Patents

Literature

93results about How to "Fine adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

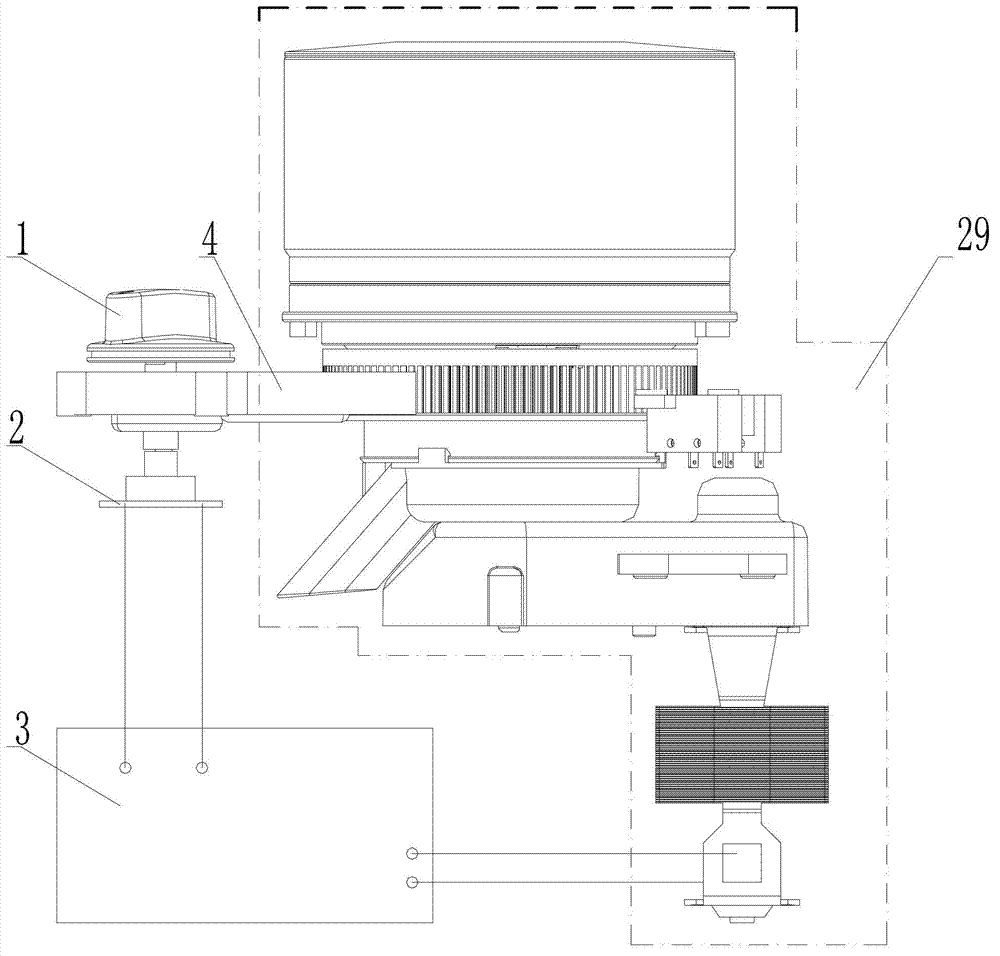

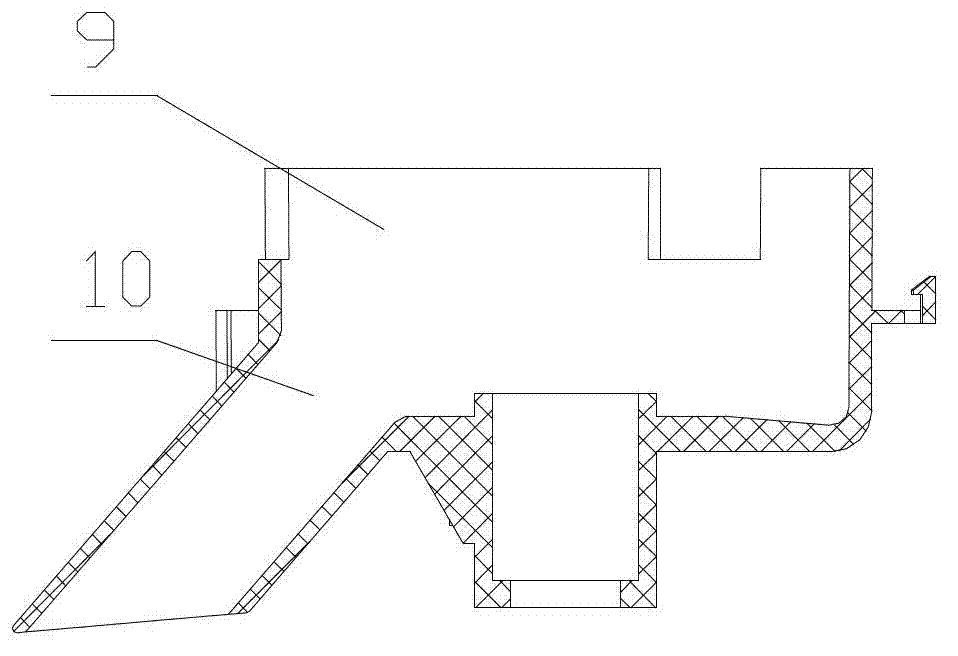

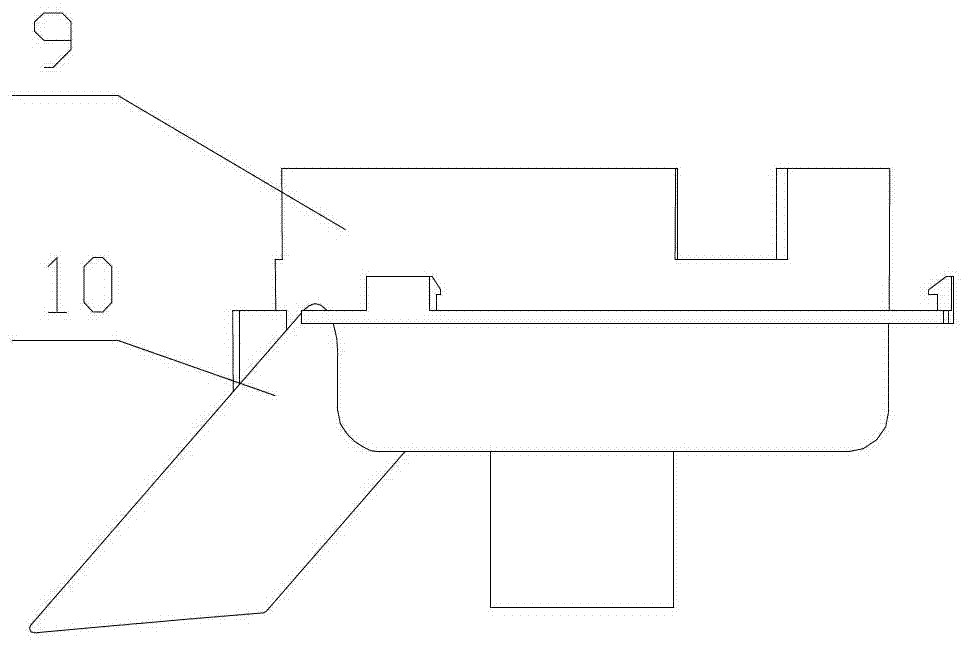

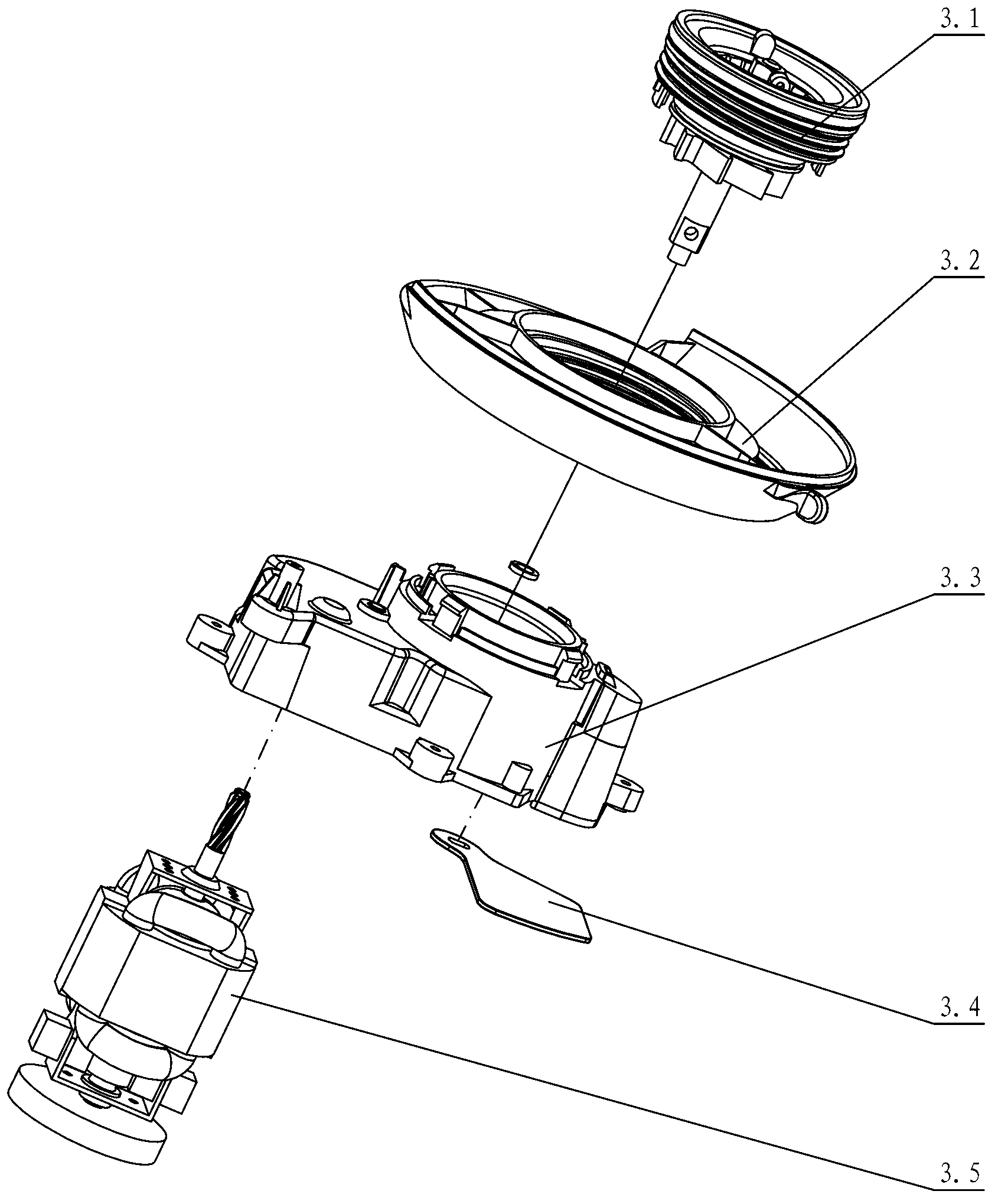

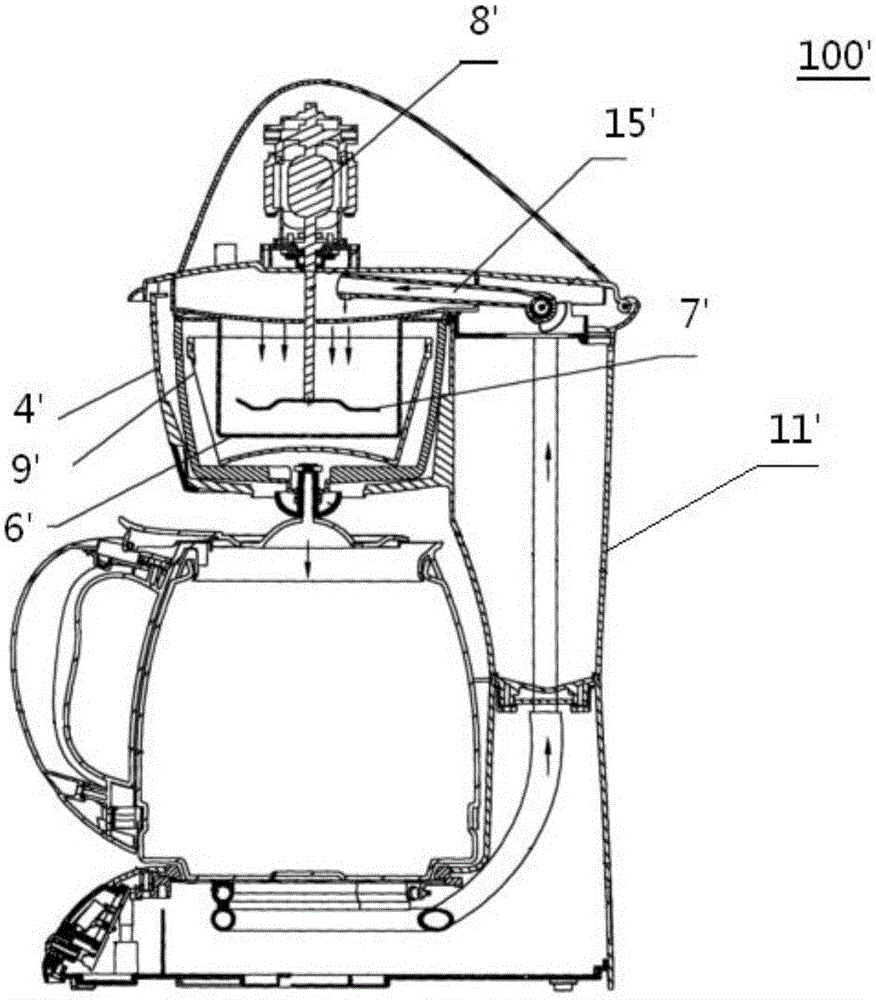

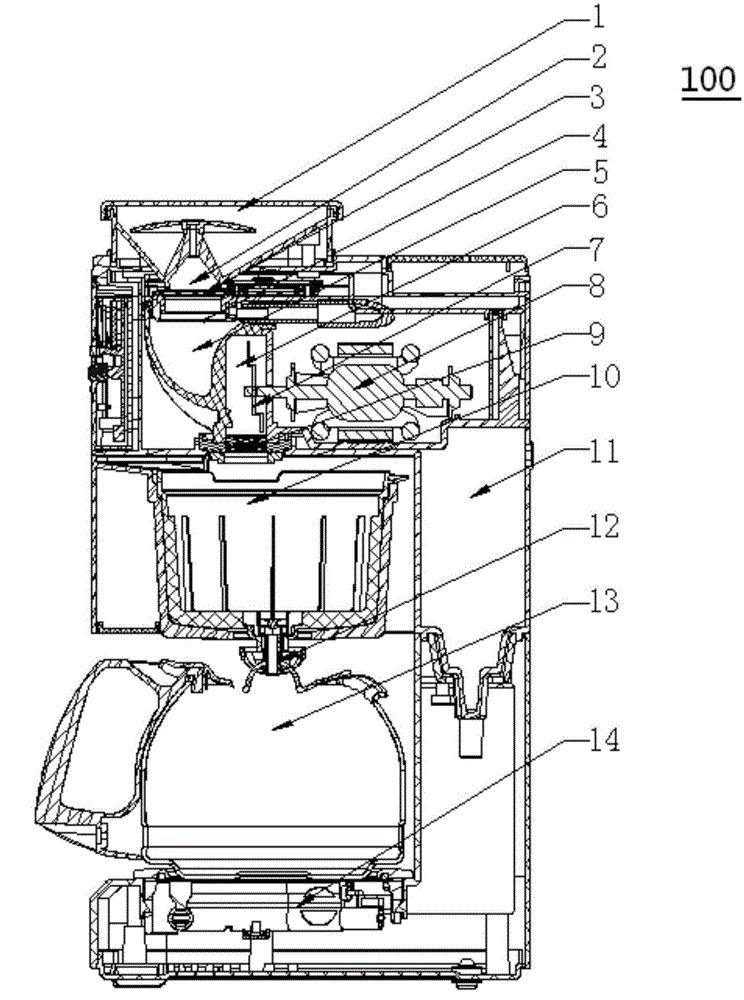

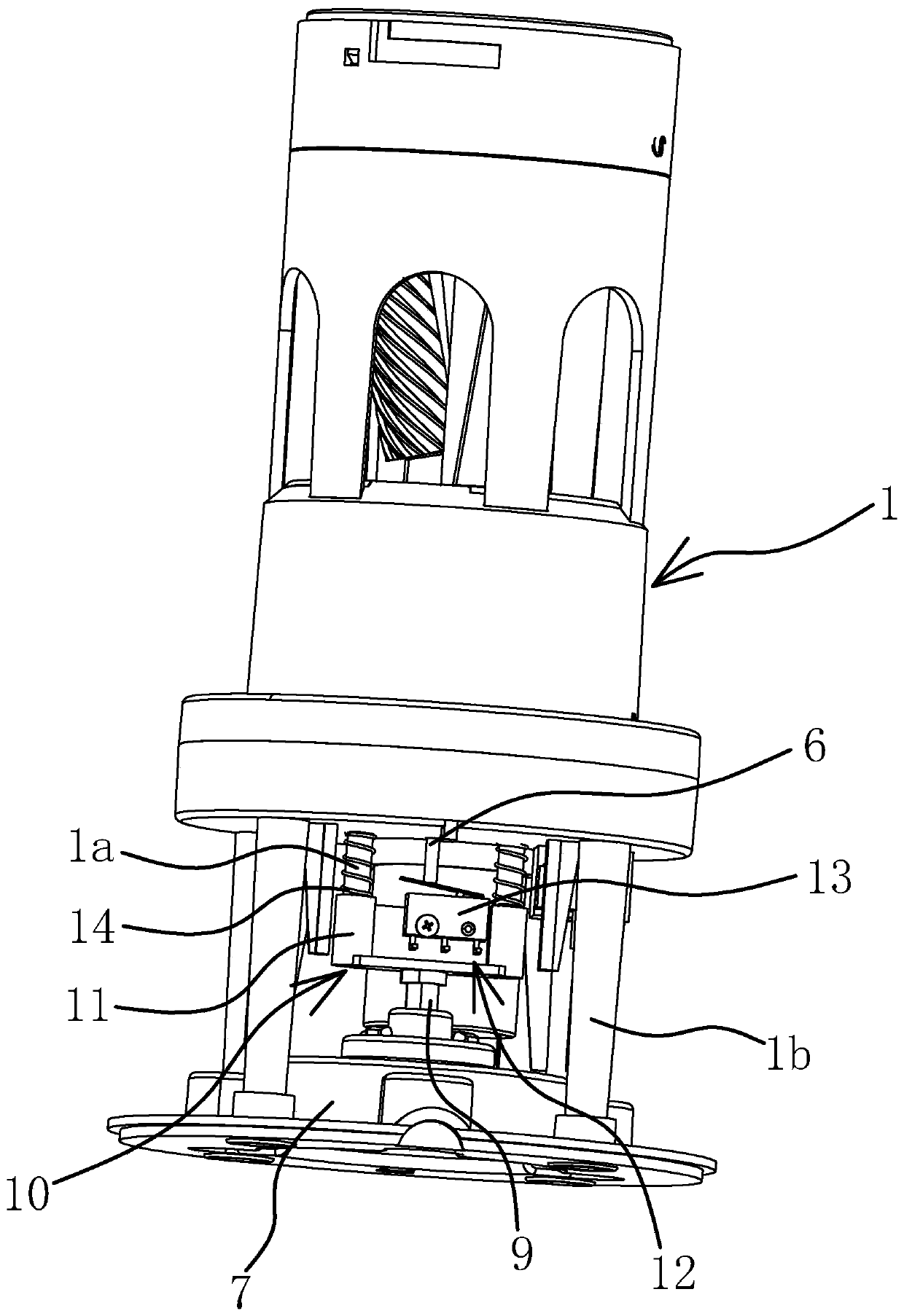

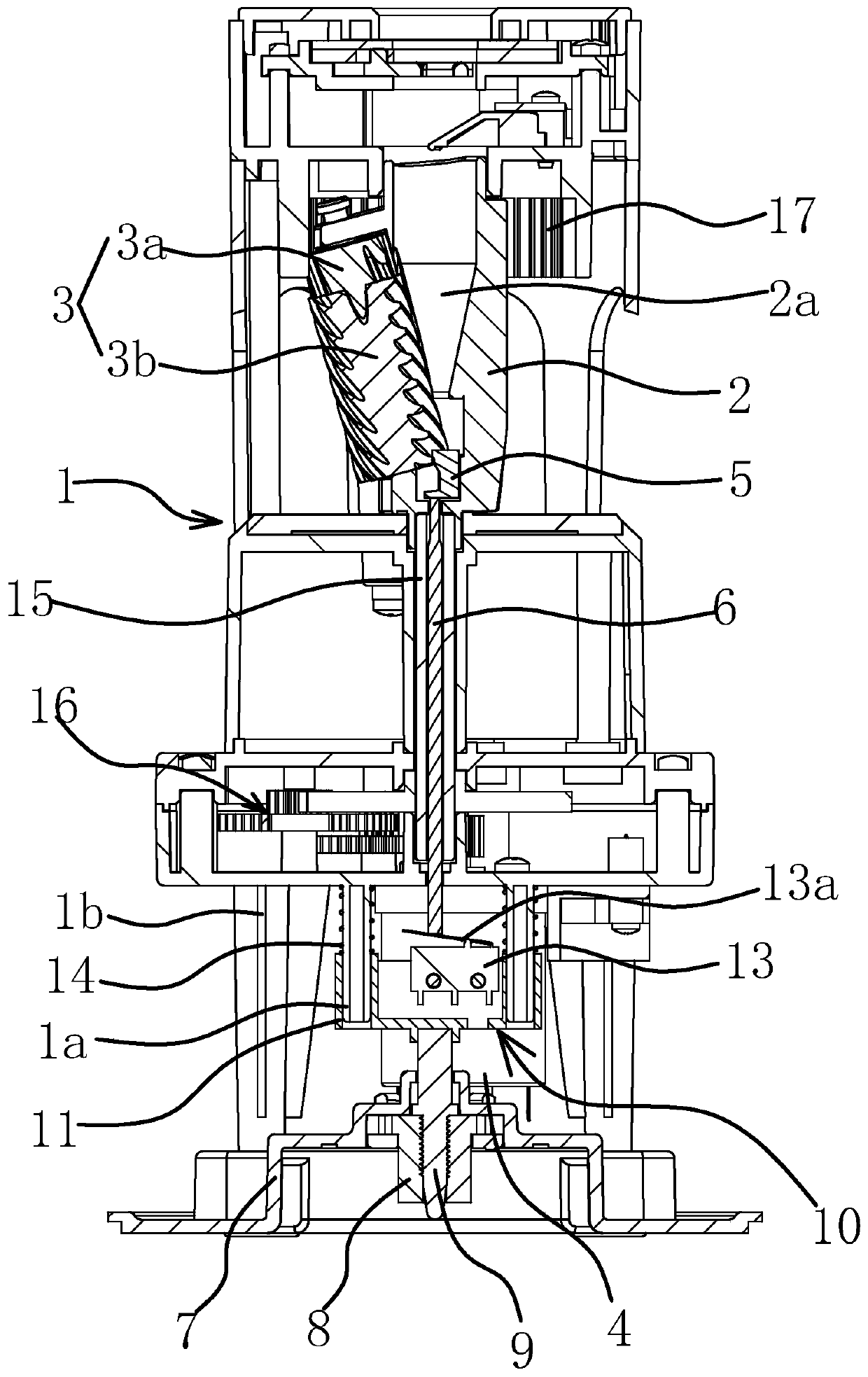

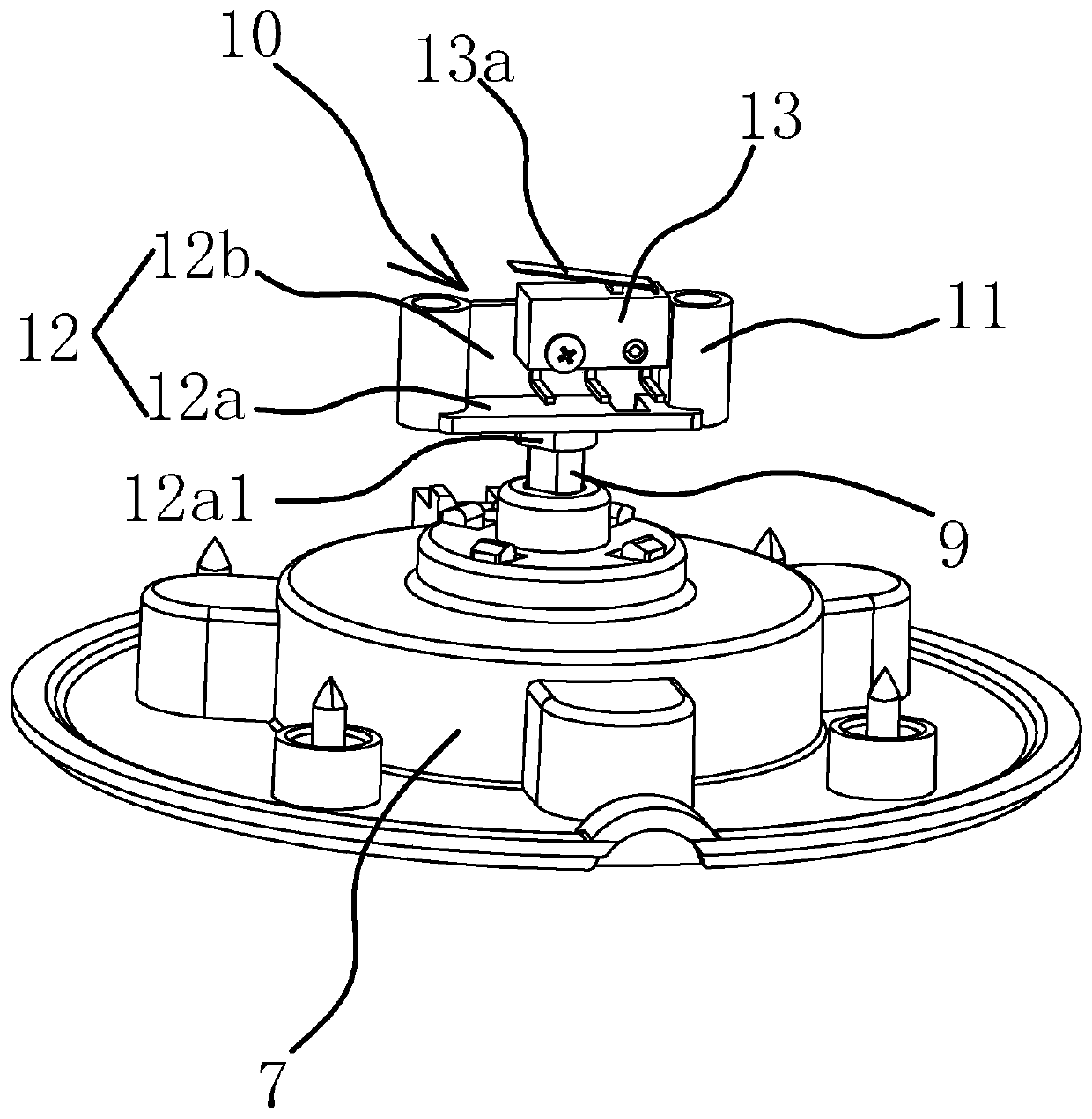

Automatic coffee maker with detachable bean grinding device

Disclosed is an automatic coffee machine with a detachable bean-grinding apparatus. A detaching / installing and adjusting mechanism for the bean-grinding apparatus comprises a connecting part connected in an easily detachable fashion with a bean case component (13), and an adjusting part able to adjust an upper grinding wheel component (14) in performing reciprocal movements so as to adjust the grinding distance of the upper grinding wheel component (14) and a lower grinding wheel component (12). Cleaning and maintenance of the grinding components by a user is facilitated while the fineness of ground powder granules can be adjusted as needed. A powder outlet channel (10) of a bean-grinding chamber (9) is an inclined pipe structure, and the top part of an opening in the initial portion of the powder outlet channel (10) intersects with a side wall (32) and a bottom face (34) of the bean-grinding chamber (9). The distance between the outermost end of a coffee grounds remover tray (11) and the rotational centreline of the coffee grounds remover tray (11) is greater than the minimum distance between the opening in the initial portion of the powder outlet channel (10) and the rotational centreline of the coffee grounds remover tray (11). By means of the inclined powder outlet channel (10) coffee powder can freely slide into a brewing apparatus, and the coffee grounds remover tray (11) plays the role of preventing the risk of and eliminating powder blocking the bean-grinding chamber (9) and the power outlet channel (10).

Owner:珠海鑫润智能家电有限公司

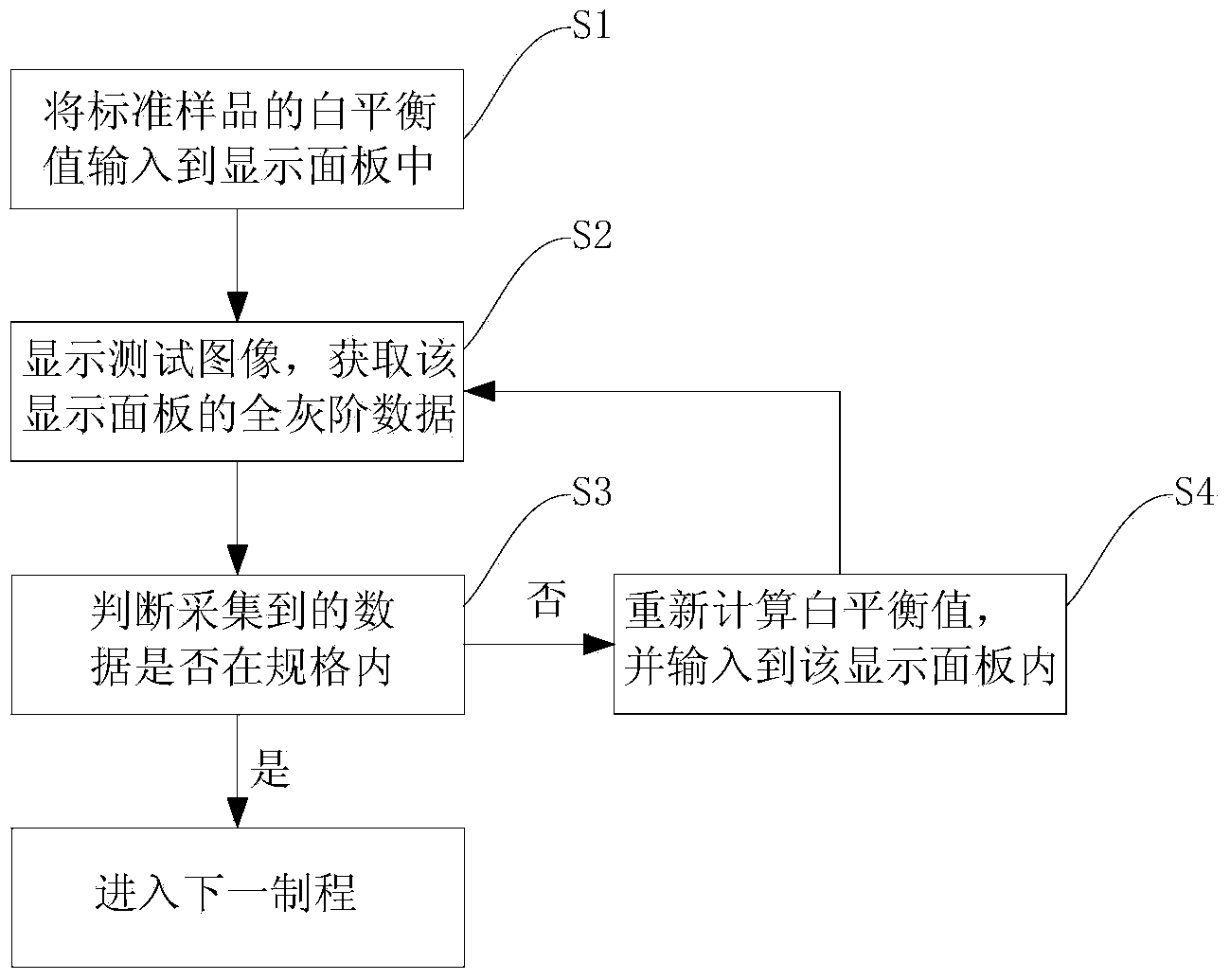

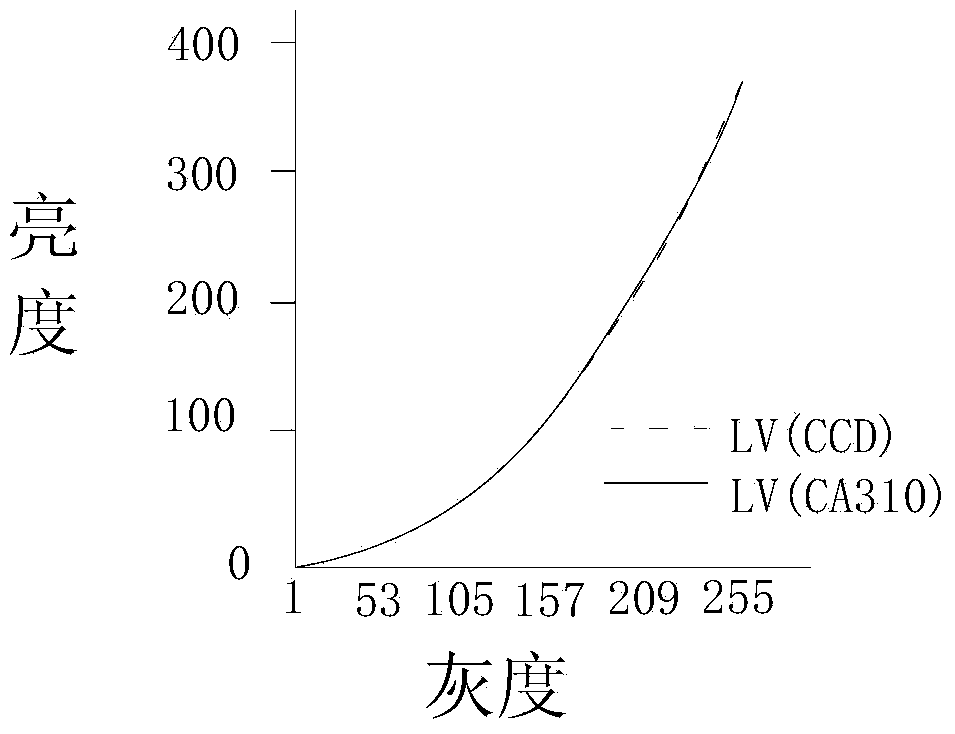

White balance adjusting method and system and LCD manufacturing method

ActiveCN103730096AFine adjustmentReduce yield lossCathode-ray tube indicatorsStandard samplesLiquid-crystal display

The invention provides a white balance adjusting method which comprises the steps that S1, the white balance value of a standard sample is input to a display panel; S2, the display panel is controlled to display a testing picture with different gray levels, and the full-gray-scale data of the display panel is acquired; S3, whether the acquired data are within a specification range is judged, if yes, the next manufacture procedure is executed, and if not, the step S4 is executed; S4, the white balance value is calculated again according to the difference value of the acquired full-gray-scale data and the full-gray-scale data of the standard sample, the calculated white balance value is input to the display panel, and the step S2 is executed again. According to the white balance adjusting method, white balance can be quickly and accurately adjusted, different modules are made to have the same visual performance, and yield loss caused by overspecification of gamma and chromaticity is reduced.

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD

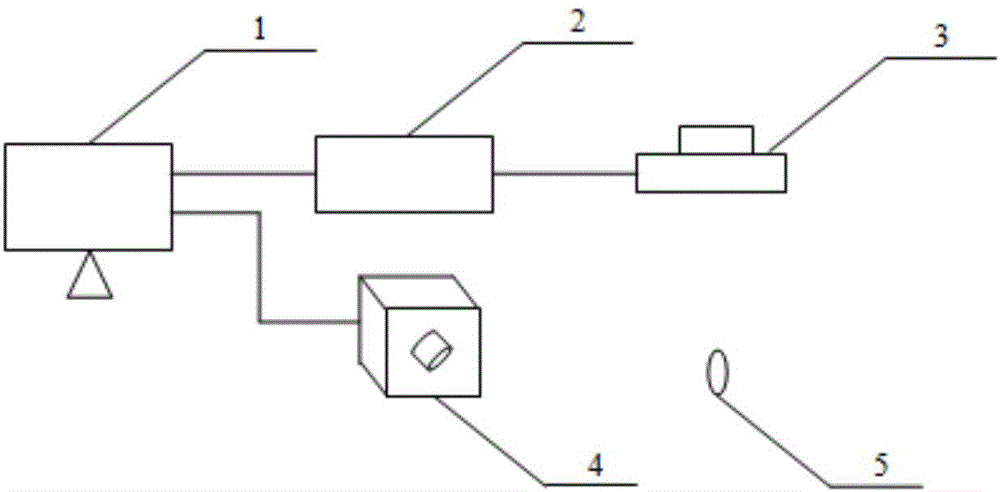

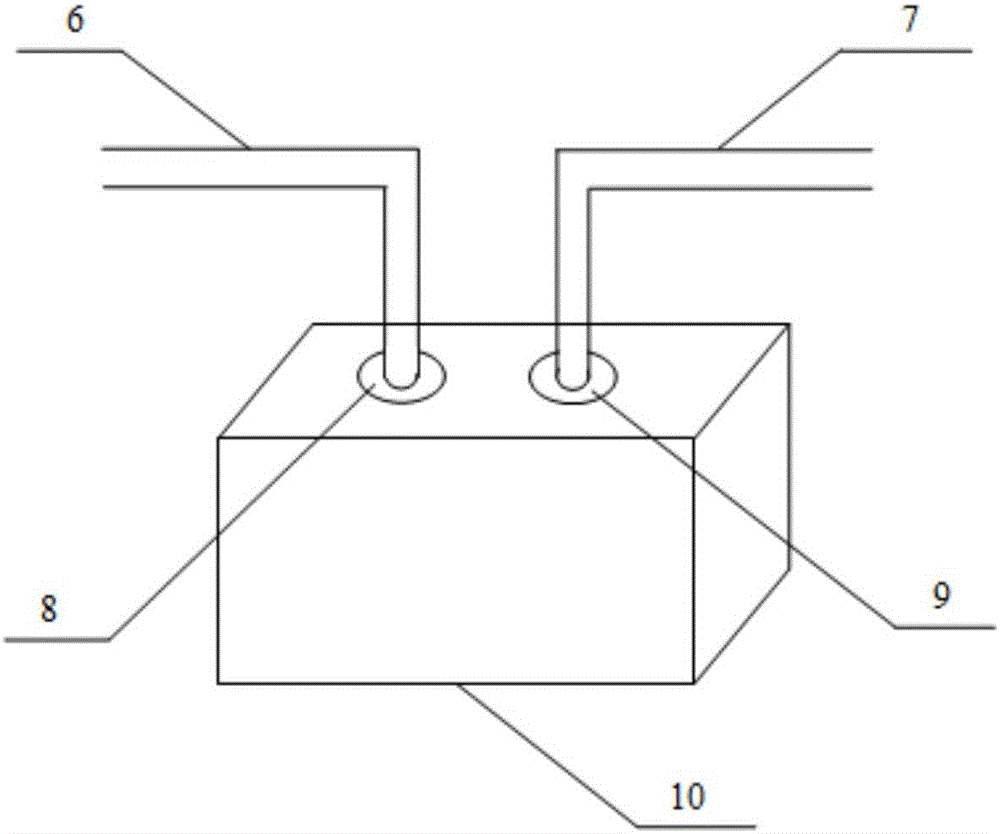

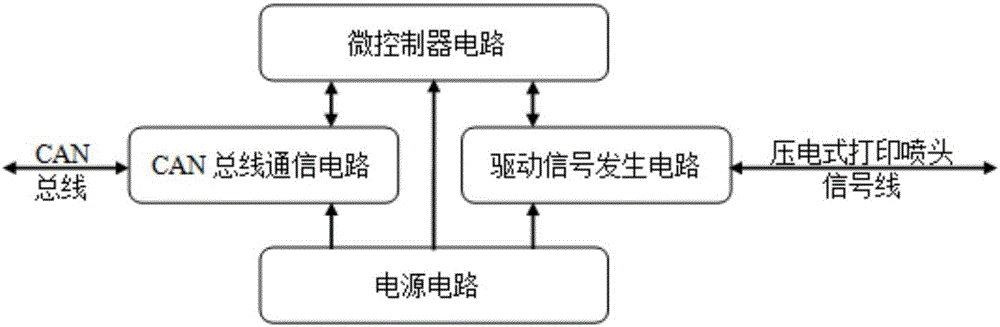

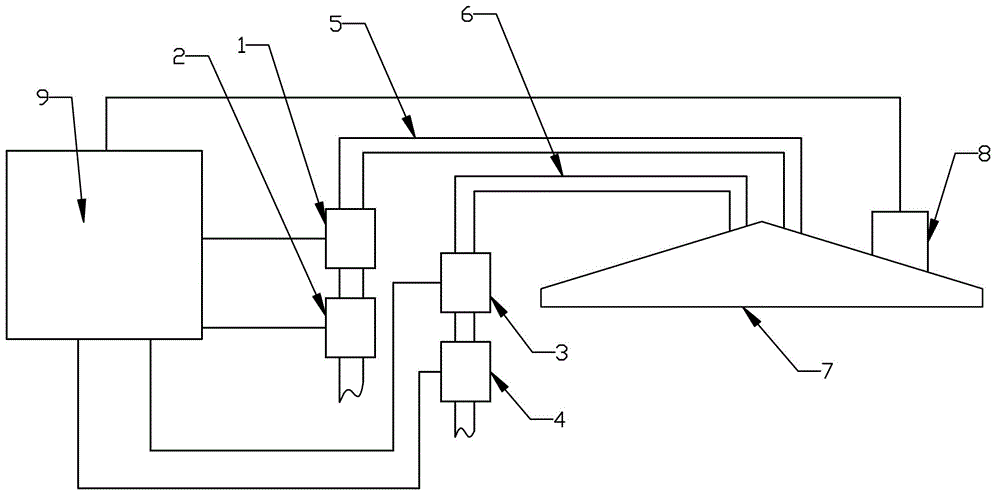

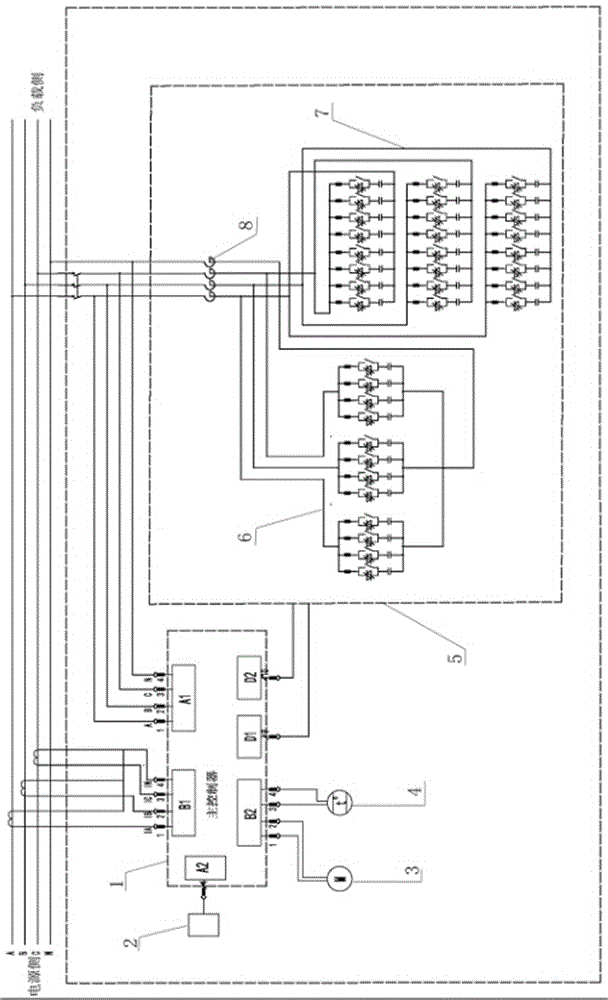

Ink droplet ejection state adjusting system and method for piezoelectric printing nozzle

The invention, which belongs to the technical field of ink-jet printing, provides an ink droplet ejection state adjusting system and method for a piezoelectric printing nozzle. The system is composed of a computer computing platform, a nozzle drive controller, a piezoelectric printing nozzle and a CCD camera. One end of the nozzle drive controller is connected with the computer computing platform and the other end is connected with the piezoelectric printing nozzle; and the CCD camera is connected with the computer computing platform. The nozzle drive controller generates a drive signal for the piezoelectric printing nozzle and simultaneously carries out time sequence controlling on the drive signal; the piezoelectric printing nozzle fluctuates in an ink cavity under the drive signal provided by the nozzle drive controller and the fluctuation is spread to spraying holes to form ink droplets; and the CCD camera captures states of ink droplets ejected by the piezoelectric printing nozzle.

Owner:天津斯沃姆科技发展有限公司

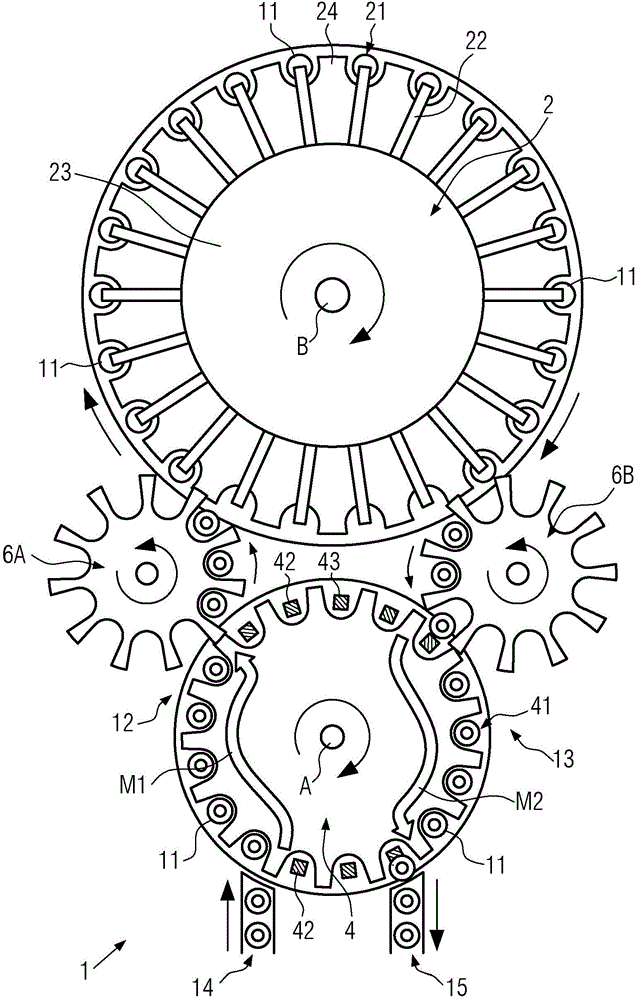

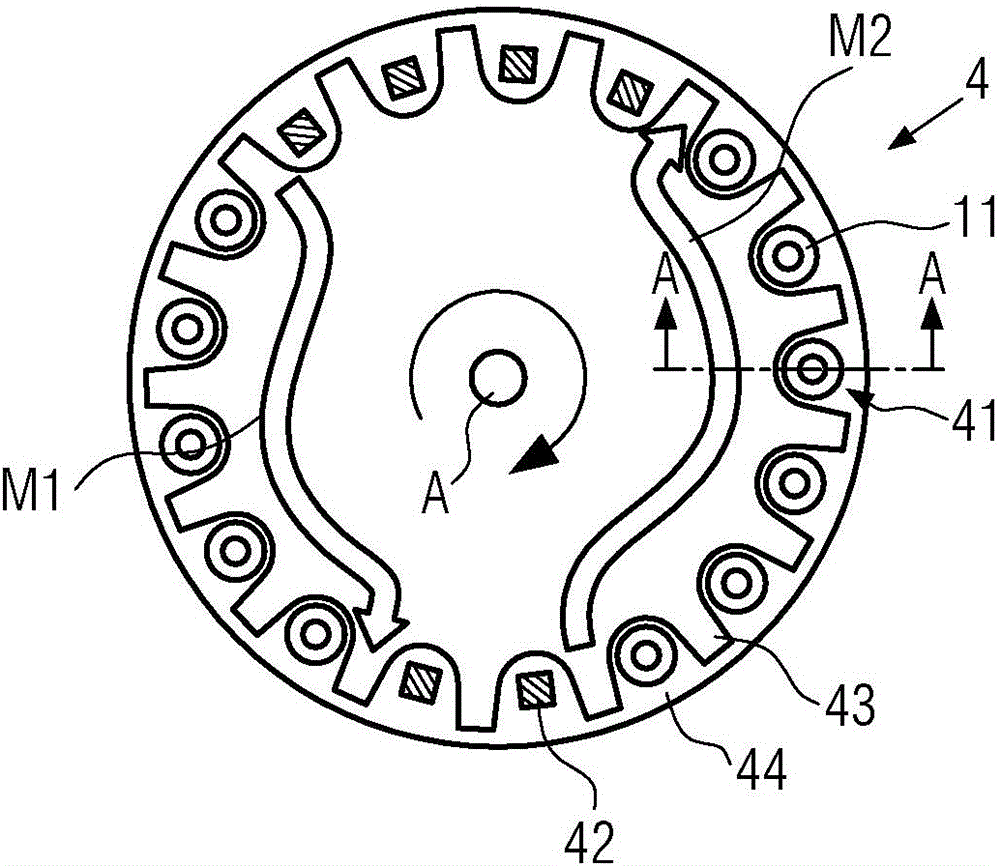

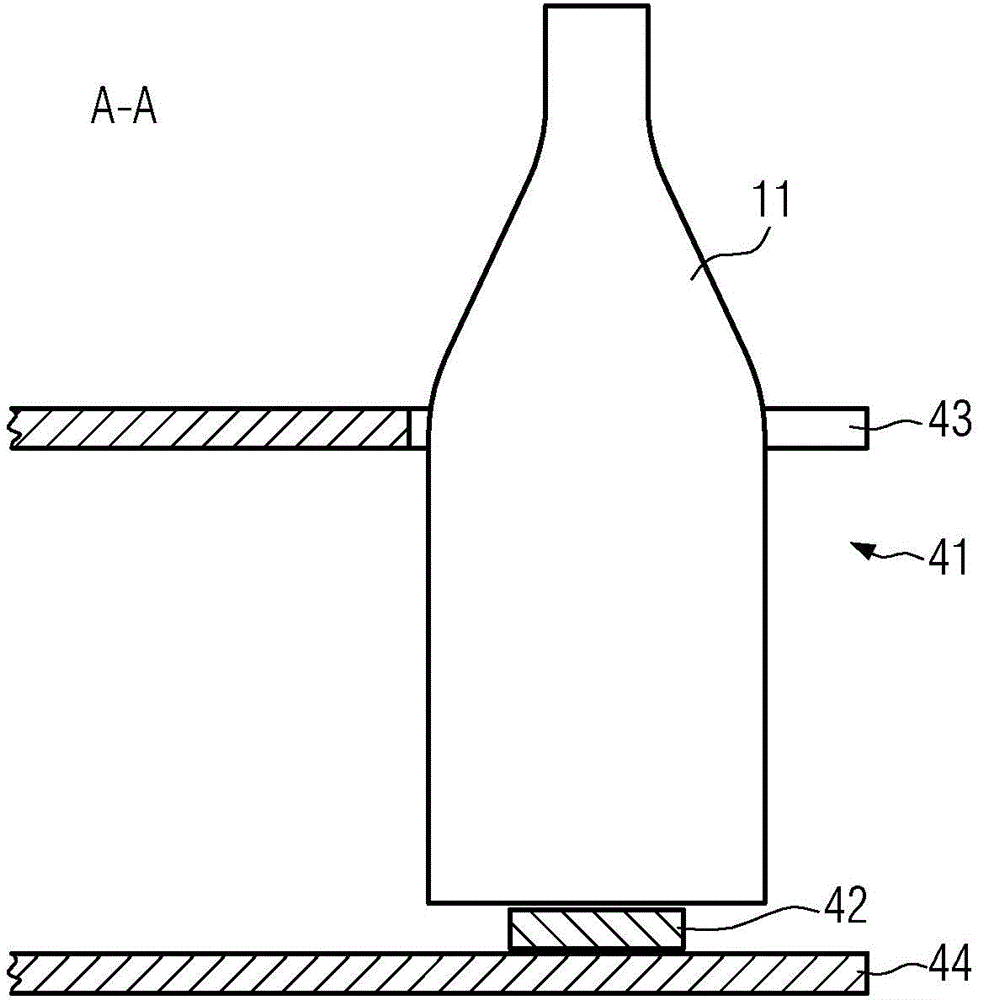

Device and method for filling container

InactiveCN103057731AFine adjustmentEasy to adjustMaterial check-weighingSolid materialMechanical engineeringNet Weight

The invention comprises a device (1) and method for filling a container (11). The device comprises a filling device (2) having multiple filling positions (21). The container (11) performs transmission to the filling positions through an inlet part (12) and performs output to the filling positions through a discharge part (13). A round wheel rotary table (4) having multiple measuring positions (41) for measuring weight of the container (11) is configured to the filling device (2) in the following manner that: a measuring segment (M1) of the round wheel rotary table (4) for measuring the net weight of the container (11) is formed in the inlet part (12) and a measuring segment (M2) of the same round wheel rotary table (4) for measuring the final weight of the container (11) is formed in the discharge part (12). The invention provides the device and method for filling the container using a more compact filling device, more effectively uses dosingmechanism and weight measuring members and more accurately determines the filling volume.

Owner:KRONES AG

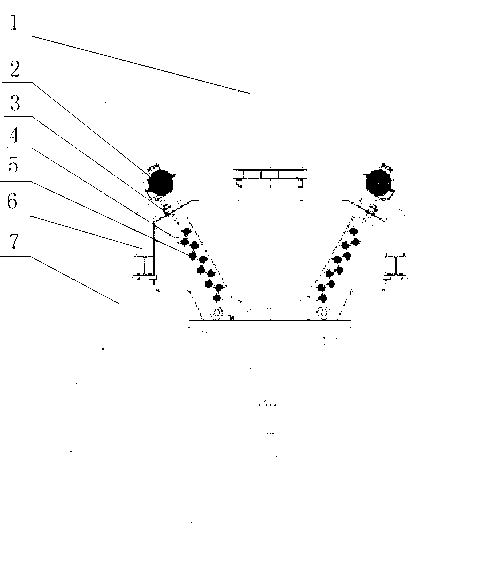

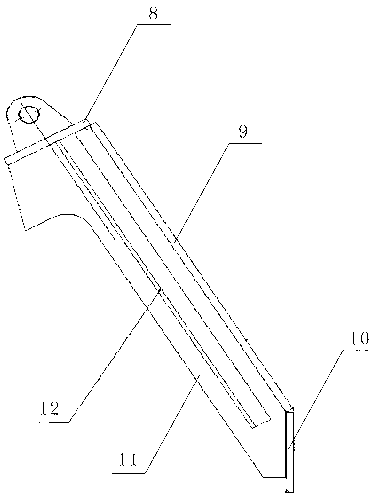

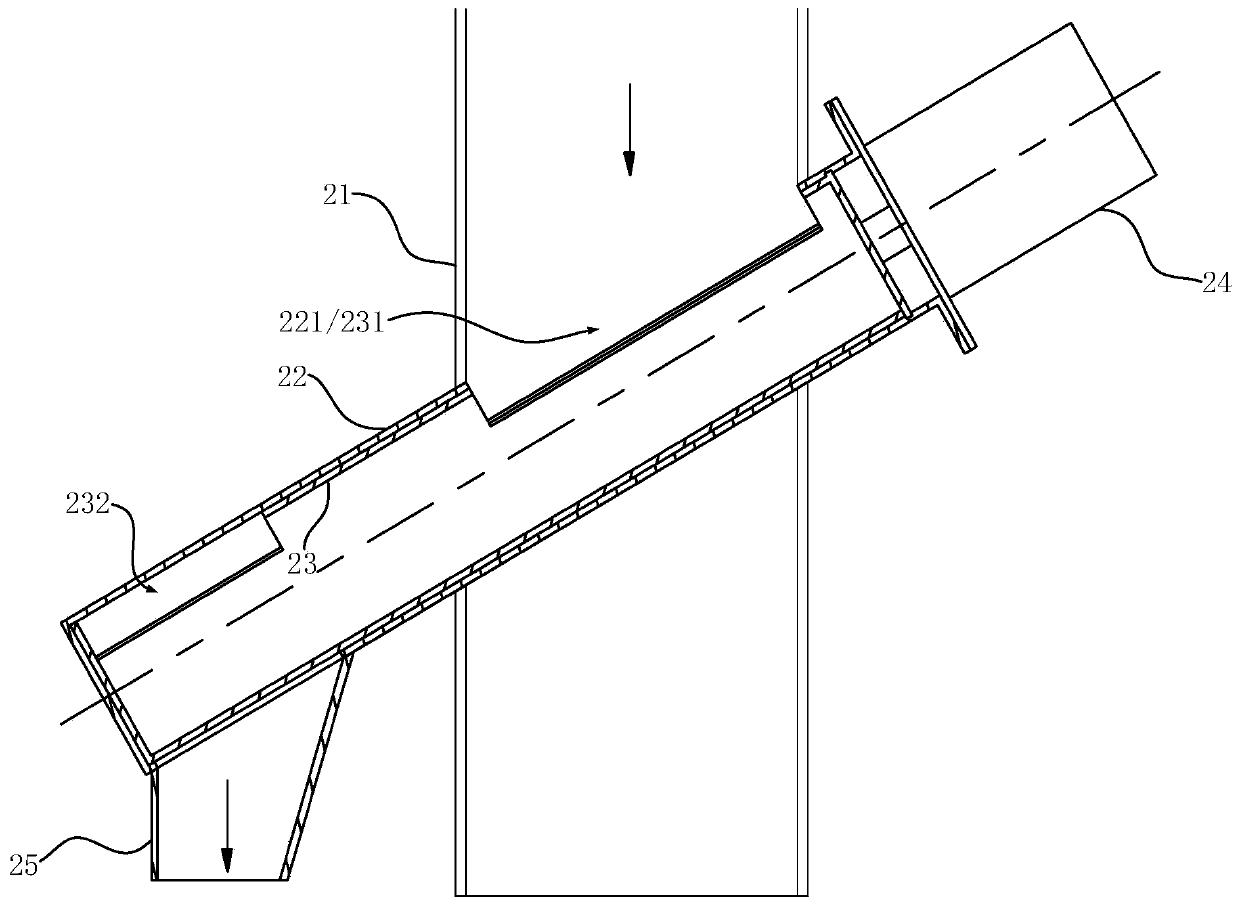

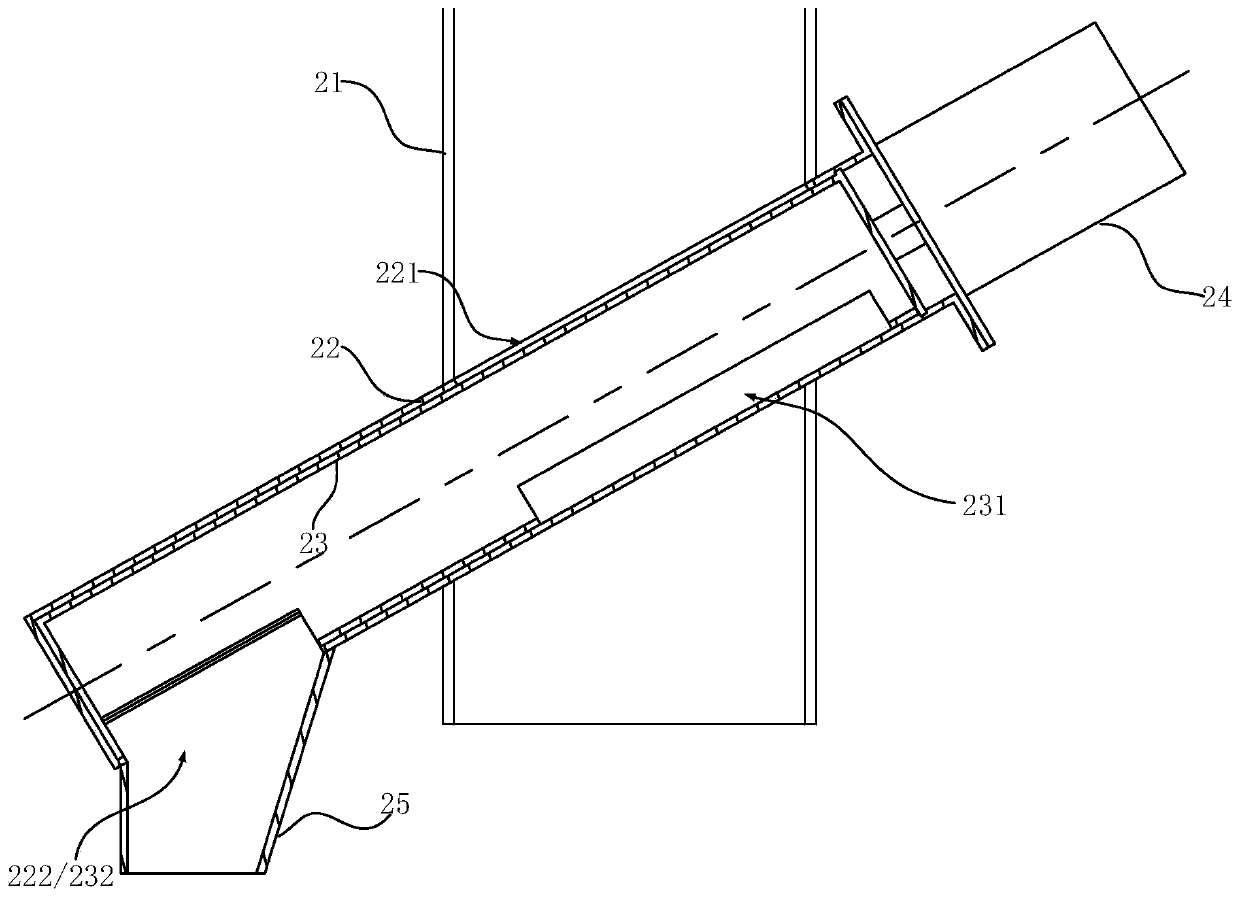

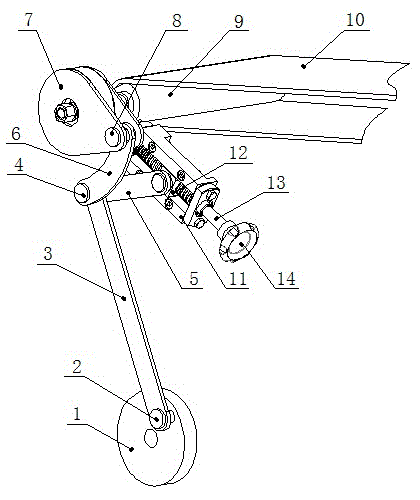

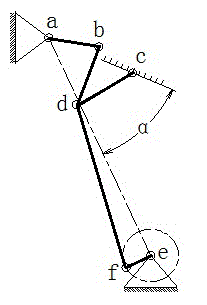

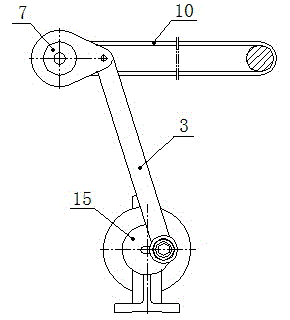

Bilateral mechanism for automatically regulating feeding of high-pressure roller mill

ActiveCN103285991AImprove operational efficiencyFine adjustmentGrain treatmentsDrive motorEngineering

The invention discloses a bilateral mechanism for automatically regulating the feeding of a high-pressure roller mill. The mechanism is installed on a feeding device of the high-pressure roller mill, is used for regulating the feeding quantity of the feeding device, and comprises two regulating devices which are respectively arranged at the left side and the right side of a material column of the feeding device and form a 30-degree included angle respectively with the left side and the right side of the material column; the feeding quantity of the feeding device is controlled further through regulating the size of an opening between the two regulating devices, and more rapid and accurate regulation is realized; the regulating amplitude is great; the quantity of materials falling on an extruding roller can be controlled accurately through regulating at two sides, so that the power of drive motors of two rollers is more approximate, so that the using situation of the high-pressure roller mill is optimized.

Owner:CITIC HEAVY INDUSTRIES CO LTD

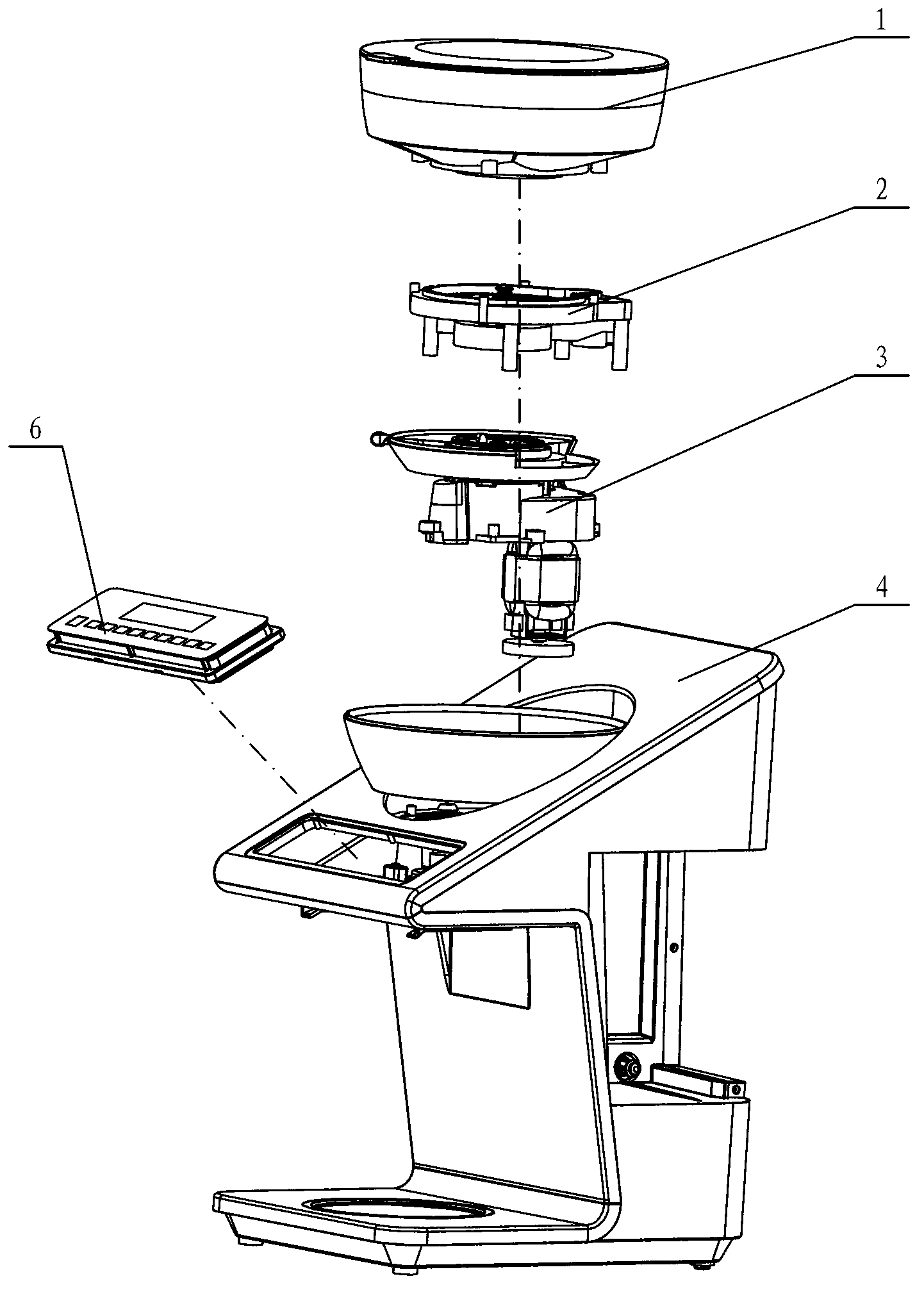

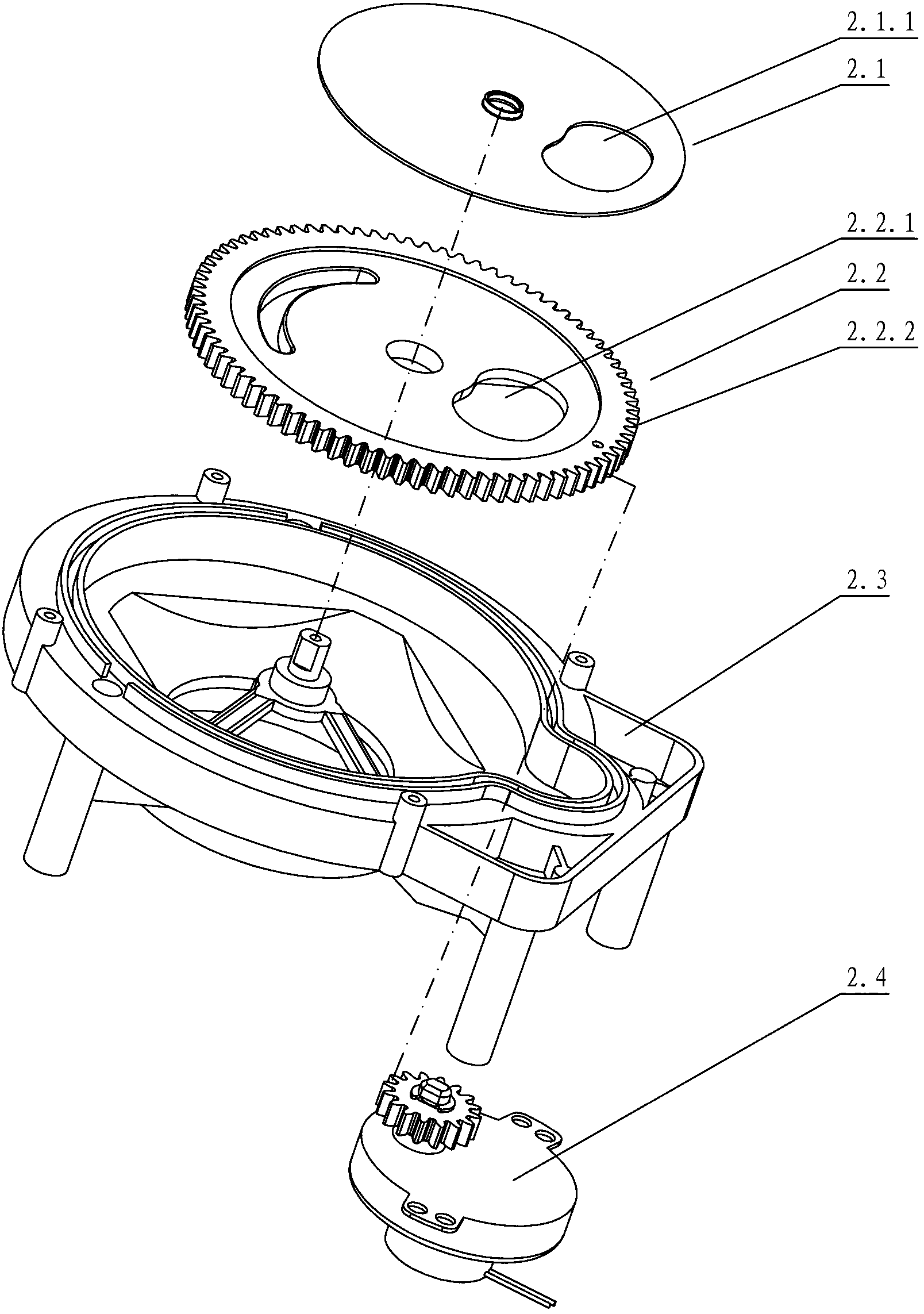

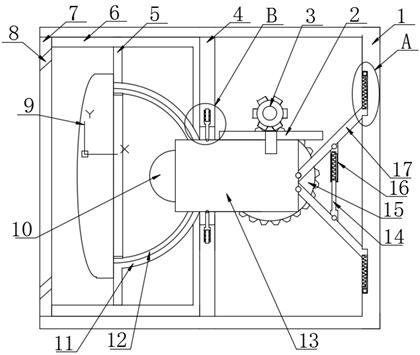

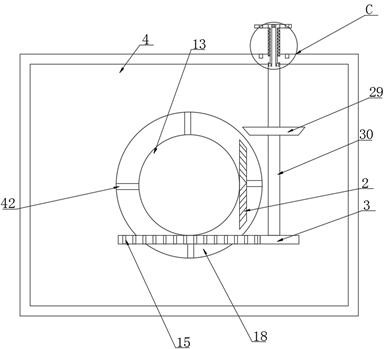

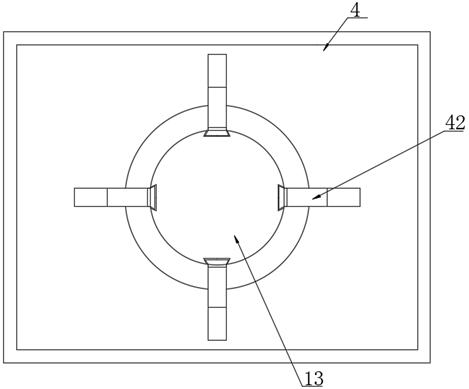

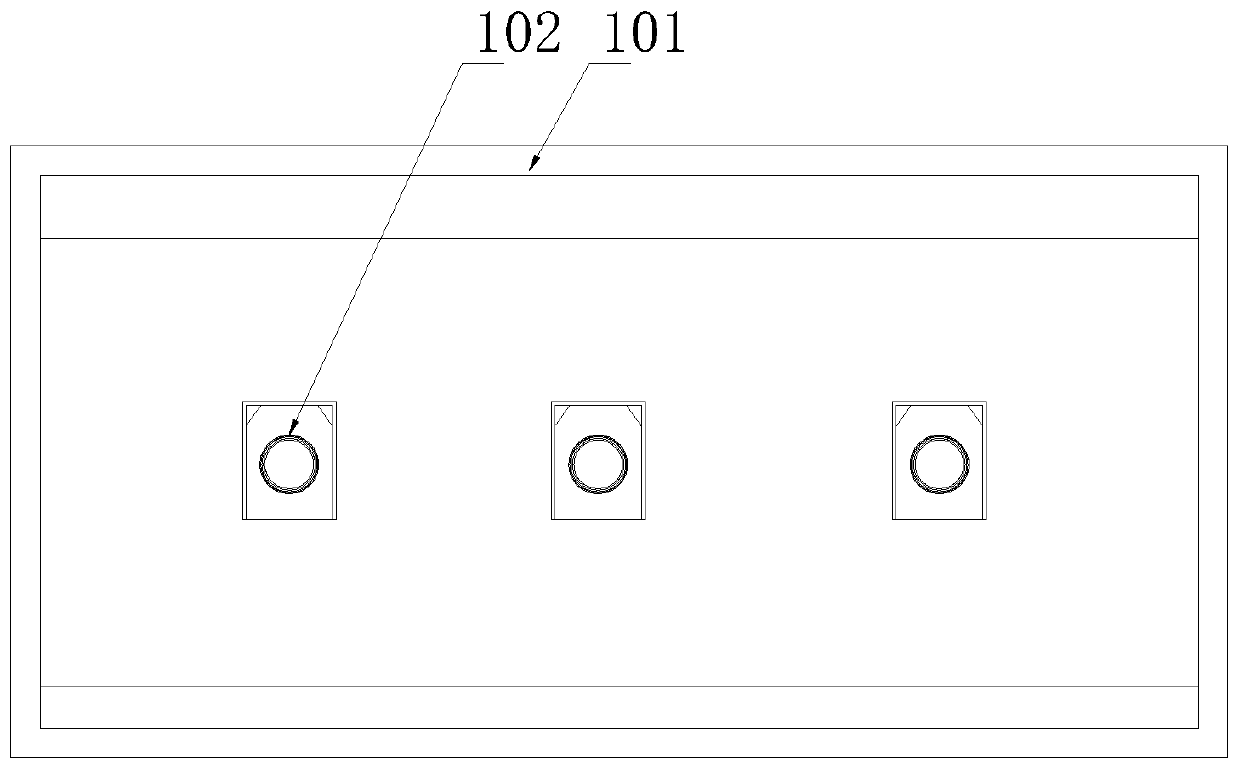

Automatic mixing bean-grinding coffee machine

InactiveCN103300731AWith memory storage functionSimplify workBeverage vesselsAgricultural engineeringElectric machinery

The invention relates to an automatic mixing bean-grinding coffee machine. The automatic mixing bean-grinding coffee machine comprises a bean storage box, a bean grinding mechanism, a brewing mechanism and a blanking mechanism, wherein the bean storage box is arranged on a machine body; the blanking mechanism is used for selecting the types and the proportion of coffee beans; the blanking mechanism comprises a turnplate connected with a driving motor; the turnplate is positioned between the bean storage box and the bean grinding mechanism; more than two coffee bean storage cavities are formed in the bean storage box; each coffee bean storage cavity is provided with a coffee bean outlet; coffee bean through holes are formed in the turnplate; the driving motor is electrically connected with a control unit of the coffee machine; the blanking mechanism also comprises a bean collecting hopper; the bean collecting hopper is arranged between the turnplate and the bean grinding mechanism; the turnplate is arranged in the middle of the bean collecting hopper; the driving motor is arranged on one side of the bean collecting hopper; an output shaft of the driving motor is connected with a pinion; gear teeth are arranged on the turnplate and are meshed with the pinion. The invention has the characteristics that the automatic mixing bean-grinding coffee machine has a simple and reasonable structure and is flexible to operate; single coffee can be provided; mixed coffee also can be provided.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

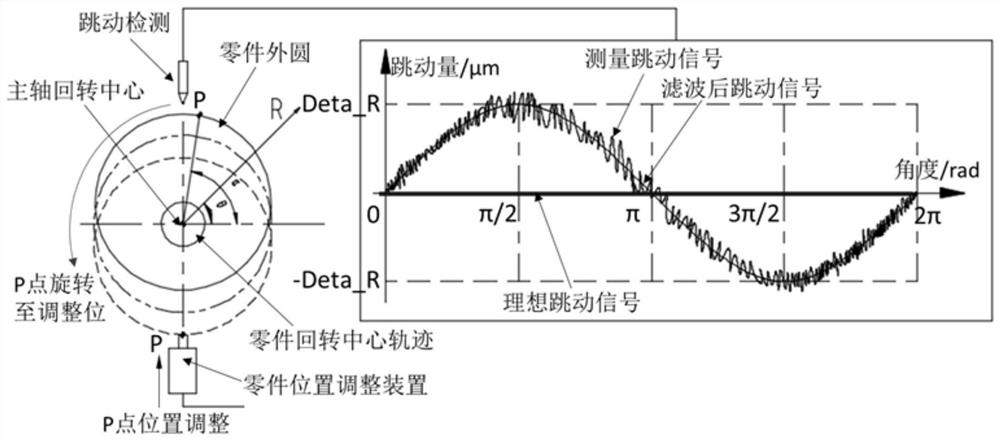

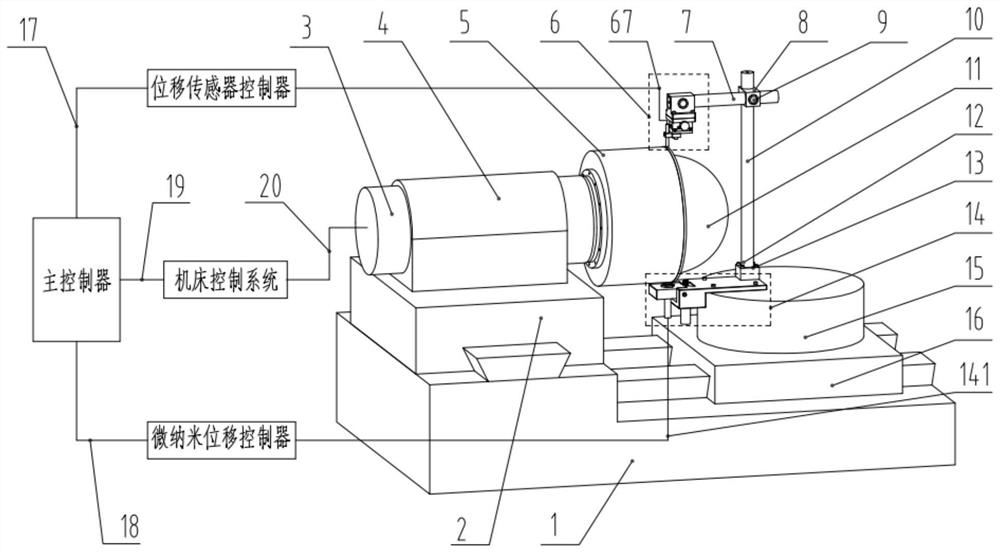

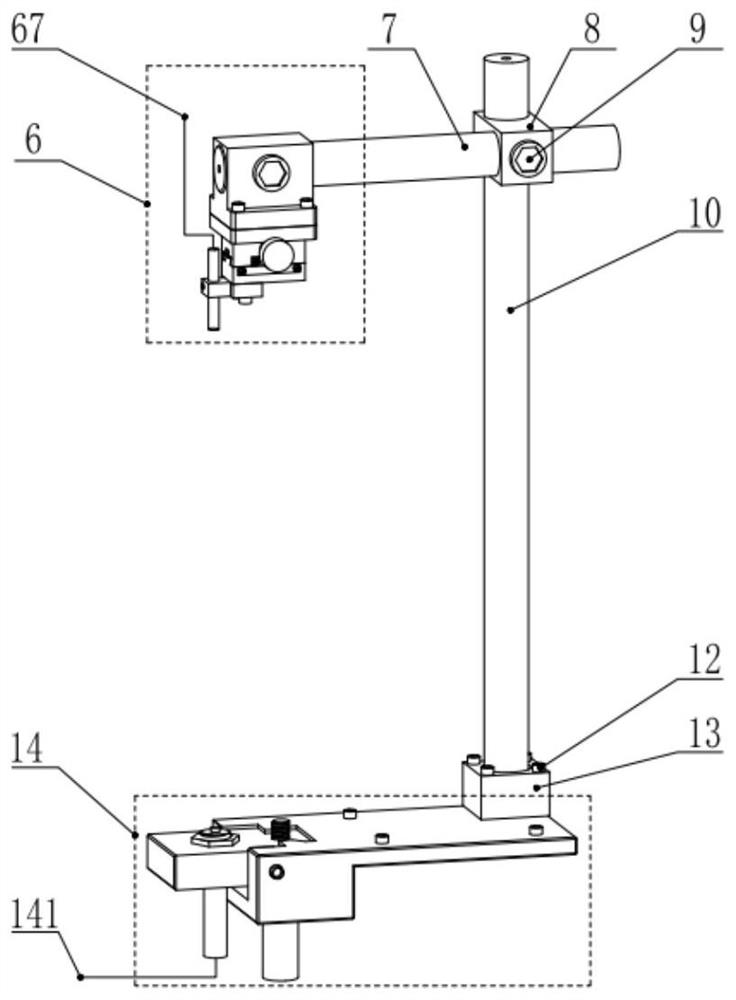

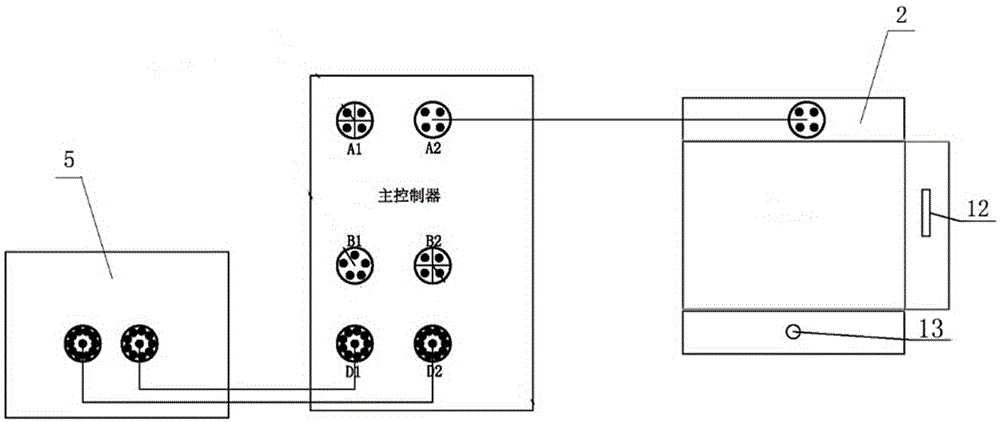

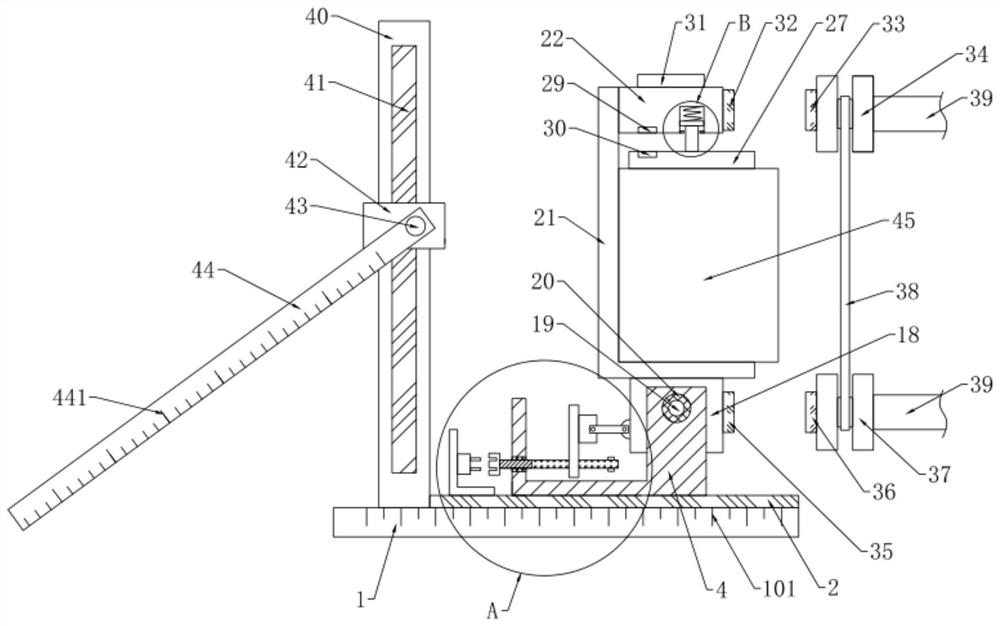

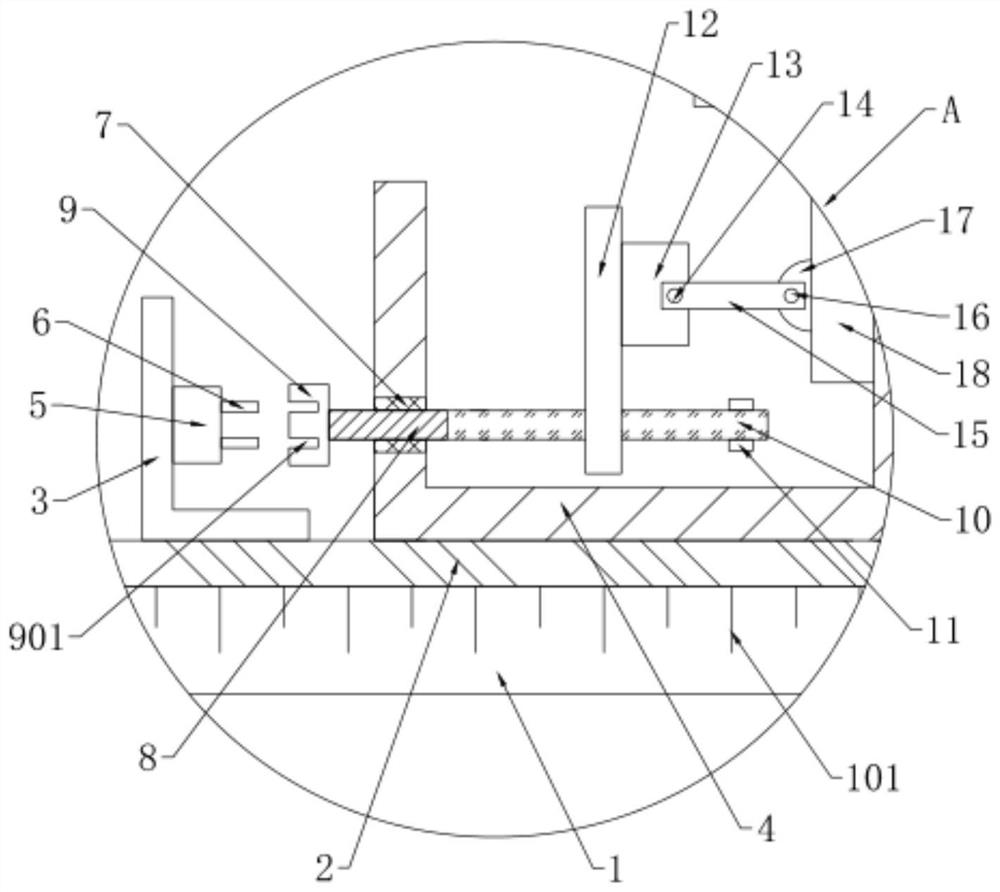

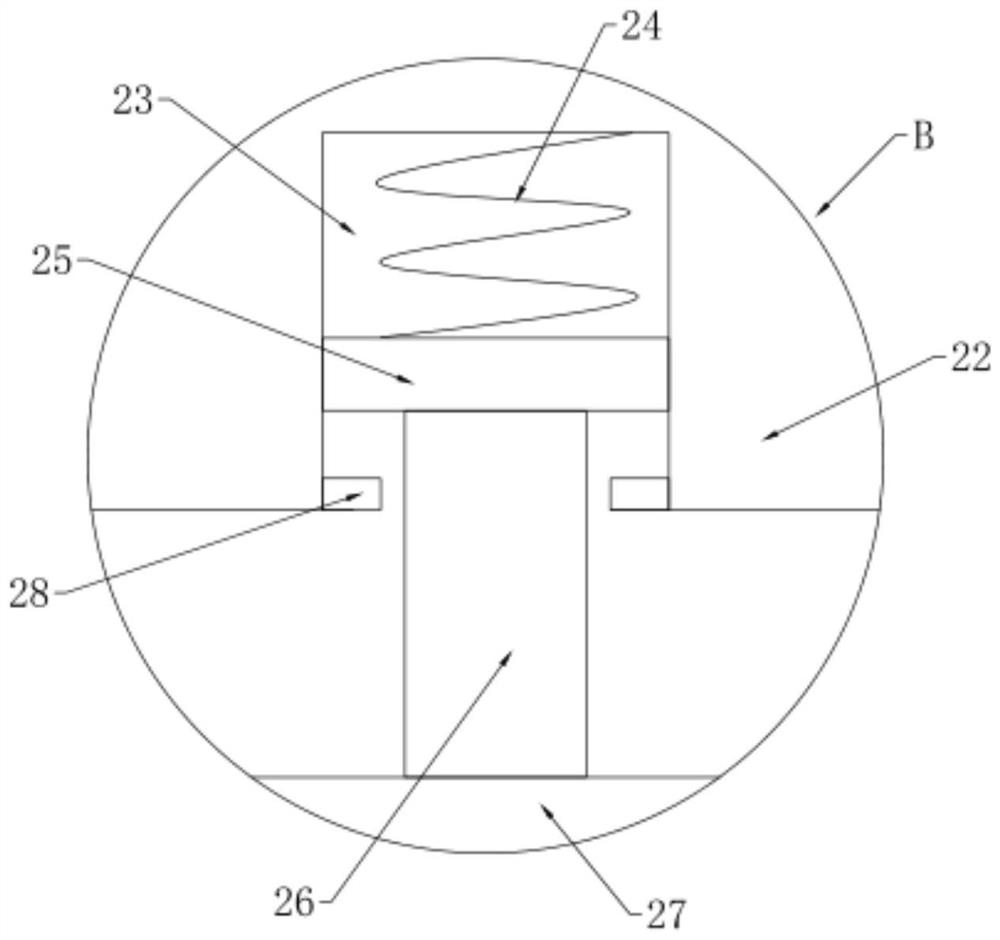

Rotary part on-machine precise and quick alignment device and method

ActiveCN111644878AFine adjustmentThe adjustment process is simple and convenientAutomatic control devicesMeasurement/indication equipmentsMicro nanoProcess engineering

The invention discloses a rotary part on-machine precise and quick alignment device and method, and belongs to the technical field of precision / ultra-precision machining. The rotary part on-machine precise and quick alignment device comprises a main controller, a high-precision displacement detection device and a micro-nano displacement adjusting device. The rotary part on-machine precise and quick alignment method comprises the steps that firstly, the high-precision displacement detection device is controlled by the main controller to conduct data acquisition on the excircle runout of a part,acquired data are subjected to low-pass filtering treatment and then least square fitting treatment is conducted; then the maximum deviation of the part and the corresponding deviation angle are calculated, a machine tool main shaft is controlled by the main controller to rotate to be located at the appointed angle, the micro-nano displacement adjusting device is adopted to adjust the displacement of the part within the nanometer-grade to micron-grade range, and then the excircle of the part is detected after adjustment is accomplished; and finally, the adjusting process is repeated until theexcircle runout of the rotary part meets the precision / ultra-precision machining requirement. The rotary part on-machine precise and quick alignment device and method have the advantages of being high in precision, being capable of achieving the submicron grade and even the nanometer grade, being convenient and fast to adjust, high in repeatability of the adjustment accuracy and low in dependenceof the technology of an operator, and easily achieving the automation.

Owner:DALIAN UNIV OF TECH

Grinding type coffee maker

ActiveCN105125083ASimple structureEasy to manufactureBeverage vesselsMechanical engineeringCoffee bean

The invention provides a grinding type coffee maker which comprises a bean grinding cavity, a bean container and a bean discharging flap door. The bean grinding cavity is used for grinding coffee beans, the bean container and the bean discharging flap door are positioned above the bean grinding cavity, and the bean discharging flap door is positioned between the bean container and the bean grinding cavity and capable of moving relative to the bean container so as to automatically adjust bean discharging amount. By the bean container arranged on the upper portion of the coffee maker, storage of coffee beans for use in several times can be realized. Opening and closing time of the bean discharging flap door can be controlled by control programs, and consequently coffee beans in corresponding amount can be discharged according to selected numbers of cups of coffee to be made.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

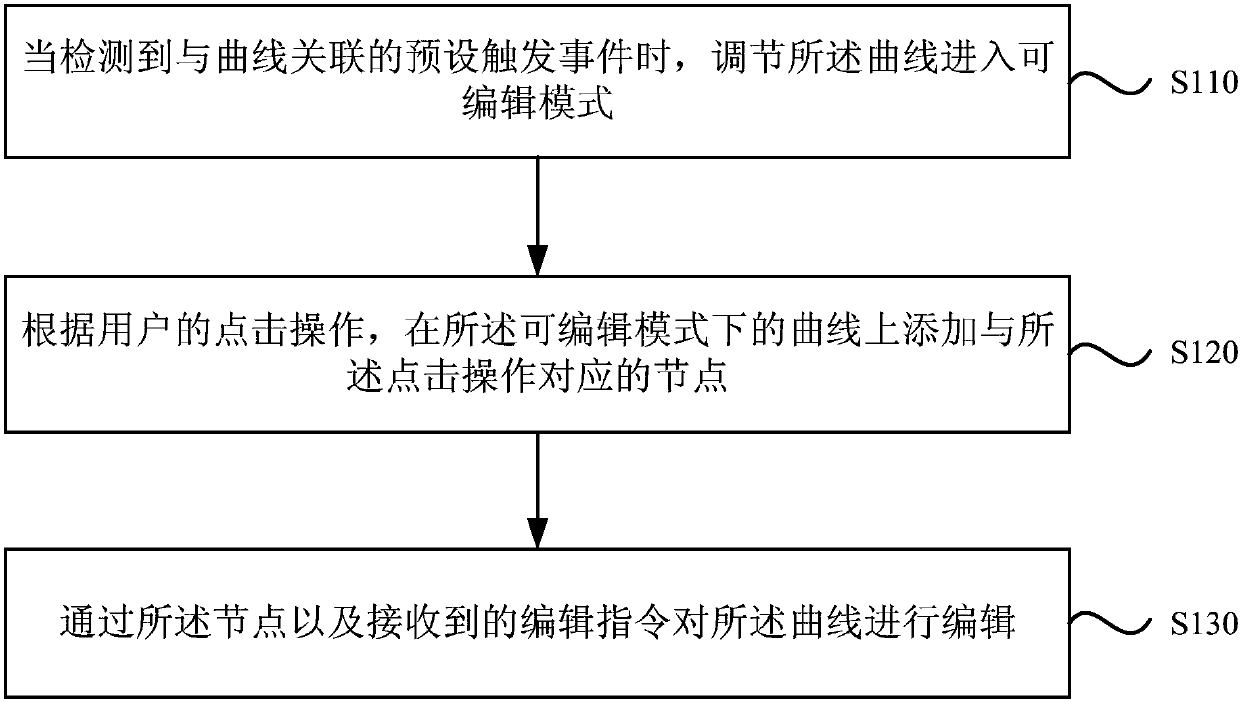

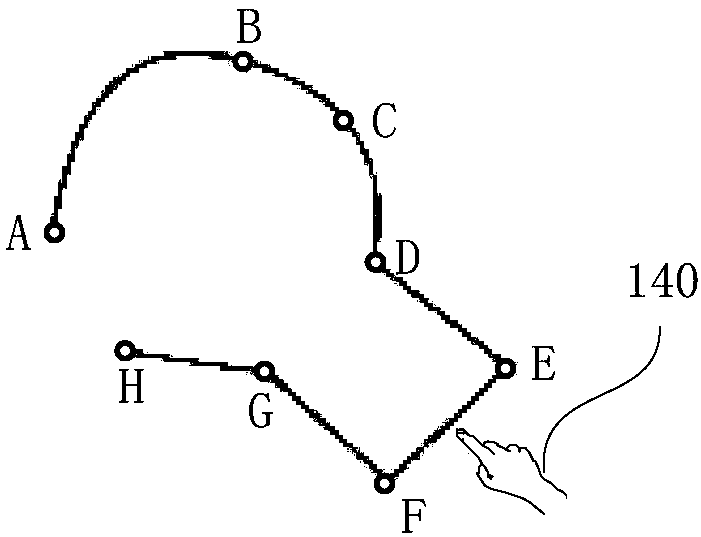

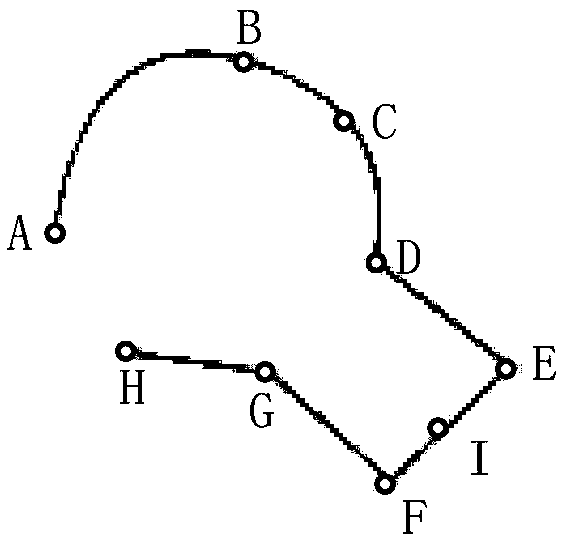

Curve editing method and apparatus, device and storage medium

InactiveCN107748639AFine adjustmentImprove user experienceInput/output processes for data processingComputer hardware

Owner:GUANGZHOU SHIRUI ELECTRONICS +1

Shower and control method thereof

The invention relates to a shower and a control method thereof. The shower comprises a hot water inlet pipe, a cold water inlet pipe and a spray head, wherein a temperature sensor is arranged in the hot water inlet pipe and the cold water inlet pipe respectively; signal circuits of the temperature sensors are connected with a control unit respectively; a flow controller is also arranged in the hot water inlet pipe and the cold water inlet pipe respectively; and control circuits of the flow controllers are connected with the control unit respectively. After a user sets the water temperature and the cold water opening quantity, the flow of the hot water can be controlled by the controller according to the temperature of the cold and hot water, and adjustment can be further made according to actual conditions such as maximum water quantity of the hot water and temperature variation of the cold and hot water, until the water temperature reaches the set temperature and is stable. The invention provides the shower and the control method thereof which have the advantages of accurately adjusting the water temperature and maximizing the water quantity, along with safety and reliability.

Owner:FUYANG TENGFEI TECH

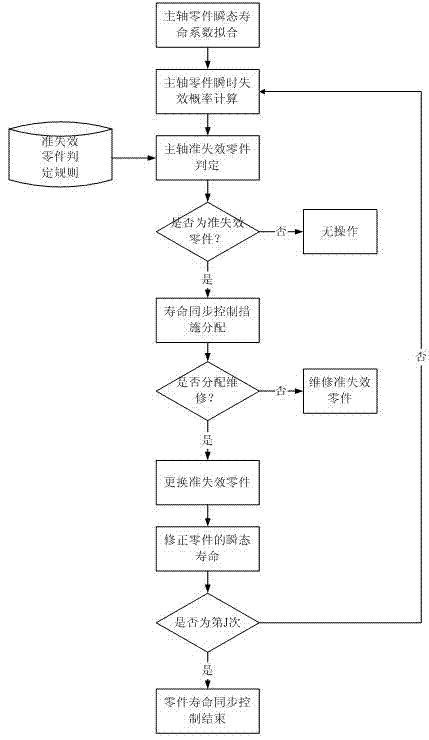

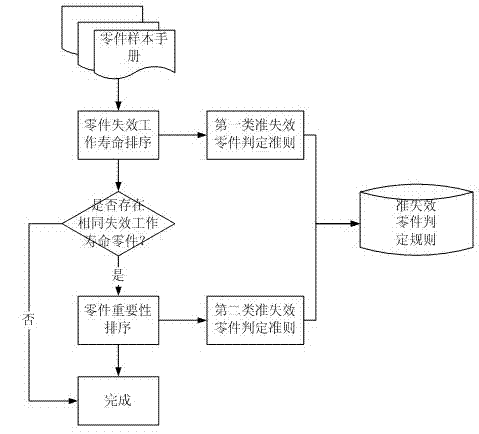

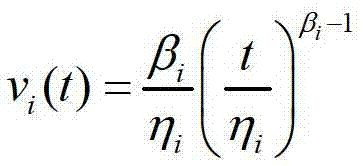

Method for synchronously controlling lives of spindle parts of numerical-control machine tool

ActiveCN103240633AFine adjustmentSolve the lack of accurate quantitative calculationMetal working apparatusWorking lifeMachine tool

The invention discloses a method for synchronously controlling lives of spindle parts of a numerical-control machine tool. The method includes fitting transient life parameters of the spindle parts according to running parameters of a spindle of the numerical-control machine tool, and building transient life models of the spindle parts of the numerical-control machine tool; computing fixed-cycle life synchronous-moment transient failure probabilities of the spindle parts according to the transient life models of the spindle parts of the numerical-control machine tool, dynamically selecting quasi-failure spindle parts with potential failure hazards according to quasi-failure part criteria, distributing life synchronous control measures and eliminating the potential failure hazards of the spindle parts; and correcting the operating lives of the spindle parts of the numerical-control machine tool according to life synchronous correction models of the parts so that the working lives of the spindle parts are synchronous and the working lives of the spindle parts and the designed working life of the spindle of the numerical-control machine tool are synchronous. The method is specifically utilized for solving problems caused by inconsistency of working lives of various parts in a running procedure of a spindle of a numerical-control machine tool, and has the advantages of simplicity, convenience and high applicability, universality and expandability.

Owner:ZHEJIANG UNIV

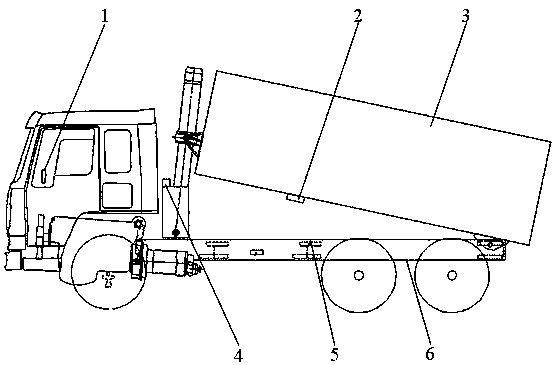

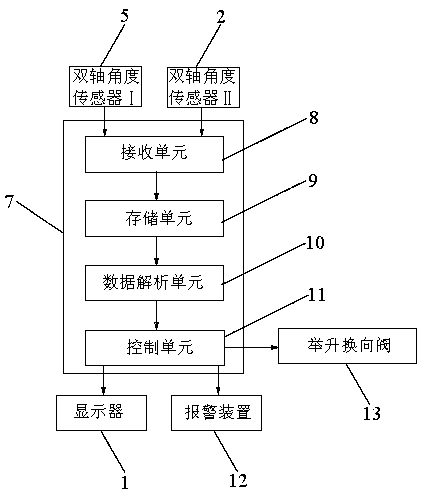

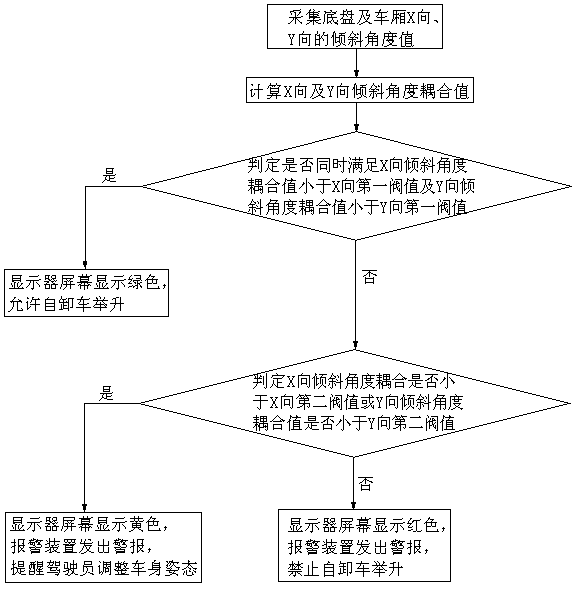

Dumper stability safety control system and method

ActiveCN109367462AFine adjustmentGuaranteed stabilitySignalling/lighting devicesVehicle with tipping movementDriver/operatorDual axis

The invention discloses a dumper stability safety control system which comprises a stable control module, biaxial angle sensors, a displayer and an alarm device. The biaxial angle sensors comprise thebiaxial angle sensor I and the biaxial angle sensor II, the stable control module is connected with the displayer and the alarm device, the stable control module is connected with the biaxial angle sensor I and the biaxial angle sensor II and used for receiving the X-direction inclination angle value and the Y-direction inclination angle value of a chassis and the X-direction inclination angle value and the Y-direction inclination angle value of a compartment, and calculating the X-direction inclination angle coupling value and the Y-direction inclination angle coupling value, the stability of the dumper lifting process is comprehensively monitored, the occurrence possibility of transverse tilting, longitudinal tilting and other dangers in the dumper lifting operation can be reduced, andsafety of a vehicle and a driver is ensured.

Owner:SINOTRUK QINGDAO HEAVY IND

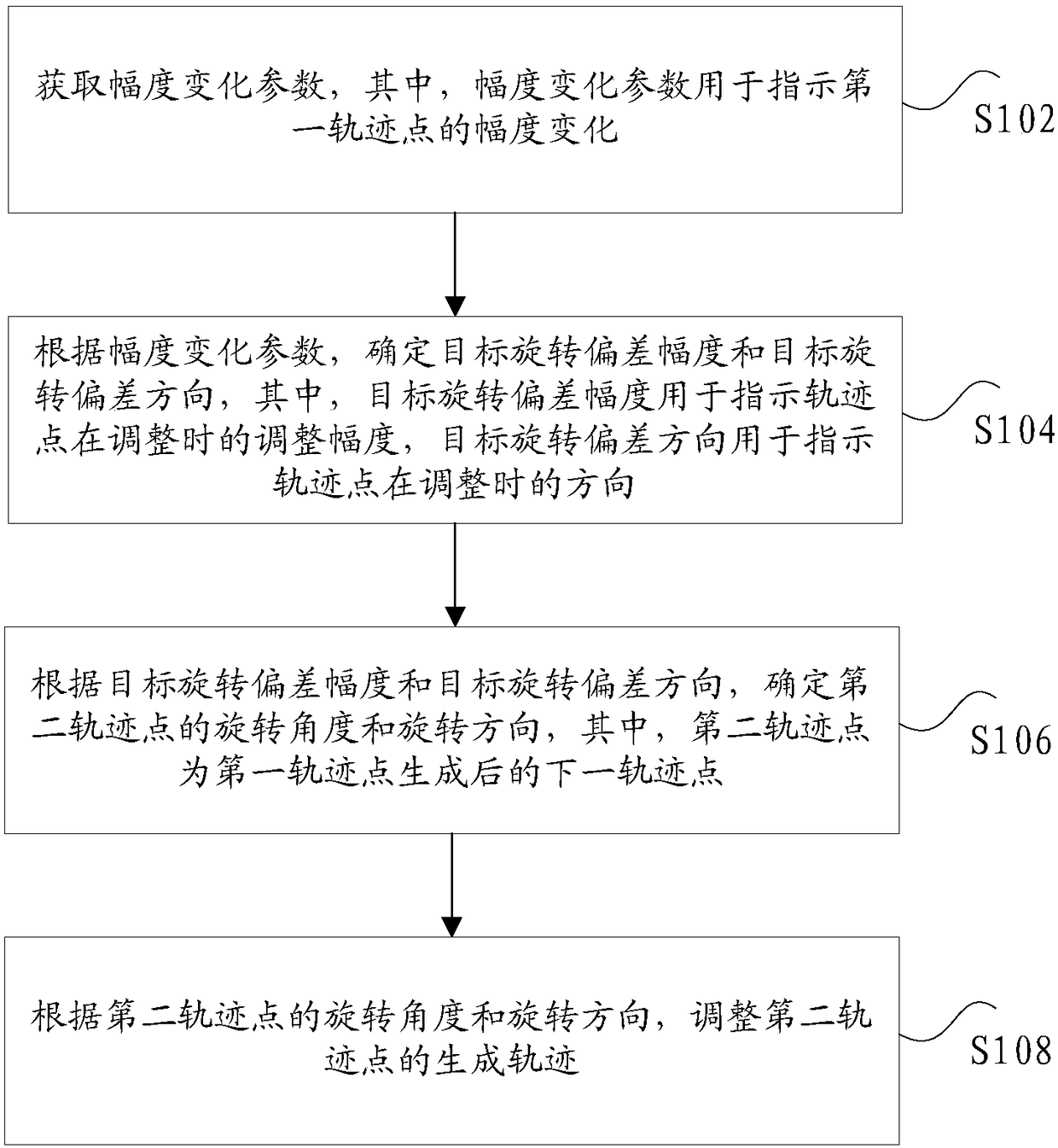

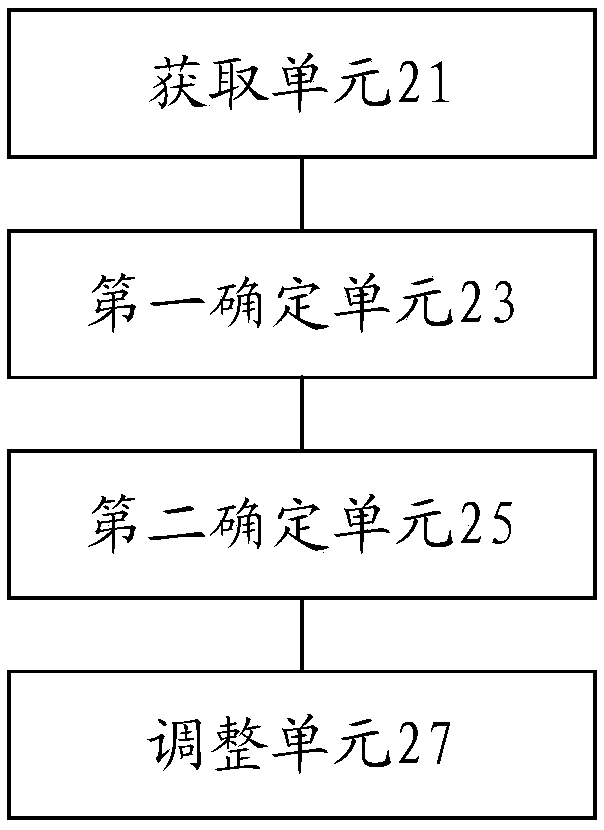

Trajectory adjusting method and device

ActiveCN108296687AFine adjustmentEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsAngular degrees

Owner:BEIJING C H L ROBOTICS CO LTD

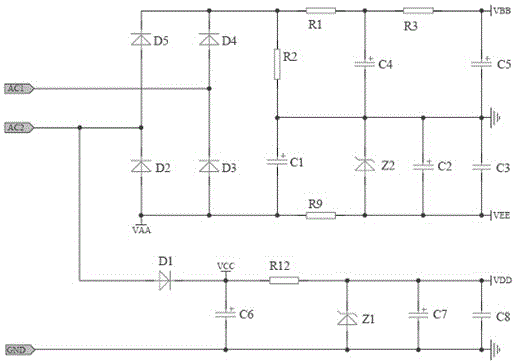

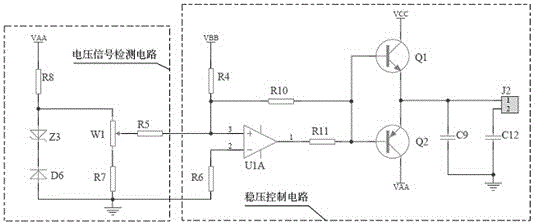

Voltage stabilizing circuit of alternating current voltage stabilizer

ActiveCN104597952AFine adjustmentAchieve adjustmentElectric variable regulationPower circuitsCircuit design

The invention relates to a voltage stabilizing circuit of an alternating current voltage stabilizer. The voltage stabilizing circuit of the alternating current voltage stabilizer comprises a power input, a power circuit and a voltage stabilizing circuit, wherein the power circuit and the voltage stabilizing circuit are connected in sequence; the voltage stabilizing circuit comprises a voltage signal detection circuit and a voltage stabilizing control circuit; the voltage stabilizing control circuit comprises capacitors C9 and C12, an operational amplifier U1A, resistors R4, R6, R10 and R11, transistors Q1 and Q2 and a direct current motor connecting terminal J2; the voltage signal detection circuit comprises resistors R5, R7 and R8, a voltage stabilizing diode Z3, a diode D6 and an adjustable resistor W1. According to the voltage stabilizing circuit of the alternating current voltage stabilizer, voltage judgment is realized by using a comparator with hysteretic characteristic, so under-voltage and over-voltage adjustment can be accurately realized; the turning direction of a direct current motor is controlled by using the double transistors in a complementary working mode; the entire circuit is simple in design, high in reliability and low in cost.

Owner:长城电器集团浙江科技有限公司

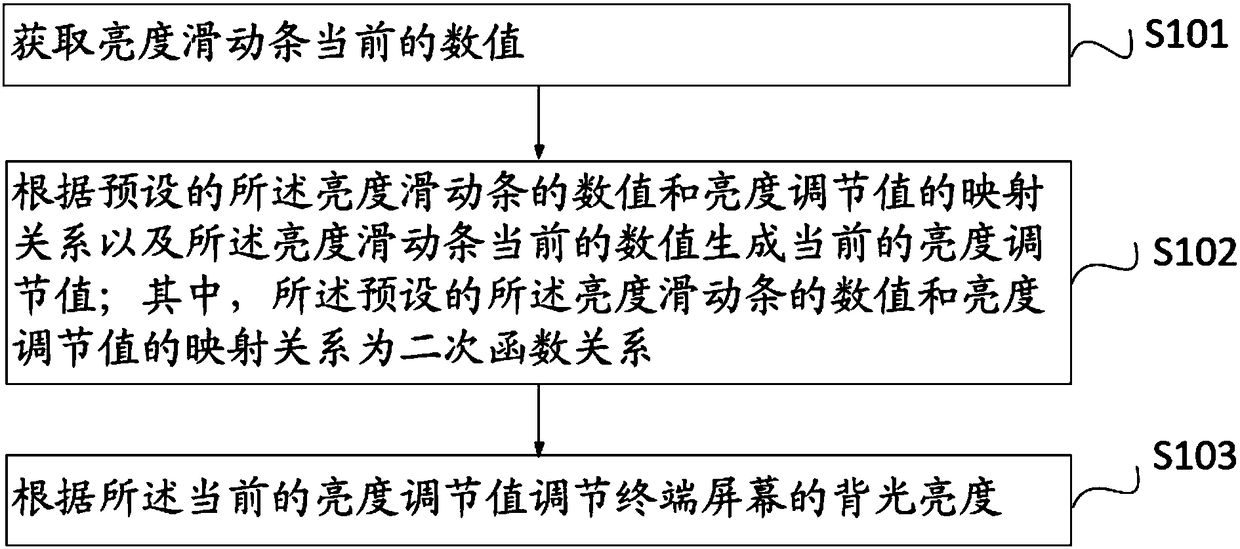

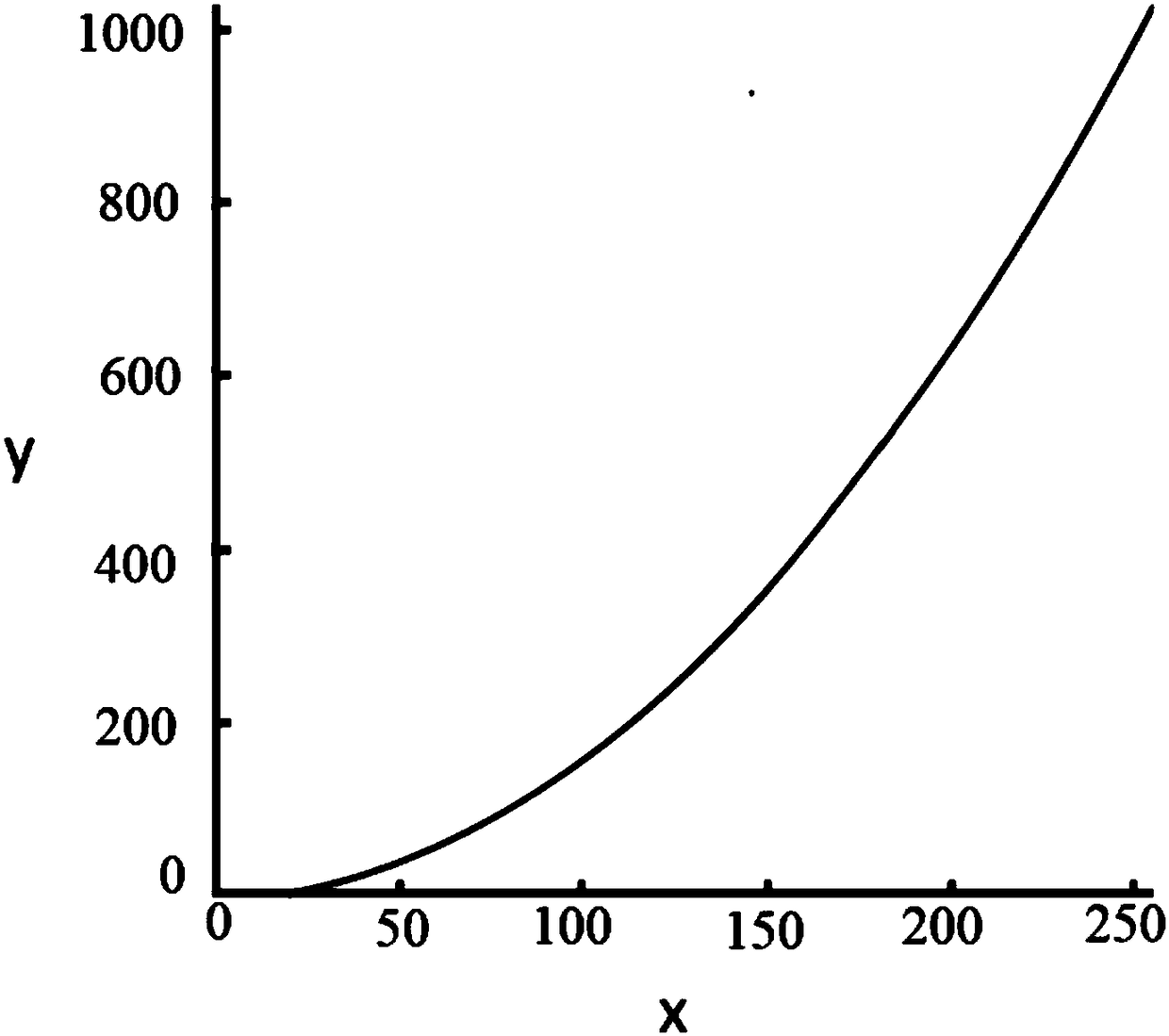

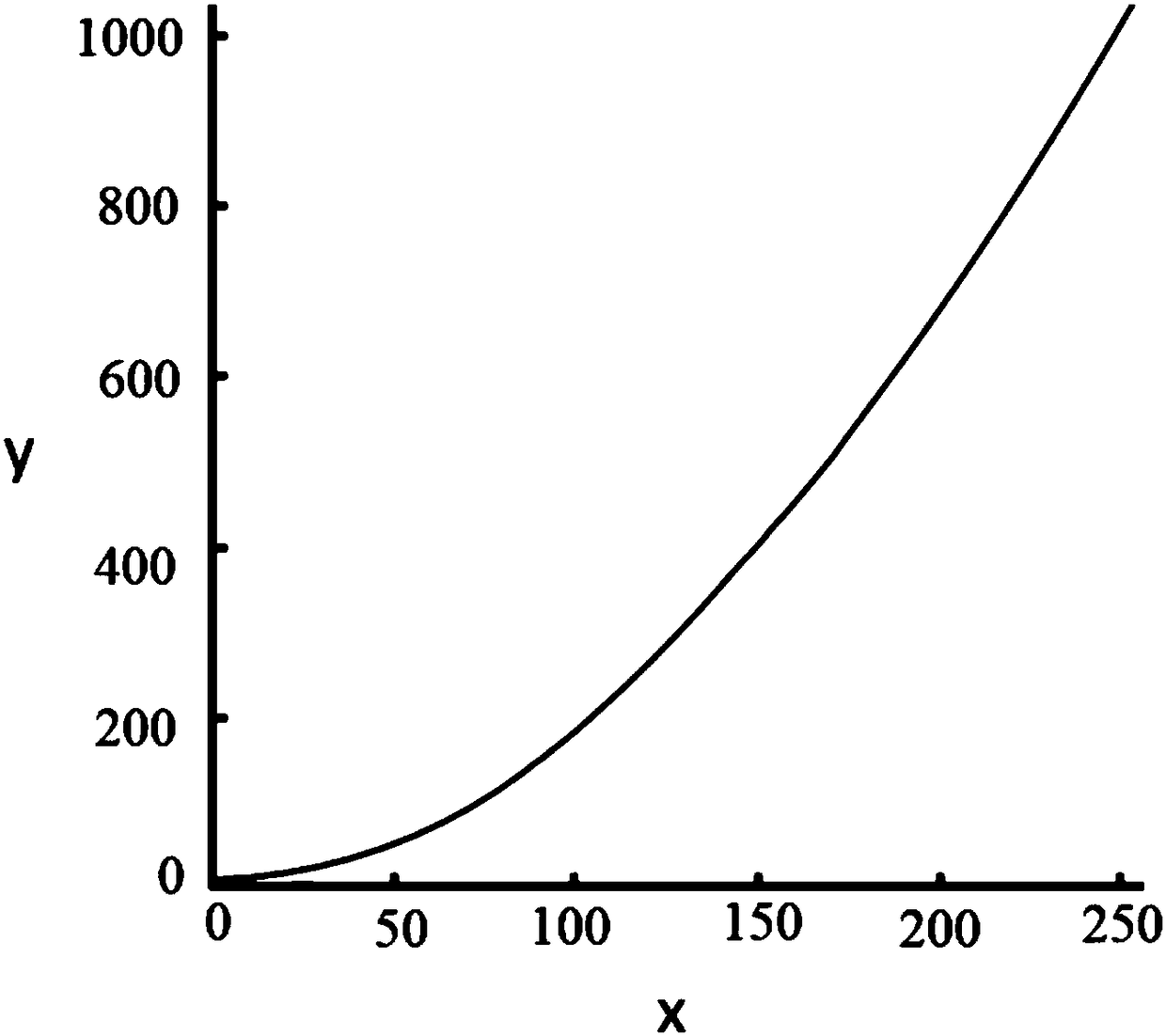

Method and system for adjusting backlight brightness of terminal screen

InactiveCN108447455AFine adjustmentSensitive adjustmentCathode-ray tube indicatorsLightnessComputer science

Owner:TP-LINK

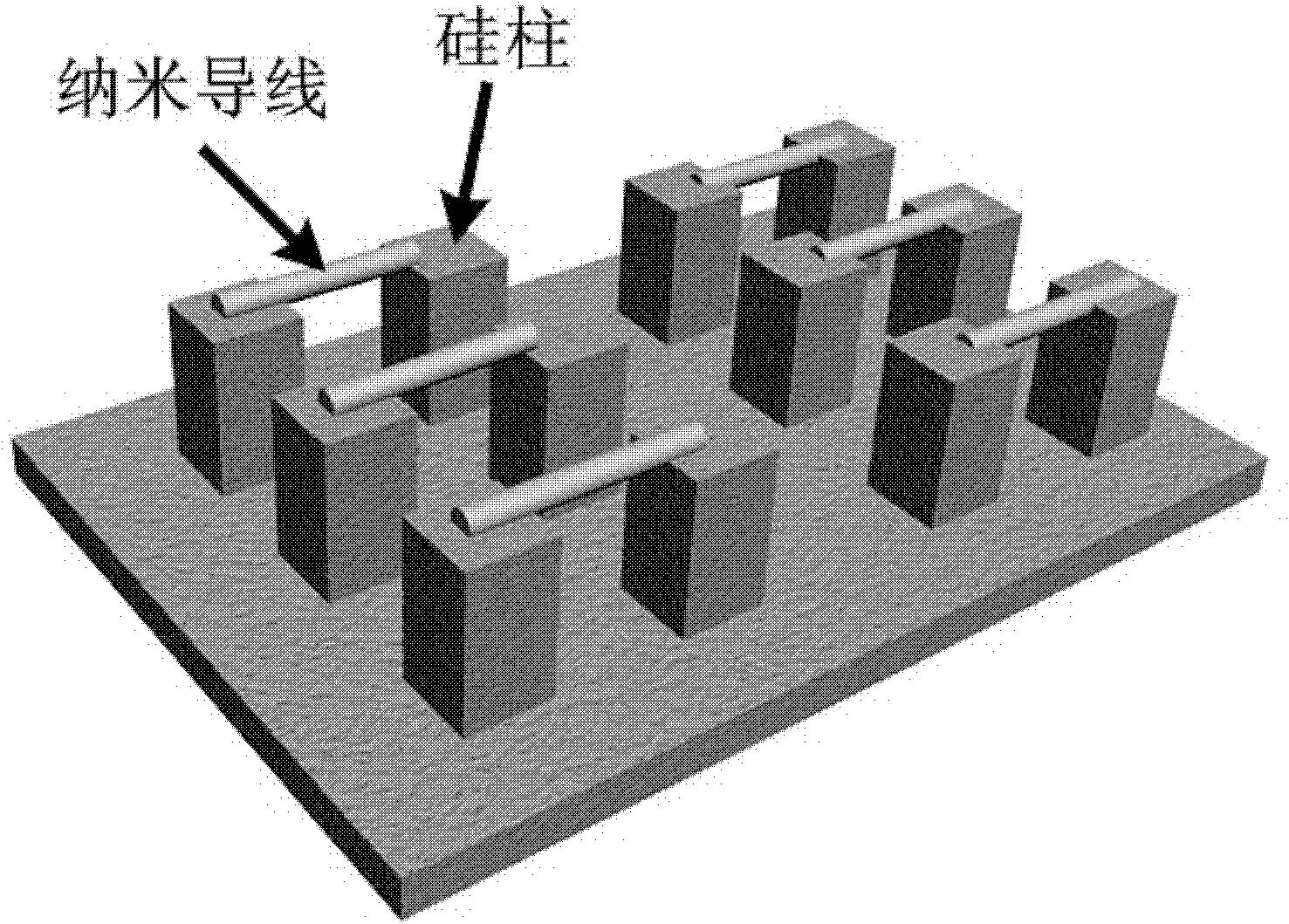

Method for constructing microelectrode pair array on surface of silicon chip containing hydrophobic silicon column

InactiveCN102730625AFine adjustmentAdjustable lengthDecorative surface effectsChemical vapor deposition coatingNanowireMicroelectrode

The invention belongs to the electronic circuit field, and relates to large area and orientationally arranged nanowires formed on a surface of a silicon chip containing hydrophobic silicon columns, and relates to a method for constructing a microelectrode pair array. According to the invention, a method for grafting silicon fluoride on the surface of the silicon chip containing the hydrophilic silicon column array is employed, thereby the contact angle of the hydrophilic silicon column array and water is increased from 10 DEG to more than 150 DEG to obtain the silicon chip containing the hydrophobic silicon column array. An aqueous solution containing a substance for forming the nanowires is driven for flowing through the surface of the hydrophobic silicon columns with a uniform speed, thereby the orientationally arranged nanowires with diameter of nano scale formed on the top of two adjacent silicon columns in the hydrophobic silicon column array can be formed with large area and rapidity, and the nanowires are connected to two silicon columns to form the microelectrode pairs; thereby several microelectrode pairs form the microelectrode pair array. The method of the invention can adjust the thickness, length and spatial arrangement mode of the nanowires.

Owner:INST OF CHEM CHINESE ACAD OF SCI

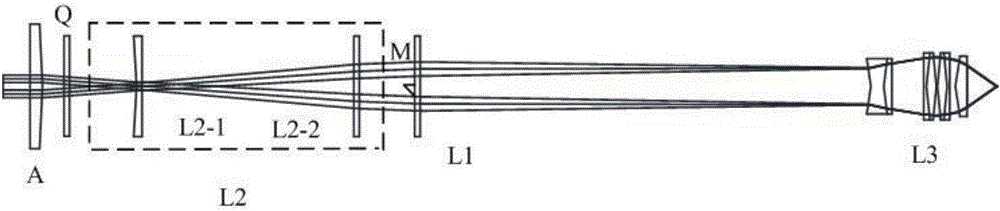

Optical module and laser cutting device

ActiveCN106695116ASolve the problem that light leakage affects the processing effect of materialsFine adjustmentLaser beam welding apparatusBeam expanderOptical Module

The invention discloses an optical module, and effectively solves the problem that the material machining effect is influenced by light leakage at the center of a conventional axial cone prism. The optical module disclosed by the invention comprises an axial cone prism (A), a beam expander (L2), a first lens (L1), a collecting lens (L3) and a reflecting lens (M) which are arranged coaxially, wherein the axial cone prism (A) is arranged at the starting end of an optical path; the conical part of the axial cone prism (A) is deviated from a laser; the axial cone prism (A) is used for producing an annular light spot; the first lens (L1) is arranged at the rear end of the axial cone prism (A) and used for performing ring focusing on the annular light spot; the beam expander (L2) is arranged at the front end of the first lens (L1); the collecting lens (L3) is arranged at the tail end of the optical path; the reflecting lens (M) is arranged at the rear end of the axial cone prism (A) and at the front end of the collecting lens (L3); and an inclined angle between the reflecting surface of the reflecting lens (M) and the optical axis is greater than 0 degree.

Owner:东莞市盛雄激光先进装备股份有限公司

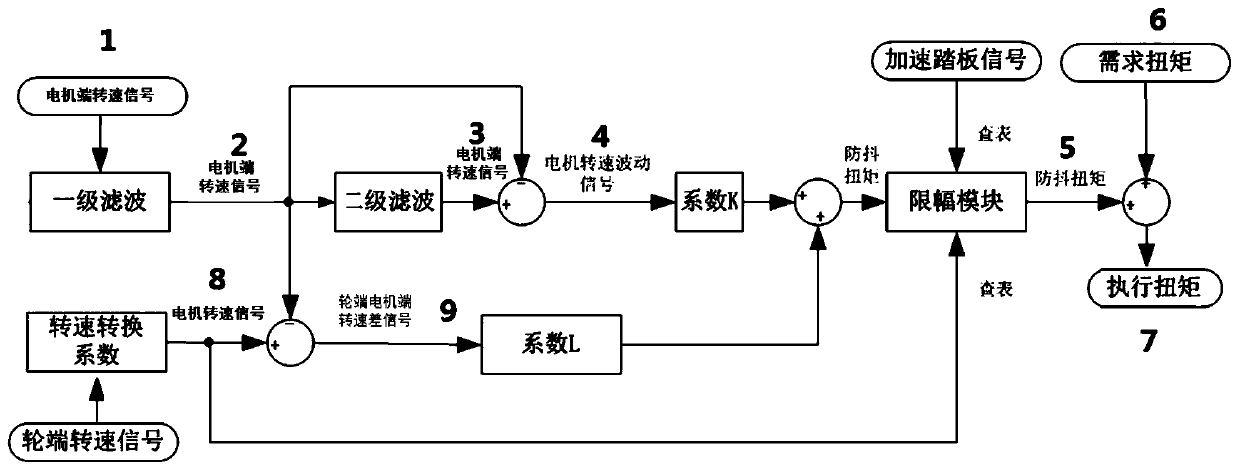

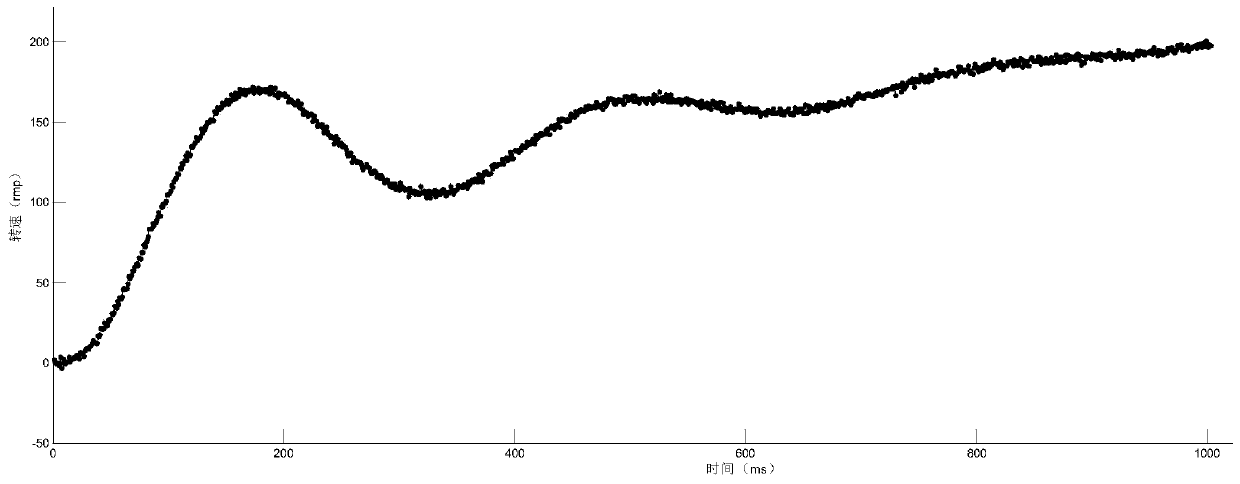

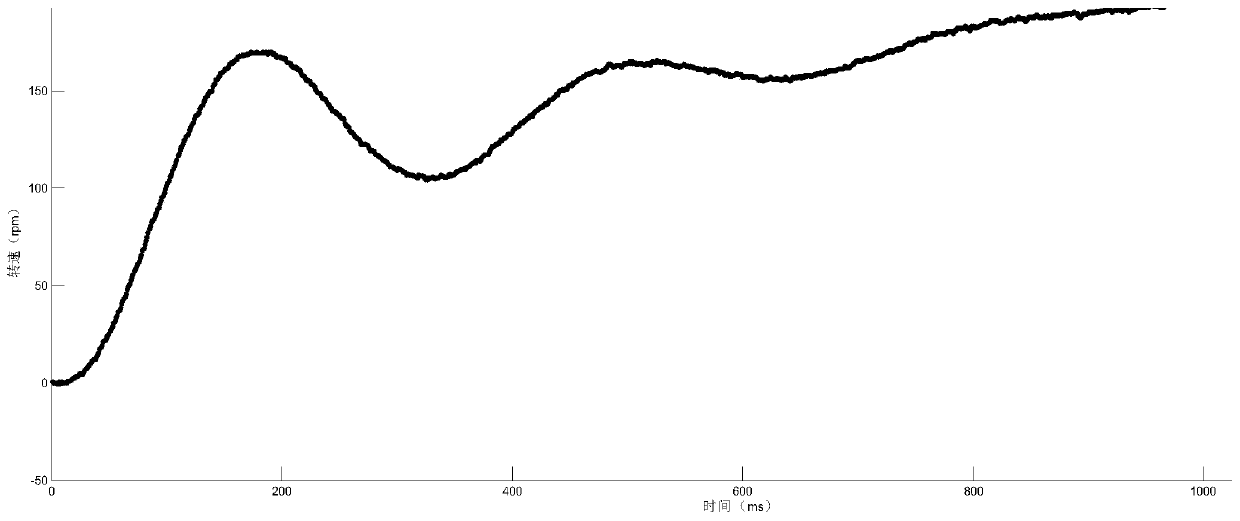

Electric vehicle motor anti-shake control method and system, electric vehicle and storage medium

ActiveCN111483330AEasy to controlFine adjustmentSpeed controllerElectric energy managementMotor speedElectric machinery

The invention discloses an electric vehicle motor anti-shake control method and system, an electric vehicle and a storage medium. The method comprises the steps: obtaining a motor end rotating speed signal and a wheel end rotating speed signal; sending the motor end rotating speed signal processed by a first-stage filter to a second-stage filter, subtracting the motor end rotating speed signal processed by the second-stage filter from the motor end rotating speed signal processed by the first-stage filter to obtain a motor rotating speed fluctuation signal, and multiplying the motor rotating speed fluctuation signal by a coefficient K to obtain an anti-shake torque I; converting the wheel-end rotating speed signal into a motor rotating speed signal through a rotating speed conversion module, subtracting the converted motor rotating speed signal from the motor-end rotating speed signal processed by the first-stage filter to obtain a wheel-end motor-end rotating speed difference signal,and multiplying the wheel-end motor-end rotating speed difference signal by a coefficient L to obtain an anti-shake torque II; summing the first anti-shake torque and the second anti-shake torque, andobtaining the final anti-shake torque through an amplitude limiting module. Fine adjustment can be achieved, and adjustment is more accurate.

Owner:深蓝汽车科技有限公司

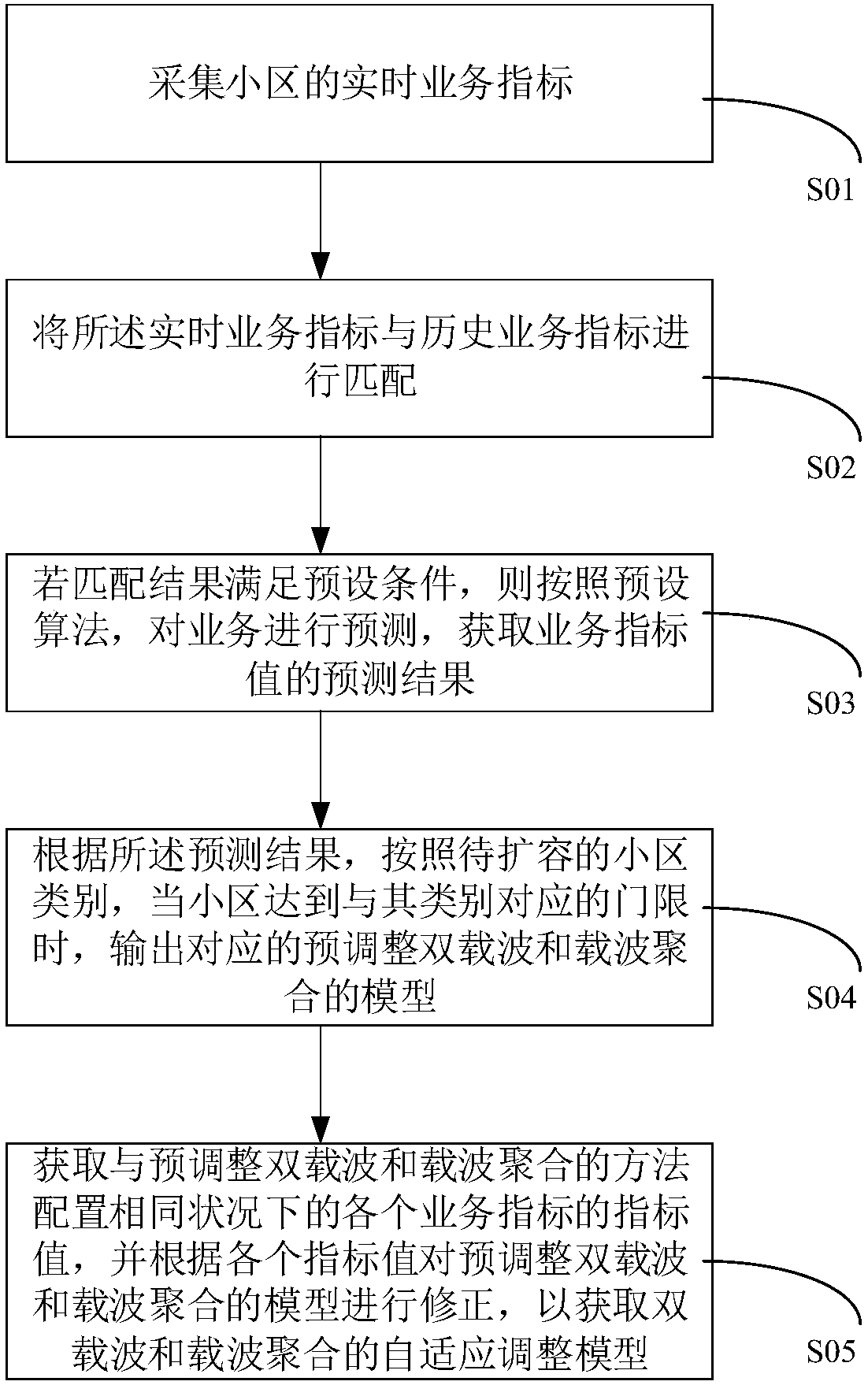

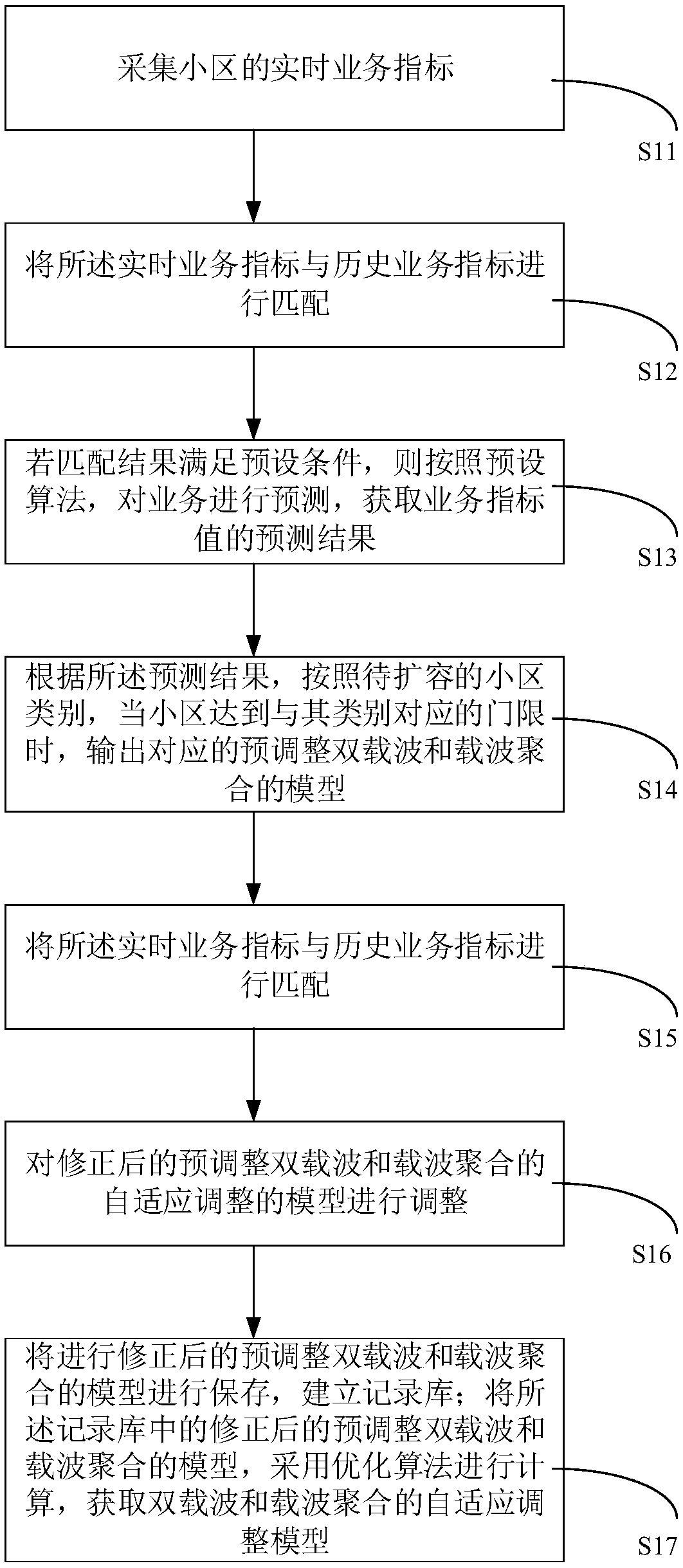

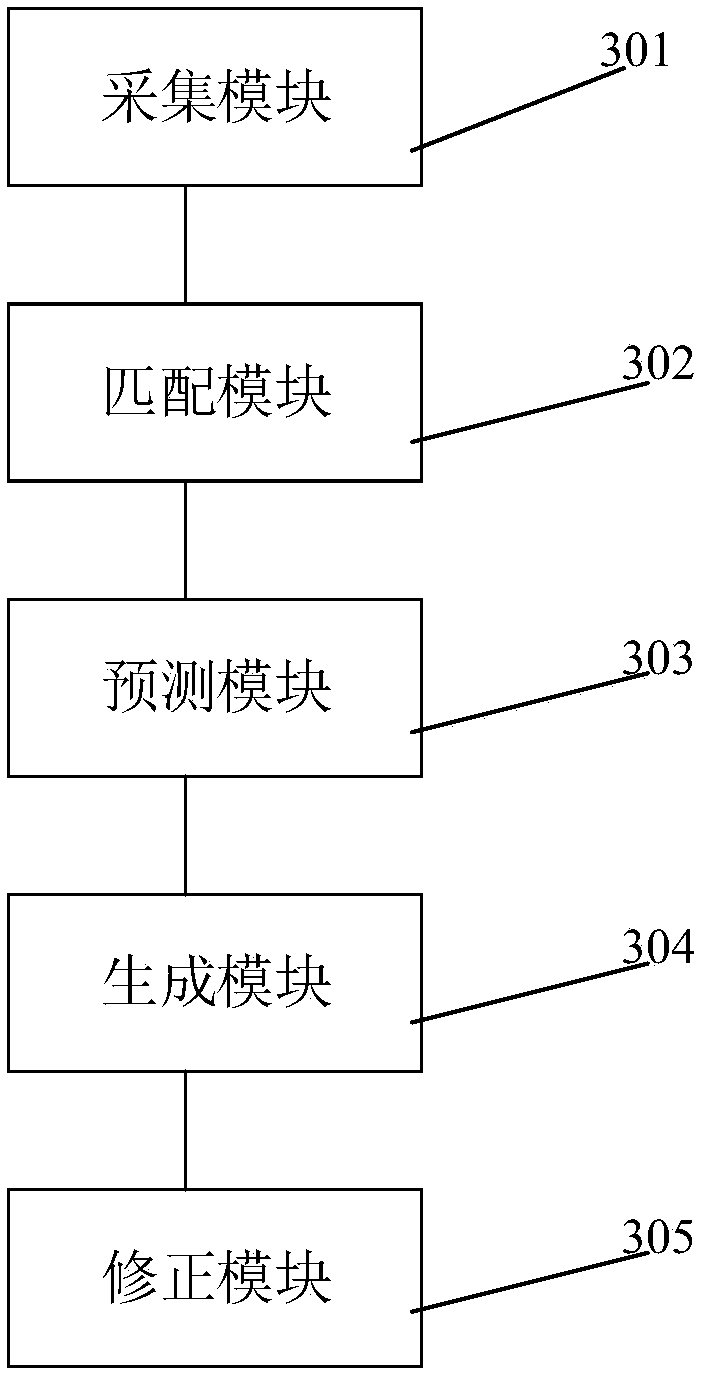

Dual-carrier and carrier aggregation adaptive adjustment method, device and apparatus and medium

ActiveCN109981234AFine adjustmentEasy to adjustTransmission path divisionWireless communicationCarrier signalSelf adaptive

The invention discloses a dual-carrier and carrier aggregation adaptive adjustment method, device and apparatus and a medium. The method comprises the following steps: acquiring a real-time service index of a cell; matching the real-time service index with a historical service index; if the matching result meets the preset condition, predicting the service according to a preset algorithm, and obtaining a prediction result of the service index value; according to the prediction result and the cell type to be expanded, when the cell reaches a threshold corresponding to the type of the cell, outputting a corresponding pre-adjusted dual-carrier and carrier aggregation model; and obtaining an index value of each service index under the same condition as the configuration of the method for pre-adjusting the dual-carrier and carrier aggregation, and correcting the model of the pre-adjusting dual-carrier and carrier aggregation according to each index value so as to obtain a self-adaptive adjustment model of the dual-carrier and carrier aggregation.

Owner:LIAONING MOBILE COMM +1

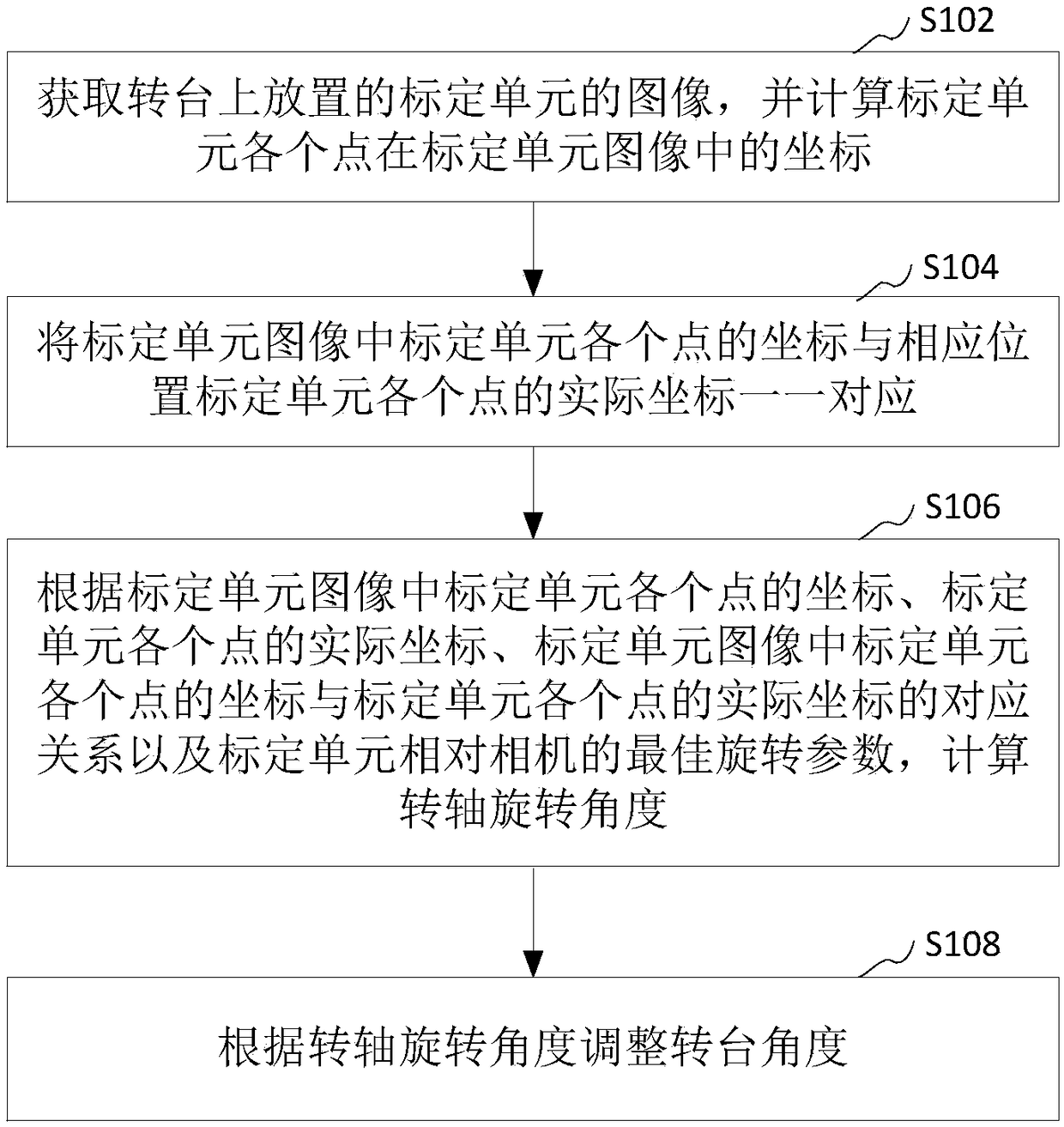

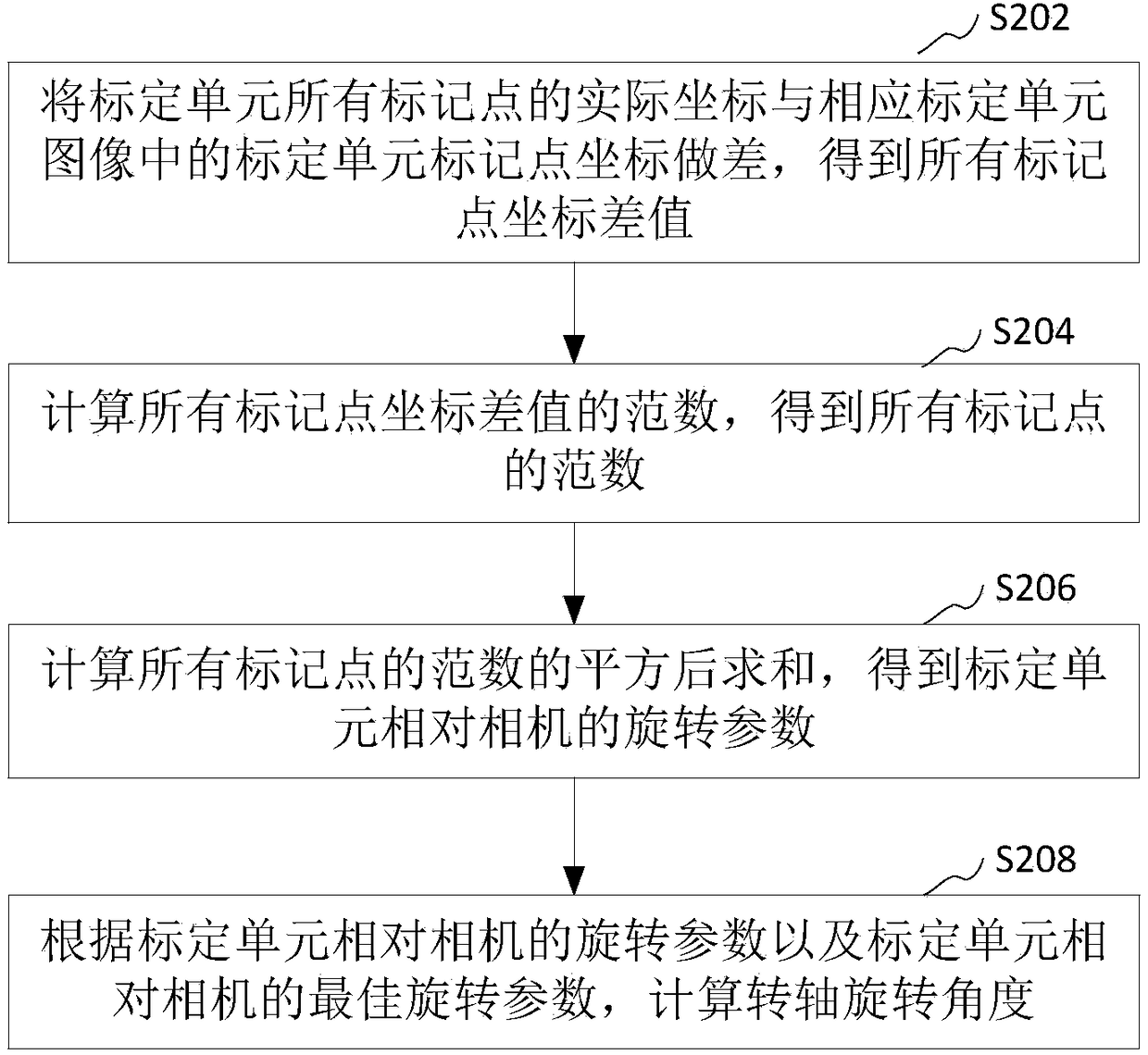

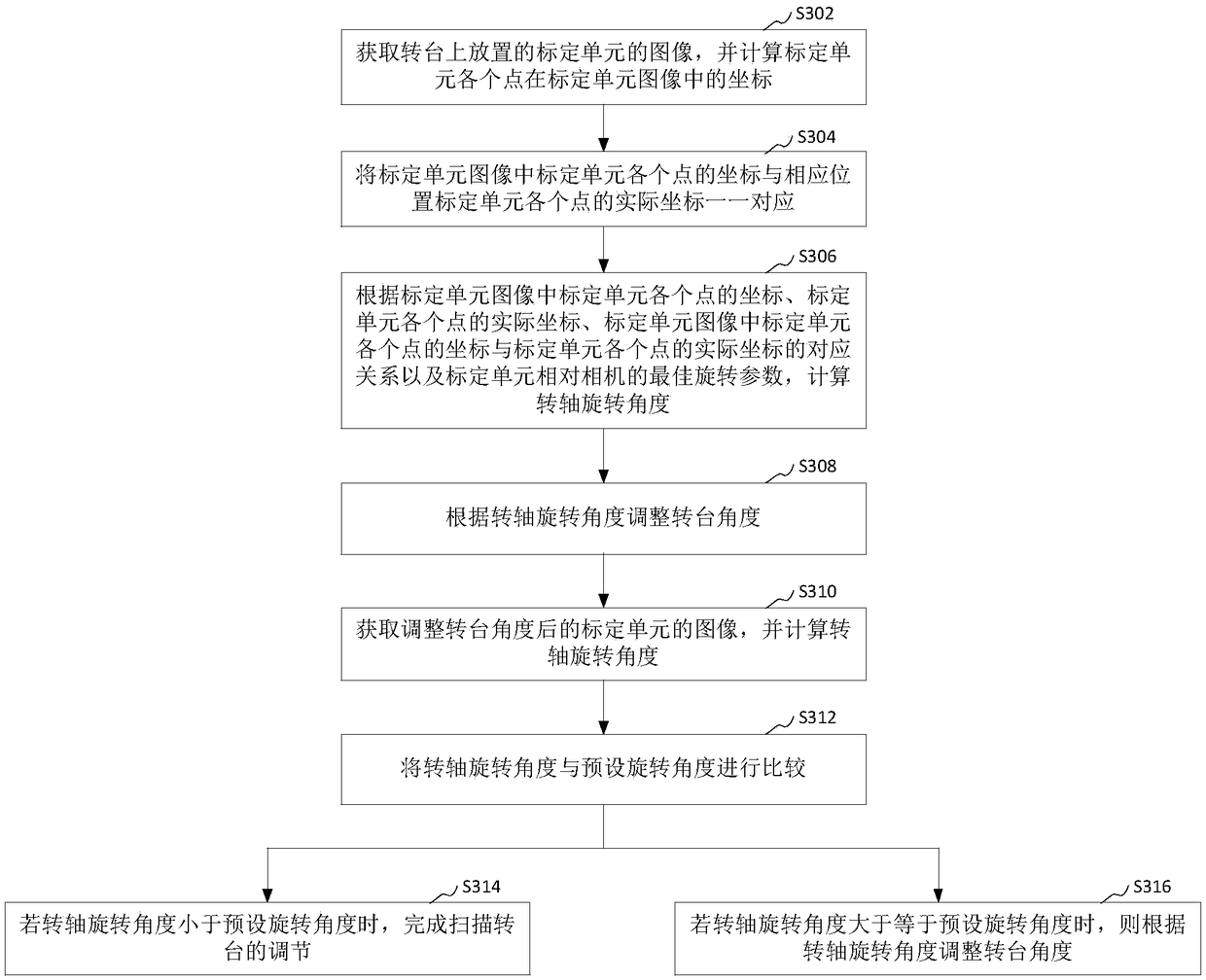

Three-dimensional scanning turntable adjustment method and device, computer device and storage medium

ActiveCN109407613AFine adjustmentEasy to adjustNumerical controlComputer deviceComputer graphics (images)

The present application relates to a three-dimensional scanning turntable adjustment method and device, a computer device and a storage medium. The method includes: acquiring an image of a calibrationunit placed on a turntable and calculating the coordinates of respective points of the calibration unit in the calibration unit image; enabling the coordinates of respective points of the calibrationunit in the calibration unit image to correspond to the actual coordinates of respective points of the calibration unit at a corresponding position one to one; according to the coordinates of respective points of the calibration unit in the calibration unit image, the actual coordinates of respective points of the calibration unit, a corresponding relationship between the coordinates of respective points of the calibration unit in the calibration unit image and the actual coordinates of respective points of the calibration unit, and the optimal rotation parameter of the calibration unit relative to a camera, calculating the rotation angle of a rotating shaft; and adjusting the angle of the turntable according to the rotation angle of the rotating shaft. According to the acquired image, the rotation angle of the rotating shaft is automatically calculated and then adjusted, so that the rotation angle can be calculated more accurately, and the adjustment of the turntable is more precise.

Owner:SHINING 3D TECH CO LTD

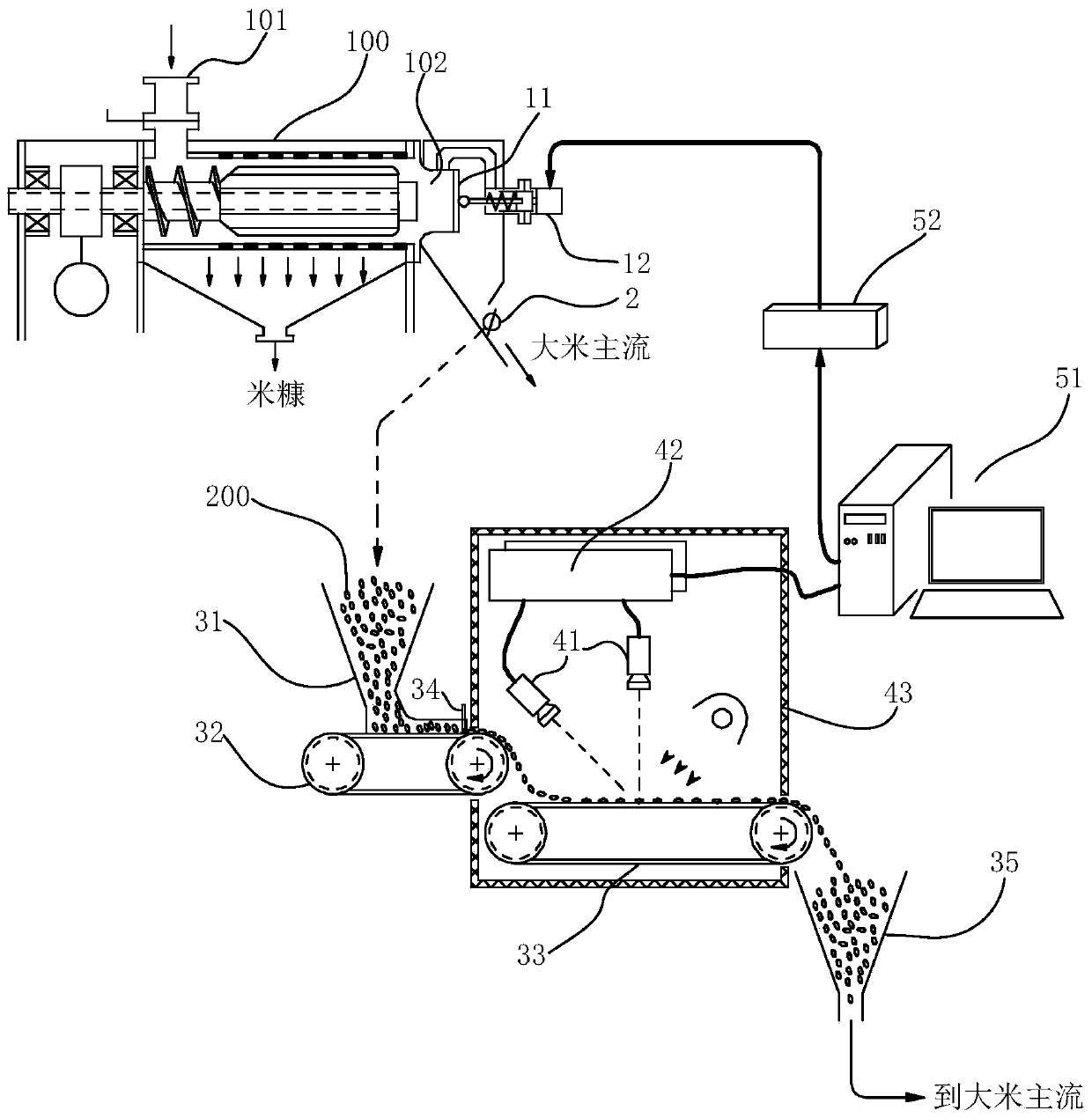

Device and method for controlling quality of milled rice and an intelligent rice milling system

ActiveCN111569982AHigh degree of automationFine adjustmentWithdrawing sample devicesIndividual particle analysisAgricultural engineeringAgricultural science

The invention discloses a device and method for controlling the quality of milled rice and an intelligent rice milling system. The device for controlling the quality of milled rice includes a door body assembly, a sampling device, a rice sample dispersion device, an image acquisition device and a control device, wherein a rice outlet of a rice miller is covered by the door body assembly, the doorbody assembly is used for adjusting the pressure of the rice outlet, and the sampling device is connected with the rice outlet so as to obtain sampled rice grains from the rice outlet; and the rice sample dispersion device is used for arranging the sampled rice grains in discrete distribution of single particles, the image acquisition device is used for capturing sampled images of the sampled ricegrains, and the control device is used for receiving and processing the sampled images so as to control operation of a driving device correspondingly. The method is applied to the device for controlling the quality of the milled rice, and the intelligent rice milling system includes the rice miller and the device for controlling the quality of the milled rice. Closed-loop control is achieved on sampling from the rice outlet, quality evaluation of the quality of the sampled rice grains and adjustment of the rice miller, a high degree of automation is achieved, and rice with higher milling precision is produced by the rice miller.

Owner:WUHAN POLYTECHNIC UNIVERSITY

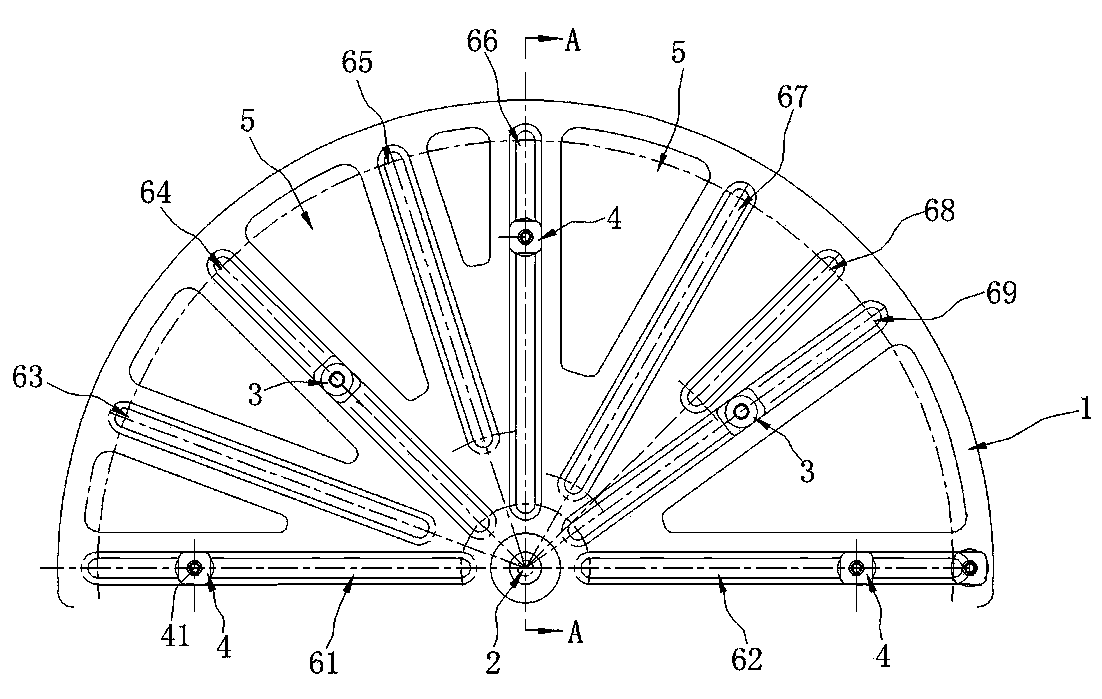

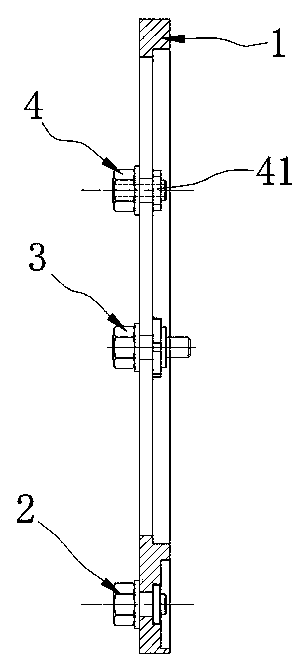

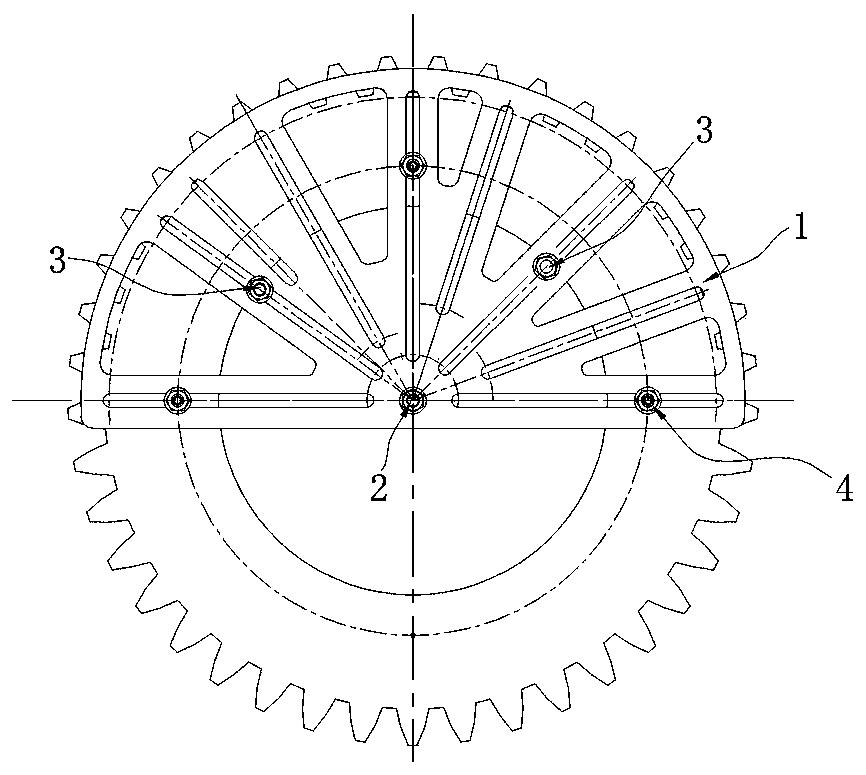

Circumference indexing scribing compass

The invention discloses a circumference indexing scribing compass, relates to a special indexing tool, and is used for solving the problems that the manual indexing scribing method in the prior art is fussy, low in efficiency, and poor in precision. The circumference indexing scribing compass comprises a fan-shaped scribing compass body, a fixed pin, a positioning pin and an indexing sliding block, wherein the fixed pin is positioned in the centre of the scribing compass body; at least four sliding grooves which are distributed radially and can be matched with the positioning pin and the indexing sliding block are formed in the scribing compass body; an indexing through hole is formed in the center of the indexing sliding block. Meanwhile, the invention also provides a circumference indexing scribing compass which aims at a large-diameter component. The two scribing compasses are easy to use and accurate in adjustment; high-efficiency indexing can be performed by changing the positions of the positioning pin and the indexing sliding block at any time according to the requirements on the size of a component at a production site; the scribing compasses are high in drilling efficiency and drilling precision.

Owner:CHONGQING XINXING GEAR WHEEL

Automobile headlamp dimming function guide structure

ActiveCN111649298AFine adjustmentPrevent dust from enteringVehicle headlampsProtective devices for lightingHeadlampGear wheel

The invention relates to the technical field of automobile parts, in particular to an automobile headlamp dimming function guide structure. The automobile headlamp dimming function guide structure includes a shell, and a lampshade is mounted on one side of the shell; and the lampshade and the shell are fixed through threads. Heat dissipation holes are formed in the lampshade, and the lampshade andthe heat dissipation holes are integrally designed. A limiting plate is mounted in the shell; the shell is welded with the limiting plate; a mounting block is mounted in the limiting plate; by rotating a rotary lever, a second gear rotates, a third gear rotates, the axial section of the third gear is larger than that of the second gear, the mounting block is adjusted more accurately in the horizontal direction, a mounting rod is extruded, a fourth gear on the surface of the rotating rod is engaged with the first gear, a fourth neck rotates to drive the first gear to rotate, the mounting blockrotates in the vertical direction, adjustment can be conducted according to needs, adjustment is more accurate, and an internal gear cannot be damaged.

Owner:广州星耀汽车科技发展有限公司

Machine core of electric pencil-peeling device

The invention provides a machine core of an electric pencil-peeling device, belongs to the technical field of machinery, and solves the problem that the pencil planing thickness cannot be adjusted andcontrolled simultaneously when an existing electric pencil-peeling device has the automatic shutdown function. The machine core includes a bracket, a pencil holder, a planing assembly, a motor and abase connected to the lower end of the bracket, a pencil blocking block is arranged in the pencil holder, a jacking rod is arranged inside the bracket in a penetrating mode, the upper end of the jacking rod is propped against the lower end of the pencil blocking block, and an adjusting head is fixedly arranged at the lower end of the base in the axial direction; and an adjusting rod is arranged onthe base in a penetrating mode, the lower end of the adjusting rod is in threaded connection with the adjusting head, the upper end of the adjusting rod extends out of the base, a switch seat is fixedly arranged at the upper end of the adjusting rod in the circumferential direction, the switch seat is fixed to the bracket in the circumferential direction, the switch seat and the bracket are slidably connected in the vertical direction, a micro-switch is fixedly arranged on the switch seat, a trigger part is arranged on the micro-switch, the lower end of the jacking rod is propped against thetrigger part, and the micro-switch can be triggered when the jacking rod moves downwards. The machine core has the advantages that the pencil planing thickness can be adjusted and controlled while theautomatic shutdown is conducted, and the adjustment is convenient.

Owner:SUNWOOD HLDG GROUP

Automatic pencil sharpener device based on infrared induction

The invention relates to an automatic pencil sharpener device based on infrared induction. The automatic pencil sharpener device comprises a shell, a power module, a pencil sharpener module, an infrared receiver, an infrared transmitter, a micro motor, a shaving box, a pencil feeding device, a pencil hole and a switch, wherein the power module, the pencil sharpener module, the infrared receiver, the infrared transmitter, the micro motor, the shaving box, the pencil feeding device and pencil hole are located in the shell, and the switch is located on the outer side of the shell; the switch controls the power module to supply power to the infrared receiver, the infrared transmitter and the micro motor, pencil sharpening action is conducted on a pencil which rotates in the pencil feeding device through the pencil sharpener module, and the micro motor rotates reversely to drive the pencil feeding device to eject the sharpened pencil. According to the automatic pencil sharpener device basedon infrared induction, the pencil sharpening function can be automatically completed, and the pencil can be automatically ejected out; and besides, the infrared induction devices are introduced, so that the intelligent degree of a pencil sharpener is improved, and the utilization rate of the pencil is increased.

Owner:KUNMING UNIV OF SCI & TECH

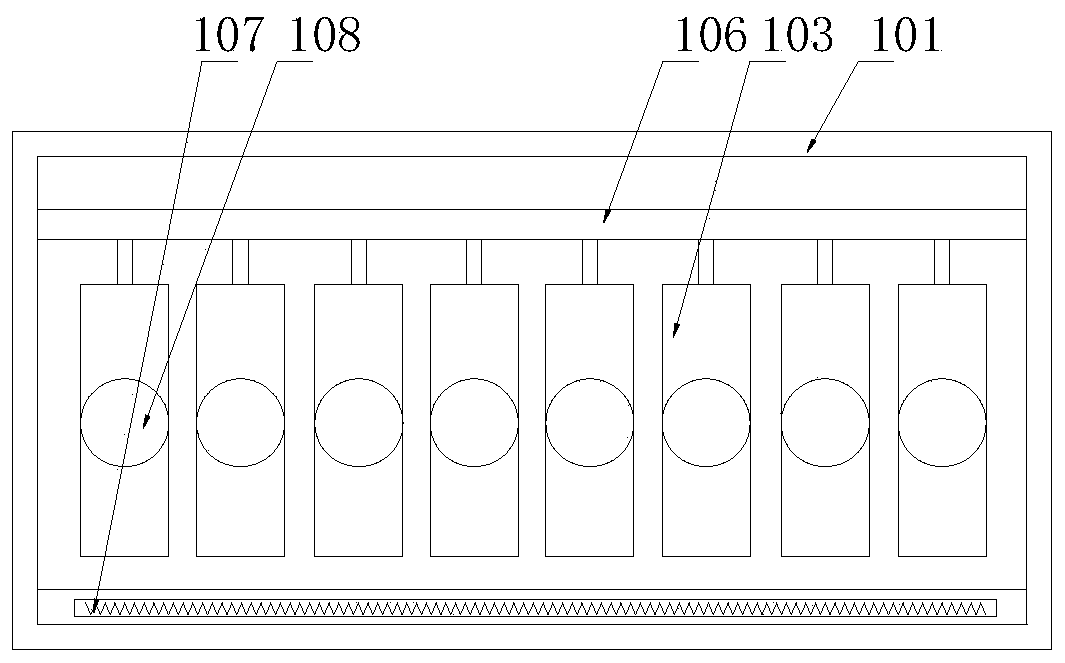

Infrared field evolution monitoring system and method of battery management system

InactiveCN110031110AFine adjustmentIncrease local temperatureRadiation pyrometryElectric vehicle charging technologyInfraredBattery management systems

The invention relates to an infrared field evolution monitoring system of a battery management system. The infrared field evolution monitoring system of the battery management system comprises an infrared monitoring system, wherein the infrared monitoring system comprises a plurality of thermal infrared imagers arranged in a battery bin; according to the invention, the temperature of the battery unit is detected by using the infrared monitoring system, the temperature field of each point of the battery unit can be detected, fine adjustment is achieved, local overhigh temperature caused by abnormity of the battery unit can be effectively detected, the temperature field data is uploaded to a big data cloud server, the big data is integrated for modeling analysis, and the intellectualizationof management is improved.

Owner:力高(山东)新能源技术股份有限公司

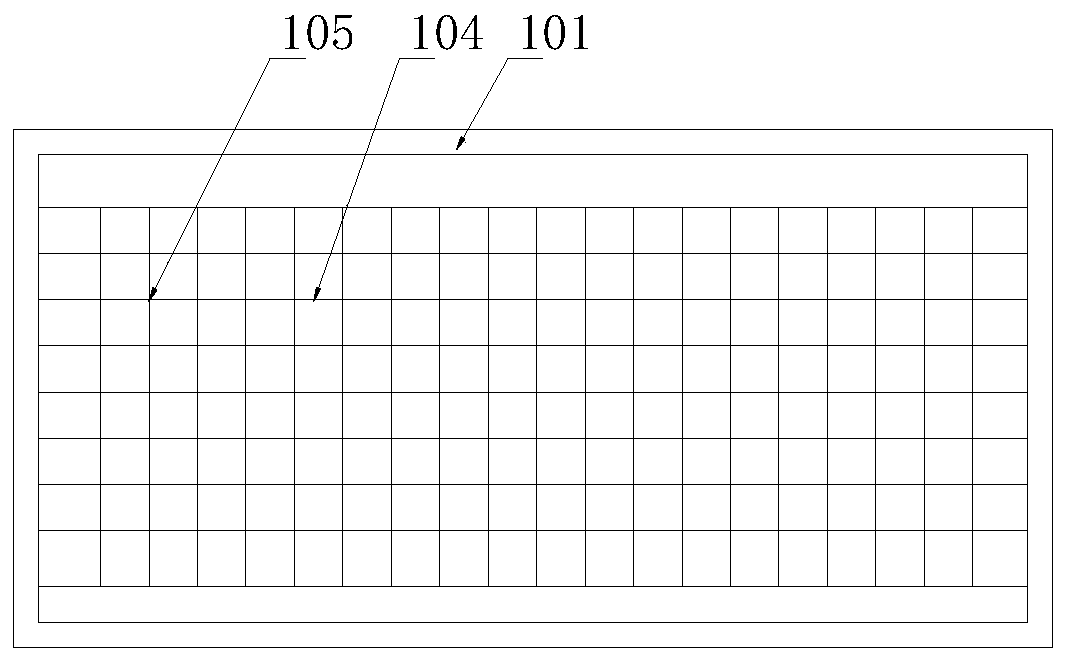

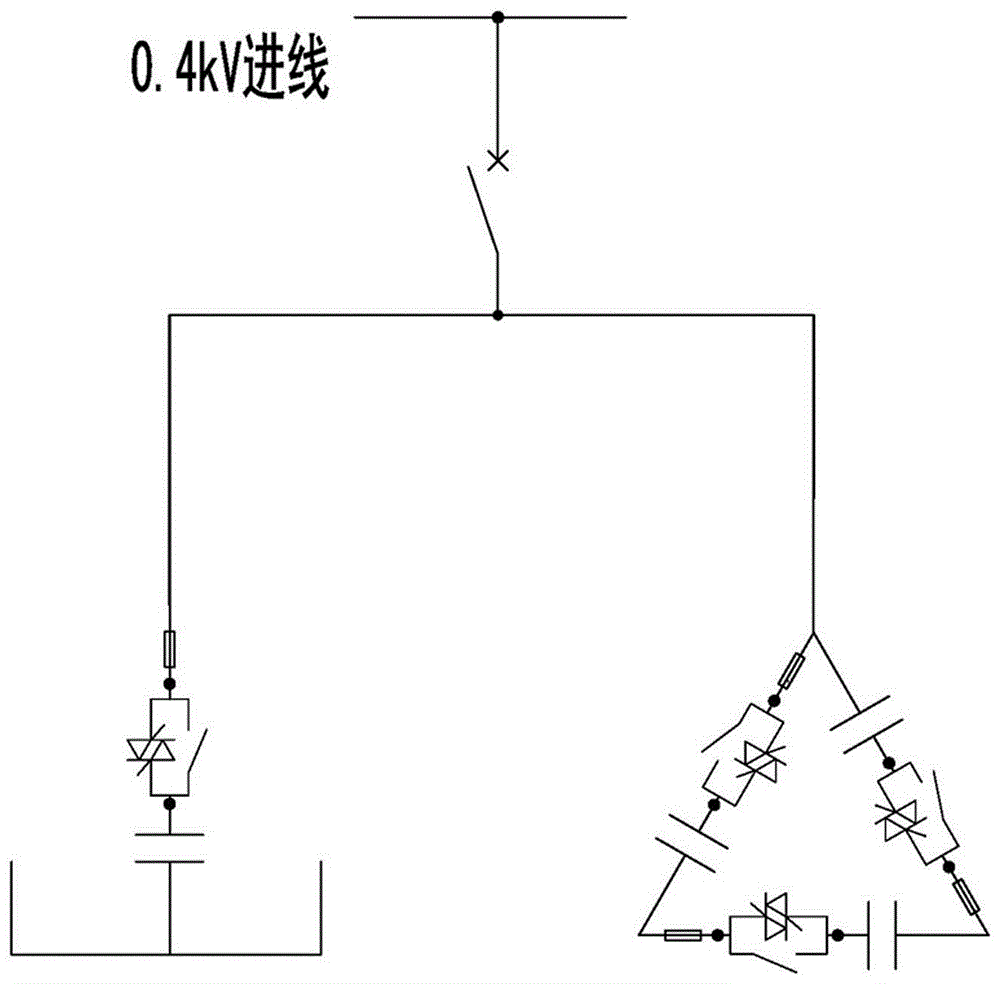

Three-phase unbalance and reactive power control device and method of interphase capacitor

ActiveCN105811441AFine adjustmentPrevent overfillingPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationThree-phase electric powerPhase balancing

The invention discloses a three-phase unbalance and reactive power control device and method of an interphase capacitor. The three-phase unbalance and reactive power control device of the interphase capacitor comprises a master controller, a current acquisition device, a voltage acquisition device and a fine reactive compensation unit, wherein the current acquisition device and the voltage acquisition device are connected with an input end of the master controller, and the fine reactive compensation unit is connected with an output end of the master controller and comprises an interphase compensation circuit and a phase-zero compensation circuit. The interphase compensation circuit and the phase-zero compensation circuit adopt capacitors to compensate, the unbalance phenomenon of a three-phase power grid can be effectively controlled; with the utilization of capacitor adjustment branches, the inductive reactive power in three-phase electricity can be effectively offset; and moreover, a plurality of capacitor adjustment branches are connected to the three-phase electricity and between the three-phase electricity and a zero line, the adjustment is more fine, and the over-compensation also can be prevented.

Owner:SHANDONG ELECTRICAL ENG & EQUIP GRP XINNENG TECH CO LTD

Adjusting mechanism of conveyer belt step of vegetable cutter

The invention discloses an adjusting mechanism of conveyer belt step of a vegetable cutter. The adjusting mechanism comprises a conveyer belt, an eccentric wheel, a long link and an overrun clutch. The long link is hinge to the eccentric wheel through an eccentric pin. The adjusting mechanism further comprises an adjusting device. The other end of the long link is hinged to a first link and a second link through a link pin; the other end of the second link is hinged to the overrun clutch; the other end of the first link is hinged to an adjusting nut of the adjusting device; the step of the conveyer belt is adjusted by adjusting the adjusting nut; the overrun clutch is connected with a front roller; the conveyer belt is mounted on the front roller; the eccentric wheel drives the overrun clutch to swing through the long link, so that the conveyer belt performs forward intermittent conveying. The adjusting mechanism has the advantages that chopping length can be accurately adjusted according to graduation without stopping the vegetable cutter, repeatedly adjusting the original mechanism is avoided, adjusting is accurate, operating is simple, and using is facilitated.

Owner:济南银鹰食品机械有限公司

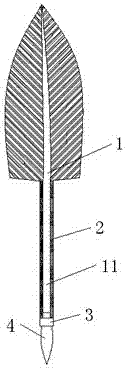

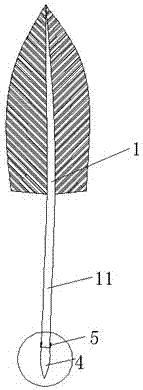

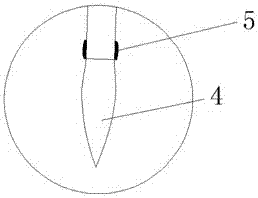

Goose feather tube writing brush and manufacturing method thereof

InactiveCN107458112AChange the phenomenon of single styleFine adjustmentOther pensEngineeringGoose feathers

The invention discloses a quill writing brush and a manufacturing method thereof, which comprises a quill pen holder, the lower part of the quill pen holder is a quill tube, the outside of the quill tube is covered with a decorative layer, the lower end of the quill tube is connected with a fixed head, and the lower end of the fixed head is plugged with a The nib, the quill brush is made by selecting hair, initial washing, degreasing washing, drying, trimming, initial cleaning of capillary, deep cleaning of capillary, drying in the shade, assembly and pen making. The invention changes the single style of the traditional writing brush, and greatly reduces the cost, and makes a breakthrough in the whole industry by making the goose feather beneficial to the writing brush industry and making it into a pen holder.

Owner:湖州湖颖文具用品有限公司

Clamp device used for correcting perpendicularity of wire electrode and medium-speed wire cutting machine

PendingCN112975016AApplicable to different working conditionsFine adjustmentElectrical-based auxillary apparatusMachine partsElectric machine

The invention provides a clamp device used for correcting the perpendicularity of a wire electrode. The clamp device comprises a bottom plate, a sliding rail is fixedly arranged on the bottom plate, an L-shaped sliding plate and a U-shaped sliding plate are movably arranged on the sliding rail, inserting rods are fixedly arranged at the output end of a rotating motor, inserting grooves are correspondingly formed in a handle, a lead screw is fixedly arranged at the end, away from the handle, of a rotating rod, a nut is movably arranged on the lead screw, and a connecting plate is fixed to a base block. An L-shaped positioning plate is arranged on the side, away from the bottom plate, of the base block, a clamping plate is fixedly arranged at the bottom of an abutting rod, and an inclinometer is fixedly arranged on a top plate. According to the clamp device used for correcting the perpendicularity of the wire electrode and a medium-speed wire cutting machine, a manual or electric driving manner can be used for enabling the base block clamping a machined part to rotate and deviate, then the perpendicularity of the machined part relative to the wire electrode is adjusted, the adjusting operation is more refined, and the machining precision is higher.

Owner:张正凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com