Novel high-speed flat ribbon loom

A ribbon loom, high-speed technology, applied in looms, small looms, textiles, etc., can solve the problems of difficult processing, high installation accuracy, strict requirements for installation personnel, and unfavorable warp tension control, and achieves low installation and maintenance costs. Guarantees smooth operation, removes the effect of body width and webbing restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

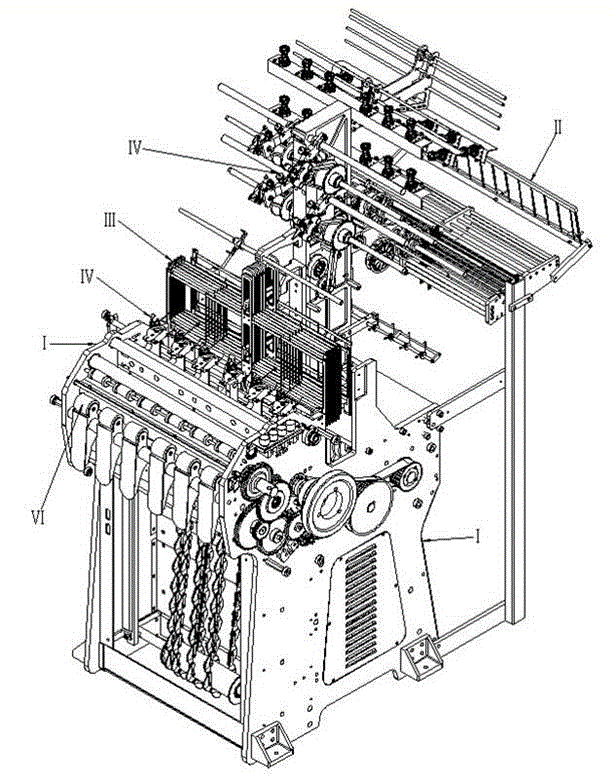

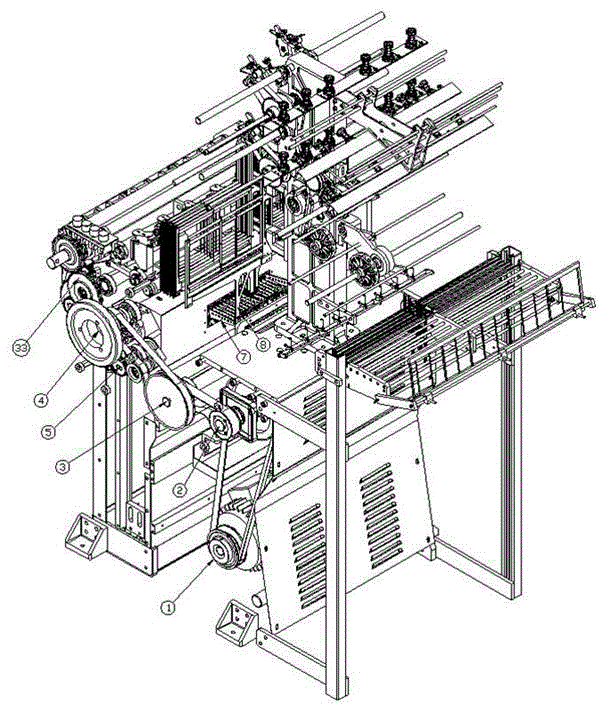

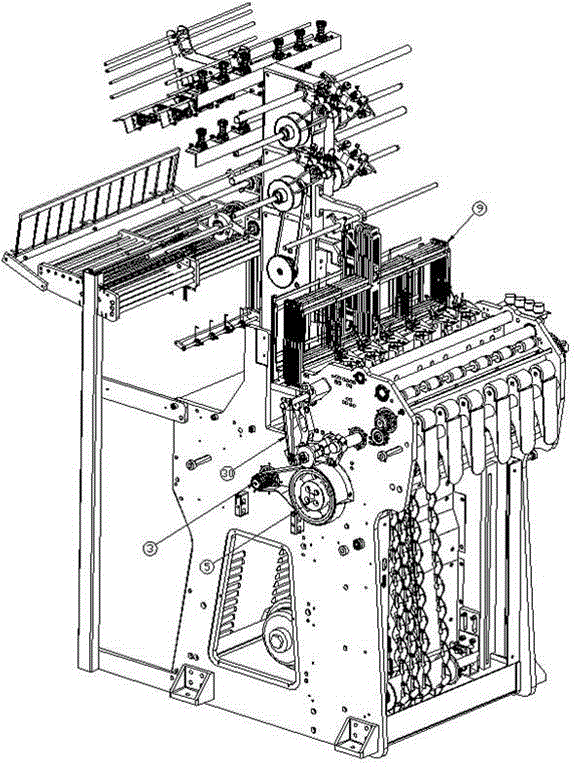

[0022] Such as figure 1 , figure 2 and image 3 As shown, a new type of high-speed flat weaving machine includes a frame on which a power mechanism, a warp feeding mechanism II, a weft yarn feeding mechanism IV, an overlock yarn feeding mechanism, an opening mechanism III, a connecting rod weaving mechanism V and The winding mechanism VI, the warp feeding mechanism II, the weft yarn feeding mechanism IV and the overlock yarn feeding mechanism constitute the yarn feeding mechanism of the ribbon loom, and the weft feeding mechanism IV includes a weft feeding variable speed shaft 10, a weft feeding umbrella wheel shaft 11, The weft-feeding umbrella wheel 12 and the belt weft-feeding device 13 installed on the weft-feeding umbrella wheel shaft 11, the overlock yarn mechanism includes a yarn-feeding axis 14, a spur gear 15, a small too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com