Device for driving crochet needle and braiding machine fitting the device

A driving device and equipment technology, used in looms, small looms, textiles, etc., can solve the problems of inability to obtain the accuracy and repeatability of knitting needles, complicated driving and control equipment, and insufficient reliability, and achieve excellent adjustability, Improved reliability and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

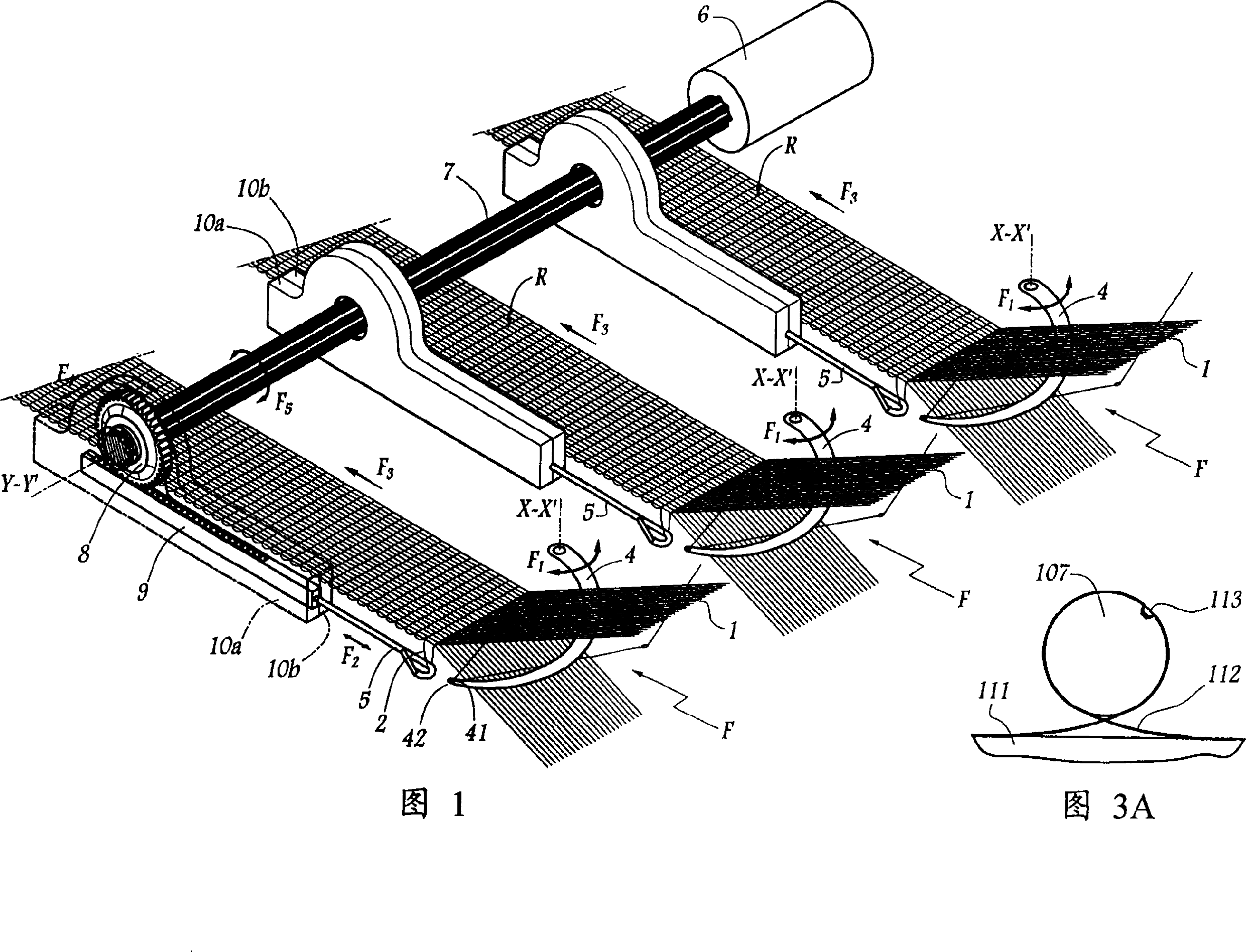

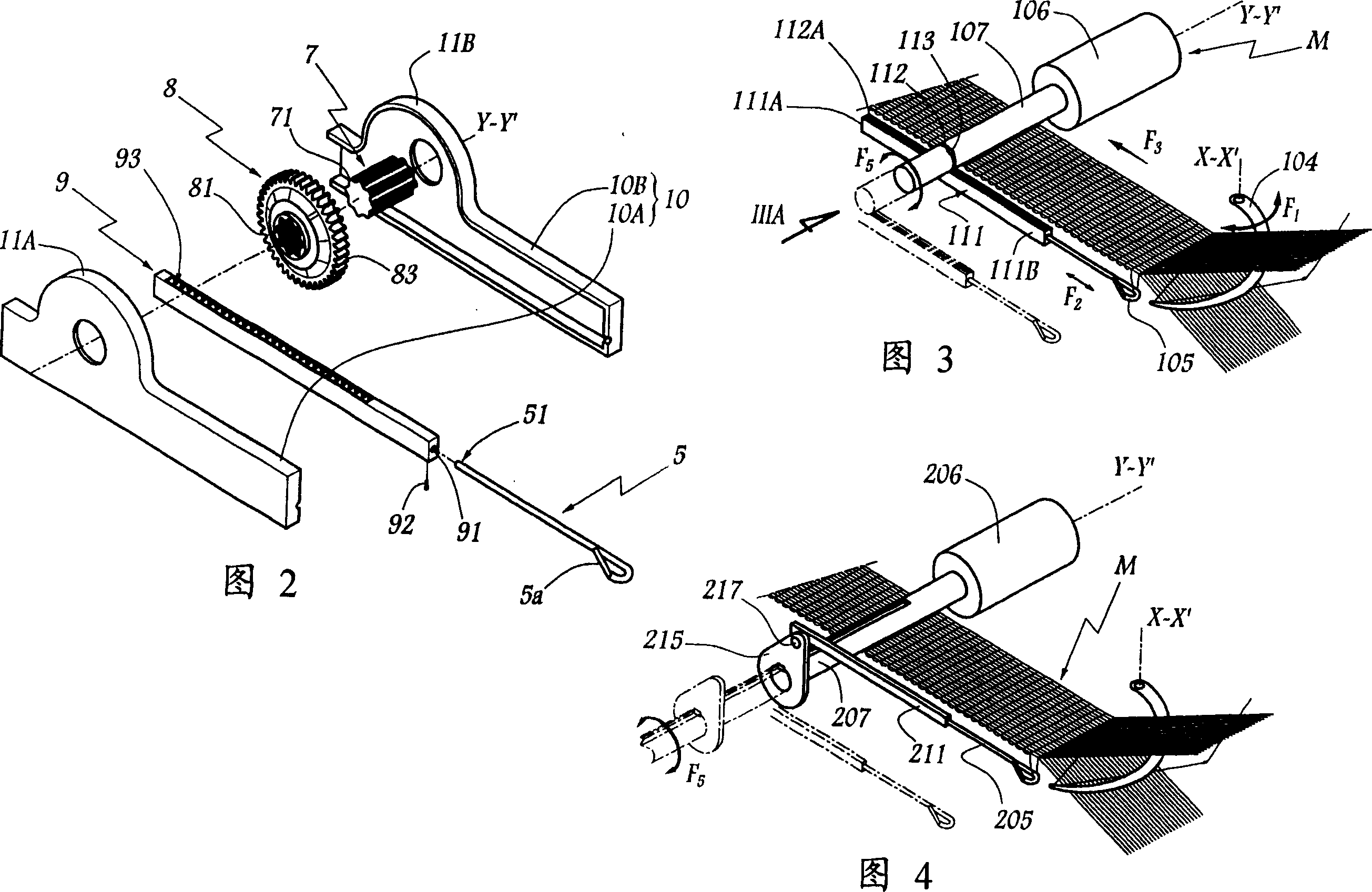

[0019] The weaving loom M partially shown in FIG. 1 can weave a plurality of ribbons R in parallel by intersecting warp yarns 1 and weft yarns 2 with each other. For each ribbon R, the weft threads are spaced more or less apart from each other to form a shed F, which can be obtained, for example, by means of a Jacquard-type mechanism , which is known per se and is not shown.

[0020] For each ribbon, the weft thread 2 is supplied by a spool (not shown) and is guided into the shed F by means of a sickle 4 which is driven by a reciprocating rotational movement F about a substantially vertical axis X-X' 1 driven by. The weft thread 2 passes through an eyelet 41 made near the free end 42 of the sickle 4, in which the mechanism for driving the shaft XX' is not shown for clarity of the drawing.

[0021] In order to keep the weft thread at the level of the selvedge closest to the observer in Fig. 1, associated with each sickle 4 is a knitting needle 5 driven by a back and forth rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com