Non-welded PHC pipe pile quick connecting method and pulling-resistant quick installing structure

A PHC pipe pile without welding technology, which is applied in the direction of foundation structure engineering, sheet pile wall, building, etc., can solve the problems that the iron plate of the pile is easy to rust, affects the quality of the project, and is not easy to be anti-corrosion and anti-rust treatment, so as to ensure the connection strength, maintaining connection strength, and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

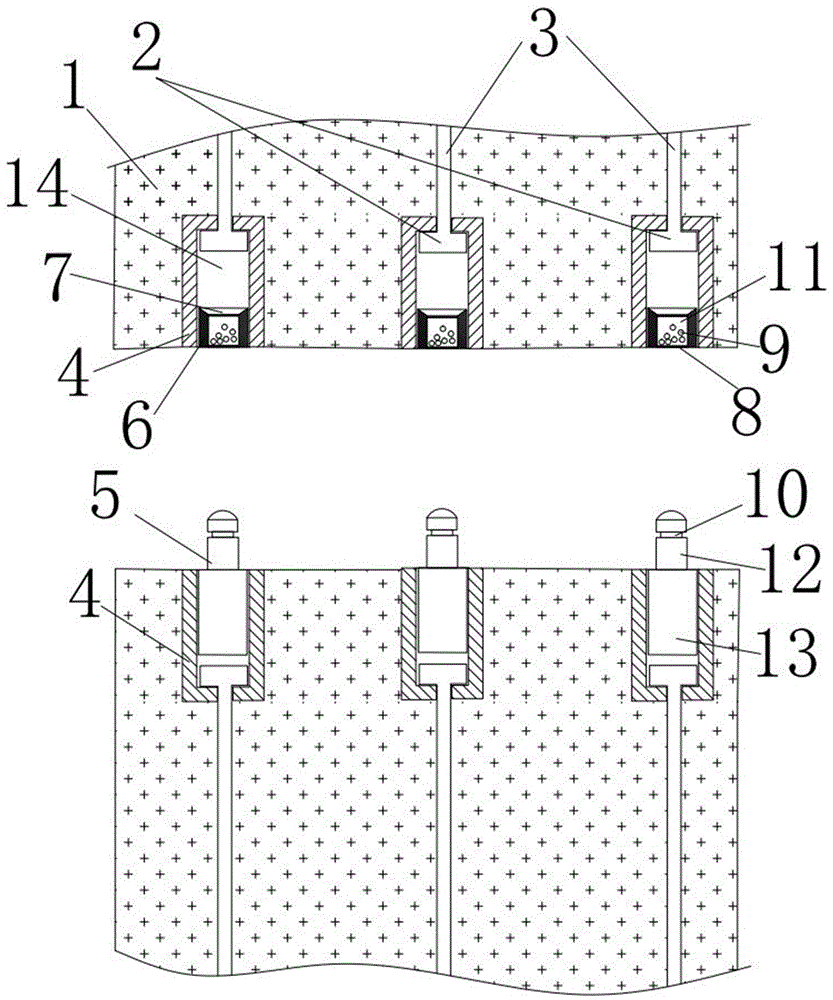

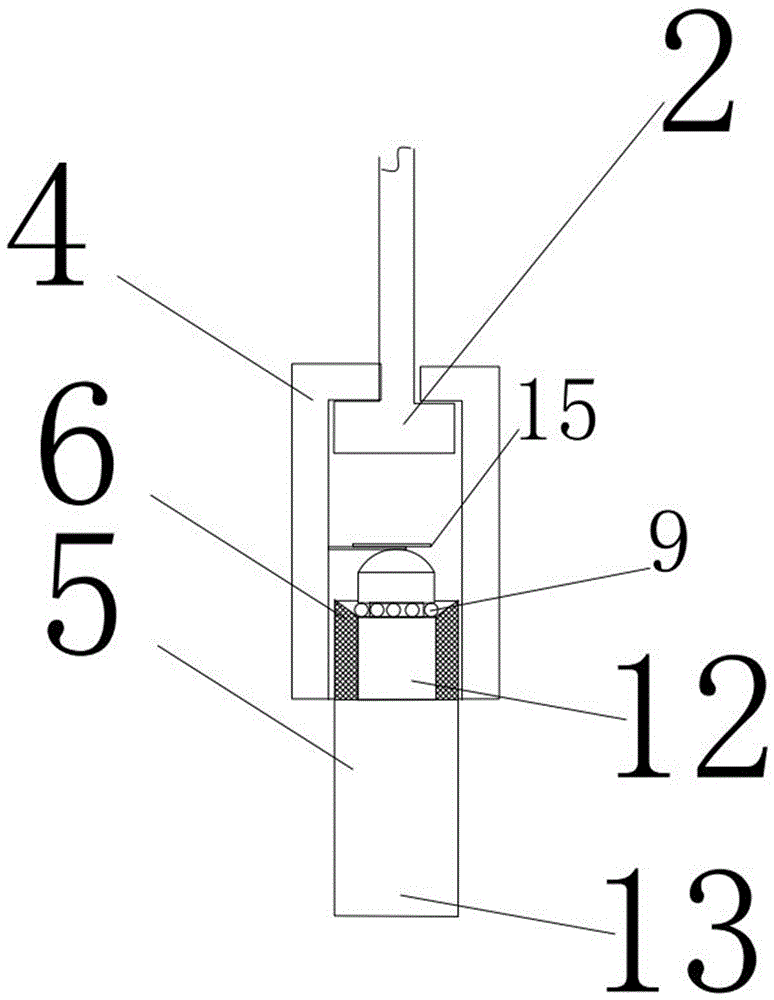

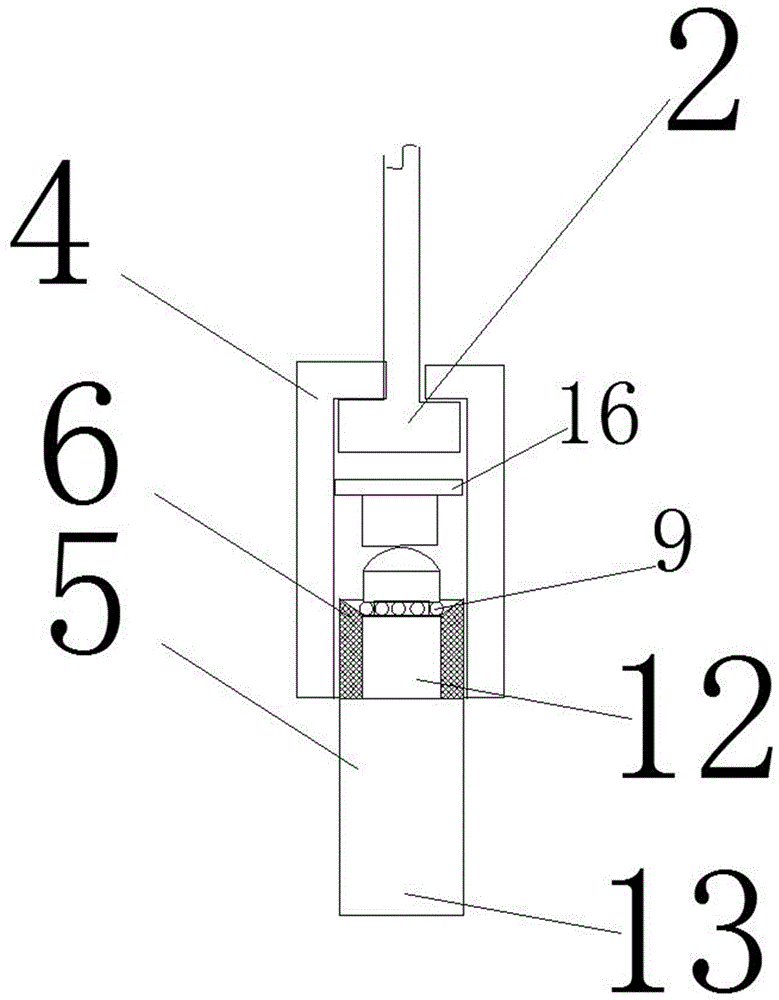

[0029] Such as figure 1 , 2 , 3, 4, and 5 show that the PHC pipe pile has no welding quick connection method and an anti-pull fast assembly structure, and the anti-pull fast assembly structure includes a steel bar head cover 4 and a quick connector fixed at the steel bar end 2 of the pipe pile; The steel bar head cover 4 is cylindrical, one end of the steel bar head cover 4 is fixed at the steel bar end 2, and the other end is fixed with a quick joint fixing structure to fix the quick joint. The quick joint of steel bar 3 of the pipe pile.

[0030] The quick connector includes a quick-connect male 5 and a quick-connect female 6, the quick-connect male 5 includes a stepped shaft, the large end 13 of the stepped shaft is connected to the inner cavity of the steel head cover 4, the small The shaft wall of the end 12 is provided with an annular groove 10 perpendicular to the stepped shaft; the quick-connect female head 6 is a tube through which the small end 12 of the stepped sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com