Ribbon Needle Loom for Manufacturing a Strip, in Particular a Label Strip, Having a Woven-In Conductive Thread, in Particular Antenna Thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

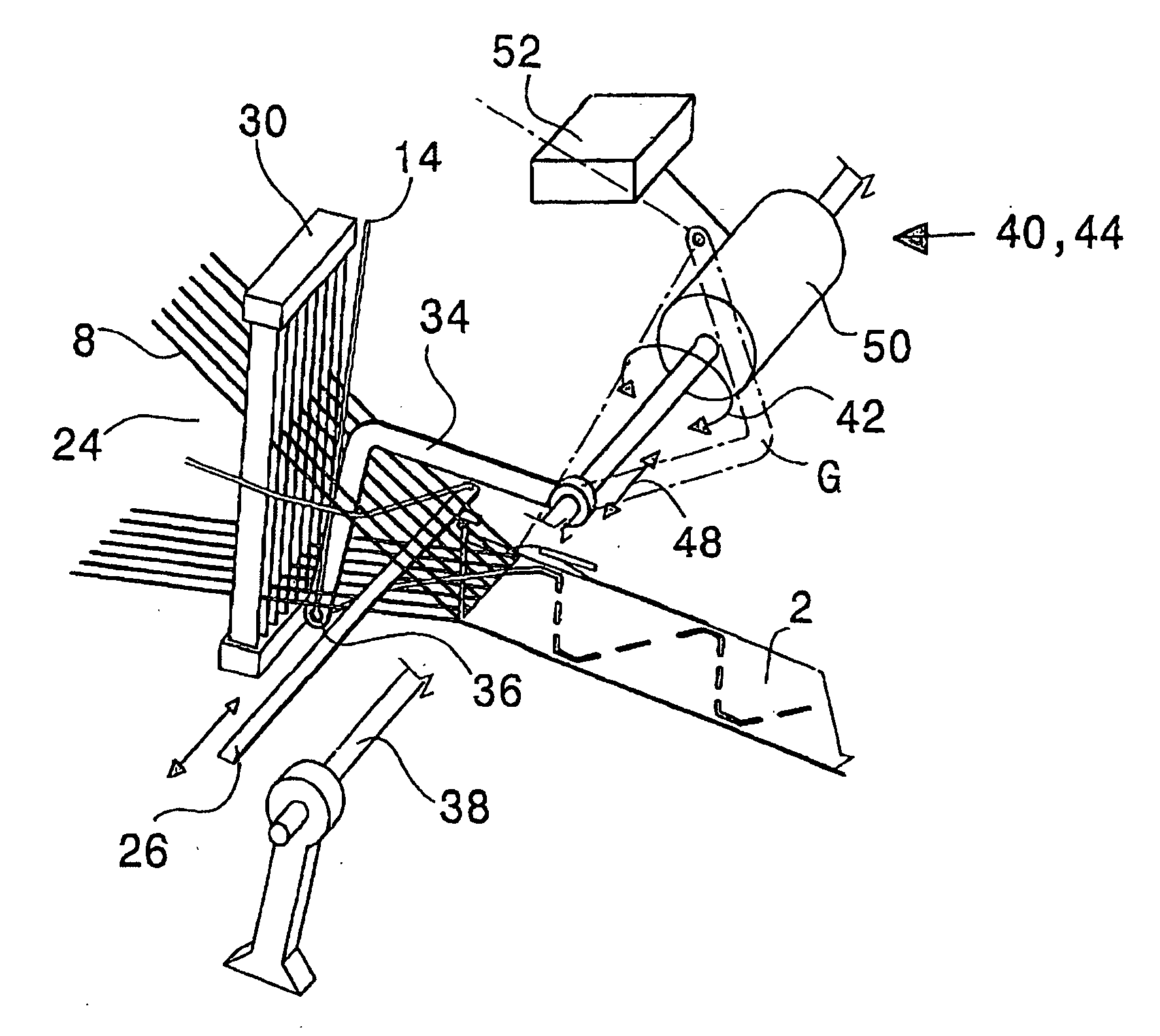

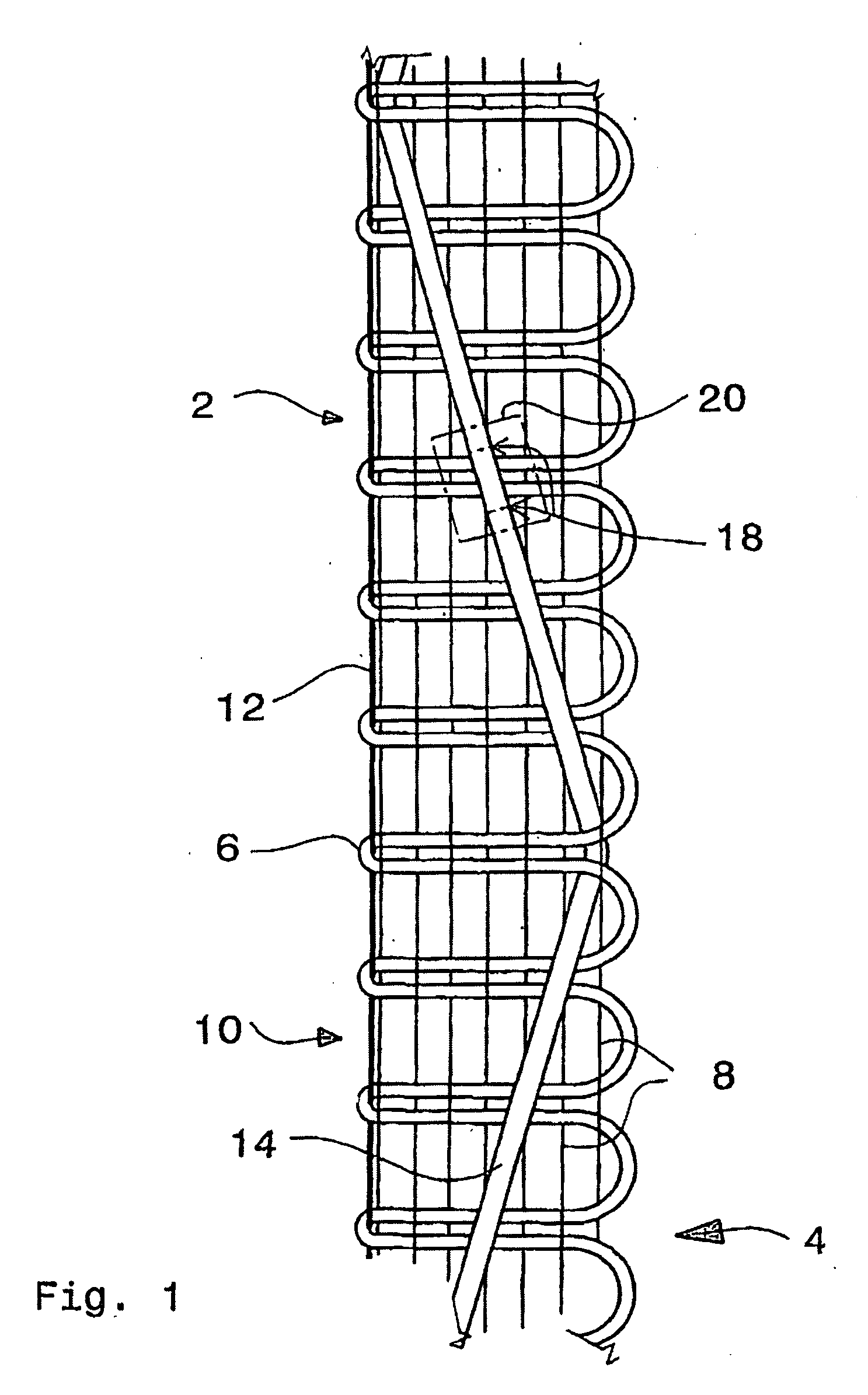

[0019]FIG. 1 shows a ribbon fabric 2 in which weft thread loops 6 are inserted from an insertion side 4 between warp threads 8. On the side 10 lying opposite the insertion side 4, the weft thread loops 6 are mutually tied off by means of stitches 12 indicated diagrammatically as a line. A conductive thread 14 runs, zigzag-shaped, on the topside of the ribbon fabric 2 and is tied in at the turning points 16 in each case by means of a weft thread loop 6. The conductive thread 14 serves as an antenna and is interrupted at 18 before the application of a transponder chip 20 which is connected to the two ends of the conductive thread. Such a connection may be implemented, for example, by welding, soldering, bonding with an electrically conductive adhesive, crimping of clamping.

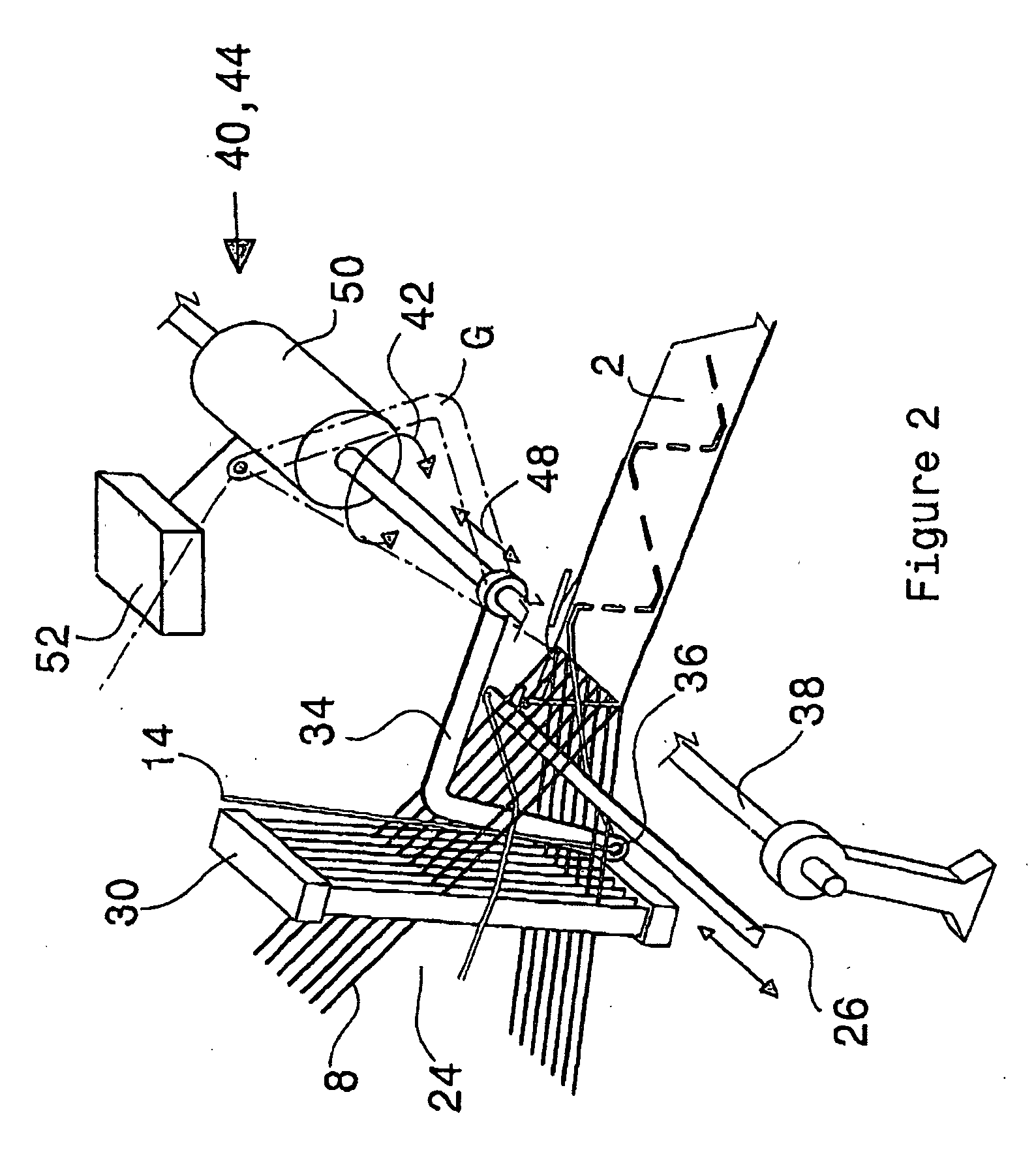

[0020]FIG. 2 shows diagrammatically a ribbon needle loom 22 which is suitable for manufacturing a ribbon fabric 2 of FIG. 1 with a conductive thread 14, but without a transponder chip 20. Warp threads 8 are opened b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com