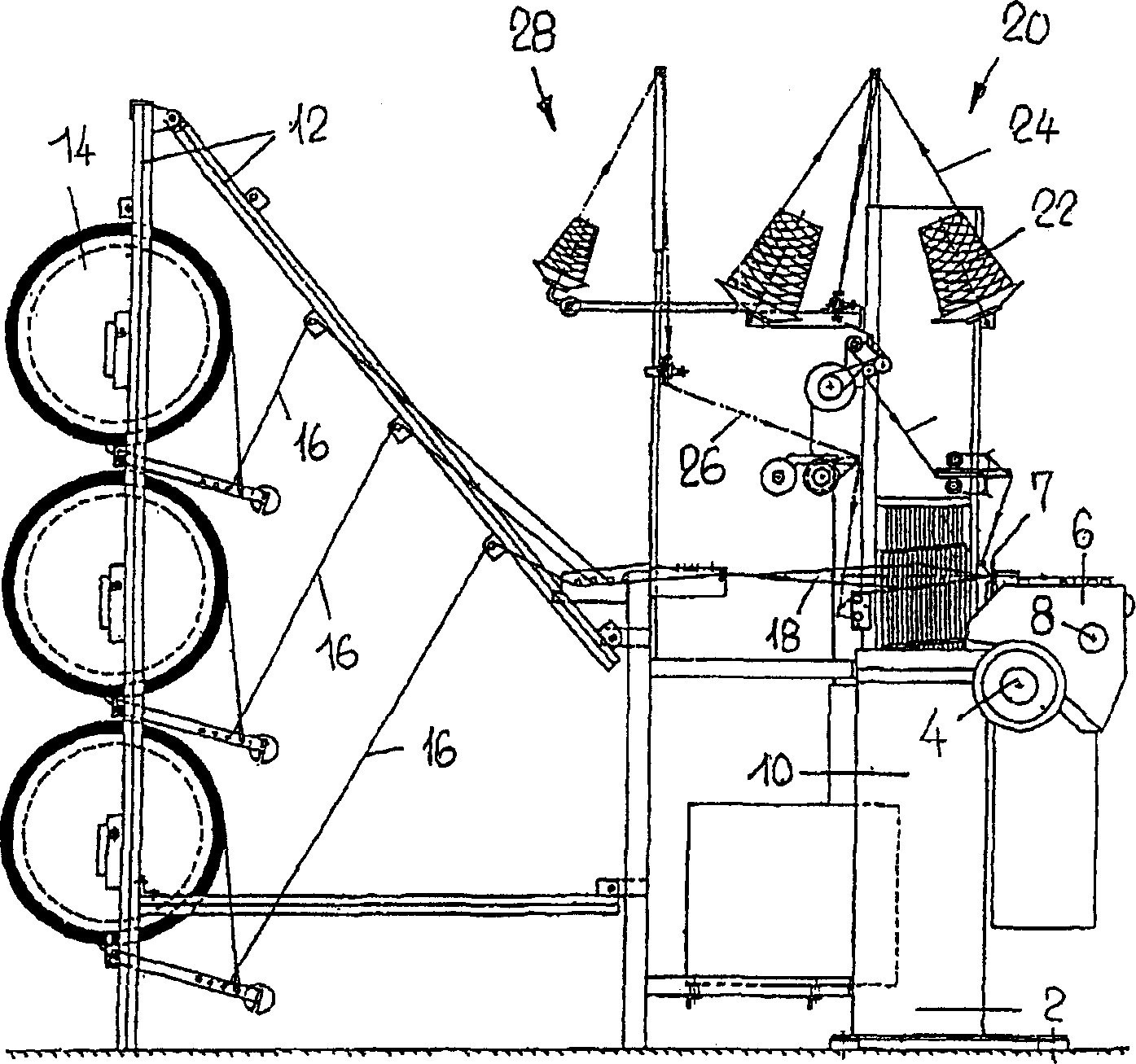

A needle webbing machine which comprises two weft needles (2a, 2b) which work simultaneously and in opposite directions on both ribbon sides, in addition to knitting needles (28a, 28b) which are arranged on both ribbon sides. A yarn lifter (18a, 18b) which works individually and which is used to advance a weft thread (4a, 4b) to a weft needle (2a, 2b), which is open, is provided on each side of the ribbon in order to improve the production thereof.

Owner:TEXTILMA AG

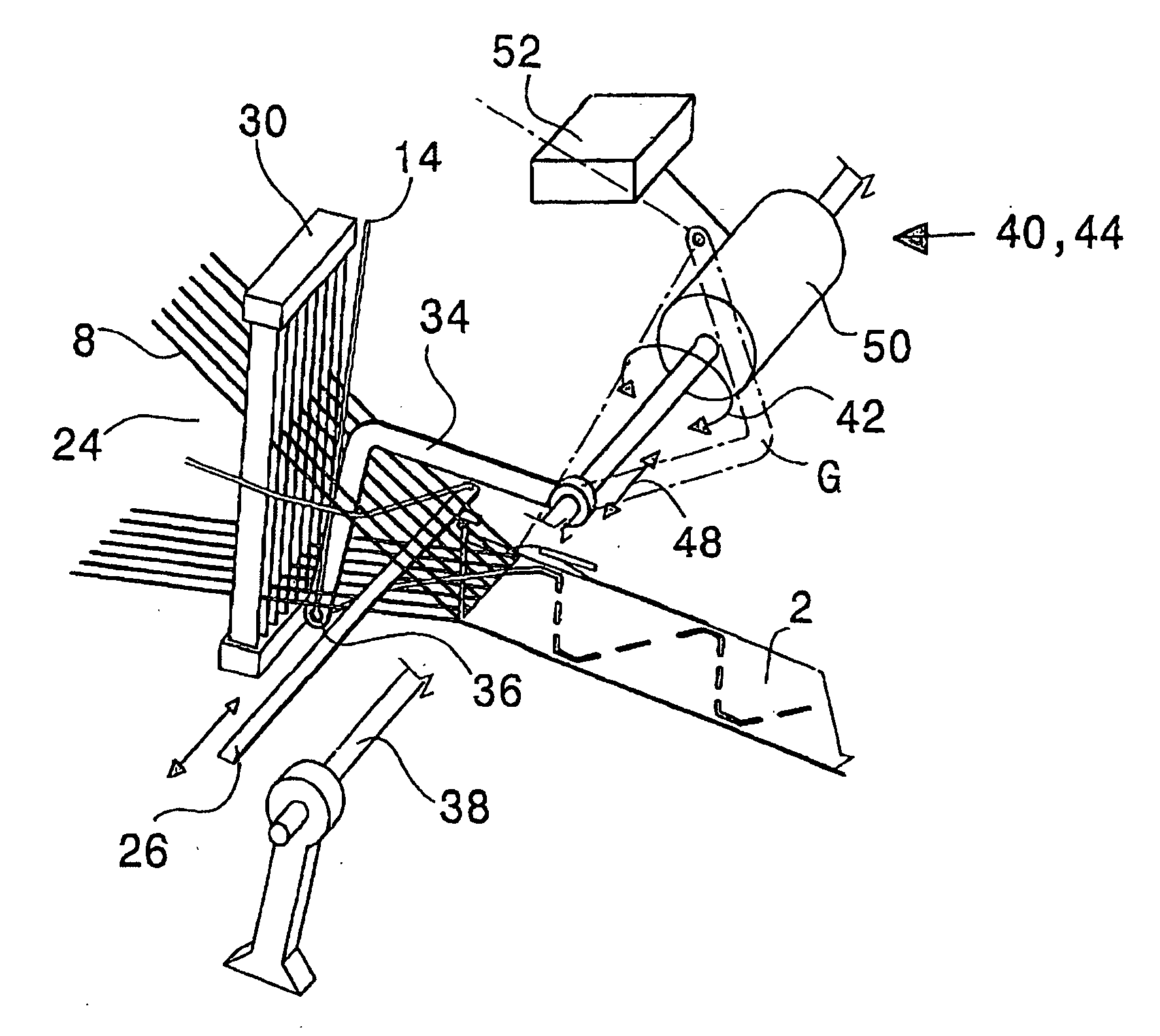

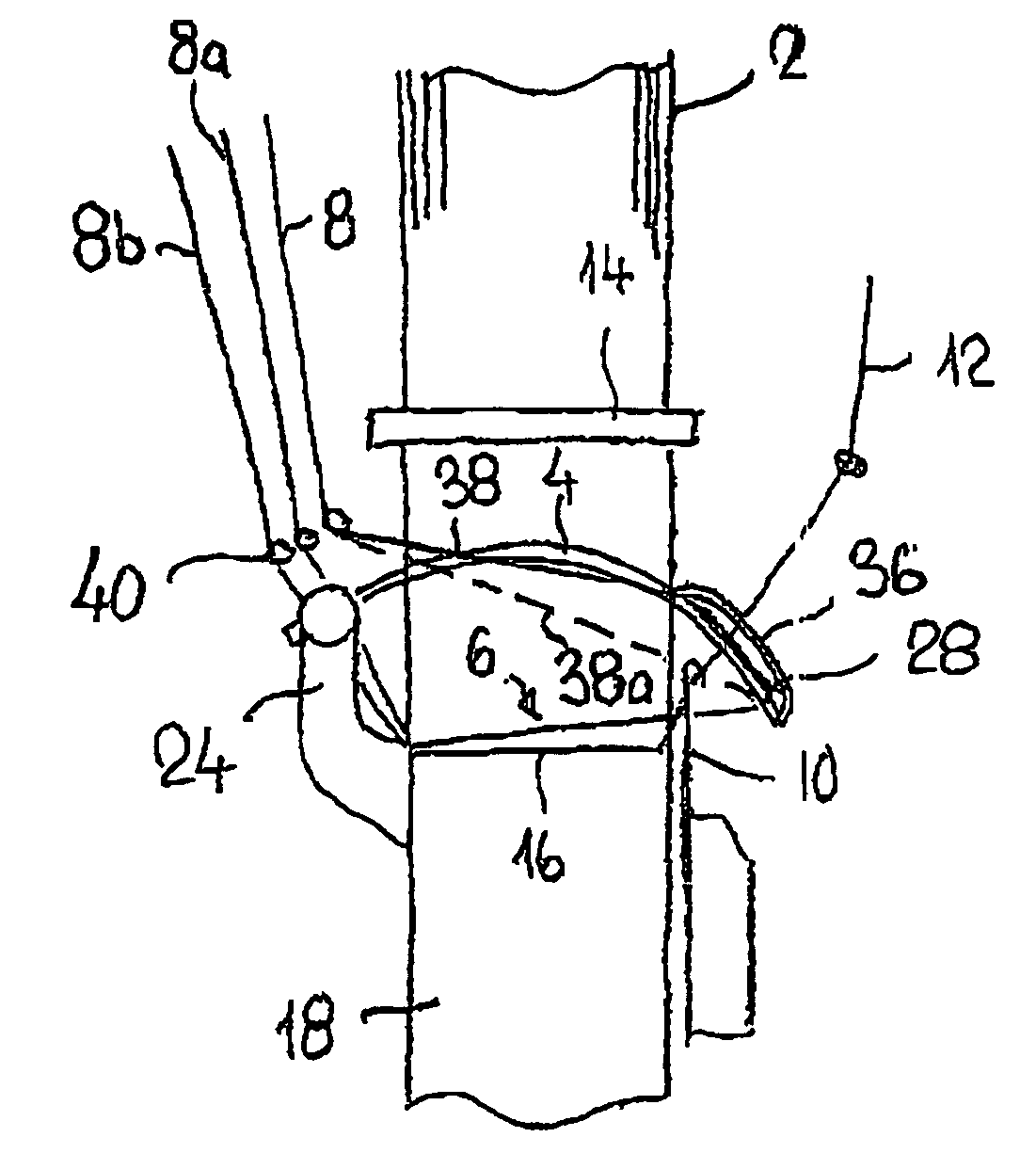

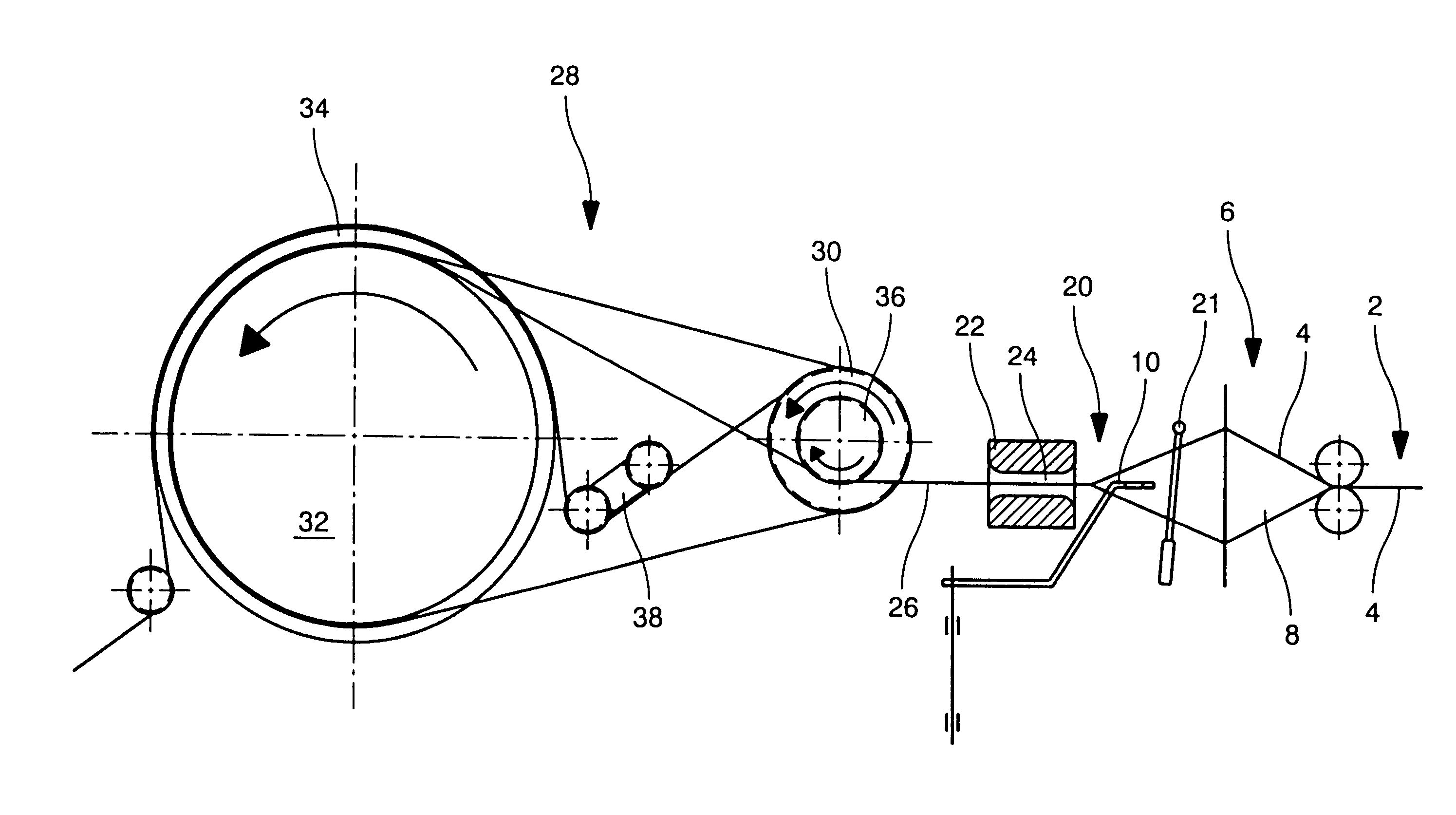

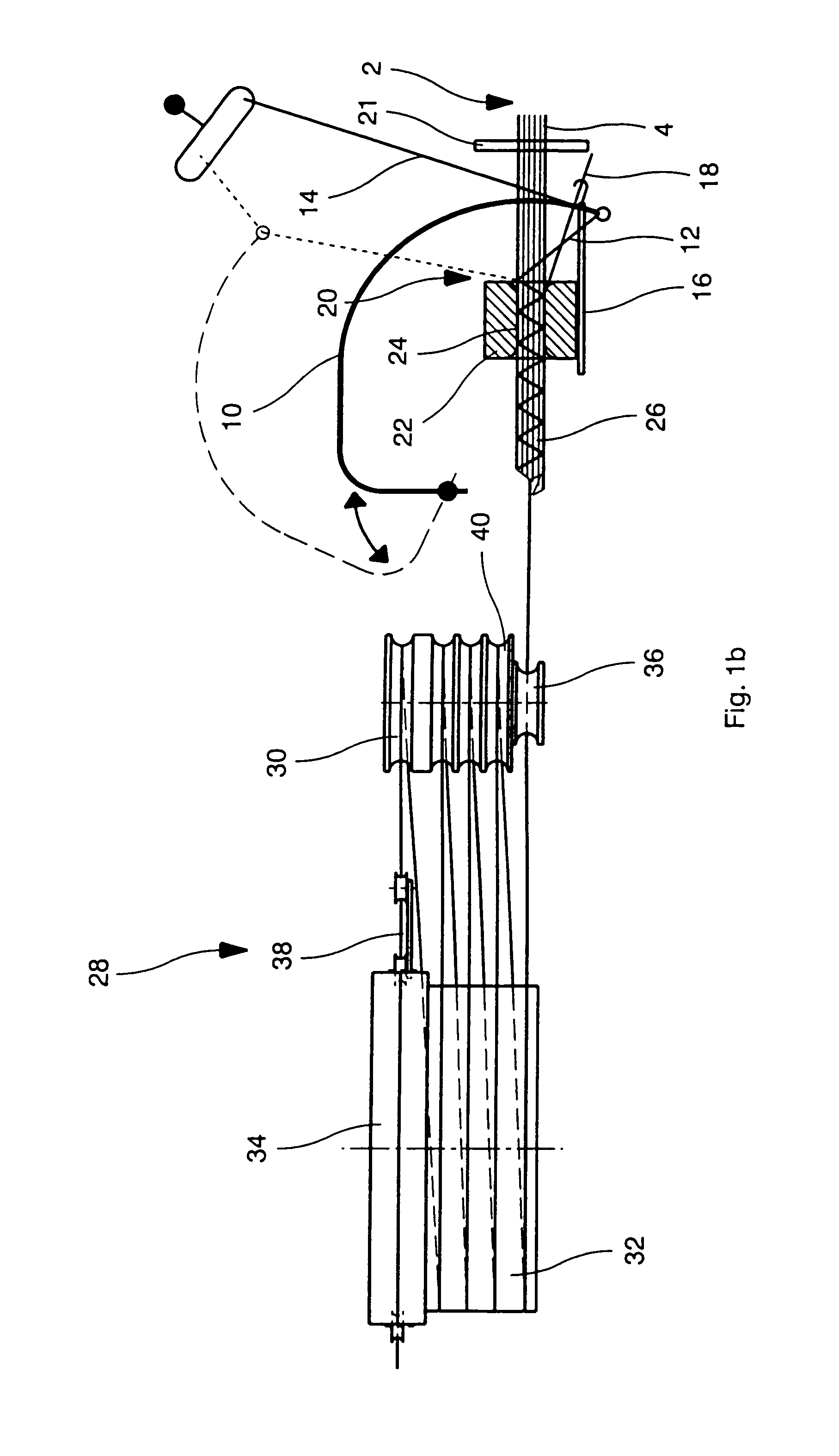

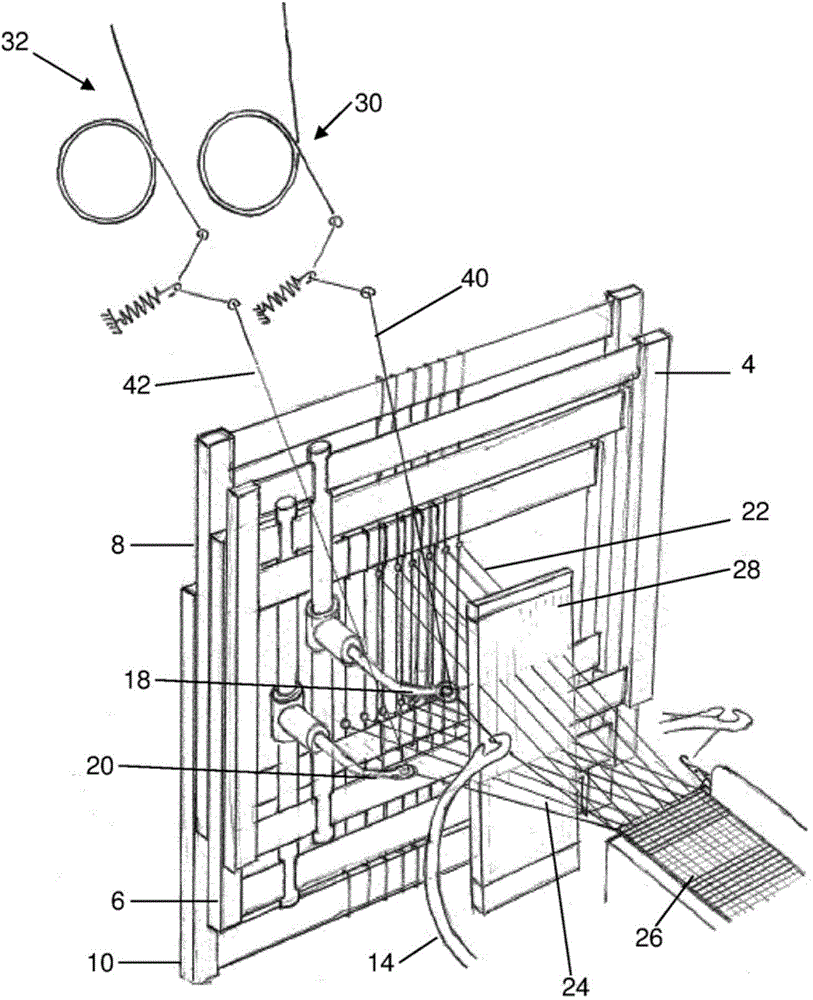

Ribbon Needle Loom for Manufacturing a Strip, in Particular a Label Strip, Having a Woven-In Conductive Thread, in Particular Antenna Thread

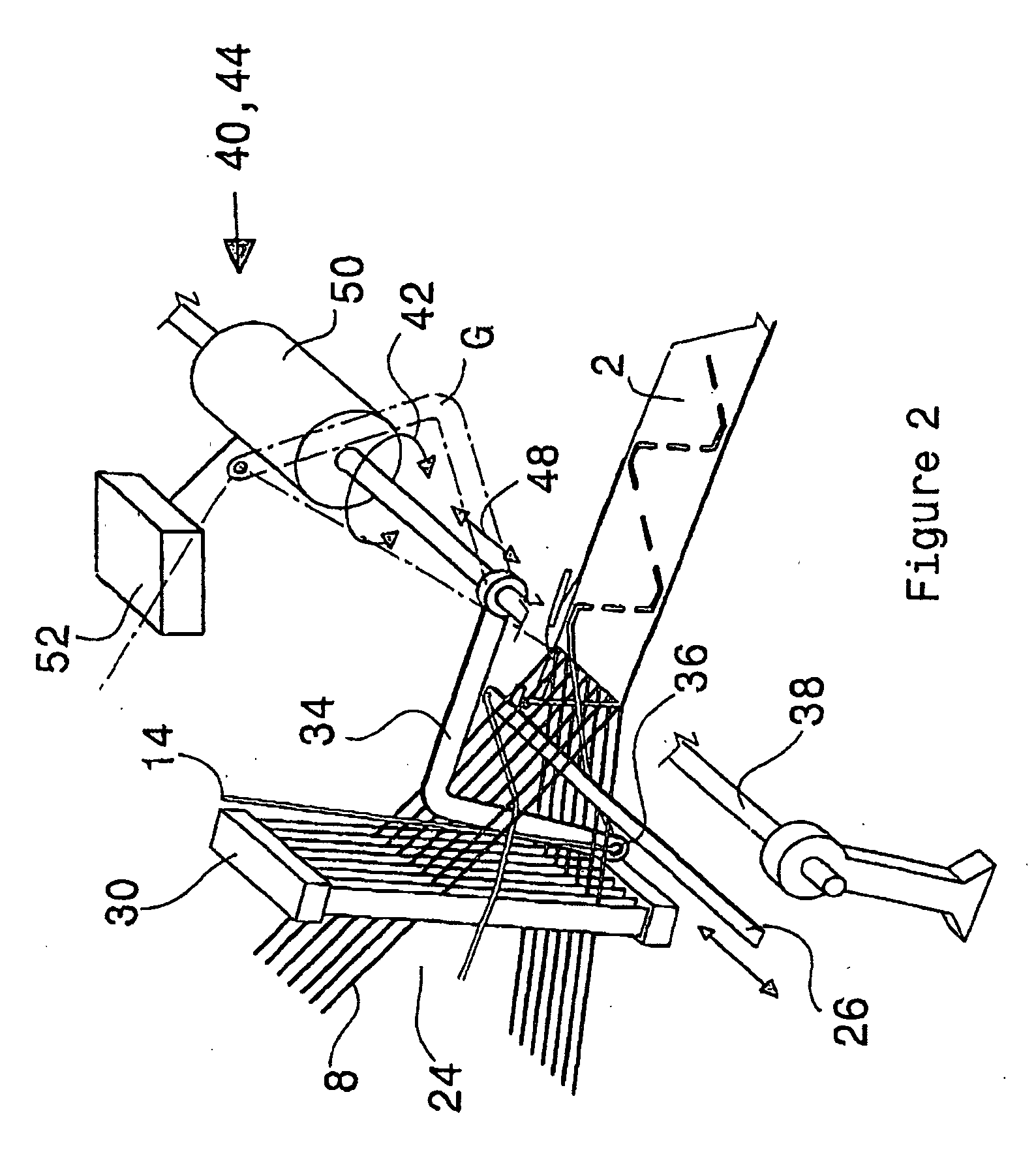

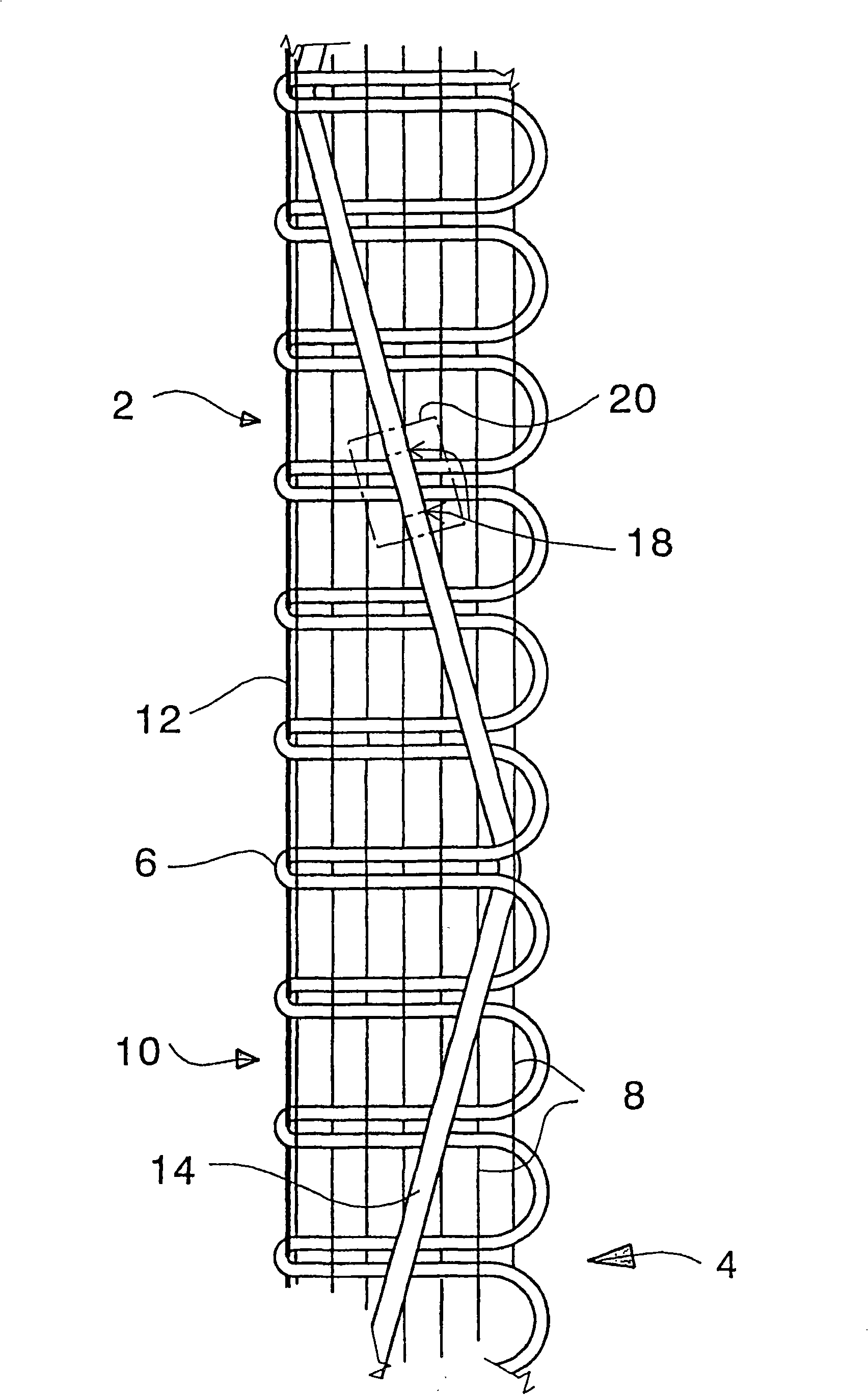

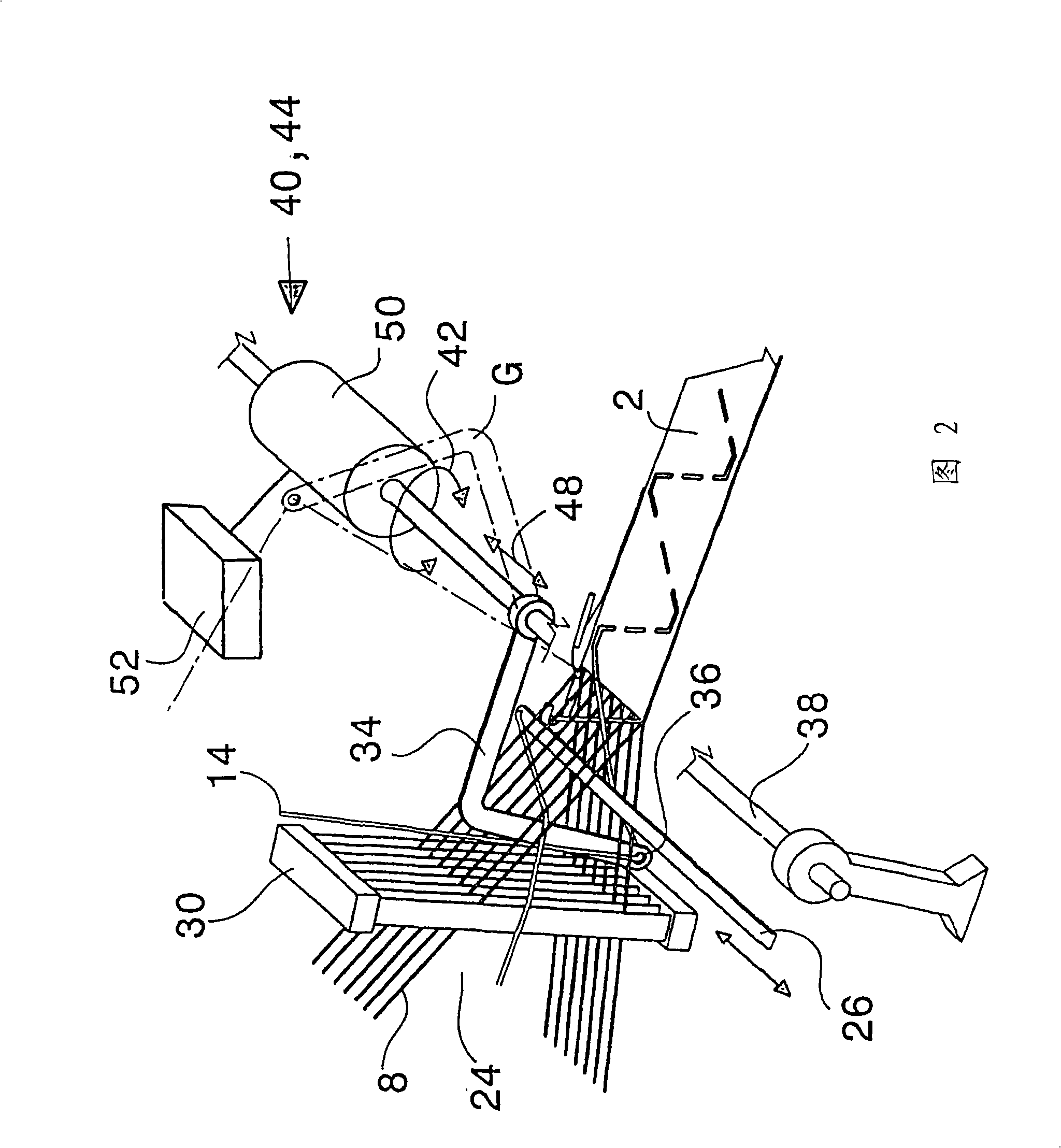

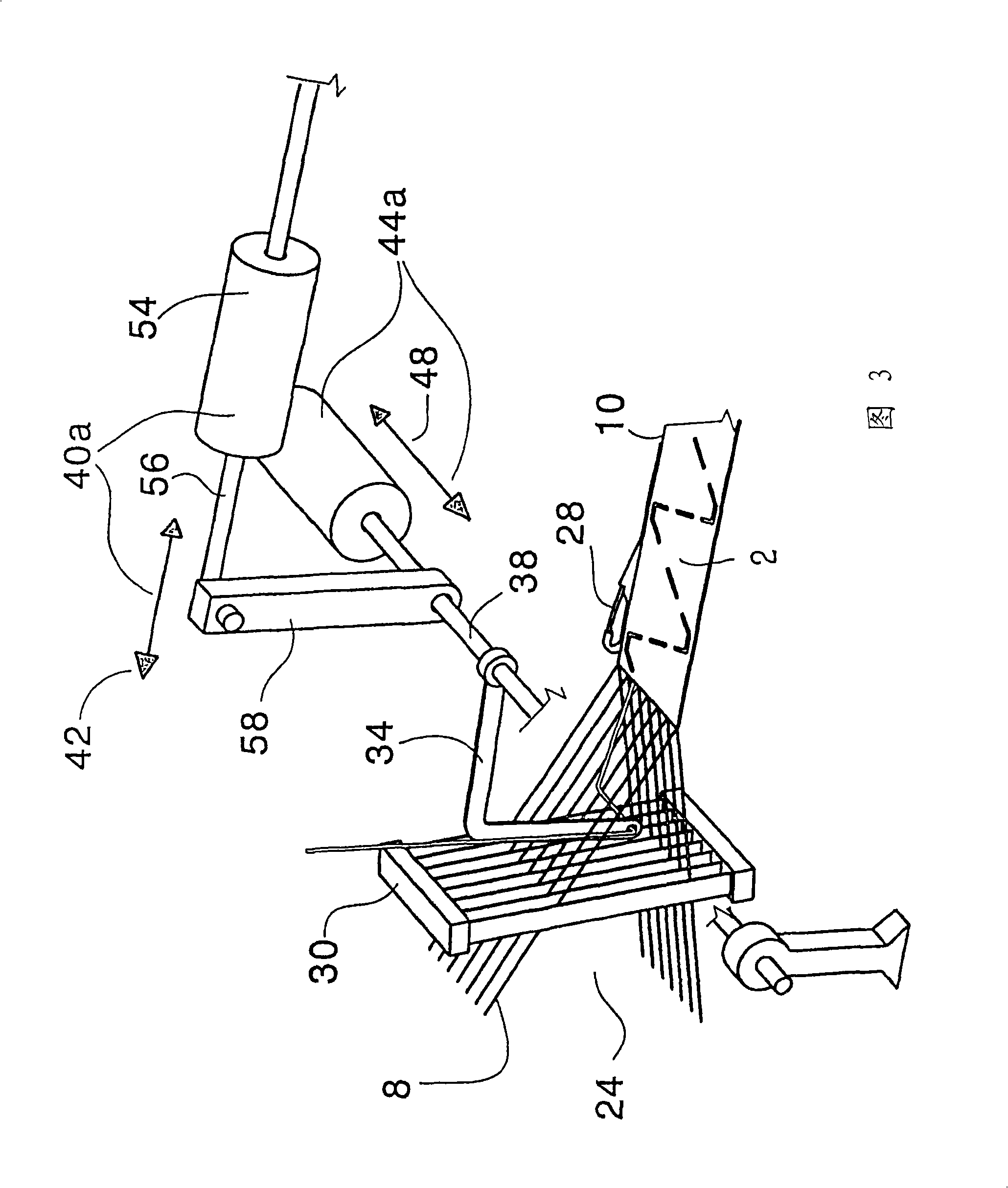

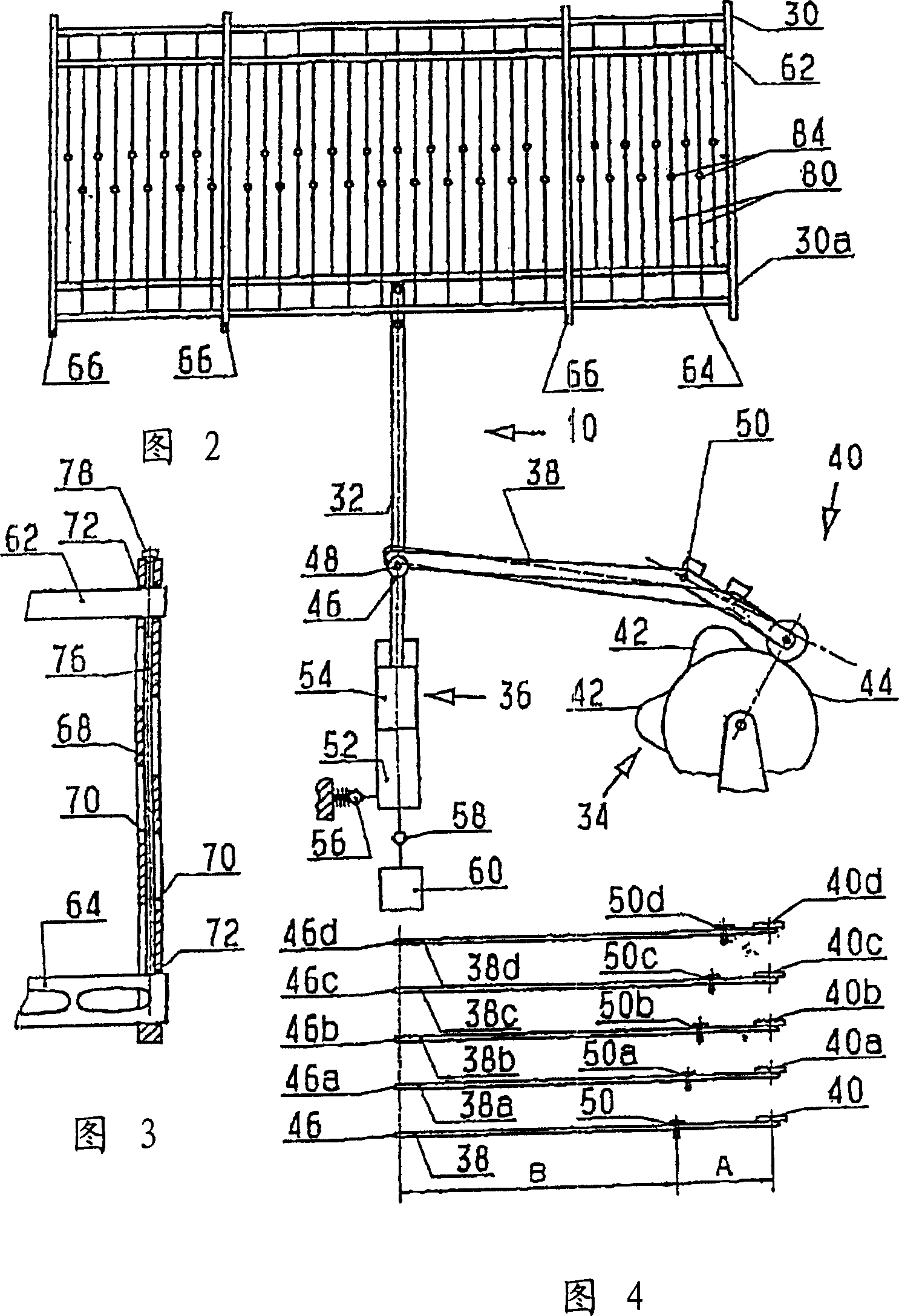

In order to make it possible to weave in a conductive thread, in particular an antenna thread, in a very wide variety of ways in a ribbon needle loom for manufacturing a strip, in particular a label strip, having a shedding apparatus for forming a shed (24) from warp threads (8), a weft insertion needle (26) for inserting weft thread loops, a reed (30) and having a feed apparatus (34) for a thread which has a blade (34) which dips into the shed (24) between warp threads (8) as far as under the insertion path of the weft insertion needle (26), it is proposed that the blade is arranged on a shaft (38) which is oriented transversely with respect to the warp direction. The shaft is connected to a first drive apparatus (40a) for performing a pivoting movement of the shaft. As a result of the pivoting, the blade (34) dips into and out of the shed (24). Furthermore, the shaft is connected to a second drive apparatus (44a) for movement in the axial direction. As a result, the blade (34) can be moved over the width of the strip (2).

Owner:TEXTILMA AG

Method for producing a woven belt strap

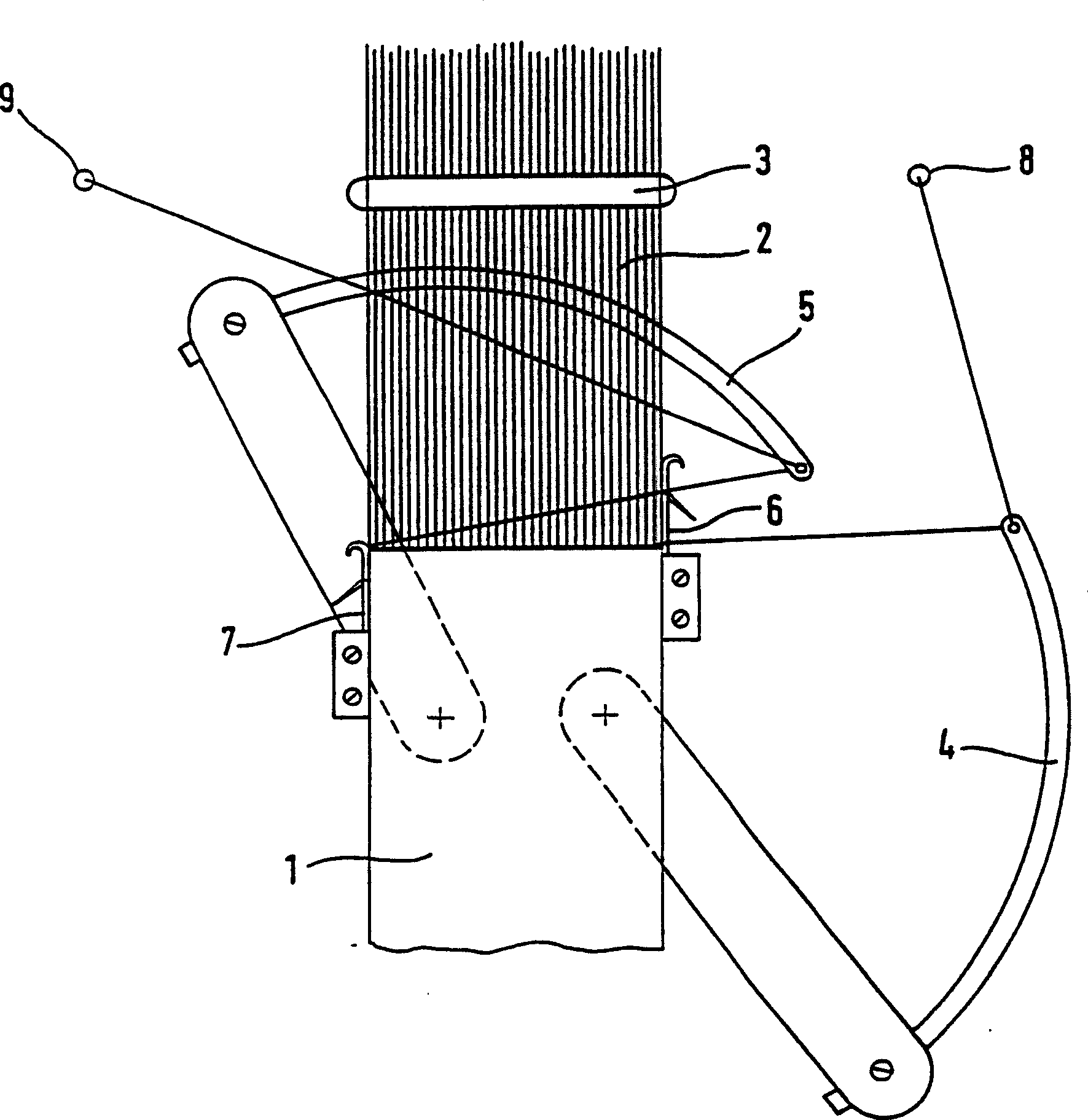

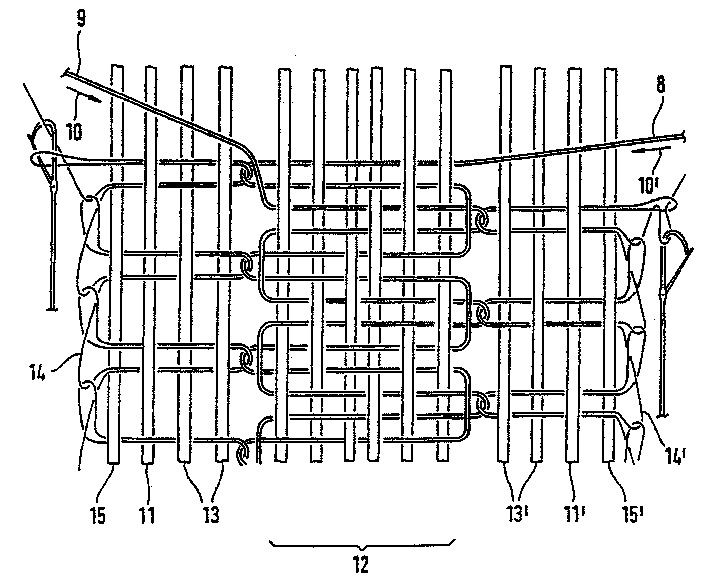

The invention relates to a method for producing a woven belt strap (1), particularly an automobile safety belt strap, which is characterized in that the weft threads (8, 9) are alternately inserted from one belt strap side and then from the other belt strap side, during which at least the first of both warp threads (11, 11', 15, 15') remain on the respective weft entry side without being woven, and a catch thread (14, 14'), which loops the weft on the weft exit side, is drawn into the weave until the warp threads, which remained unwoven with the preceding weft, are woven by the catch thread loop.

Owner:BERGER & HLDG

Weft insertion belt knitting machine used for producing belt, especially label belt knitted with conductive fine yarn specifically antenna fine yarn

Owner:TEXTILMA AG

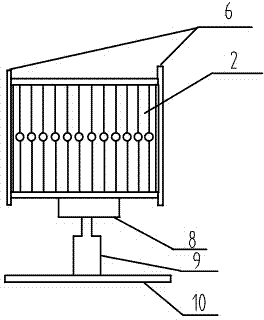

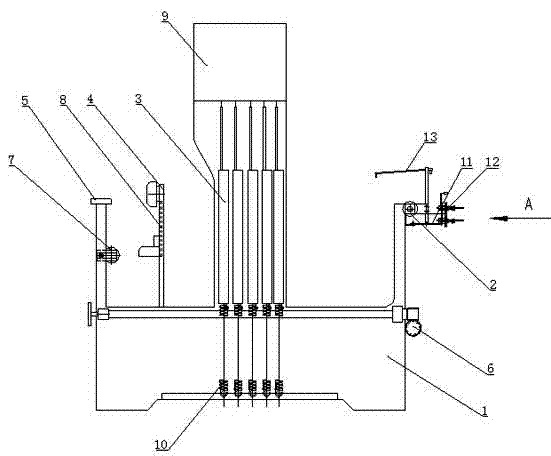

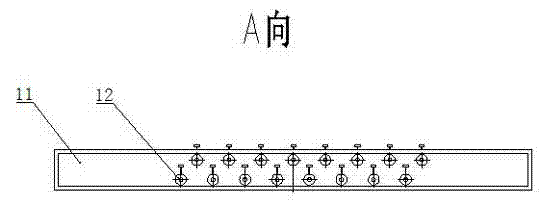

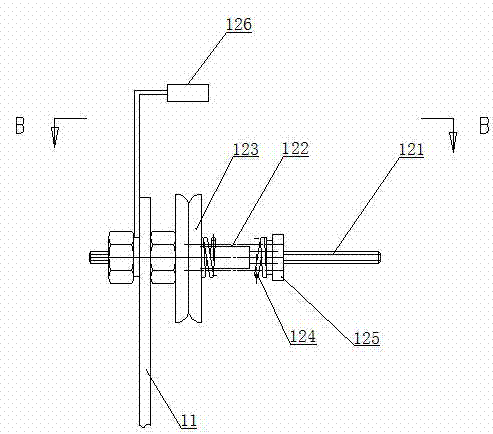

Tapestry weaving semi-automatic sample weaving machine

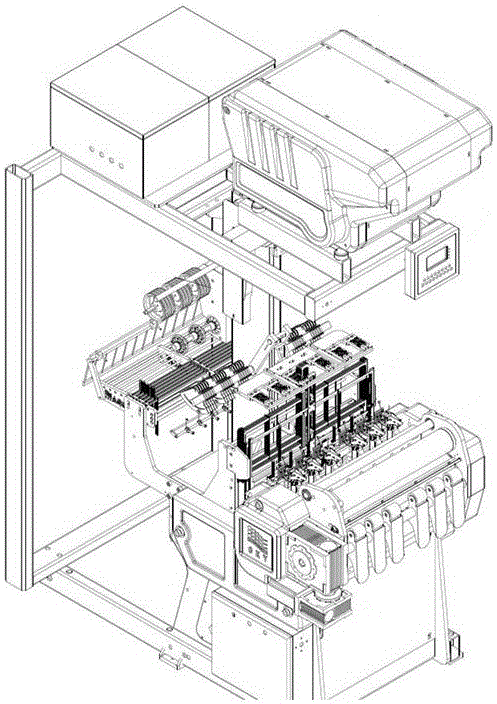

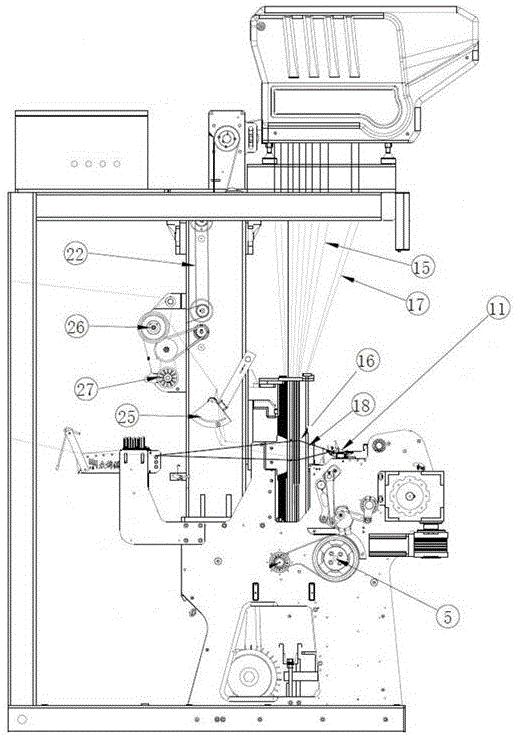

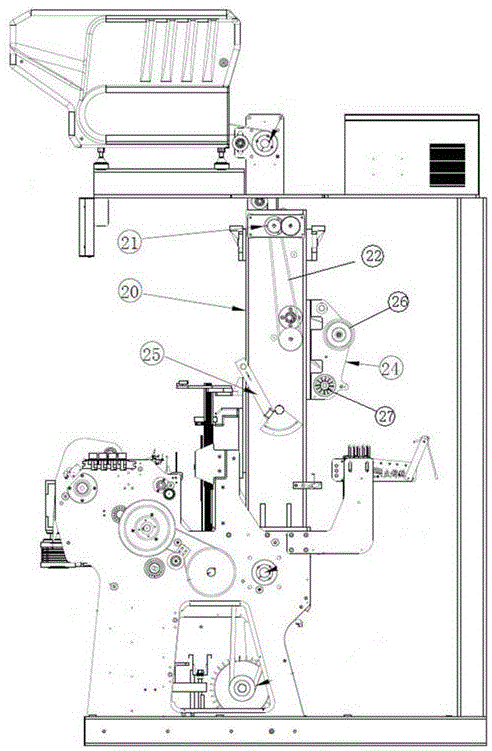

ActiveCN104727001AIncrease productivityReduce labor intensityJacquardsSmallware loomsSemi automaticUltimate tensile strength

The invention designs a tapestry weaving semi-automatic sample weaving machine. The semi-automatic sample weaving machine comprises a weft insertion device, a beating-up device, a let-off device and a take-up device and is characterized by further comprising a pneumatic opening device and an electronic jacquard opening device. The electronic jacquard opening device is fixed between the let-off device and the take-up device. The pneumatic opening device is fixed in front of the electronic jacquard opening device. The semi-automatic sample weaving machine has the advantages that the pneumatic opening device and the electronic jacquard opening device are effectively combined with a traditional sample weaving machine, a traditional purely-manual tapestry weaving machine is changed into the semi-automatic tapestry weaving machine, equipment automation level is further increased, labor intensity of operators is relieved, and production efficiency is increased effectively.

Owner:IANGSU COLLEGE OF ENG & TECH

Weft introduction needle for a ribbon needle loom

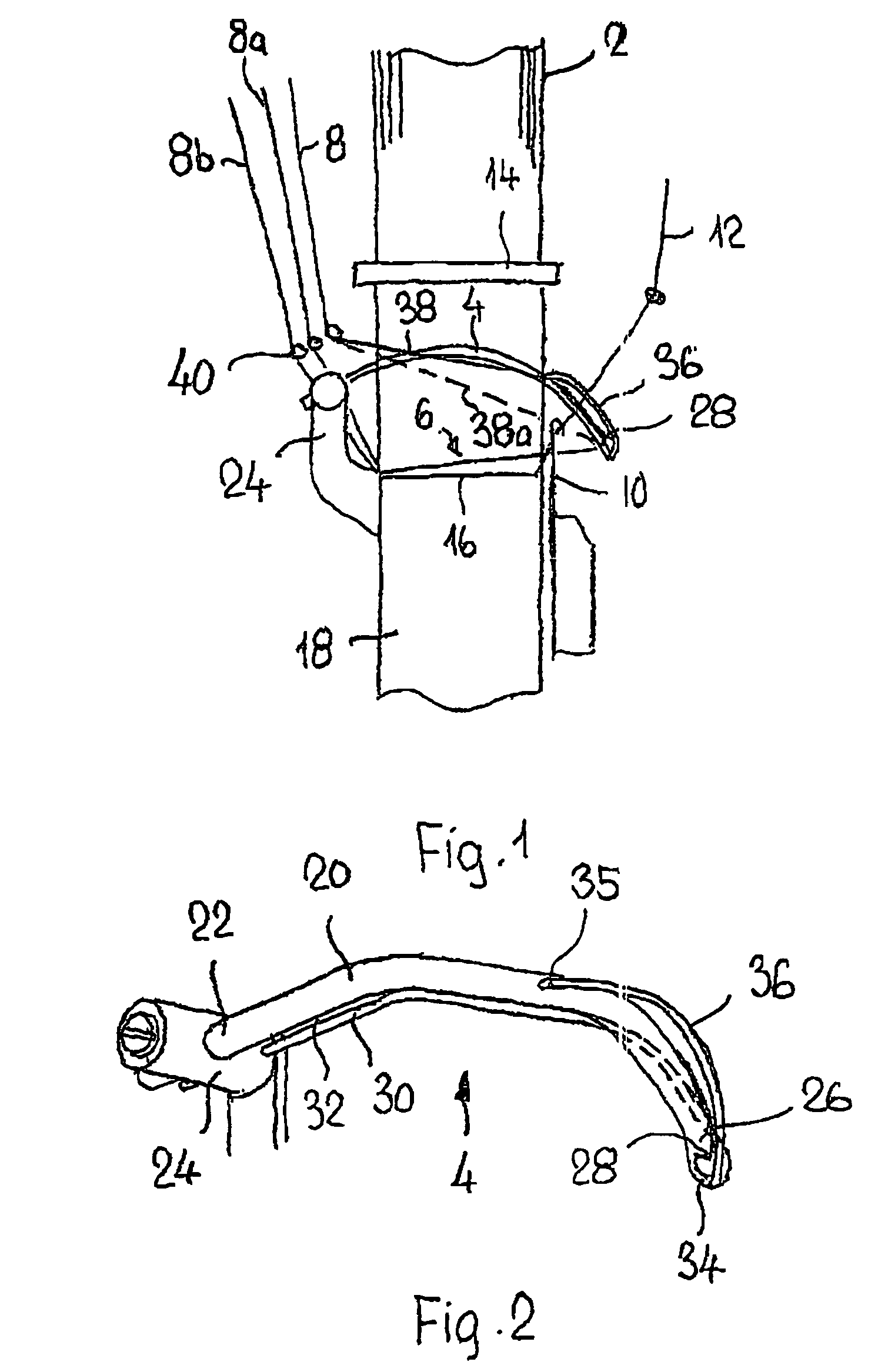

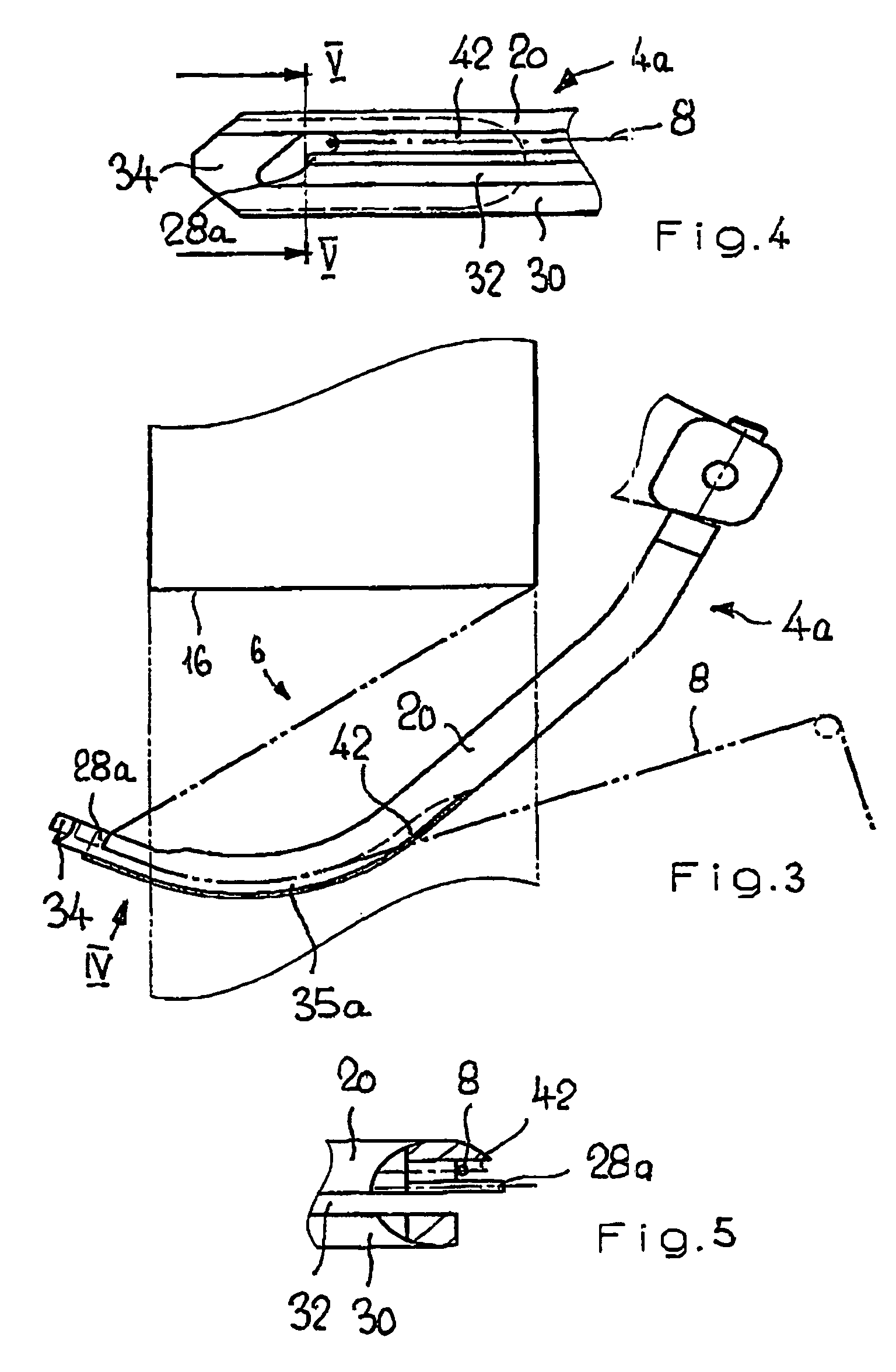

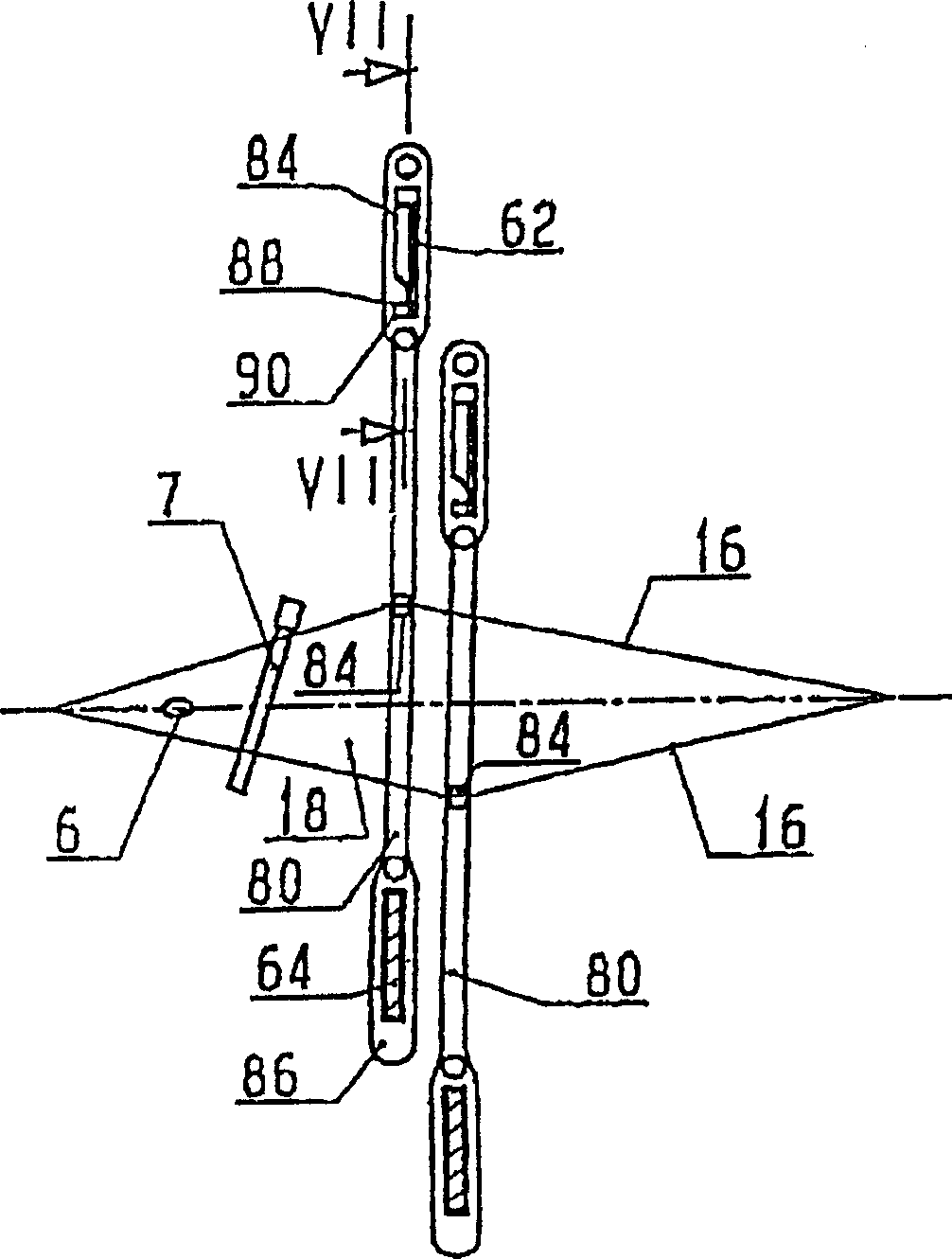

The weft introduction needle for a ribbon needle loom comprises a bent arm (20), which may be fixed at one end (22) to a drive element (24) of a ribbon needle loom and comprises a hook (28) at the other end (26), for registering an exposed thread loop. The arm (20) is provided with a guide piece (30) essentially over the whole length thereof, forming a longitudinal slot (32) with the arm (20) for accommodating at least one weft thread. At the end away from the hook (28), the guide piece is connected to the arm (20), by means of a connector piece (34). A guidance element (36) is arranged on the side of the arm (20) facing away from the guide piece (30) in order to improve the guiding of a weft thread loop, extending over only a section of the length of the arm, starting from the vicinity of the hook (28), whereby the guidance element (36) forms a diverter point (35) in the region away from the hook (28), for diverting the free flare (38) of the weft thread loop (6).

Owner:TEXTILMA AG

Narrow fabric needle loom for producing a strip-shaped tissue, and corresponding strip-shaped tissue

InactiveCN1422342AGood lookingGood physical propertiesSmallware loomsSelvedgesRotational axisDevice form

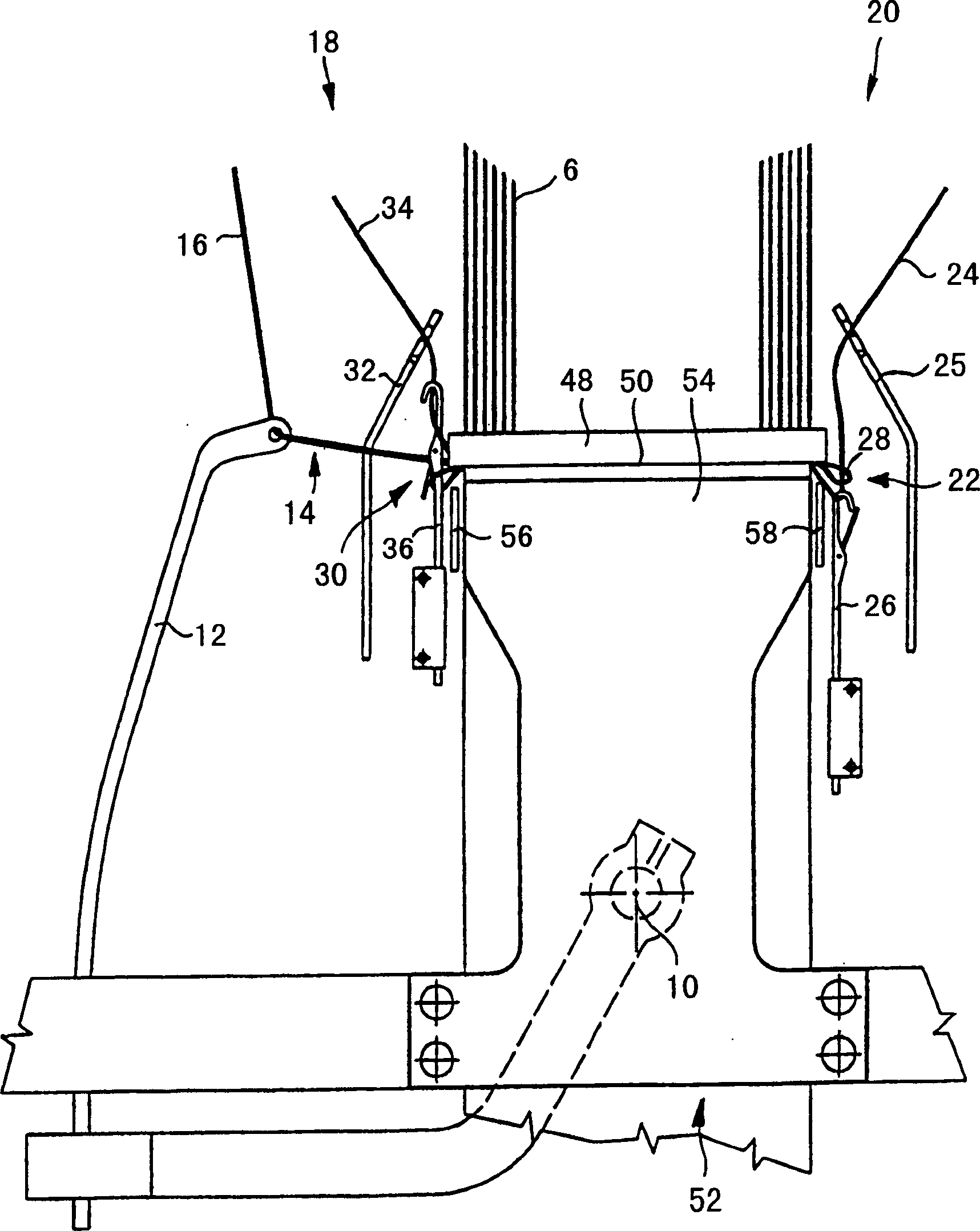

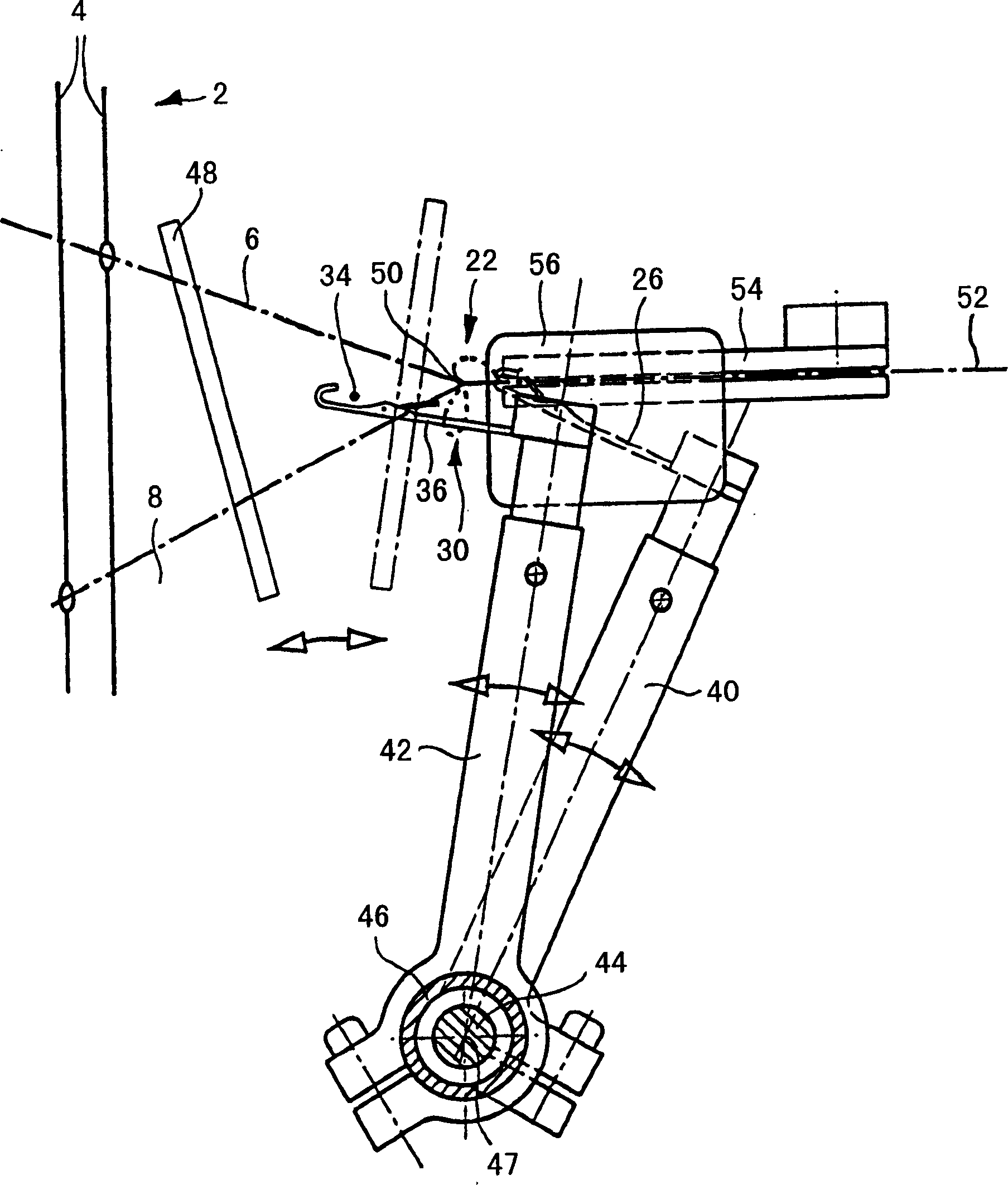

The invention relates to a narrow fabric needle loom, comprising a shedding device forming a shed, and a weft insertion needle (12) for at least one weft loop (14). A knitting needle (26) is provided on the discharge end (20) of the shed facing away from the feed end (18) of the weft insertion needle (12) and secures the weft loops (14) by meshing (22). A second knitting needle (36) that meshes (30) the loops is provided on the feed end (18) of the weft insertion needle (12). The knitting needles for the feed end (18) and the discharge end (20) are mounted so that they can be swiveled about the same rotational axis (47).

Owner:TEXTILMA AG

Ribbon needleloom

InactiveCN1856608ASupport (hold) improvementForced motion volume reductionSmallware loomsHealdsEngineeringMechanical engineering

Owner:TEXTILMA AG

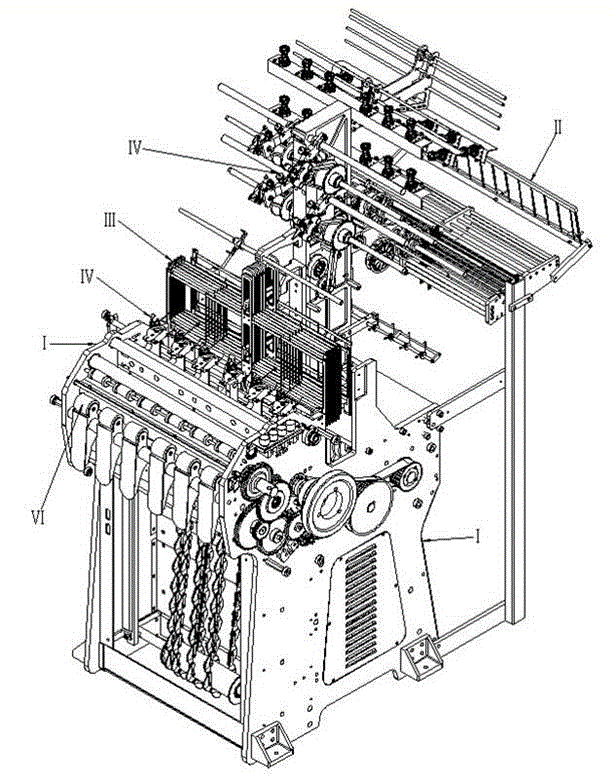

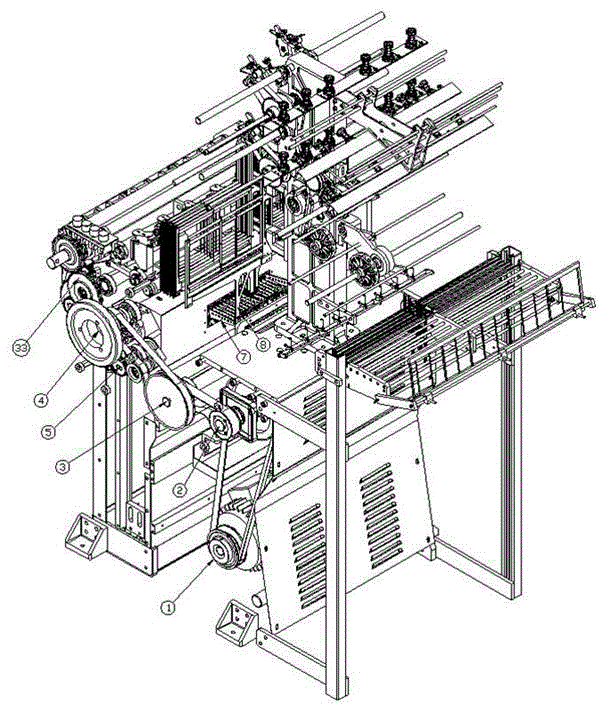

Multi-color warp and weft dual-jacquard type high-speed flat ribbon loom

ActiveCN105063861ARich patternsColorfulSmallware loomsHealdsProtection mechanismPulp and paper industry

The invention discloses a multi-color warp and weft dual-jacquard type high-speed flat ribbon loom. The flat ribbon loom comprises a rack with a middle stand column and a weaving base, and a transmission mechanism, a warp yarn delivery mechanism, a weft yarn delivery mechanism, a catch end delivery mechanism and an electronic head needle selection mechanism are arranged on the rack. A connecting rod weaving mechanism, a heald frame opening mechanism, a warp yarn breaking power outage protection mechanism and a winding mechanism are arranged on the weaving base. By means of the loom, while warp yarn jacquard weaving is performed, multi-color jacquard weaving can also be performed on weft yarn, the weft yarn is changed into multiple colors from a single color, ribbons brighter in color can be obtained without increasing the thickness of the ribbons, and the usage amount of colorful warp yarn is greatly reduced.

Owner:泉州众锦源精密机械有限公司

Loom for producing a woven article with a profiled cross section, in particular a rope

InactiveUS20110155276A1Relieve pressureAvoid analysisSmallware loomsAuxillary apparatusYarnWoven fabric

The loom contains a weaving station, at which warp yarns can be interwoven by means of at least one weft yarn, a device for supplying the warp yams, and a device for supplying the at least one weft yam. A shedding device for forming a shed from the warp yarns, and a weft insertion needle for inserting a weft yarn loop into the shed, are also present. The weft yam loop is tied off with a knitting needle and beaten with a reed. A take-down device serves to draw off the woven fabric that is produced. In order to produce a profiled woven article, the weaving station is assigned a fabric holder with a shaping aperture whose opening cross section corresponds substantially to the cross section of the profiled woven article that is to be produced with a round or polygonal cross section.

Owner:TEXTILMA AG

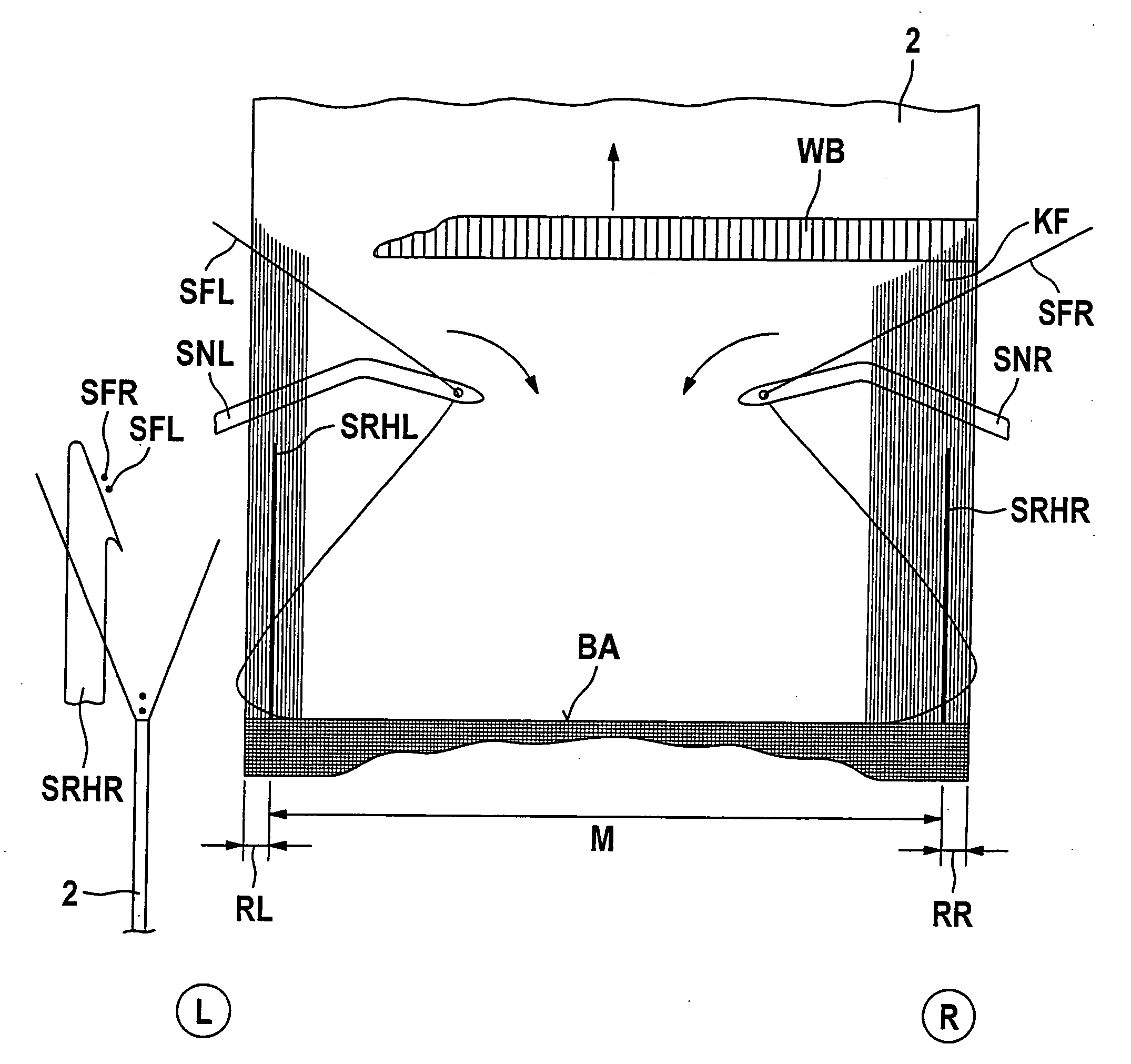

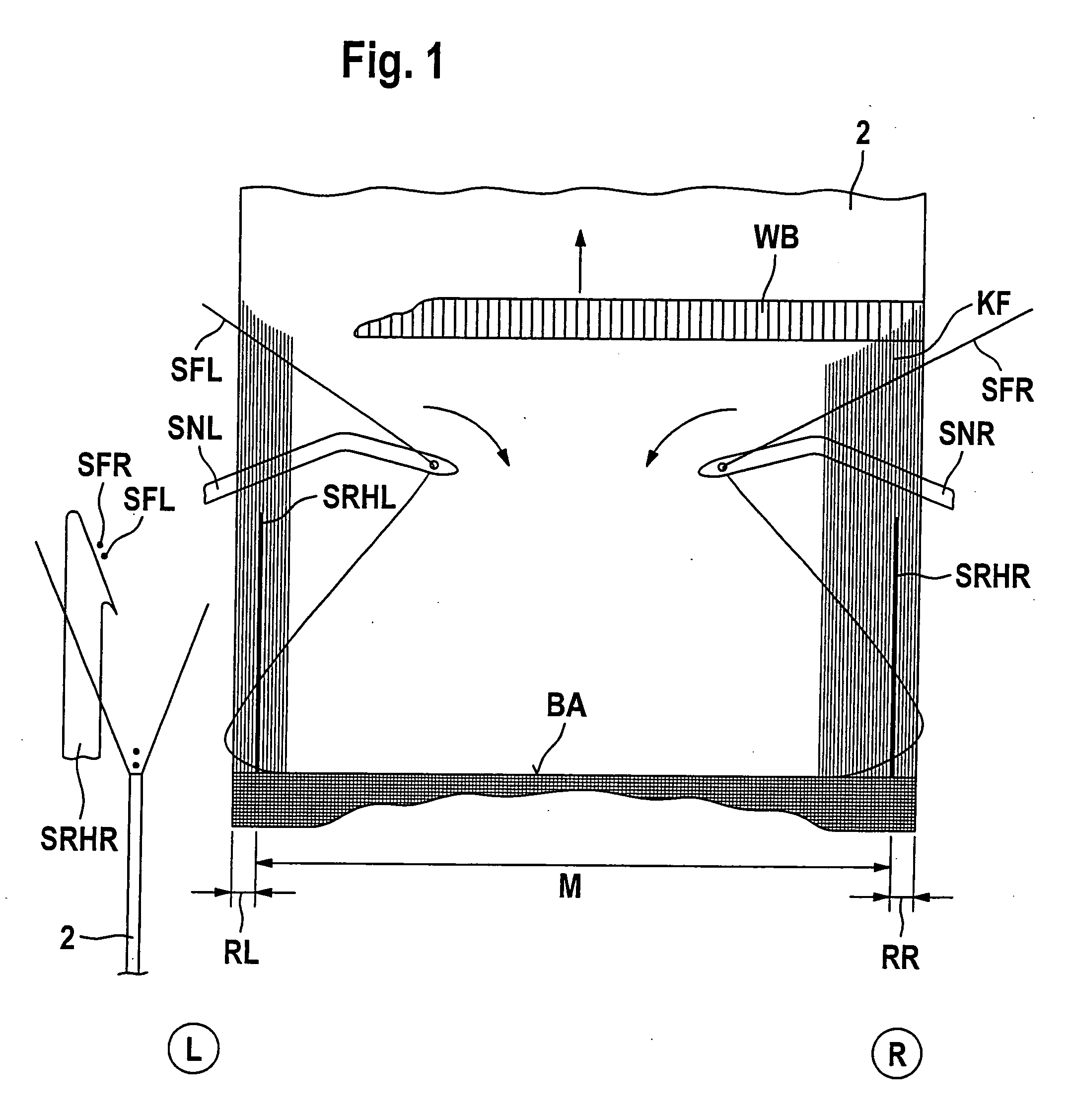

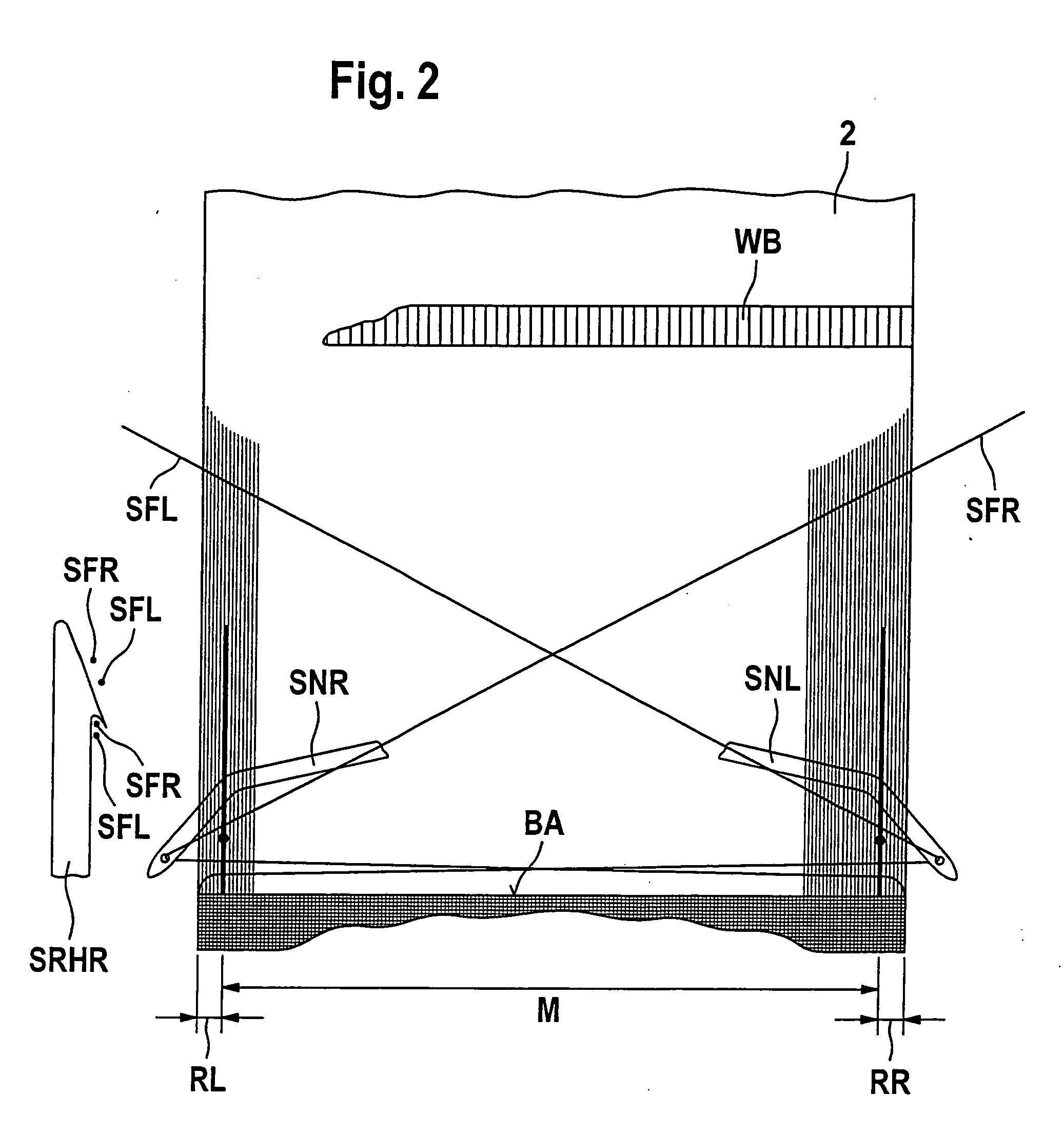

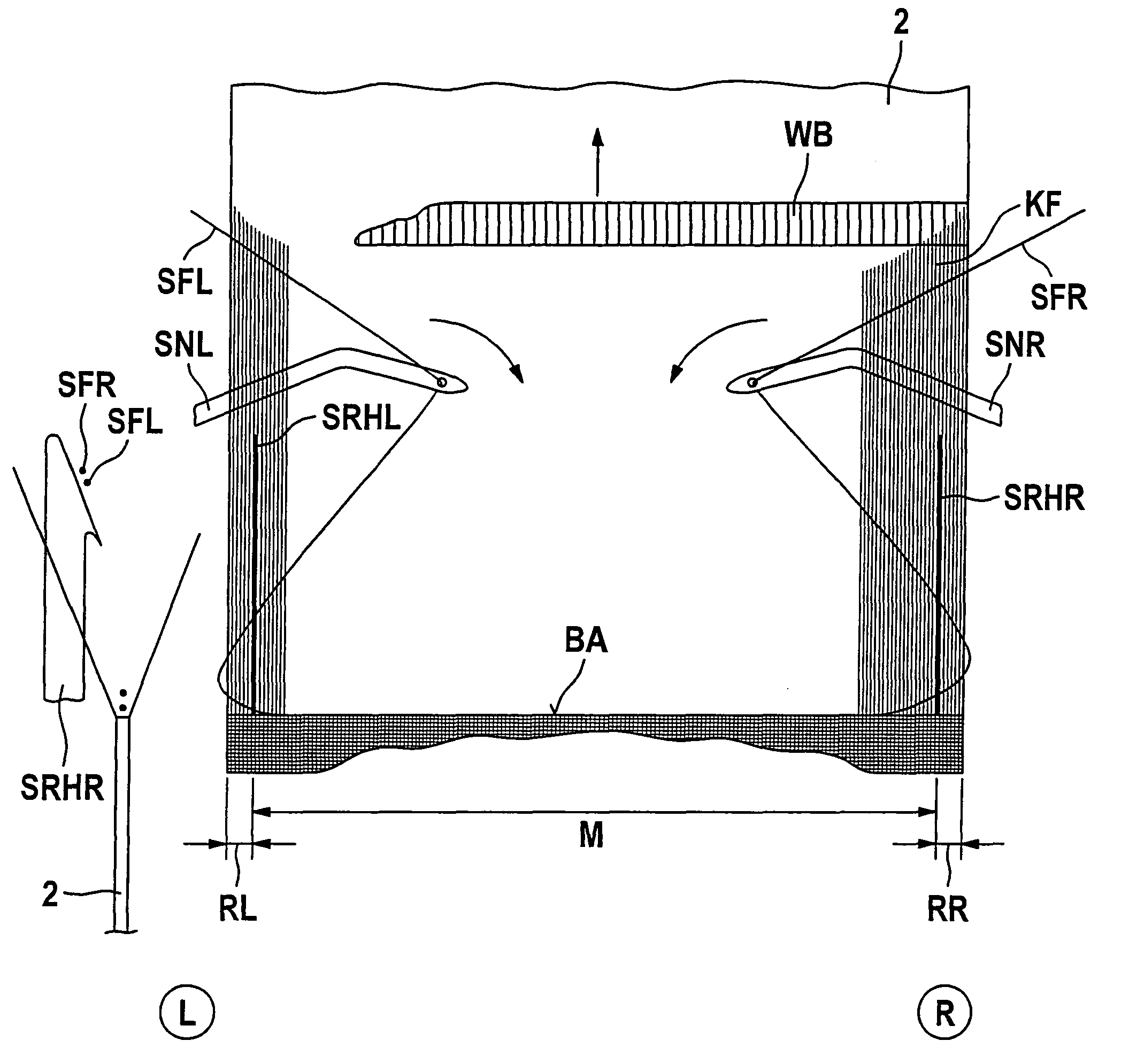

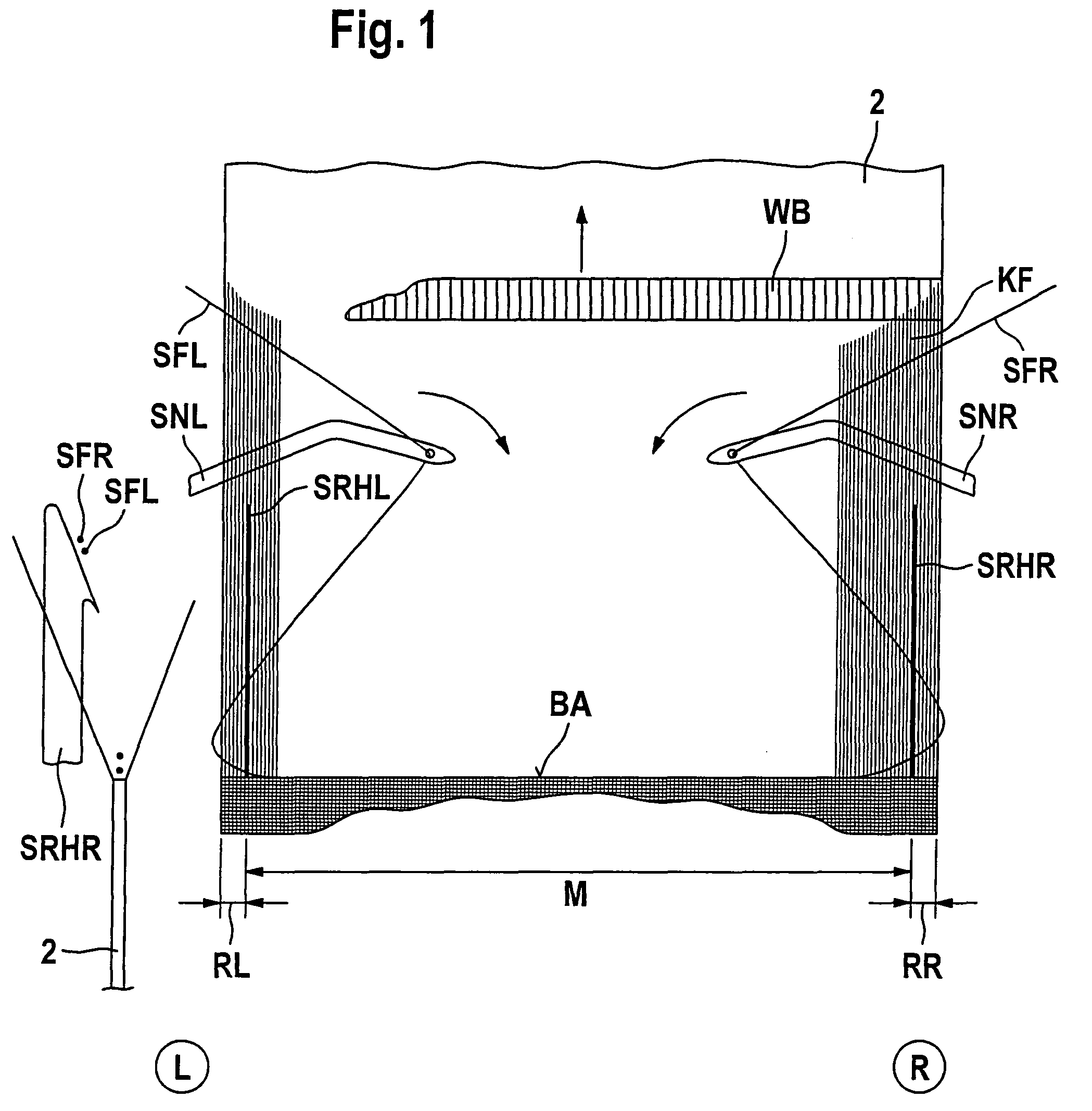

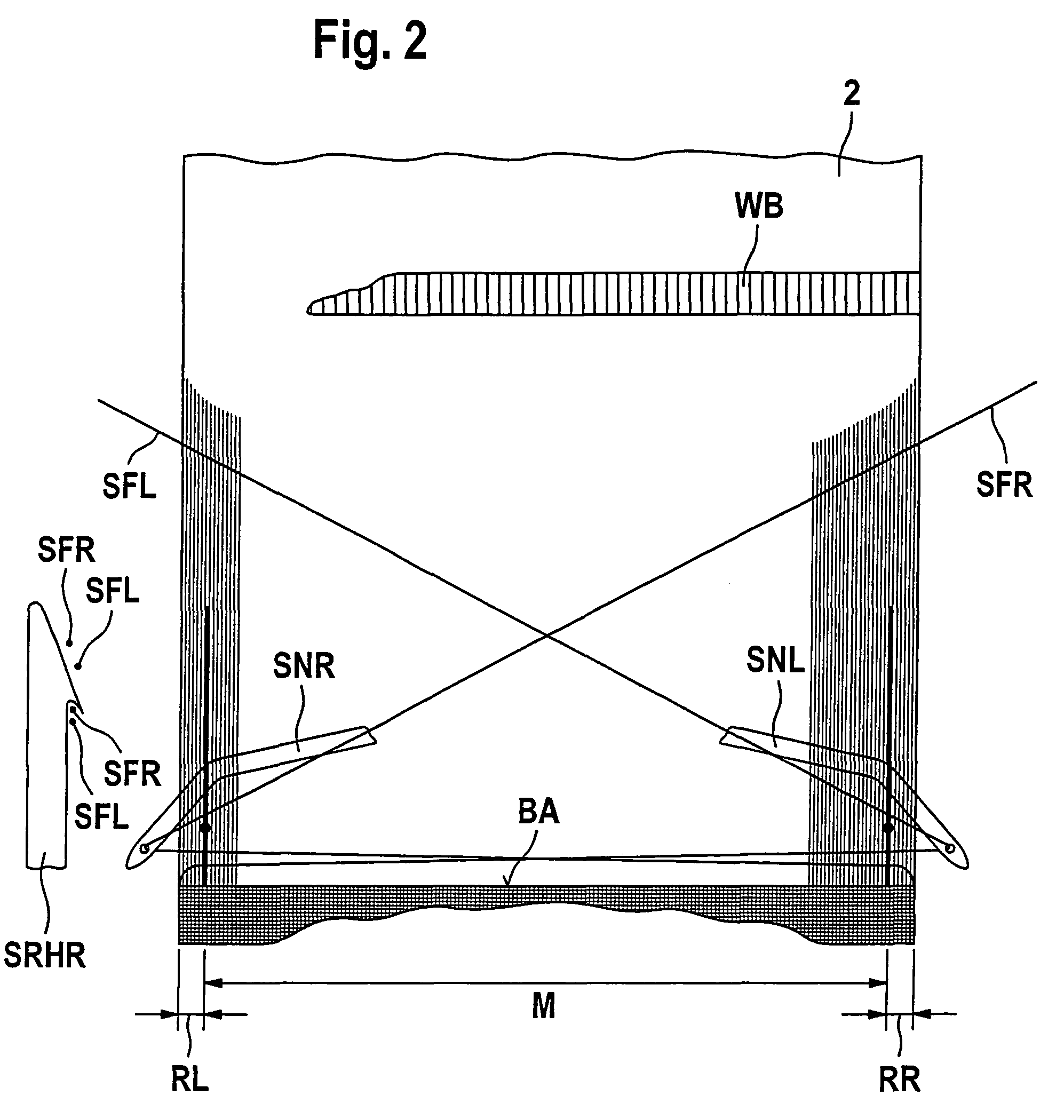

Seat Belt Webbing, Method and Narrow Fabric Needle Loom for Production of Same

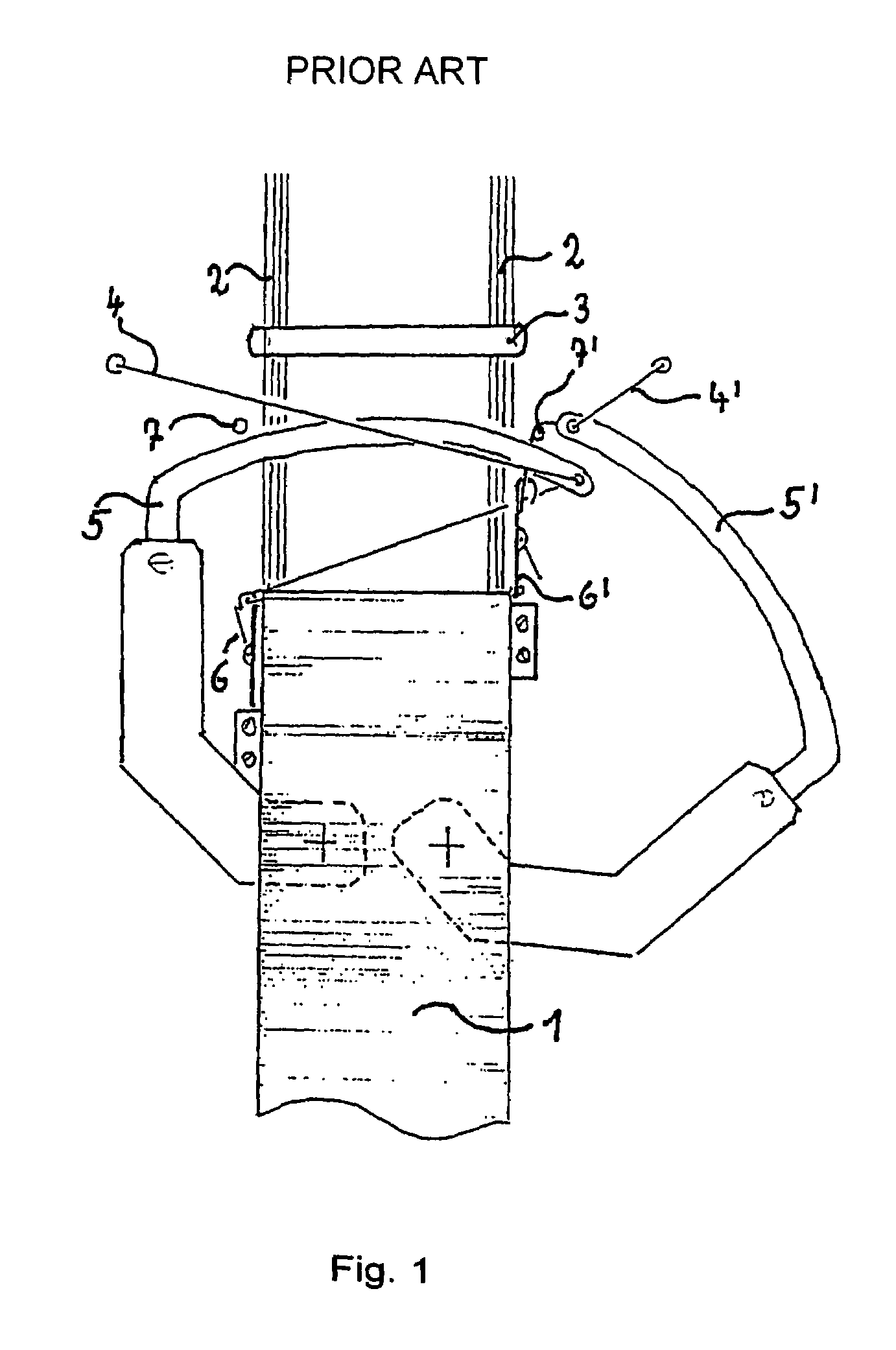

The invention relates to a method for weaving a webbing, comprising at least one first (right-hand) weft thread and at least one second (left-hand) weft thread, characterized in that the two weft threads are introduced into the same shed from both sides of the webbing, are wound around weft thread retainers in weft change loops, are substantially retained by the weft thread retainers until shed change and are then stripped off from the left thread retainers by the reed and after shed change and are bound against the stop.

Owner:BERGER JOHANN

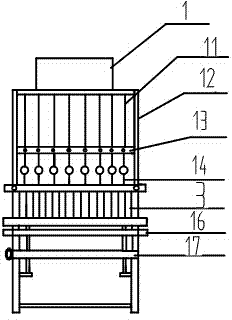

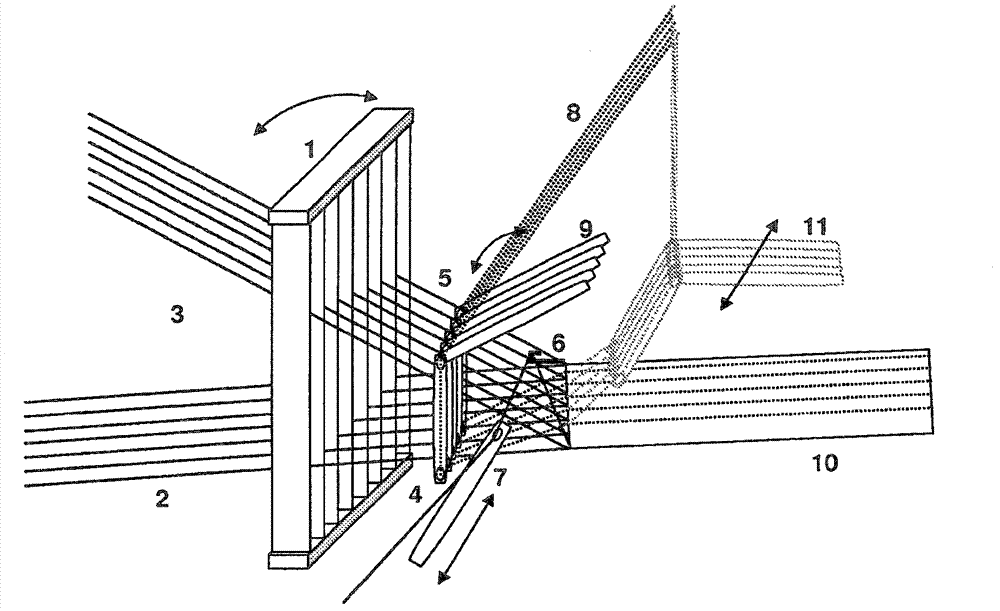

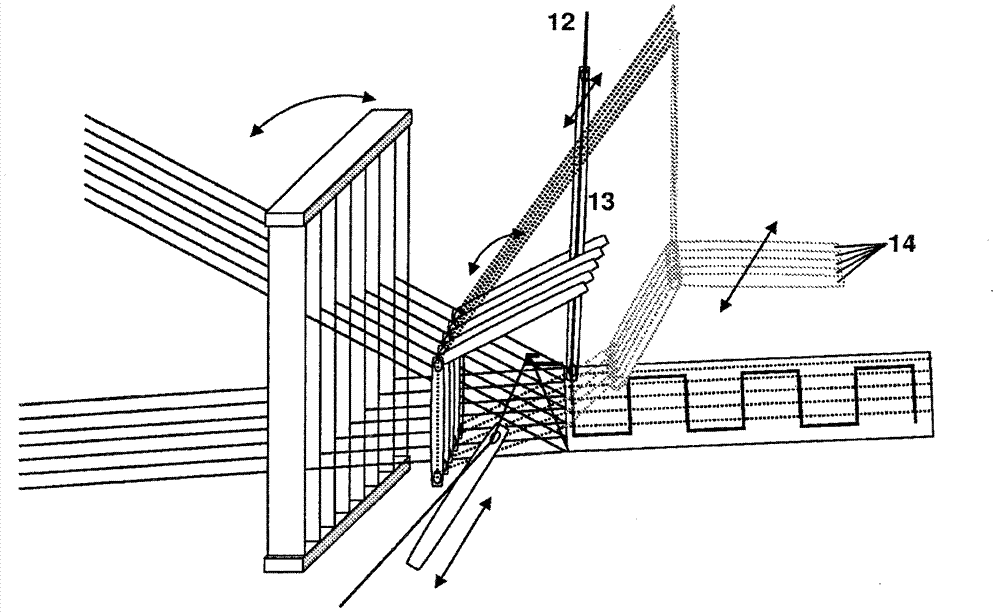

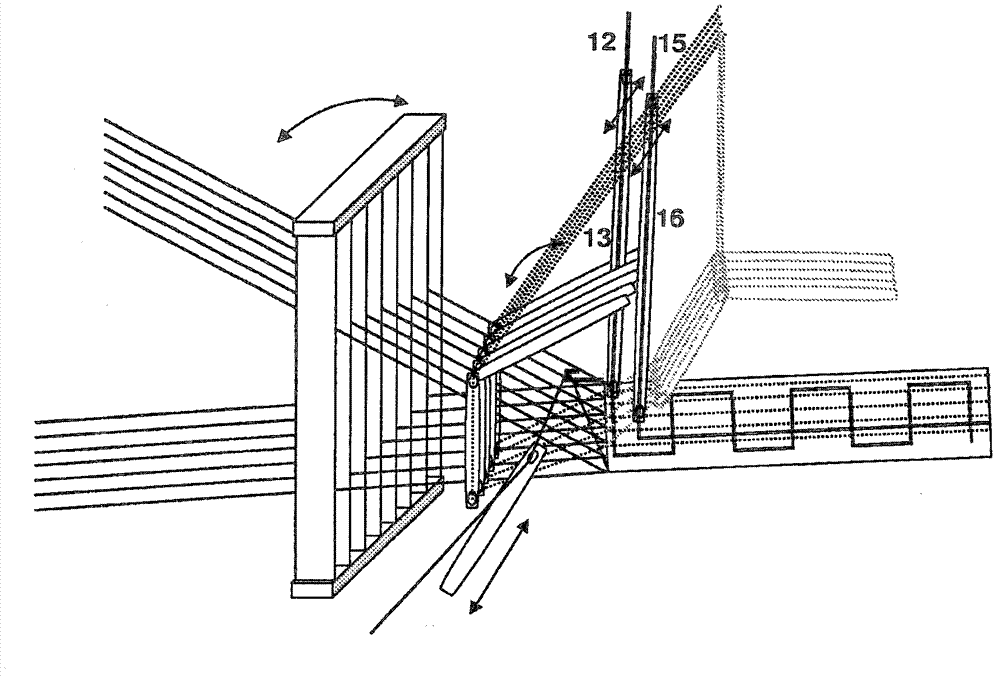

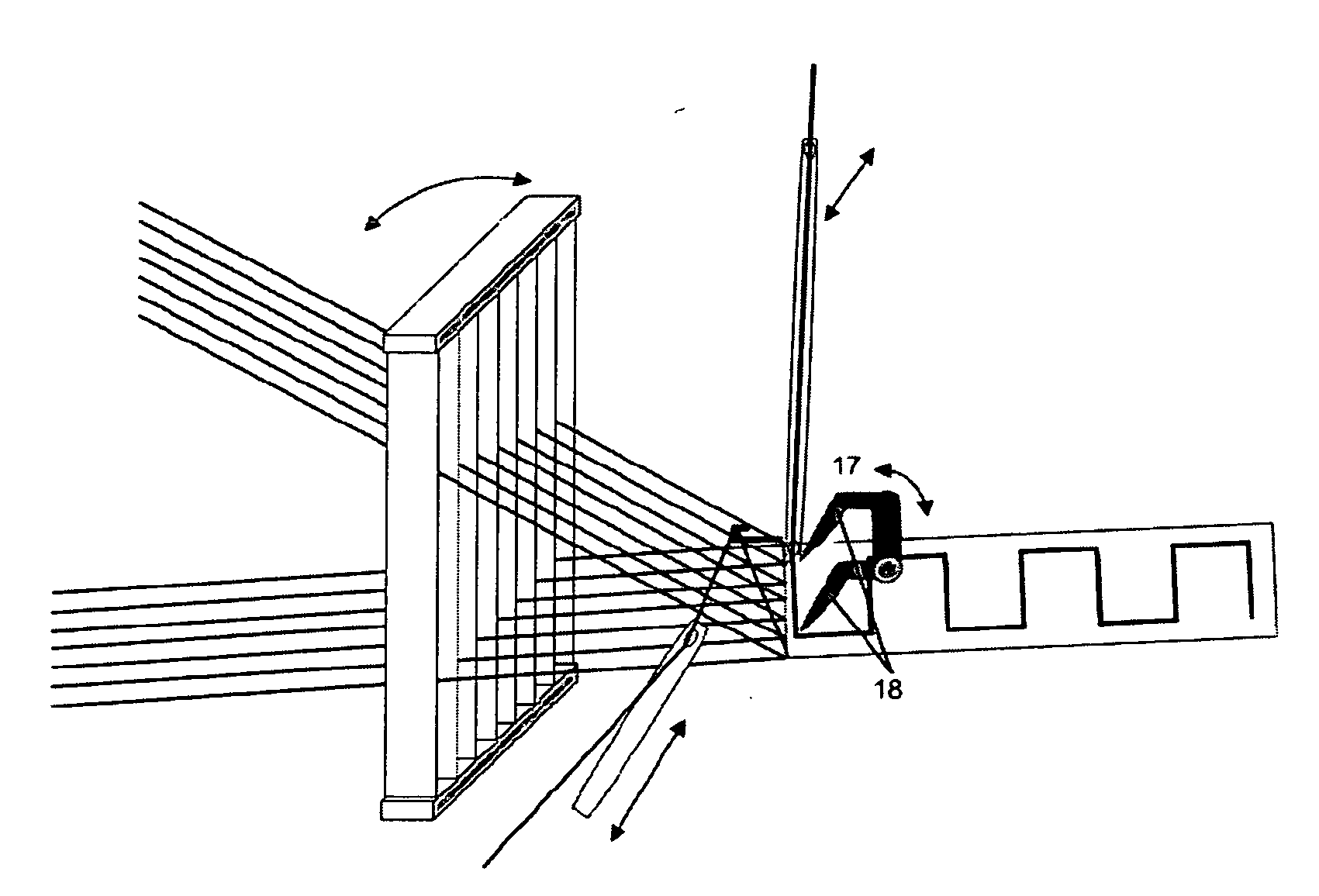

Loom for producing woven goods or material with an incorporated cover thread

InactiveCN103097597ADefects that change the structureChange defectsSmallware loomsLappetYarnInsertion device

In order to improve a loom for producing woven goods or material (10) with an incorporated cover thread (12), it is proposed to provide a laying device at least one cover thread (12) and also a warp-laying device (9) with warp-laying elements (14) for laying further warp threads (8). The warp- laying device (9) is designed such that it can make the further warp threads (8) penetrate from a starting position through the upper shed (5) to the lower shed (4), or through the lower shed to the upper shed, and therefore the weft-insertion device (7) crosses the further warp threads (8). The laying device has at least one cover-thread guide (13) which, in the starting position of the warp-laying device (9), can be displaced transversely to the warp threads (2) by way of a transverse-movement means.

Owner:TEXTILMA AG

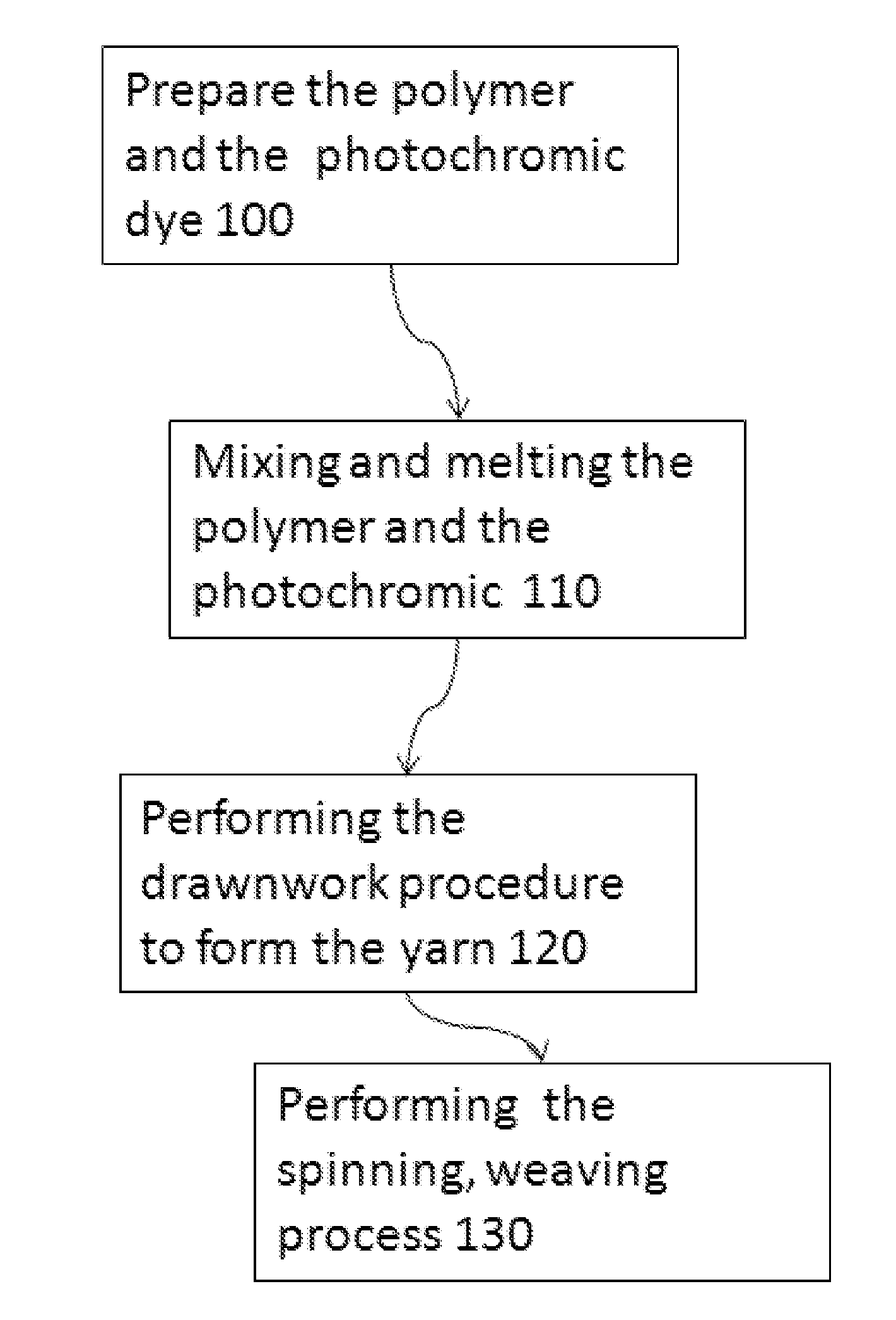

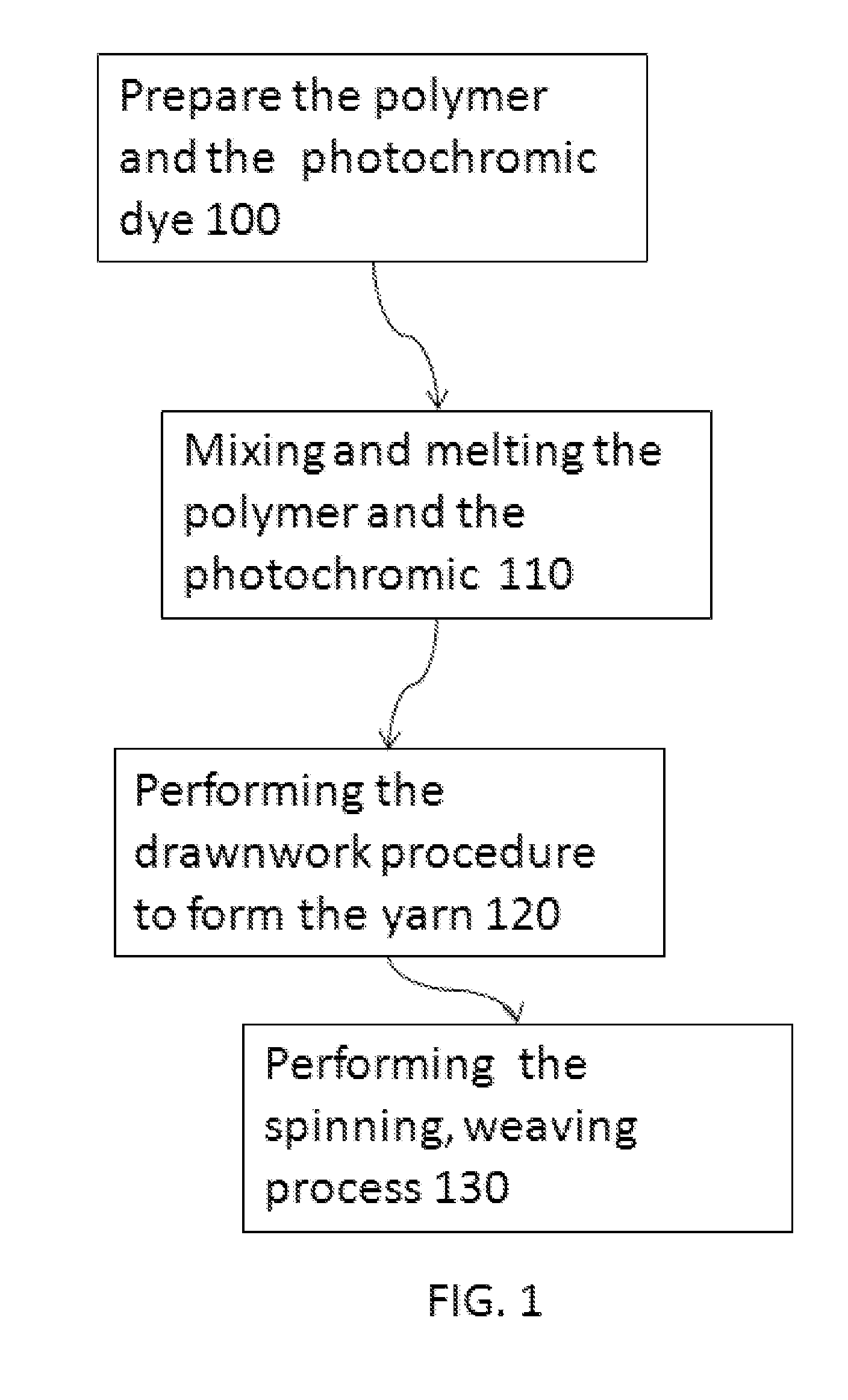

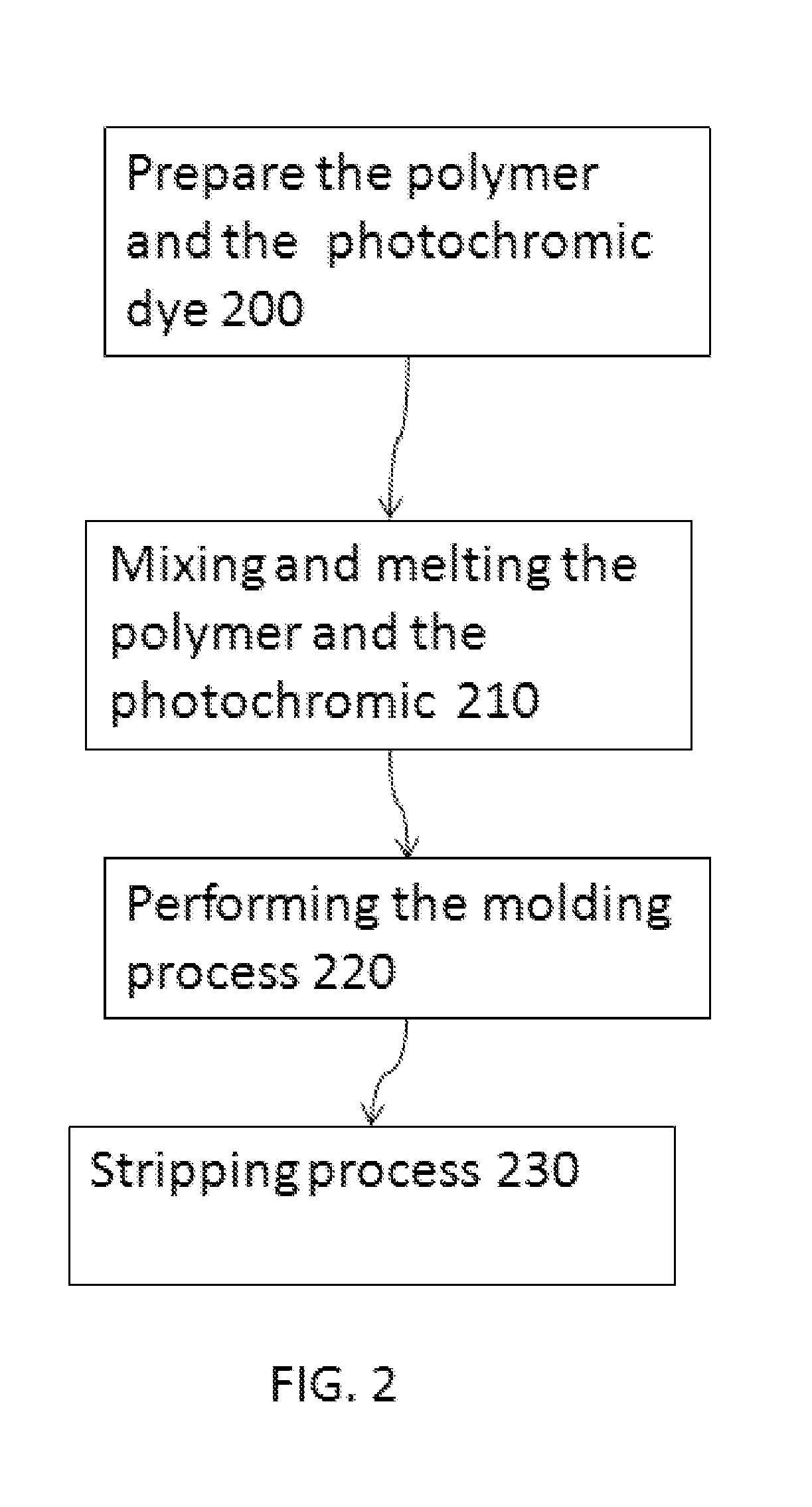

Anti-UV Fiber and Method of Manufacturing thereof

A method of forming color change fiber, comprises preparing polymer base material and preparing color changeable material; mixing said polymer base material and said color changeable material with a weight percentage ratio; loading said mixed said polymer base material and said color changeable material into a melting apparatus; forming polymer fiber by spinning, weaving process, wherein said polymer fiber is color changeable when sunlight irradiates on said polymer fiber.

Owner:CHIANG KUO CHING +1

Novel high-speed flat ribbon loom

ActiveCN104088062AImprove structural strengthHigh strengthSmallware loomsEngineeringUltimate tensile strength

The invention discloses a novel high-speed flat ribbon loom which comprises a rack. A power mechanism, a warp feed mechanism, a weft feed mechanism, a catch end feed mechanism, an opening mechanism, a connecting rod weaving mechanism and a winding mechanism are arranged on the rack. The opening mechanism comprises a heald frame, a long-handled scimitar and spline pieces installed on a hub shaft. Due to the fact that wallboards of the rack are of an integrated structure, structural strength of the flat ribbon loom is improved, installation difficulty is lowered at the same time, the problem that a fault is prone to occurring due to the fact that bearing holes of the two wallboards are not concentric in a high-speed operation process is avoided, stable operation of the flat ribbon loom is guaranteed, and the service life of the shaft and bearings is prolonged; meanwhile, a transmission structure of the flat ribbon loom is redesigned, worm gear cases and a worm and gear structure with high machining and mounting difficulty are omitted, a mechanical structure is simpler and durable, and installation and maintenance cost is lower; loom body width and braid ribbon number limits are eliminated, the speed and yield of ribbons can be greatly improved, and production efficiency is improved.

Owner:泉州众锦源精密机械有限公司

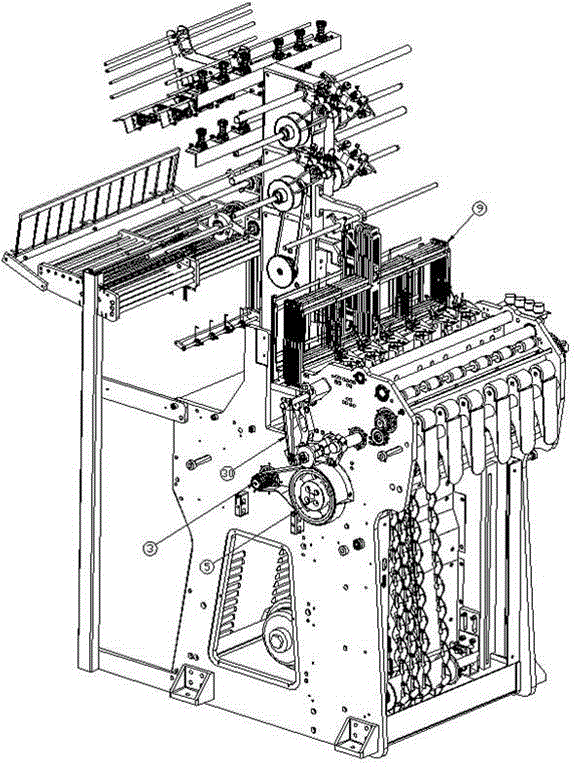

Rapier looms and corresponding textile methods

ActiveCN103582725BIncrease spinning speedAdjustable traction biasSmallware loomsOther shedding mechanismEngineeringLinear motor

In order to improve rapier looms with multiple heald frames, especially alternating devices for weft yarns, it is proposed that the heald frames (4, 6, 8, 10) are respectively connected to linear motors, through whose control the heald frames (4 , 6, 8, 10) Movement from the maximum position above to the maximum position below and reverse. In one embodiment, the rapier loom has a plurality of weft selection devices, such as color control needles (18, 20), for selectively introducing different weft yarns (40, 42) into the warp shed and alternating weft yarns (40 , 42). The weaving machine includes a control device for controlling the linear motor, which control device is configured to control the heald frame (4, 6, 8, 10) at a predetermined time between an upper maximum position and a lower maximum position. the predetermined position. The control device here has a sensor device by means of which the position of the individual heald frames (4, 6, 8, 10) can be detected continuously.

Owner:TEXTILMA AG

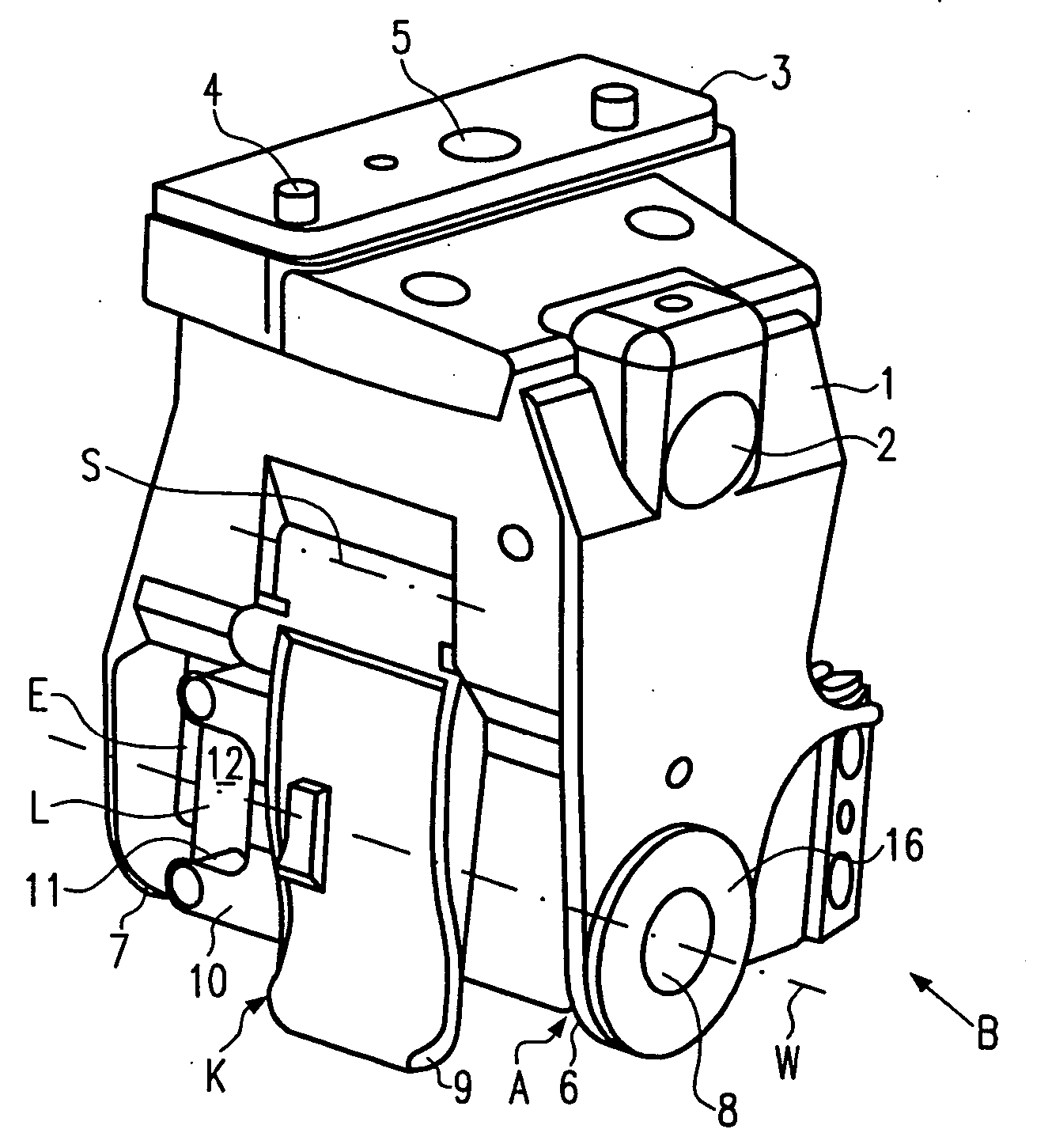

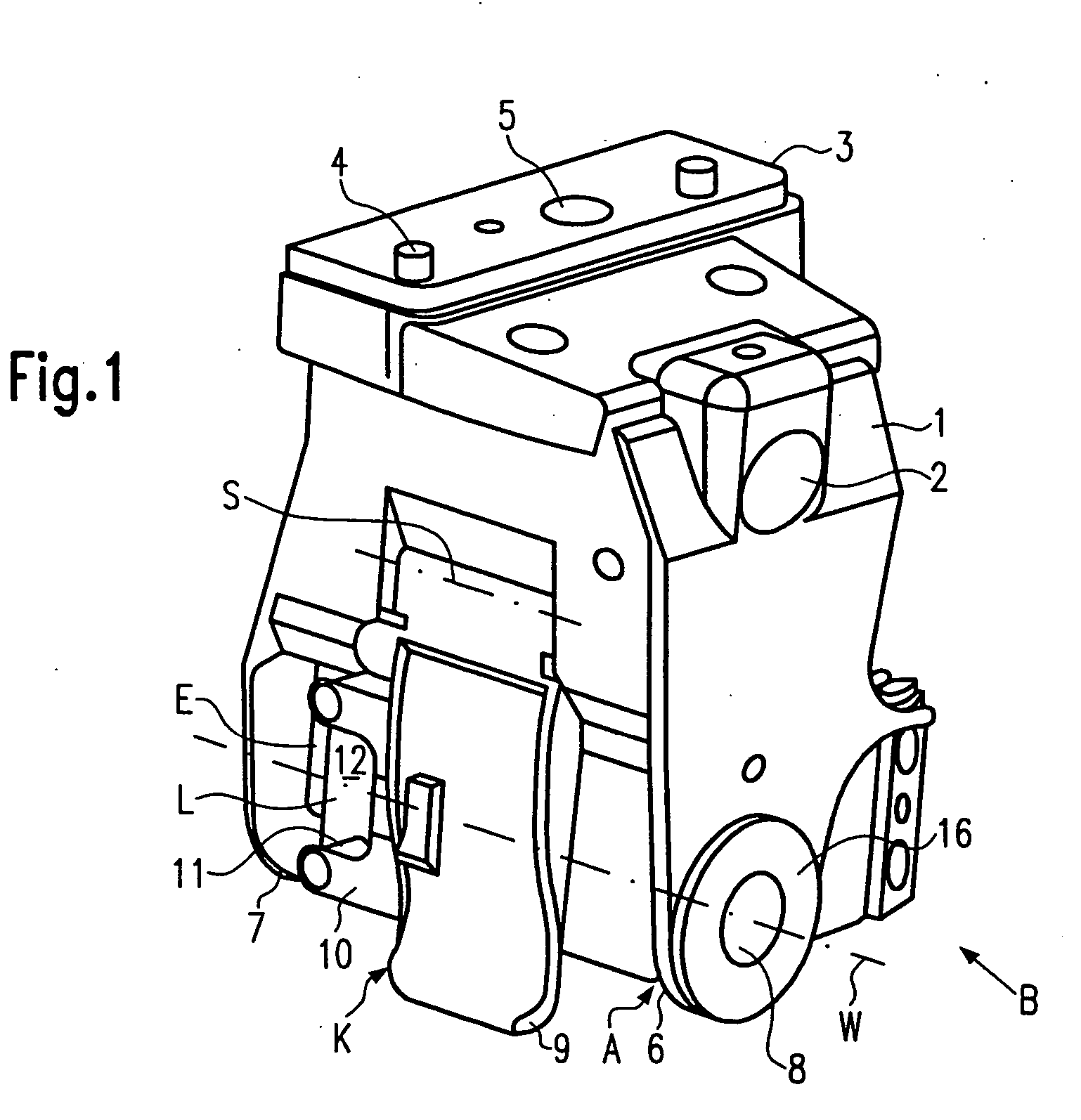

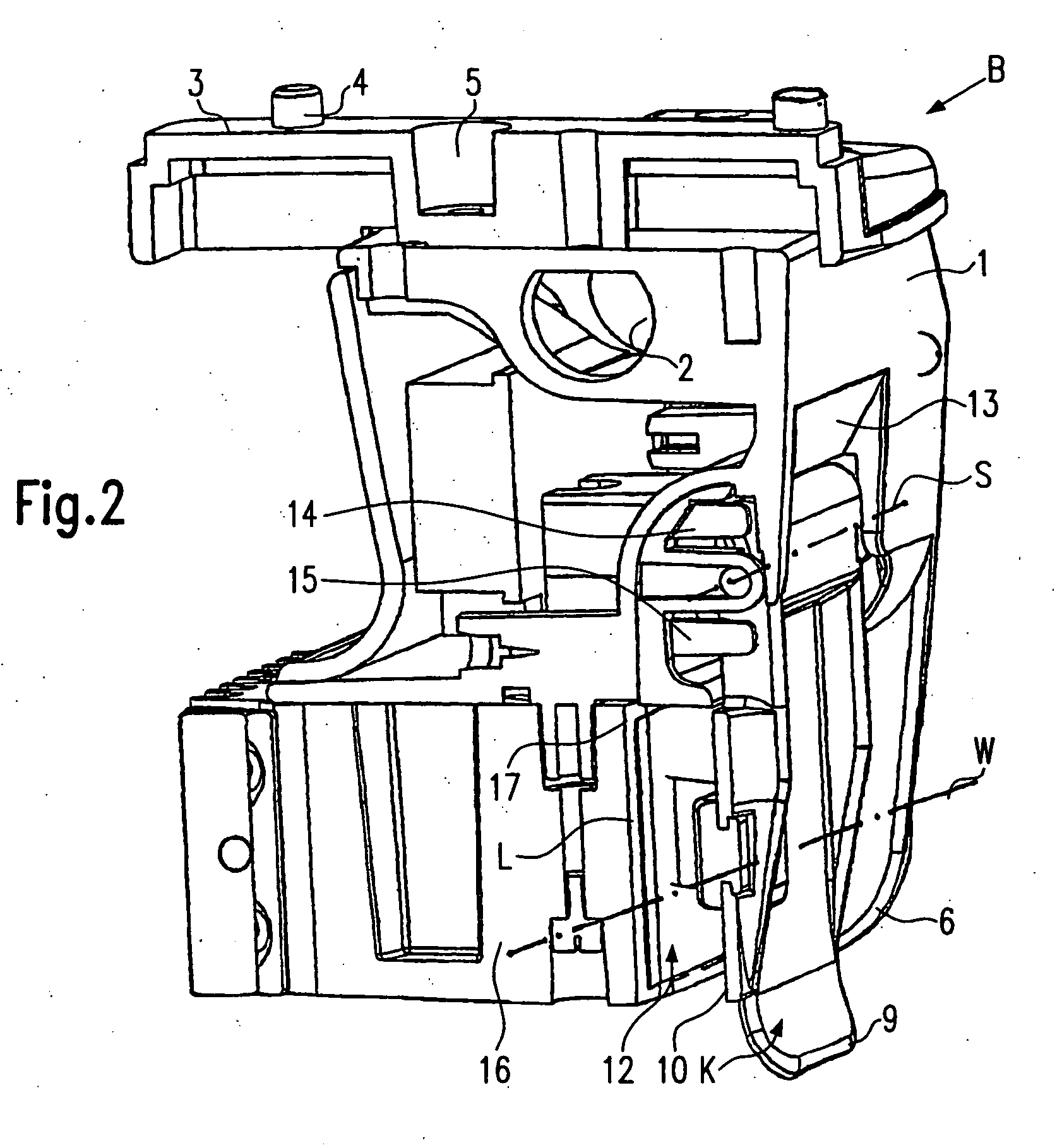

Yarn tension device

InactiveUS20050145290A1Easy to cleanComfortable handlingSmallware loomsFilament handlingEngineeringYarn tension

The invention concerns a yarn brake (B) comprising a brake (L) electromagnetically stressed against a fixed braking surface (17), a housing (1) whereon the cover bearing the brake (L) is mounted such that it is capable of being lifted relative to the fixed braking surface (17), and at least an adjusting arbor (S) controlling the lifting movements of the cover, said arbor being mounted on the housing (S) in geometric association to the path of the yam (W). The invention is characterised in that the cover is a flap cover (K) mounted so as to be capable of being lifted about the adjusting arbor (S) for completely clearing the braking zone (12) of the yam tension device (B).

Owner:IROPA AG (CH)

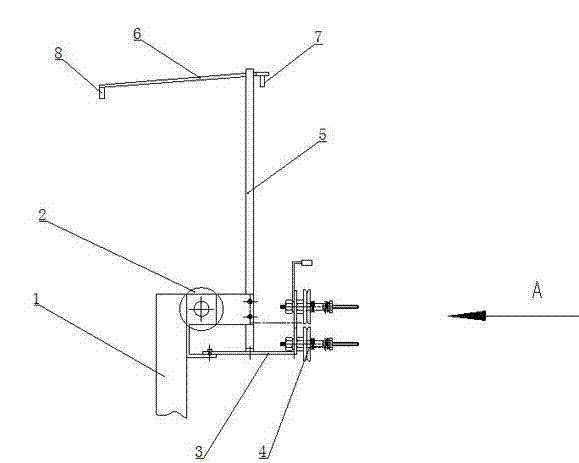

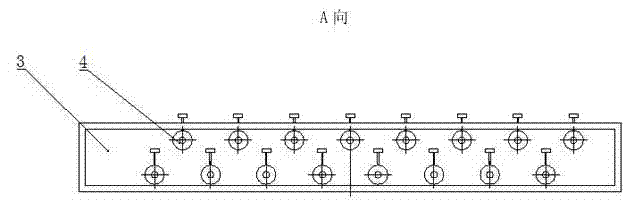

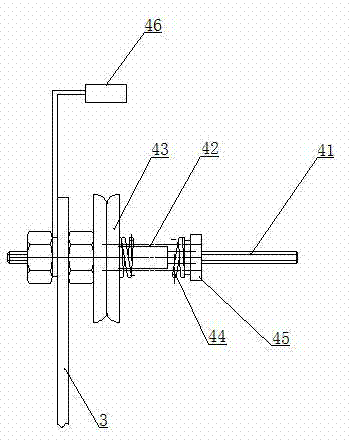

Tension control and compensation mechanism of sample loom

InactiveCN102817163AExpand the scope of trial weavingReduce tensionSmallware loomsEngineeringYarn tension

The invention relates to a tension control and compensation mechanism of a sample loom. The tension control and compensation mechanism is characterized by comprising a let-off support, let-off tension disks and a tension compensation mechanism, wherein a plurality of let-off tension disks for clamping warp yarn at certain pressure are uniformly distributed on the let-off support along the horizontal direction, and the tension compensation mechanism is installed above the let-off support. When the warp yarn tension is higher, a strip-shaped elastic sheet is bent to reduce the warp yarn tension so that the warp yarn tension keeps consistent, so that cracked ends caused by ultra-high tension are avoided. When the warp yarn tension decreases, a strip-shaped tension compensating sheet resets and unbends to return to the original position, and the warp yarn is tensioned so as to avoid the unclear shed. The structure is utilized for being matched with an original warp yarn system of the sample loom to realize the independent and stable let-off control on two or more types of warp yarn, so that the sample loom can be used for test weaving of seersucker, spandex fabric and patterned fabric, the test weaving range of the sample loom is expanded, and the equipment investment cost is reduced.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

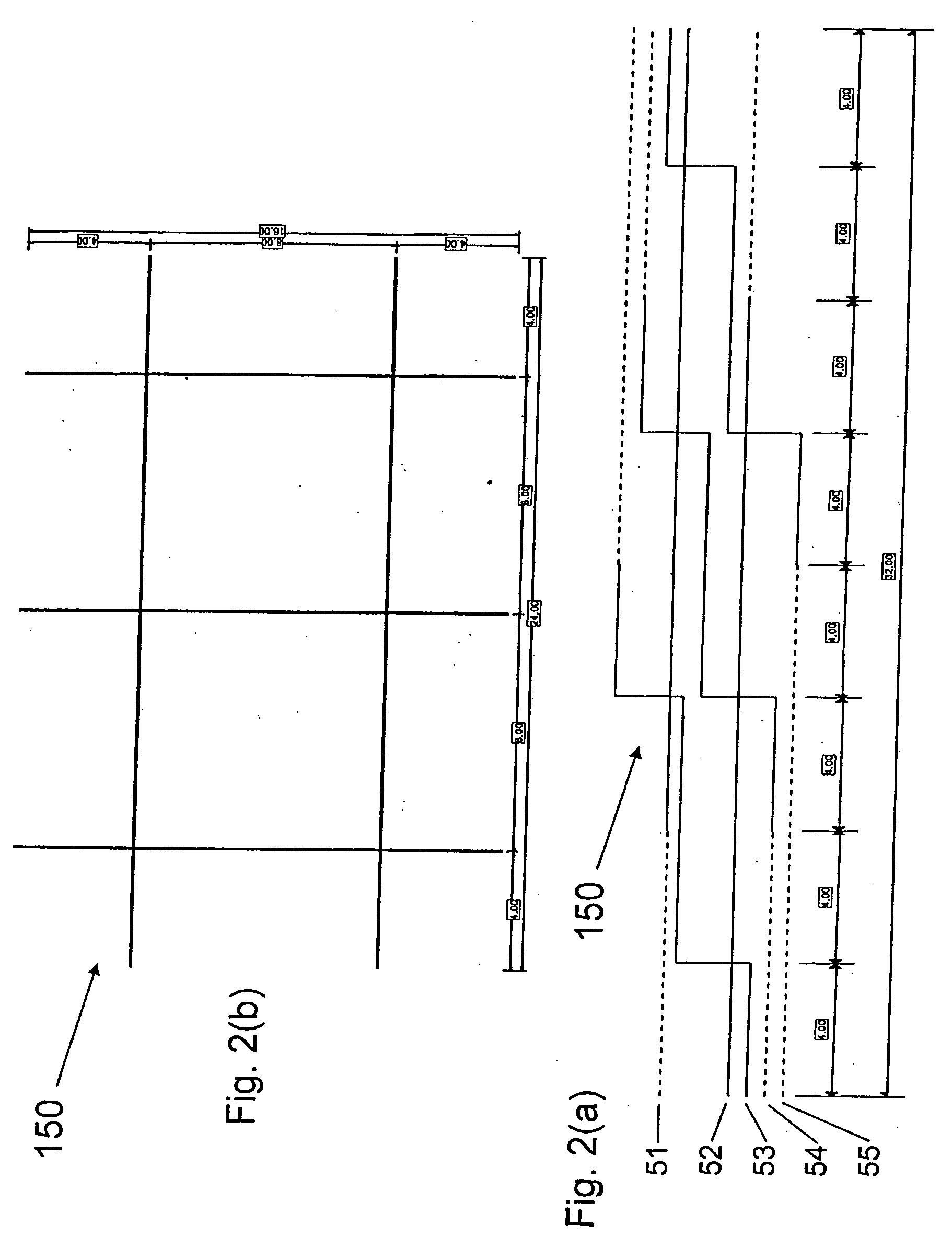

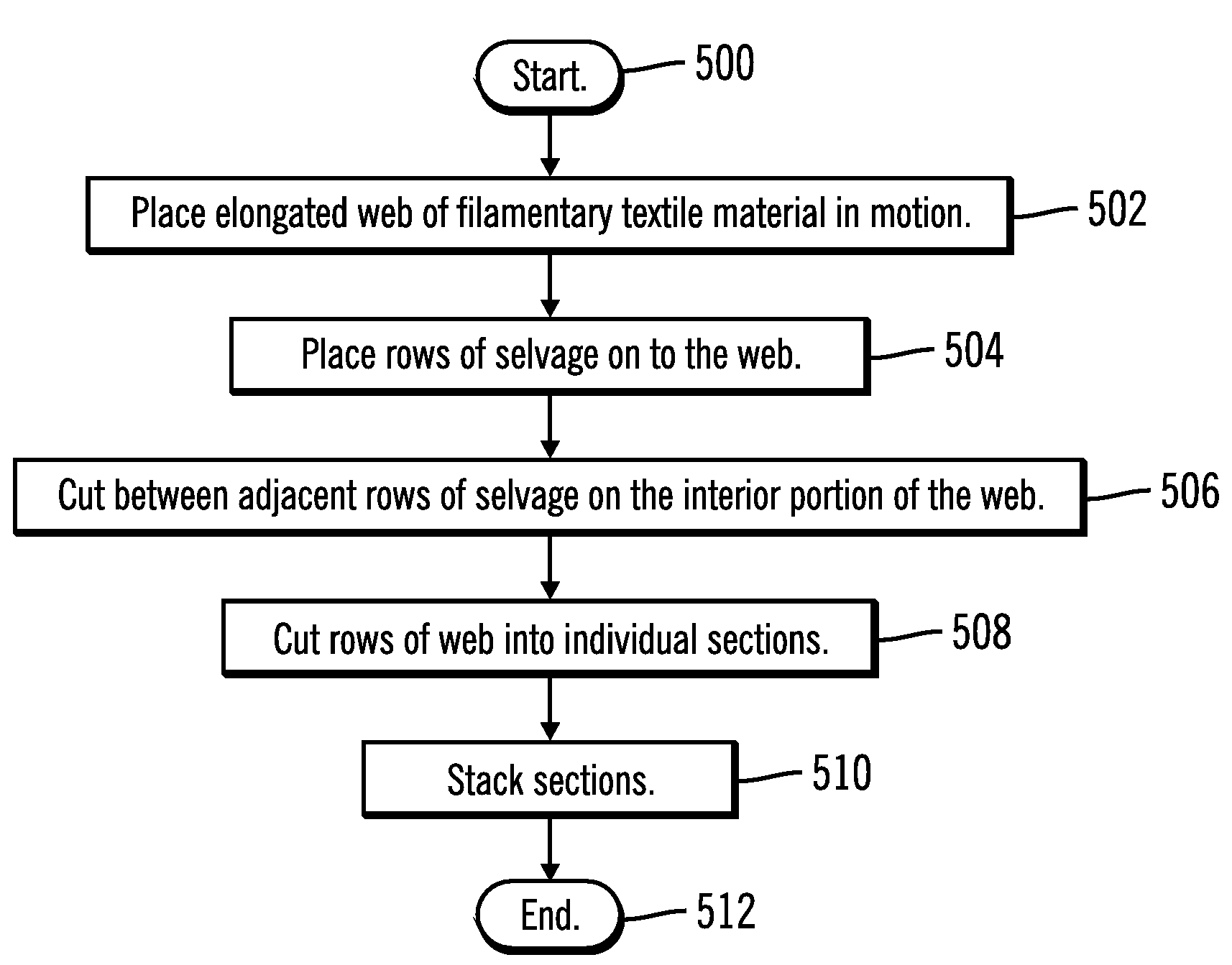

Method of Making Soft Edge Textile Labels to be Applied to Garments

A method of converting an elongated web of filamentary textile material into lengths; of coherent labels for application to garments includes placing a first row of selvage on the web at a first predefined distance from a first outer edge thereof, the first predefined distance being greater than zero, placing a second row of selvage on the web at a second predefined distance from a second outer edge thereof, the second predefined distance being greater than zero, and placing at least a third row and a fourth row of selvage on the web between the first and second rows, a portion of the filamentary material separating each of the rows from the other. A following step includes cutting the web along a line lying between the third and fourth rows of selvage and at a predefined distance away from each of the third and fourth rows of selvage, the predefined distance being greater than zero.

Owner:YIDI JR CARLOS

Method of producing on needle weaving looms a woven ribbon with the same edges in terms of weaving

ActiveUS7380573B2Cheap productionSimplified serviceabilitySmallware loomsWarp knittingEngineeringVehicle safety

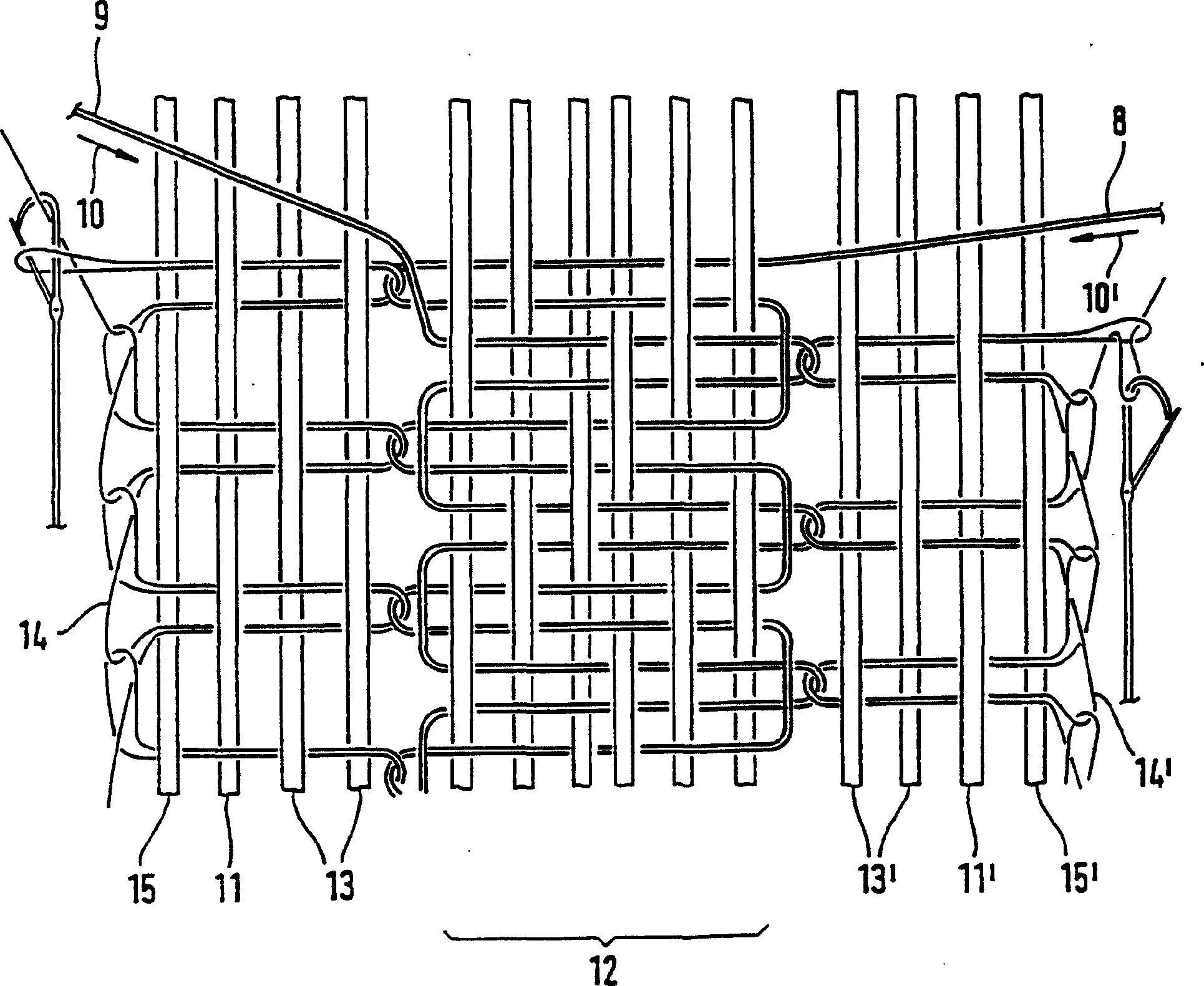

A woven ribbon, preferably a vehicle safety belt strap, is produced on a needle weaving loom. The weft yarns alternately picked from right and left are crocheted with the respective preceding weft already picked.

Owner:KIKUCHI KOGYO

Seat belt webbing, method and narrow fabric needle loom for production of same

InactiveUS7743794B2Increase lateral stiffnessEasy to produceSmallware loomsWoven fabricsEngineeringBelt safety

The invention relates to a method for weaving a webbing, comprising at least one first (right-hand) weft thread and at least one second (left-hand) weft thread, characterized in that the two weft threads are introduced into the same shed from both sides of the webbing, are wound around weft thread retainers in weft change loops, are substantially retained by the weft thread retainers until shed change and are then stripped off from the left thread retainers by the reed and after shed change and are bound against the stop.

Owner:BERGER JOHANN

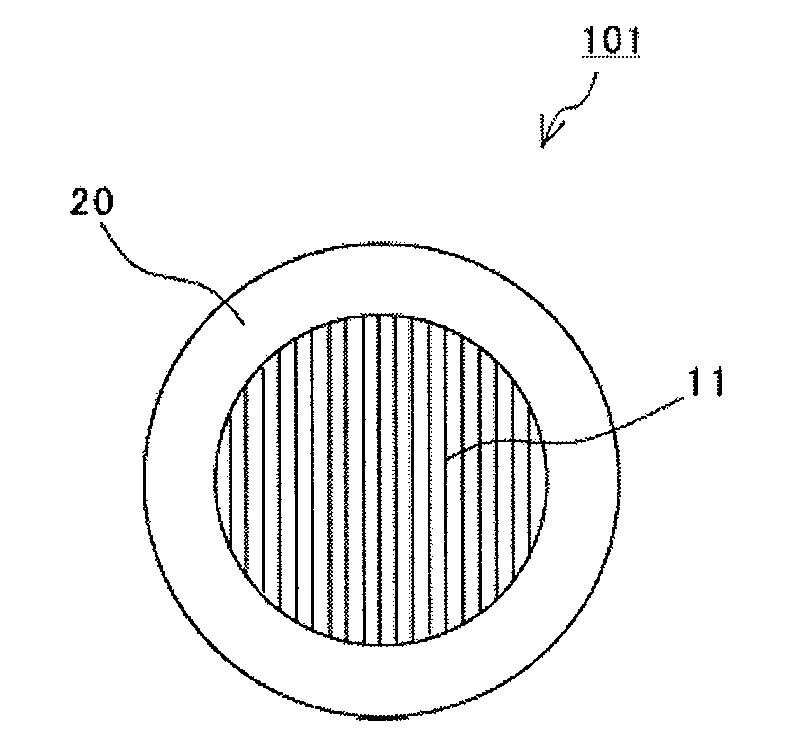

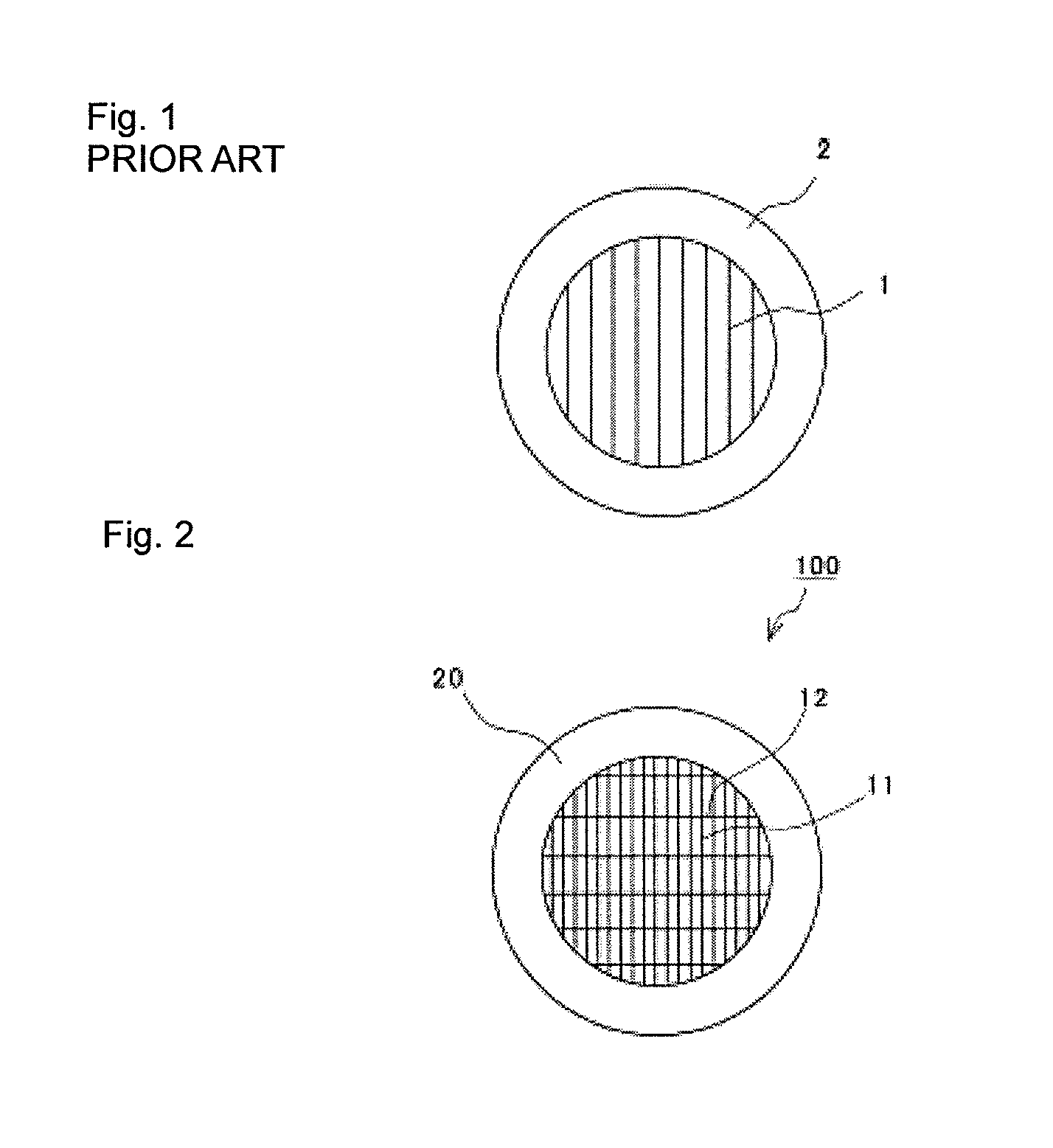

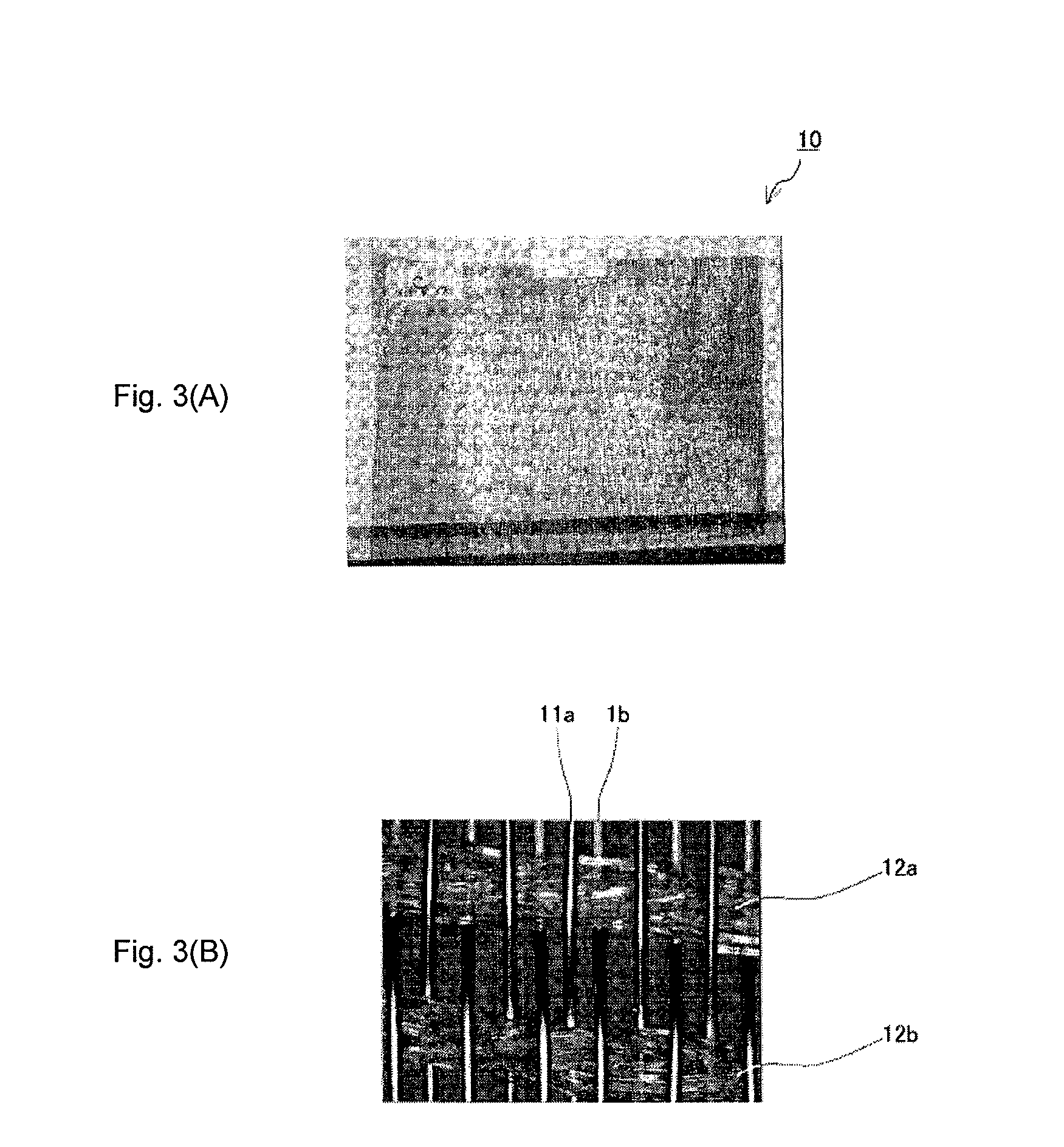

Wire Grid and Manufacturing Method Thereof

ActiveUS20100142047A1Easy to makeEasy to manufactureSmallware loomsPolarising elementsWoven fabricWeft yarn

A textile made by weaving while crossing stainless wires as warp yarn and silk yarns as weft yarn one by one alternately, and this textile is attached to a frame body to configure a wire grid. The pitch for the stainless wires is determined depending on a wavelength to be polarized and analyzed. Furthermore, the silk yarns are removed if necessary. This configuration avoids problems with cutting of metal wire or irregular intervals between metal wires because of long fine metal wires tightened parallel to each other in the frame body, and problems such as multiple reflection or interference on a substrate or a base material because of fine wire patterns made by etching or the like with the use of the substrate or base material, thereby obtaining an easily-manufactured, low-cost and high-precision wire grid for polarization and analysis of electromagnetic waves.

Owner:MURATA MFG CO LTD

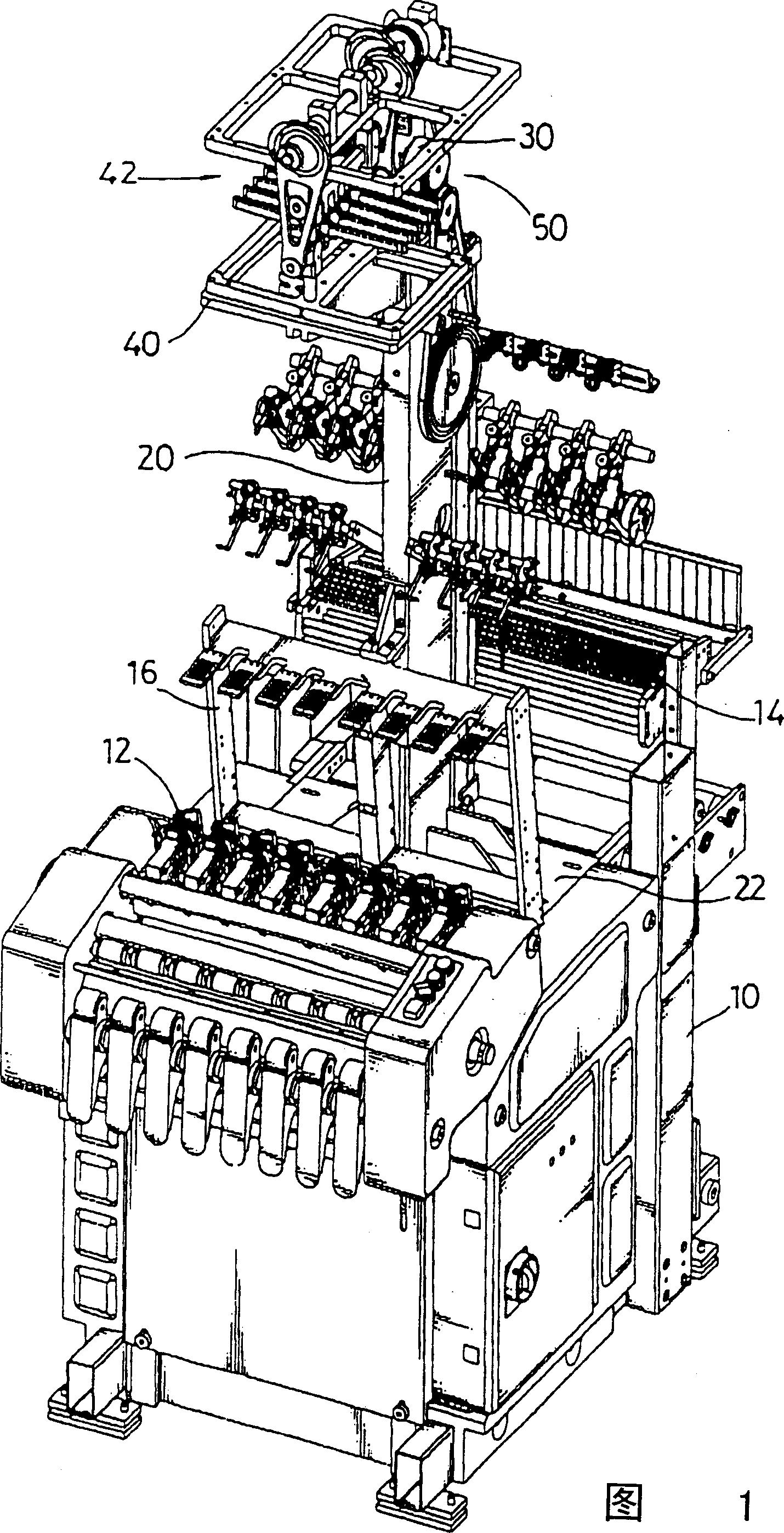

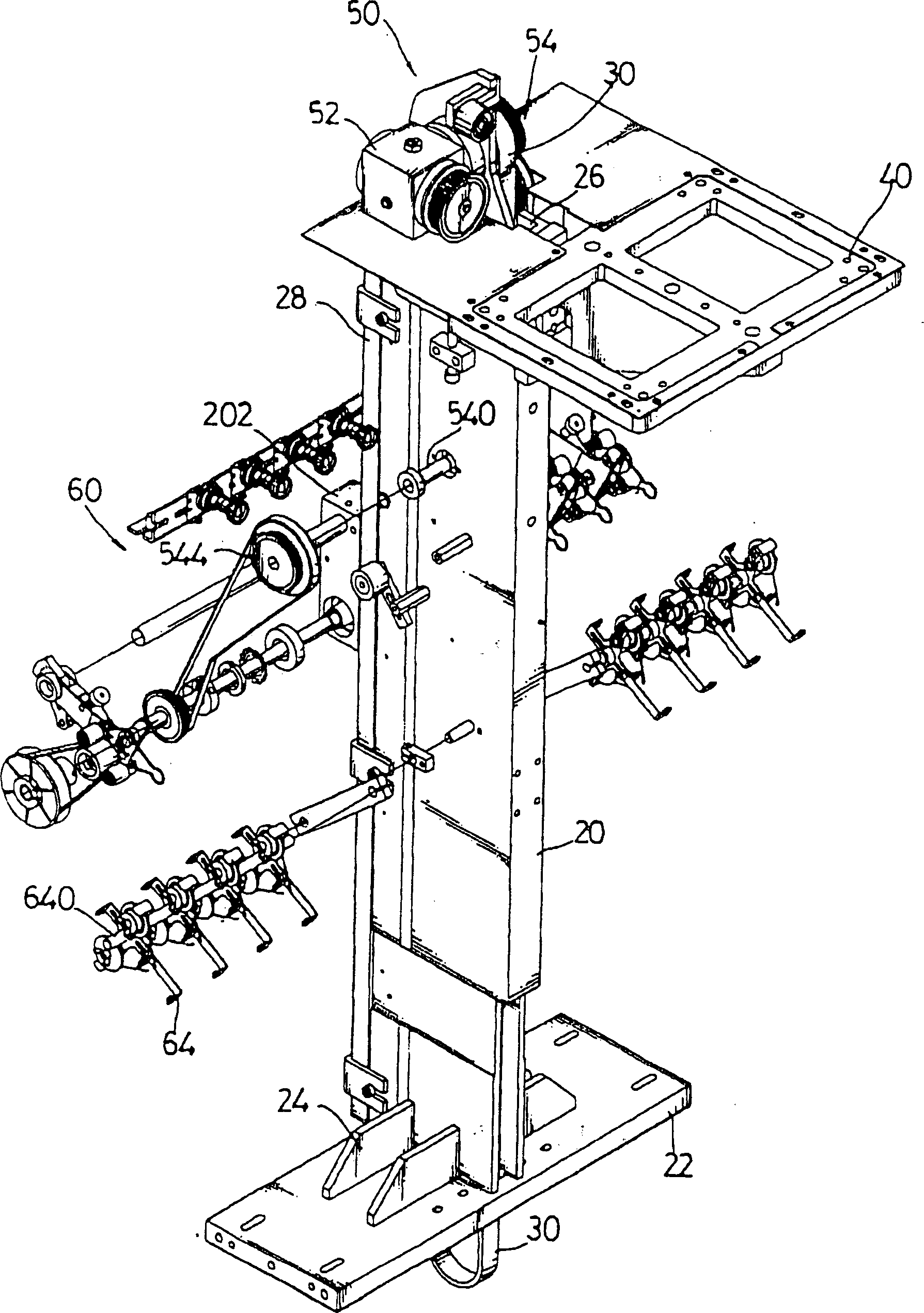

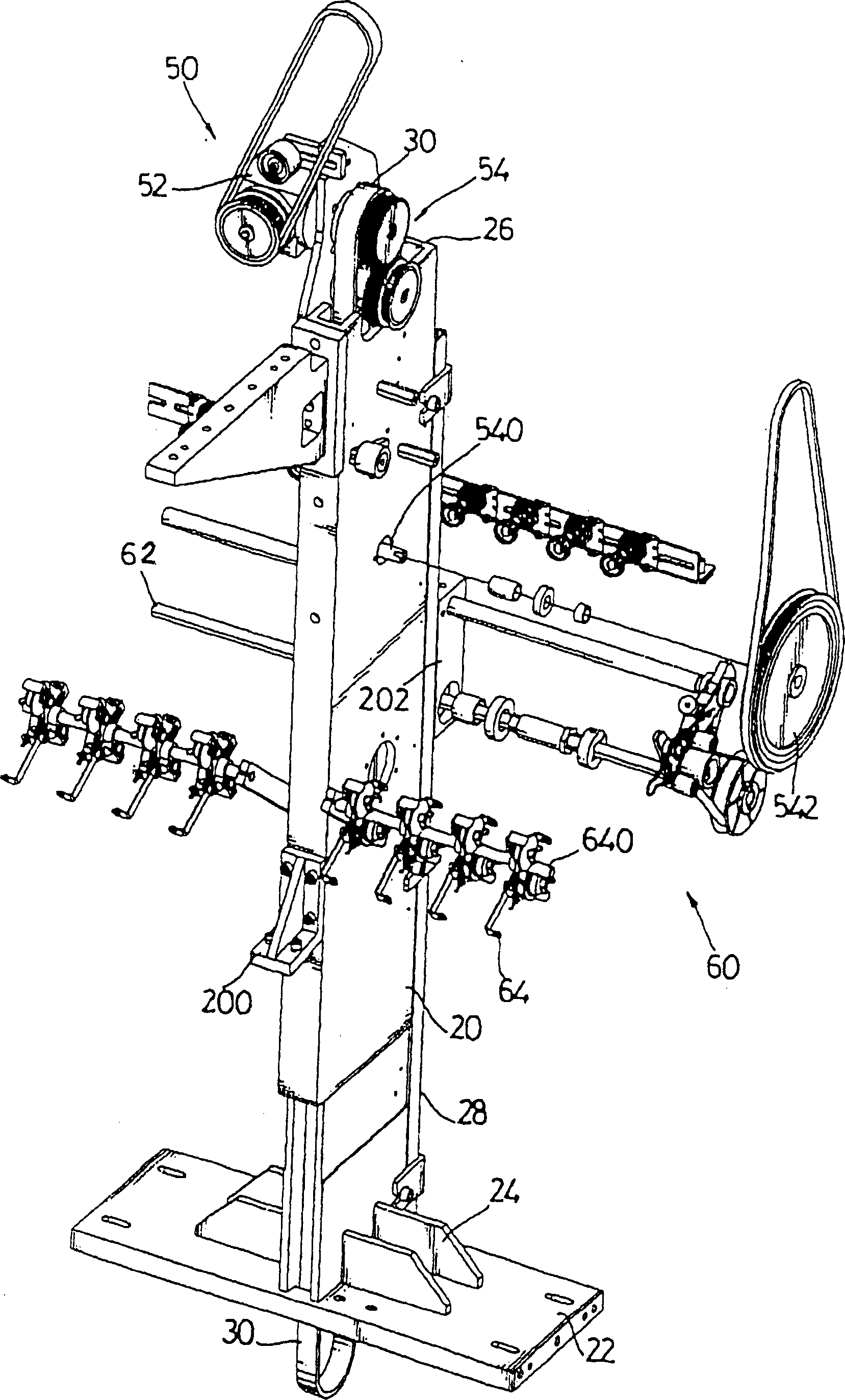

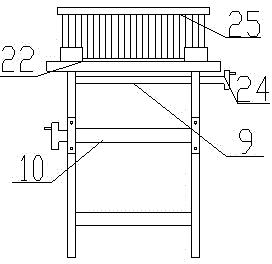

Jacquard ribbon loom with mainstay

InactiveCN1485475AReduce manufacturing costEasy maintenanceJacquardsSmallware loomsEngineeringLeather belt

A jacquard ribbon loom with a central column, comprises a hollow central column over the machine platform, the main driving belt in the central column, a spigot and a power transmission member on thetop end of the central column, weft transmission member symmetrically on the two sides of the central column. The light jacquard ribbon loom is compact and stable due to the hollow central column.

Owner:林贞惠

Portable semi-automatic Kesi-weaving machine device

The invention discloses a portable semi-automatic Kesi-weaving machine device. The portable semi-automatic Kesi-weaving machine device comprises a frame, a warp-conveying device, a wefting device and a coiling device. A motor opening device is arranged between the warp-conveying device and the coiling device. A pattern-reflecting plate is further installed between the motor opening device and the coiling device. The position, where the right side of the pattern-reflecting plate protrudes out of the frame, is provided with a pattern-reflecting plate hand wheel. A weft-beating device is arranged between the wefting device and the coiling device. The portable semi-automatic Kesi-weaving machine device has following advantages: the portable semi-automatic Kesi-weaving machine device is conveniently carried and favorably used for modern teaching; transfer from factorization to small-sized home-based design is achieved; a conventional mode of drawing on warp yarns is discarded so that a weaving mode is further realized; by adoption of the method of the pattern-reflecting plate, the effect of not deforming a finished product is achieved; and the opening device is flat during opening operation so that bright light rays are realized for facilitating selecting wefts.

Owner:IANGSU COLLEGE OF ENG & TECH

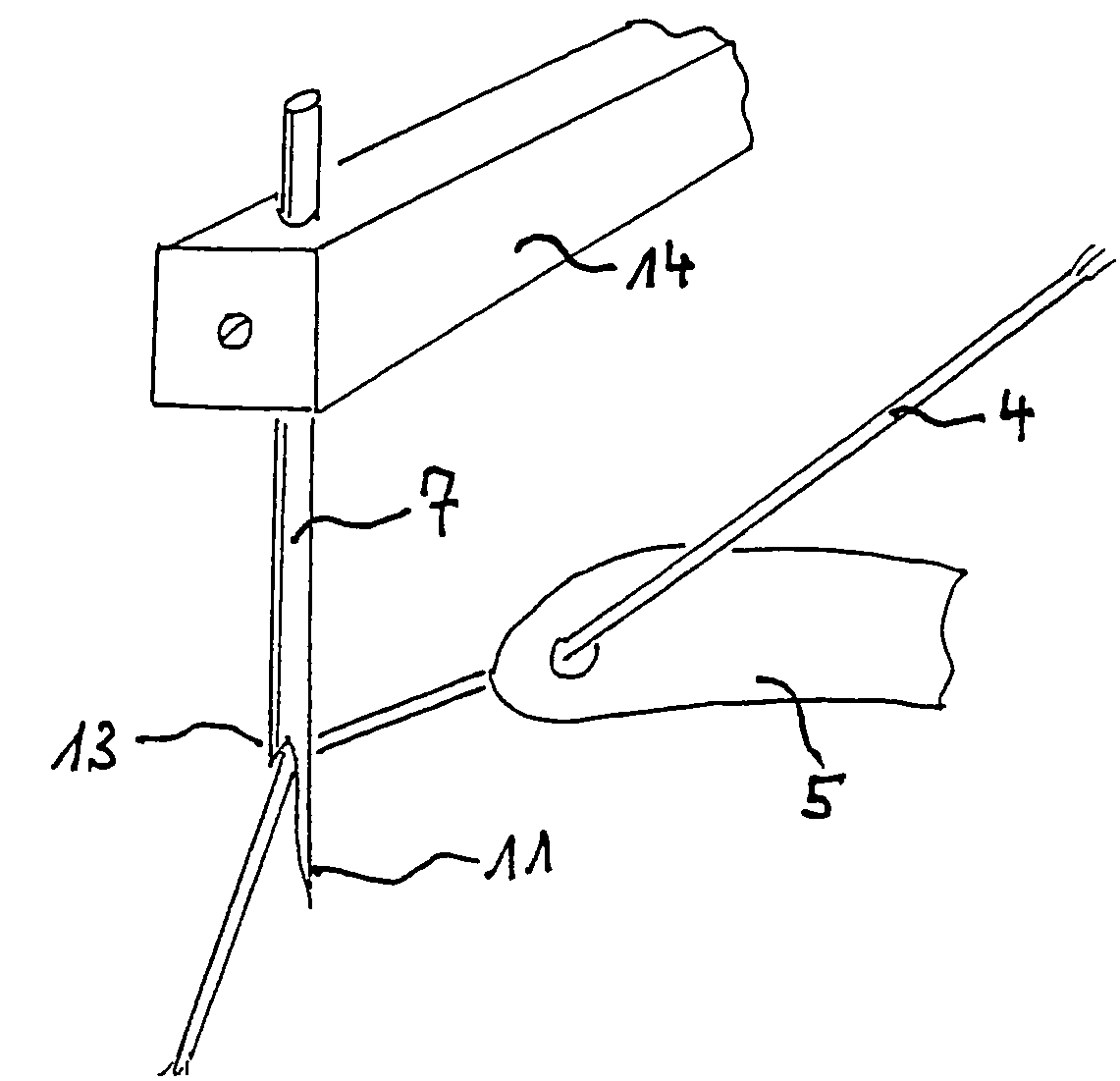

Loom for producing woven goods or material with an incorporated cover thread

In order to improve a loom for producing woven material (10) with an incorporated cover thread (12), it is proposed to provide a laying device for at least one cover thread (12) and also a warp-laying device (9) with warp-laying elements (14) for laying further warp threads (8). The warp-laying device (9) is designed such that it can make the further warp threads (8) penetrate from a starting position through the upper shed (5) to the lower shed (4), or through the lower shed to the upper shed, and therefore the weft-insertion device (7) crosses the further warp threads (8). The laying device has at least one cover-thread guide (13) which, in the starting position of the warp-laying device (9), can be displaced transversely to the warp threads (2) by way of a transverse-movement means.

Owner:TEXTILMA AG

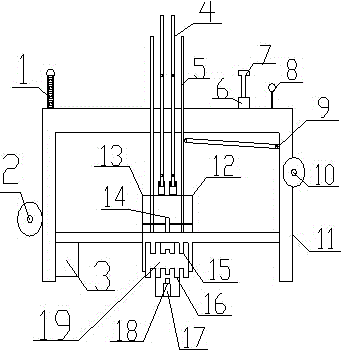

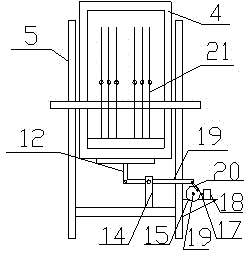

Sample loom used for test weaving of leno weave

The invention relates to a sample loom used for test weaving of leno weave. The sample loom comprises a frame, wherein the frame is sequentially provided with a back rest, heald frames, a sley and a breast beam from back to front, wherein a warp beam and a cloth roller are installed below the back rest and the breast beam; and a reed is installed on the sley. The sample loom is characterized in that each heald frame comprises a leno heald frame provided with leno heald; the upper end of each heald frame is connected with an electronic heald lifting mechanism for driving the lifting of the heald frame; the lower end of the heald frame is connected with a heald returning spring; and the back rest is provided with a let-off tension control mechanism. By utilizing the let-off tension control mechanism for controlling the doup end tension, the doup end tension keeps consistent, cracked ends and unclear shed caused by ultra-high tension born by doup ends in the twisting of the doup ends and standard ends are avoided, and leno weave samples are woven by combining conventional heddle with the doup ends. The woven leno weave sample fabric is small in difference and strong in representativeness, and the test weaving of samples does not need to be conducted on a large loom. The sample loom is simple in structure and low in equipment cost, reduces the research and development investment, and saves effective resources.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

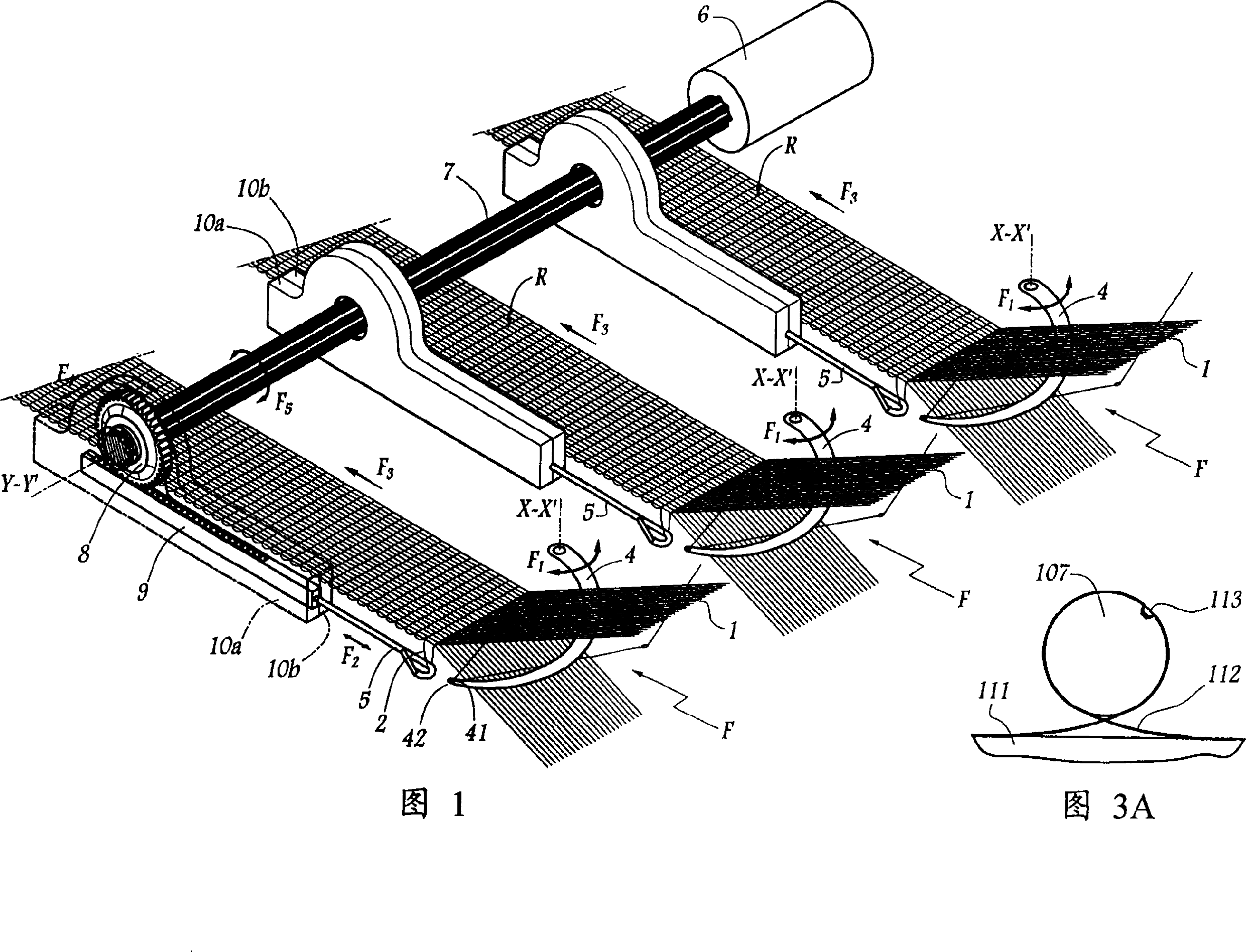

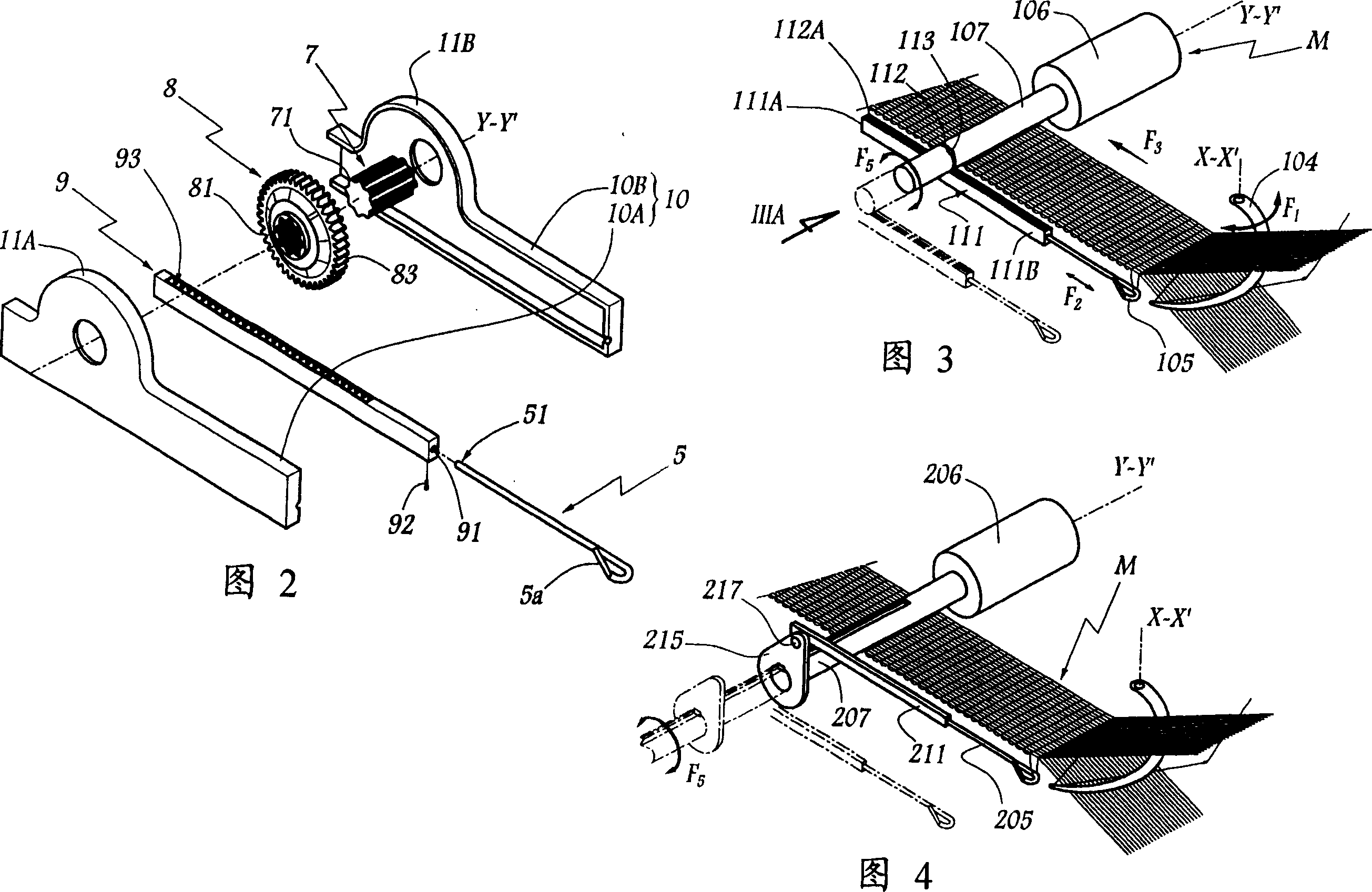

Device for driving crochet needle and braiding machine fitting the device

A device for driving crochet needles of a reaphook type braiding machine is provided, which comprises a rotary electrical actuator (6), the output shaft (7) of the rotary electrical actuator (6) is connected with a plurality of crochet needles (5)in dynamic linkage through devices (8,9) used for converting the rotation (F5) to translation (F2).

Owner:施托布利里昂公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com