Patents

Literature

833results about How to "Ensure connection stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

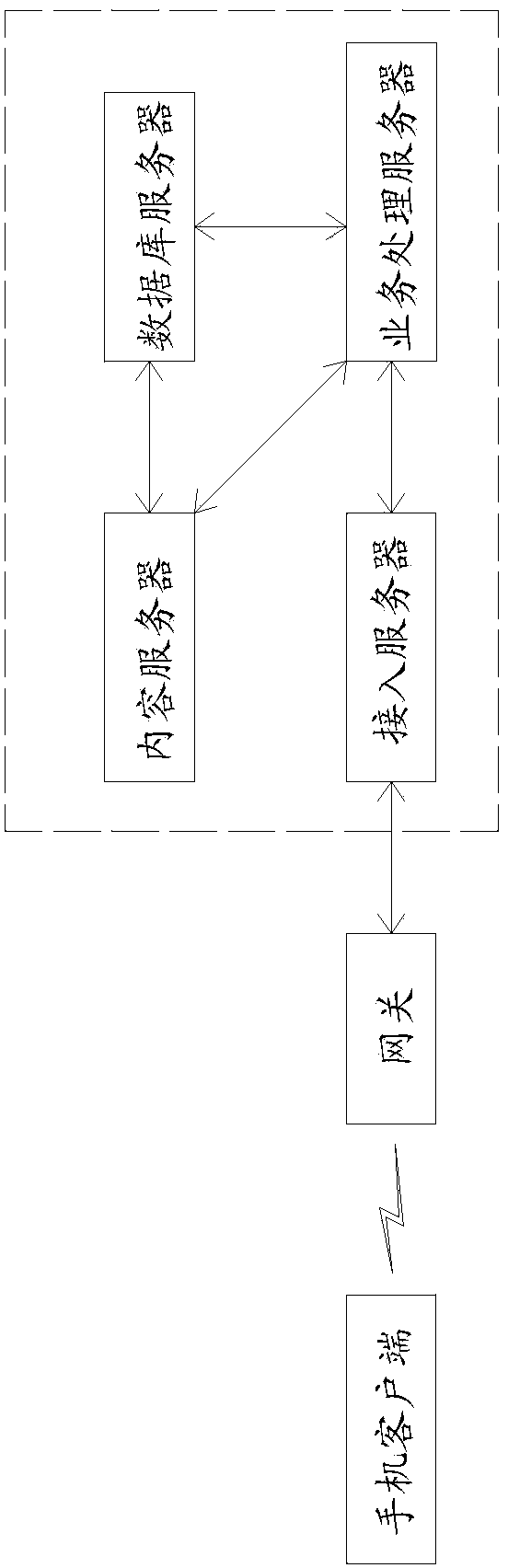

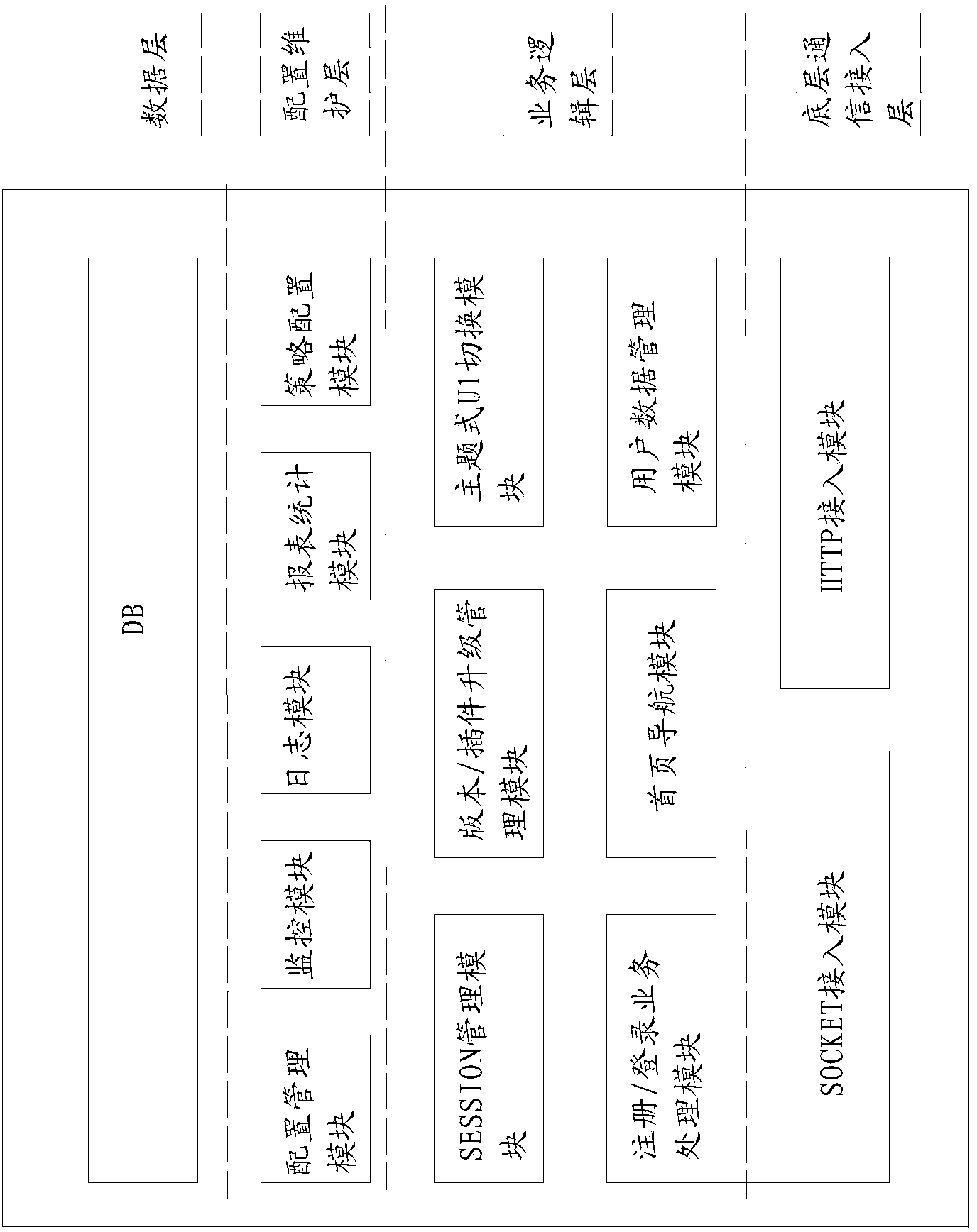

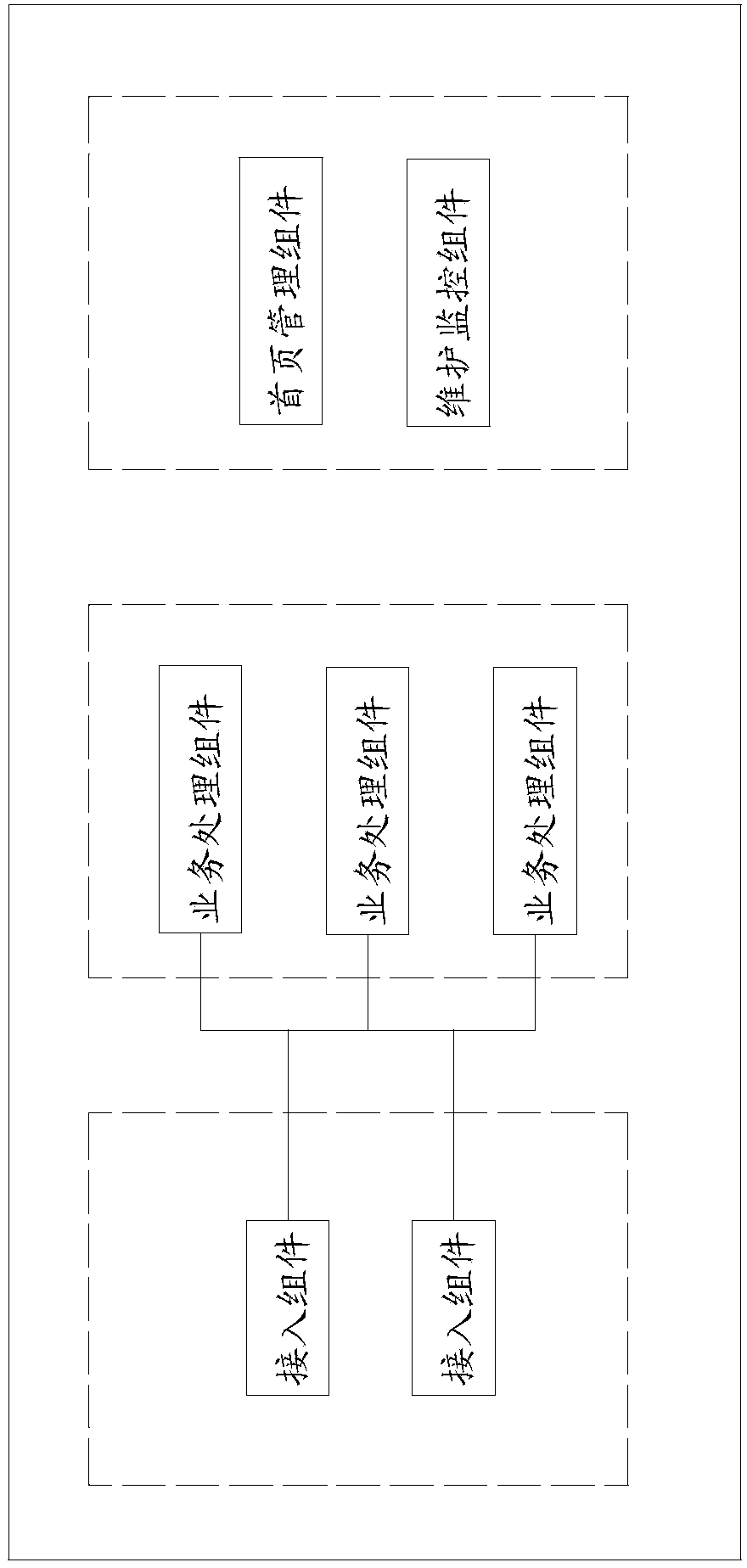

Method for providing large concurrent processing and flow control for mobile phone client sides

InactiveCN103369601AReduce the number of concurrent connectionsGuaranteed connection reliabilityNetwork traffic/resource managementData switching networksData acquisitionClient-side

The invention discloses a method for providing large concurrent processing and flow control for mobile phone client sides, and the method is applied to interaction between the mobile phone client sides and a server cluster. The method includes the steps that step1, the mobile phone client sides send connection requests to an access server in a server cluster, a DNS gets access to the server in a dispatching mode, the DNS and the access server carry out delay detection, when a detected delay is smaller than a strategy parameter, a UDP is adopted for communication of the client sides and the access server, and otherwise, a TCP is used for the communication; step2, the access server receives the requests of the mobile phone client sides and controls the quantity of concurrent requests, if the number of the concurrent requests is larger than a preset value, connection is rejected, and if not, the requests are distributed to a service processing server with the fewest loads; step3, the service processing server receives the service requests distributed by the access server, sorts the service requests according to logging, logout, heartbeat, data collection and page requesting, and then respectively carries out processing according to sorted types of the service requests.

Owner:XIAMEN ZHUOXUN INFORMATION TECH

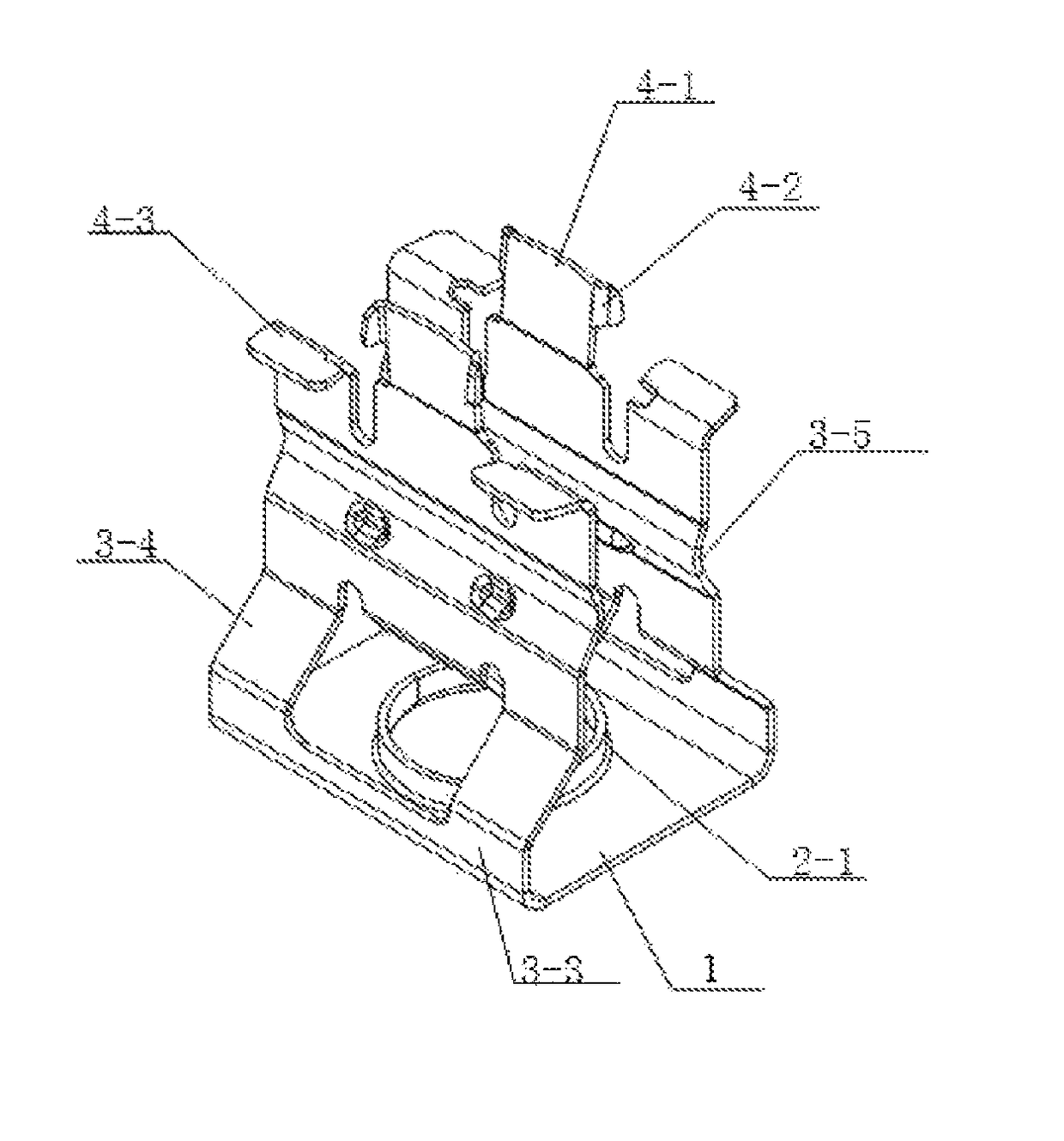

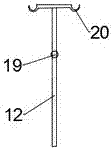

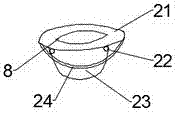

Connectable cable organizer

ActiveUS9879803B2Simple structureEasy to manufacturePipe supportsElectrical apparatusMechanical engineering

Owner:MAXDAO

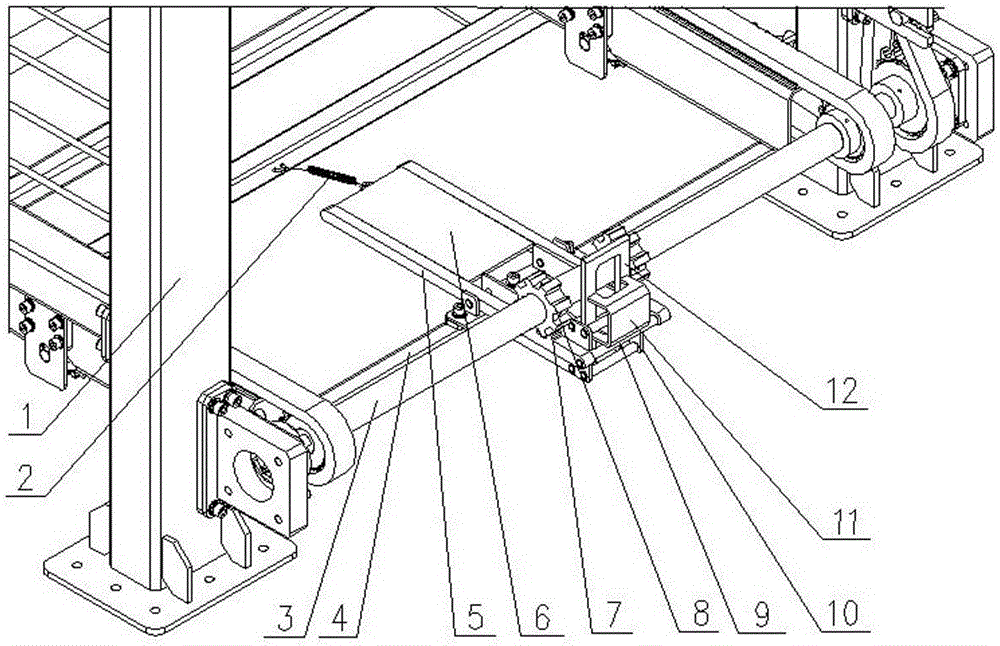

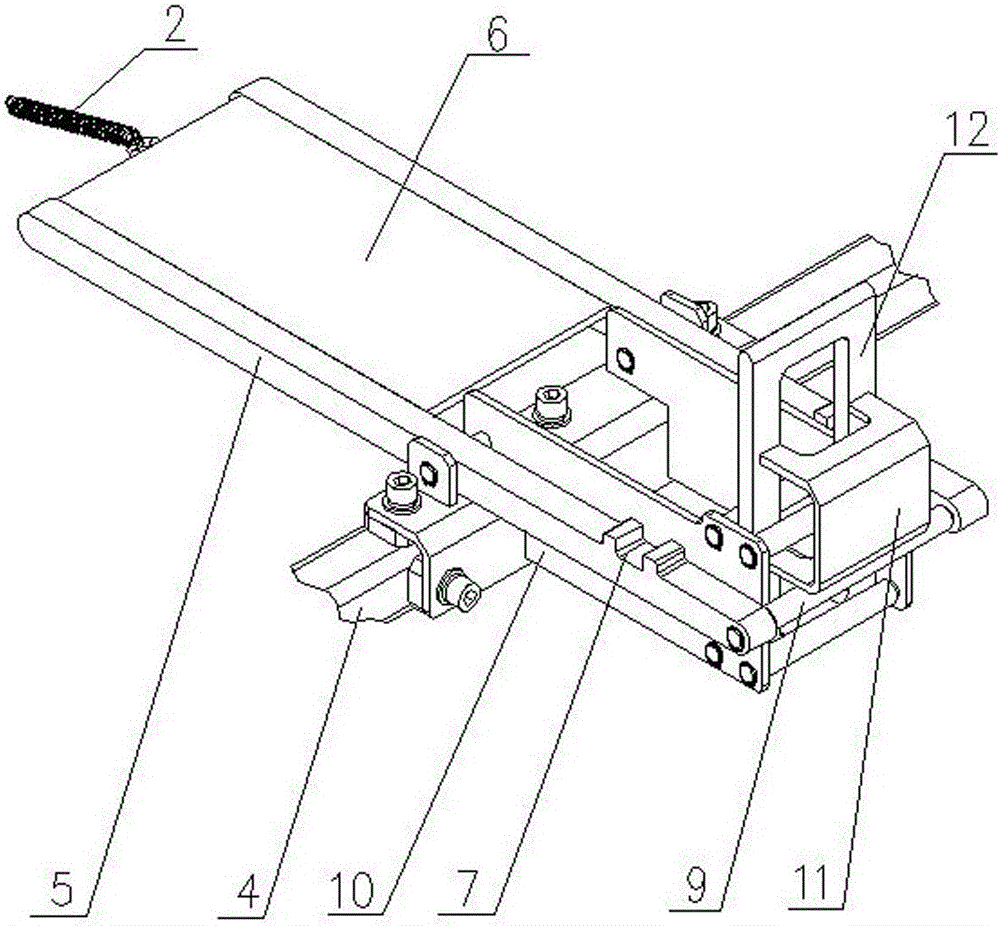

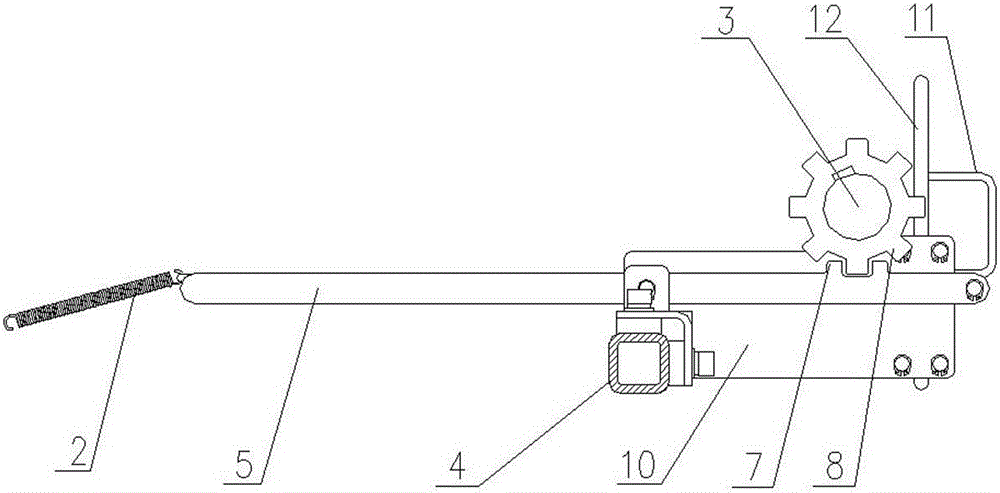

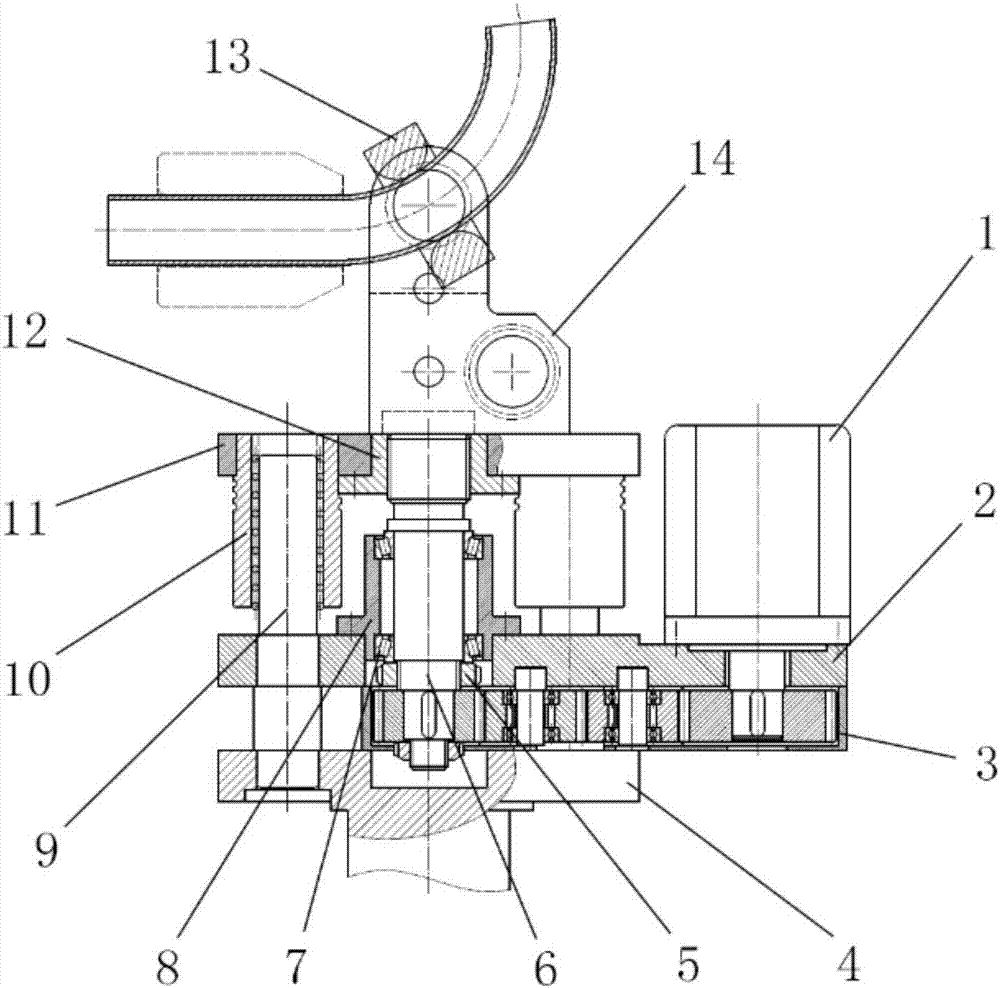

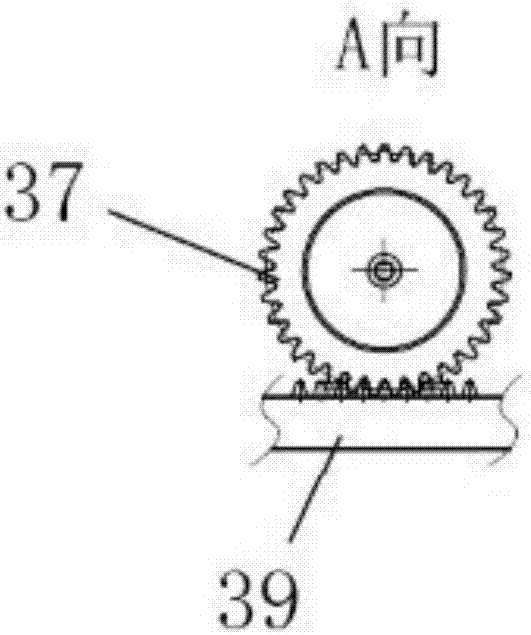

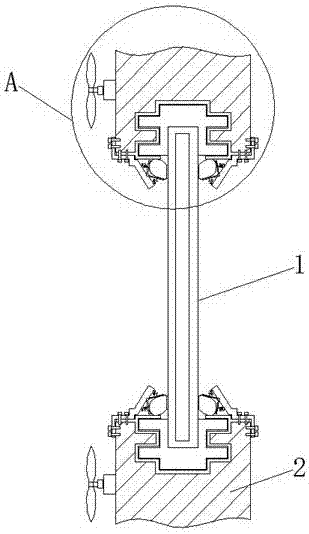

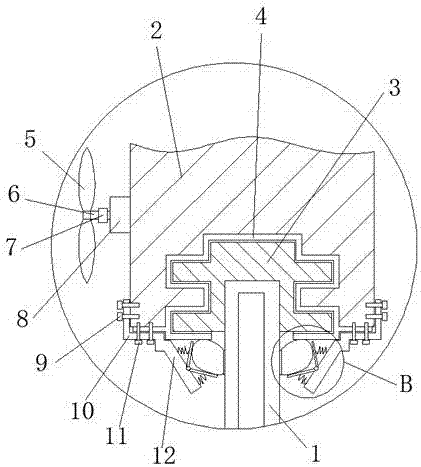

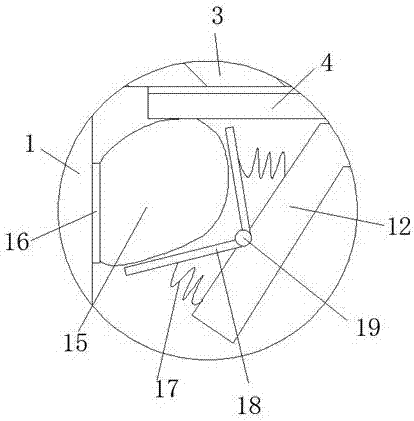

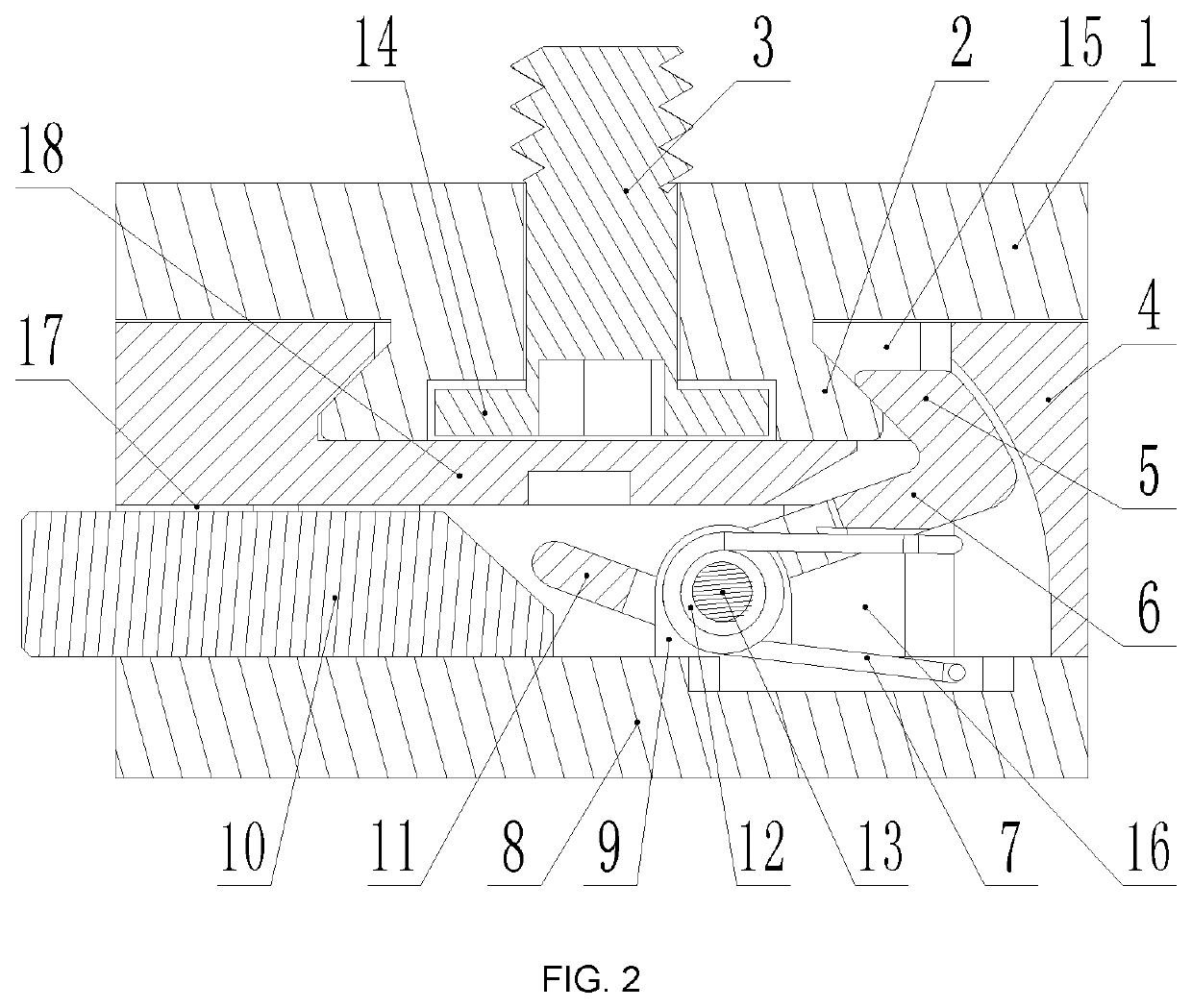

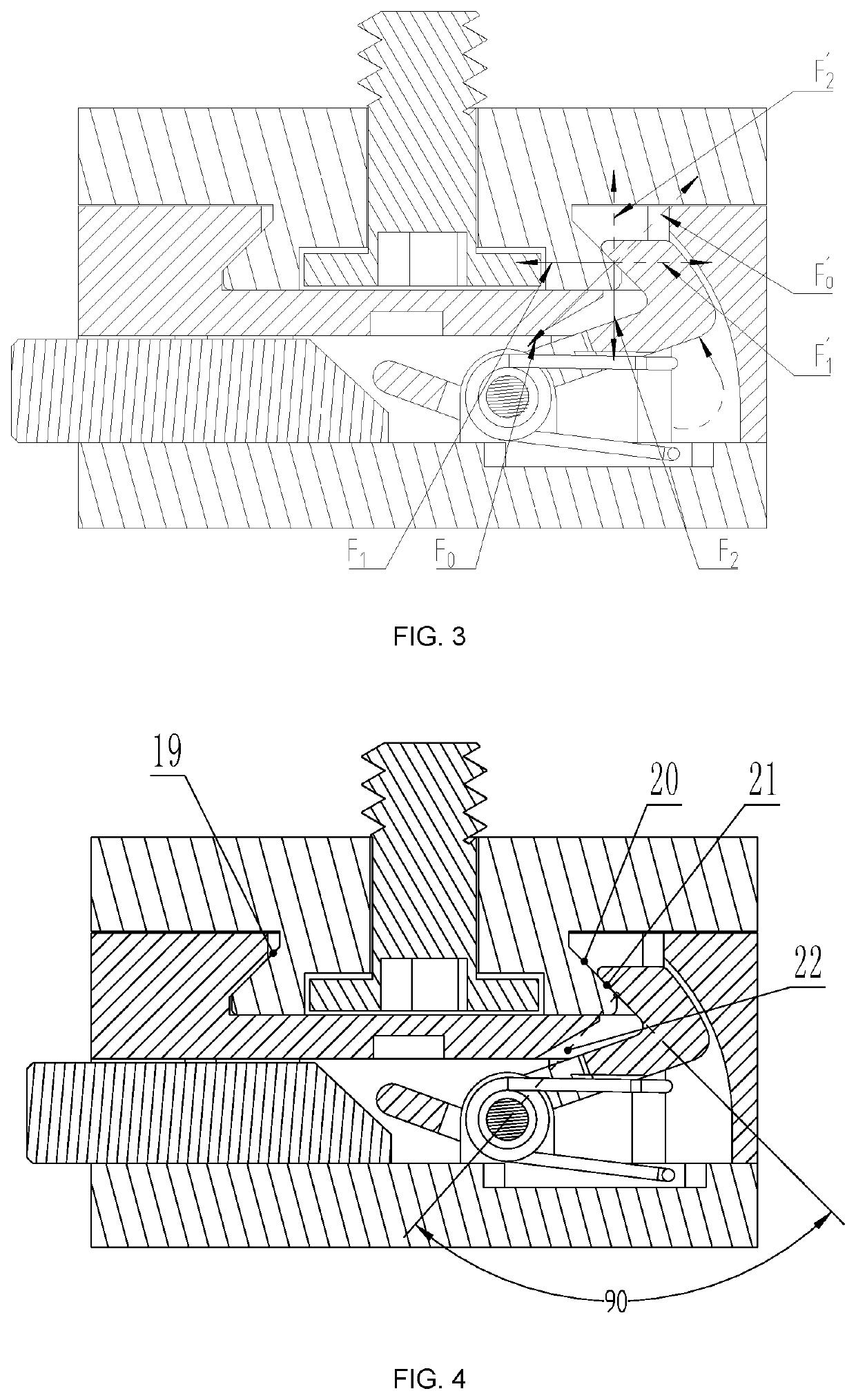

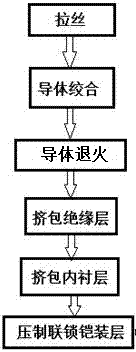

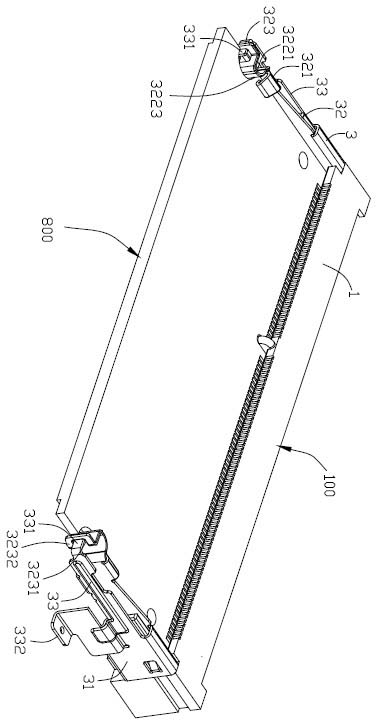

Locking and releasing device of transmission shaft for automatic goods shelf

The invention relates to a locking and releasing device of a transmission shaft for an automatic goods shelf. The locking and releasing device comprises the goods shelf, wherein the transmission shaft is arranged on the goods shelf. The locking and releasing device is characterized in that a bracket rod is arranged on the goods shelf on the lower side of the transmission shaft; the bracket rod is parallel to the transmission shaft; levers are hinged to the bracket rod; gears are fixed in the positions, corresponding to the levers, of the transmission shaft; racks are arranged in the positions, below the gears, of the levers; when the gravity centers of the levers are positioned on the side, away from the transmission shaft, of the bracket rod, the gears on the transmission shaft mesh with the racks on the levers through the gravity action of the levers; when the gravity centers of the levers are positioned on the side, close to the transmission shaft, of the bracket rod, an extension spring is connected between the ends, away from the transmission shaft, of the levers and the goods shelf below the levers, and the gears on the transmission shaft mesh with the racks on the levers through the tension action of the extension spring. According to the device, the transmission shaft of the automatic goods shelf can be effectively locked, goods are prevented from moving or sliding, the structure is simple, the mounting space is small, the processing cost is low, and the automation requirement can be met.

Owner:WUXI HAIHE EQUIP TECH CO LTD

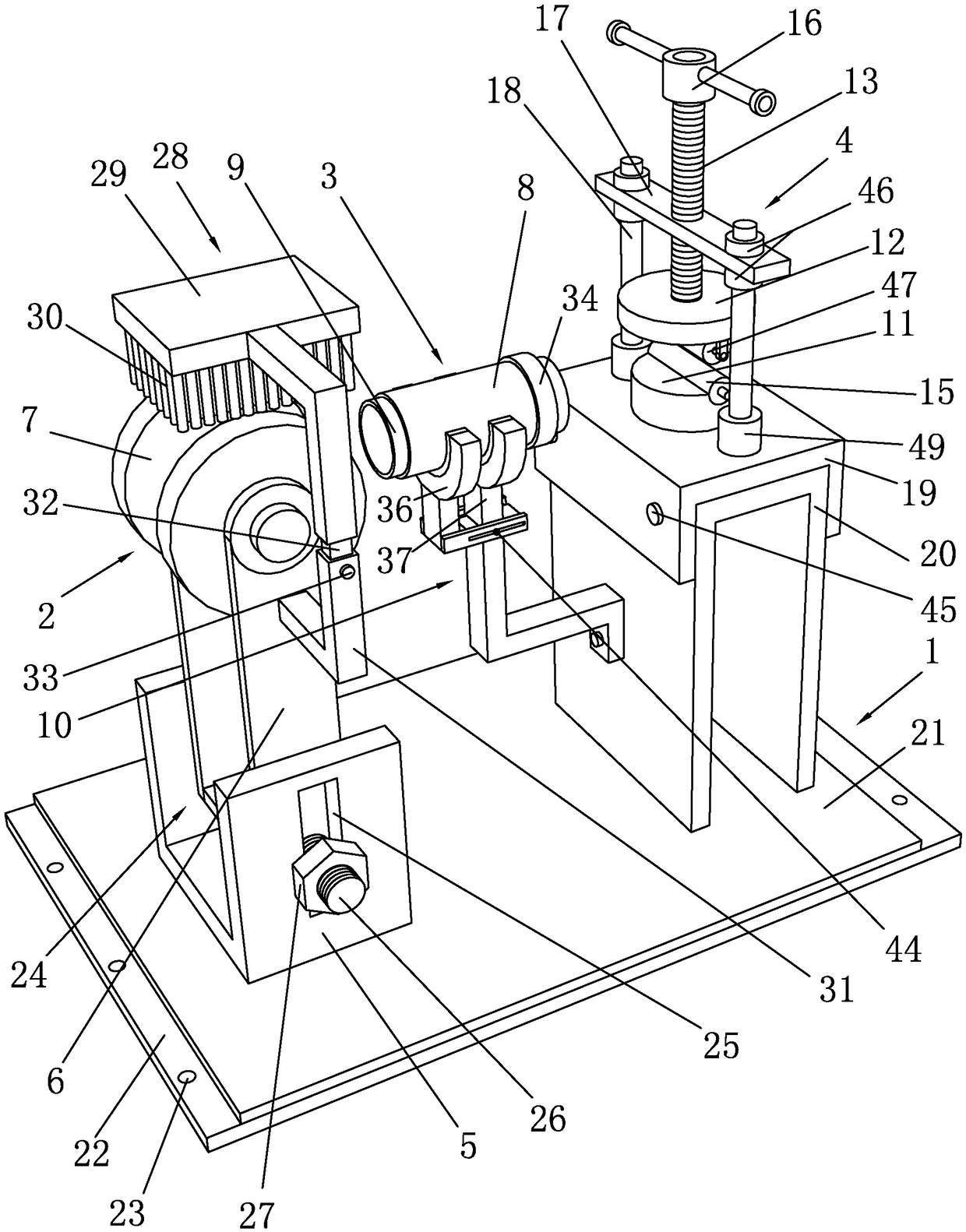

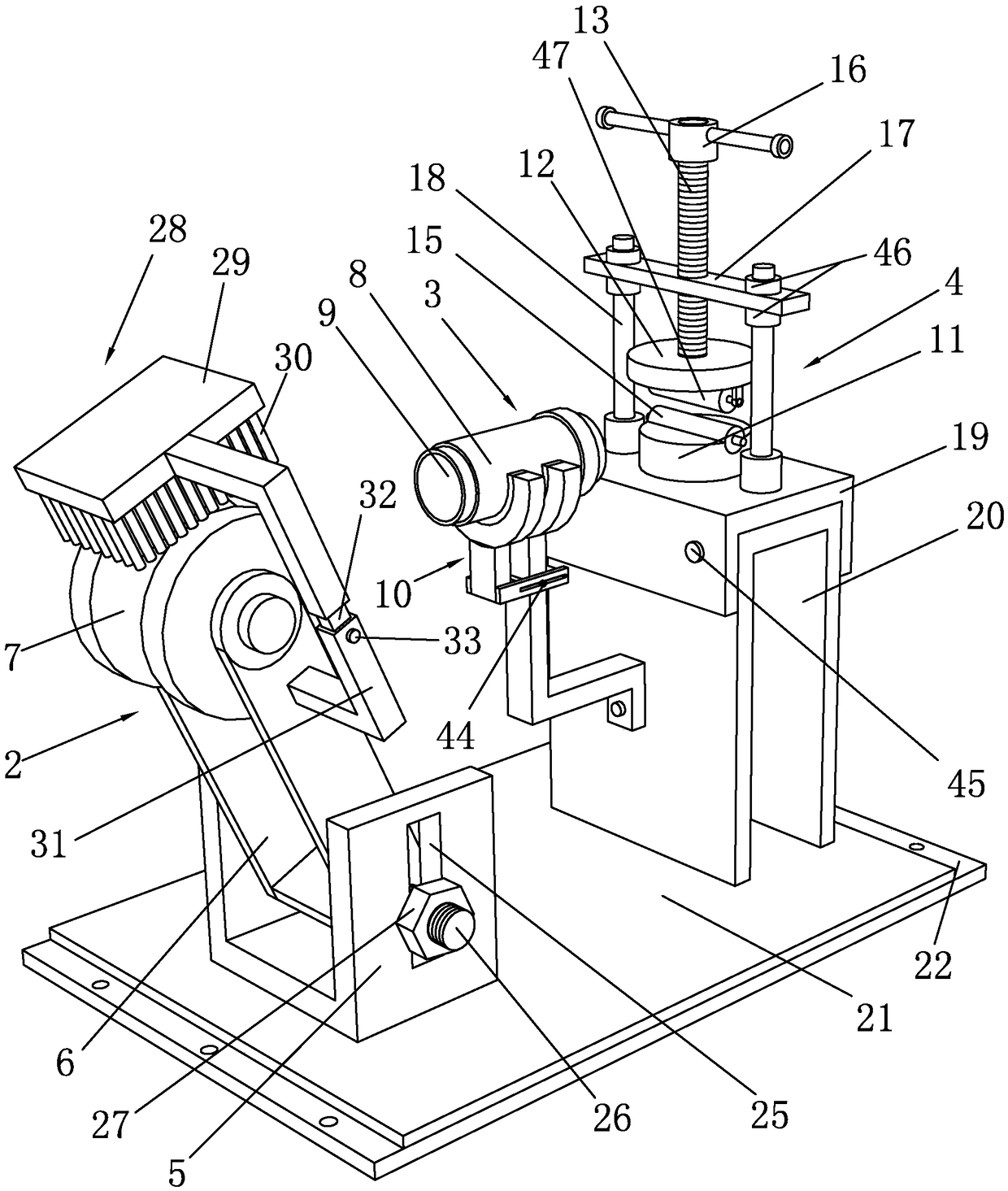

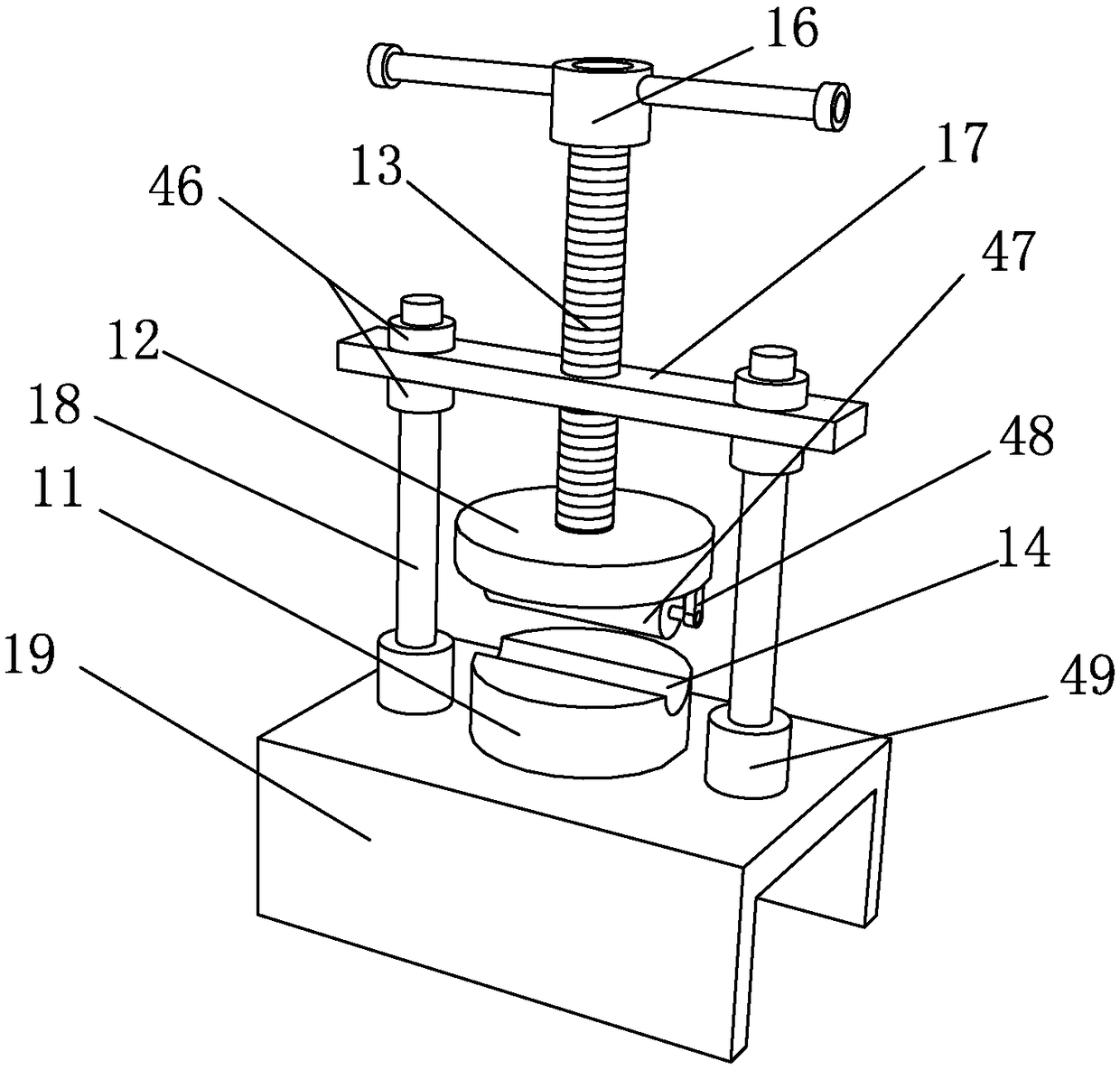

Yarn guiding device for textile product production

InactiveCN109281021AReduce mechanical vibrationEasy to assemble and disassembleYarnYarnPulp and paper industry

The invention discloses a yarn guiding device for textile product production. The device comprises a fixing bottom plate, a guiding assembly, a burr removing assembly and an adjusting assembly, the burr removing assembly comprises a guiding tube, a heating sleeve tube and a supporting frame, the heating sleeve tube is sleeved with the guiding wire, a heating wire is arranged in the heating tube, the adjusting assembly comprises a fixing plate, an adjusting plate and a pressurizing screw rod, the fixing plate is located on the limiting frame, a tensioning roller is arranged below the bottom ofthe adjusting plate, and the pressurizing screw rod is sleeved with the limiting plate. According to the yarn guiding device, yarns can be welled guided to prevent the yarns from breaking in the conveying process, the adjustment of the angle of the yarns can be conducted according to the conveying angle of the yarns, the using range of the guiding device is expanded, burrs, impurities and the likeon the yarns are removed through the burr removing mechanism to improve the quality of the yarns, and tensioning force in the yarn conveying process can be conducted by the adjusting assembly according to the conveying demands of the yarns to help the conveying of the yarns.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

Mobile phone middle frame and production process of mobile phone frame comprising same

PendingCN107322245AImprove bindingFirmly connectedTelephone set constructionsMetal stripsEngineering

The invention relates to a mobile phone middle frame and a production process of a mobile phone frame comprising the same. The mobile phone middle frame comprises a metal frame formed by allowing the end parts of a bent metal strip to be butted; and a plurality of metal support pieces are welded on the inner side surface of the metal frame at intervals. the production process comprises the following steps: a, performing cutting machining on the metal strip and the metal support pieces; b, bending the metal strip to form the metal frame; c, performing shaping on the metal frame; d, welding the joint of the end parts of the metal frame; e, welding the required metal support pieces in sequence on the inner wall surface of the metal frame; and f, placing the metal frame on which the metal support pieces are well welded in a casting die, performing die-cast formation to obtain a middle phone middle plate, and integrally combining the mobile phone middle plate with the metal frame through the metal support pieces. According to the mobile phone middle frame and the production process of the mobile phone frame comprising the same, through the structural style and the machining manner, CNC machining is greatly reduced even avoided, the machining cost is greatly reduced, the production efficiency is improved, and the machining time of the mobile phone frame is shortened by 40%-50%.

Owner:DONGGUAN XIANGJIANGXIN HARDWARE PROD

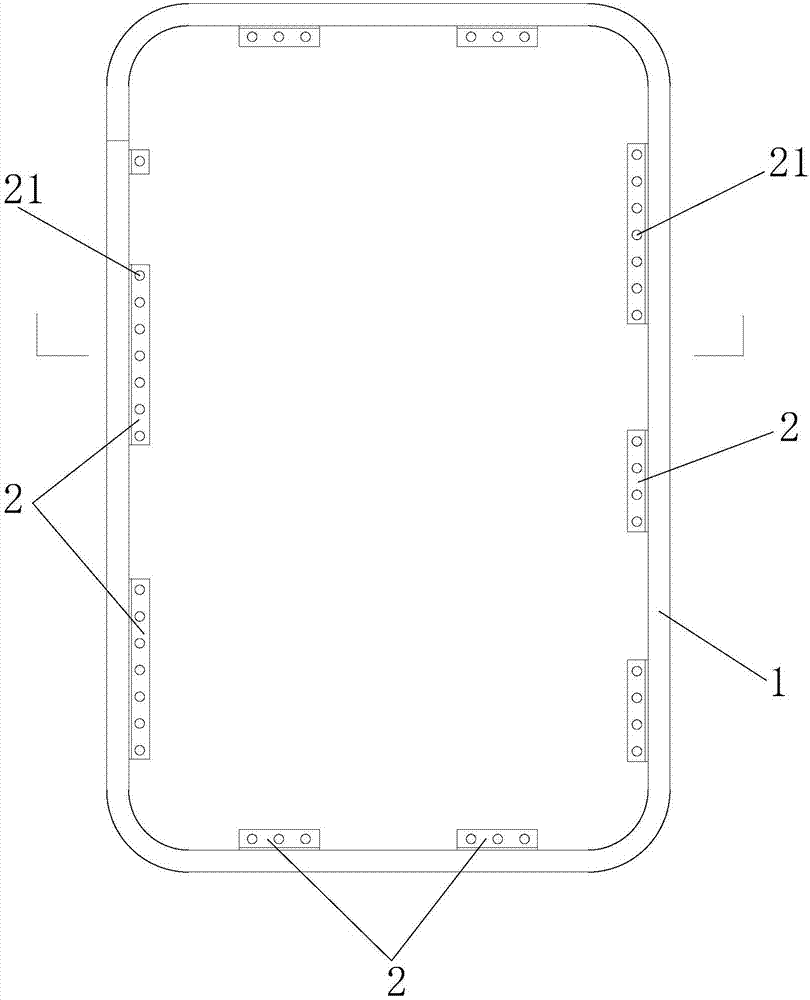

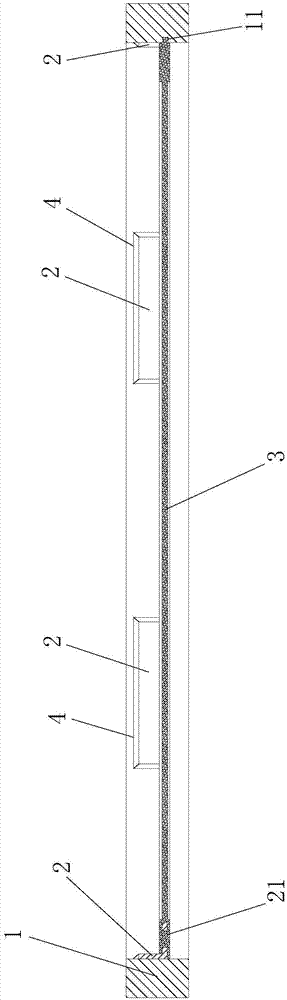

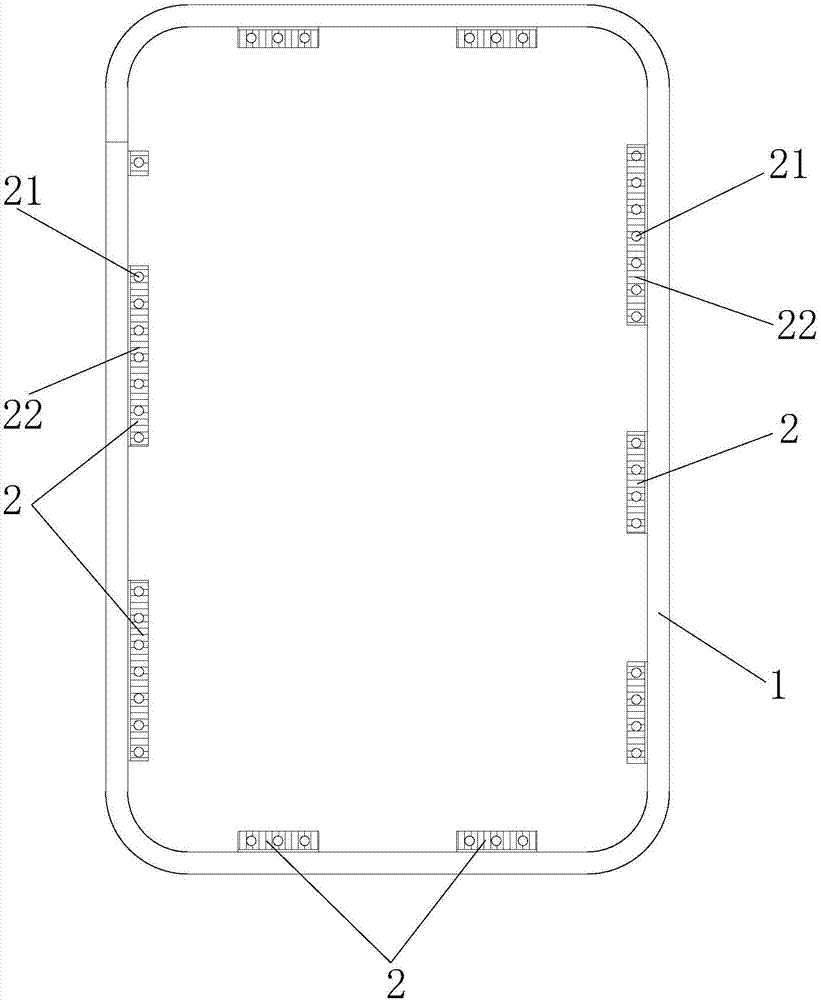

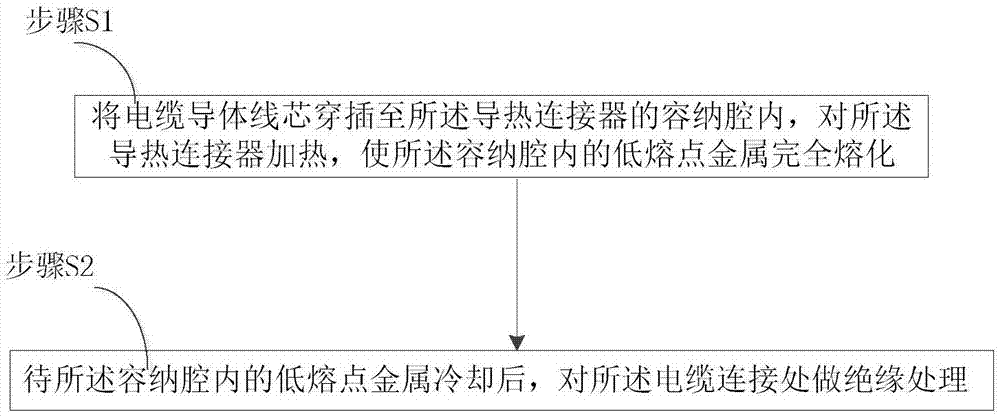

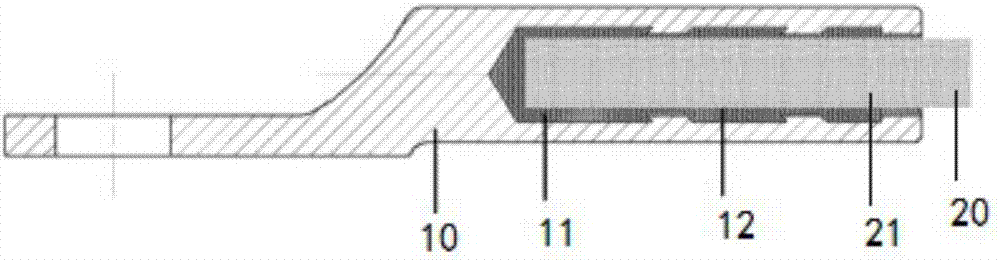

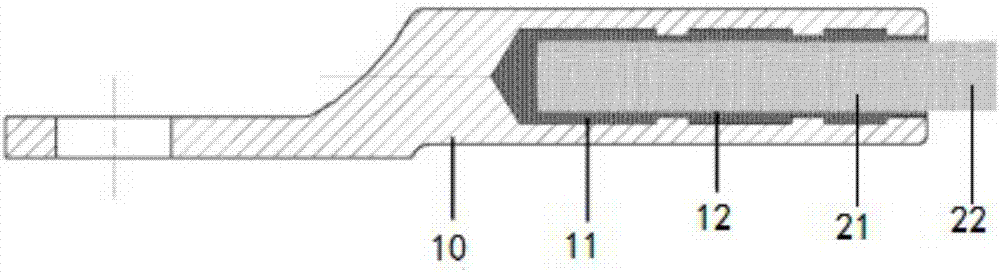

Low-melting metal cable connection device, and use method thereof, connection structure

PendingCN107302142AEnsure connection stabilitySafe and stable operationSoldered/welded conductive connectionsElectrical resistance and conductanceSoldering

The invention provides a low-melting metal cable connection device and a use method thereof. The use method comprises the following steps: encapsulating the low-melting metal in a heat-conducting connector, inserting the conductive core of the to-be-connected cable into the low-melting metal, heating the heat-conducting connector to enable the low-melting metal to completely contact with the conductive core of the cable; guaranteeing the connection stability between the cable cores by using the conductivity of the low-melting metal, thereby guaranteeing the safe and stable running of the cable connecting point under the situations that the sustained cable works in normal and works overload within short time; and meanwhile, the soldering flux is further used for effectively removing an oxide film with bad conductivity on the surface of the cable core; the contact resistance of the cable is reduced, and the power transmission efficiency of the cable is improved.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

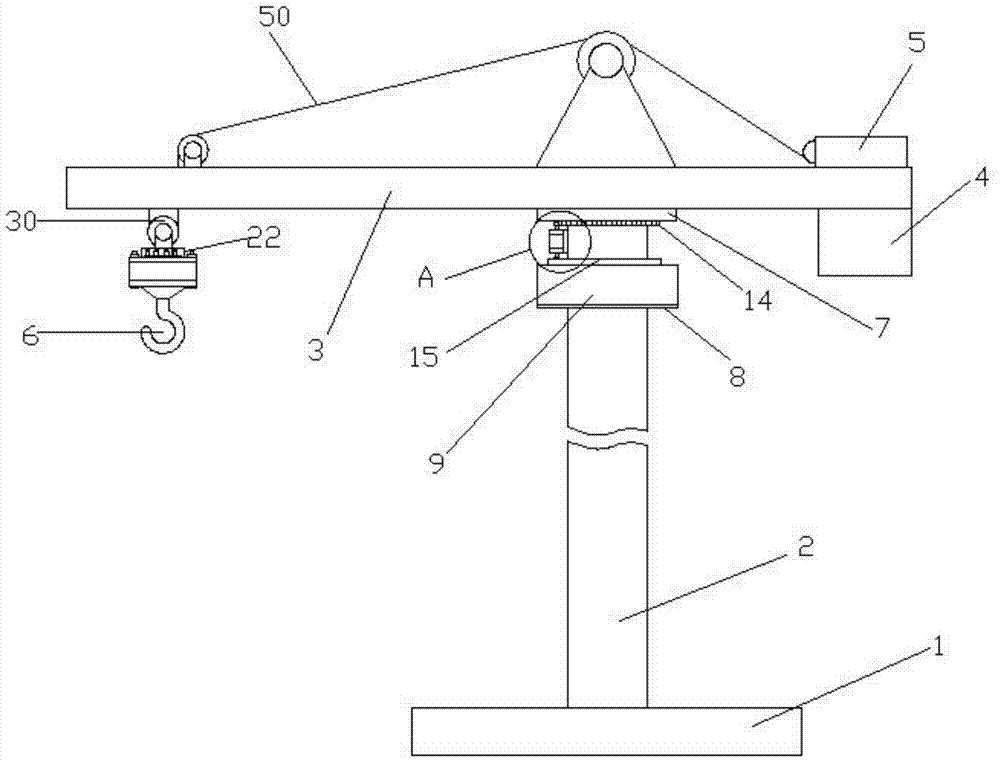

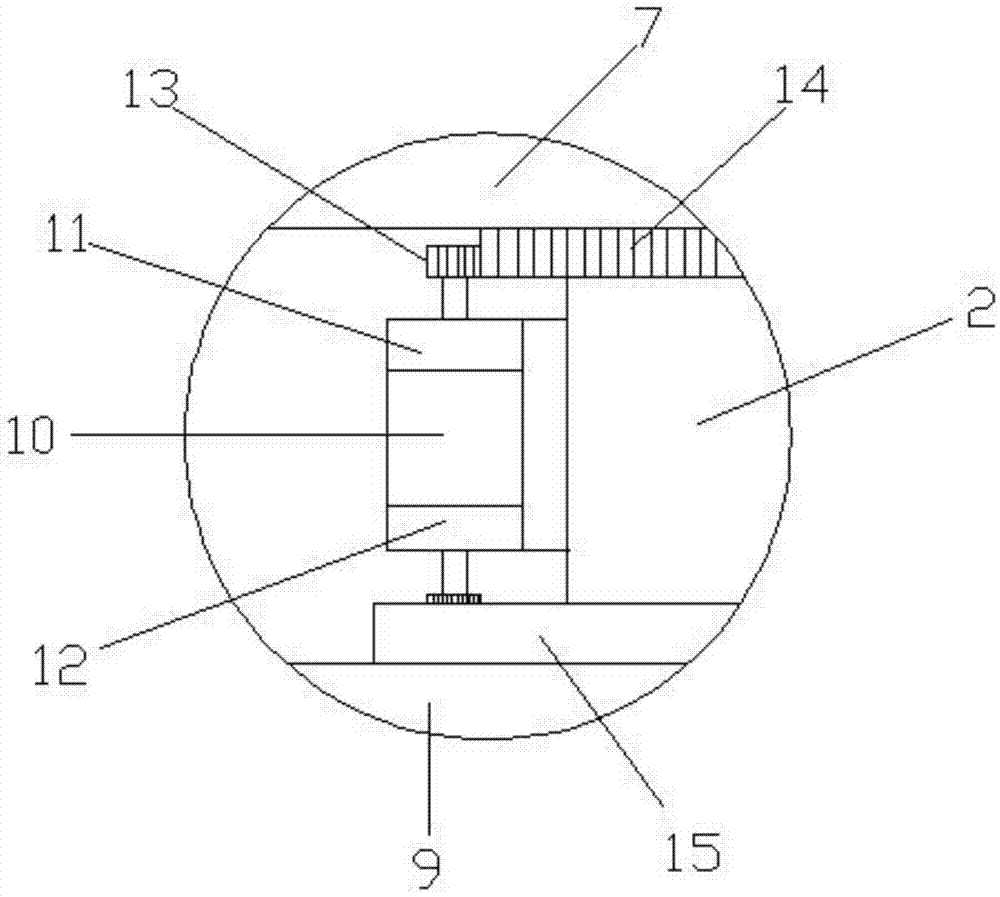

Tower crane structure with weight detection

ActiveCN104843600AEnsure connection stabilityEasy to useCranesLoad-engaging elementsEngineeringTower crane

The invention relates to the technical field of engineering hoisting equipment and discloses a tower crane structure with weight detection. The tower crane structure comprises a base and a tower body vertically fixed on the base, wherein a suspension arm is arranged at the top of the tower body; a weight base block and a winch are arranged at one end of the suspension arm; the other end of the suspension arm is provided with a pulley; a steel rope on the winch winds around the pulley to be connected with the suspension arm; a hook is arranged under the steel rope; a rotary table is arranged in the middle of the suspension arm and is rotationally connected with the top of the tower body; the pulley is provided with a connection shaft; the bottom of the hook is provided with a connection plate; a supporting ring is arranged at the outer end of the connection plate; a cover plate is arranged at the outer end of the supporting ring; a central hole is formed in the center of the cover plate; the outer end of the connection shaft is provided with an anti-releasing baffle; a pressure sensor is arranged between the anti-releasing baffle and the inner end of the cover plate; and the outer end of the cover plate is provided with an alarm lamp connected with the pressure sensor. The tower crane structure can be used for detecting the weight of objects in real time so that whether the tension of an object on the steel rope is in a steel rope load range or not is judged and the utilization is relatively safe.

Owner:上海水纹信息科技有限公司

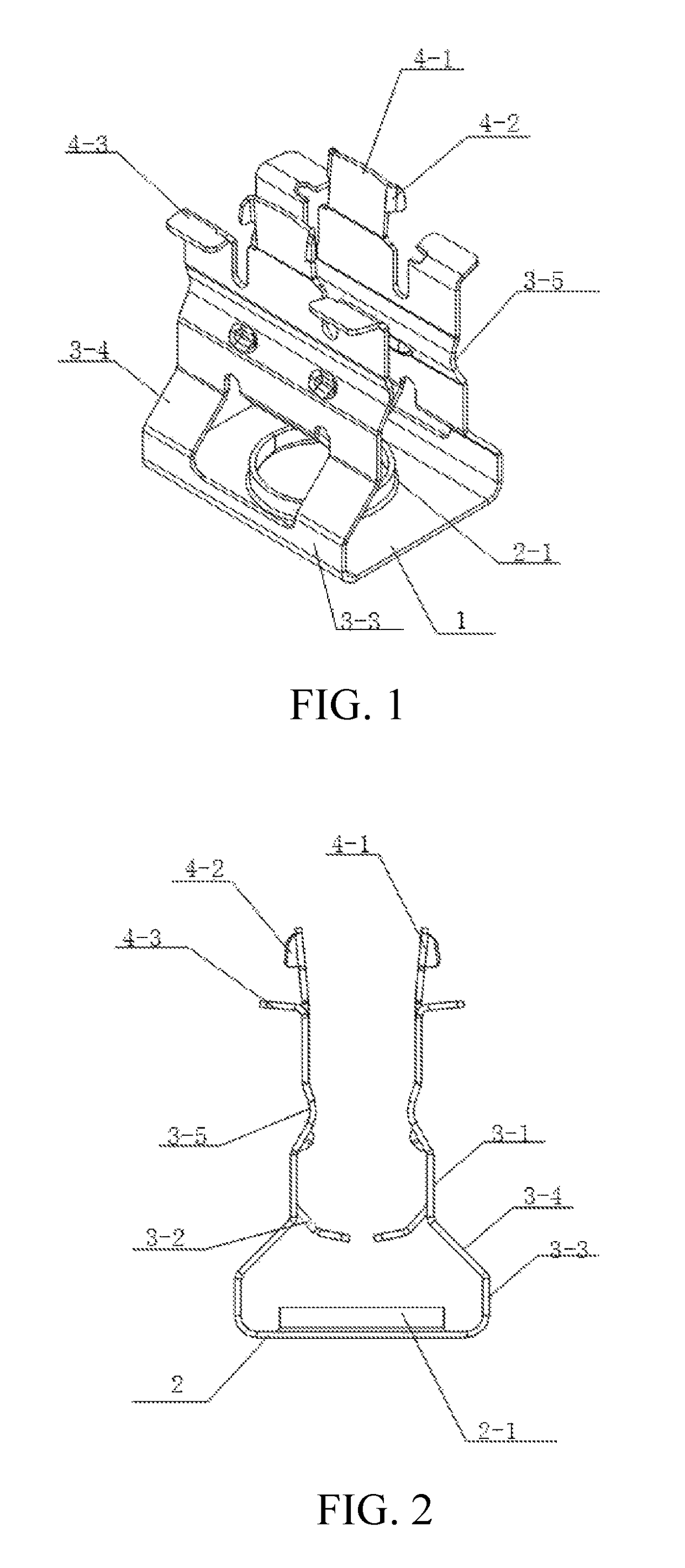

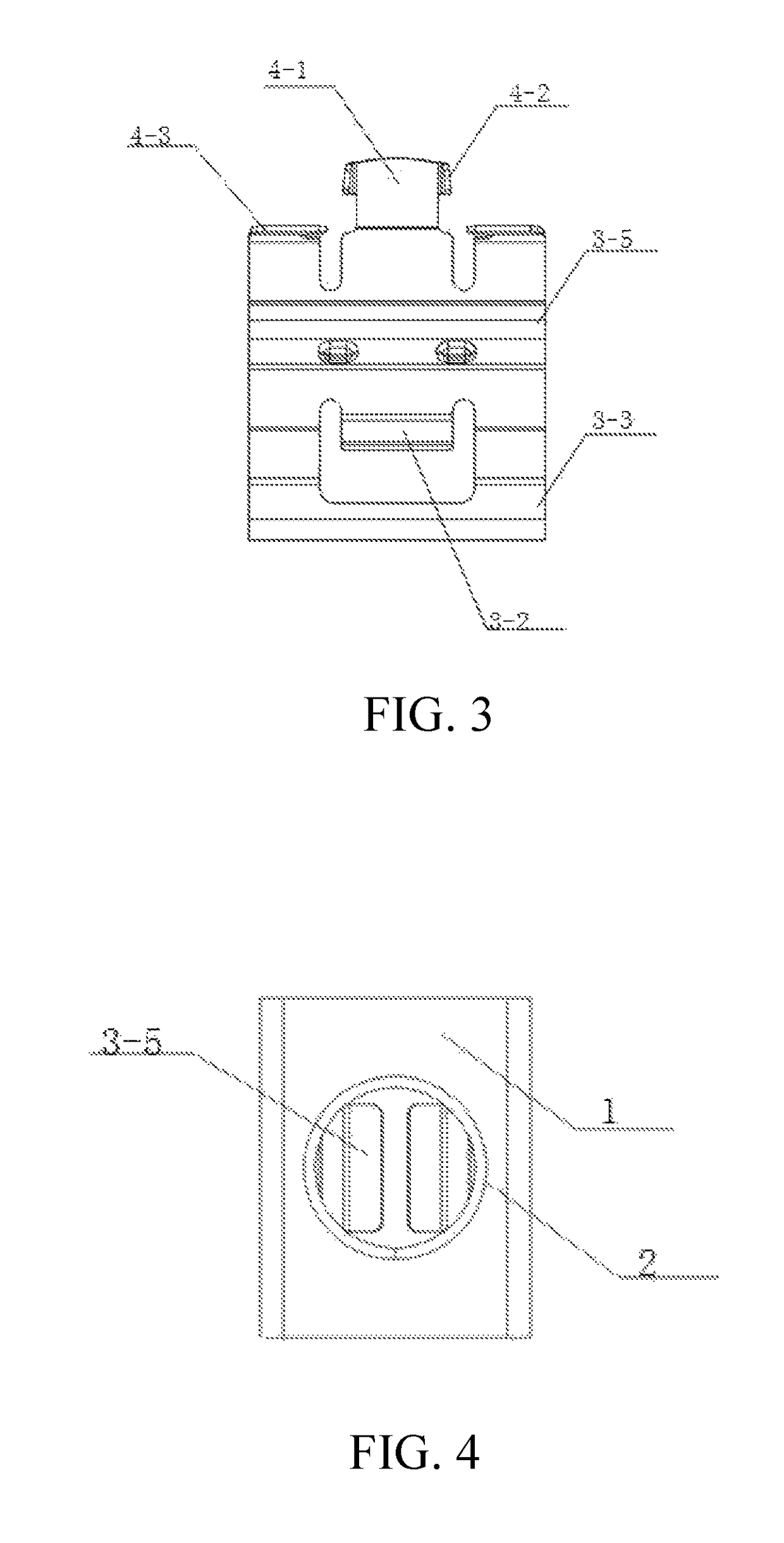

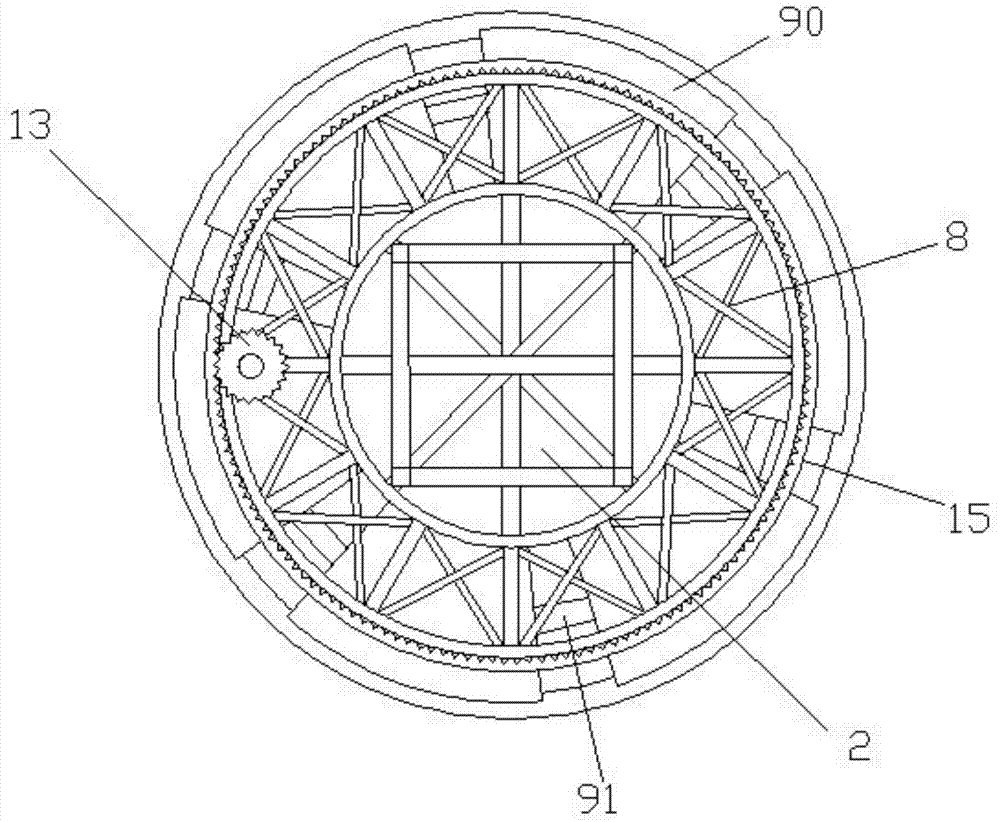

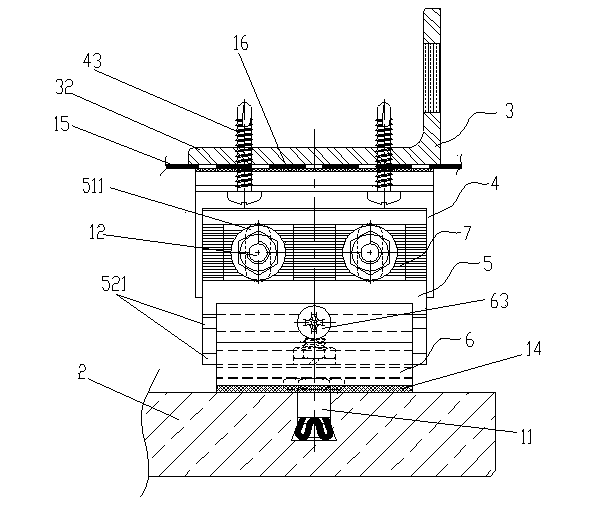

Split series solar junction box

InactiveCN102118011AImprove cooling effectStable jobPhotovoltaicsPhotovoltaic energy generationAdhesiveEngineering

The invention discloses a split series solar junction box which comprises a base and a box body, wherein the base and the box body are connected and are made from heat conduction materials; multiple groups of terminal blocks are distributed in parallel between the base and the box body; and every two terminal blocks are connected through one or multiple diodes so as to perform a bypass protection function. Each terminal block is correspondingly connected with a bus bar on a solar component, and the terminal block and the diode are encapsulated by heat conductive adhesives. According to the junction box disclosed by the invention, the radiating effect of the junction box is enhanced, a solar photovoltaic cell component works more stably, and solar photovoltaic components with different power adopt the same junction boxes of three specifications, thereby being convenient in production and management.

Owner:JIANGSU SHANGKUN BIOLOGICAL EQUIP

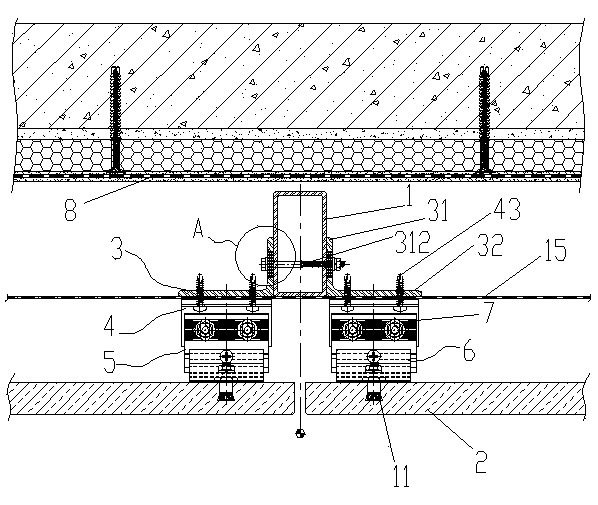

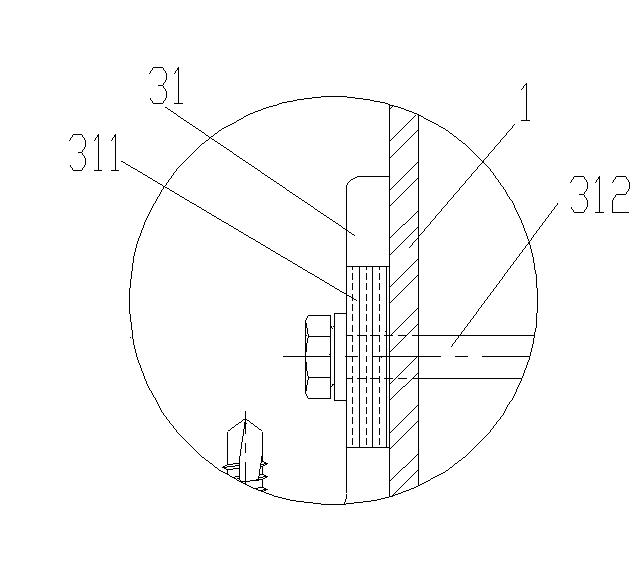

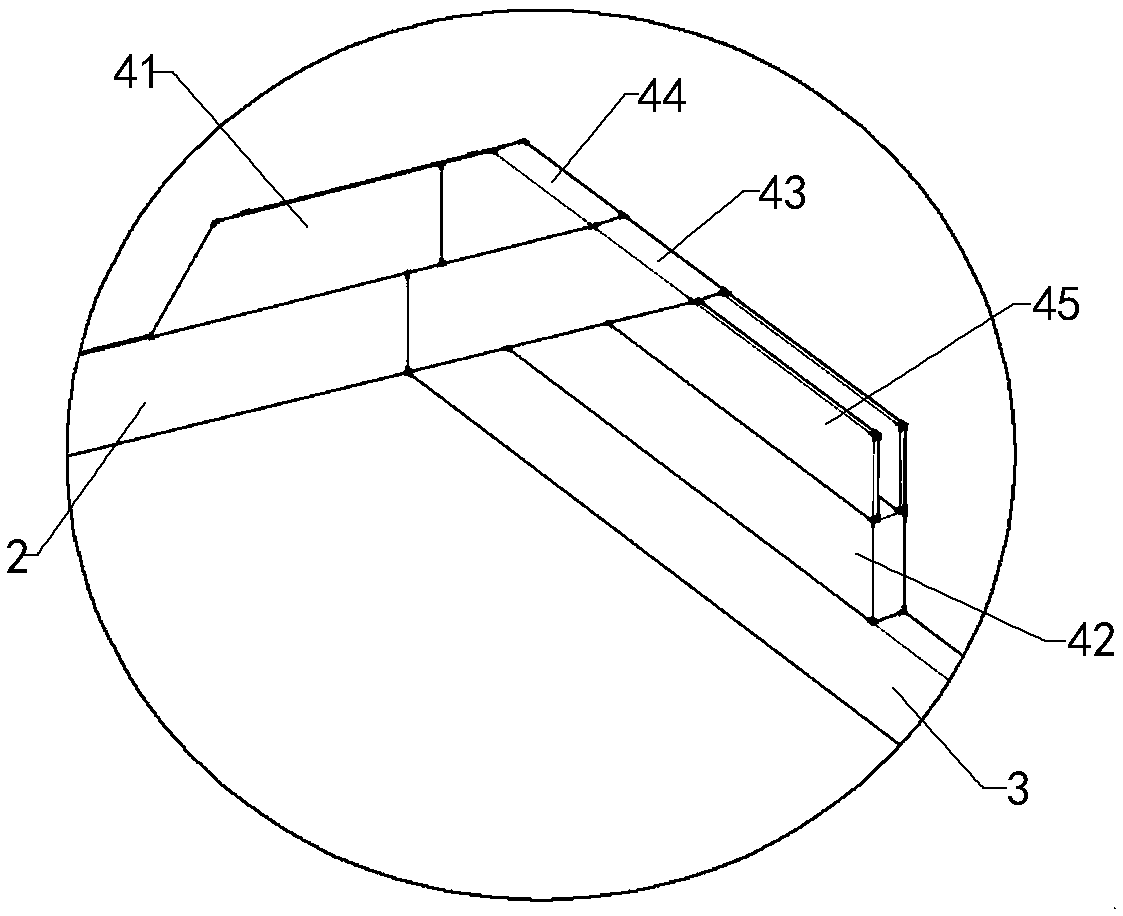

Back-bolt type dry-hang curtain wall system

The invention relates to a back-bolt type dry-hang curtain wall system. The back-bolt type dry-hang curtain wall system comprises a panel, a stand column arranged on the back face of the panel, and dry-hang assemblies used for connecting the panel with the stand column, wherein each dry-hang assembly comprises a back bolt piece connected with the panel. The back-bolt type dry-hang curtain wall system is characterized in that at least one side of the stand column is provided with L-shaped supporting pieces, each L-shaped supporting piece comprises a first sheet portion and a second sheep portion, each first sheet portion is perpendicular to the corresponding second sheet portion, the first sheet portions are connected with the stand column, and the second sheet portions are connected with the dry-hang assemblies. According to the back-bolt type dry-hang curtain wall system, traditional beams are replaced by the L-shaped supporting pieces, consumed materials are greatly saved on the basis that connection stability is ensured, and cost is reduced. The back-bolt type dry-hang curtain wall system is particularly suitable for panel plates based on transverse mesh division, namely, panel plates with the transverse size larger than the vertical size, and the material saving effect is better. By means of the special structure design of the L-shaped supporting pieces, a support and hook supports, the position of the panel can be adjusted in the corresponding direction and even in the three-dimensional direction, construction and installation can be more conveniently and more flexibly conducted, and the installation position is more accurate.

Owner:苏州苏明装饰股份有限公司

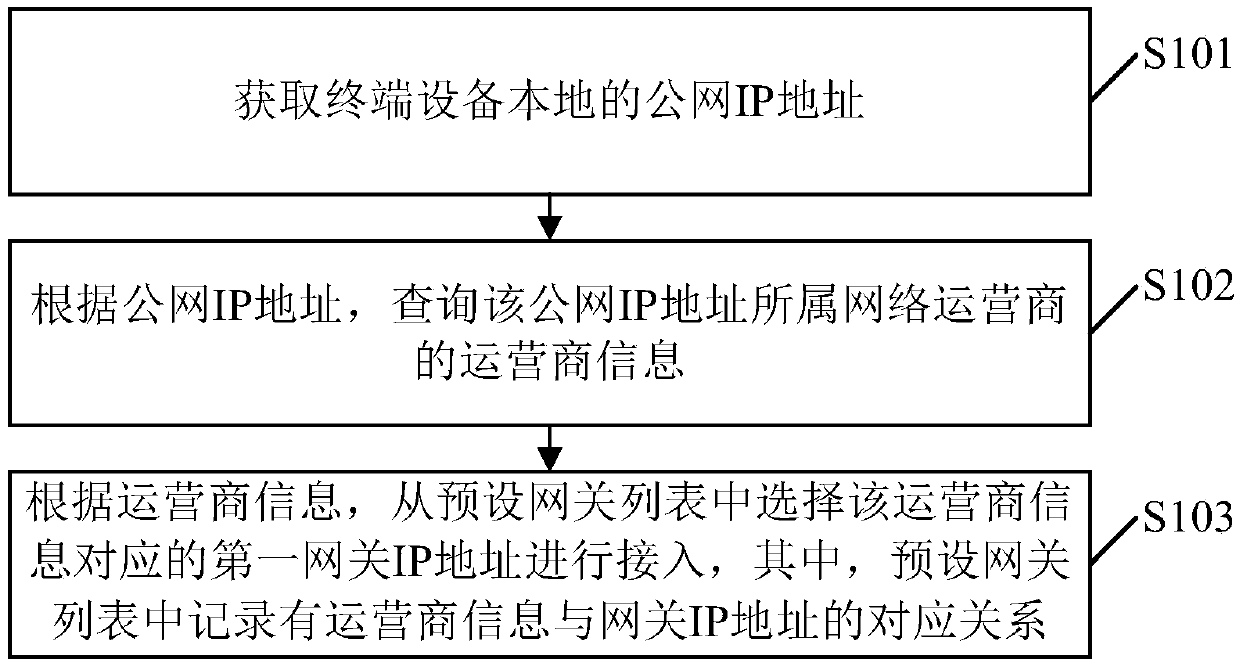

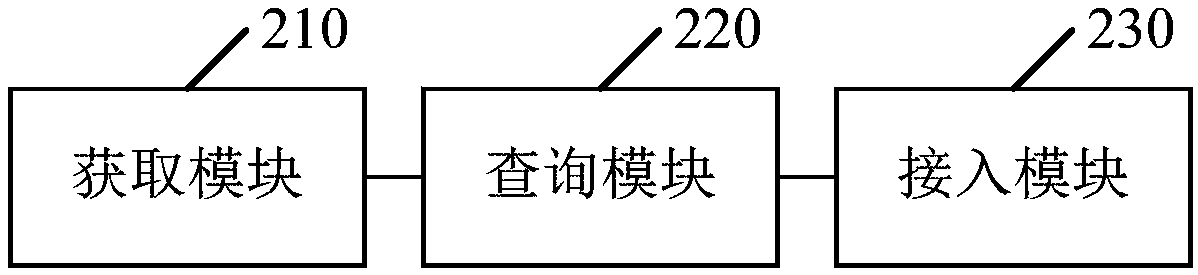

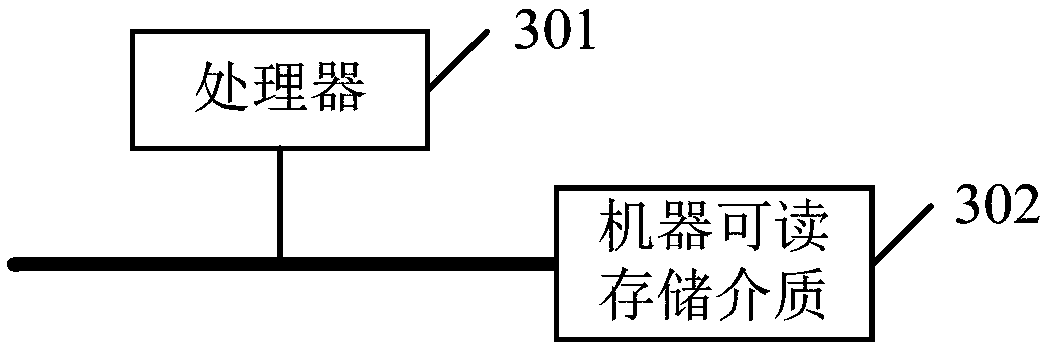

Network access method and device, terminal equipment and machine readable storage medium

InactiveCN109617780AQuality improvementAvoid accessAssess restrictionNetworks interconnectionAccess methodIp address

Embodiments of the invention provide a network access method and device, a client and a machine readable storage medium. A local public network IP address of terminal equipment is obtained; accordingto the public network IP address, operator information of a network operator to which the public network IP address belongs is inquired; and according to the operator information, a first gateway IP address corresponding to the operator information is selected from a preset gateway list to carry out access, wherein a corresponding relation between the operator information and the gateway IP address is recorded in the preset gateway list. Through the scheme, the network quality is improved.

Owner:NEW H3C TECH CO LTD

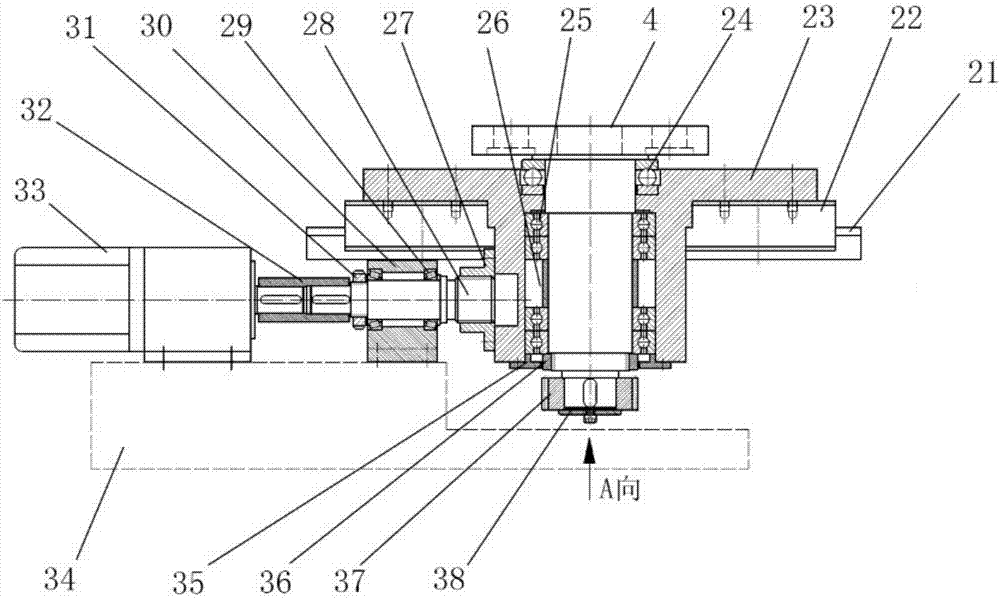

Bending forming device for multiplanar tube

PendingCN107511416AImprove surface qualityGuaranteed forming accuracyShaping toolsOperabilityEngineering

The invention discloses a bending forming device for a multiplanar tube. the device is characterized in that a Y-direction operating and controlling die set and an X-direction operating and controlling die are arranged, wherein the X-direction operating and controlling die is used for operating and controlling a bending die to move along an Ox axis and rotate around an Oy axis; the Y-direction operating and controlling die set is used for operating the bending die to move along the Oy axis and rotating around the Ox shaft; the X-direction operating and controlling die set is fixed to the Y-direction operating and controlling die set; the bending die can randomly move and be correspondingly rotated and positioned in the xOy by movement composition. According to the device, the technical parameters are conveniently and simply set; the operability is improved; the axis of the bending die is vertical to the axis of a pipe blank during the bending process, so that the resistance is small, and as a result, the surface quality of a formed tube can be improved; in case that the bending die does not move, the rotating degree of freedom is in a locking state, and thus the bending die can be accurately positioned, and the bent pipe forming accuracy can be ensured.

Owner:陕西合众联航科技有限公司

Energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance

ActiveCN107989515APlay a role in corrosion resistanceEffective shock absorptionClimate change adaptationWindow/door framesAdhesiveCorrosion resistant

The invention discloses an energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance and belongs to the field of energy-saving aluminum alloy doors and windows. The energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance comprises a vacuum window body, wherein the vacuum window body is connected to a wall,the periphery of the vacuum window body is fixedly connected with connecting profiles, and connecting slots corresponding to the connecting profiles are formed in the wall. Corrosion-resistant rubbergaskets can play a corrosion-resistant role and effectively realize buffering and shock absorption to improve the wind pressure resistance, every two rotating buffer plates are connected with on oblique buffer plate through buffer springs, effective buffering and shock absorption can be realized, the wind pressure resistance effect can be improved, an inflatable buffer air bag is arranged betweenevery two rotating buffer plates and sealed and fixedly connected to the vacuum window body and the corresponding corrosion-resistant rubber gasket respectively through an adhesive, a sealed space canbe formed to surround the connecting profiles, corrosion of the connecting profiles can be effectively prevented, effective buffering and shock absorption can be realized, and the wind pressure resistance capacity of the aluminum alloy door and window can be guaranteed.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

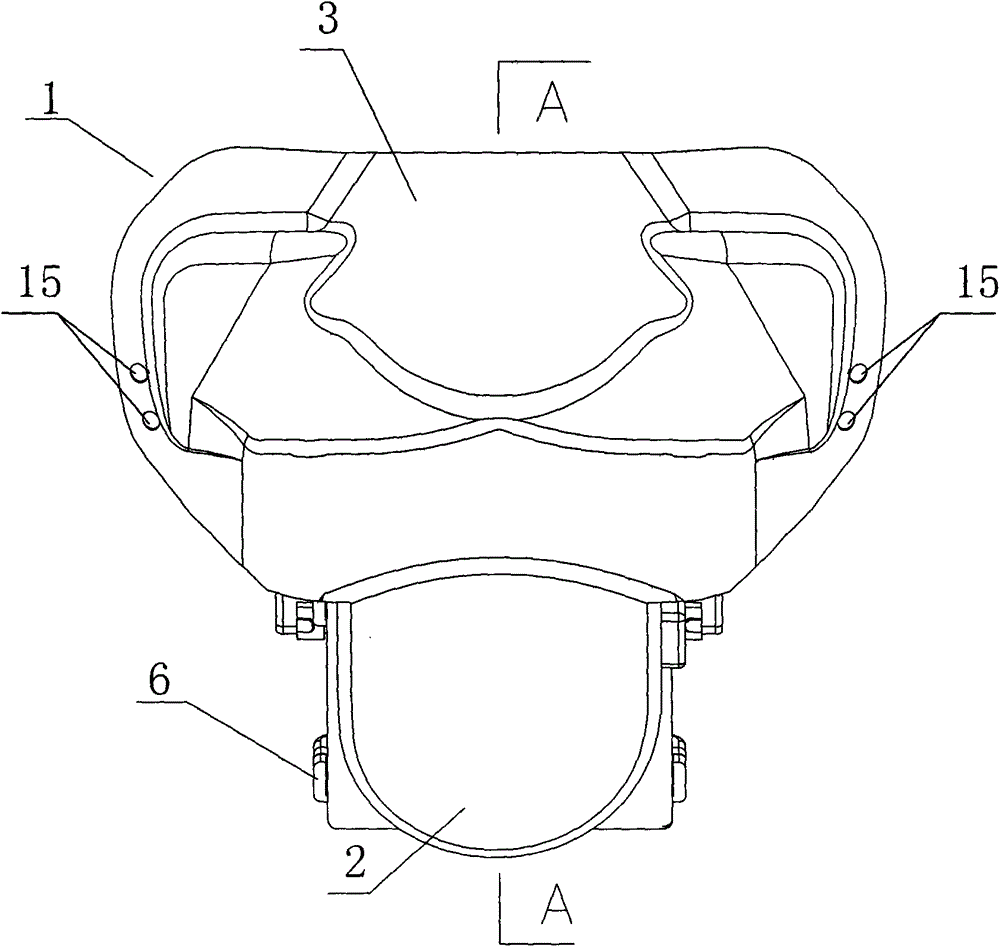

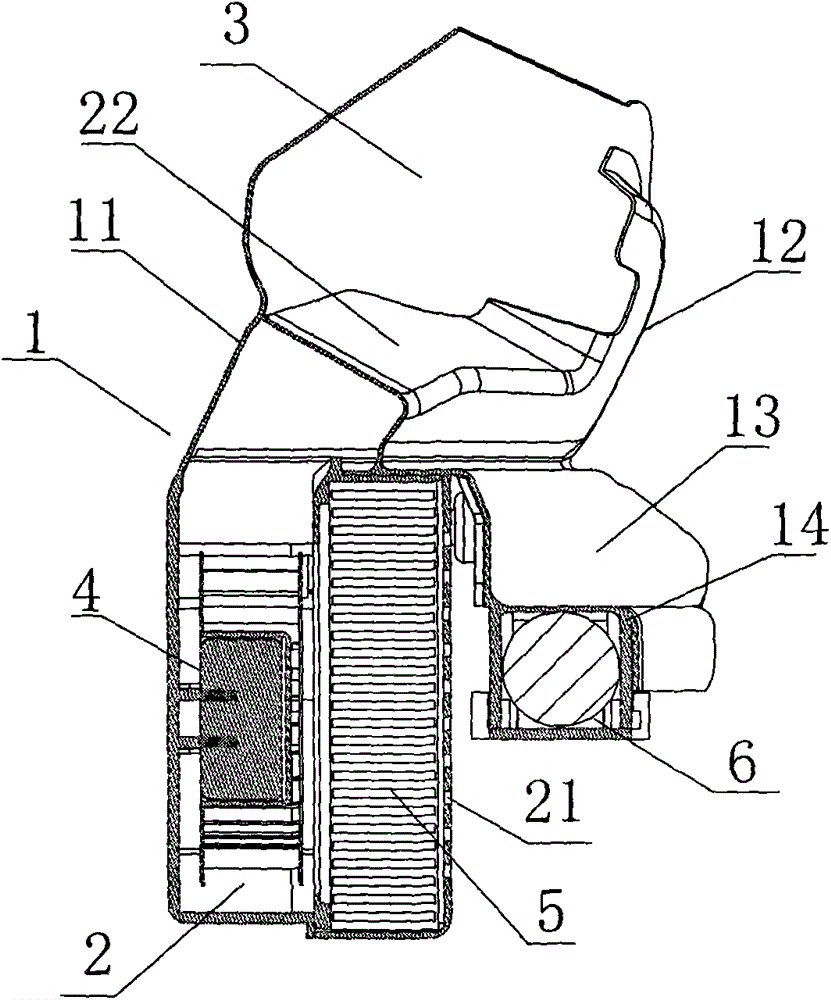

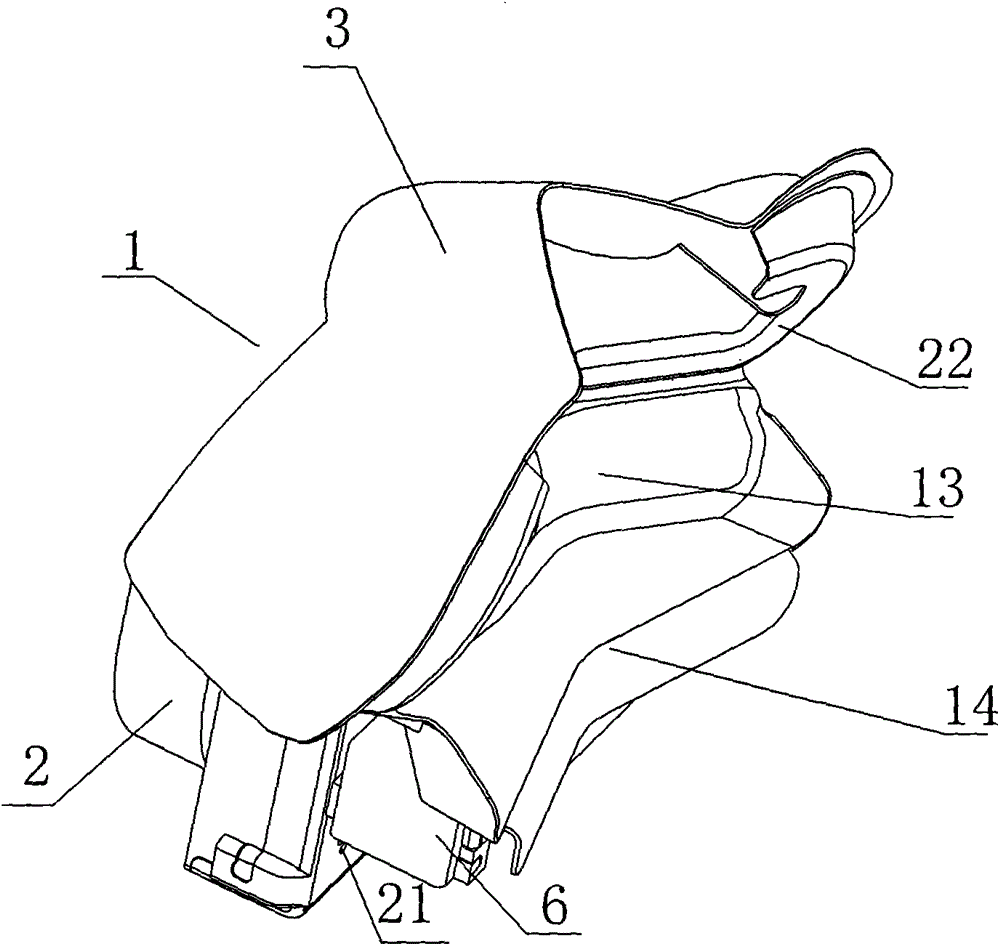

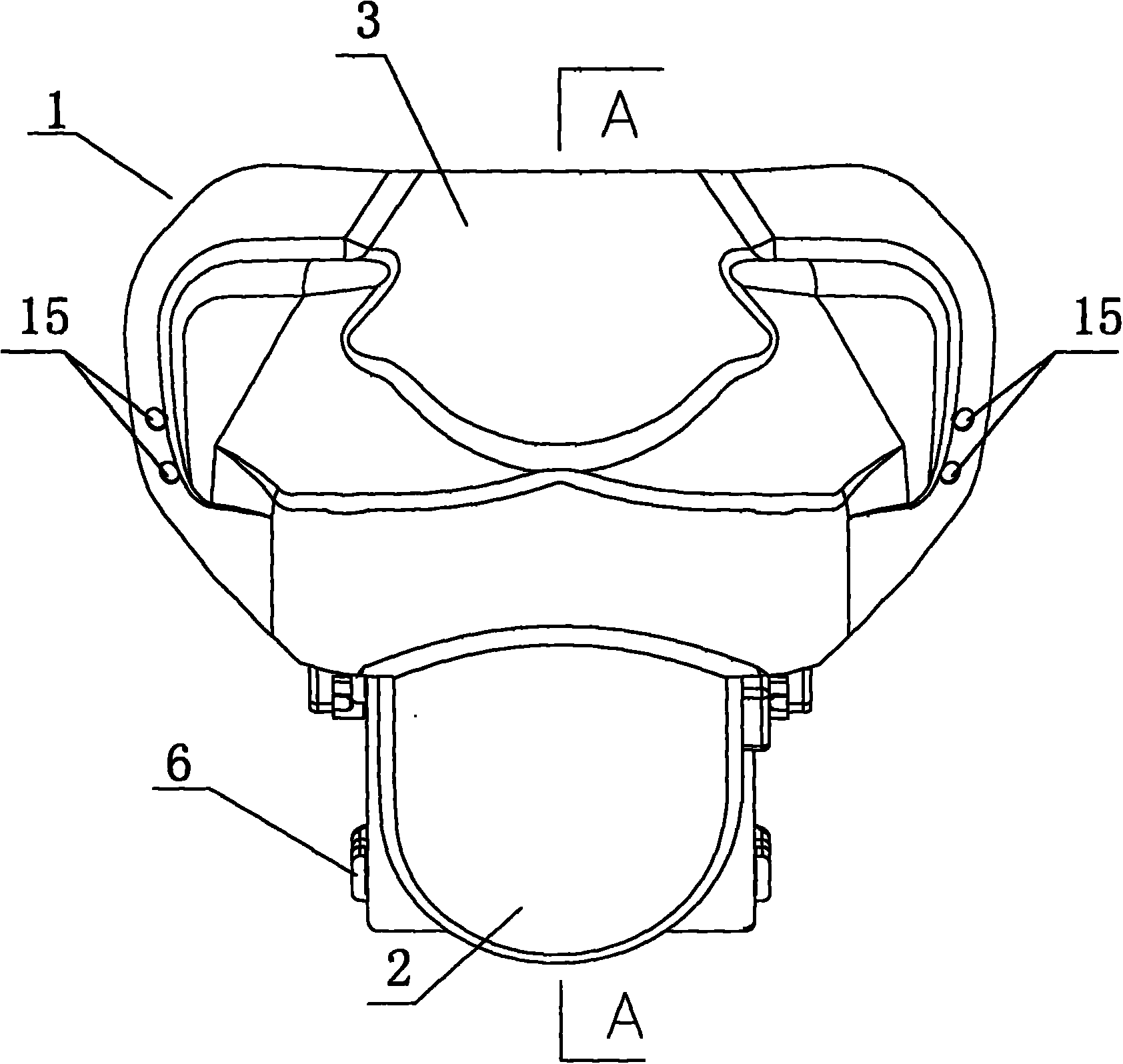

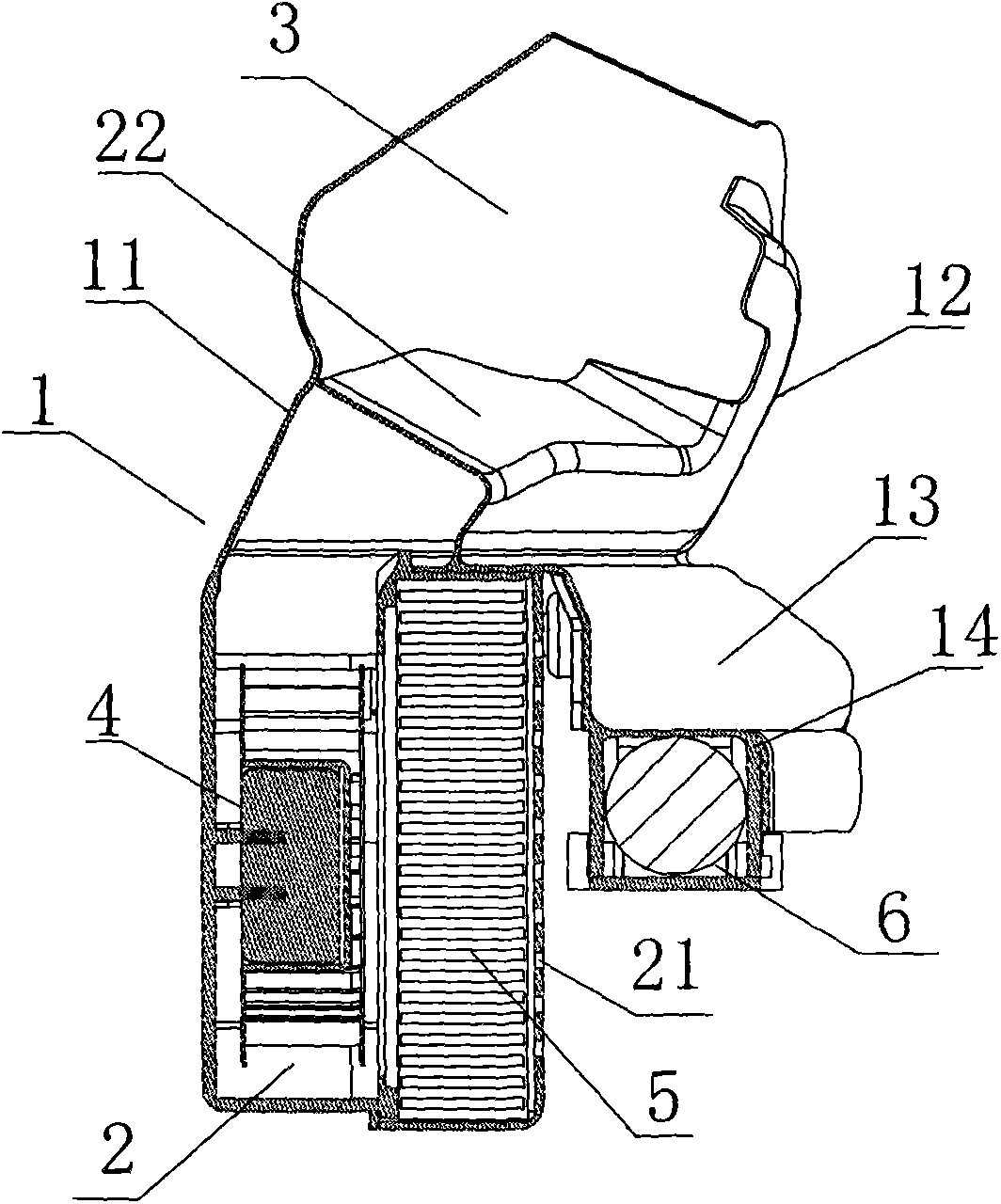

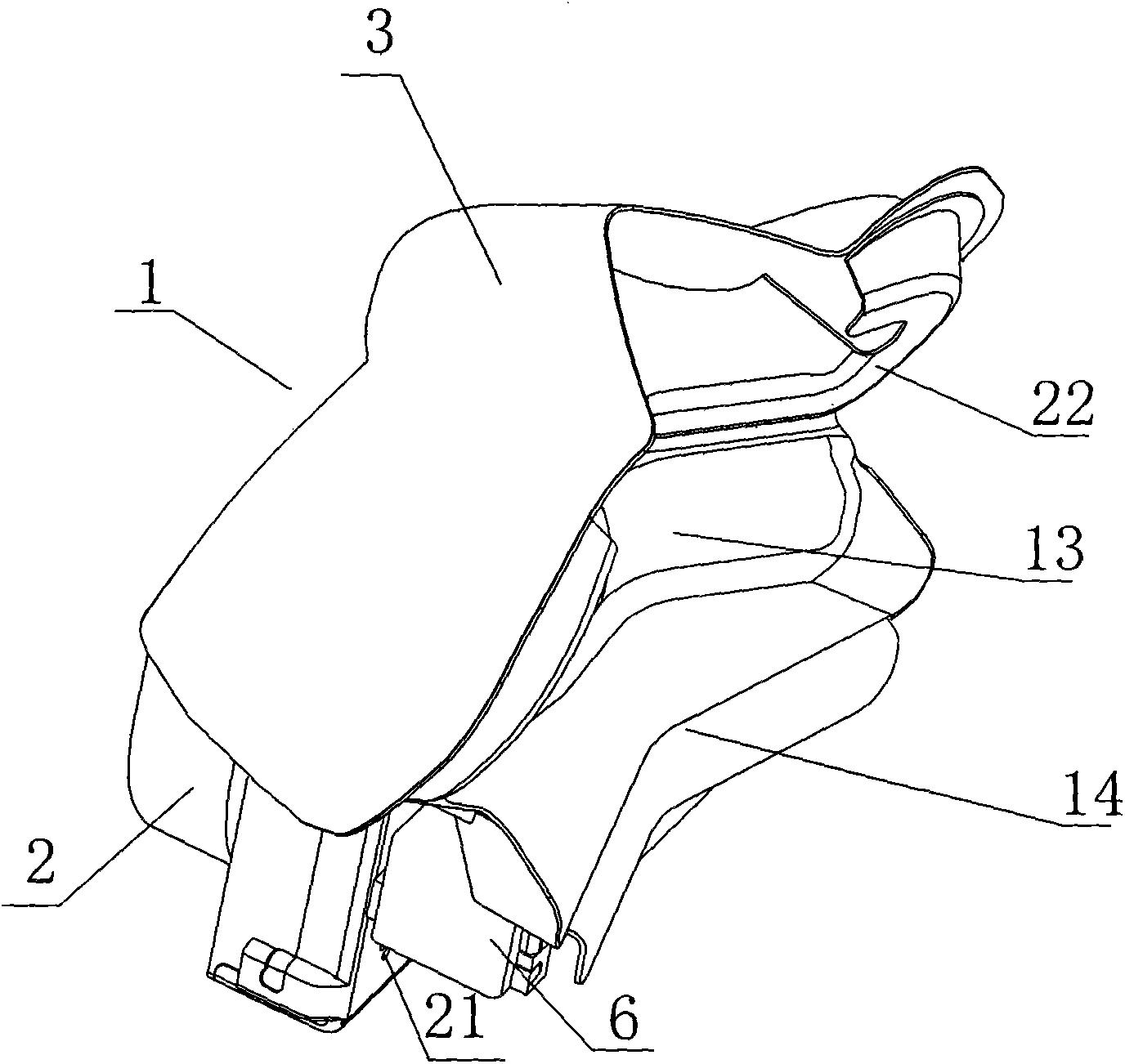

Active air supply mask

ActiveCN103919304BEnsure connection stabilityEnsure consistencyChemical protectionHeat protectionDirect currentWaste management

Owner:河源市乐正环保科技有限公司

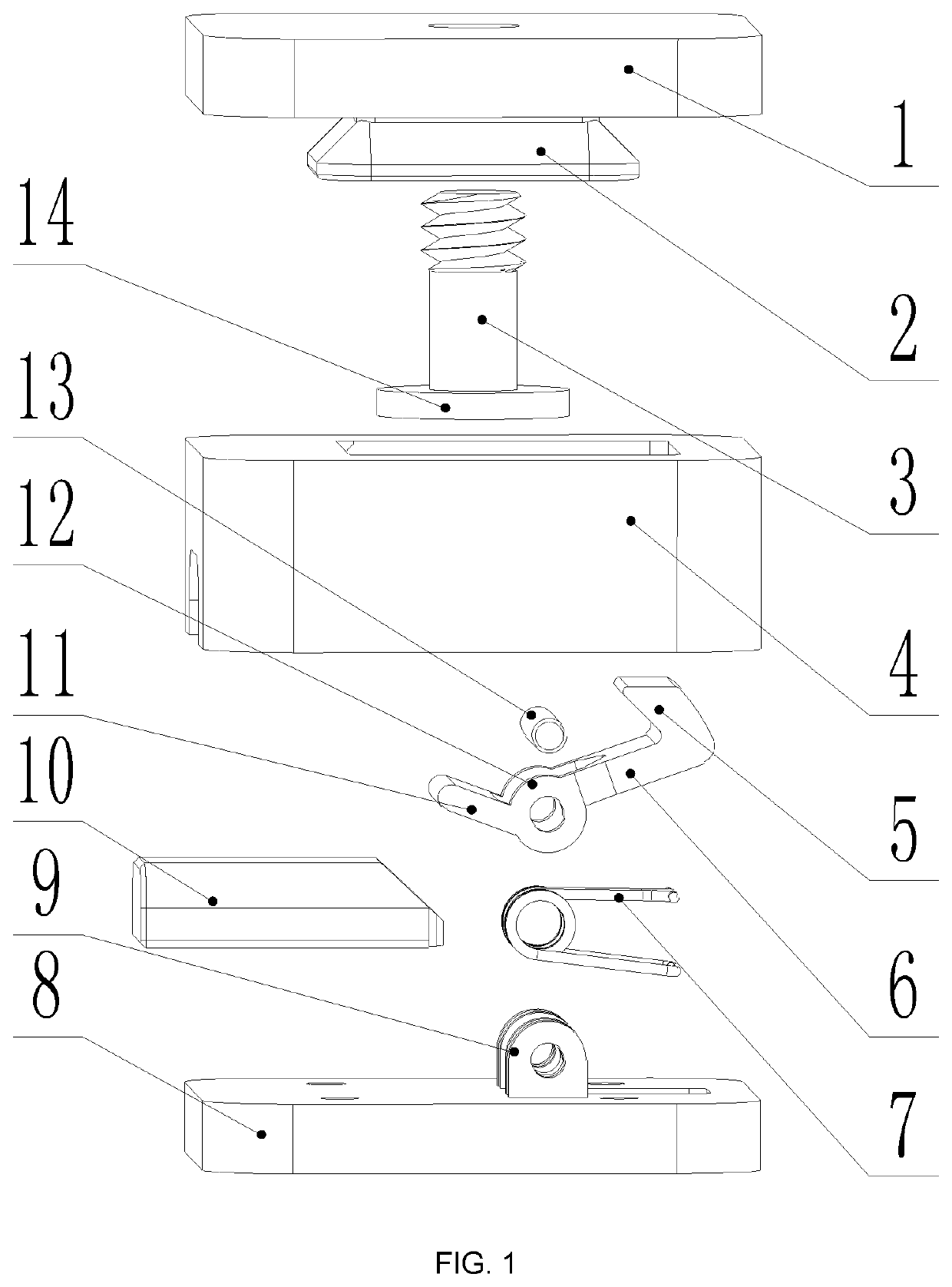

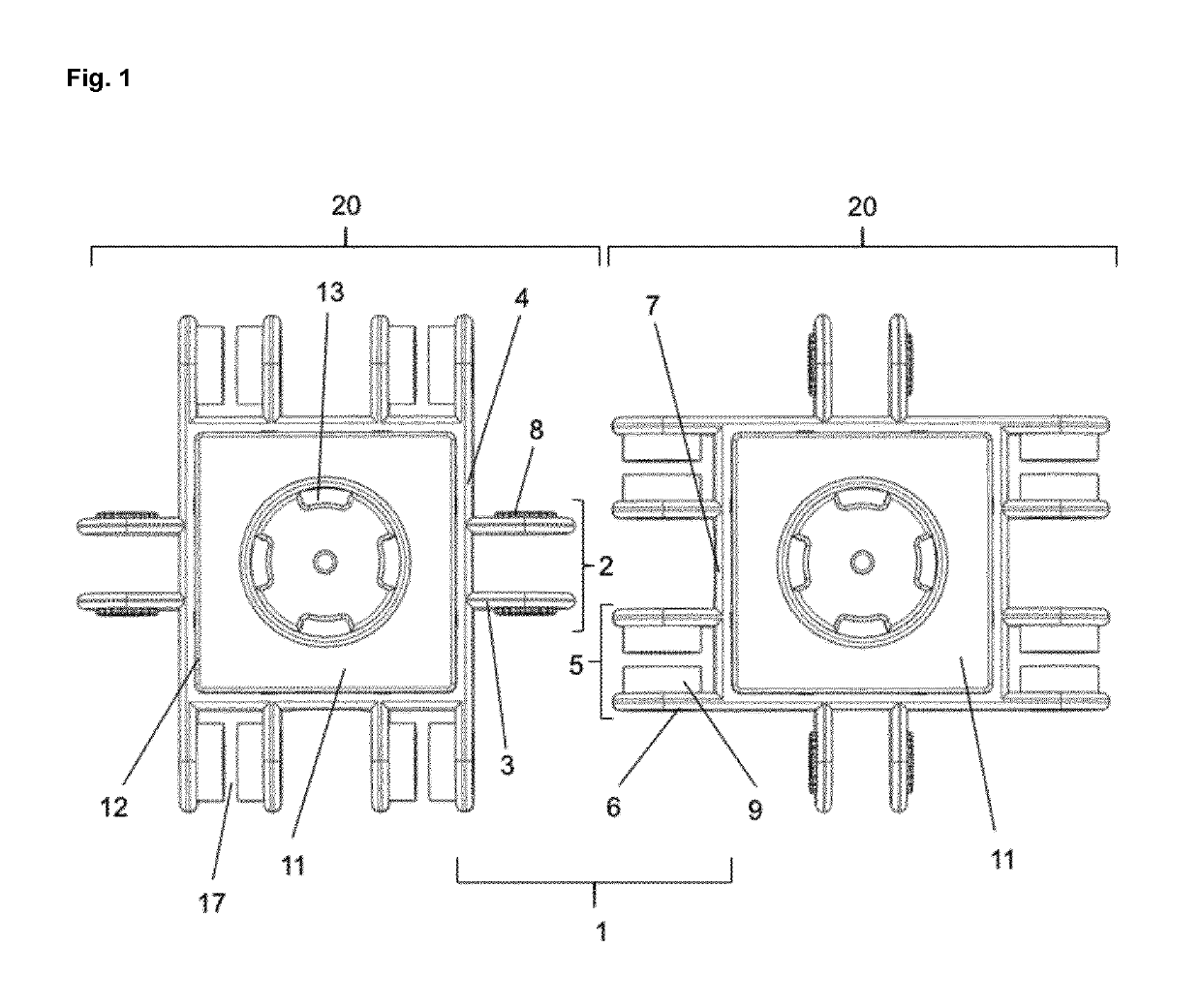

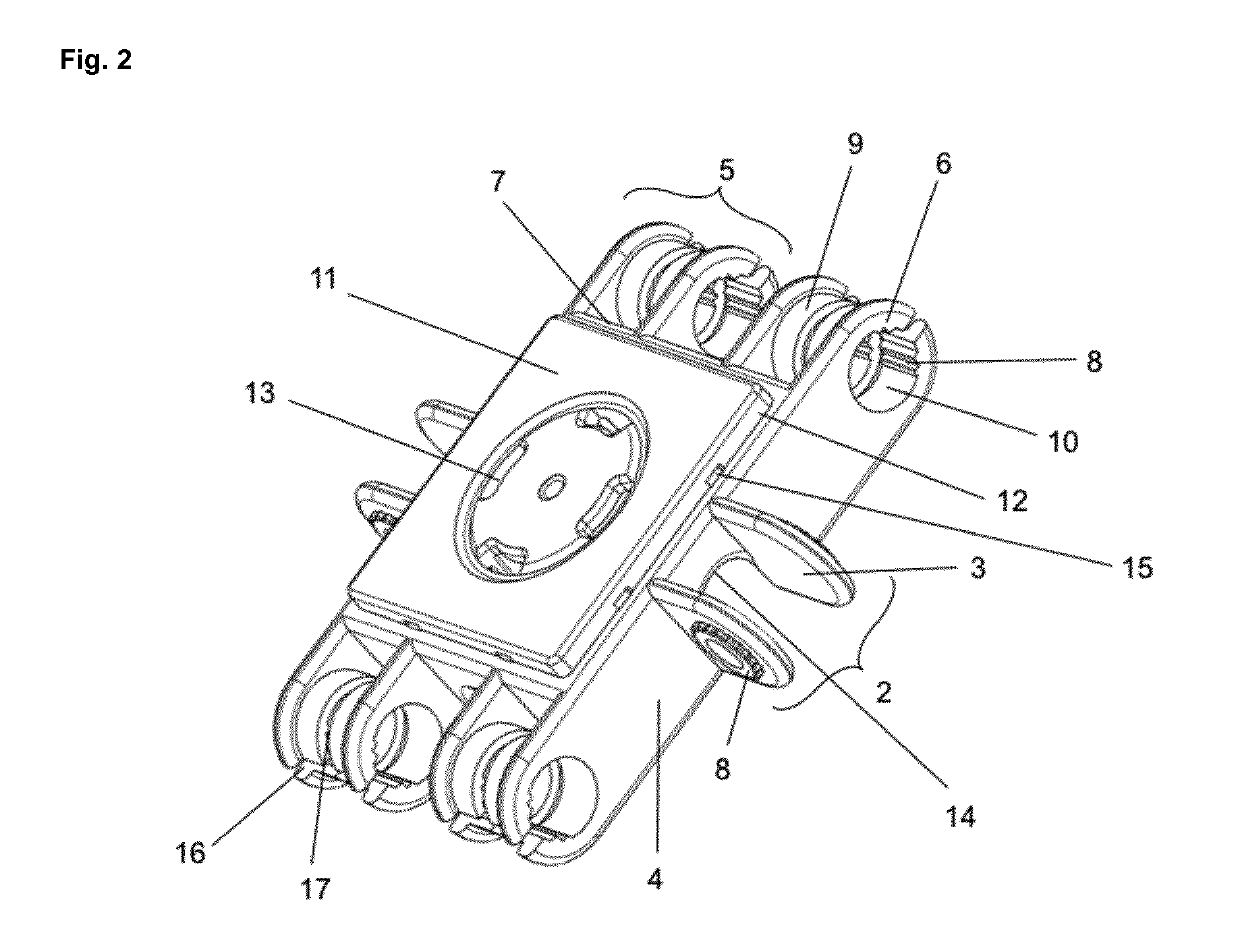

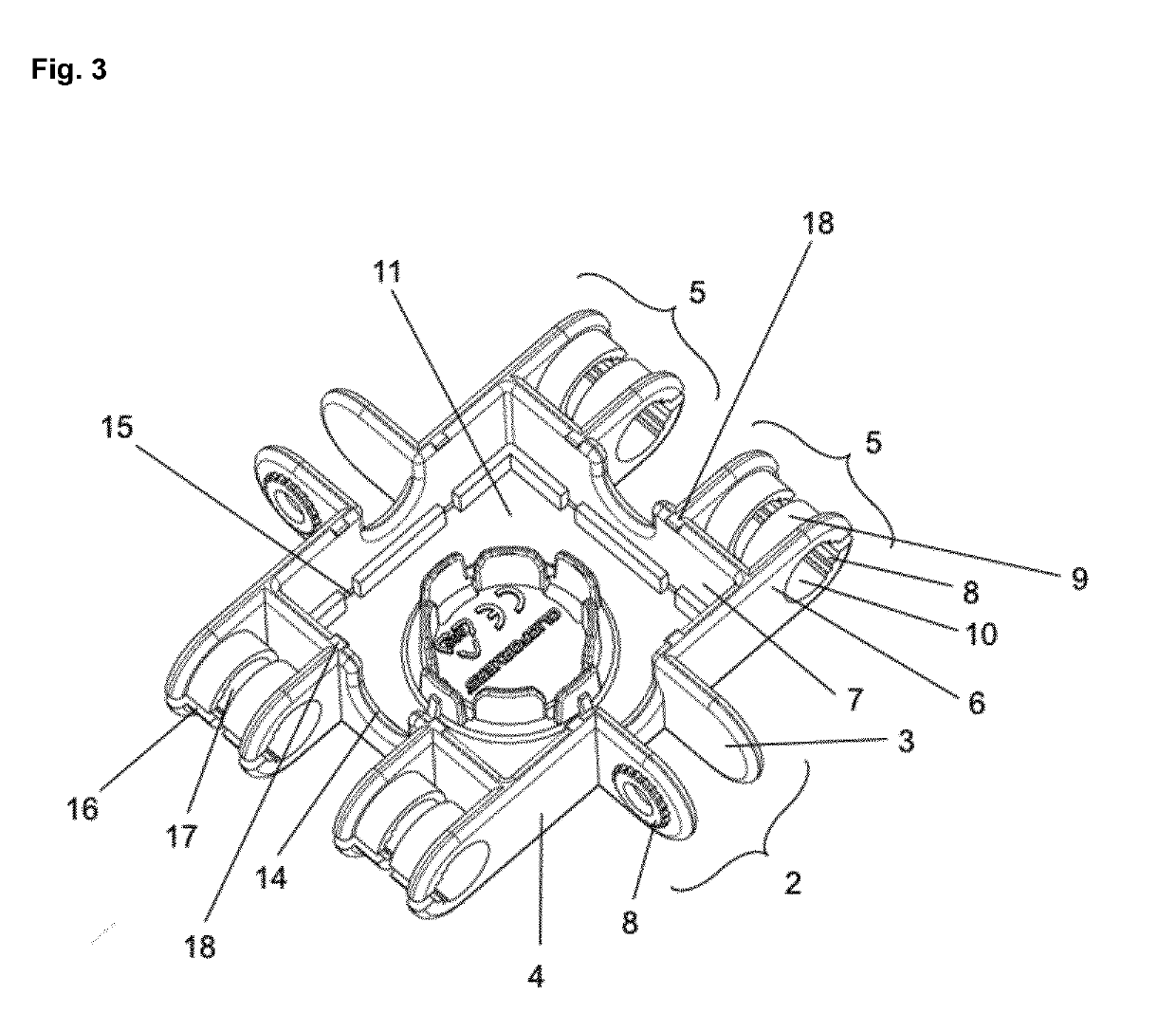

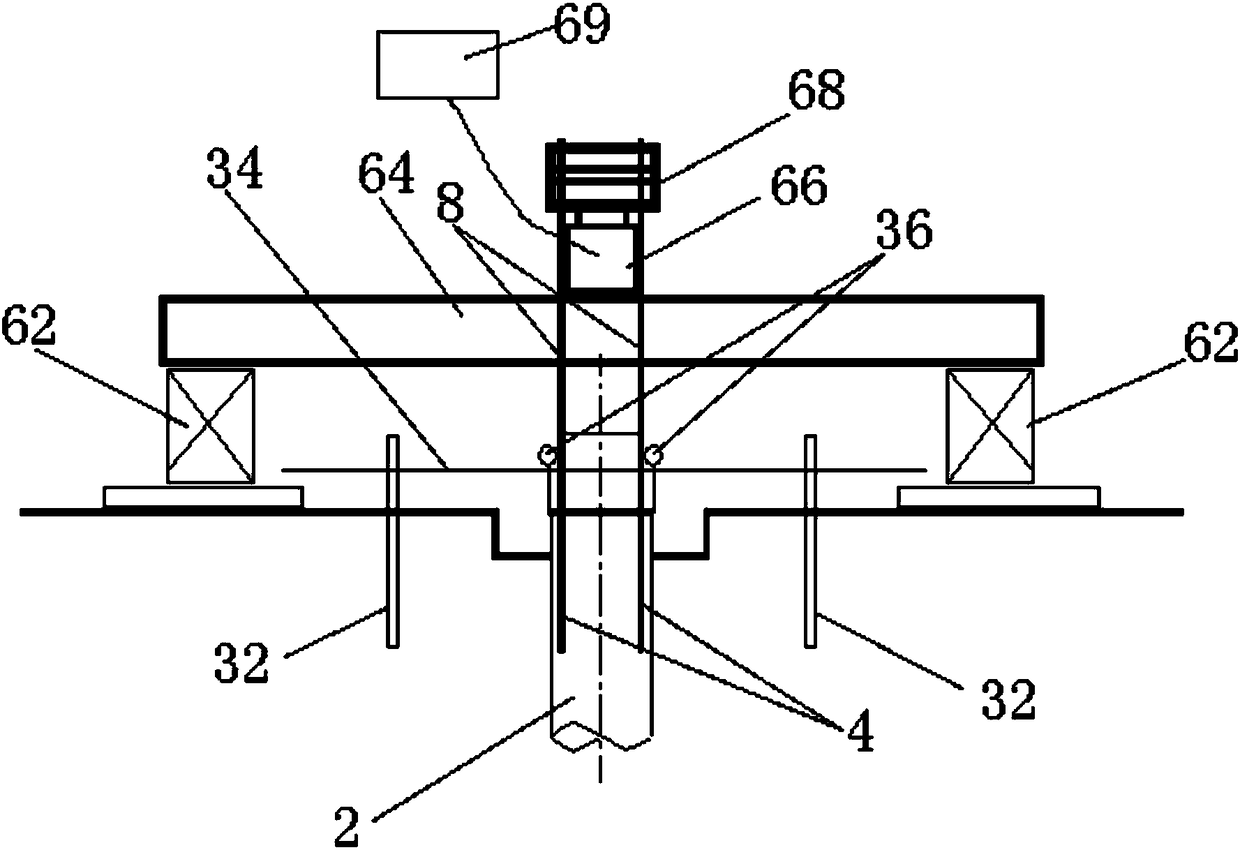

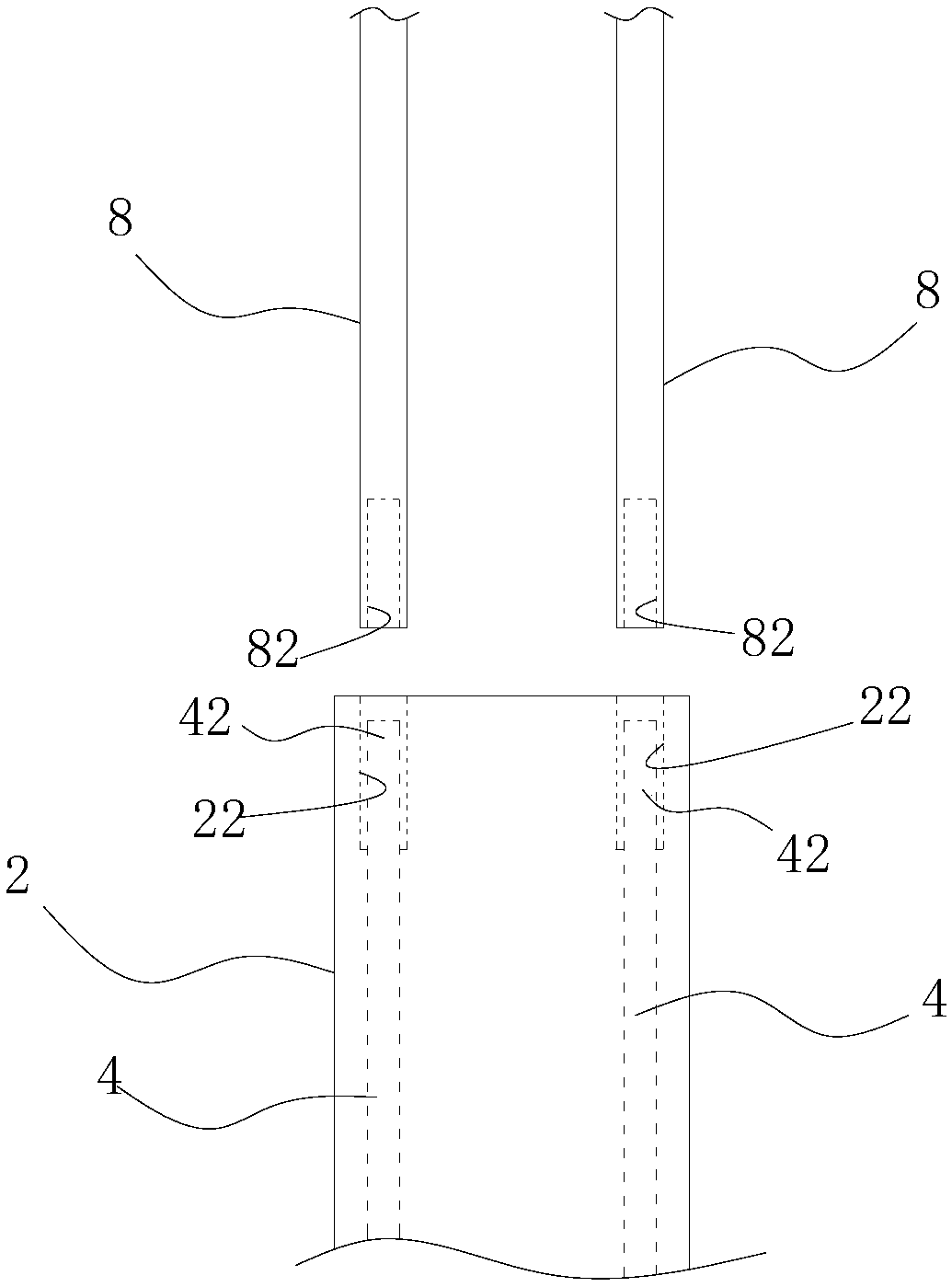

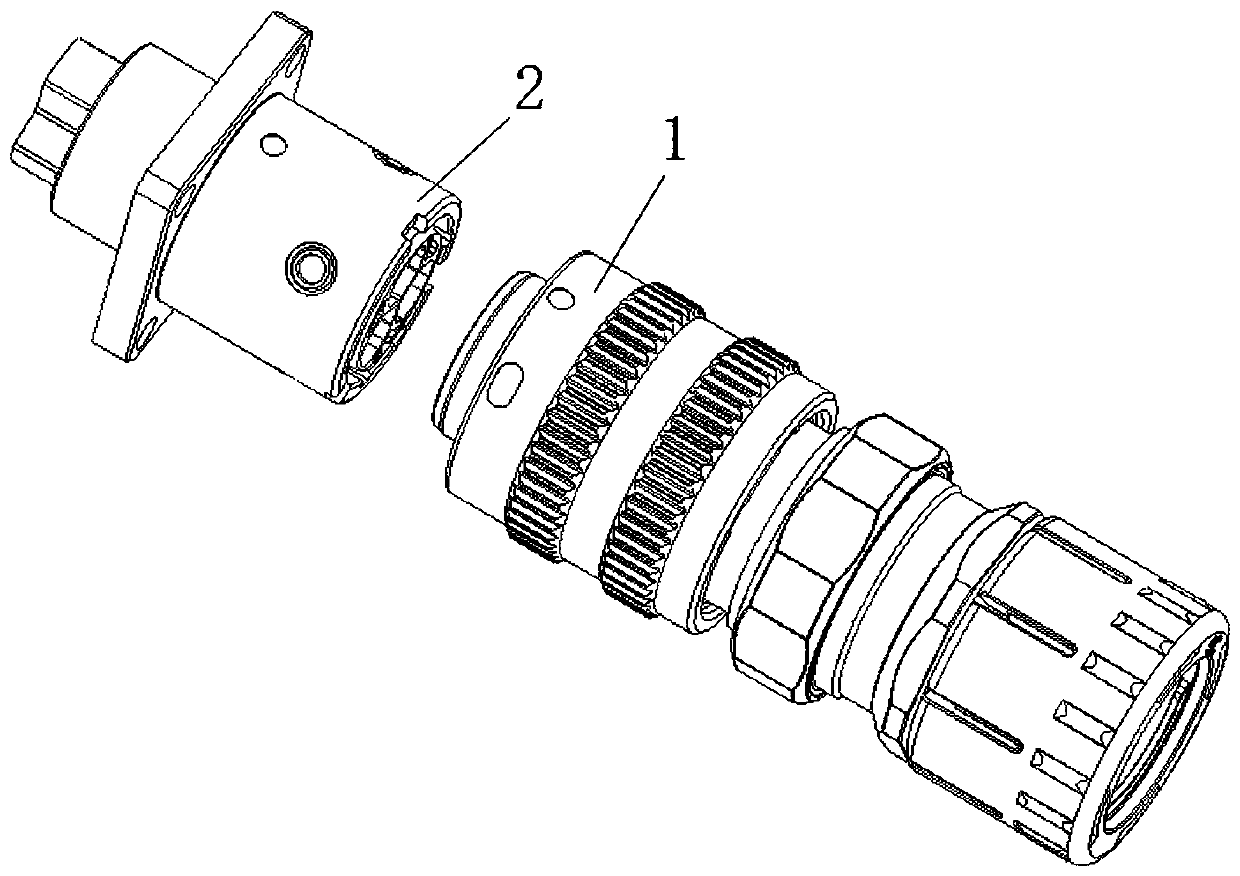

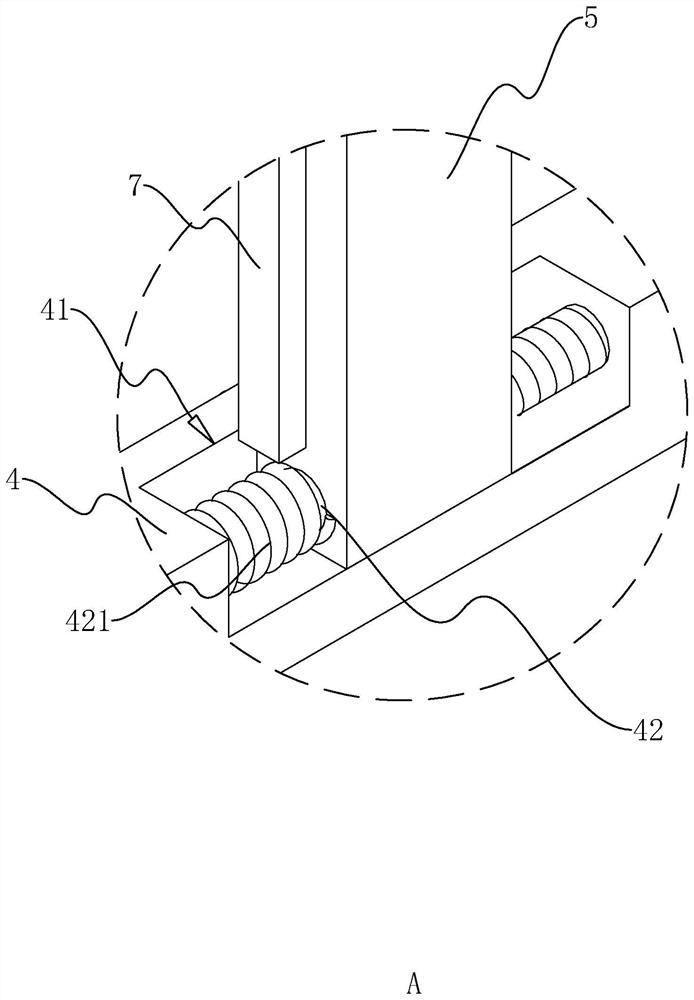

Quick Mounting Structure

ActiveUS20220214602A1Improve stabilityEnsure connection stabilityStands/trestlesCamera body detailsEngineeringMechanical engineering

The quick mounting structure includes a first connector, a second connector, and a self-locking mechanism; the self-locking mechanism is on the second connector, and the first connector is connected to the second connector through the self-locking mechanism; the self-locking mechanism includes a quick mounting block, a transmission arm, a locking block, a rotating shaft, and a first elastic member; the quick mounting block is connected to the first connector; the second connector is provided with a quick mounting groove, and all of the transmission arm, the locking block, the rotating shaft, and the first elastic member are arranged in the quick mounting groove; the transmission arm is rotationally connected to the second connector through the rotating shaft; the first elastic member is connected to the transmission arm or the locking block for enabling the locking block to be in a locked state in a normal state.

Owner:PGYTECH CO LTD

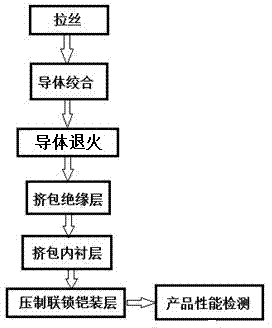

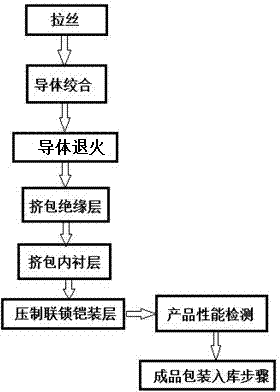

Manufacturing method for interlocked armored aluminum alloy flat cable

ActiveCN102969087APrevent disconnectionImprove conductivityFlat/ribbon cablesFlexible cablesElectrical conductorManufacturing technology

The invention discloses a manufacturing method for an interlocked armored aluminum alloy flat cable. According to the manufacturing technology, the manufacturing method comprises the following steps in sequence: drawing wires, stranding a conductor, annealing the conductor, extruding an insulating layer, extruding a lining layer, and pressing an interlocked armored layer, wherein the conductor annealing step comprises the steps: through boxcar type heating and annealing steps, heating the stranded conductor to 370-400 DEG C, lasting for 4-5 hours at the environment of 370-400 DEG C, and then naturally cooling to the room temperature; and the interlocked armored layer pressing step is that an aluminum alloy tape with the thickness of 0.5mm-0.6mm is arranged on the surface of the lining layer and pressed into a Z-shaped interlocked armored form with the arc-shaped height of 2mm-4mm according to pitches of 6mm-24mm. according to the manufacturing method, the conductivity property and creep property can be improved, the service life of the cable can be effectively prolonged, the system can have good radiating effect in short time under overload state, and can be ensured to run safely.

Owner:SICHUAN MINGXING CABLE

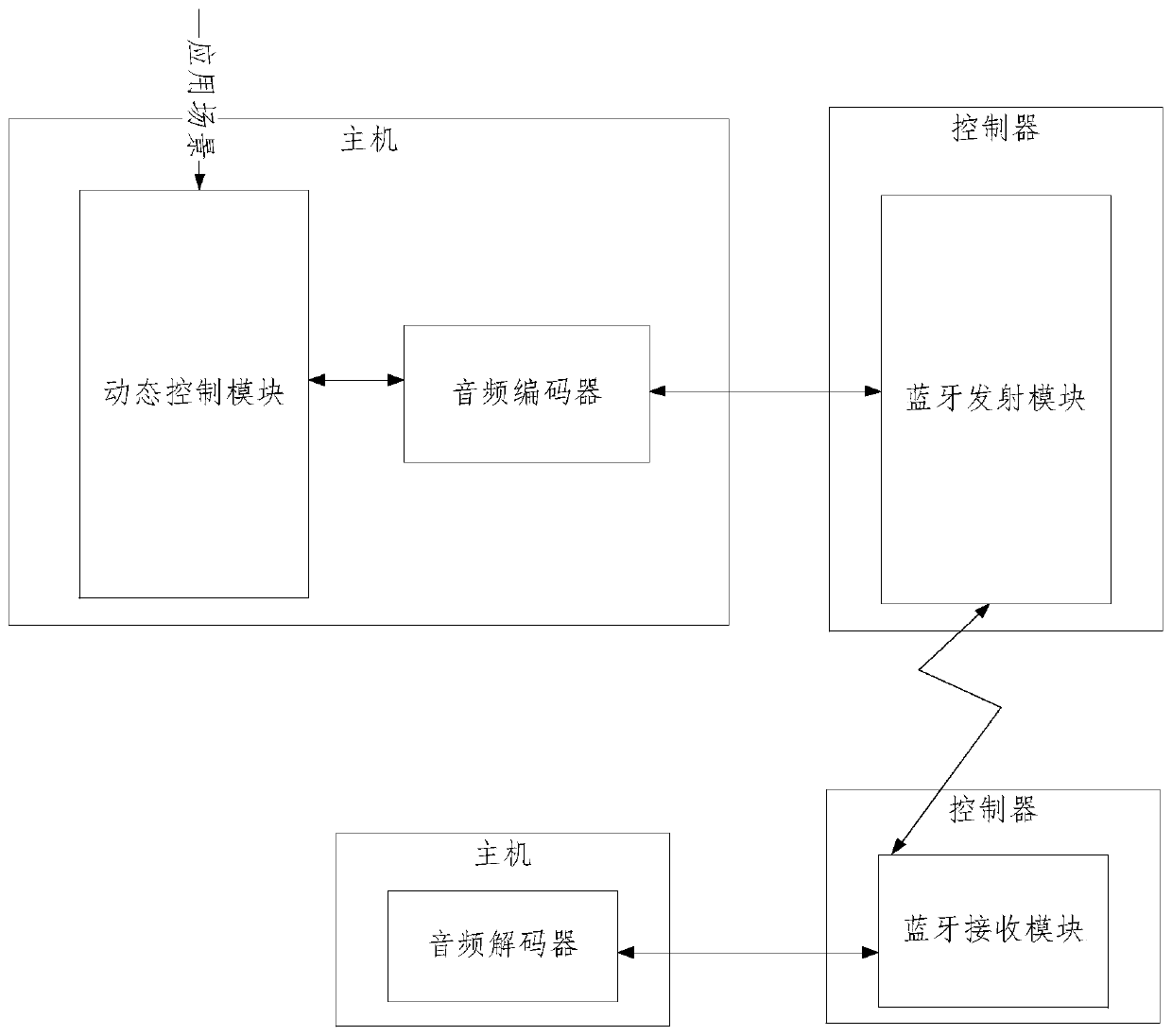

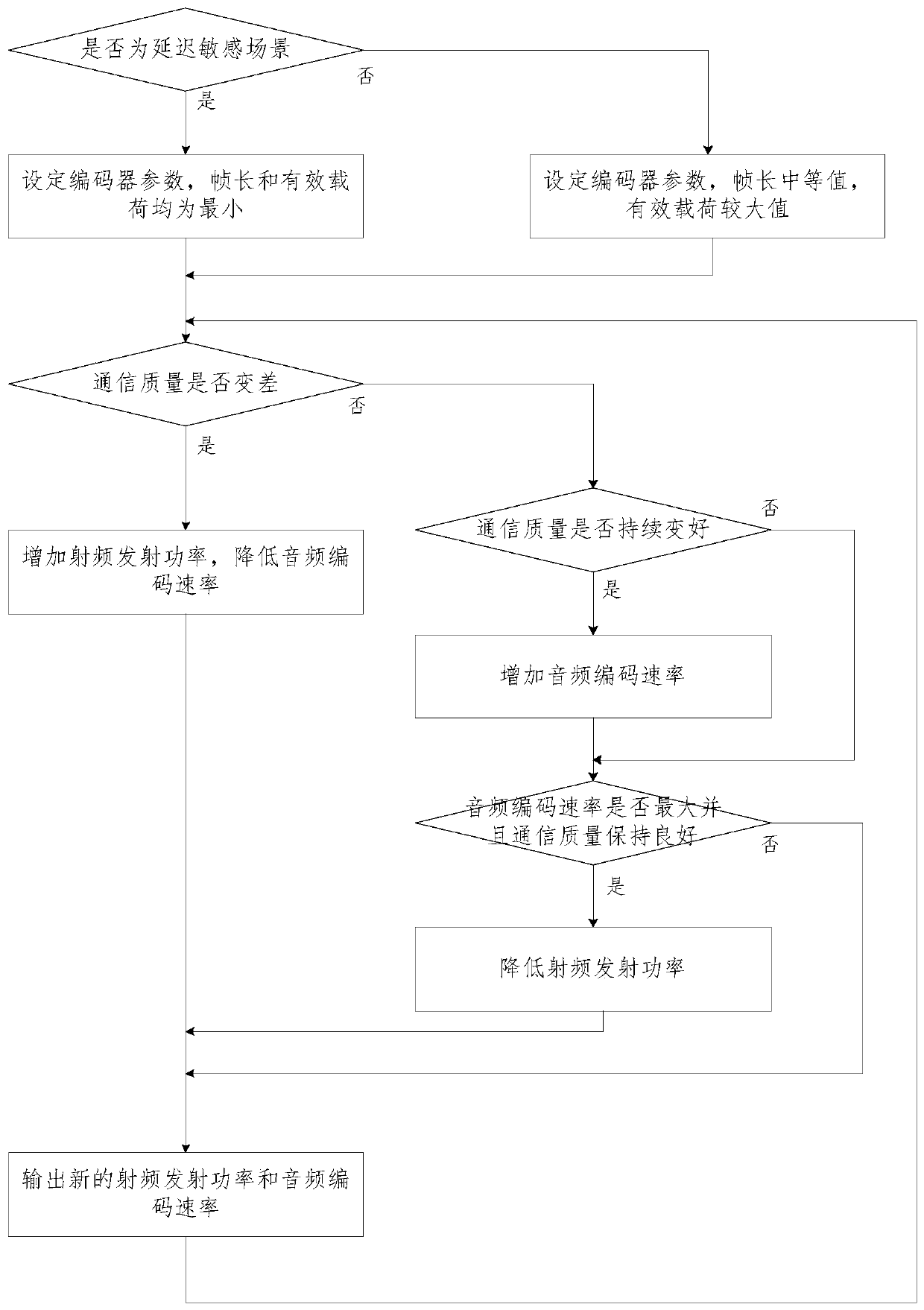

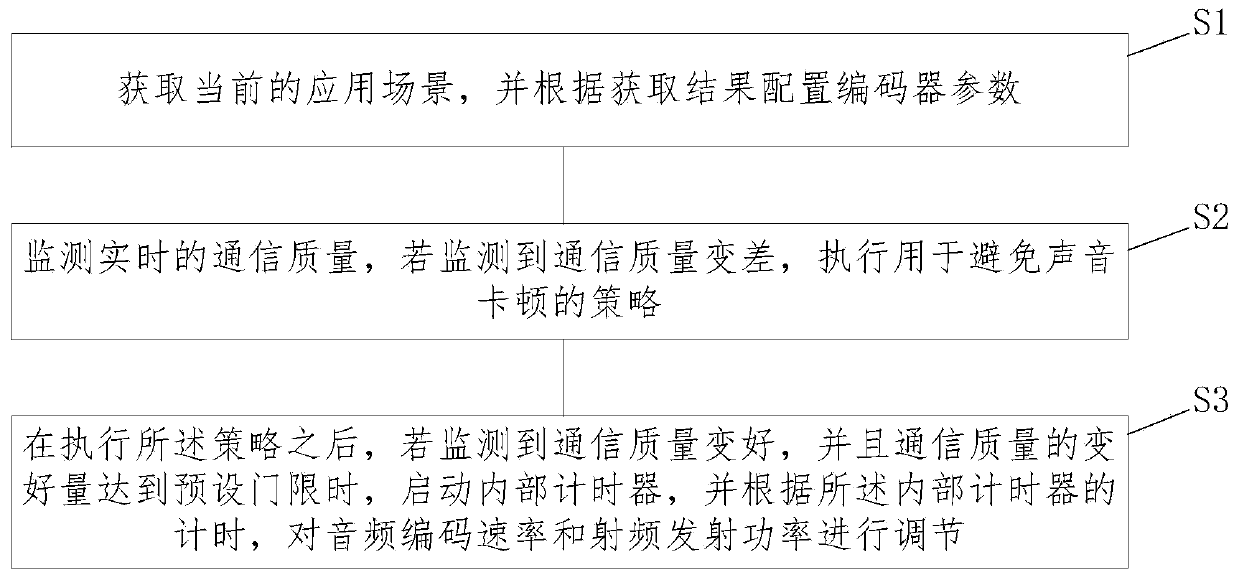

Dynamic regulation method and system for Bluetooth audio

InactiveCN110689899AImprove sound qualityLow costPower managementSpeech analysisCommunication qualitySound quality

The embodiment of the invention relates to a dynamic regulation method and system for a Bluetooth audio. The method comprises the steps of: acquiring a current application scene, and configuring encoder parameters according to an acquired result; monitoring real-time communication quality, and if monitoring that the communication quality becomes poor, executing a strategy for avoiding sound jamming; and after executing the strategy, if monitoring that the communication quality is improved and when an improvement quantity of the communication quality reaches a preset threshold, starting up an internal timer, and according to timing of the internal timer, regulating an audio encoding rate and a radio frequency transmission power. According to the technical scheme provided by the invention, tone quality of the Bluetooth audio can be promoted, time delay can be reduced, connection stability can be reinforced and use time can be prolonged.

Owner:CHONGQING BAIRUI INTERNET ELECTRONICS TECH CO LTD

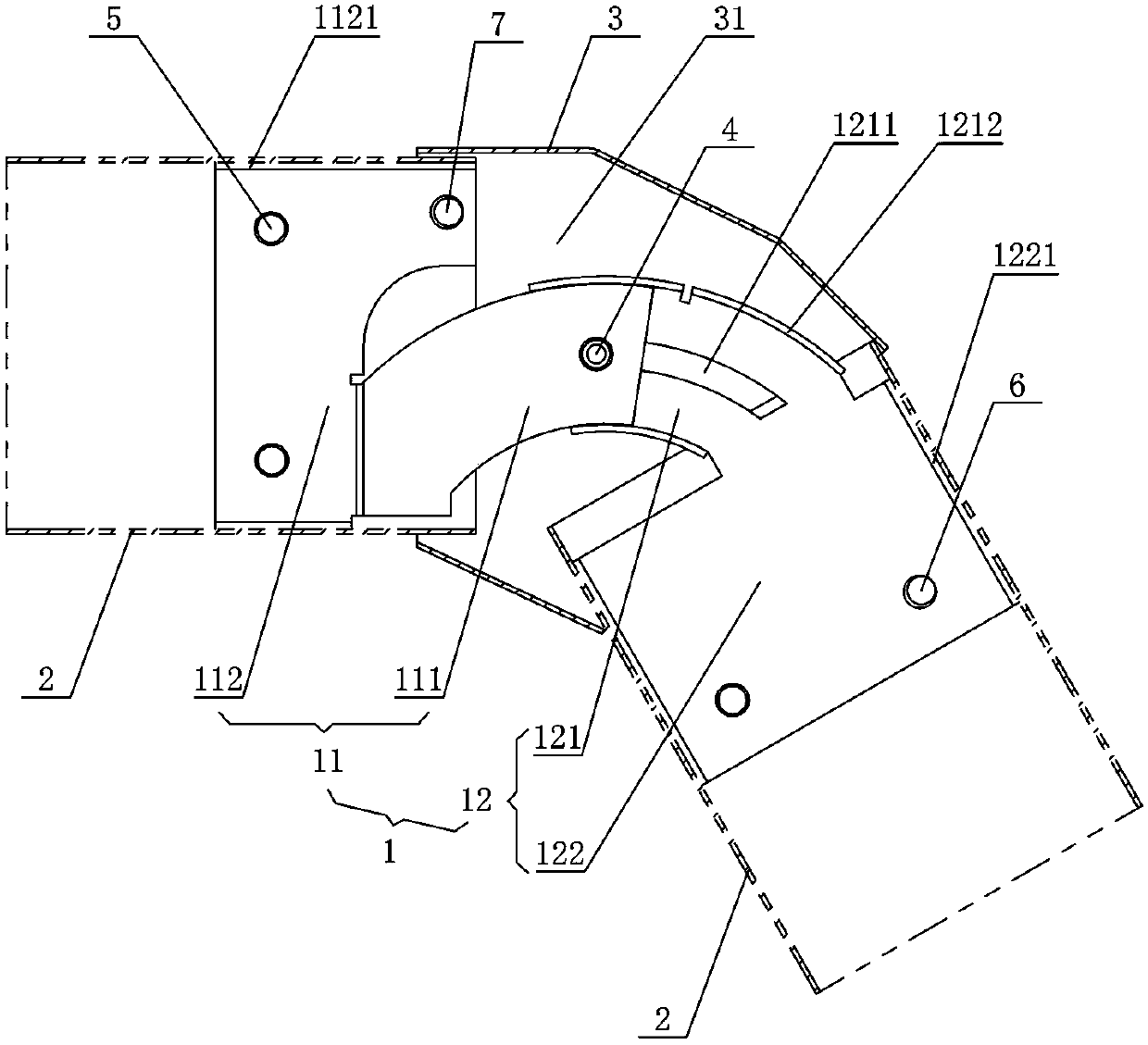

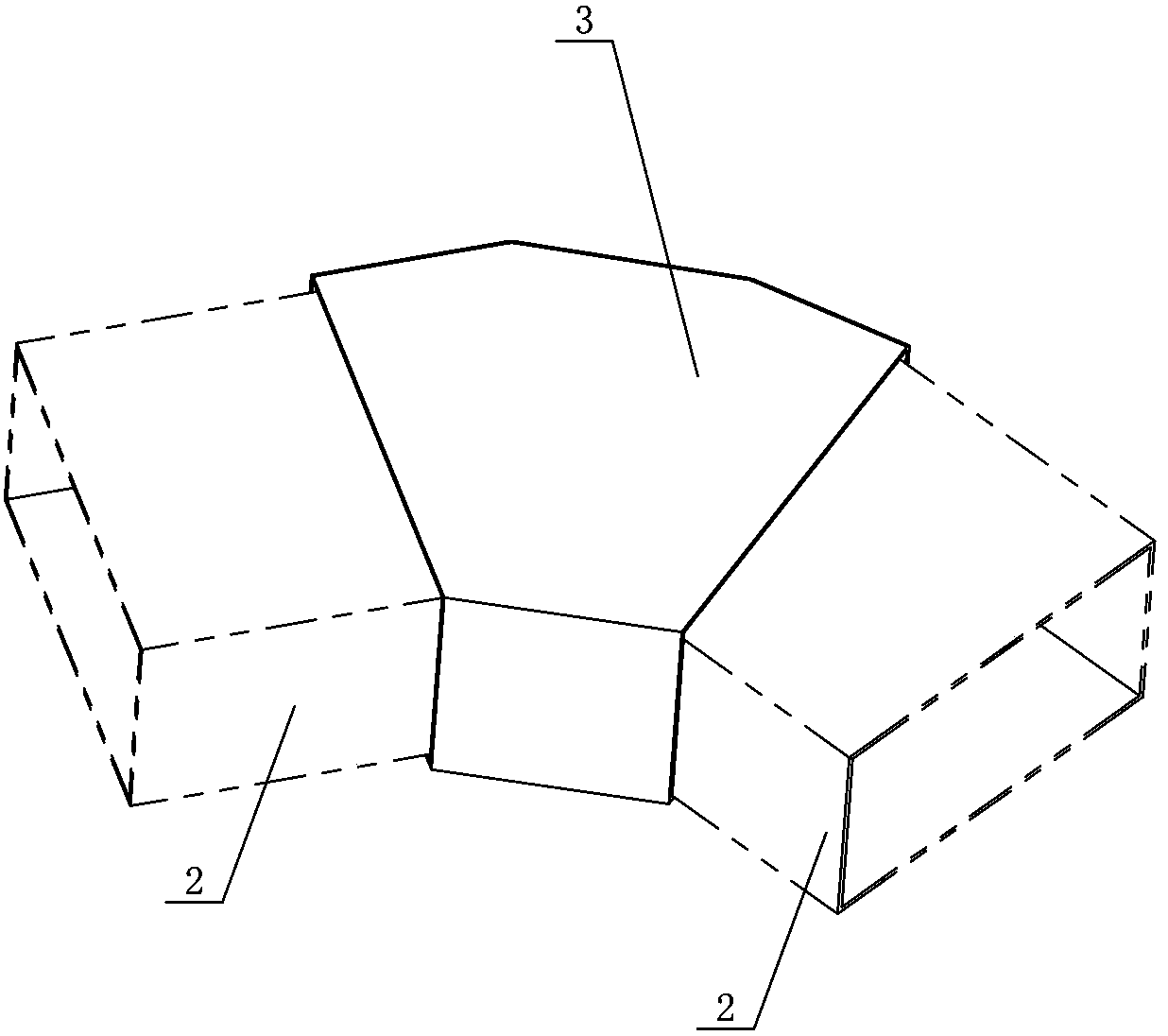

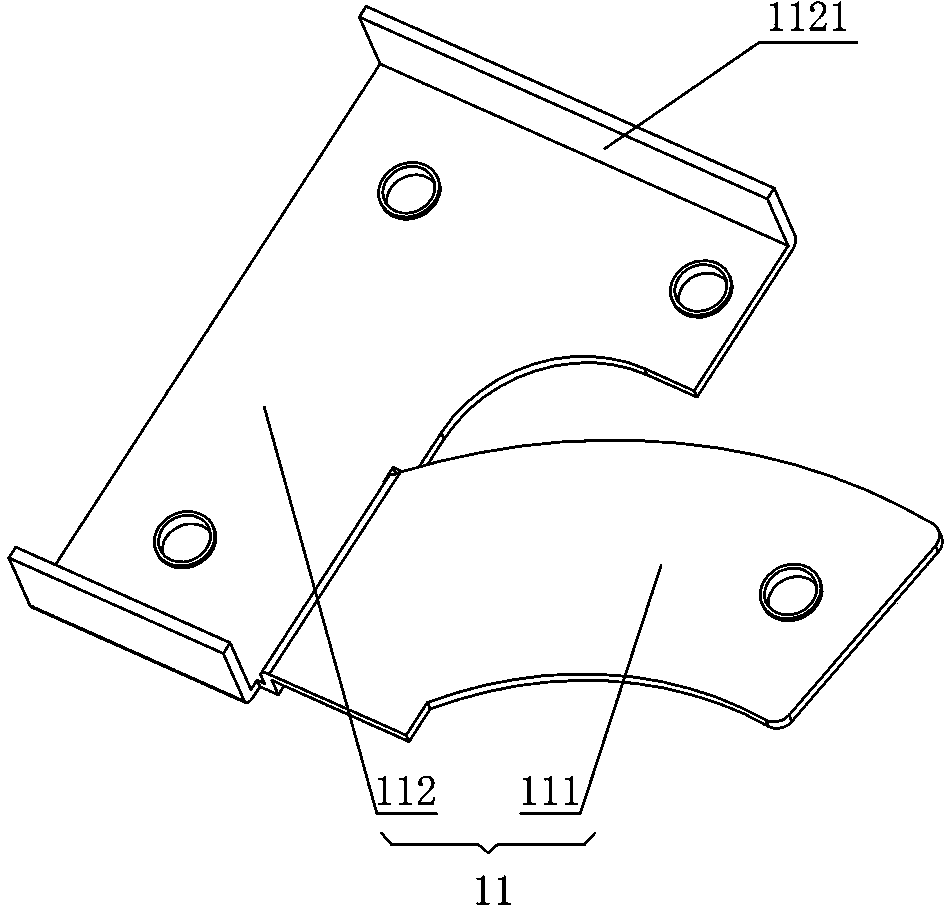

Corner connecting fitting for surface tubes

ActiveCN103696545ASimple structureEasy to installStairway-like structuresFastenerIndustrial engineering

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

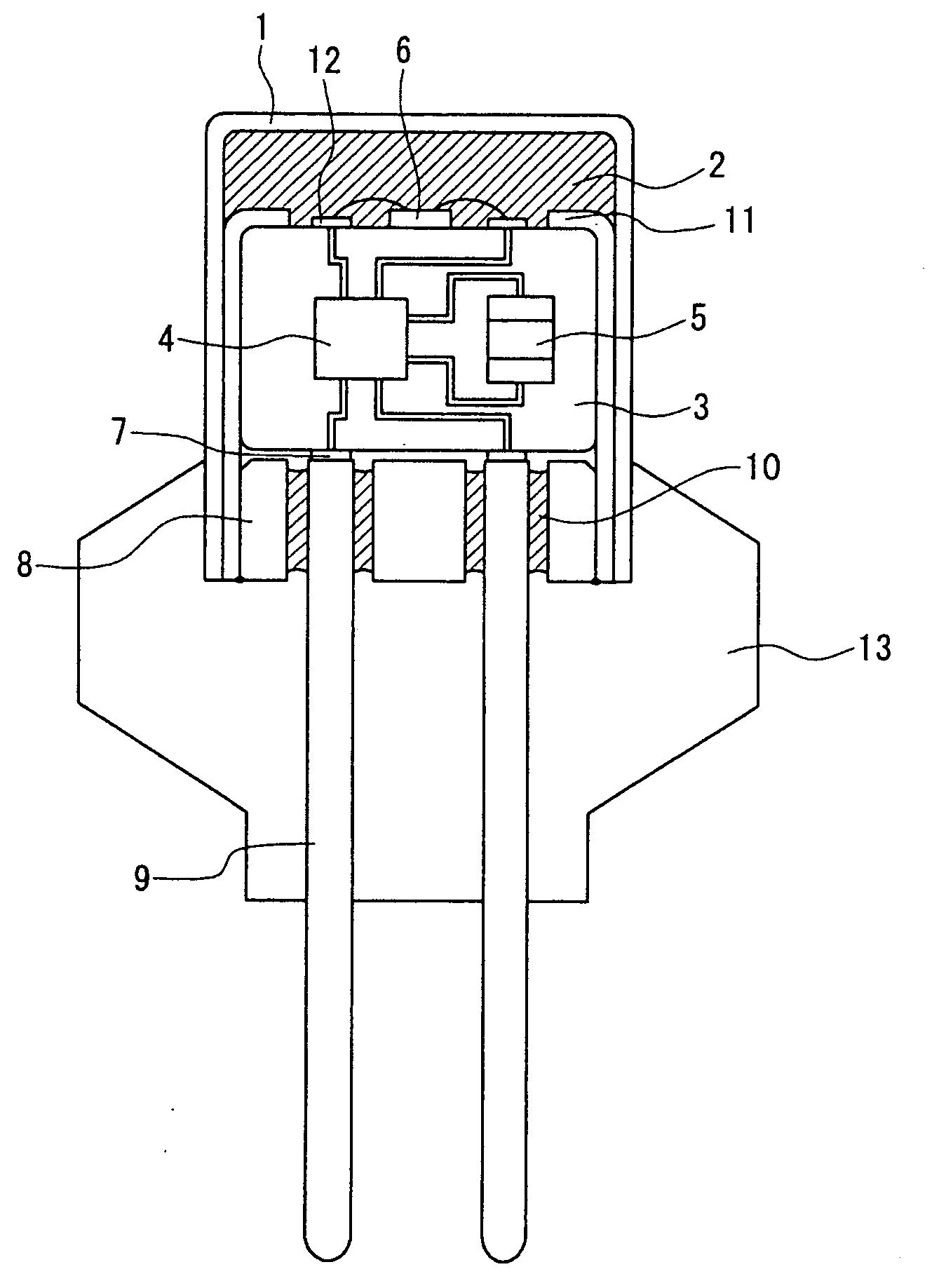

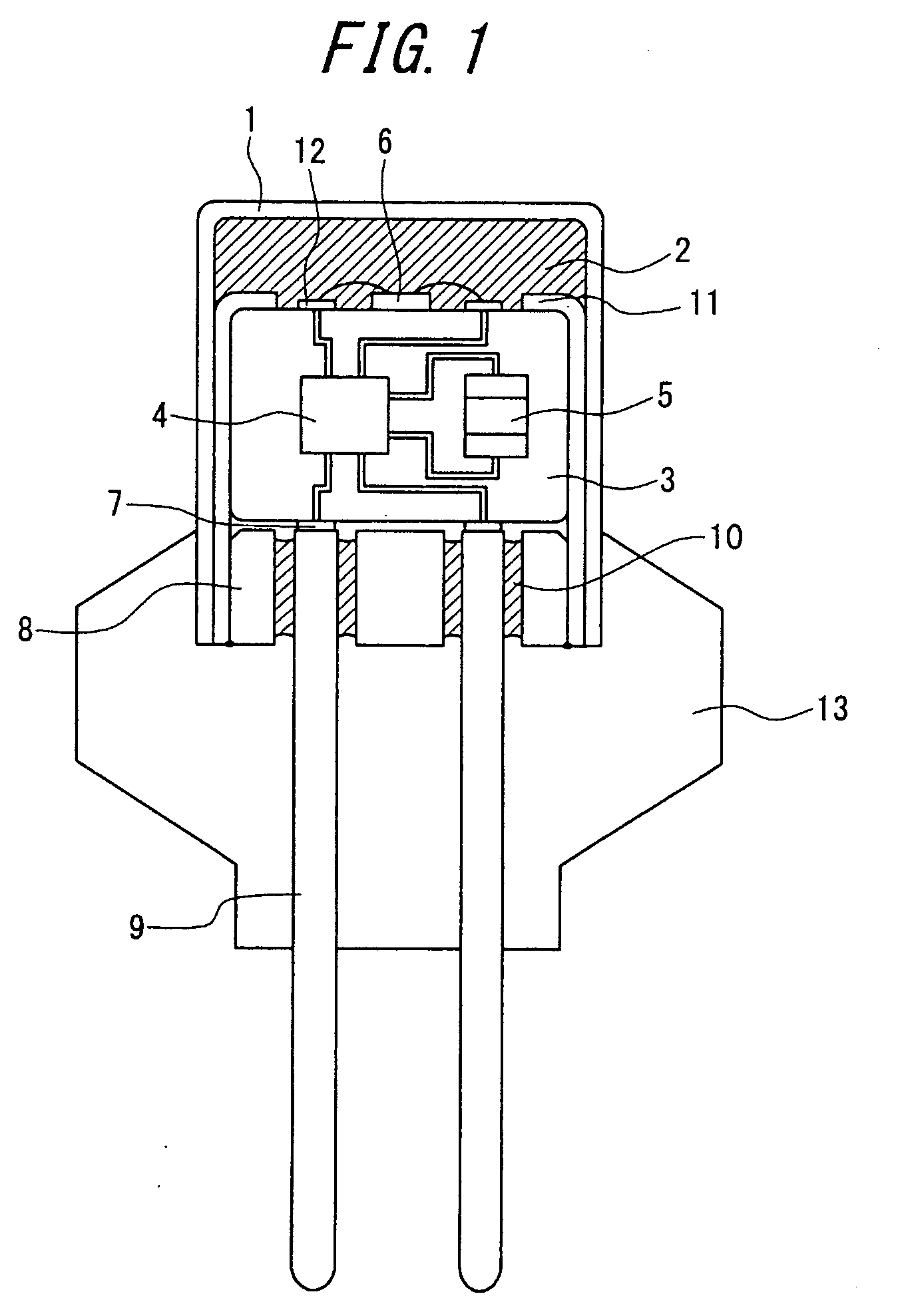

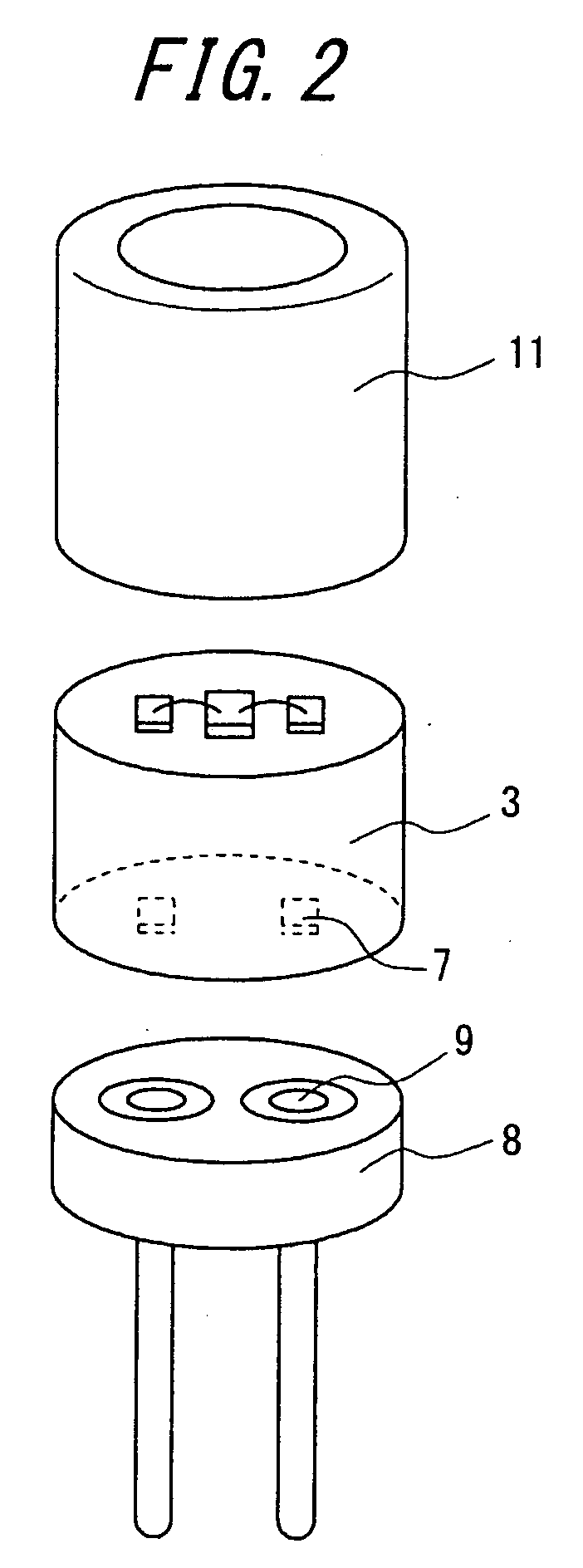

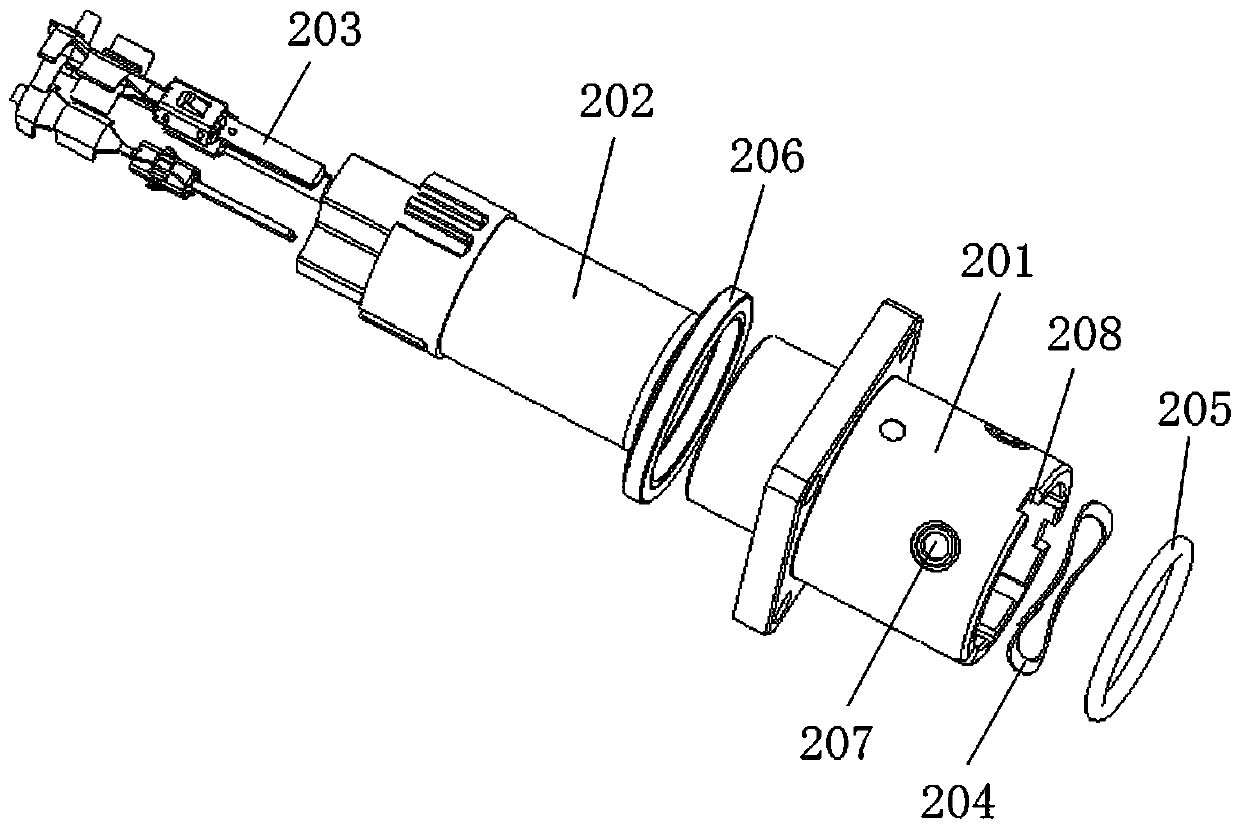

Squib, Gas Generator for Air Bag and Gas Generator for Seat Belt Pretensioner

InactiveUS20100018431A1Ensure connection stabilityGuaranteed smooth progressBelt retractorsBlasting cartridgesSeat beltEngineering

A squib includes a cup body and a closure plug for holding a plurality of electrode pins insulated from one another and closing the opening of the cup body, and further includes, in the cup body, ignition powder and an ASIC component formed by molding a resin around electric circuits including an ASIC and a capacitor, a heating element connected to the ASIC and located at the top of the resin molding of the ASIC component, and connection electrodes located at the bottom of the resin molding for connecting the ASIC to the electrode pins. The squib includes a cylindrical metal fixture having at the center of its top an opening of a size sufficient to expose the heating element and being fixed to the closure plug in a state covering the top circumferential periphery and side surface of the ASIC component and pushing the connection electrode of the ASIC component against the electrode pins. With the squib thus constructed, electric current can be reliably supplied to the electric circuits incorporated in the squib, and upon operation of the squib the resin molding and its broken pieces are effectively prevented from flying in all directions.

Owner:NIPPON KAYAKU CO LTD

Stackable hinge connection

InactiveUS20190321741A1Increased ease of use without loss of stability of the hinge connectionReduce thicknessChiropractic devicesToysElectrical and Electronics engineeringBuilding construction

The present invention relates to a hinge connection comprising a male member applied on a base plate, and having protrusions provided to be hinged and resiliently fitted between a pair of female members applied on a further base plate. The male member of the hinge connection is being formed by two parallel male legs, wherein each leg comprises protrusions comprising cogs or cut teeth. The female member is formed by two parallel female legs and each of the female members comprises a through hole for engaging said protrusions of the male legs. The present invention further provides construction elements comprising the hinge connection members of the instant application. In a particular embodiment such construction elements are stackable, and allow the construction of complex three-dimensional structures without loss of flexibility.

Owner:CLICFORMERS NV

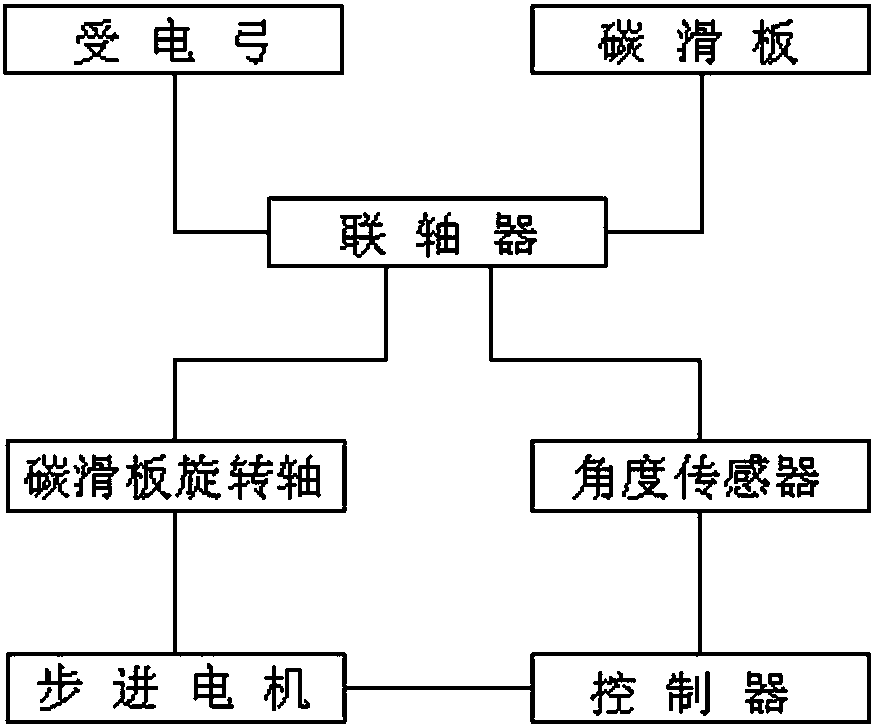

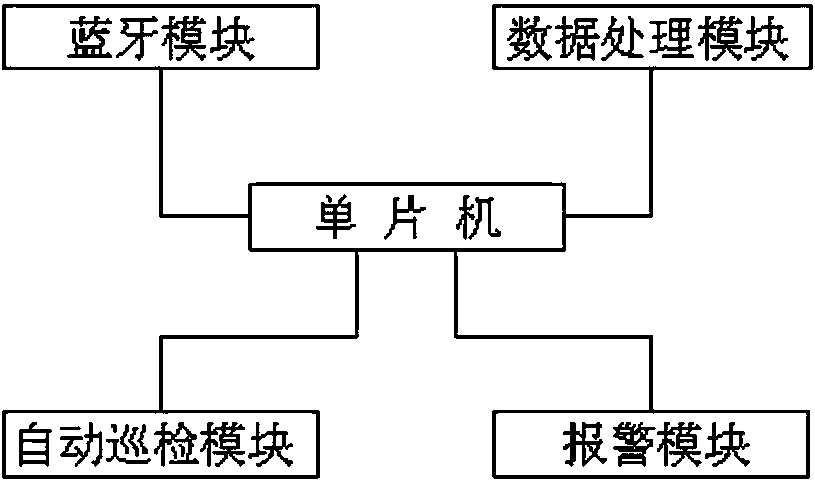

Pantograph carbon contact strip dip angle measuring and monitoring device and its method

InactiveCN108116235AReduce rail accidentsImprove securityMeasurement devicesElectric vehicle charging technologyMicrocontrollerSlide plate

The invention discloses a pantograph carbon contact strip dip angle measuring and monitoring device and its method. The pantograph carbon contact strip dip angle measuring and monitoring device comprises a pantograph and a carbon contact strip; the pantograph and the carbon contact strip are connected through a shaft joint, and the end part of the shaft joint is connected with a carbon contact strip rotating shaft and an angle sensor, the angle sensor is connected with the controller; the controller is electrically connected with a stepping motor through a communication interface, a steel ropeis arranged between the stepping motor and the carbon contact strip rotating shaft, the stepping motor and the carbon contact strip rotating shaft are in driving connection through the steel rope; the inner part of the controller is provided with a single chip, and a connecting end of the single chip is connected with a data processing module, a Bluetooth module, an alarm module and an automaticrouting inspection module. The pantograph carbon contact strip offset angle is provided with three threshold values which are normal level, alarm level and sudden stop level; the measurement time interval of the pantograph carbon contact strip is 0.1 second; the safety of high-speed train driving is greatly promoted.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

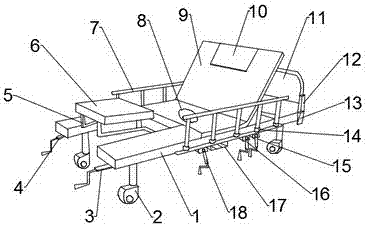

Multifunctional medical care nursing bed

InactiveCN107028716AEasy to moveEasy to follow upNursing bedsAmbulance serviceEngineeringMedical treatment

The invention discloses a multifunctional medical care bed, which comprises a bed board, medical universal silent rollers are installed at the four corners of the bed board, a curved desktop is installed at the lower part of the bed board, a toilet is installed at the middle part of the bed board, and a toilet is installed at the upper part of the bed board. A backrest is installed, a shampoo turnover plate is installed above the backrest, an infusion pole is installed on both sides of the backrest, guardrails are installed on both sides of the bed board, and a storage rack is installed under the bed board; the multifunctional medical care bed, Due to the setting of medical universal silent rollers, the bed can change its direction arbitrarily during use, which is convenient for movement. The curved table top is set so that users can directly eat or watch activities on the bed, without having to add an additional table and set up a toilet, so that there is no need It is convenient for users who get out of bed to excrete on the bed. With the detachable toilet bucket, it is convenient for family members to follow up. The shampoo flip plate is set so that users can wash their hair directly on the bed to avoid wetting the bed.

Owner:CHENGDU XUNDE SCI & TECH

Anchoring connection method pulling-resistant device for single pile vertical pulling-resistant static load test

InactiveCN108487340AFirmly connectedImprove Field Work EfficiencyFoundation testingSteel barCost savings

The invention discloses an anchoring connection method pulling-resistant device for a single pile vertical pulling-resistant static load test. The structure of the anchoring connection method pulling-resistant device differs from tradition, a form that other high-strength connection parts are detachably anchored with pulling rods directly or indirectly is adopted, a series of problems brought by an existing form of utilizing base seat main steel bar namely regular steel bar welding are avoided, the anchoring connection method pulling-resistant device is suitable for filling piles and preformedpiles, convenient and stable in connection, uniform in force bearing and is safe and reliable, improvement of the site work efficiency and cost saving are facilitated, the accuracy of the measurementresult is also guaranteed, furthermore, when both vertical compression resistance and vertical pulling-resistant static load test are required to perform on a same foundation pile, limit of sequential order also does not exist, and the anchoring connection method pulling-resistant device for the single pile vertical pulling-resistant static load test is convenient and capable of saving time.

Owner:南京市建筑安装工程质量检测中心 +1

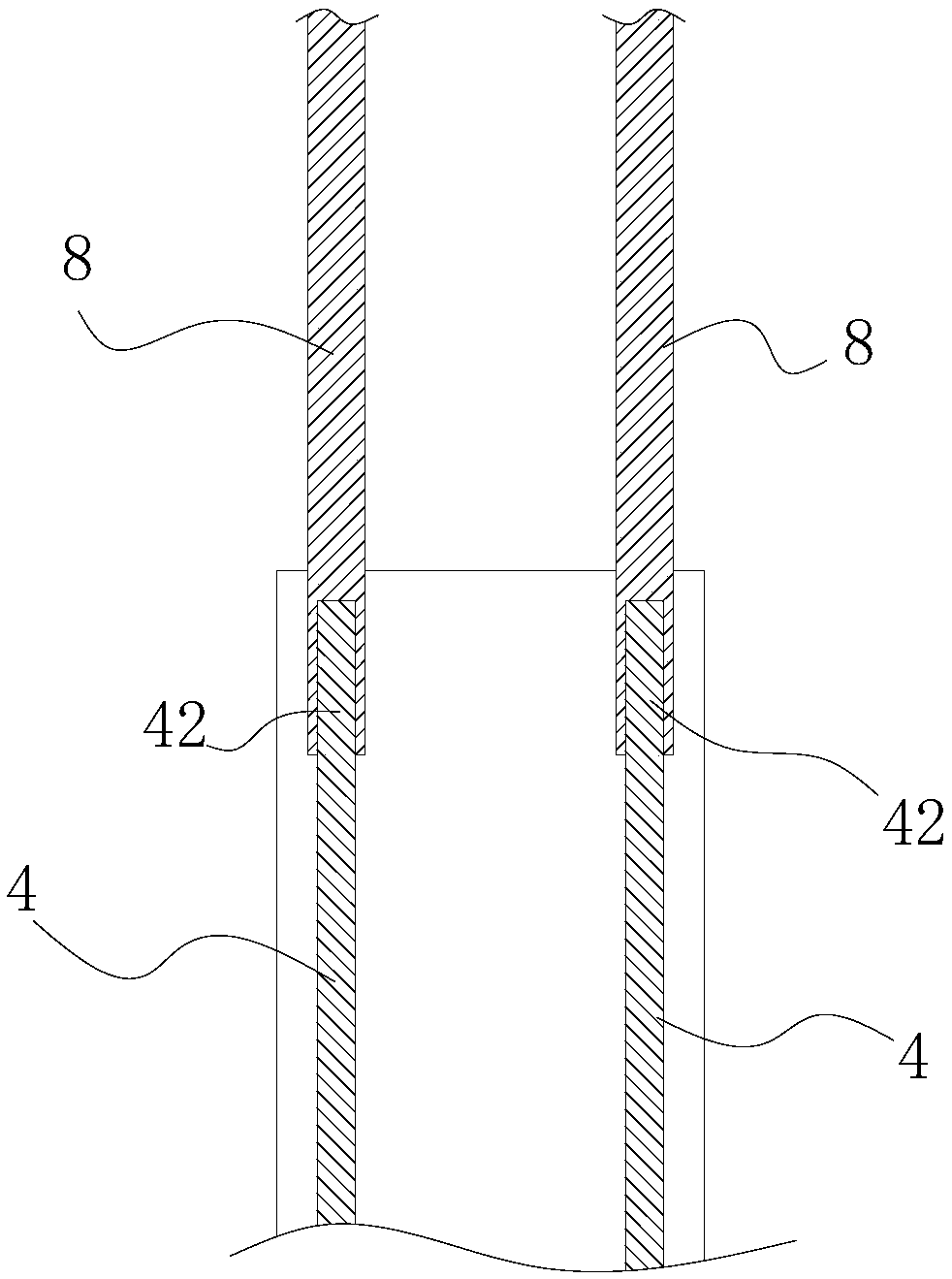

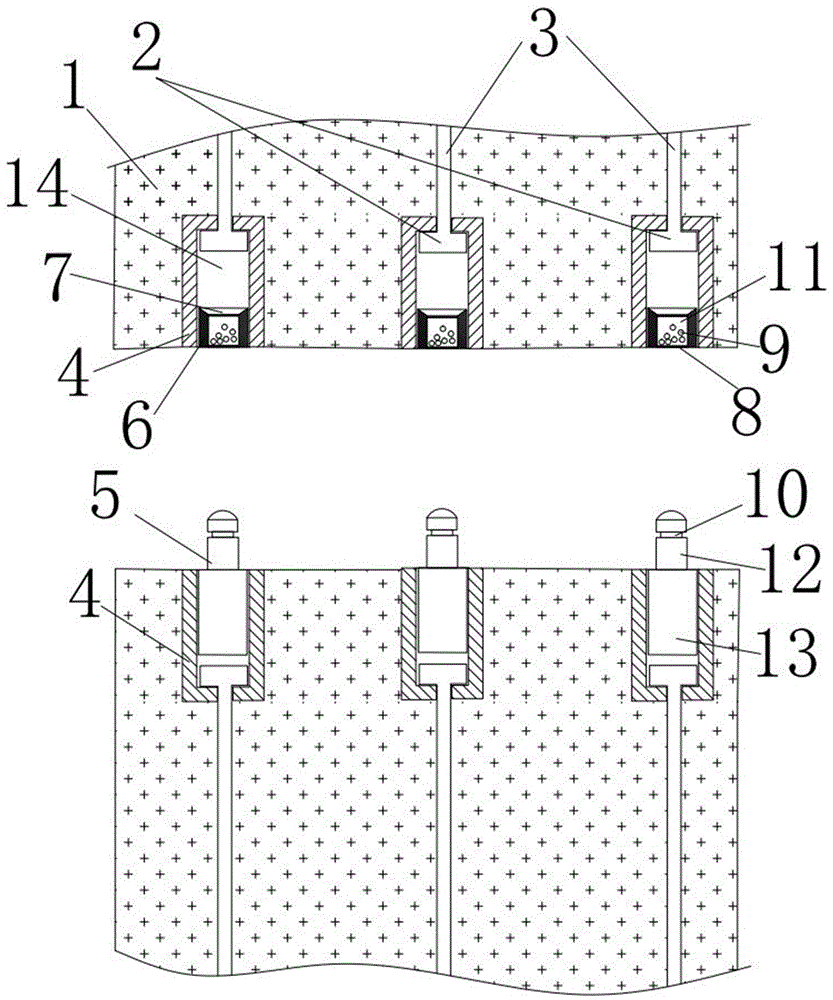

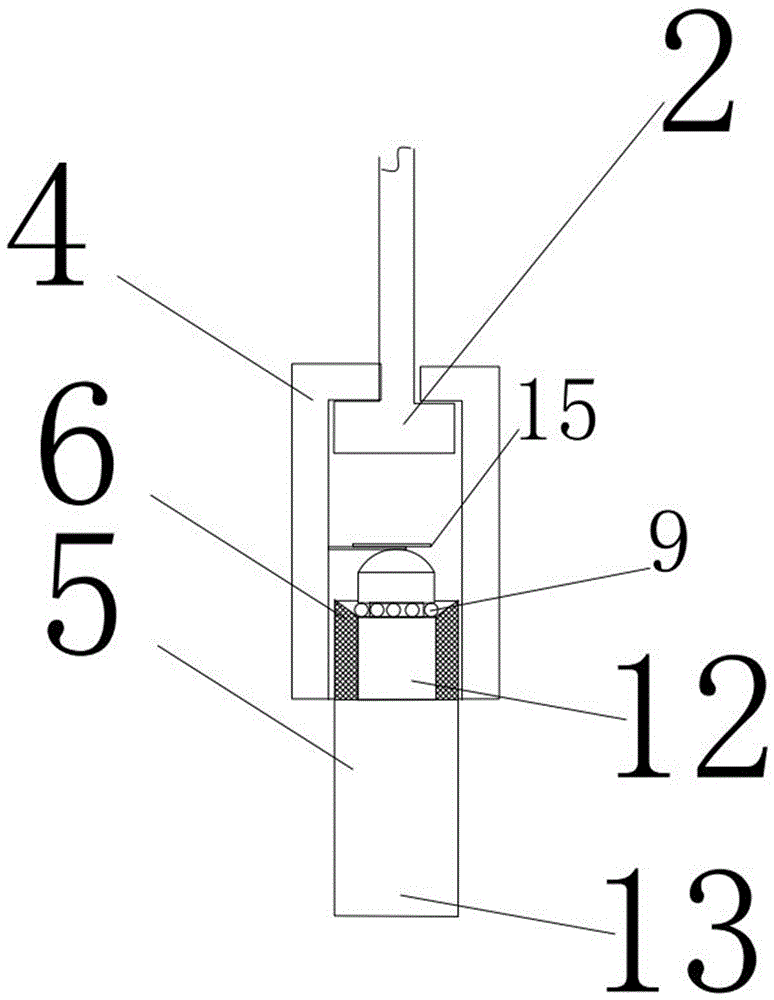

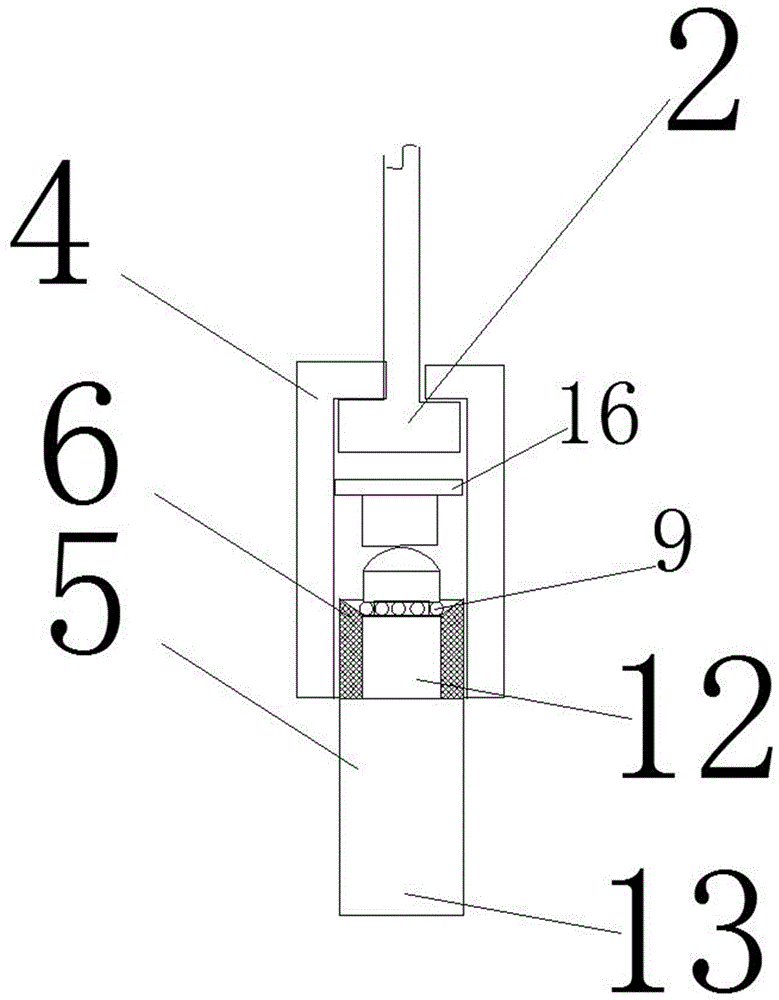

Non-welded PHC pipe pile quick connecting method and pulling-resistant quick installing structure

The invention provides a non-welded PHC pipe pile quick connecting method and a pulling-resistant quick installing structure. The pulling-resistant quick installing structure comprises pipe pile steel bars, steel bar head sleeves and quick connectors; the quick connectors of the steel bars of a pipe pile are perpendicularly and fixedly connected to the quick connectors of the steel bars of another pipe pile in an inserted mode; the quick connectors comprise the male quick connectors and the female quick connectors, when the quick connectors are fixedly connected in an inserted mode, the male quick connectors are perpendicularly inserted into the female quick connectors from inserting openings to push out rolling balls into inserted connection fixing cavities, and the rolling balls fall to the bevels of rolling ball releasing openings; when annular grooves formed in the stepped shaft small ends of the male quick connectors arrive at the bevels of rolling ball releasing openings, the rolling balls roll into the annular grooves, the annular groove walls and the bevels of rolling ball releasing openings clamp and lock the rolling balls in the annular grooves under the gravity action of the pipe piles to form annular ball zones, the male quick connectors are fixedly hung on the female quick connectors through the annular ball zones formed on stepped shafts, and then the pipe piles are connected in a butt-joint mode through the quick connectors. According to the non-welded PHC pipe pile quick connecting method and the pulling-resistant quick installing structure, the stable high-strength non-welded pipe pile quick connecting structure can be provided in the PHC pipe pile connecting work, and corrosion and rust protection treatment is easy to conduct.

Owner:许伟敏

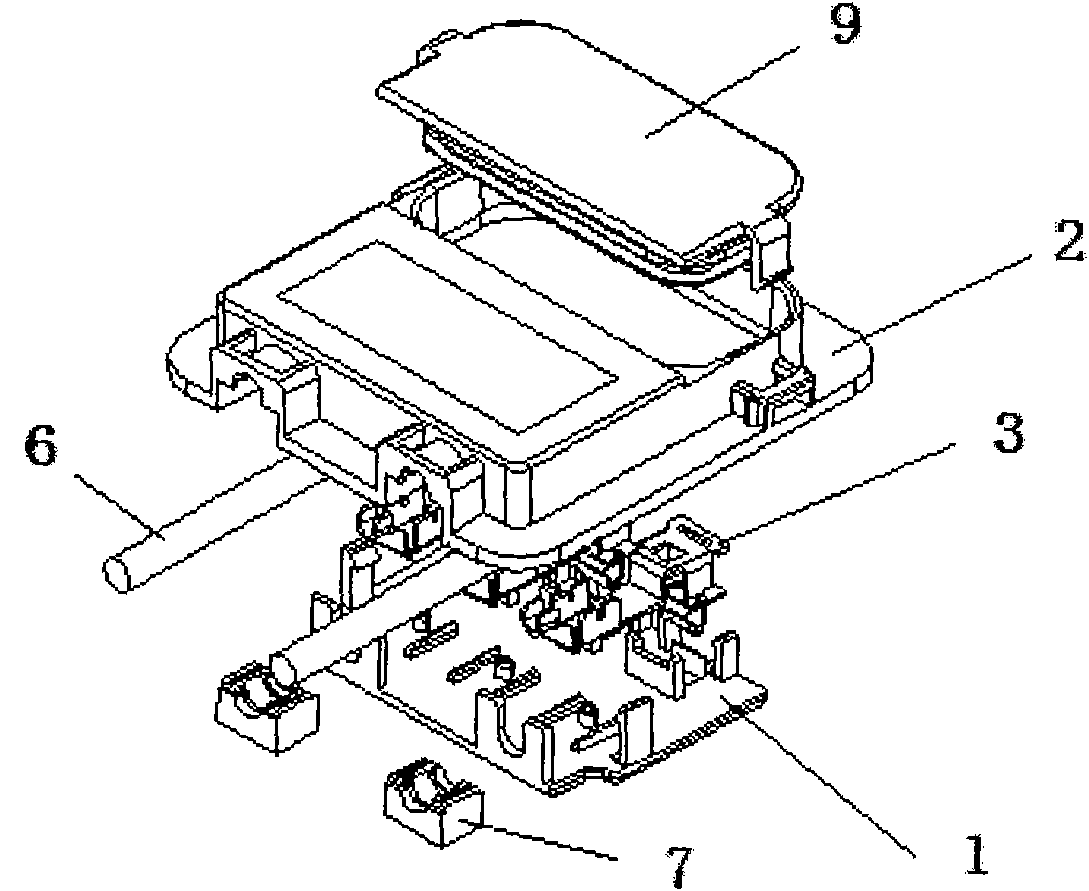

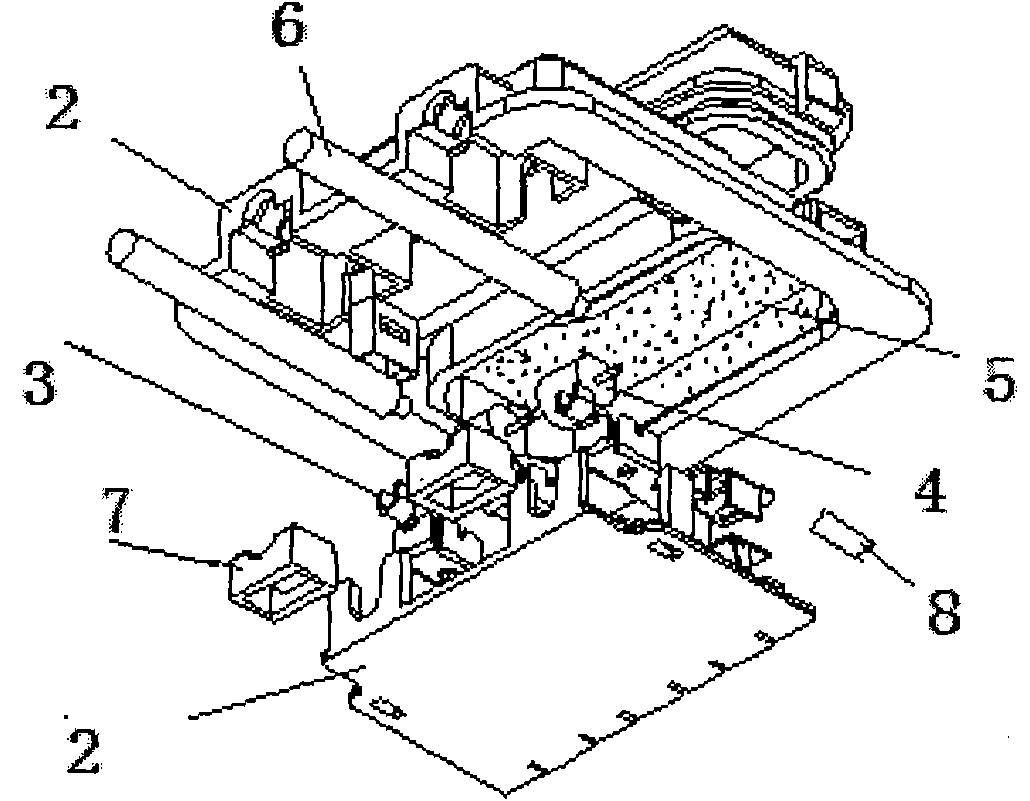

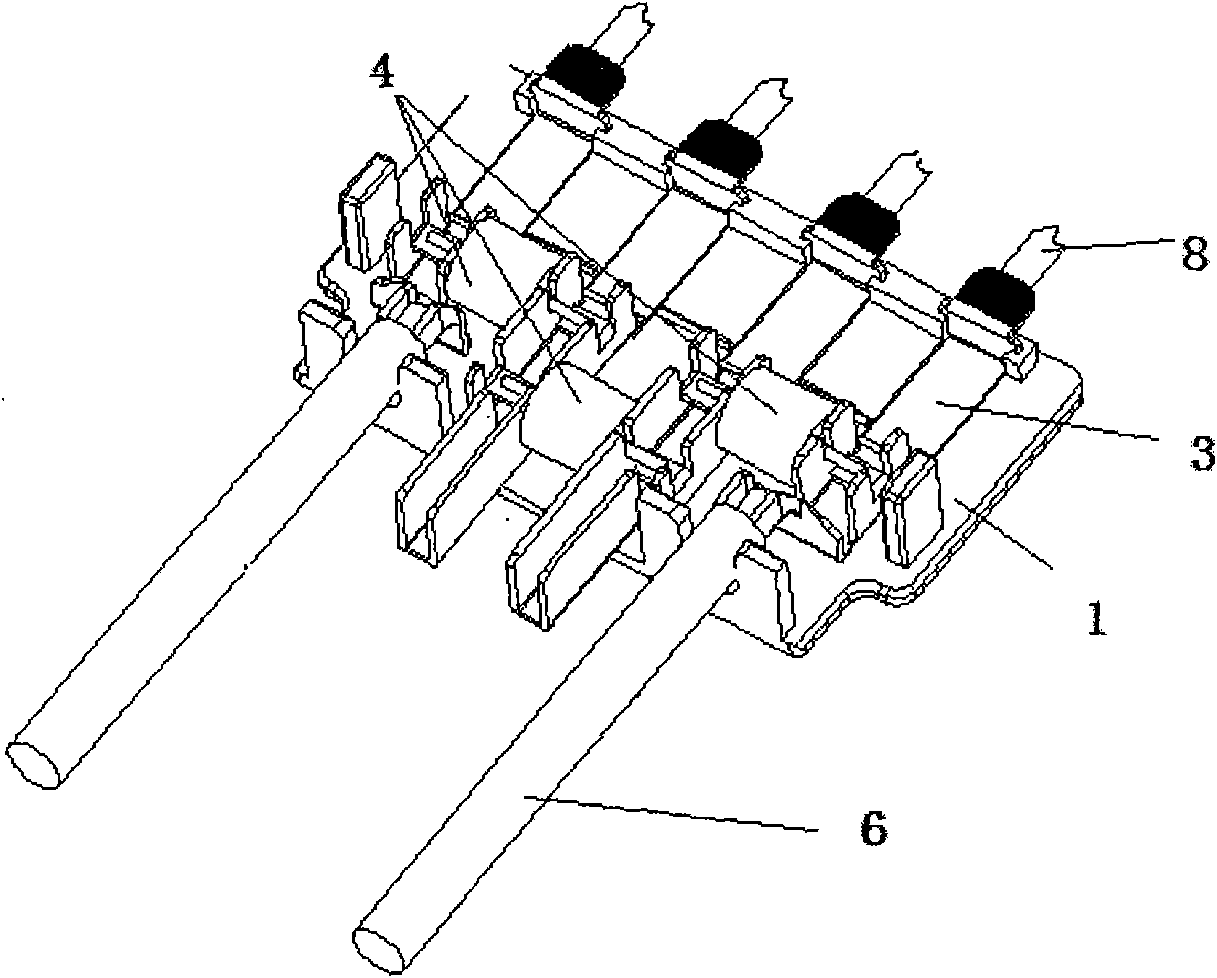

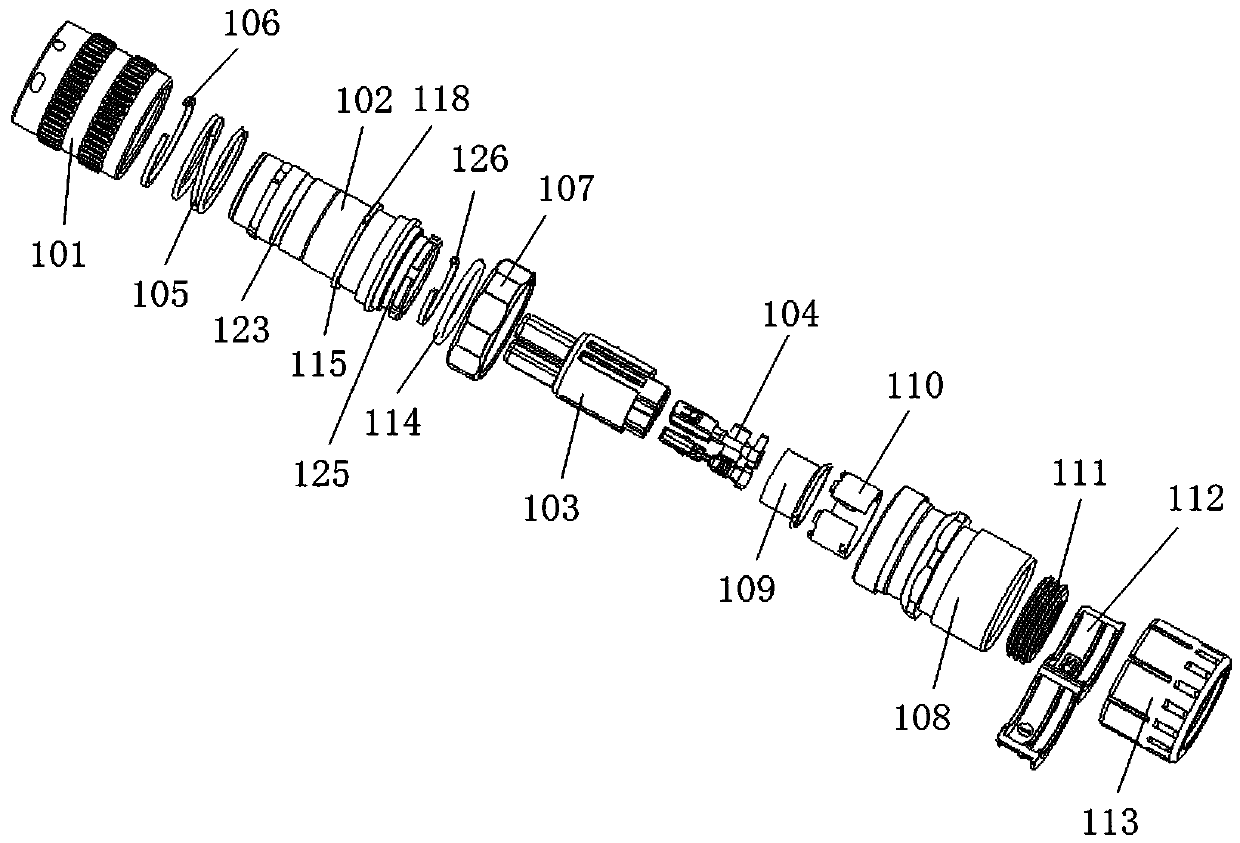

High-voltage connector with secondary locking structure

PendingCN110676651AEnsure connection stabilityFirmly connectedRelieving strain on wire connectionTwo-part coupling devicesAdhesive beltEngineering

The invention discloses a high-voltage connector with a secondary locking structure. The high-voltage connector comprises a plug and a socket. The plug consists of a connecting cap, a plug shell, a plug insulator and a jack which are sequentially sleeved from outside to inside. The socket includes a socket shell, a socket insulator and a pin which are sequentially sleeved from outside to inside. At least one boss is arranged at the front end of the connecting cap; a main key groove, a short key groove and a first annular groove are formed in the rear end of the connecting cap; the first annular groove is communicated with the main key groove and the short key groove; and A groove matching the boss is formed in the end face of the socket shell. The provided high-voltage connector has advantages of different kinds of key positions, small size, and great convenient and rapidness of connection. On the basis of a secondary locking structure, the stability of connection between the plug andthe socket is ensured; effective connection with a penetrating corrugated pipe harness is realized and the procedure of adhesive tape winding or heat shrink tube winding is omitted, so that the assembly efficiency is greatly improved; and the assembly retention force is far larger than that of adhesive tape winding or heat shrink tube winding, so that the product attractiveness is effectively improved.

Owner:郑州赛川电子科技有限公司

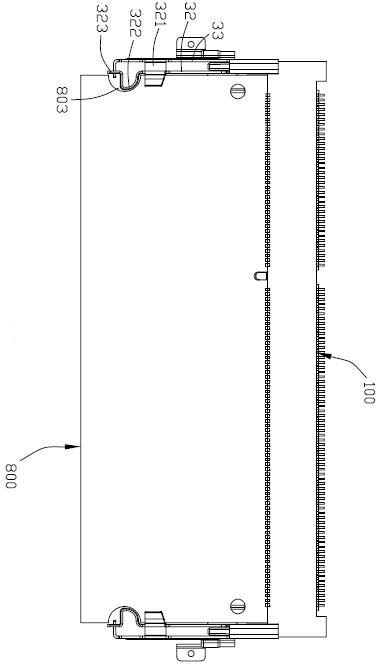

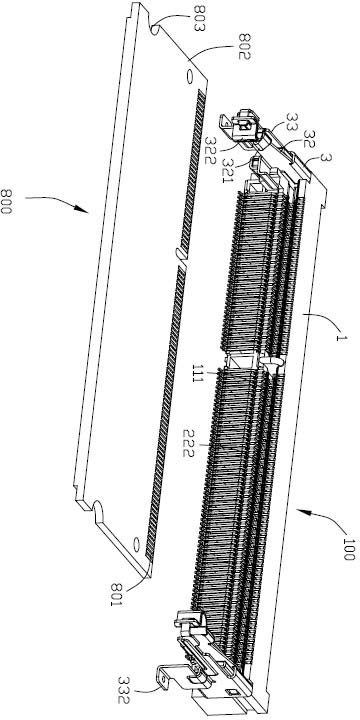

Edge connector

InactiveCN102684007AEnsure connection stabilityCoupling device detailsEngineeringMechanical engineering

The invention provides an edge connector. The edge connector comprises a lengthwise insulation body, a plurality of conducting terminals which are fixedly arranged on the insulation body and a pair of metal holding pieces which are fixedly arranged at two opposite sides of the insulation body, wherein the insulation body is provided with a center slot which is provided with an forward opening and is used for plugging a sub circuit board; the conducting terminals are provided with contact parts stretching into the center slot in a protruding way; and each metal holding piece is provided with a fixed holding arm which is fixedly held on the insulation body, an elastic arm which forwards and obliquely stretches from the fixed holding arm and a limit arm which is positioned at one side of the elastic arm, and the elastic arm is provided with a pressing-against body which downwards and obliquely stretches from the top part, a limit groove which penetrates through the elastic arm along a lengthwise direction of the insulation body and a first separation blade which is used for covering the lower position of the limit groove. The limit arm is provided with a limit piece stretching in the limit groove in a bending way, and thus the elastic arm is prevented from moving upwards.

Owner:KUNSHAN JIAHUA ELECTRONICS

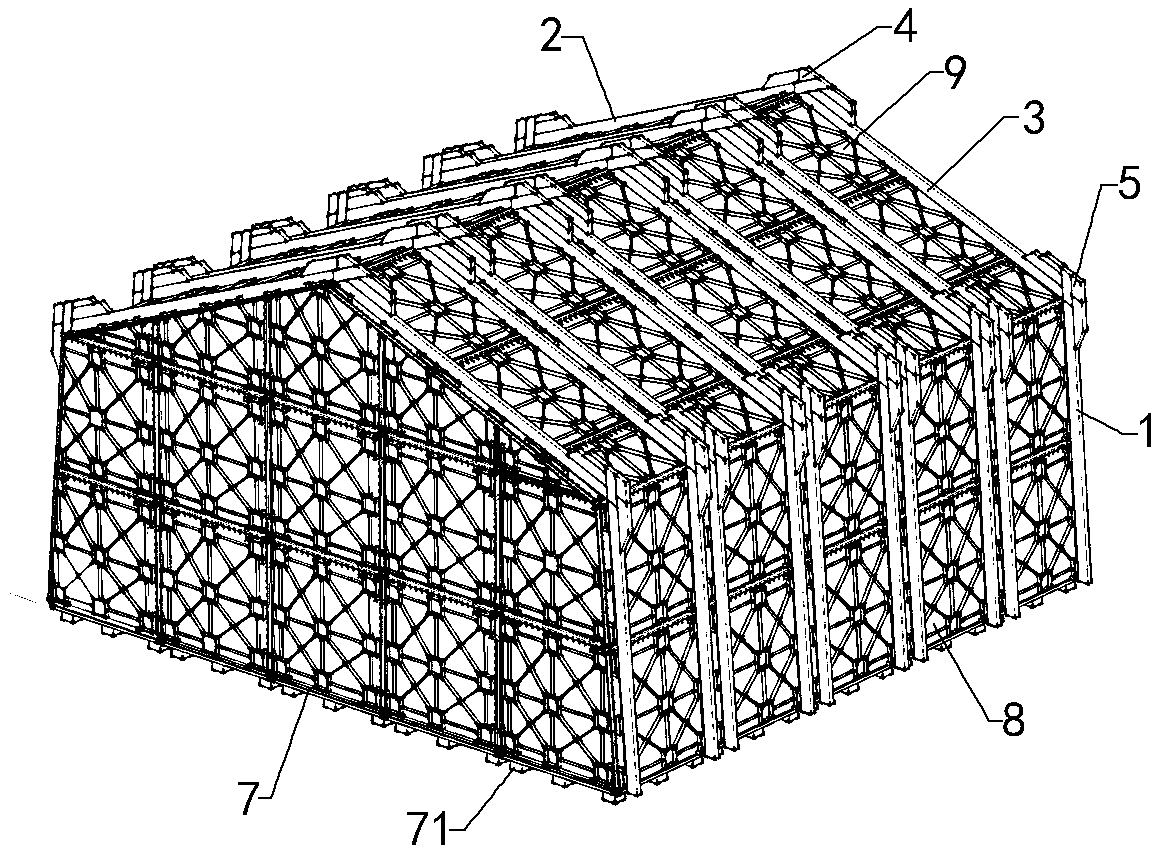

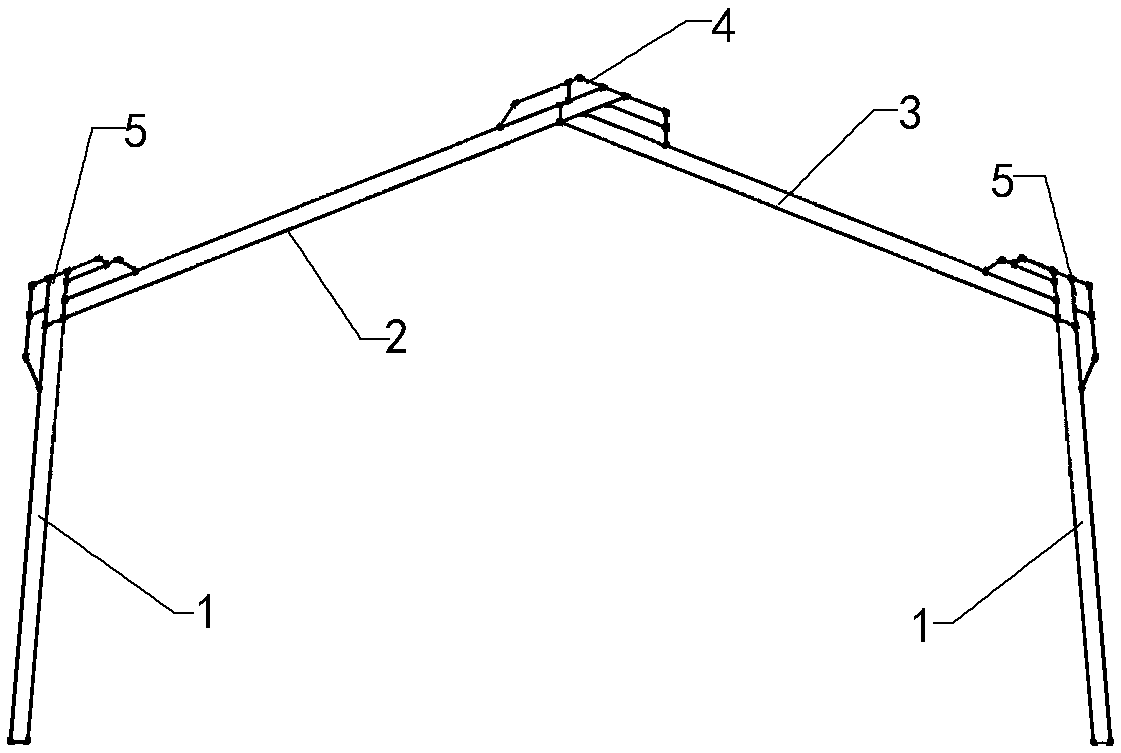

Modular assembling house and construction method thereof

The invention relates to the technical field of prefabricated buildings, and discloses a modular assembling house and a construction method thereof. The modular assembling house includes keel supporting frames and a building outer shell, the building outer shell is formed by splicing a plurality of bottom plates, side plates and roof plates, and the bottom plates, the side plates and the roof plates are compression-injection module plates; the keel supporting frames are single-span double way gradient gate-type steel structure frames and are distributed at intervals along the horizontal central axis of the house, each keel supporting frame includes two batter posts arranged symmetrically, roof beams and connecting assemblies, and the roof beams are detachably connected to the batter poststhrough side position connecting assemblies; the roof beams include the first roof beams and the second roof beams which are arranged symmetrically, and every two roof beams are detachably connected by one top position connecting assembly; and the compression-injection module plates are connected detachably. The modular assembling house is convenient to mount and dismount, modules can be reused, and connecting soundness is good.

Owner:侯宝权

Active air supply mask

ActiveCN103919304AAvoid enteringEnsure normal dischargeChemical protectionHeat protectionEngineeringDirect current

The invention discloses an active air supply mask. The active air supply mask comprises a mask body. The lower portion of the mask body is provided with an air supply cavity, a respiration mask matched with the mouth and the nose is formed on the upper portion of the mask body, a direct-current fan for supplying air is arranged in the air supply cavity, an air inlet is formed in the inner side face of the air supply cavity, a filtering layer is arranged in the air supply cavity along an air inlet and an air conveying channel is formed between the air supply cavity and the respiration mask. The active air supply mask enables respiration to be smooth and is good in protection effect.

Owner:河源市乐正环保科技有限公司

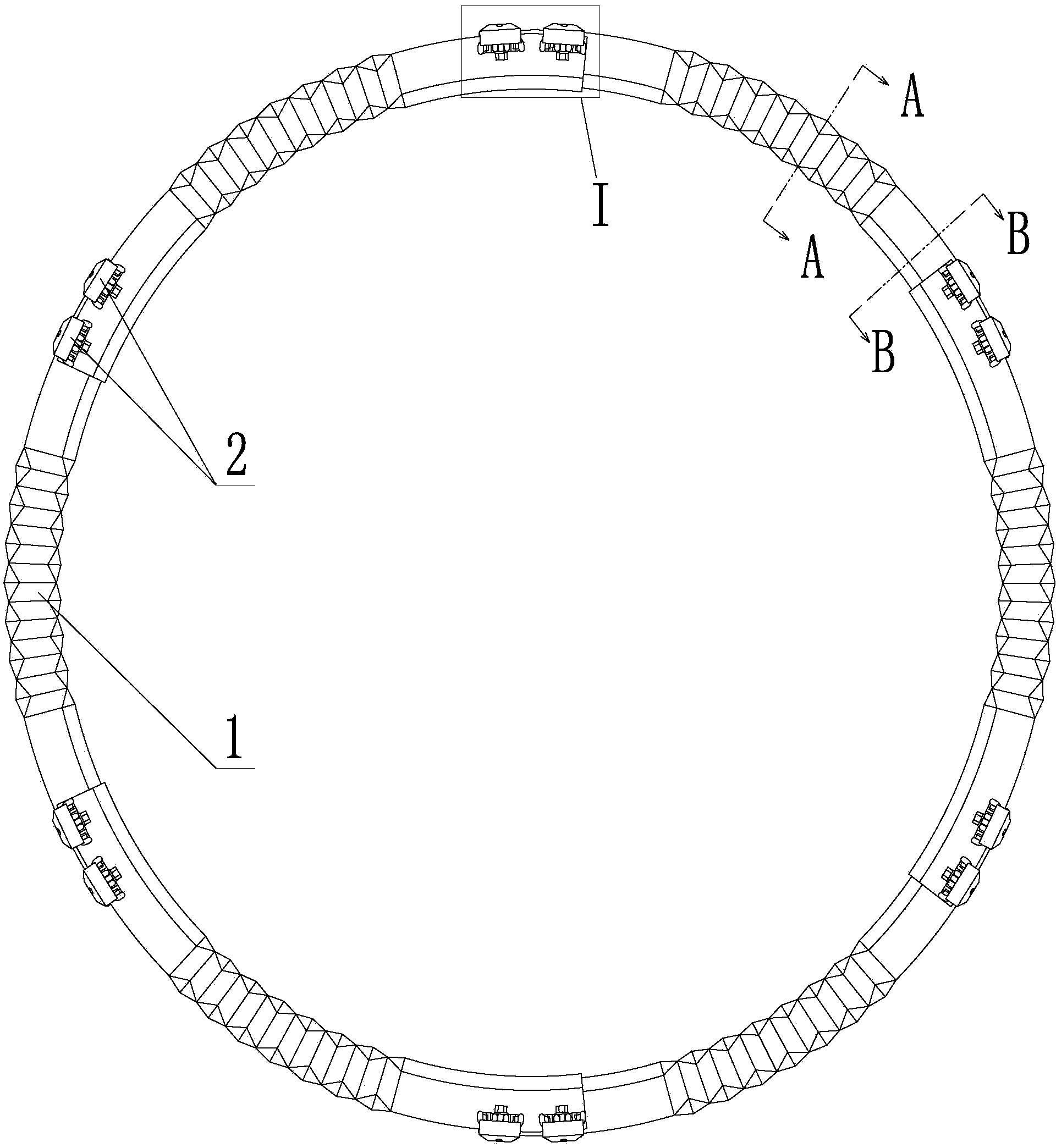

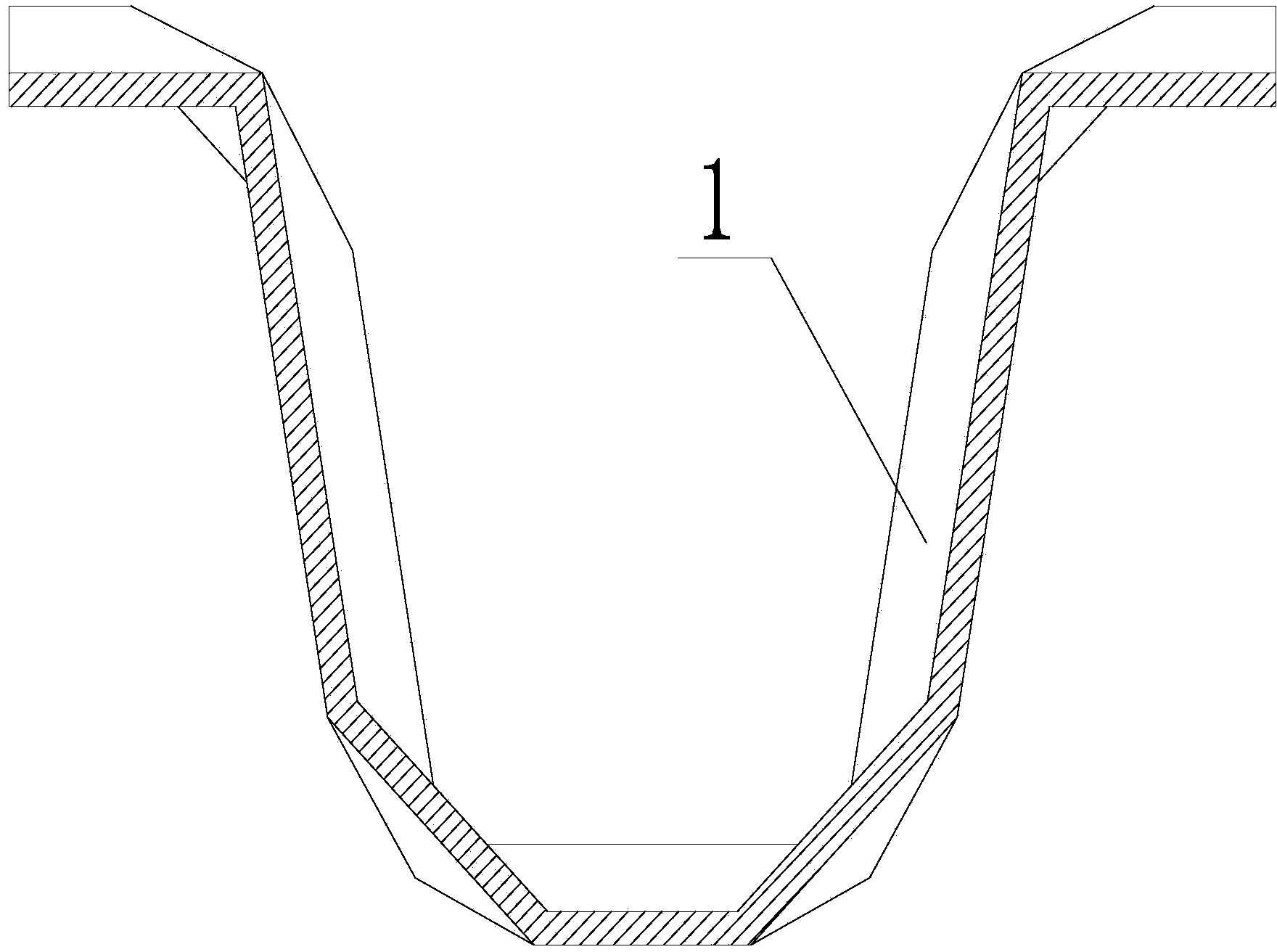

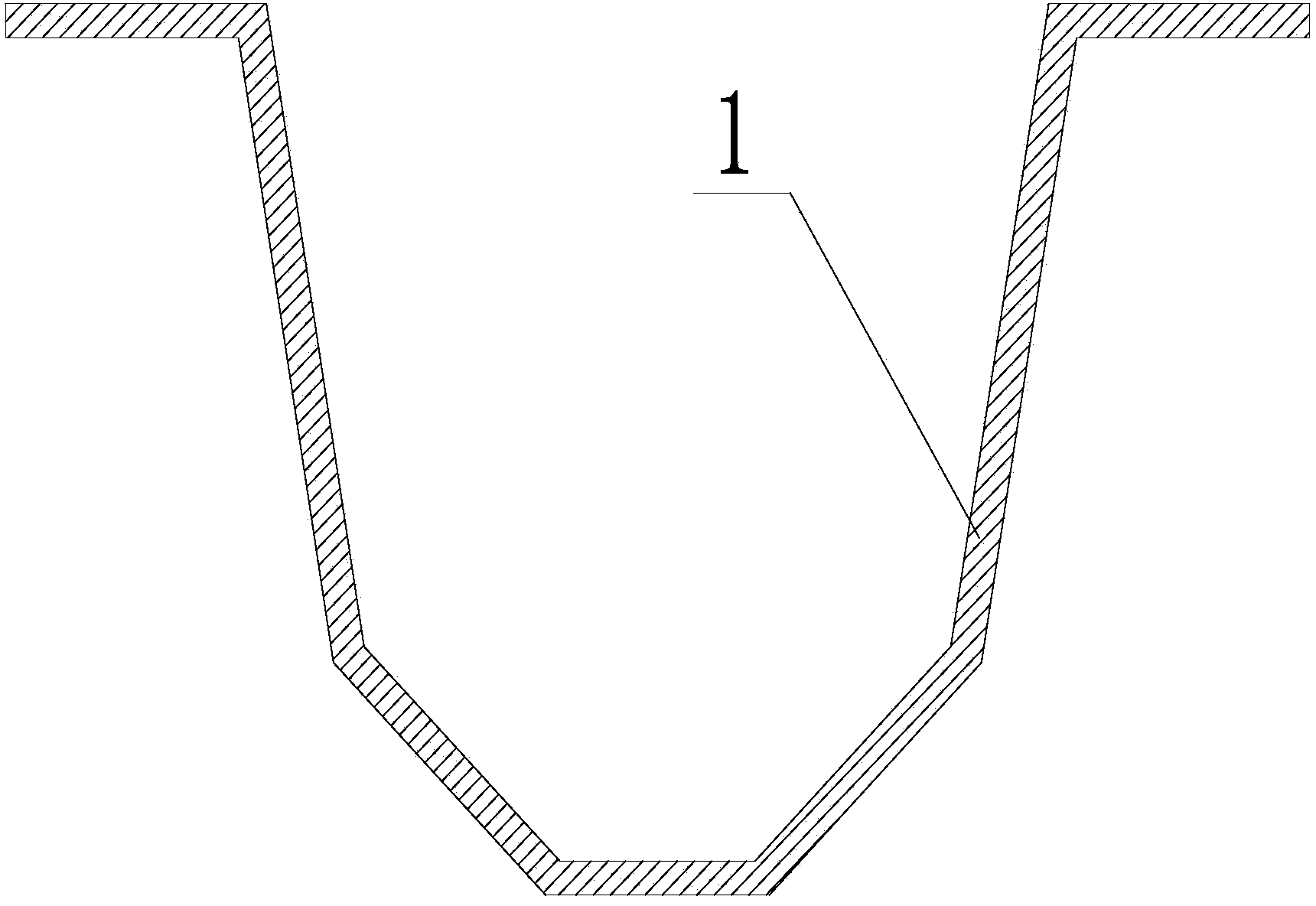

Anti-collision support with corrugated face

InactiveCN103821542ARapid contractionEasy to shrinkUnderground chambersTunnel liningShaped beamStructural engineering

An anti-collision support with a corrugated face belongs to the technical field of coal mine roadway supporting. Compared with the U-shaped steel support in the prior art, a corrugated face structure is additionally arranged on the middle section of an arc-shaped beam of the support, due to the corrugated face structure, the whole or part of the support can contract rapidly when encountering rock burst, the avoidance of surrounding rock is realized by the contraction of the support, and further the avoidance and energy consumption of the whole support are realized; according to the anti-collision support provided by the invention, the traditional mode of connecting two adjacent arc-shaped beams by a clamp cable is abandoned, a W-shaped elastic strip buckle is adopted to be a limiting member and realize composure control, and when rock burst is encountered, connecting components between the beams can dislocate mutually along with the two adjacent beams and follow the beams to move, so that the failure of connection at the connecting part of the two adjacent arc-shaped beams is avoided, meanwhile the contraction of the whole support is facilitated, and the stability of connection is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

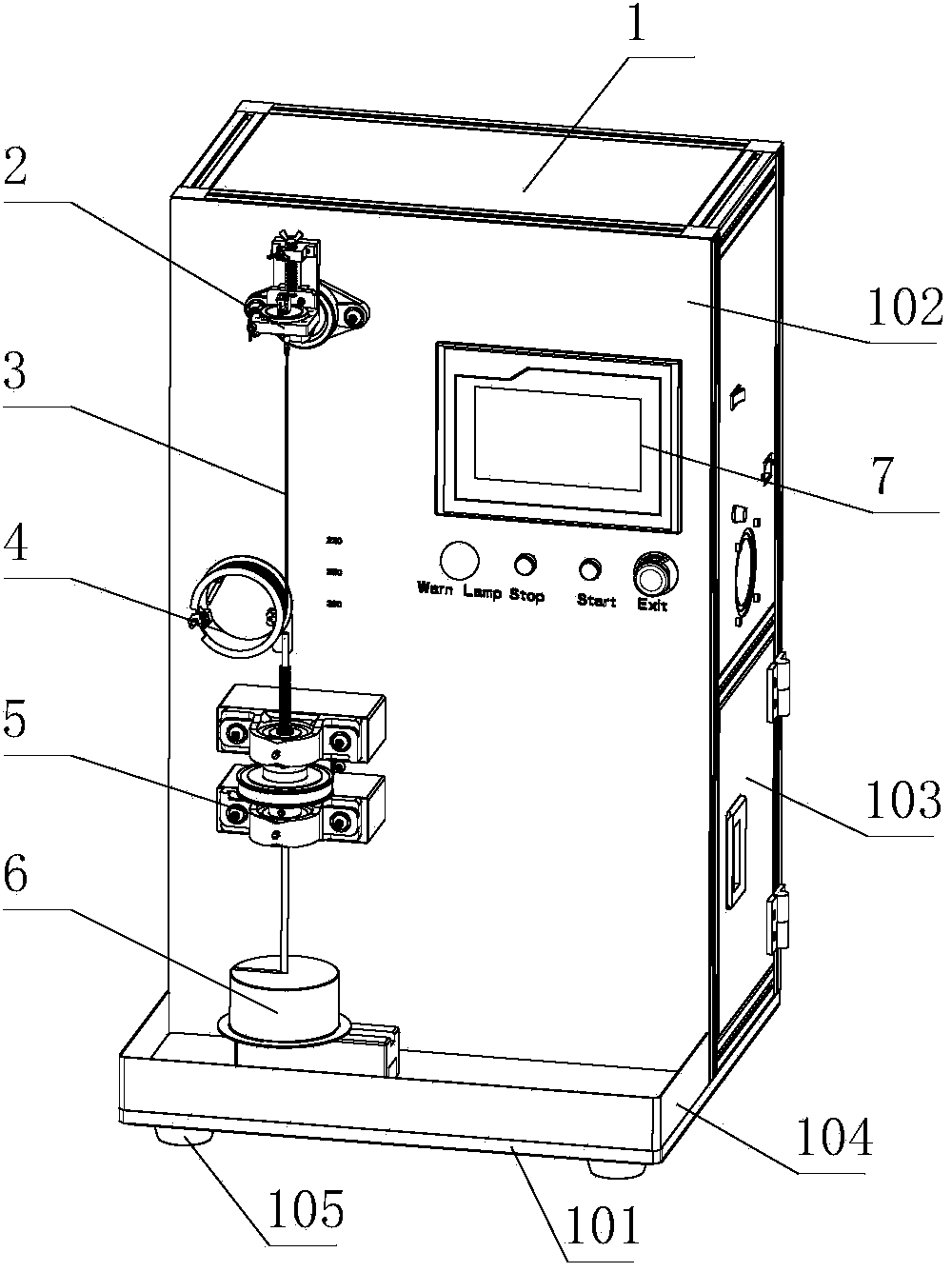

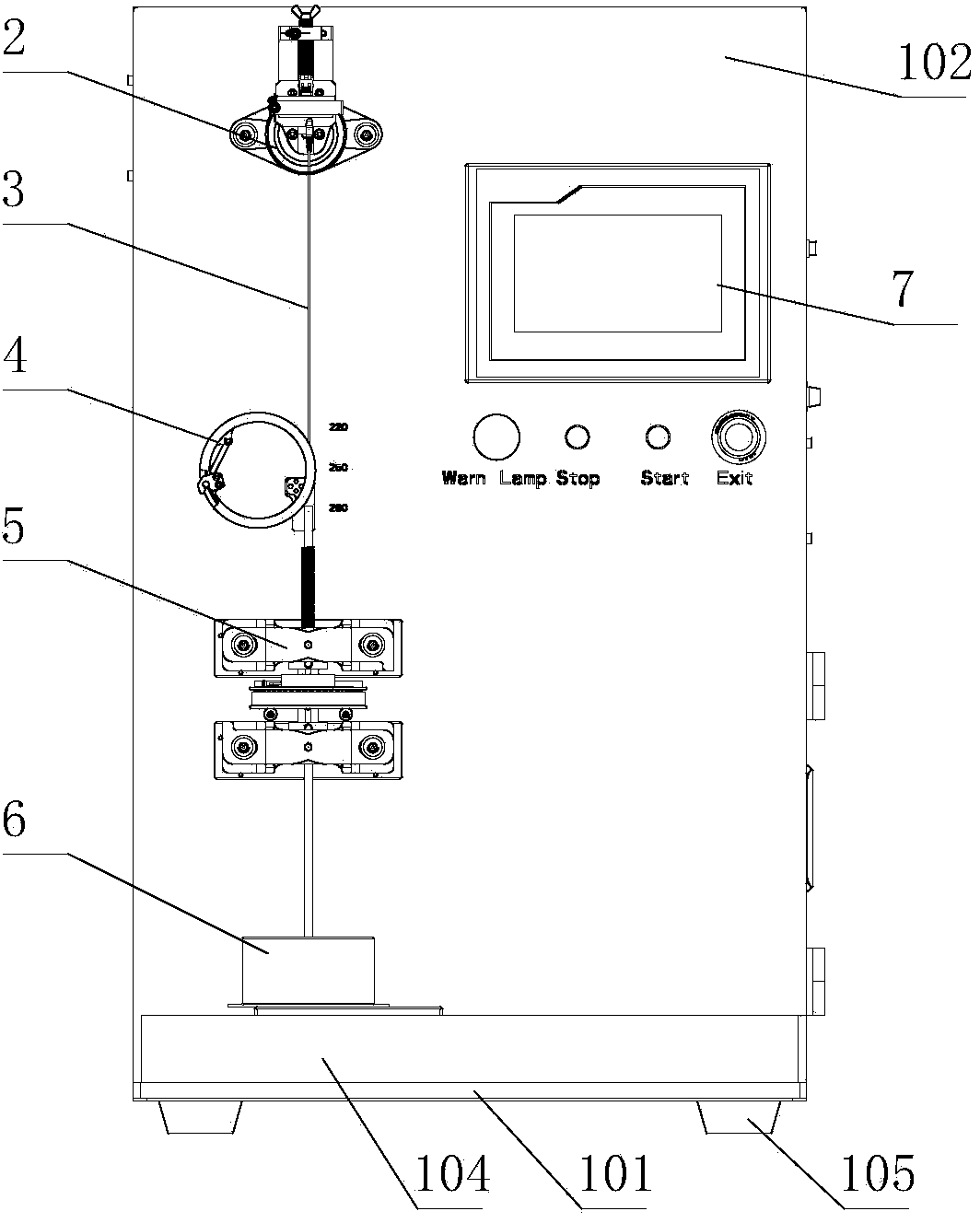

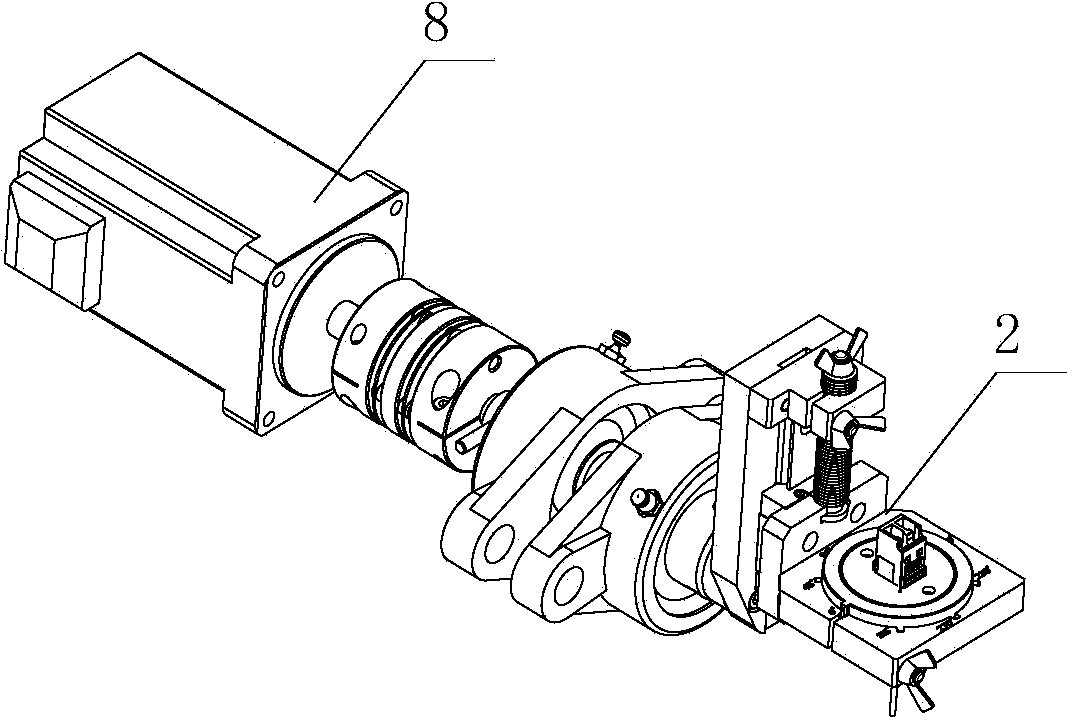

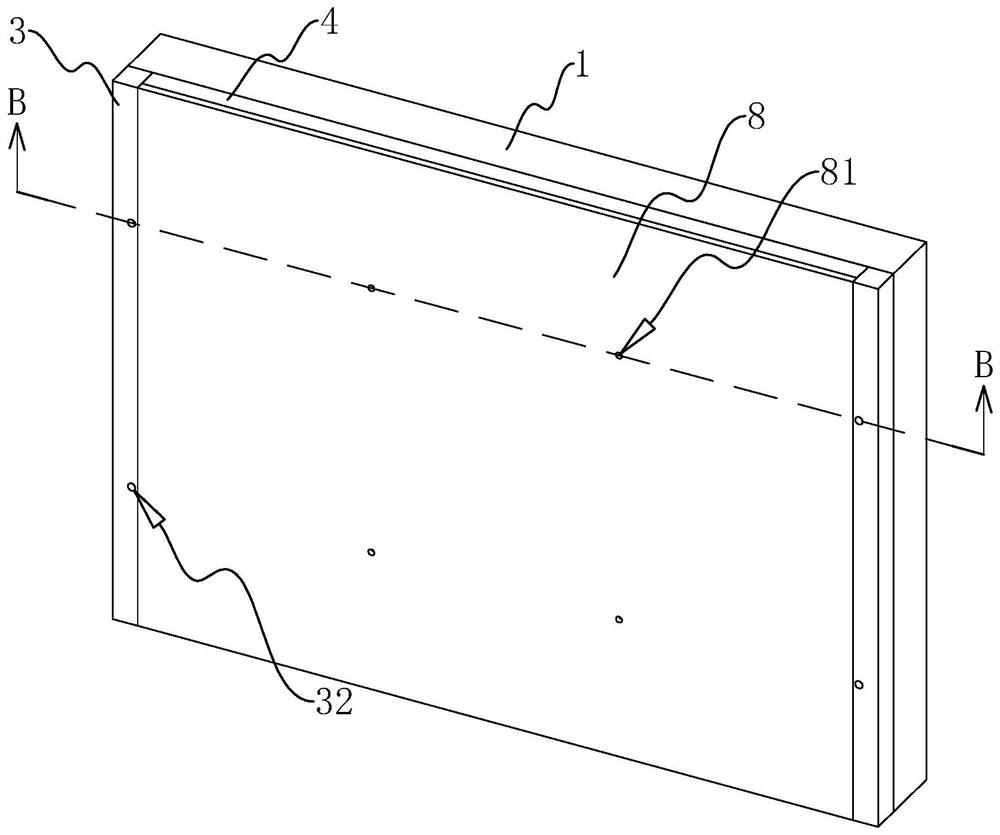

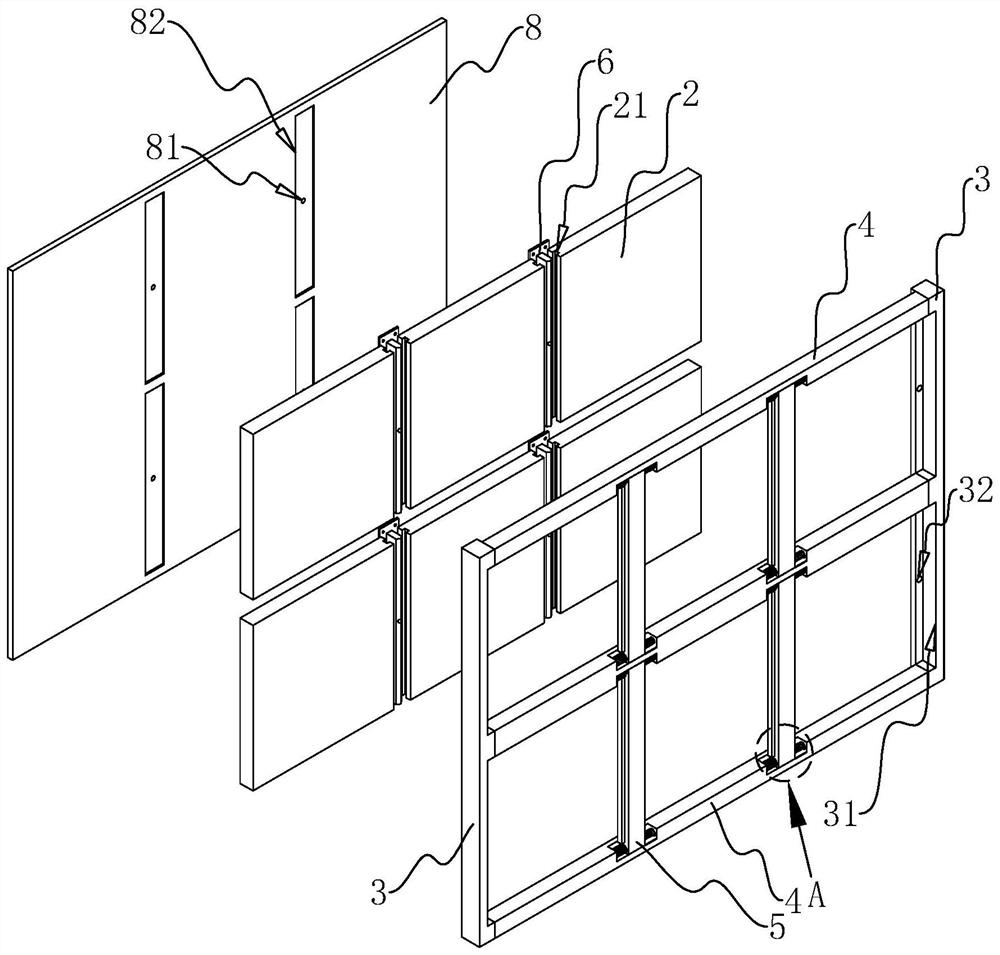

Optical fiber jumping fiber testing device

ActiveCN103543063AEasy to installSimple and efficient operationStrength propertiesEngineeringSurface plate

The invention discloses an optical fiber jumping fiber testing device. The optical fiber jumping testing device comprises a machine case, wherein a bending test clamping mechanism capable of rotating in the plane on which a front panel is arranged is arranged on the front panel of the machine case, and comprises a limit body, wherein an adapter installation component used for installing an adapter is arranged on the limit body detachably. The optical fiber jumping testing device can rapidly replace various optical fiber jumping fibers for testing, so that the testing efficiency is improved.

Owner:SUS TELECOMM

Energy-saving and environment-friendly thermal insulation wall and construction method thereof

ActiveCN113684945ANot prone to offset effectsEnsure connection stabilityCovering/liningsWallsInsulation layerThermal insulation

The invention discloses an energy-saving and environment-friendly thermal insulation wall and a construction method thereof. The energy-saving and environment-friendly thermal insulation wall comprises a wall body and a plurality of prefabricated insulation boards, two vertical main keels are symmetrically arranged on the wall body, mounting grooves are formed in the opposite side walls of the two vertical main keels, a plurality of horizontal keels are arranged between the two vertical main keels, and a plurality of vertical auxiliary keels are movably arranged between every two adjacent horizontal keels; the two ends, in the vertical direction, of each prefabricated insulation board are matched with the every two adjacent horizontal keels in an abutting mode correspondingly, and the ends, in the horizontal direction, of the prefabricated insulation boards are matched with the vertical auxiliary keels in an abutting mode or are matched with the mounting grooves in an inserted mode; and a plurality of buckle plates corresponding to the vertical auxiliary keels in a one-to-one mode are fixed between the two horizontal keels, and the buckle plates are matched with the prefabricated insulation boards on the two sides in an abutting mode. The energy-saving and environment-friendly thermal insulation wall has the effect that the splicing position between the every two adjacent prefabricated insulation boards is not prone to deviation, the connection stability of the splicing position between the every two adjacent prefabricated insulation boards can be kept, and the risk of cracking of an insulation layer can be reduced.

Owner:湖北金漳水利水电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com