White balance adjusting method and system and LCD manufacturing method

An adjustment method and white balance technology, applied to static indicators, cathode ray tube indicators, instruments, etc., can solve the problems of complex algorithm pages, waste of collected data, unfavorable adjustments, etc., to reduce yield loss, accurate adjustment, Reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the technical characteristics and structure of the present invention, the following is a detailed description in conjunction with preferred embodiments of the present invention and accompanying drawings.

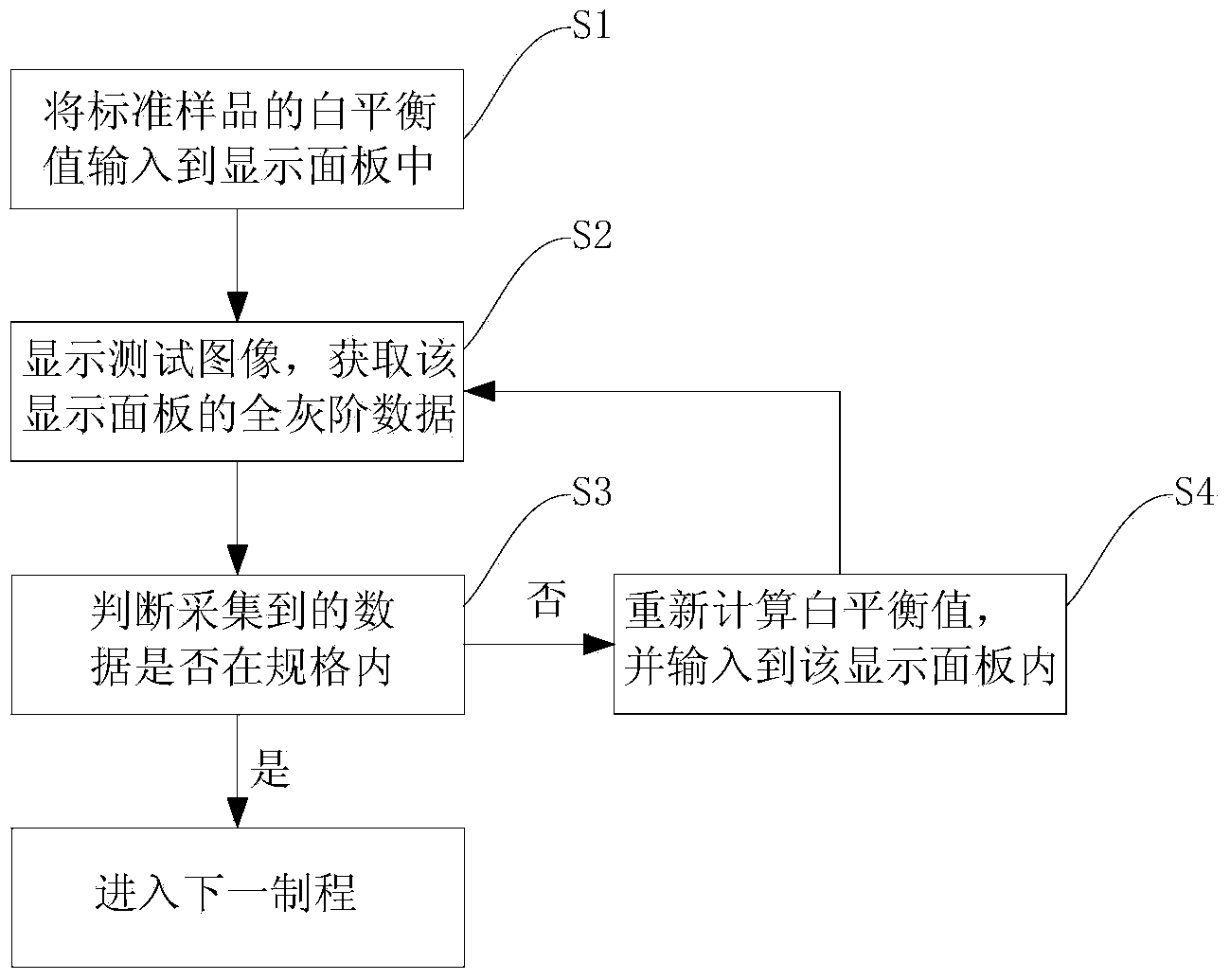

[0036] refer to figure 1 , a flow chart of a white balance adjustment method provided in this embodiment, including steps:

[0037] S1: Input the white balance value of the standard sample into the display panel;

[0038] S2: controlling the display panel to display a test image with different grayscales, and obtaining full grayscale data of the display panel;

[0039] S3: Determine whether the acquired data is within the specification range, if so, enter the next process; if not, enter step S4;

[0040] S4: Recalculate the white balance value according to the difference between the obtained full gray scale data and the full gray scale data of the standard sample, input the calculated white balance value into the display panel, and retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com