Machine core of electric pencil-peeling device

A pencil sharpener, electric technology, applied in sharpening devices, printing, office supplies, etc., can solve the problem of inability to adjust and control the thickness of pencil sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

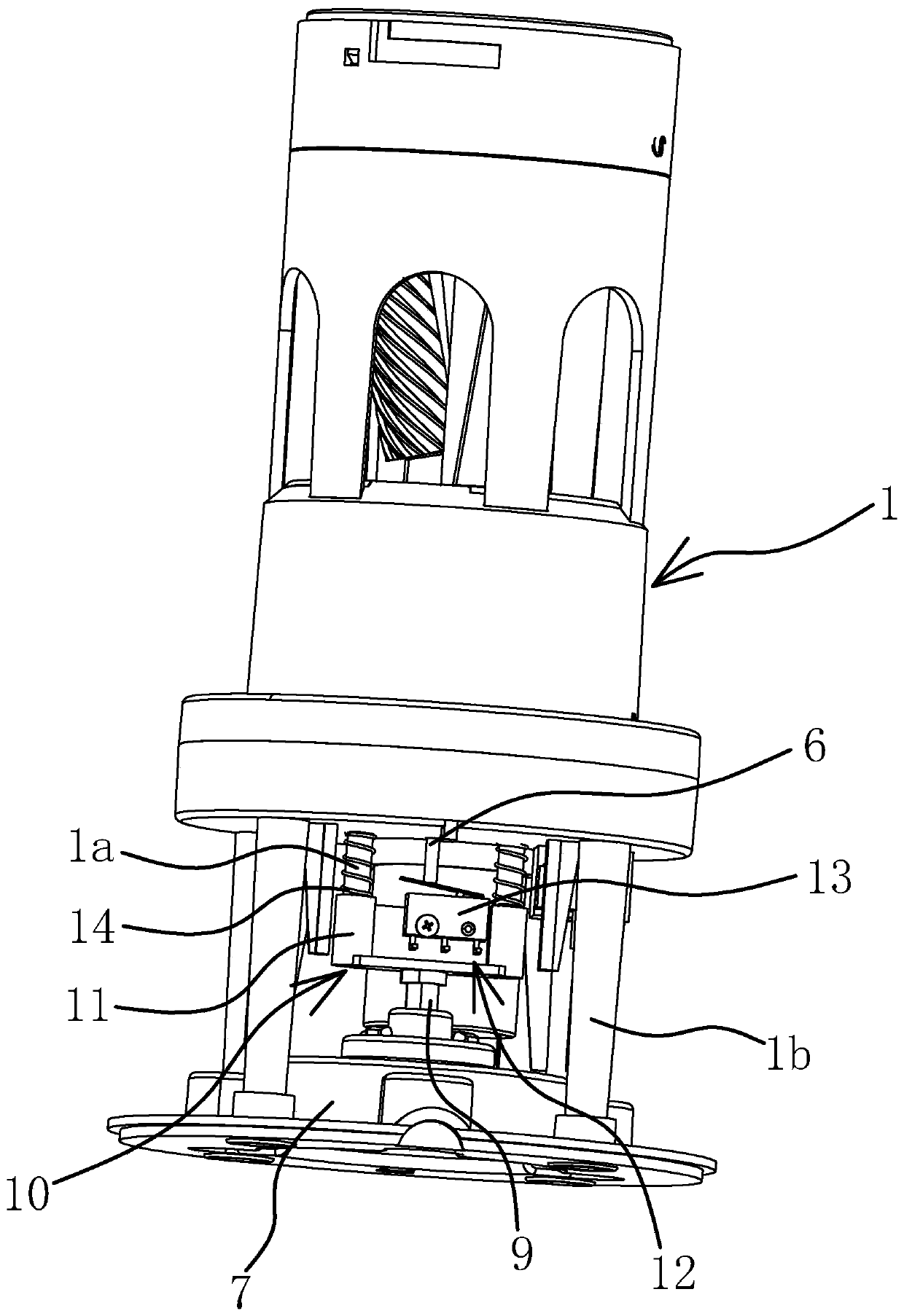

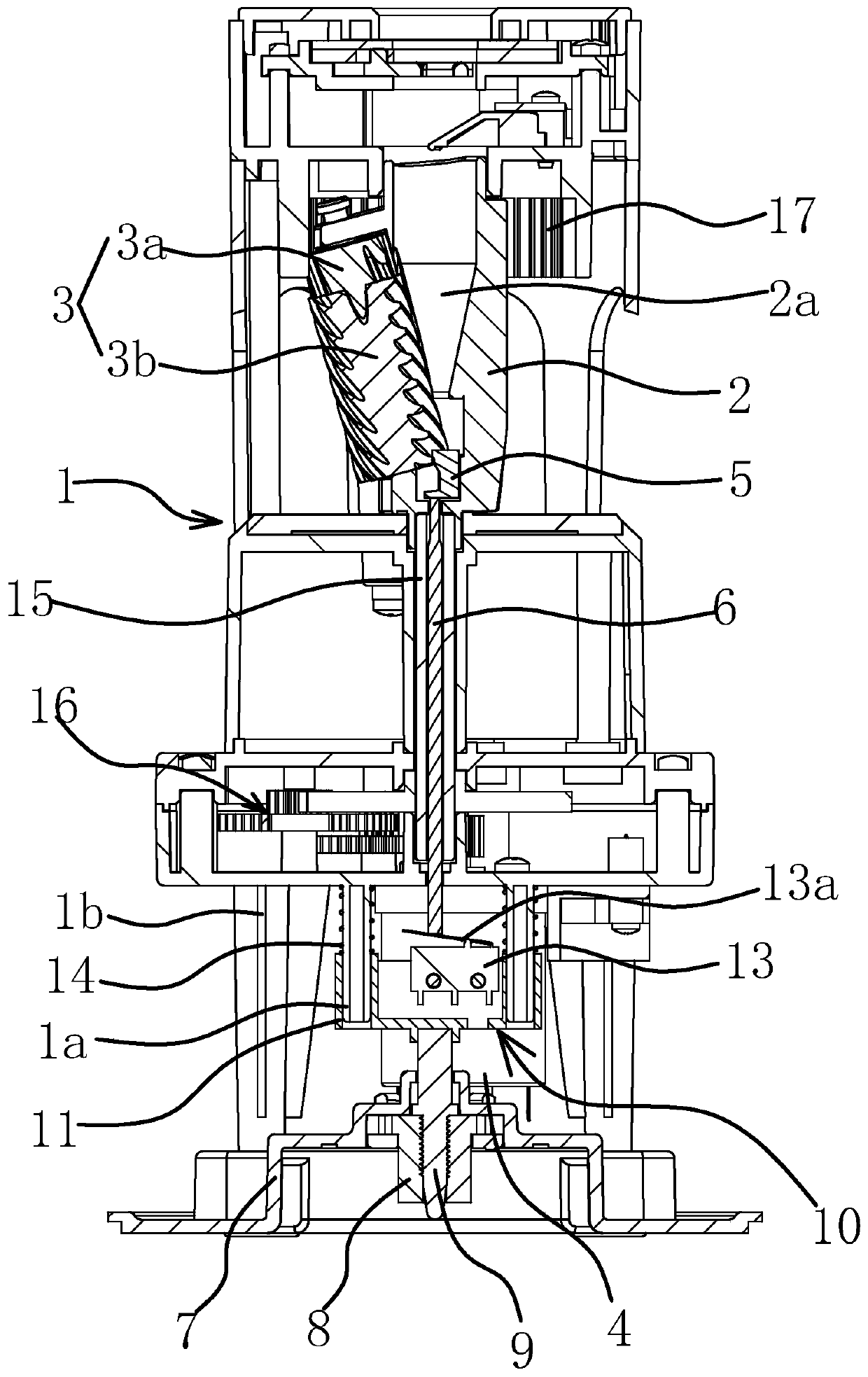

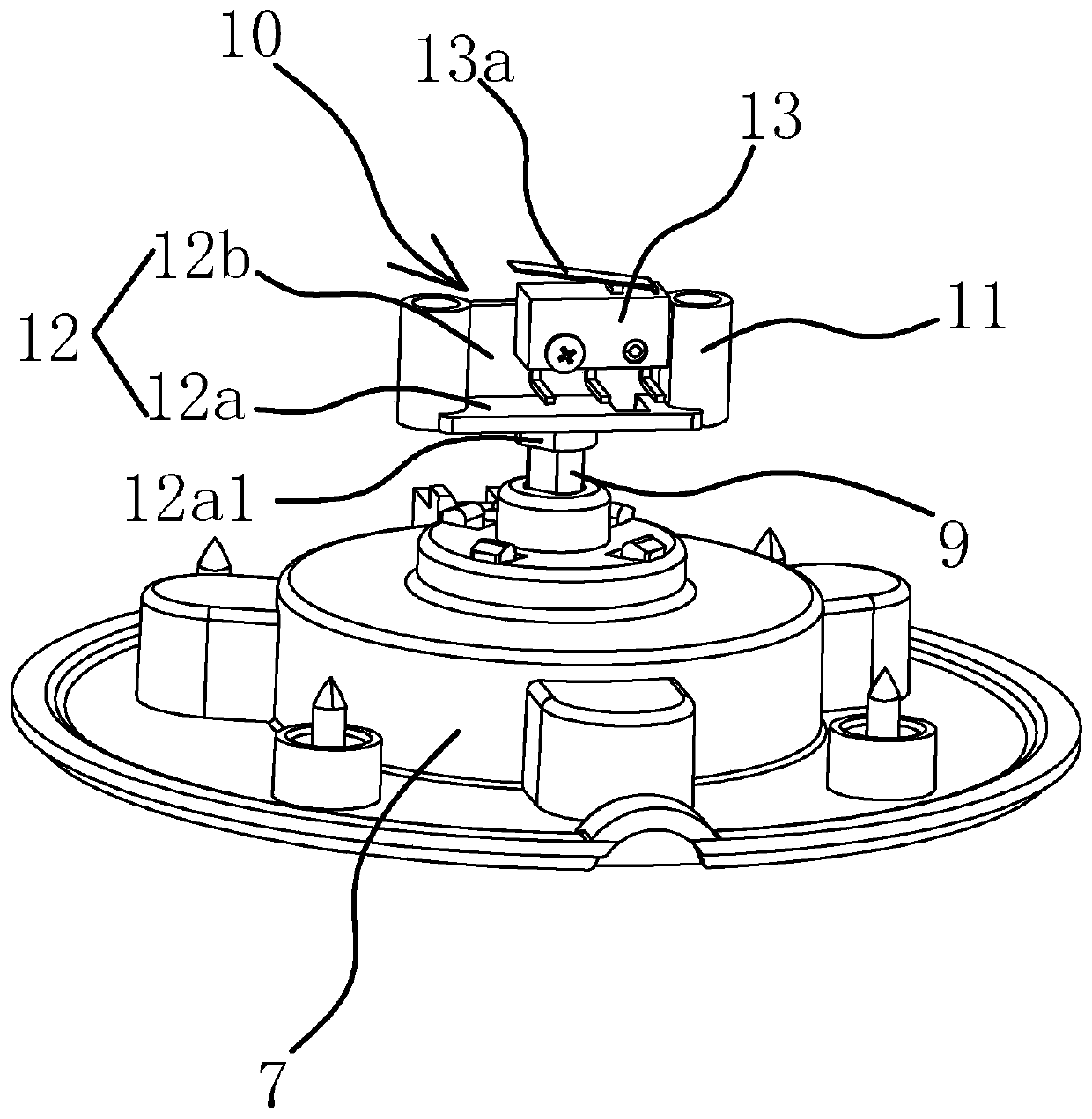

[0030] Such as figure 1 and figure 2 As shown, the movement of the electric pencil sharpener includes a bracket 1, on which a pen holder 2 with a channel 2a along the vertical direction is arranged, and a planing assembly 3 is arranged on one side of the pen holder 2, and part of the planing assembly 3 is located in the channel 2a Inside, the lower end of the support 1 is provided with a motor 4 that can control the start and stop of the planing assembly 3. Specifically, the support 1 is provided with a rotating shaft 15 along the vertical direction, and the pen holder 2 is fixed on the upper end of the rotating shaft 15. The power is transmitted between the output shafts through the gear mechanism 16. The ring gear 17 is fixed on the support 1. The planing assembly 3 includes a gear 3a that can rotate freely and a hob 3b that is coaxially arranged with the gear 3a and can rotate synchronously with the gear 3a. , The hob 3b is partly located in the channel 2a, and the gear 3...

Embodiment 2

[0039] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the base body 12 includes a horizontal plate 12a and a vertical plate 12b fixedly connected with the horizontal plate 12a, and the micro switch 13 is fixed On the inner side of the vertical plate 12b, the lower end of the horizontal plate 12a is fixedly connected with the upper end of the adjusting rod 9 as a whole.

Embodiment 3

[0041] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the switch base 10 includes two vertical positioning columns and a seat body 12 fixed between the lower ends of the two positioning columns. , the micro switch 13 is fixed on the seat body 12 and the adjusting rod 9 is circumferentially fixed to the seat body 12, the lower end of the bracket 1 is provided with two guide heads which are hollow, and the upper ends of the two positioning posts are respectively inserted into the corresponding guide heads. Both positioning posts are equipped with spring two, the lower ends of the two springs are all against the upper end of the seat body 12, the upper ends of the two spring two are respectively against the lower end surface of the corresponding guide head, and the lower end of the seat body 12 is provided with a non-circular shape. Shaped connecting hole, the shape of the upper end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com