Patents

Literature

147 results about "Ball release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

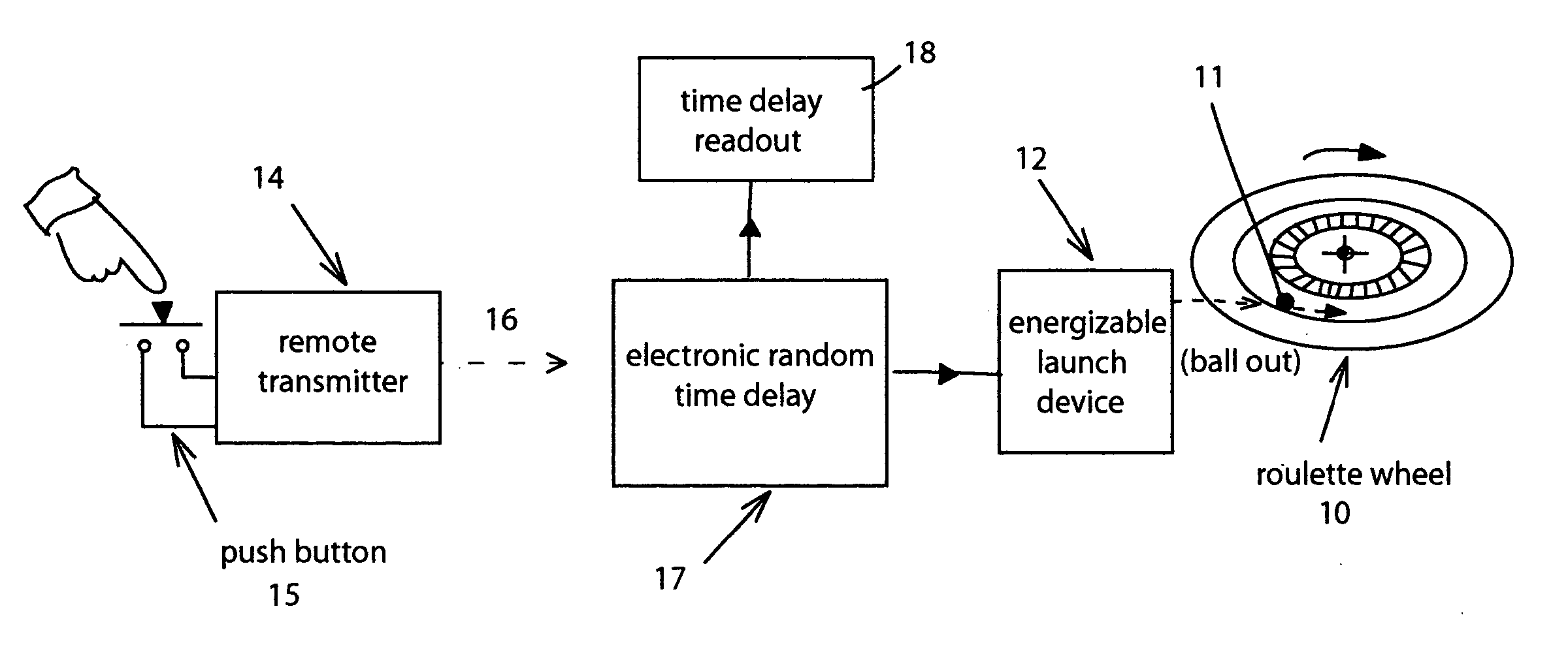

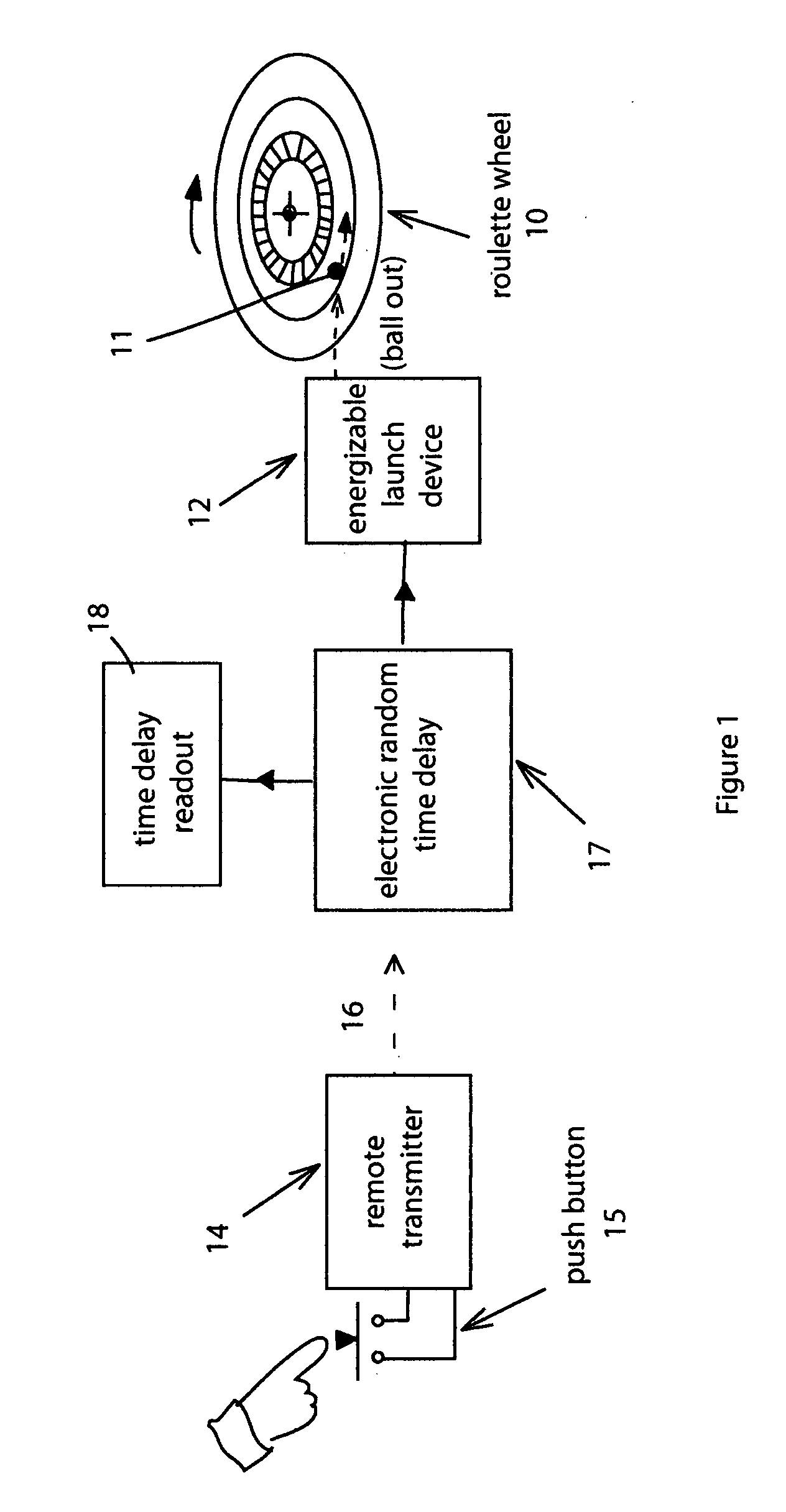

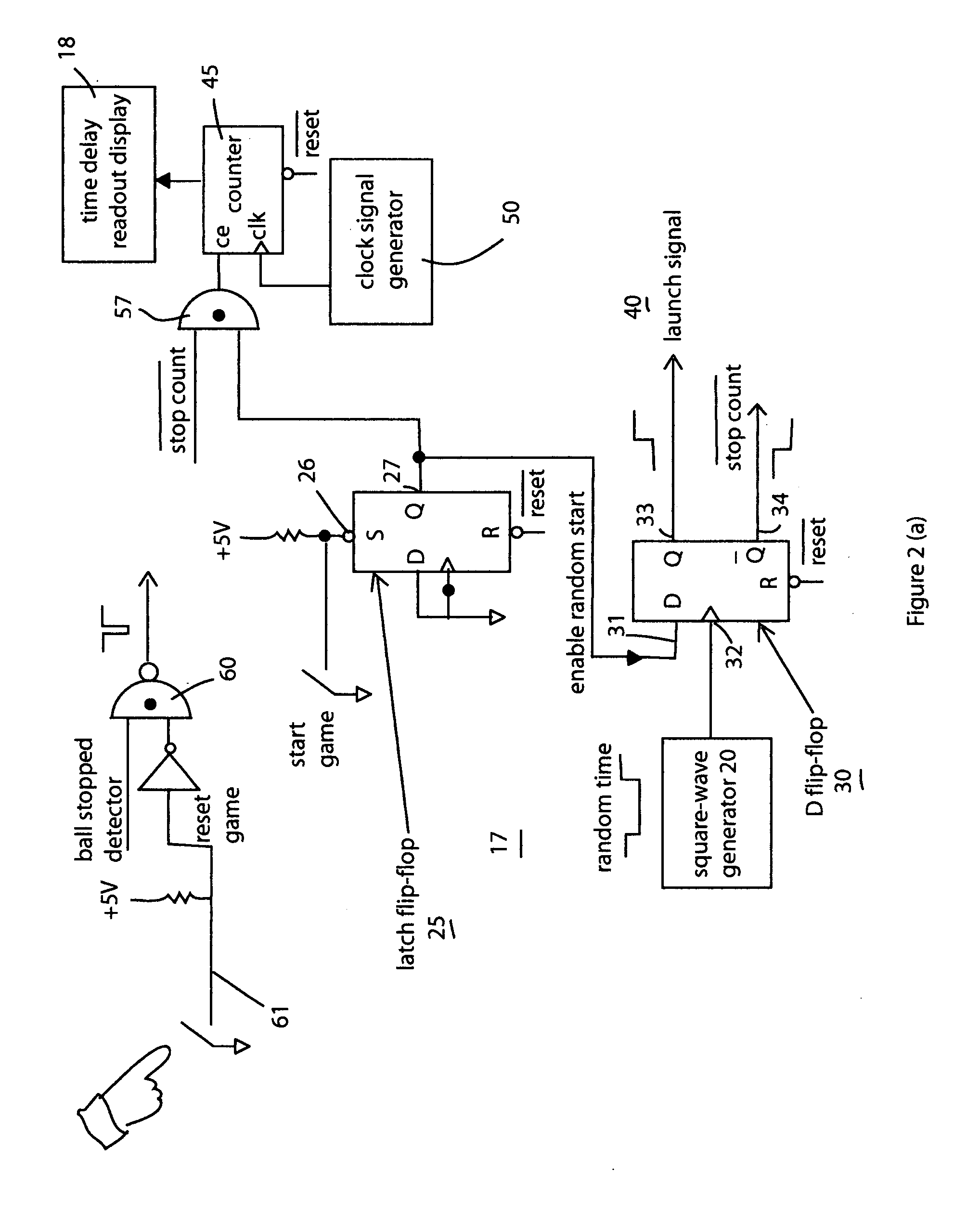

Roulette game random ball release

An improved roulette type game in which an electronic Start signal triggers a Launch signal, but only after an electronically generated random time delay.

Owner:RHOTEN LARRY D

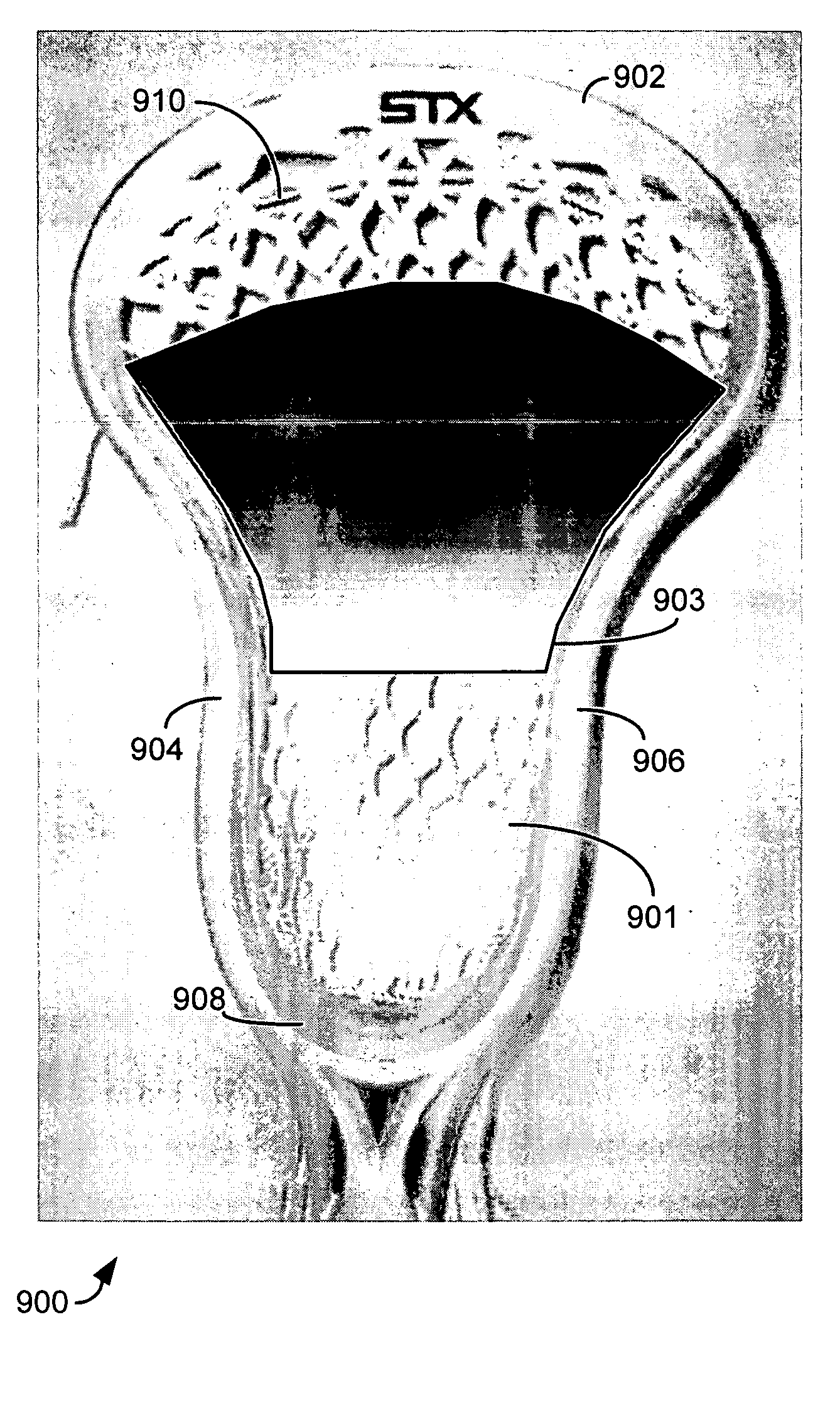

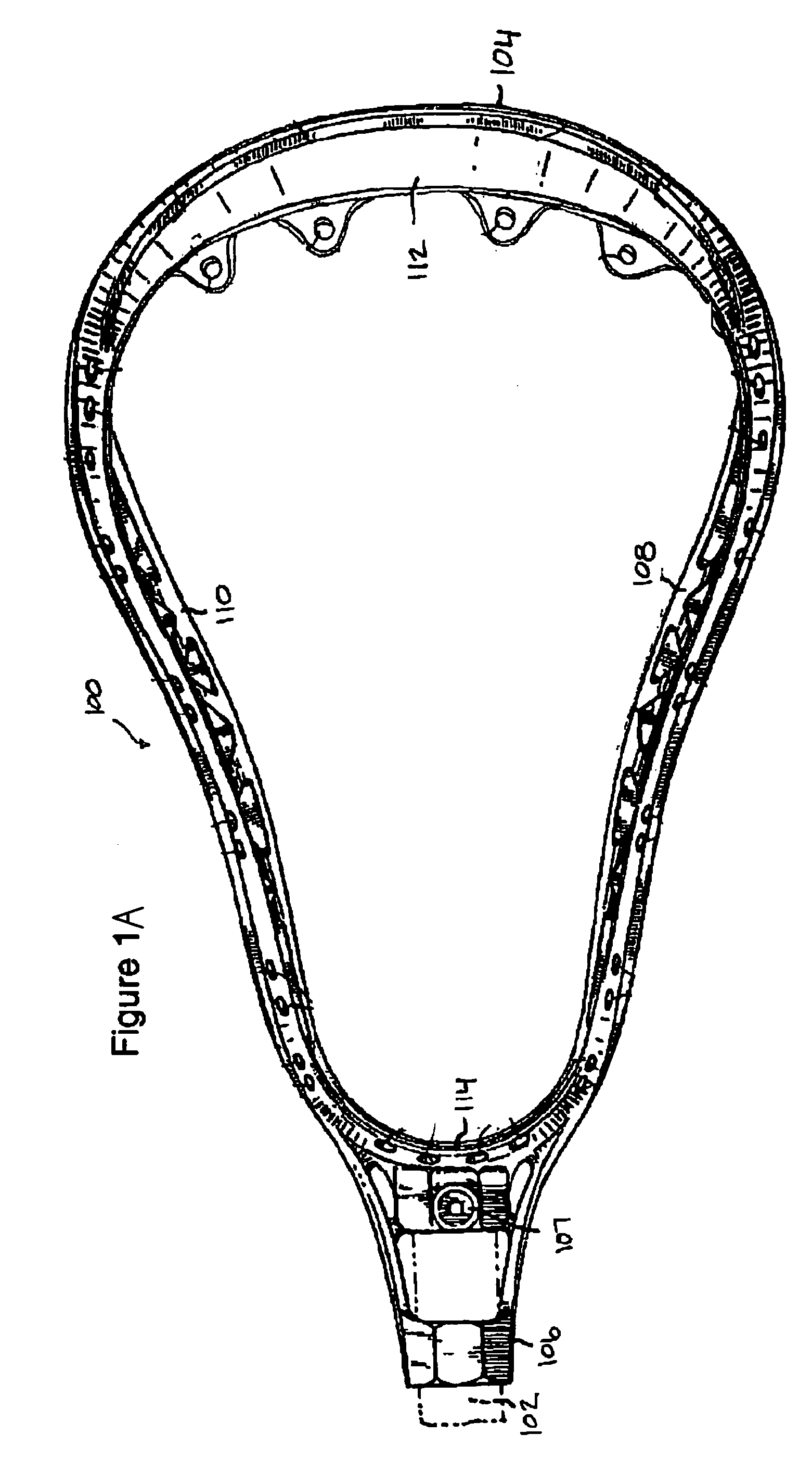

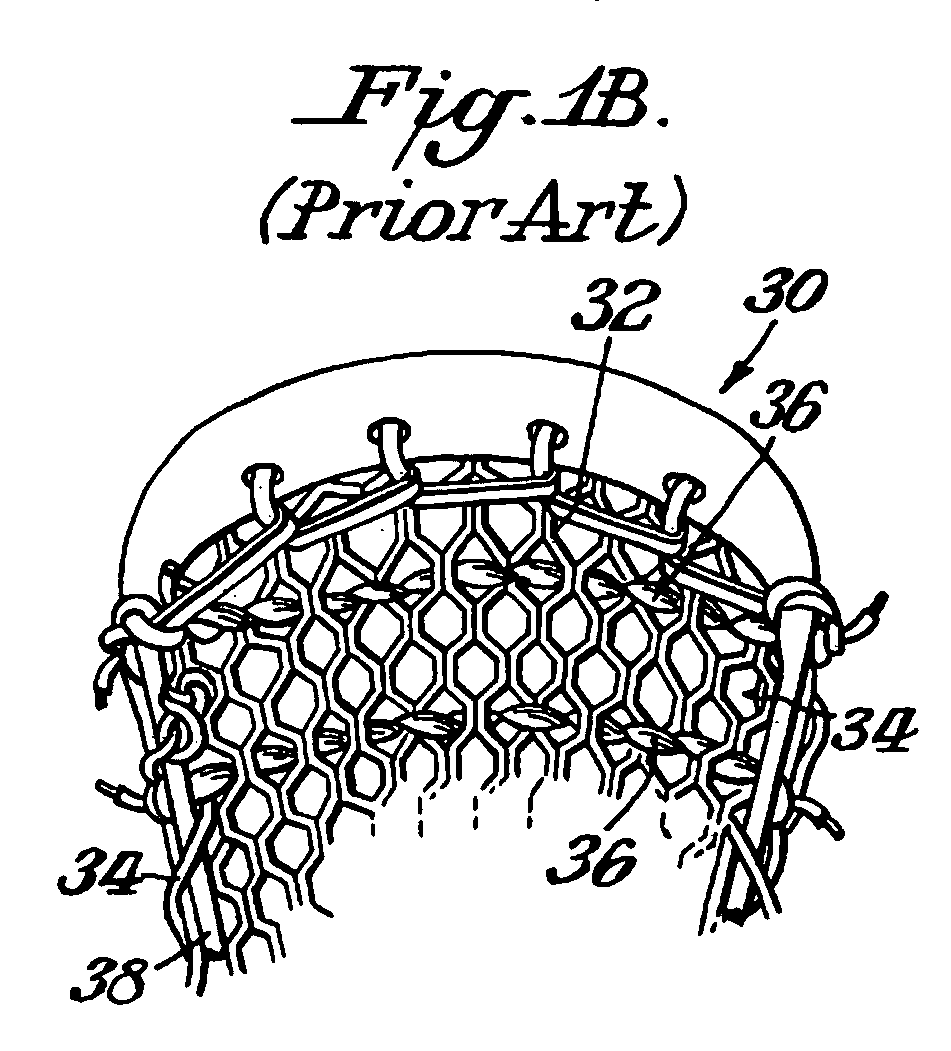

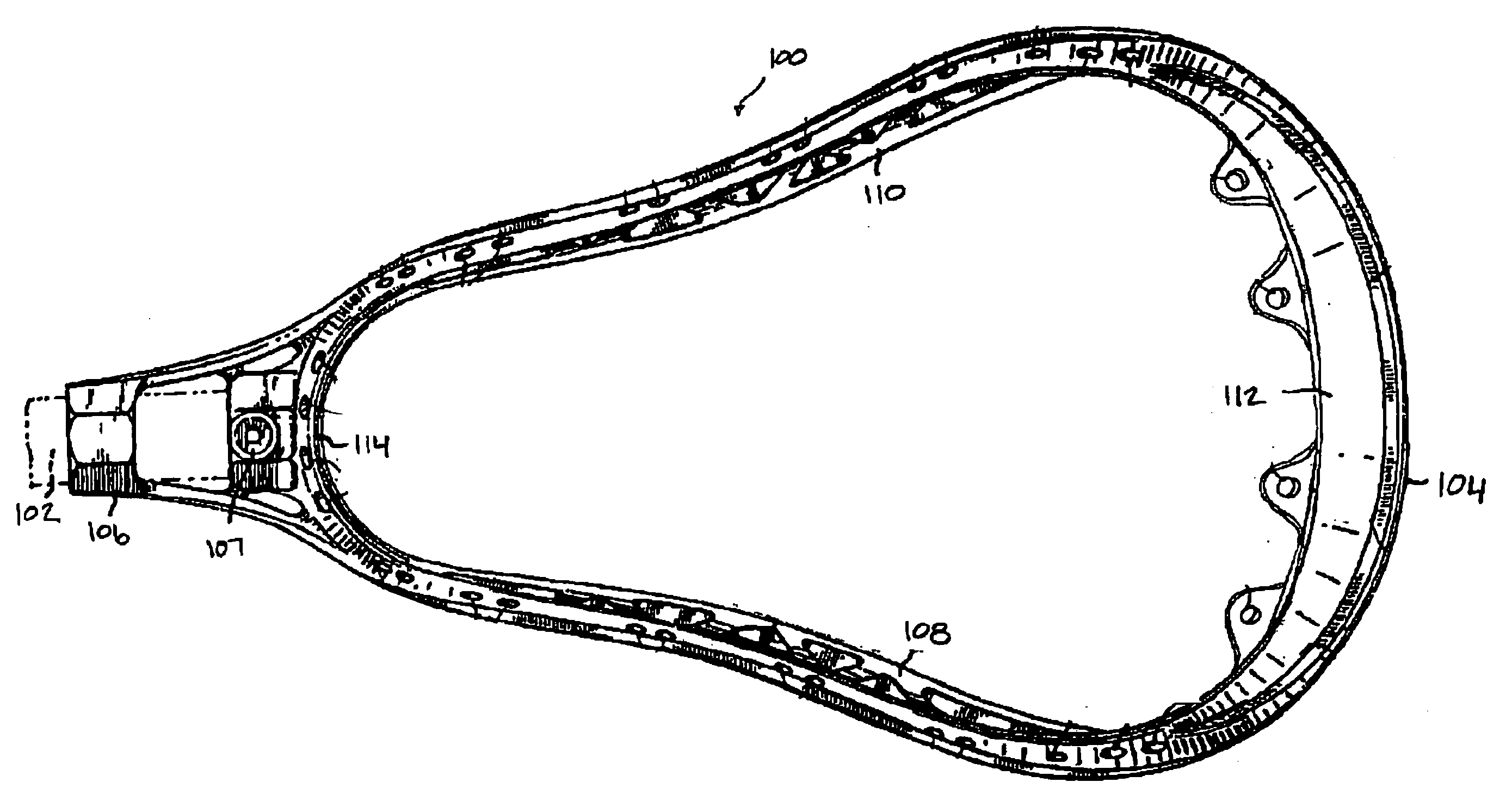

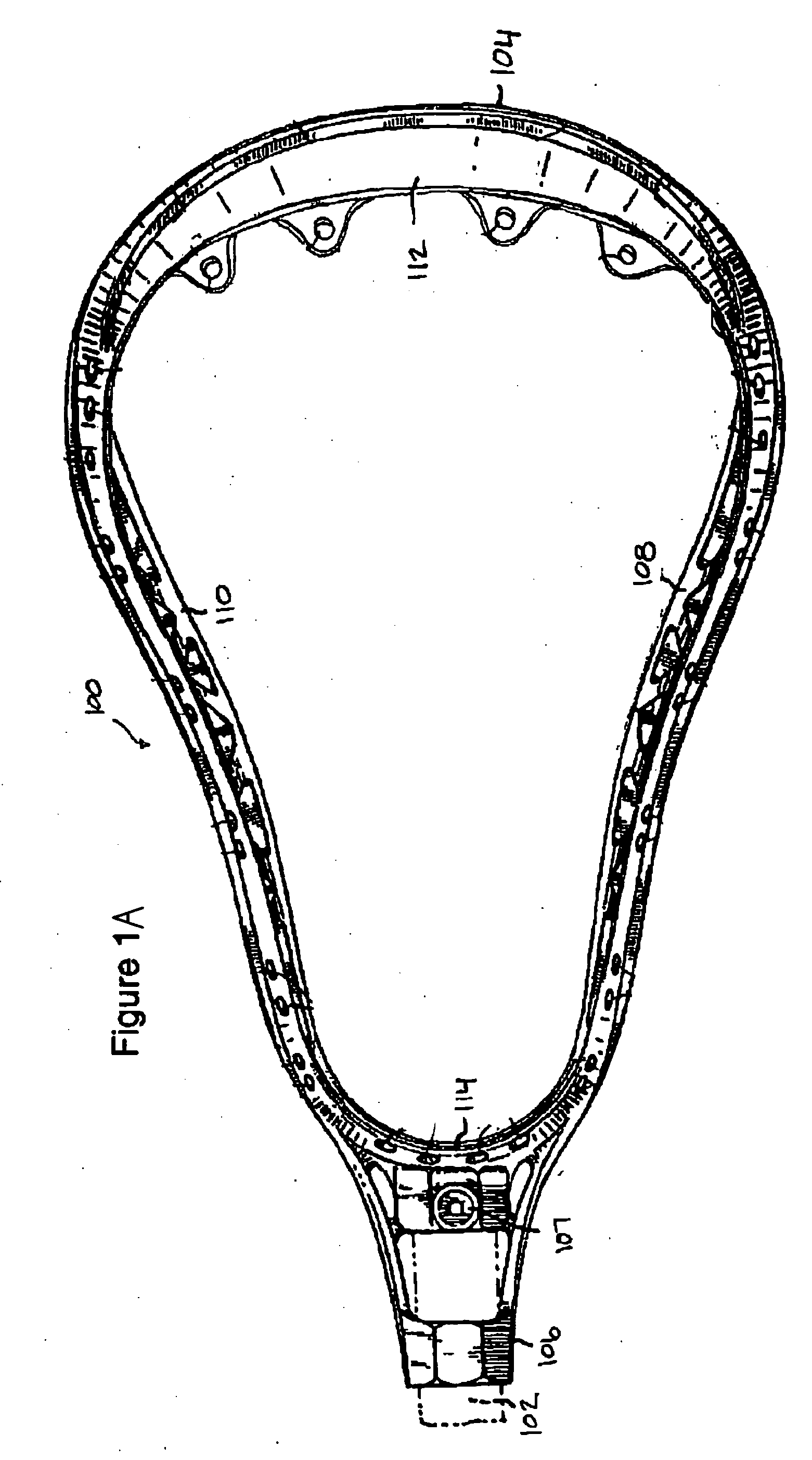

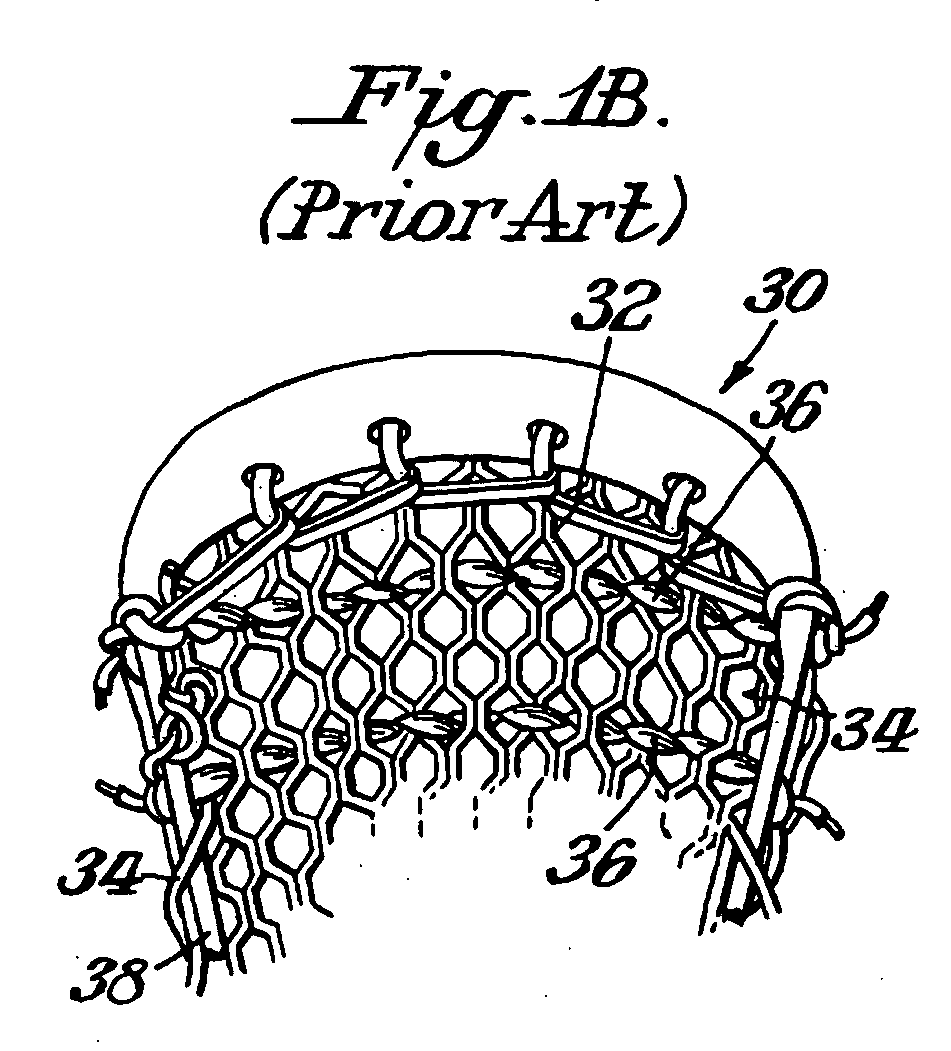

Soft mesh lacrosse head pocket having selectively coated strings

ActiveUS7278936B2Eliminates or minimizes many of the drawbacksPerformance advantageThrow gamesStringed racketsBall releaseEngineering

Owner:WM T BURNETT IP

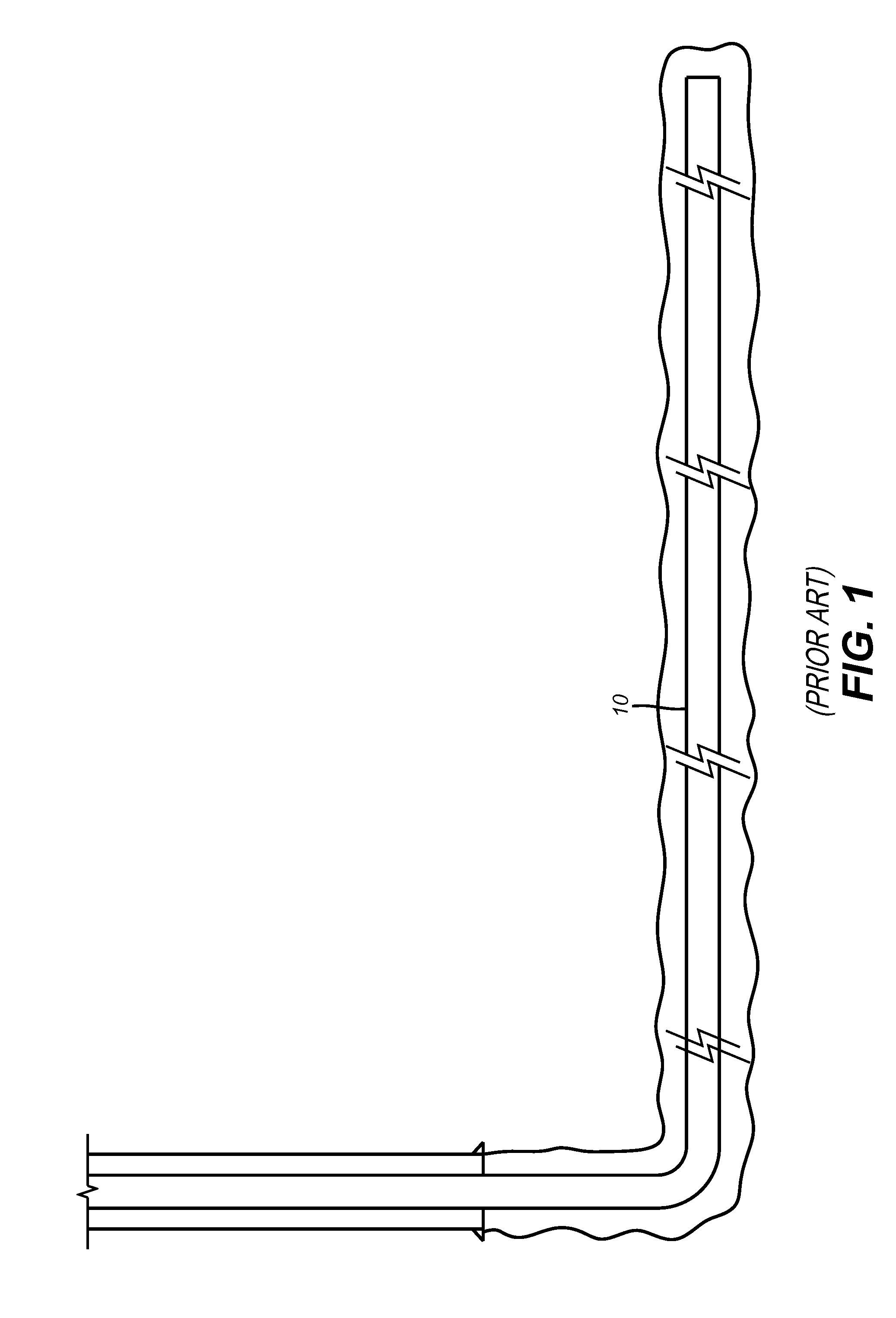

Downhole ball dropping apparatus

A ball release mechanism is mounted near the intended seat. The ball or balls are kept out of the circulating stream. High circulation rates followed by curtailment of circulation places an outlet port in position to allow the ball or balls to be pushed out by a spring. The spring or one of the balls prevents the return of an ejected ball back into the protected pocket. The ball is delivered to the seat without circulation.

Owner:BAKER HUGHES INC

Soft mesh lacrosse head pocket having selectively coated strings

ActiveUS20060046876A1Performance advantageEliminates or minimizes many of the drawbacksThrow gamesStringed racketsBall releaseHead parts

A lacrosse head having a soft mesh pocket with an area of its strings coated with stiffening material. The coated area defines, for example, a ball release area, a ball pocket, and / or a throwing channel. One embodiment provides a lacrosse head pocket that includes a continuous piece of mesh, and a stiffening material coating a first area of the mesh, with a second area of the mesh being uncoated. The first area defines, for example, a ball release area, a ball pocket, and / or a throwing channel.

Owner:WM T BURNETT IP

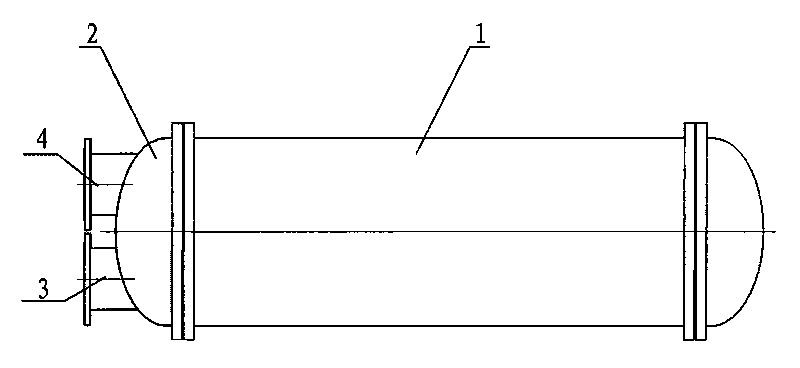

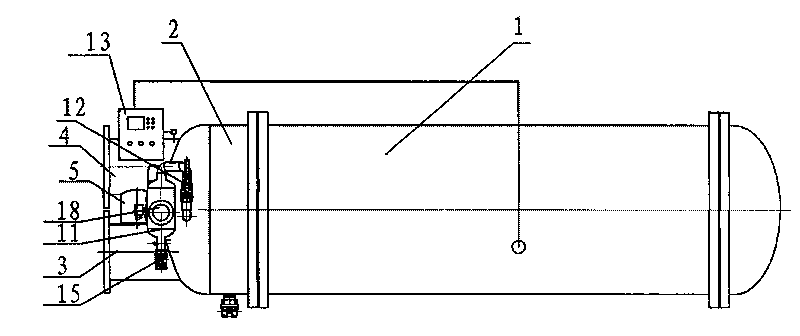

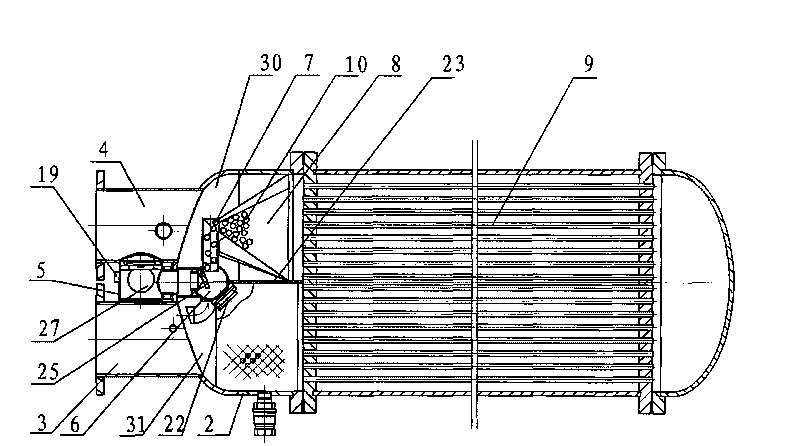

Front-end end enclosure channel box of shell and tube condenser of water-cooling water chilling unit with rubber ball online cleaning function

ActiveCN101691980AWith automatic online cleaning functionSimple structureEnergy industryHeat exchanger casingsAutomatic controlWhole body

The invention discloses a front-end end enclosure channel box of a shell and tube condenser of a water-cooling water chilling unit with a rubber ball online cleaning function. The front-end end enclosure channel box and a rubber ball automatic online cleaning device are designed into a whole body, and in addition to a structure of a general front-end end enclosure channel box, the front-end end enclosure channel box also comprises a ball recovering device, a rubber ball collecting chamber, a ball releasing device, a subarea drainage device, a ball releasing subarea clapboard, a ball observing device, a ball recovering and releasing automatic control valve, an end error automatic monitoring and recording device and a rubber ball automatic cleaning controller. The front-end end enclosure channel box automatically achieves subarea cleaning, online observation and rubber ball replacement, automatically displays and records running end errors of the water chilling unit, has the functions of adjusting the frequency, the period and the start and the stop manually, and can ensure that the end error increment of the water chilling unit is not over 0.3 DEG C so that the water chilling unit is always in a high-efficient running state. The front-end end enclosure channel box has a simple and compact structure, the rubber ball recovering, releasing and cleaning processes are completely achieved by means of a hydraulic power principle and the pressure difference of entering and exiting cooling water, no external power is needed, and the front-end end enclosure channel box is energy-saving and environment-friendly and can leave a factory together with the water-cooling water chilling unit.

Owner:倪永刚

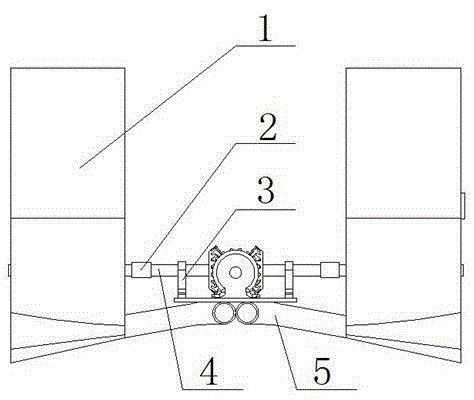

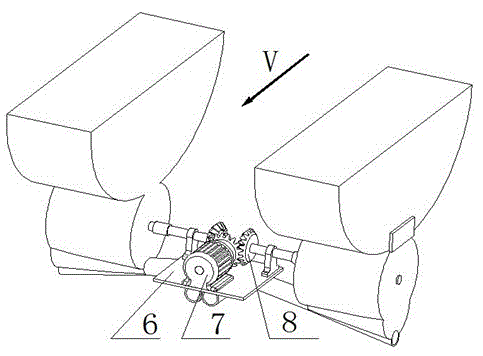

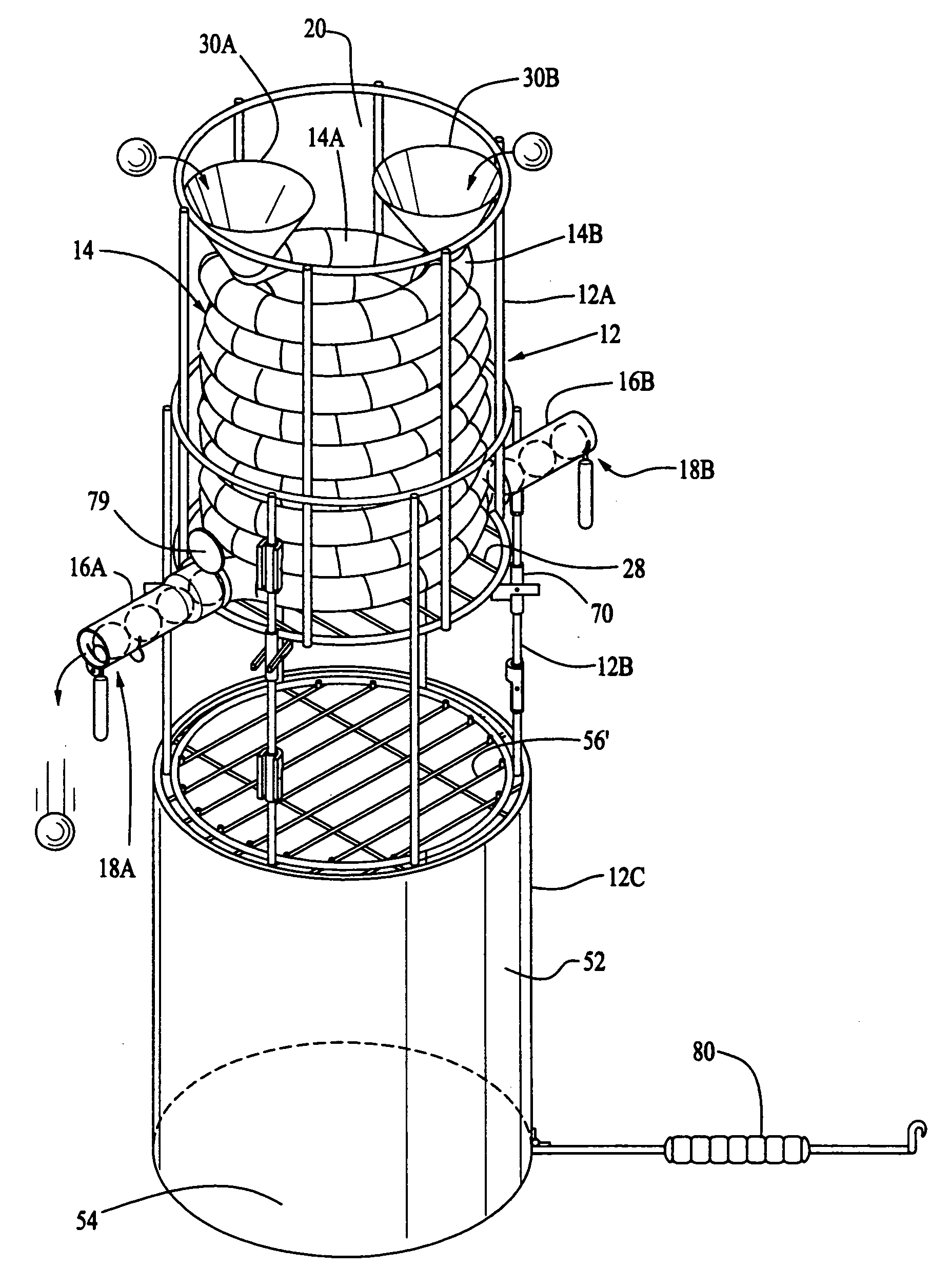

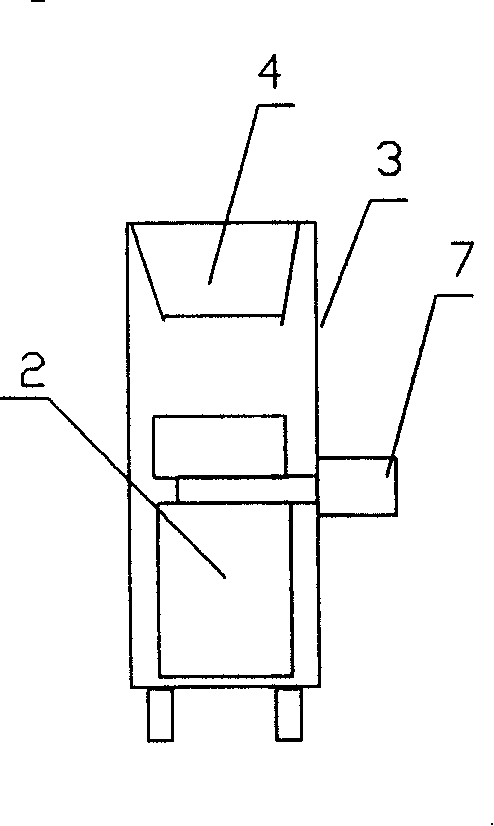

Biological control ball releasing device matched with airplane

ActiveCN105197244AStable center of gravityRealize mechanized deliveryAircraft componentsLaunching weaponsMotor driveGravity center

The invention discloses a biological control ball releasing device matched with an airplane, which relates to the field of agricultural plant protection machinery. Two ball releasing devices are arranged at two sides of the airplane, so that the stability of the gravity center of the airplane is guaranteed; when the whole device works, a motor drives outer groove wheels in the left and right ball releasing devices to rotate, and the outer groove wheels drive the balls to reach a cylindrical ball guiding groove, and then the balls are discharged from the ball releasing devices; in addition, the releasing amount of the balls is regulated by regulating the rotating speed of the motor or the length of a ball releasing groove baffle; the left-right space between every two balls reaching the ground is regulated by regulating the size of an air inlet of an air inlet pipeline; the whole device realizes mechanical releasing of natural enemy insects in biological control, so that labor intensity is greatly reduced.

Owner:JIANGSU UNIV

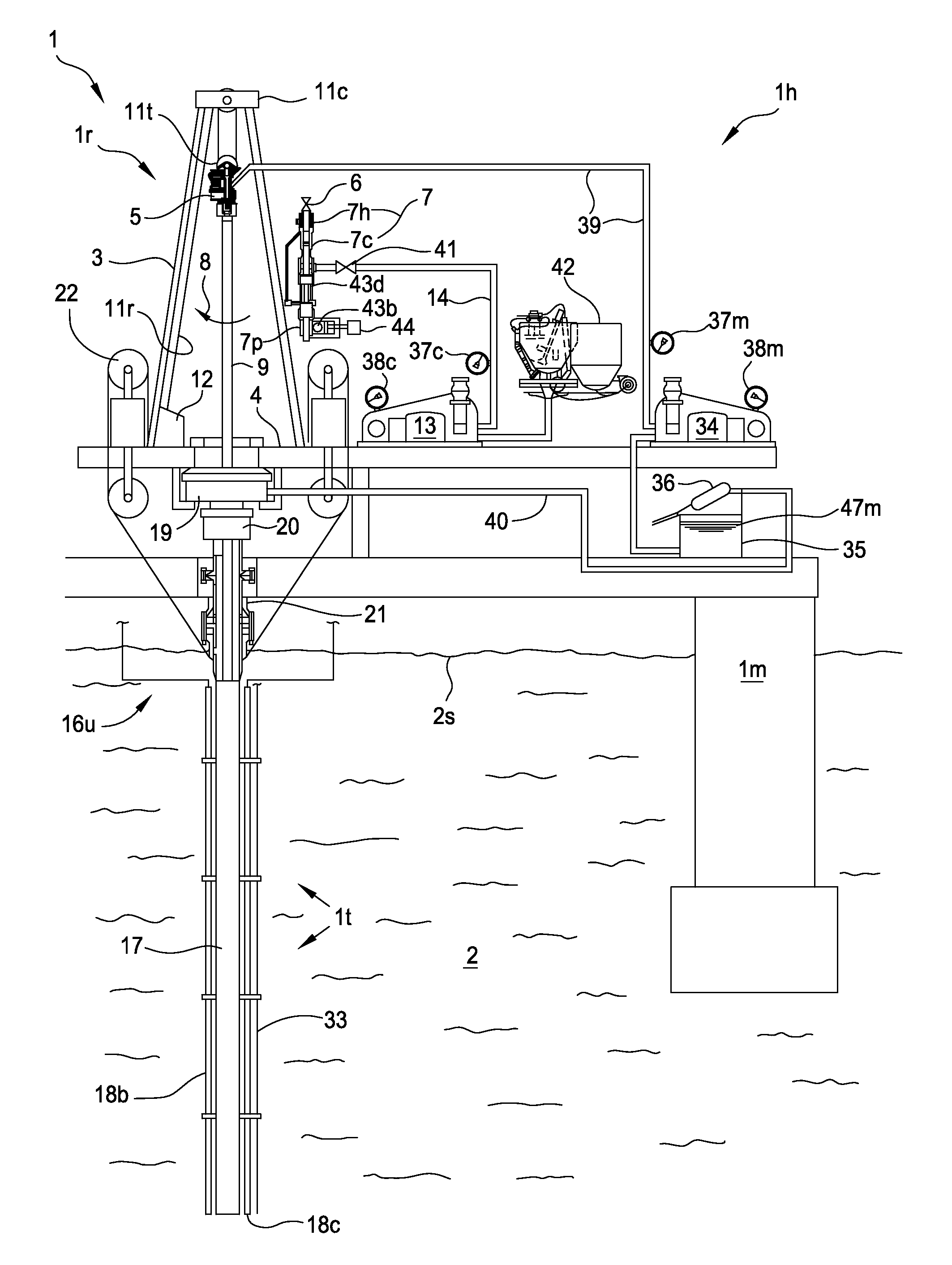

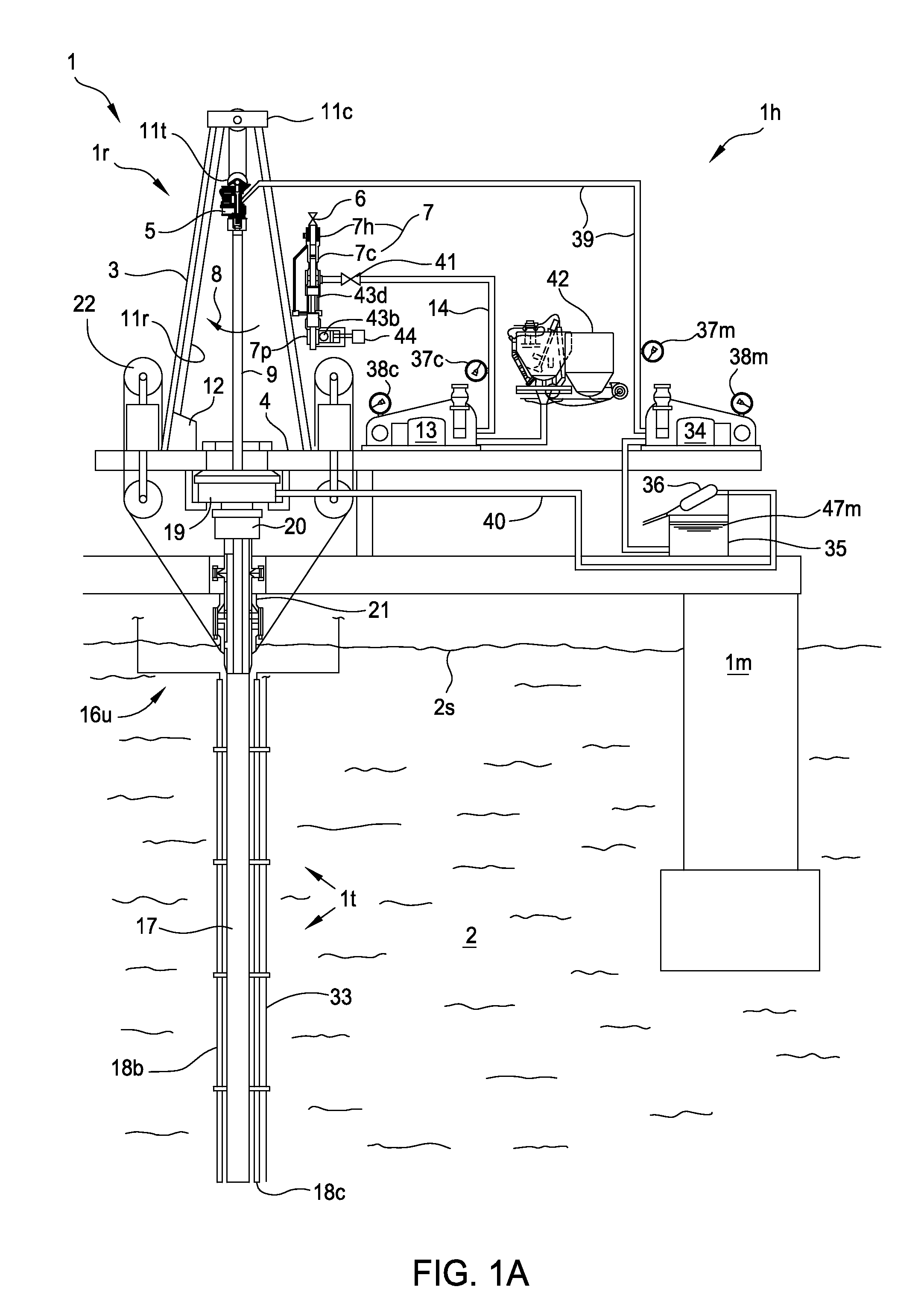

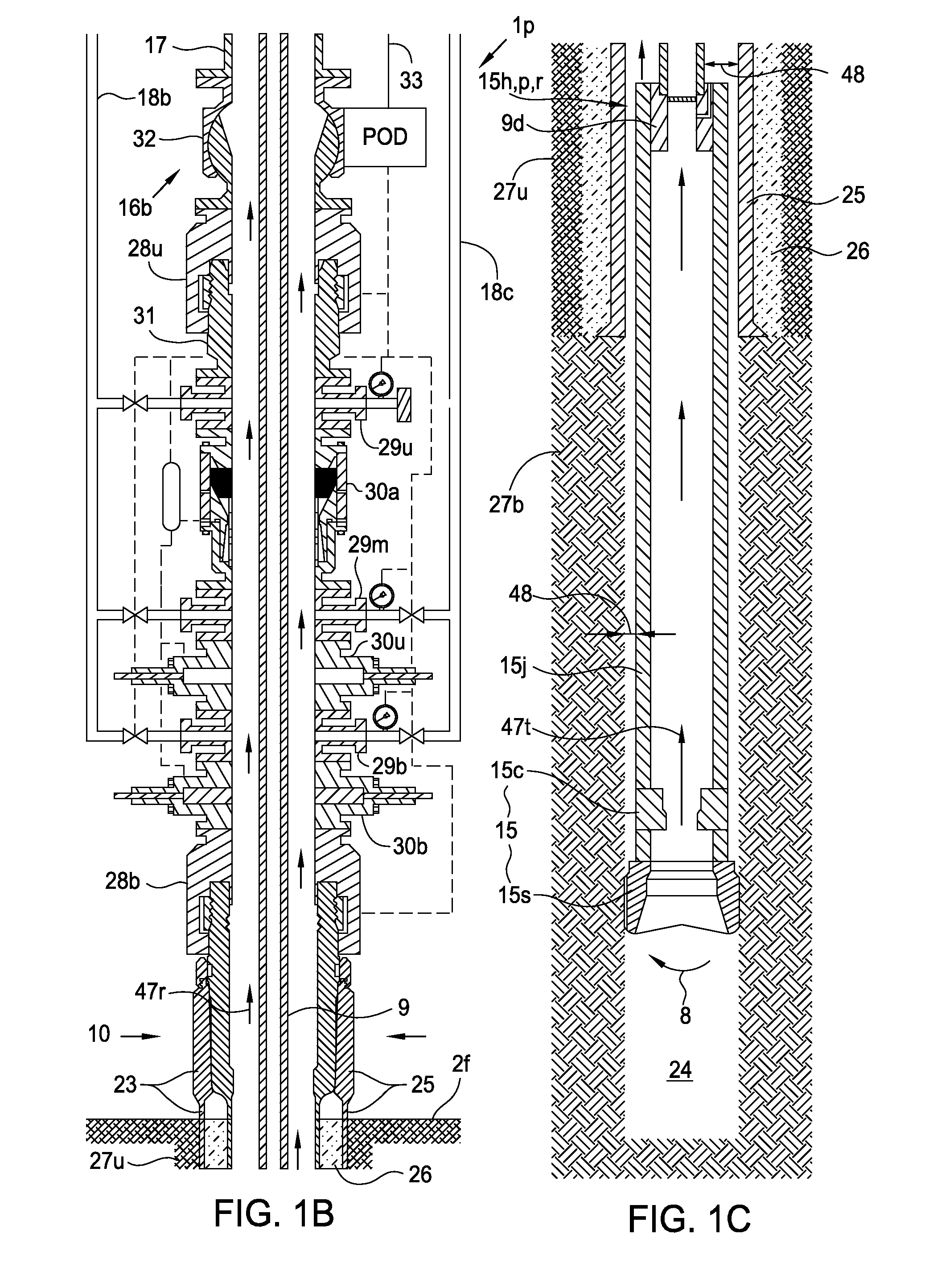

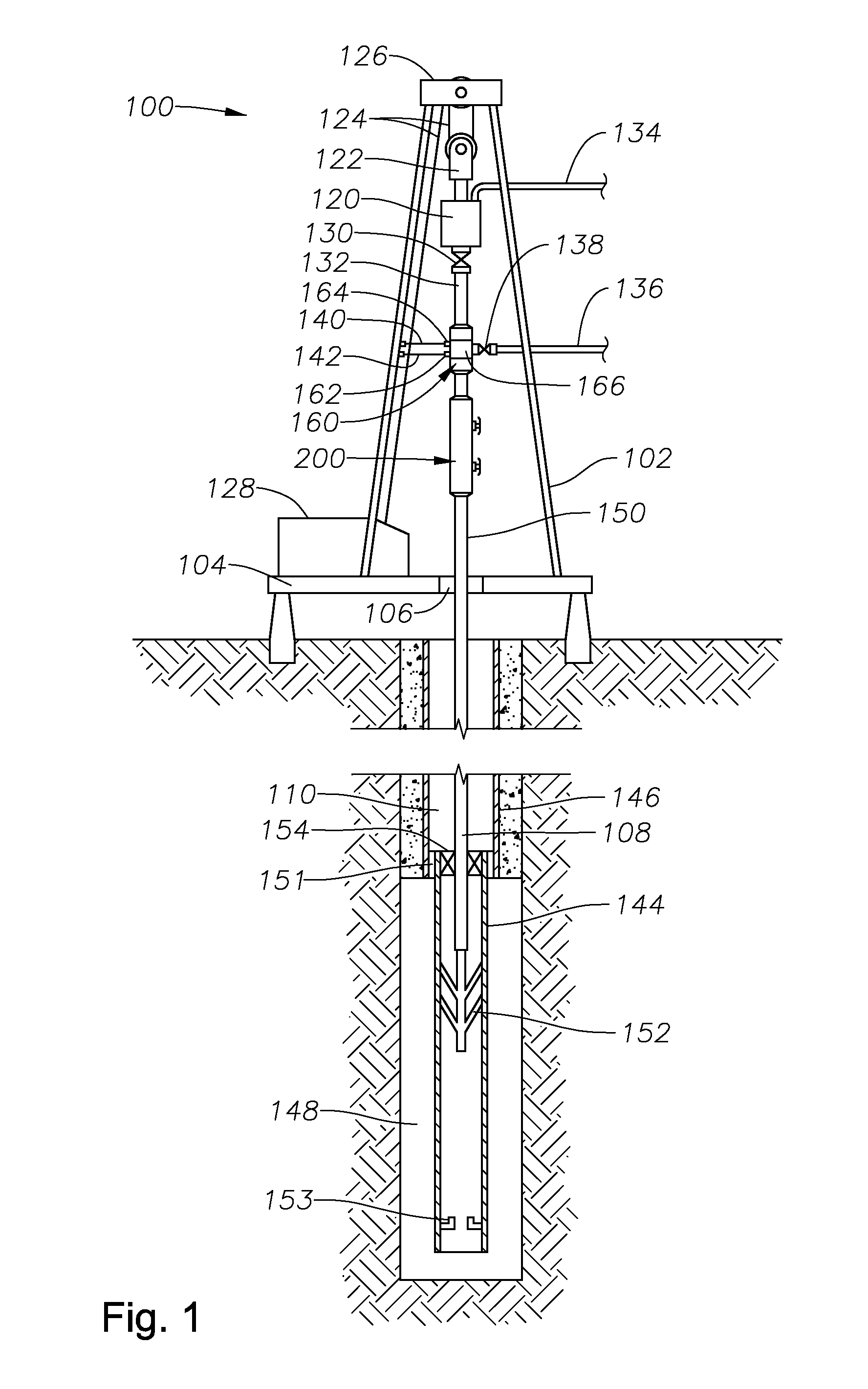

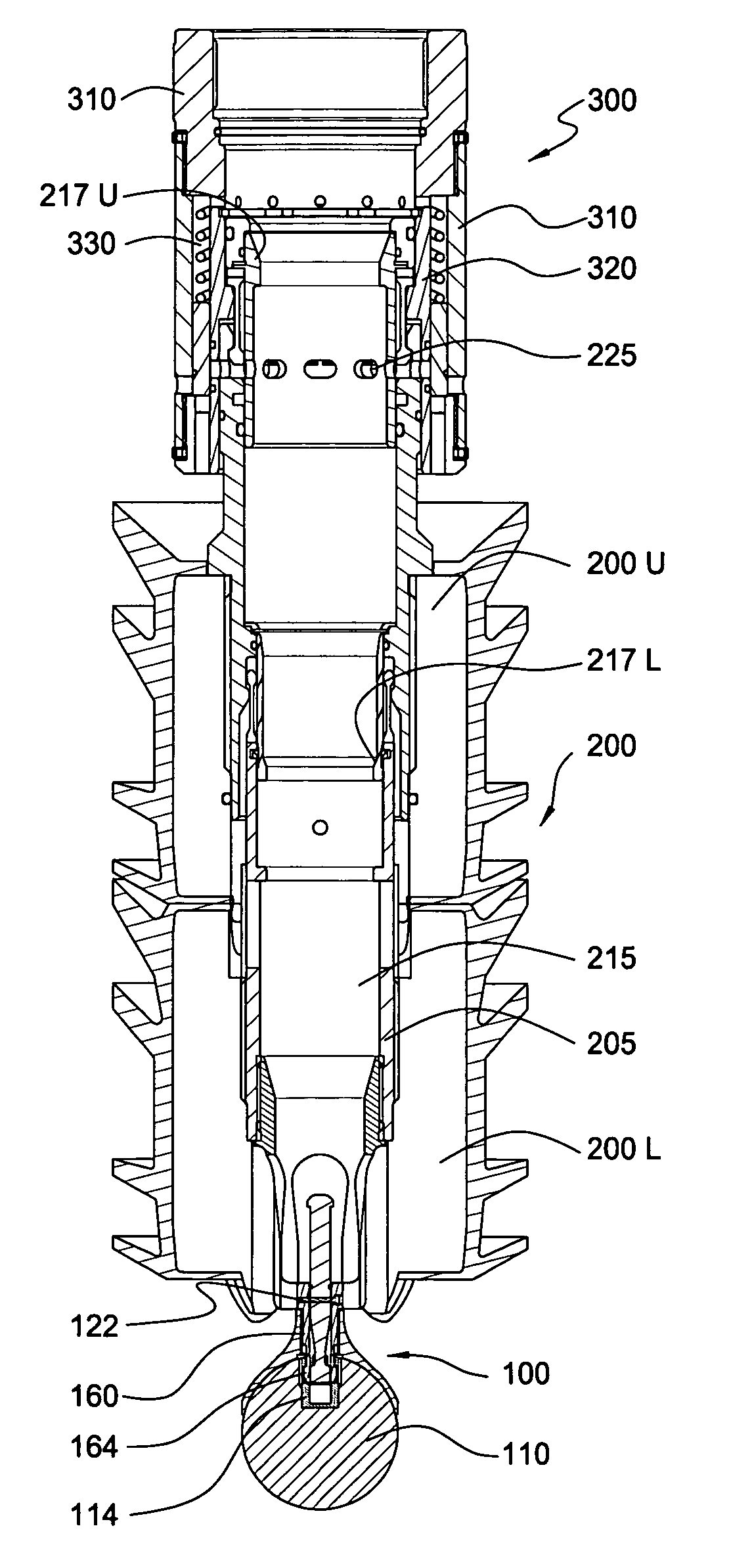

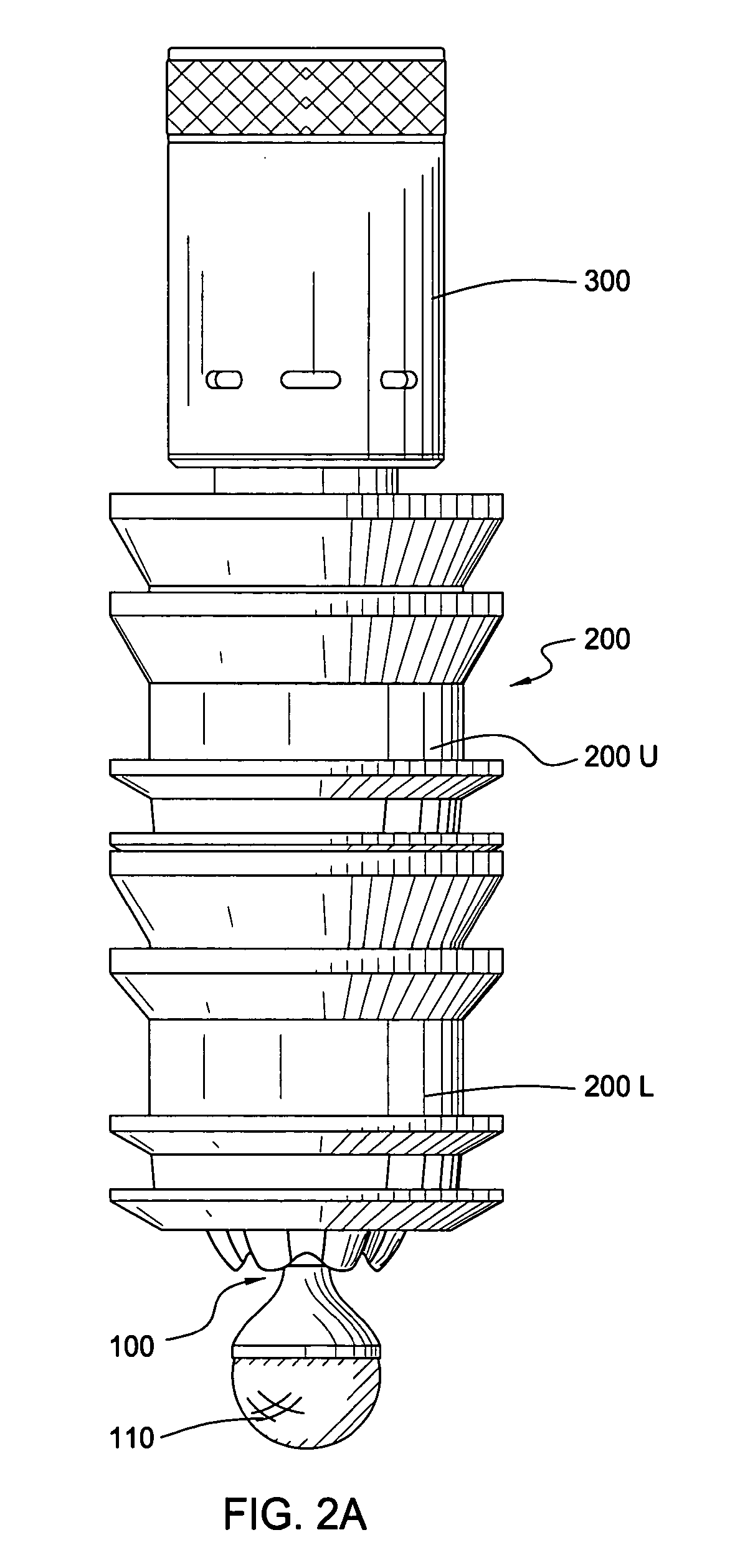

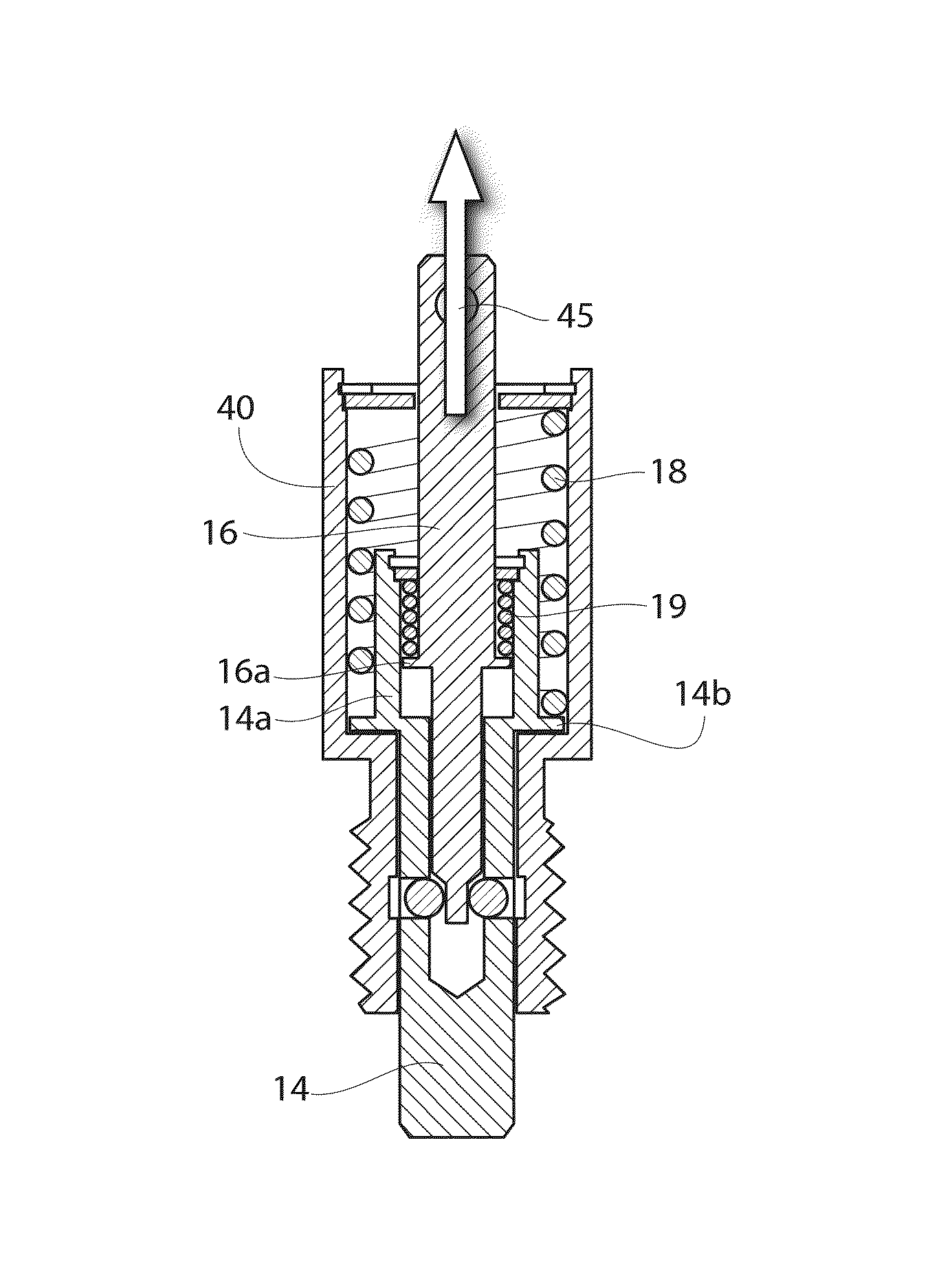

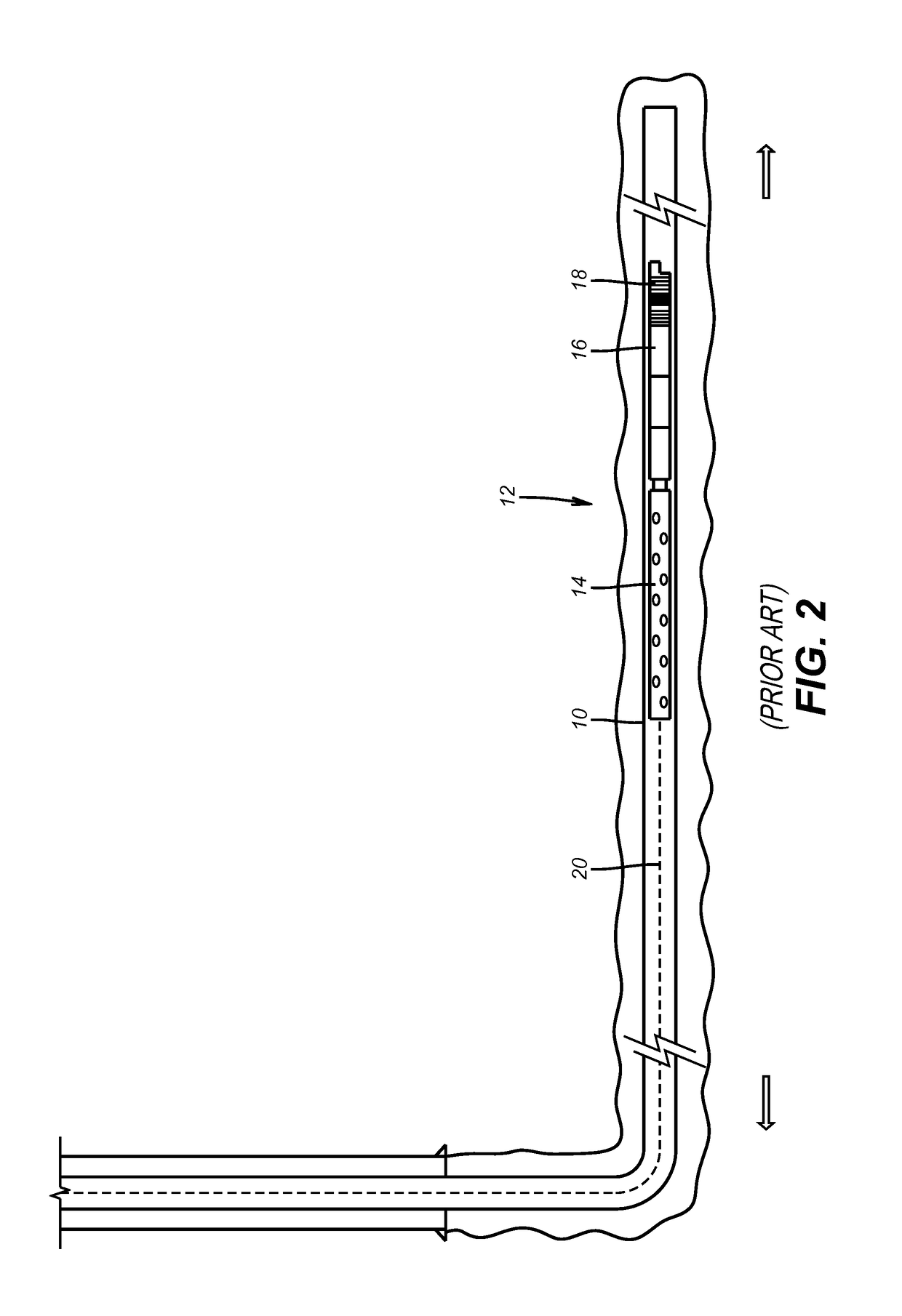

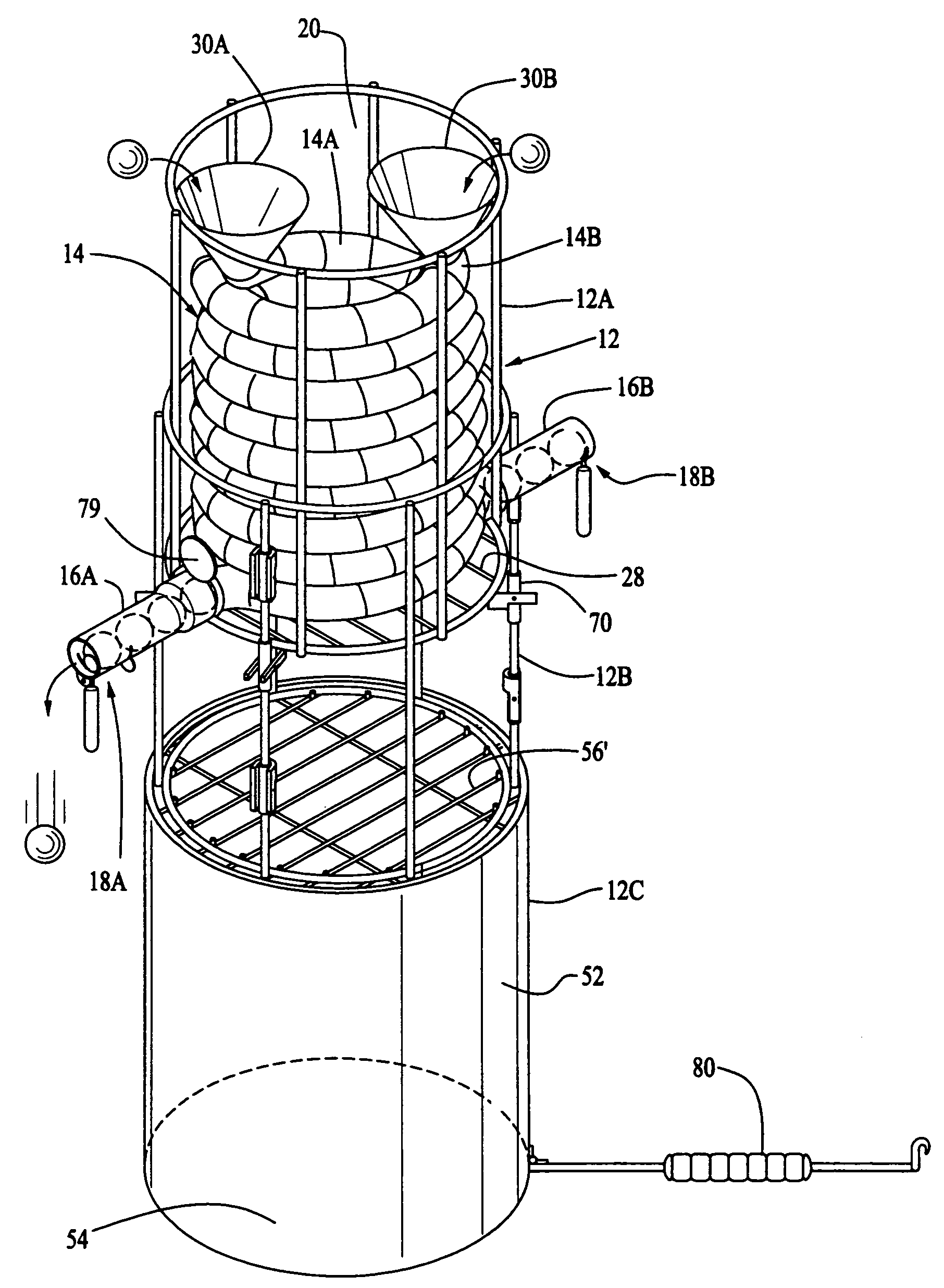

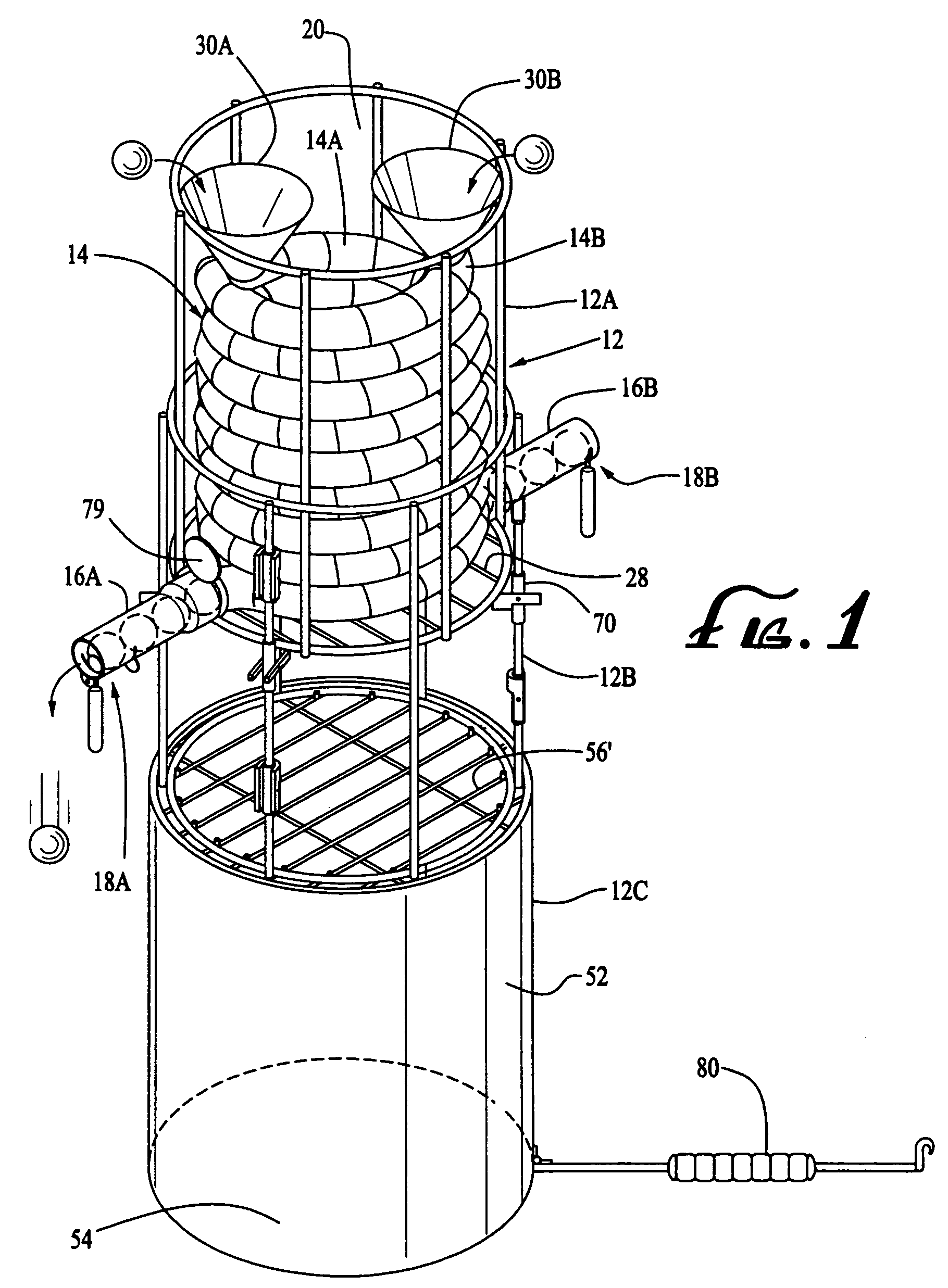

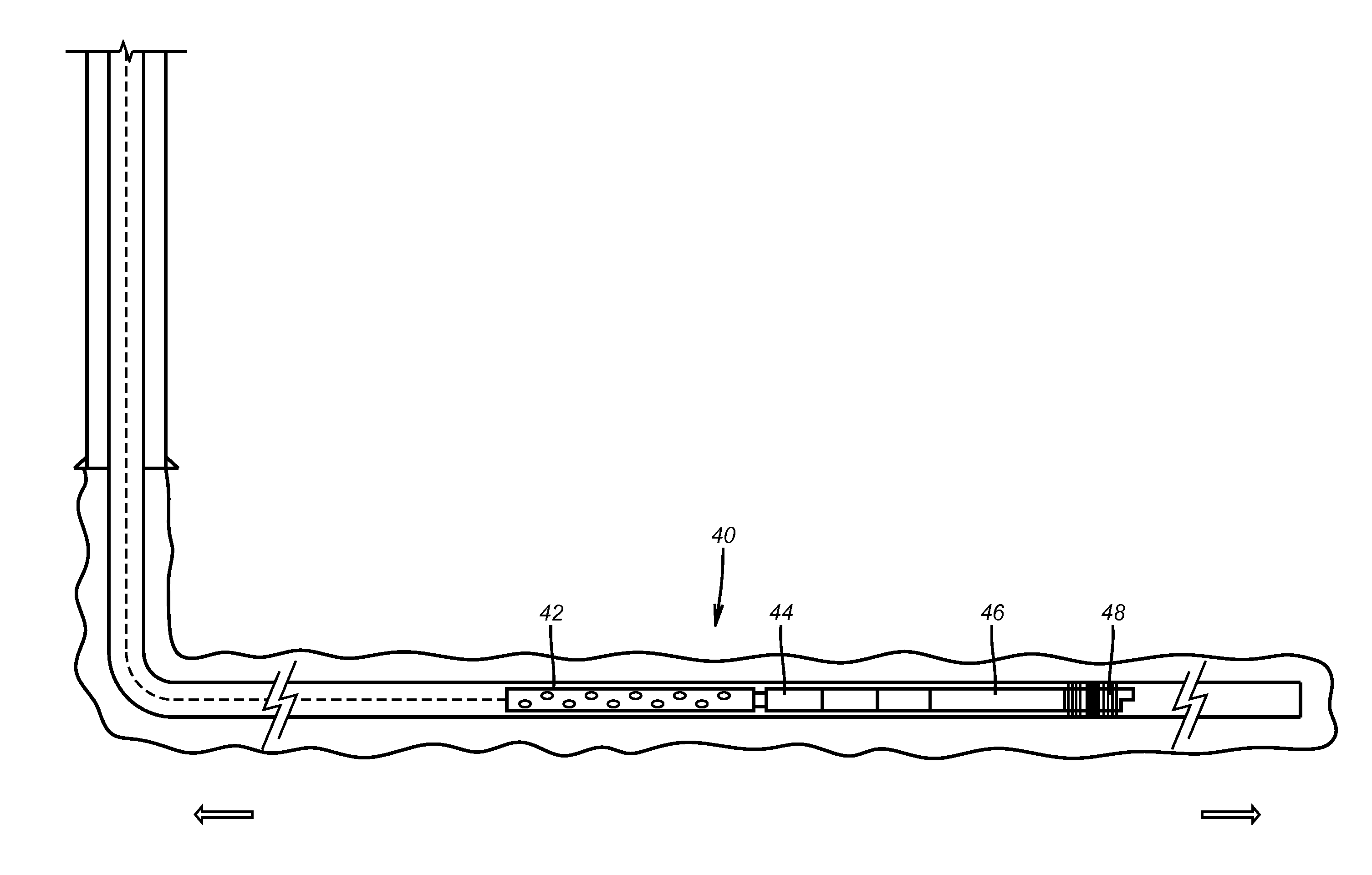

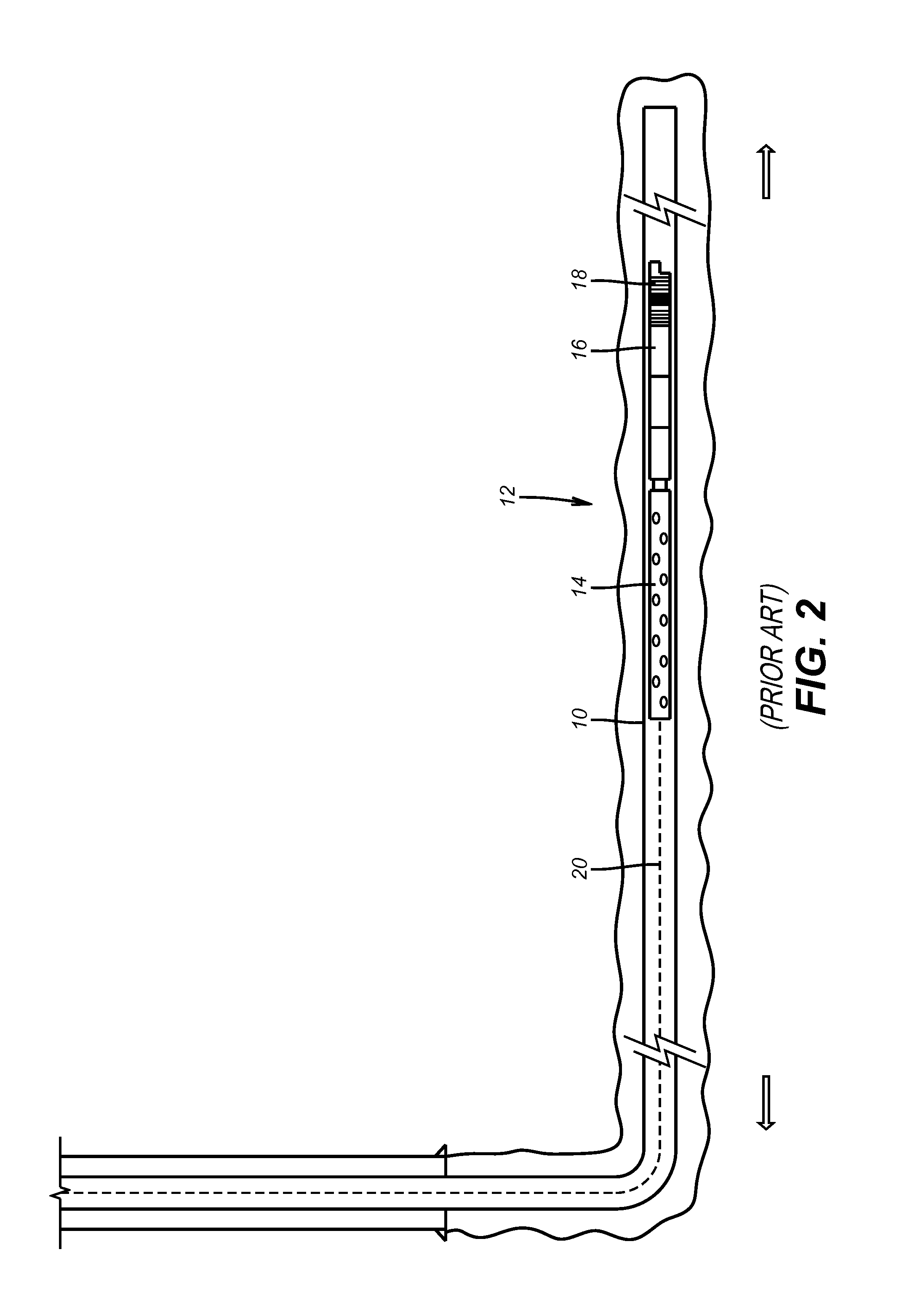

Telemetry operated ball release system

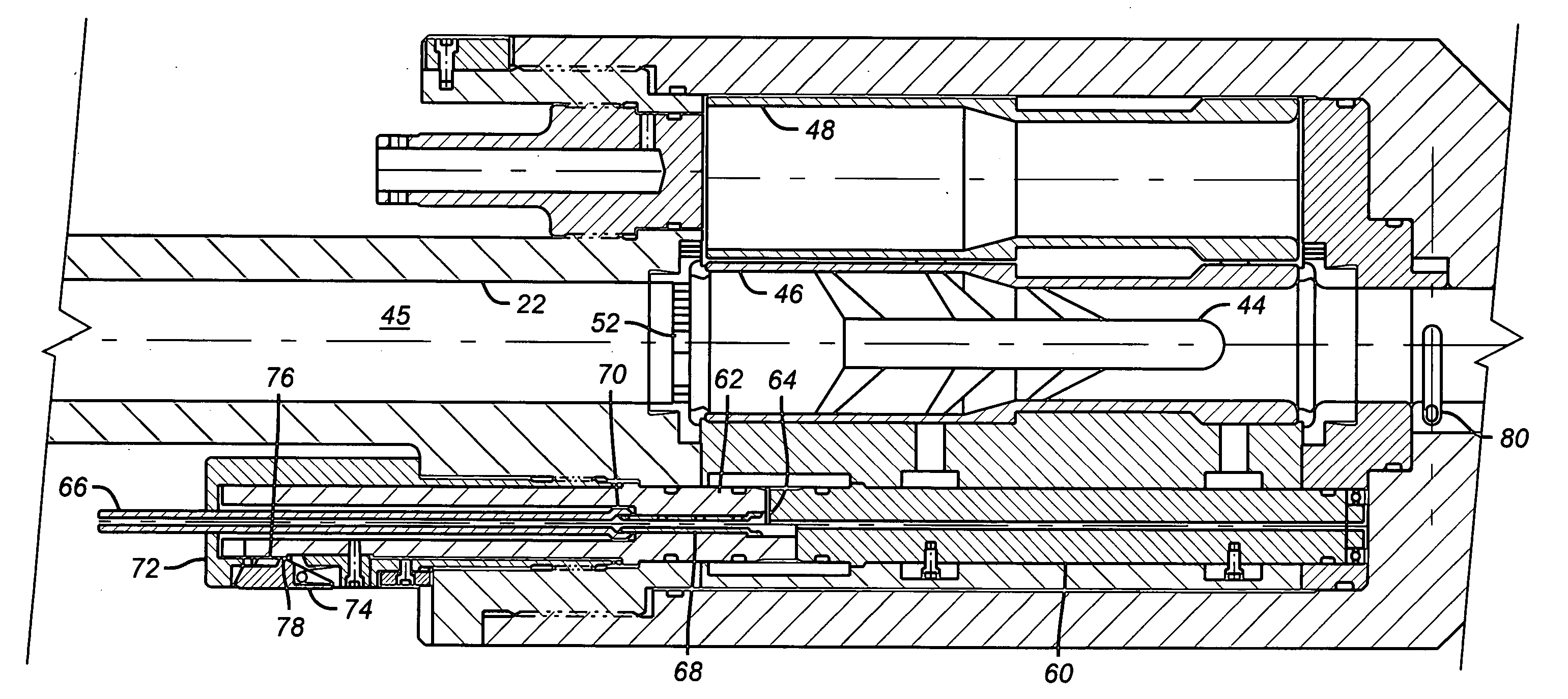

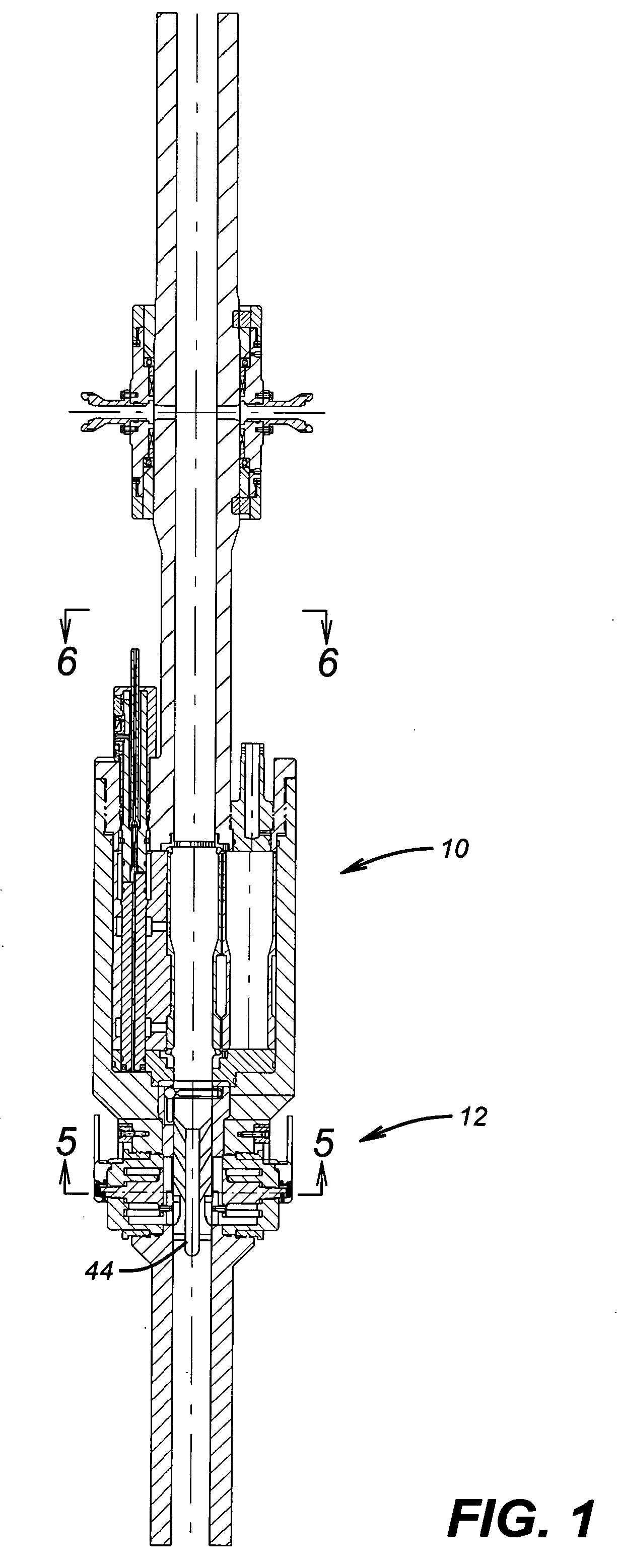

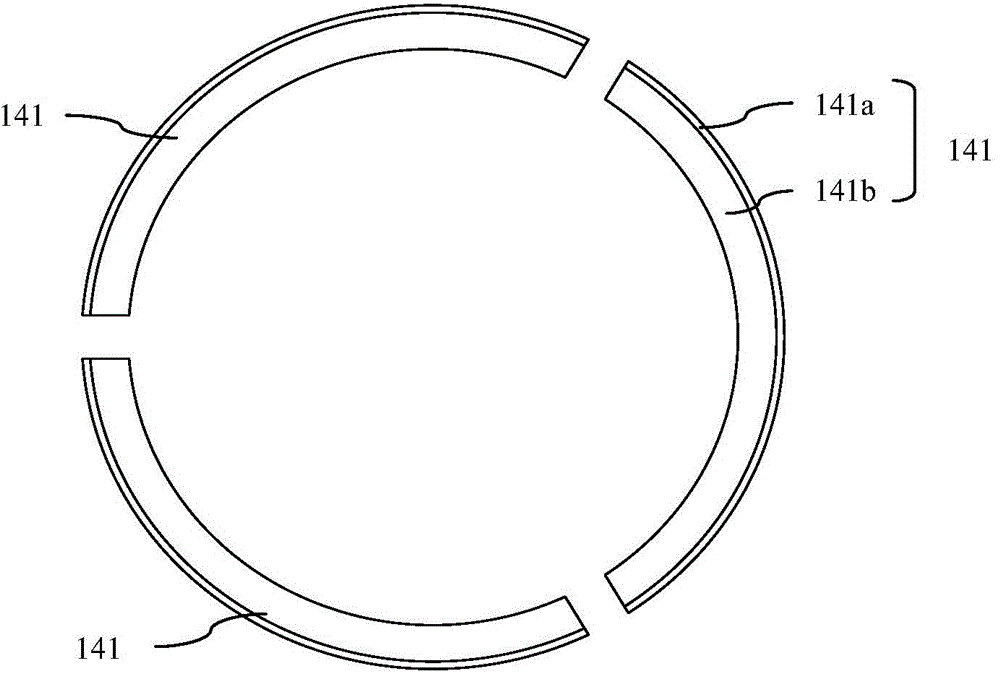

In one embodiment, a ball release system for use in a wellbore includes a tubular housing, a seat disposed in the housing and comprising arcuate segments arranged to form a ring, each segment radially movable between a catch position for receiving a ball and a release position, a cam disposed in the housing, longitudinally movable relative thereto, and operable to move the seat segments between the positions, an actuator operable to move the cam, and an electronics package disposed in the housing and in communication with the actuator for operating the actuator in response to receiving a command signal.

Owner:WEATHERFORD TECH HLDG LLC

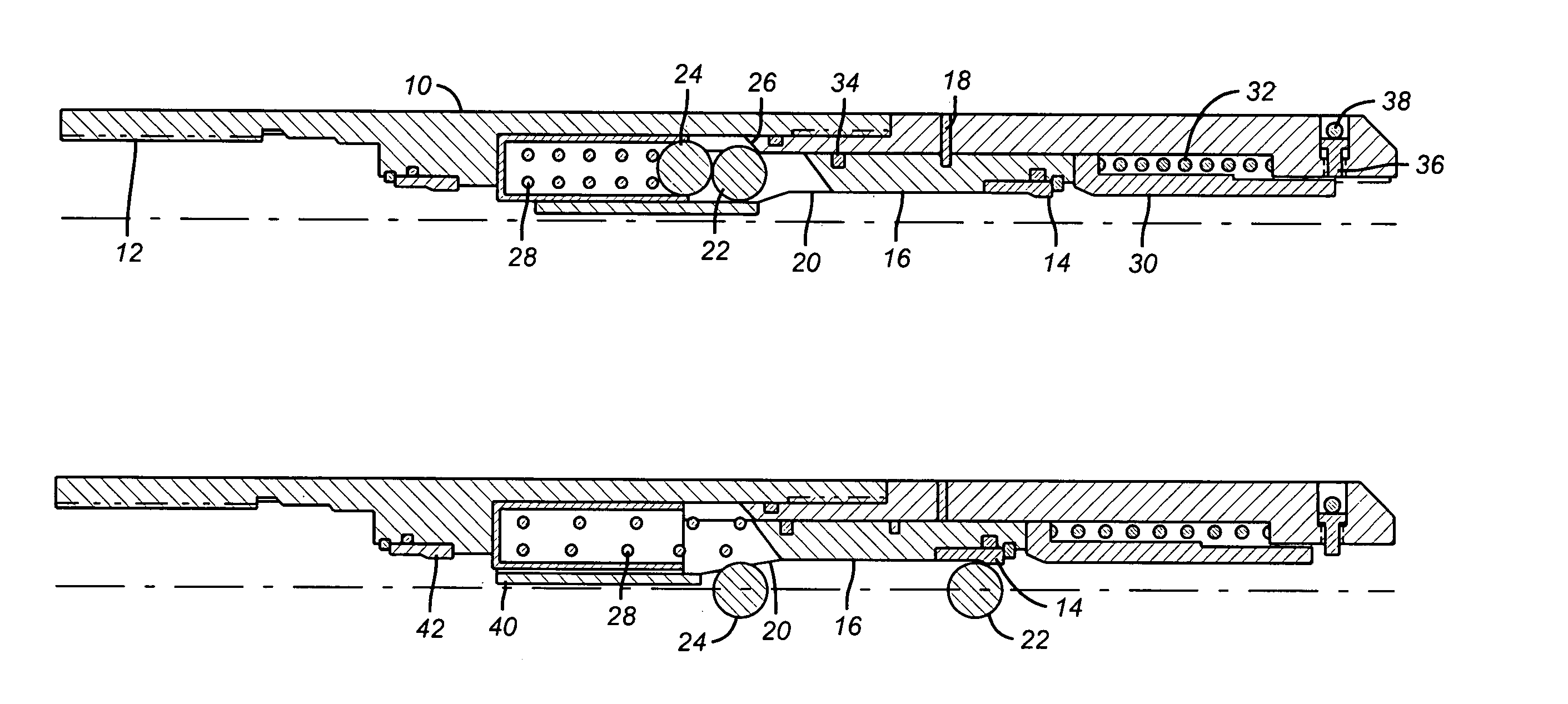

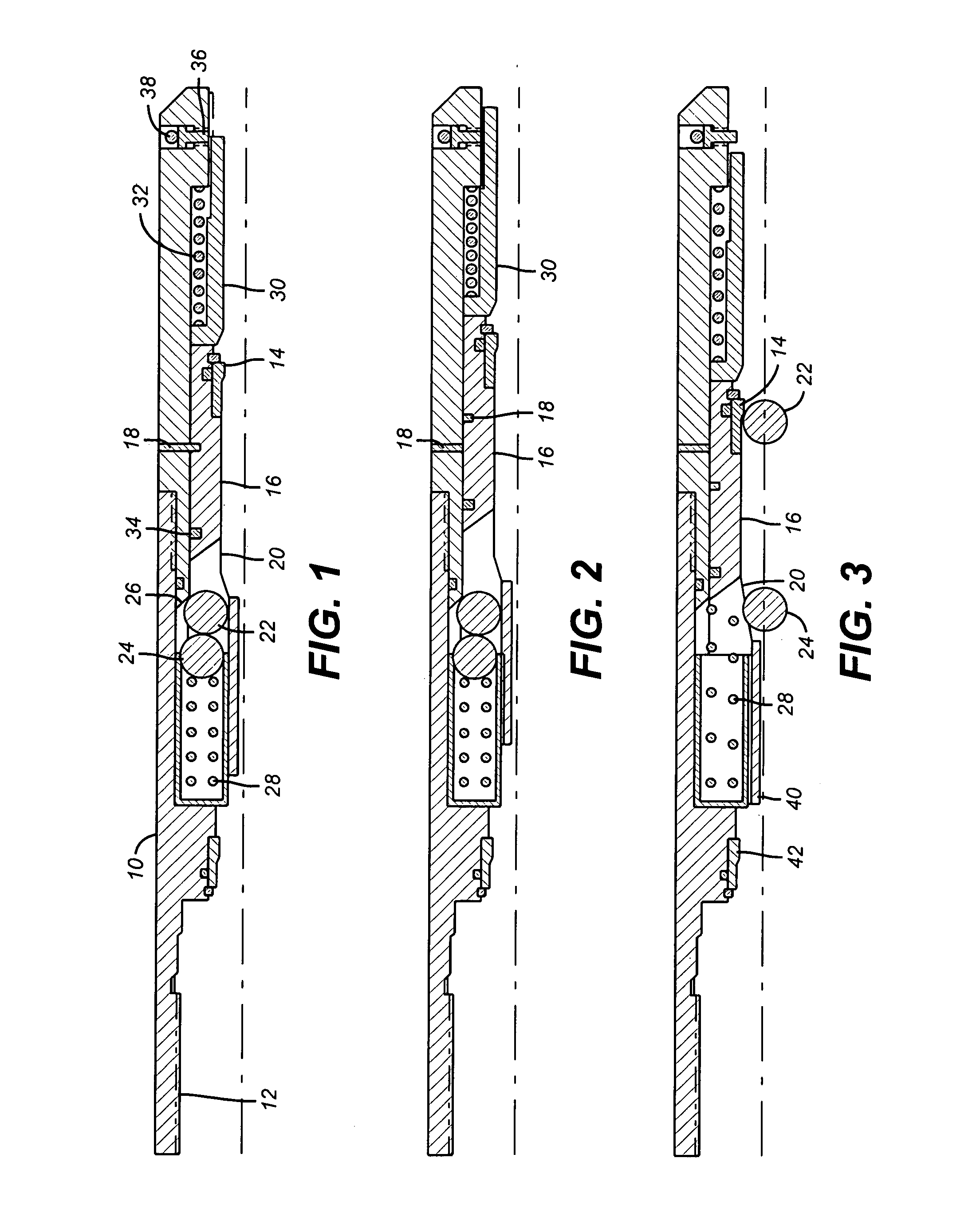

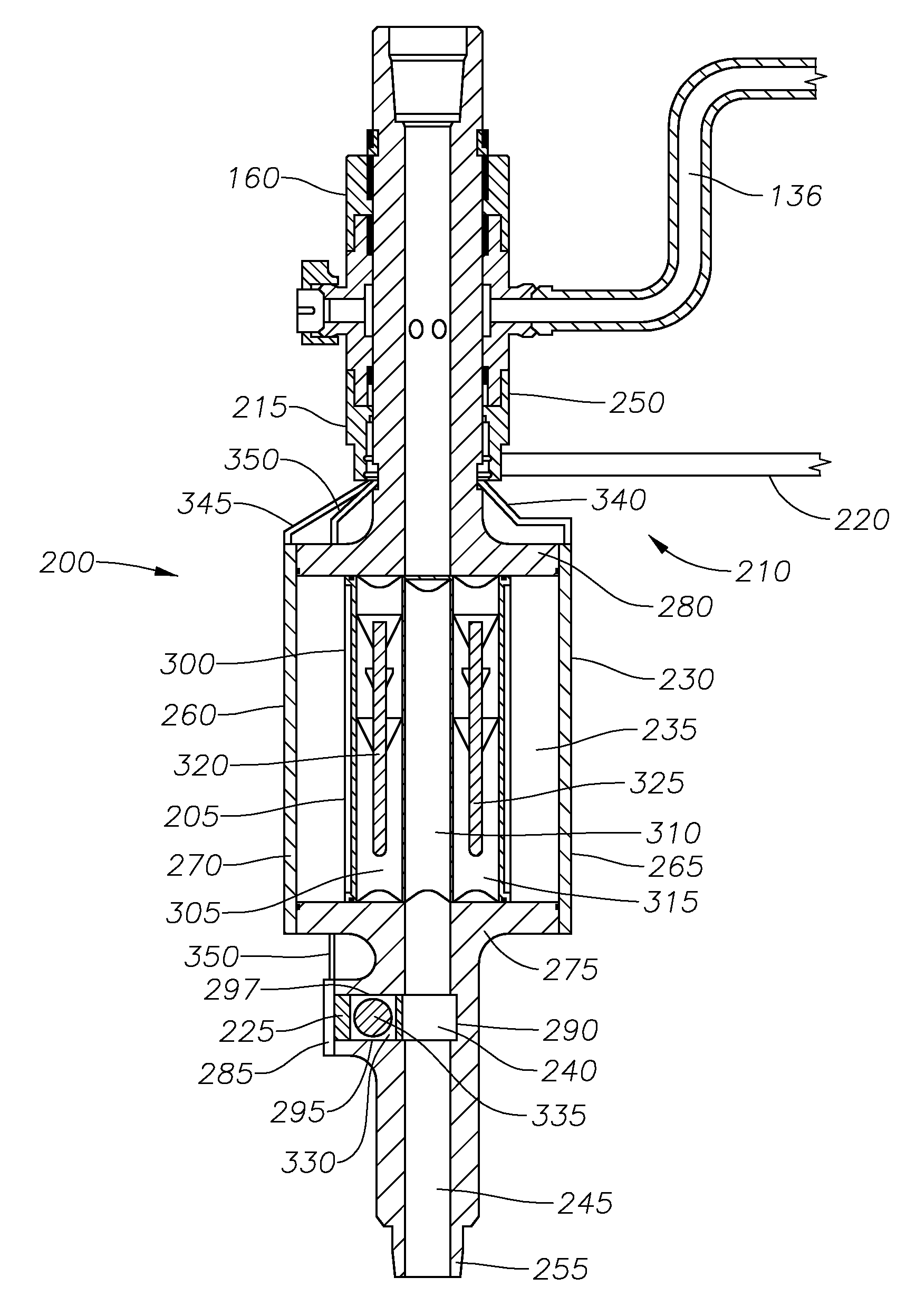

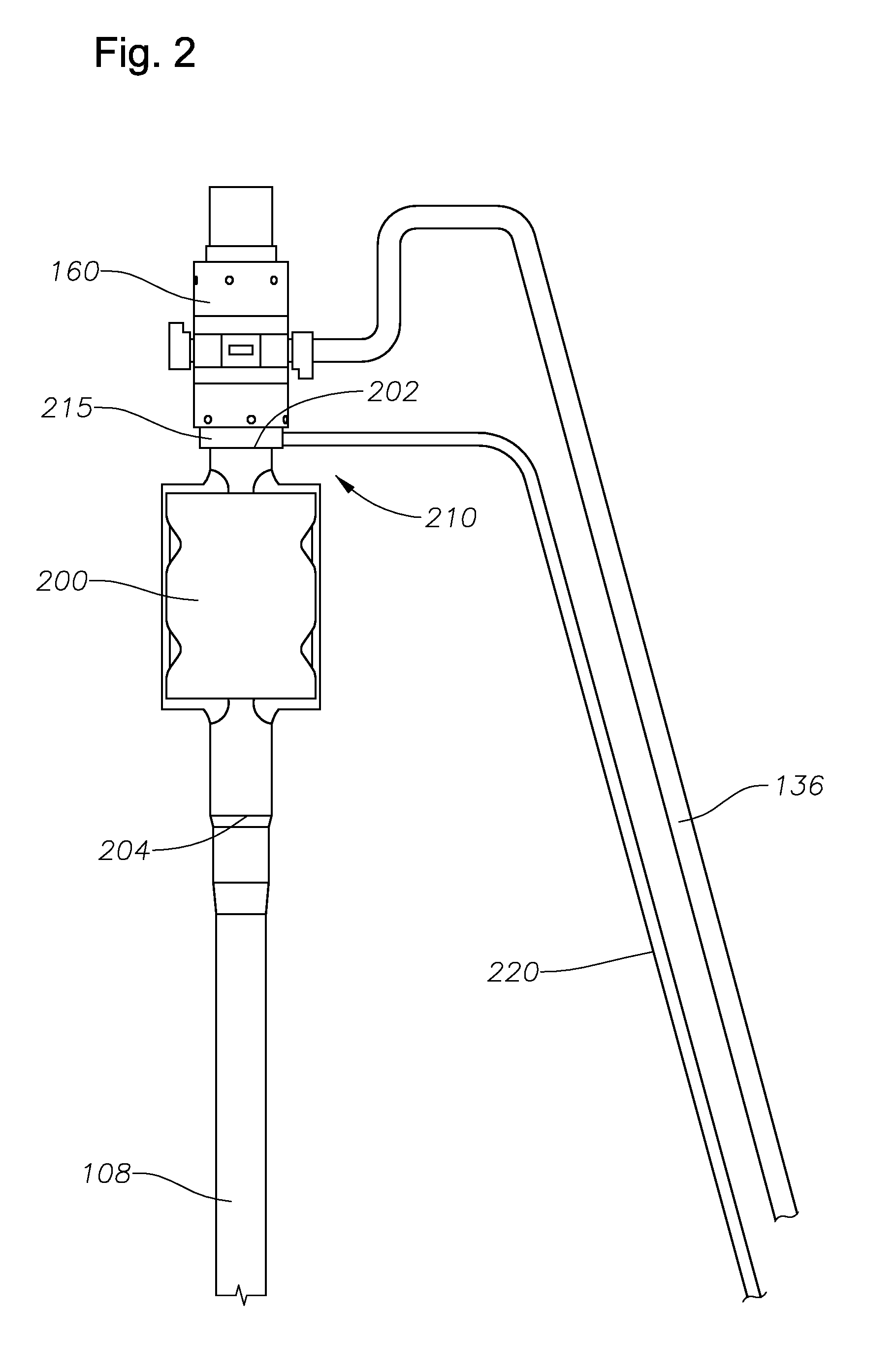

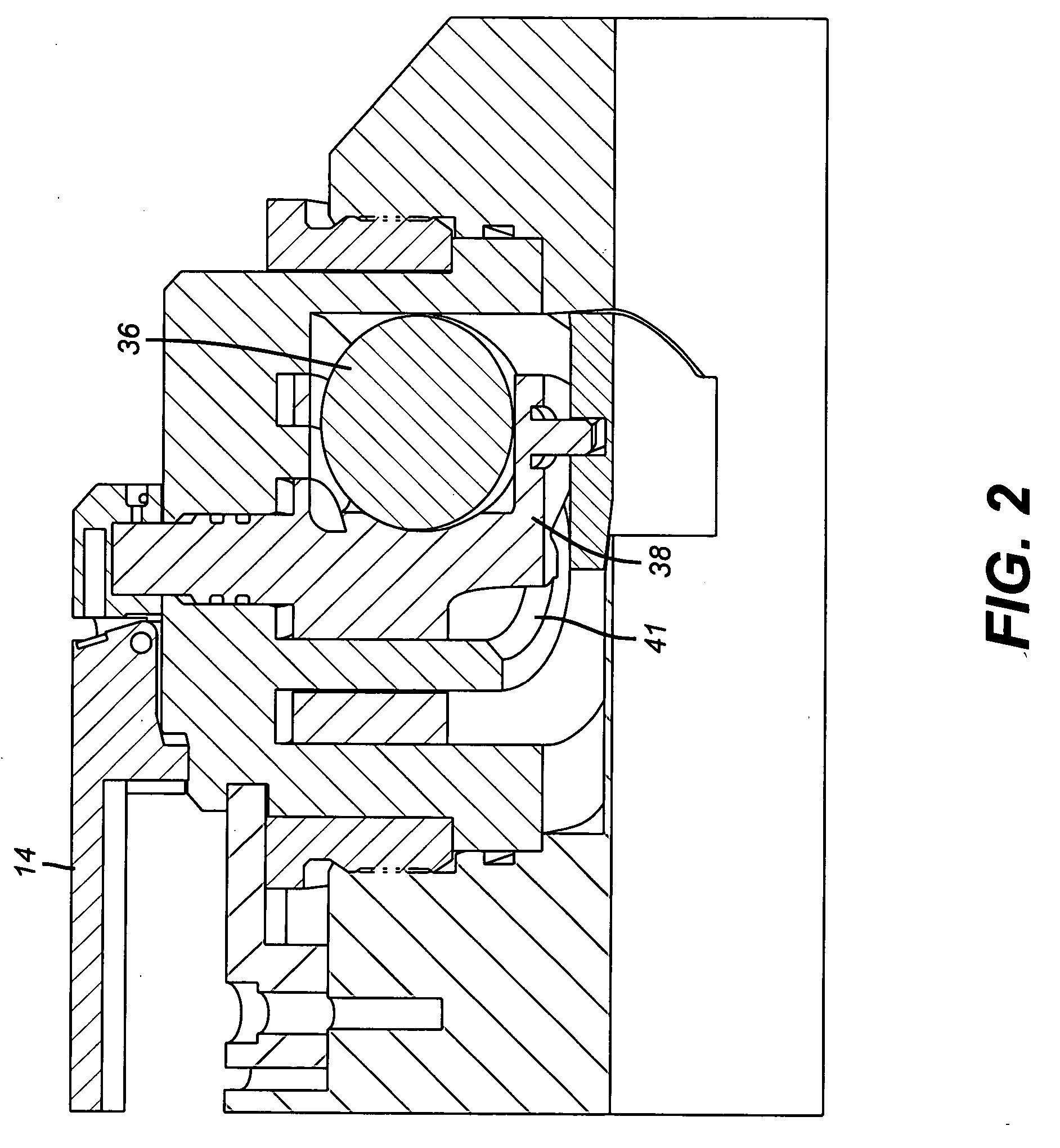

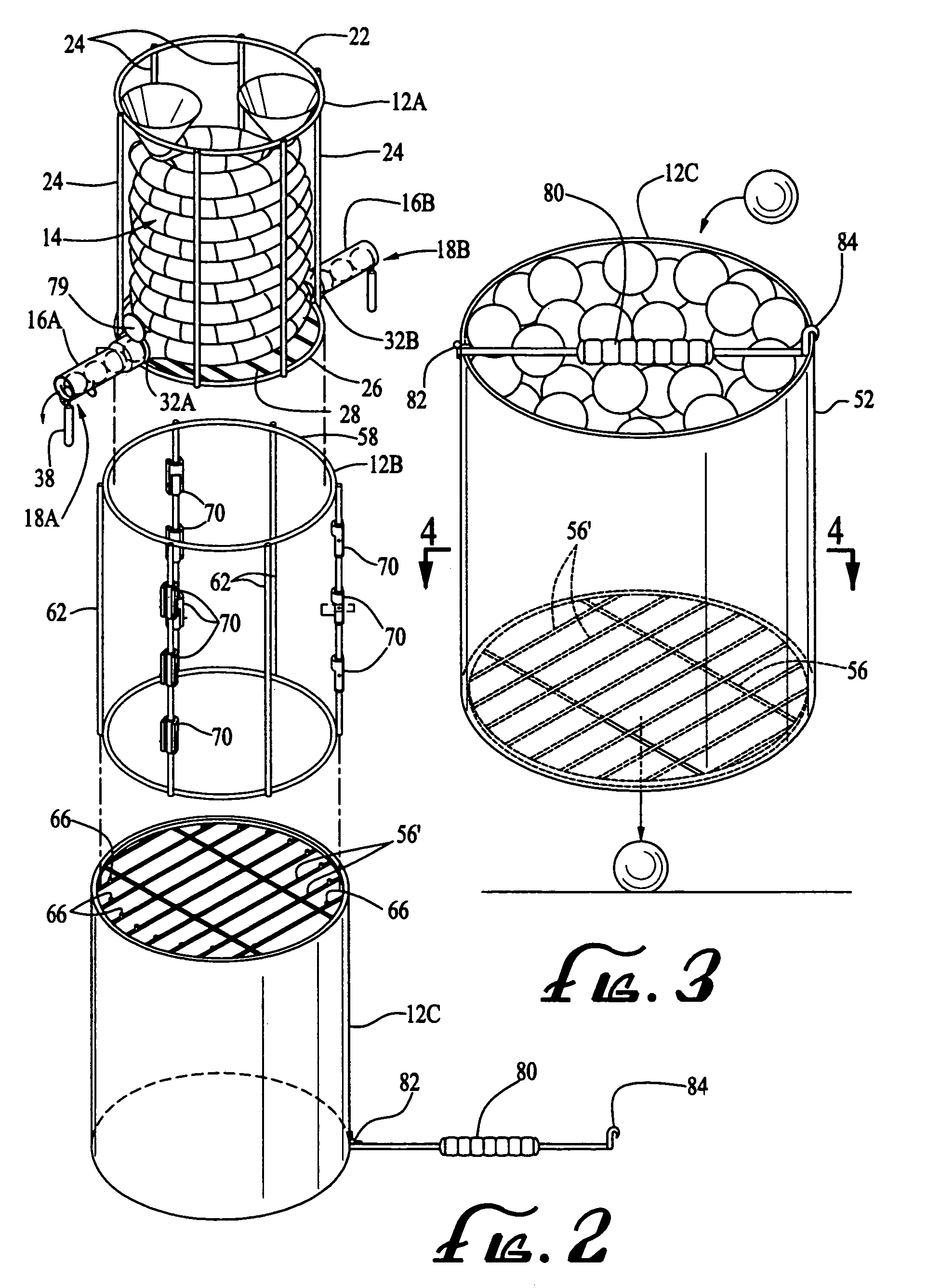

Cementing manifold with canister fed dart and ball release system

Apparatus and methods for cementing tubulars in a borehole are disclosed In some embodiments, the apparatus includes a housing, a cartridge disposed within the housing, and an actuator. The housing includes a fluid entry port and a fluid exit port The cartridge includes a first chamber and is moveable between a first and a second position In the first position, the first chamber is out of fluid communication with the entry port and the exit port. In the second position, the first chamber is in fluid communication with the entry port and the exit port. The actuator is adapted to move the cartridge between the first and second positions.

Owner:SMITH INT INC

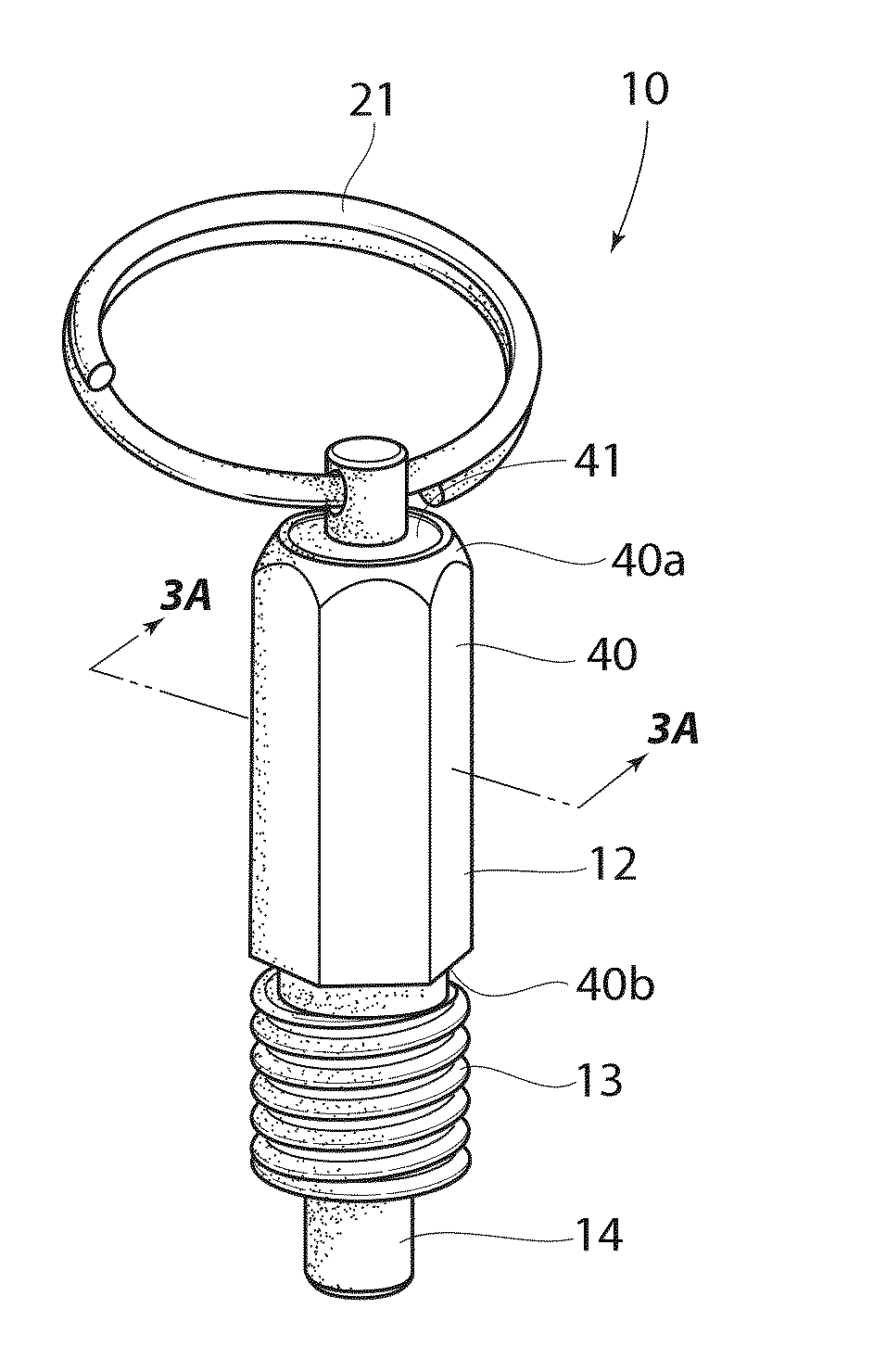

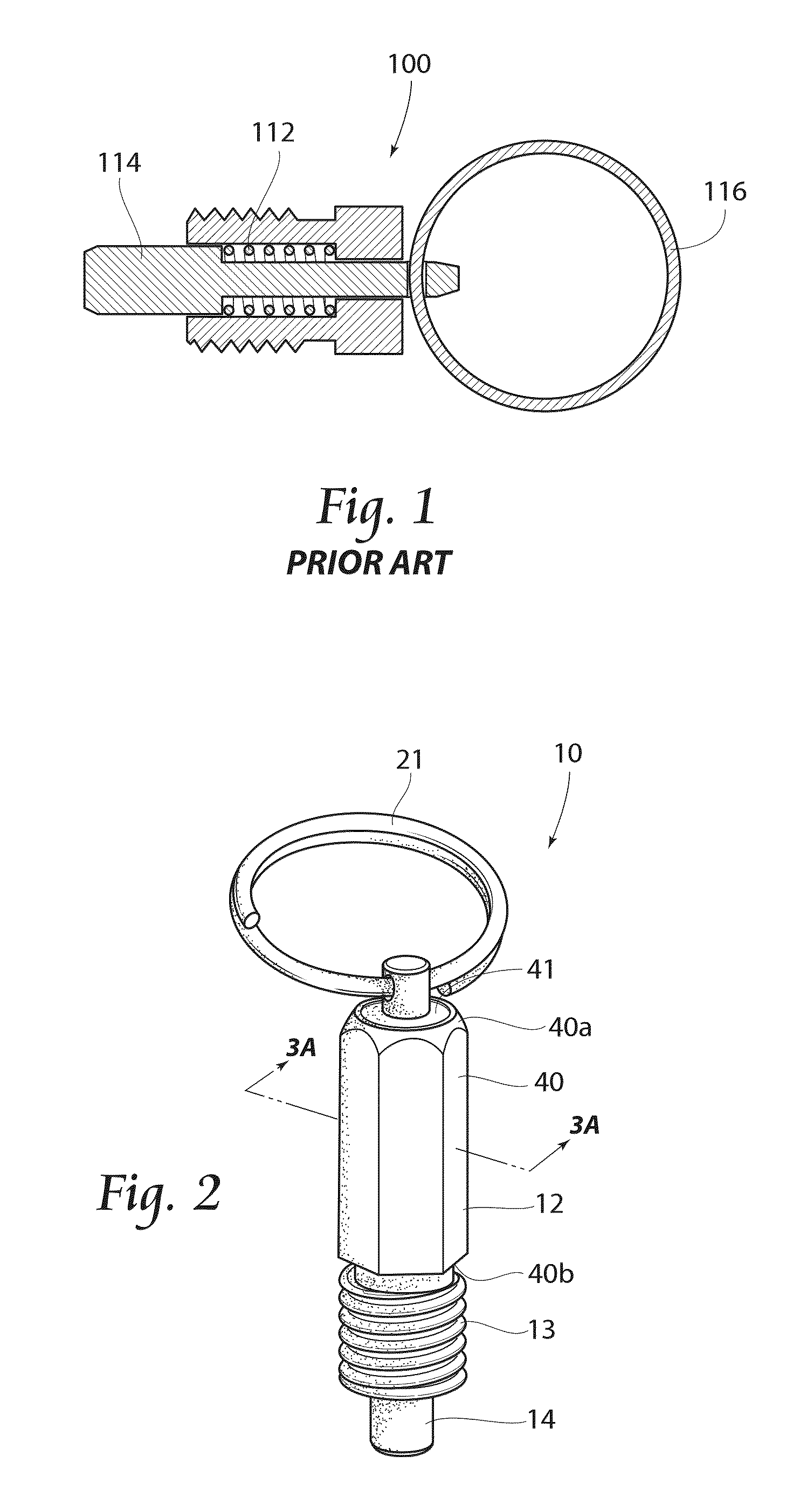

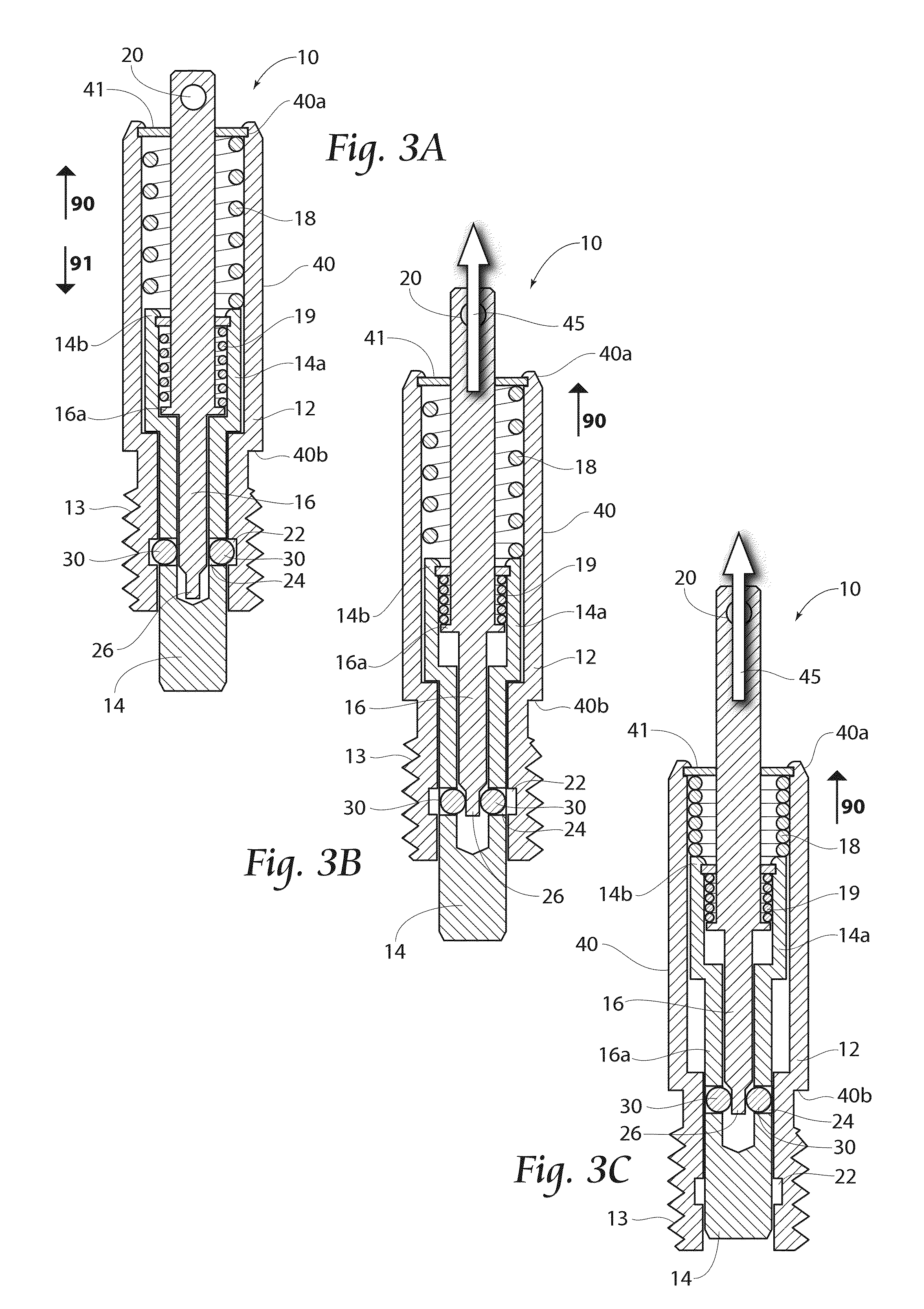

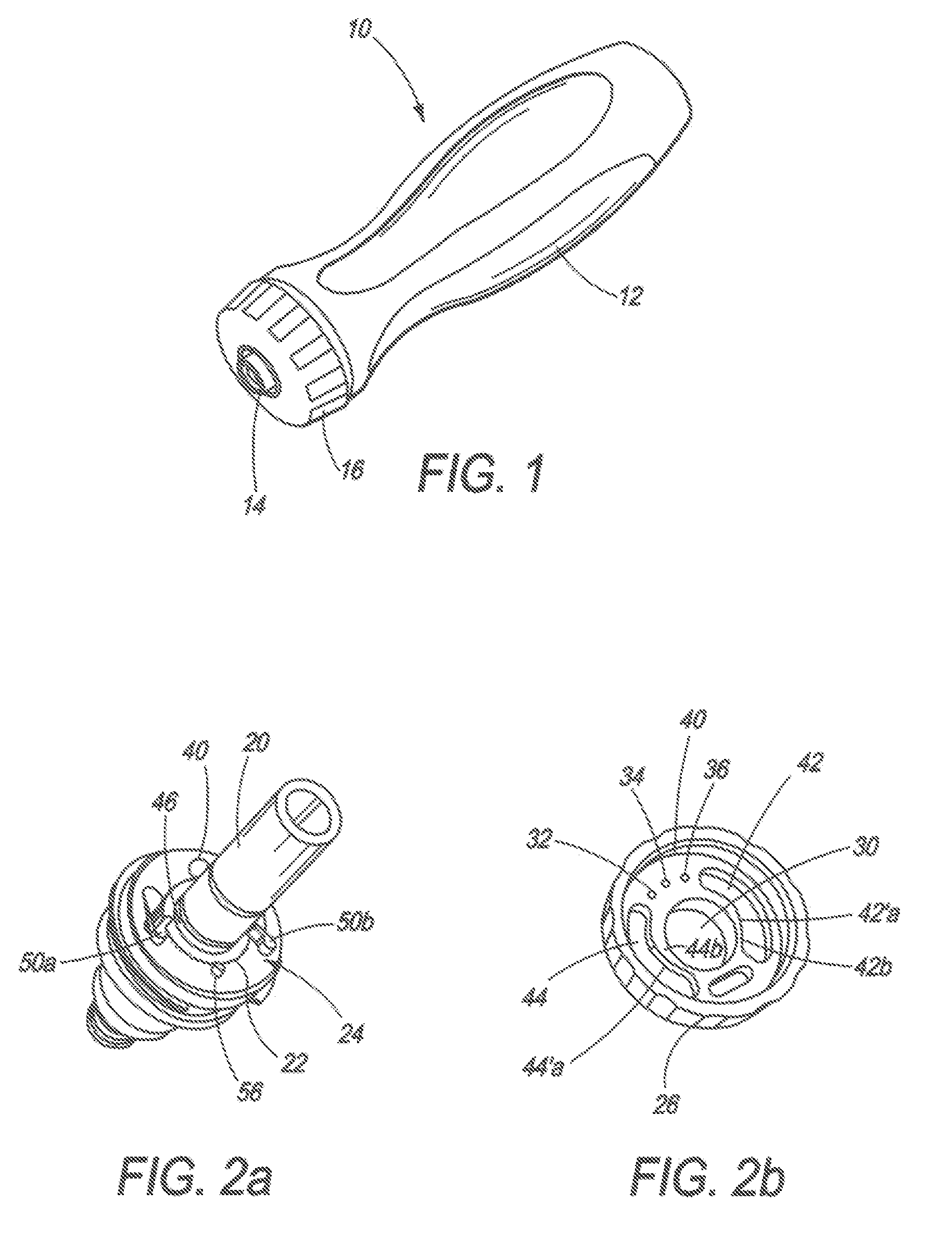

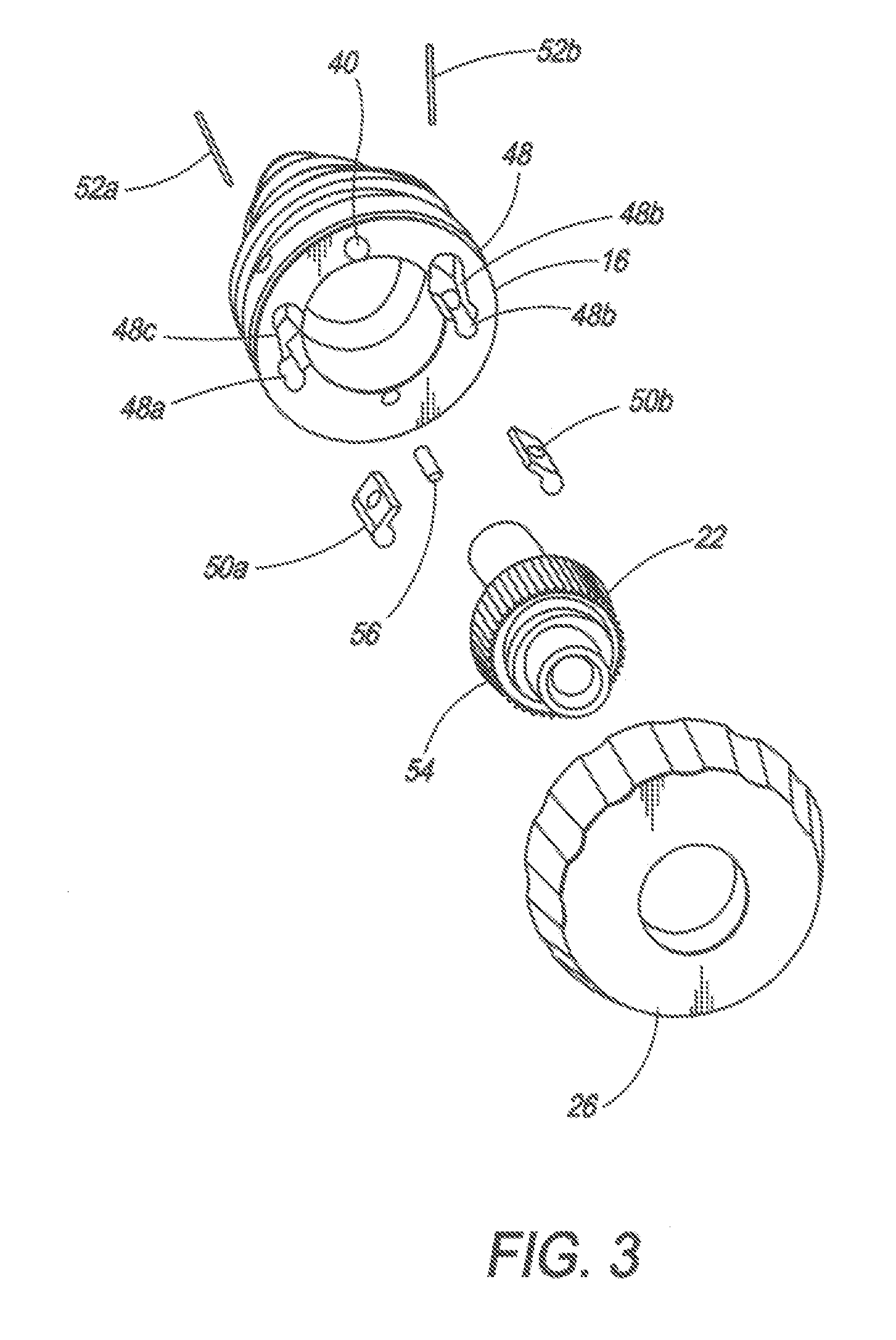

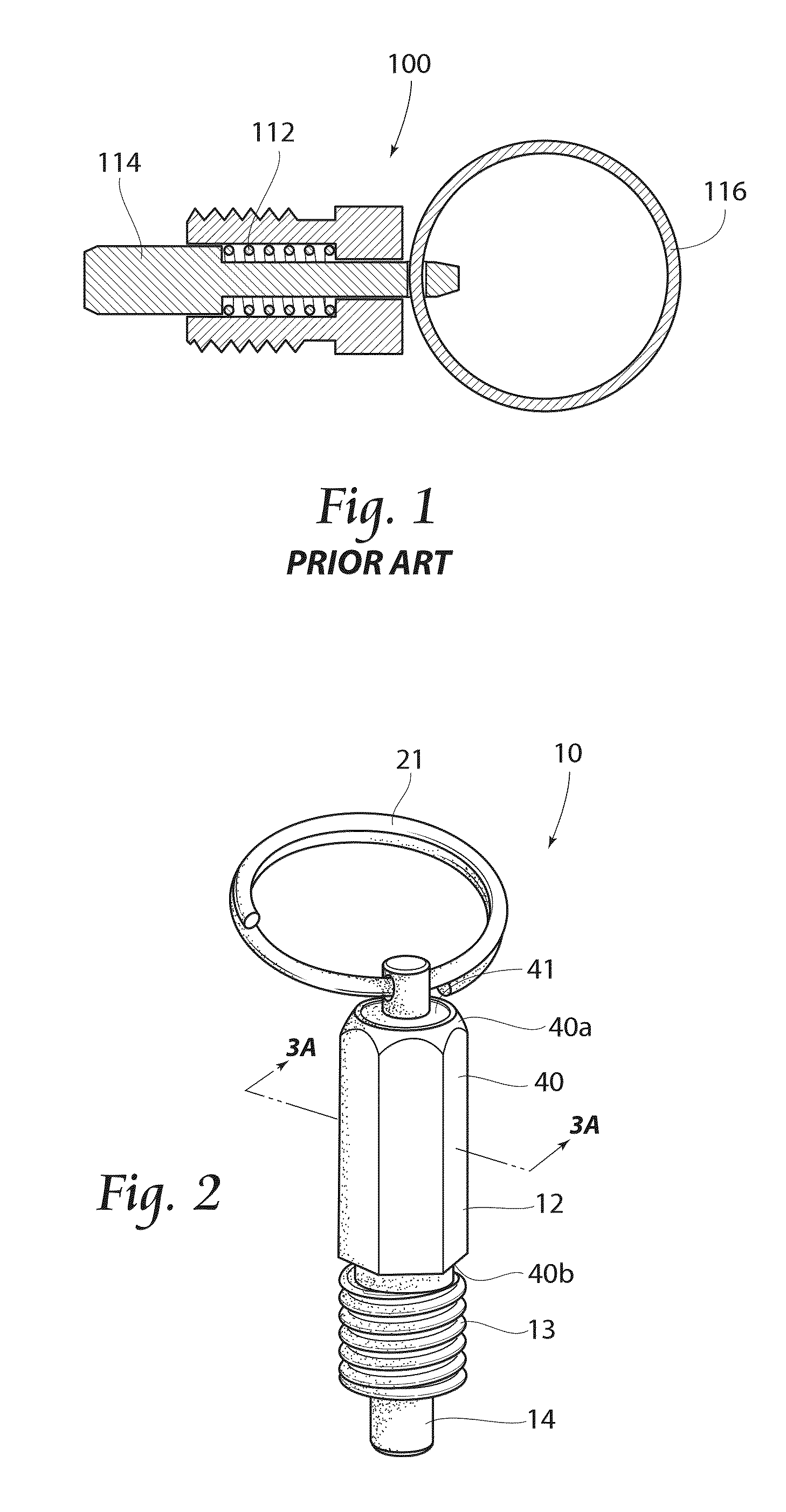

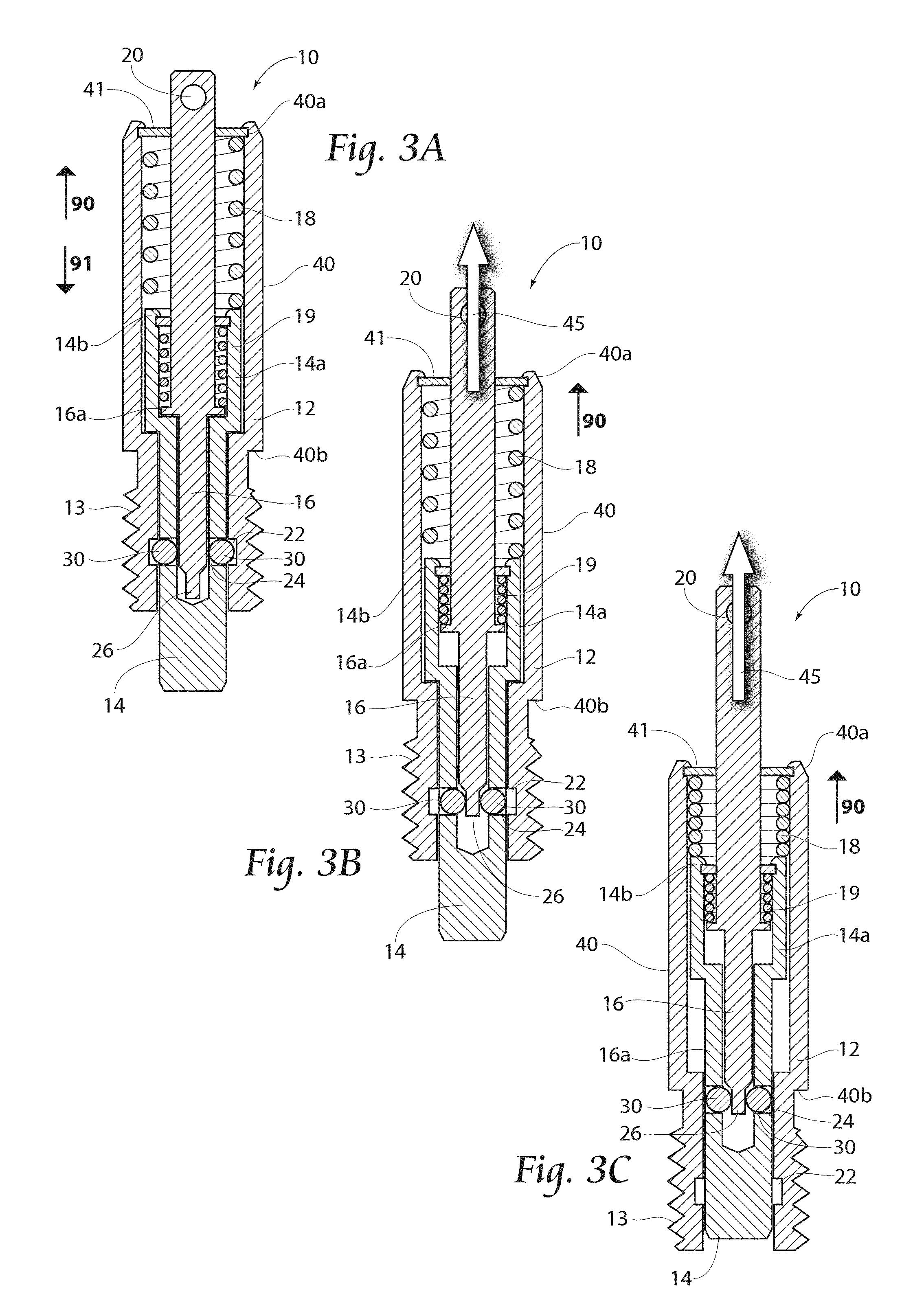

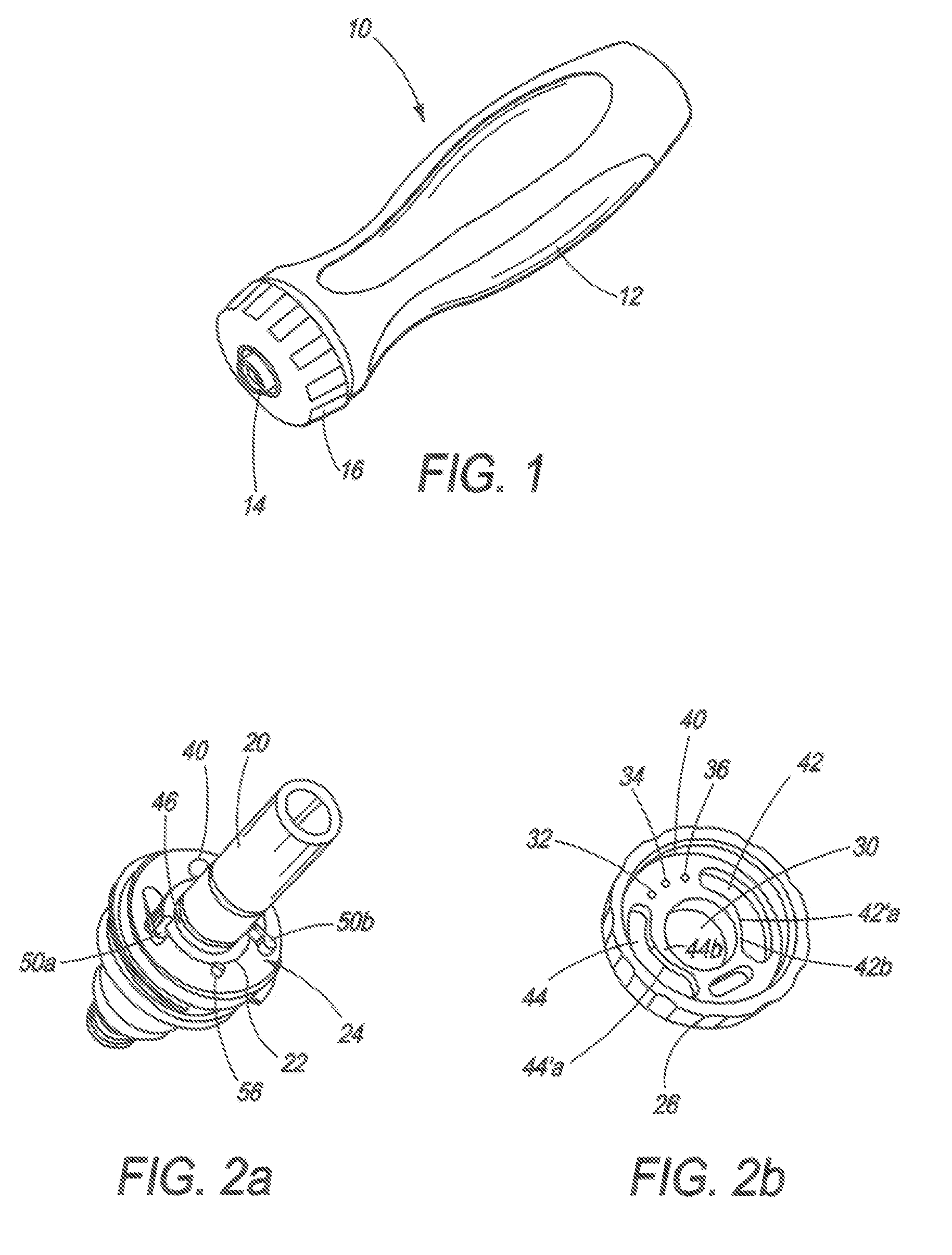

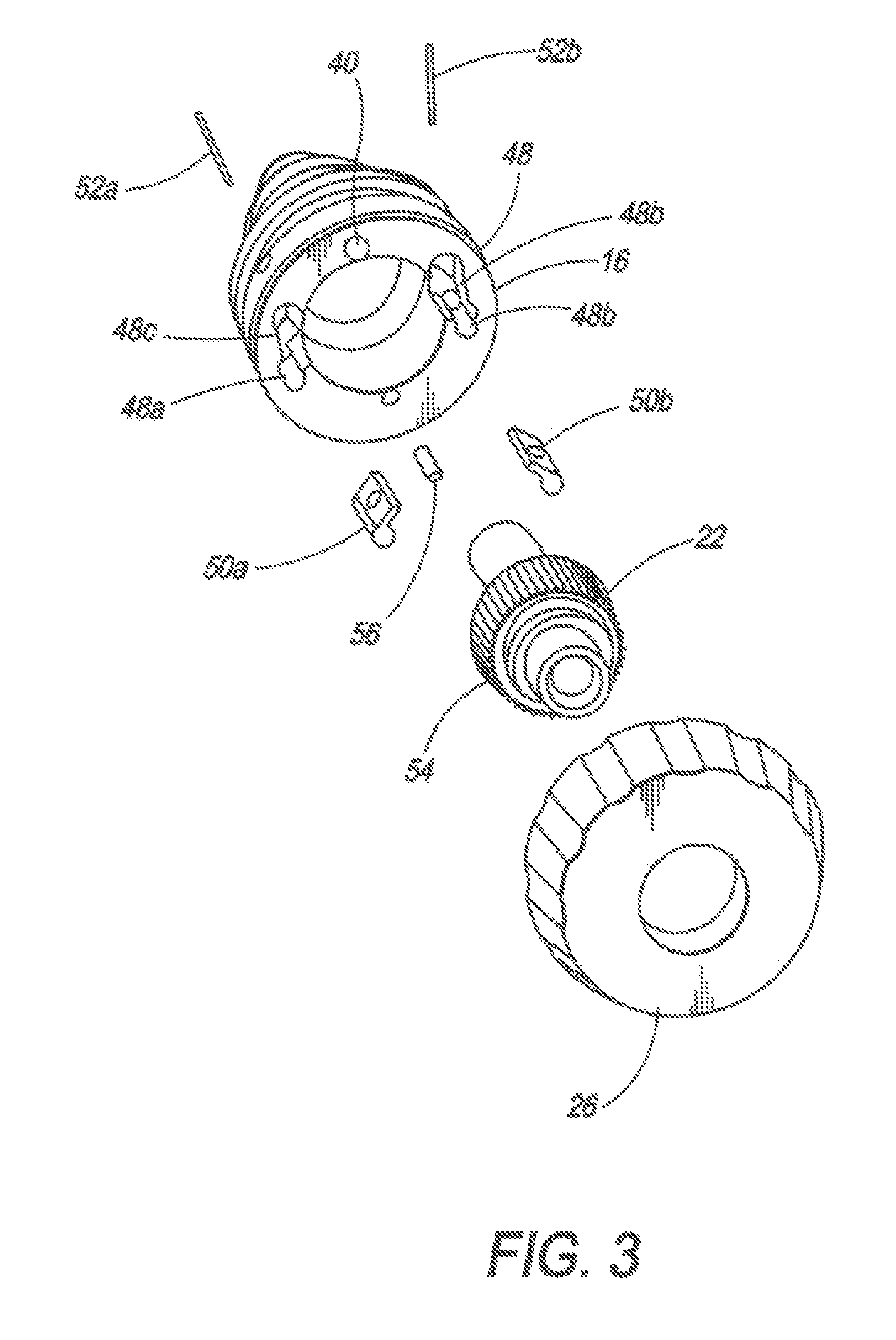

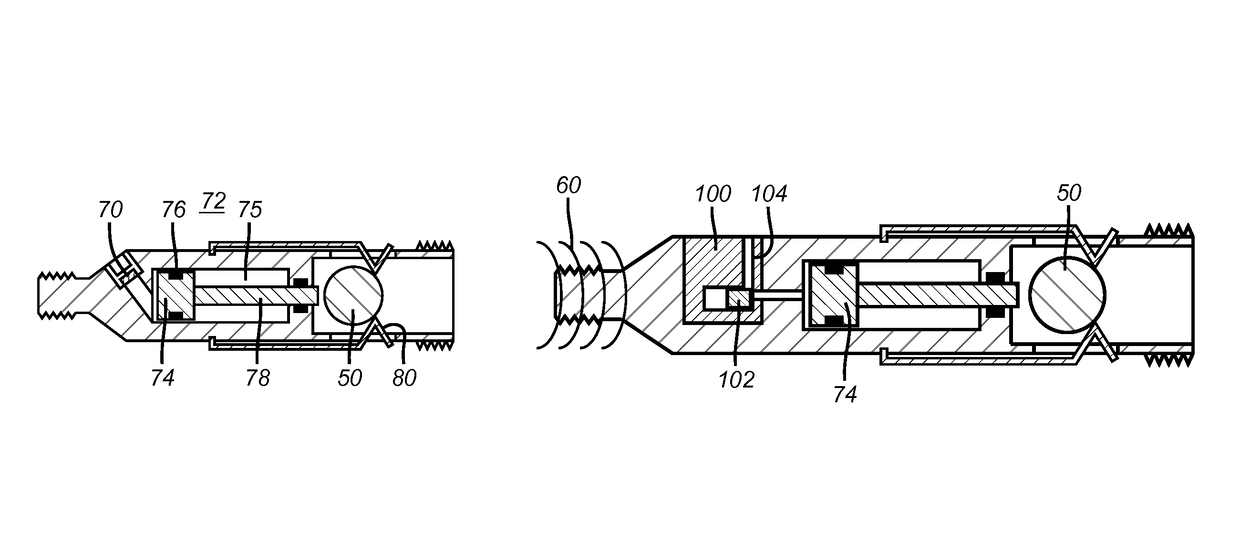

Forward locking pull pin

ActiveUS20130336719A1Prevent movementRod connectionsCouplings for rigid shaftsBall releaseMechanical engineering

Provided is a pull pin that is configured to lock in a forward position to prevent accidental or undesirable retraction of the pull pin. The pull pin has a housing, a pull pin shaft, an inner shaft, a first and second spring, and at least one ball bearing. The housing has a ball locking space, which holds the ball bearing between the locking space and a ball aperture formed in the pull pin shaft to thereby lock the pull pin shaft in the forward position. Only upon the application of an external force to the inner shaft, which aligns a ball release portion with the ball aperture, can the ball bearing move into the ball release portion and thereby move out of said locking space, allowing for the retraction of the pull pin shaft.

Owner:PIVOT POINT

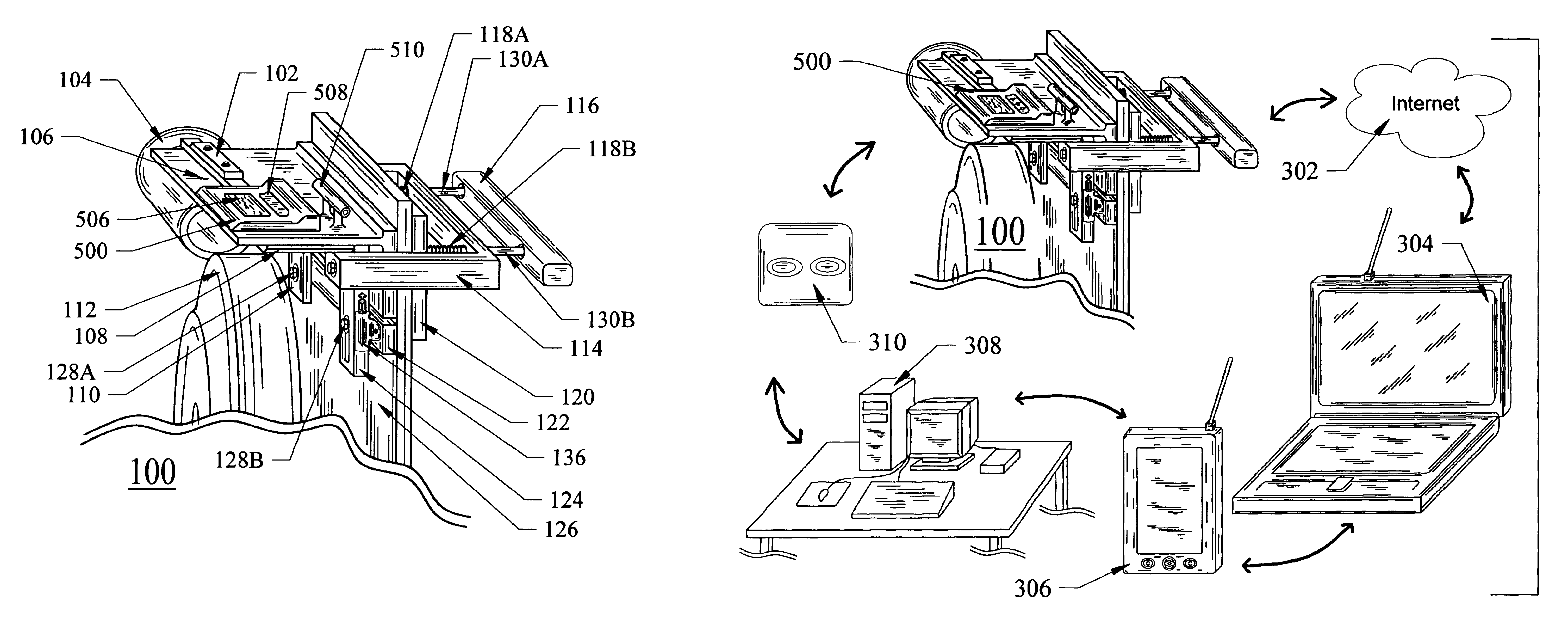

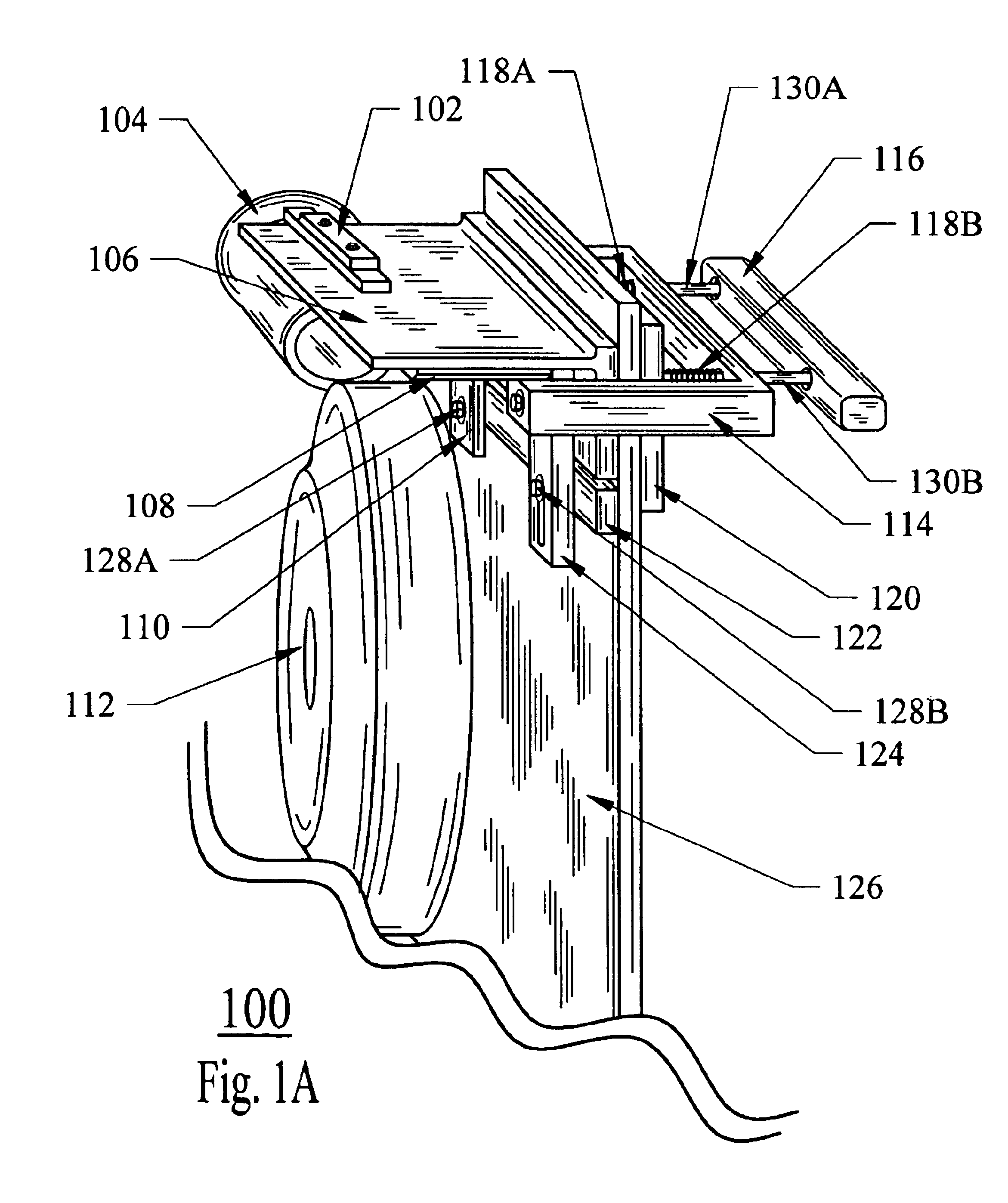

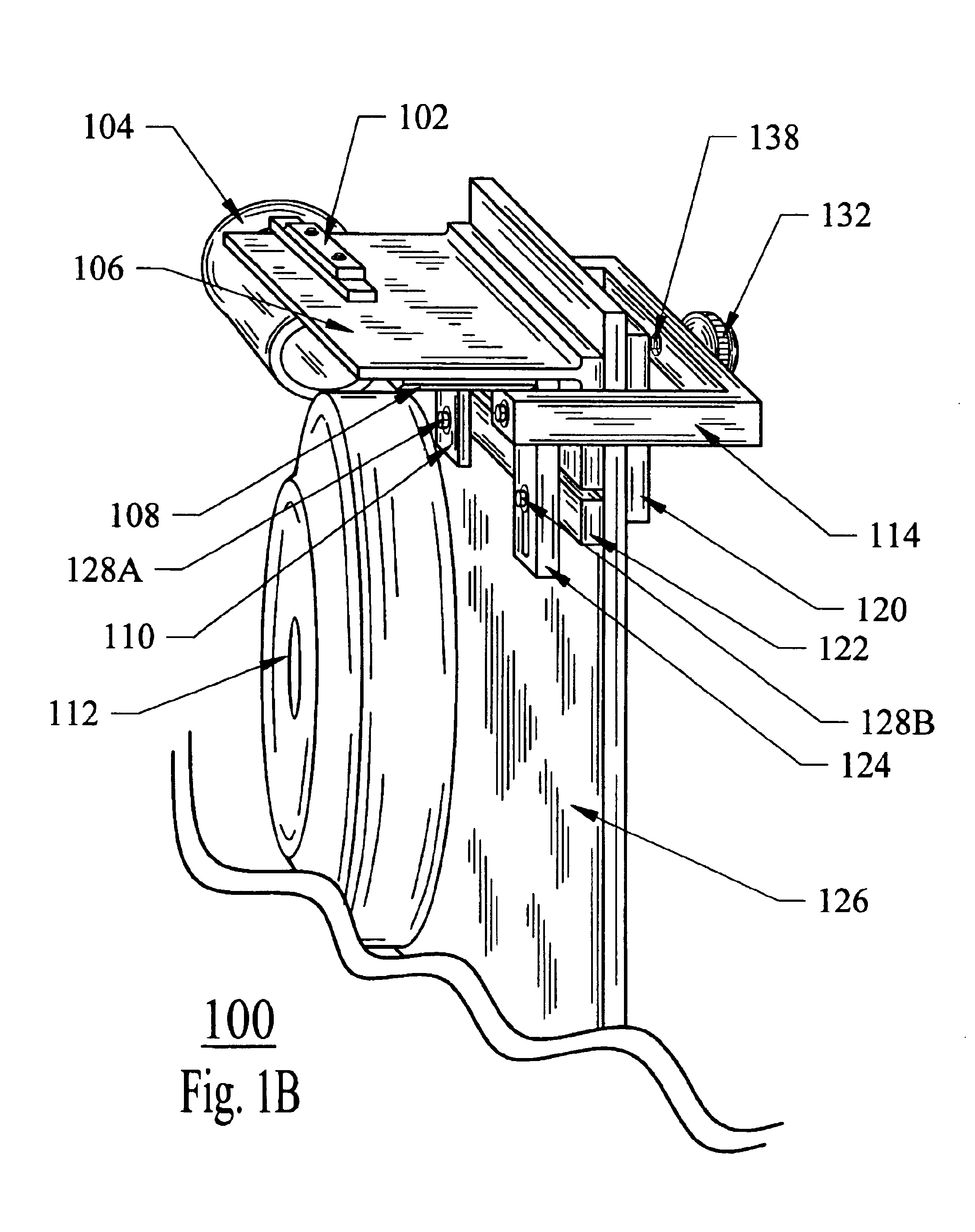

Pitch dynamics device for controlling the pitch dynamics of fast-speed and off-speed pitches thrown from a single-wheel pitching machine

InactiveUS6895949B1Similar location accuracyVerify accuracyFriction-wheel launchersSling weaponsEngineeringBall release

The present invention relates to a pitch dynamics device, the pitch dynamics device being interconnected with a pitching machine for causing the pitching machine to vary the pitch dynamics of pitched balls. Optimally, variances in pitch dynamics can include varying pitch speed, pinch plate angle, and the pitch release point. The pitch dynamics device can vary the pitch dynamics of pitched balls by adjusting a pinch plate position and angle to control the location of a pitch release point, trajectory angle, and ball release speed. The resultant is that the pitch dynamics device can allow a single-wheel pitching machine to throw different speed pitches with similar accuracy, in a batter's strike zone area, without changing the pitching machine setup which may include recalibrating the pitching machine, throwing a series of test pitches to verify pitch accuracy, changing pitching machine wheel speed, or adjust pitching machine tilt angle.

Owner:STEPHENS STACY W

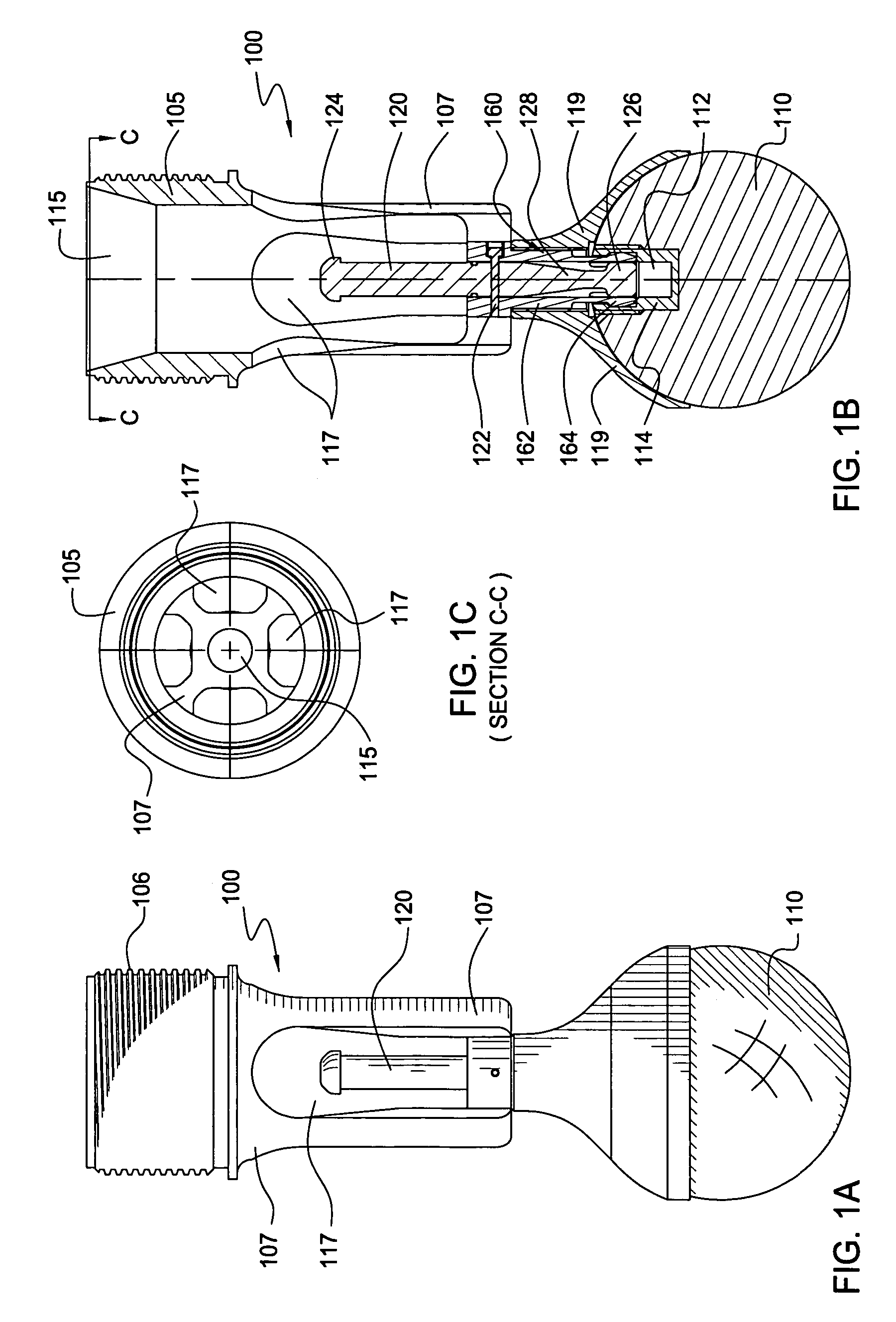

Apparatus for releasing a ball into a wellbore

The present invention relates to an apparatus for dropping a ball into a wellbore. The apparatus is particularly useful for dropping a ball that has a diameter that is larger than the diameter of a bore within a wellbore tool above the apparatus. The ball-releasing apparatus first comprises a tubular body. The tubular body has a bore therethrough that is in fluid communication with the bore of the wellbore tool. A piston is placed within the tubular body. The piston has a top end disposed within the tubular body, and a bottom end disposed below the bore of the wellbore tool. The ball-releasing apparatus further comprises a connector for releasably connecting the piston to the ball. In one arrangement, the ball-releasing apparatus is connected to the bottom of a wiper plug for dropping a ball during a wellbore cementing operation. In one aspect, the ball is dropped by dropping a second ball having a diameter that will pass through the wellbore restriction, and then injecting fluid under pressure against the second smaller ball in order to actuate the releasable connection.

Owner:WEATHERFORD NETHERLANDS BV

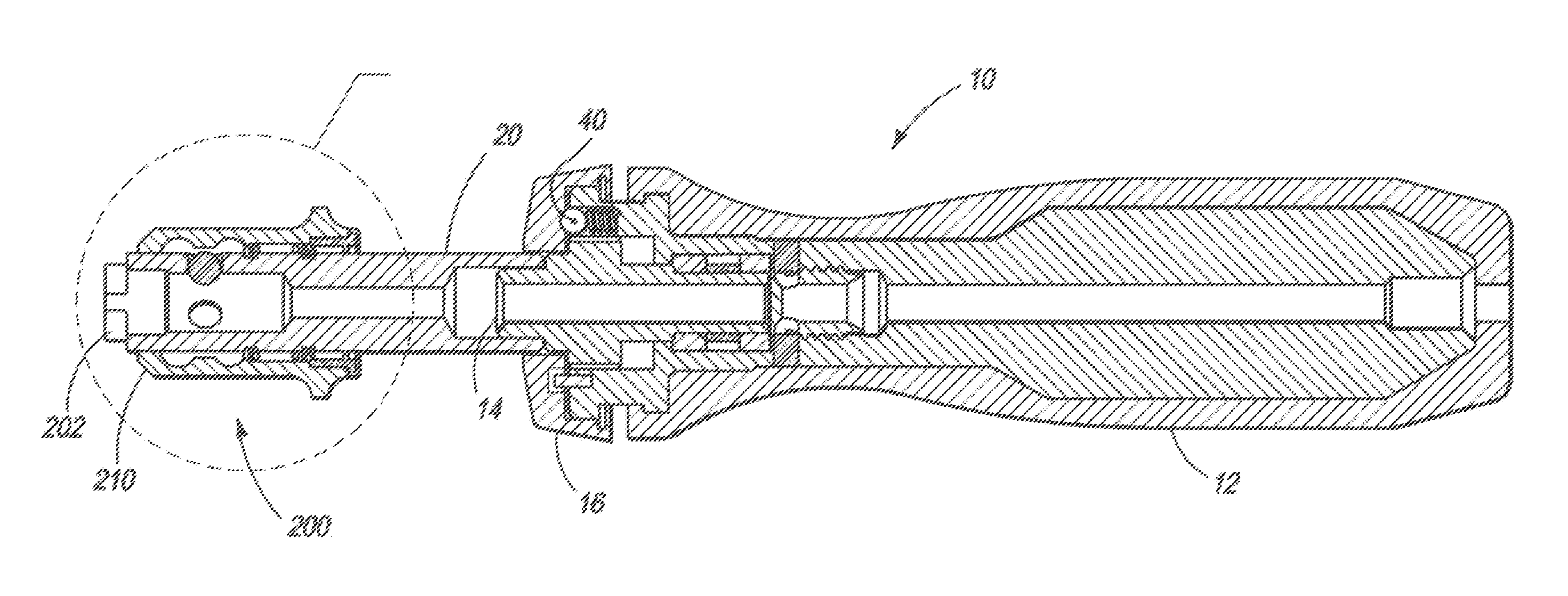

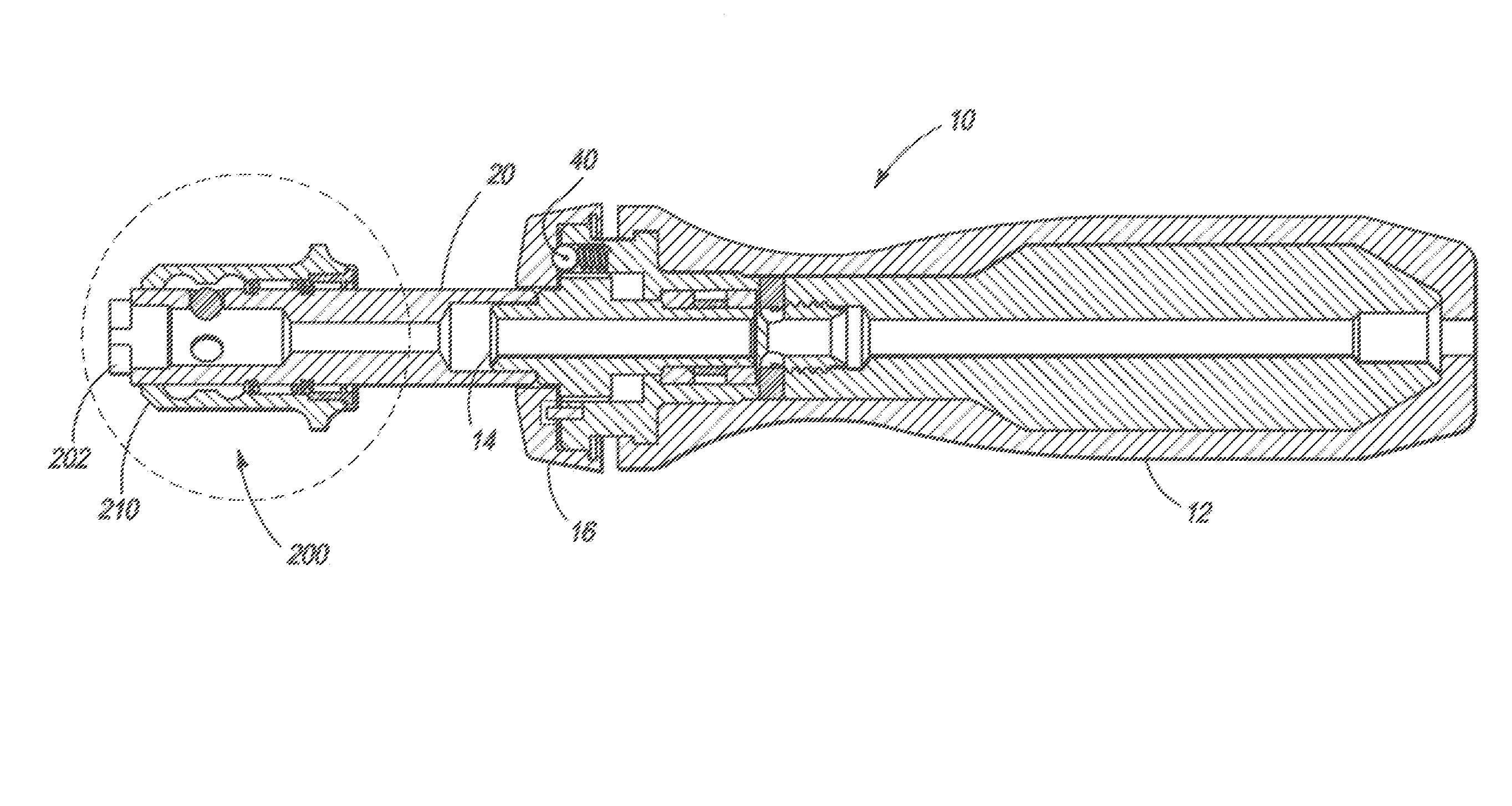

Coupling device with configurable actuator

A driving tool includes a shank, a sleeve, and a return spring disposed therebetween. The shank has a ball recess with a ball received therein. The shank has an interior interface adapted for receiving a tool bit. The ball recess substantially extends into the interior interface. The sleeve mounts on the shank to slide between limits. The sleeve has a first interior ball release recess followed by an interior ball lock surface and then a second interior ball release recess. The release recesses and surface are oriented with respect to the ball recess so as to permit selective displacement of the same over the ball recess to unlock the ball with movement in either direction. A return spring is disposed between the shank and the sleeve. The spring has a first and second end. One of the ends of the spring acts against a feature fixed with the shank and the other end of the spring acts against a feature fixed with the sleeve in a manner so, as to permit selective displacement of the ball release recess and lock surface over the ball recess. The position of least spring potential energy is the position with the surface located just above the ball recess so as to tend to lock the ball into engagement with tool bit when the sleeve is in a rest position.

Owner:WILSON GREATBATCH LTD

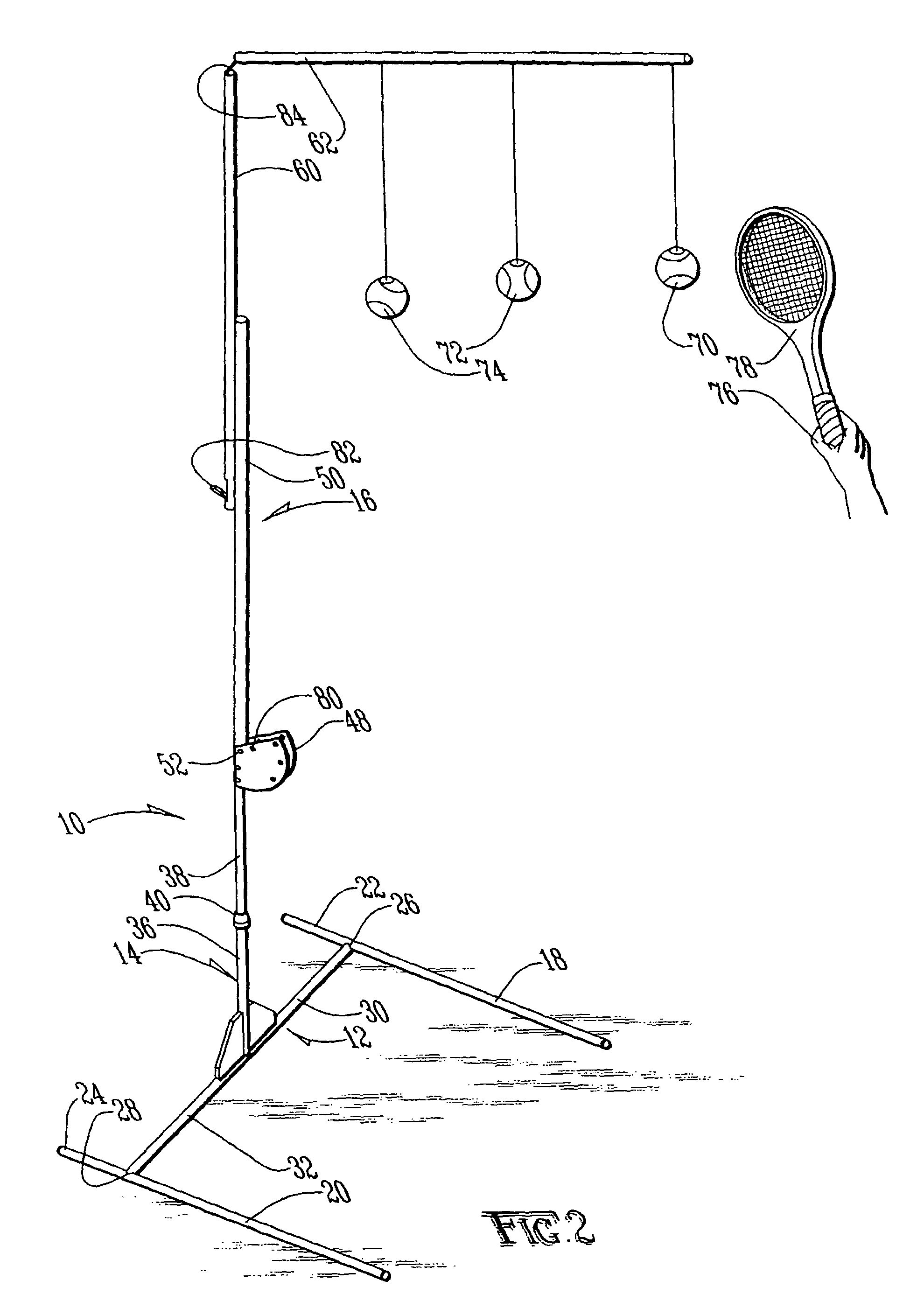

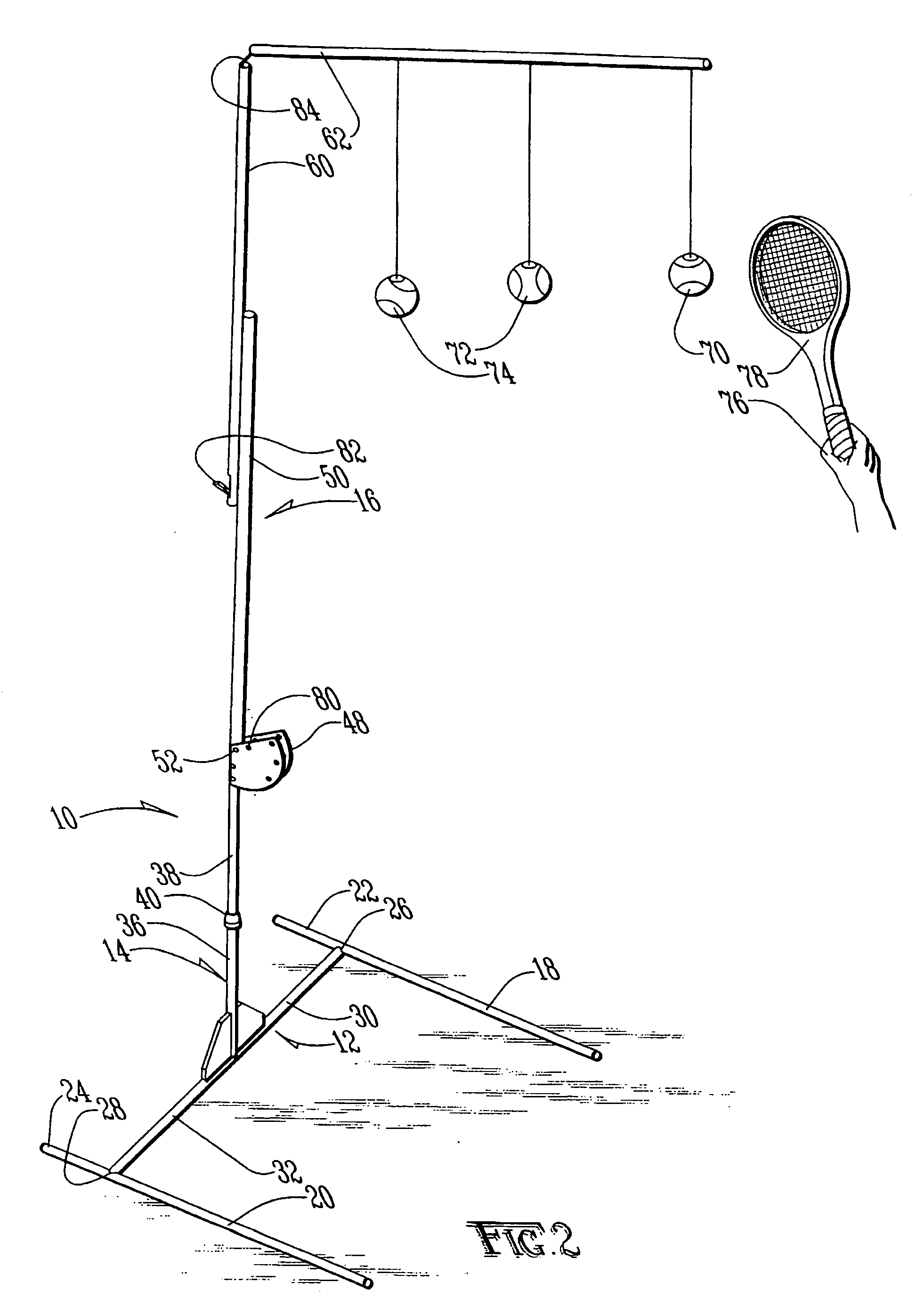

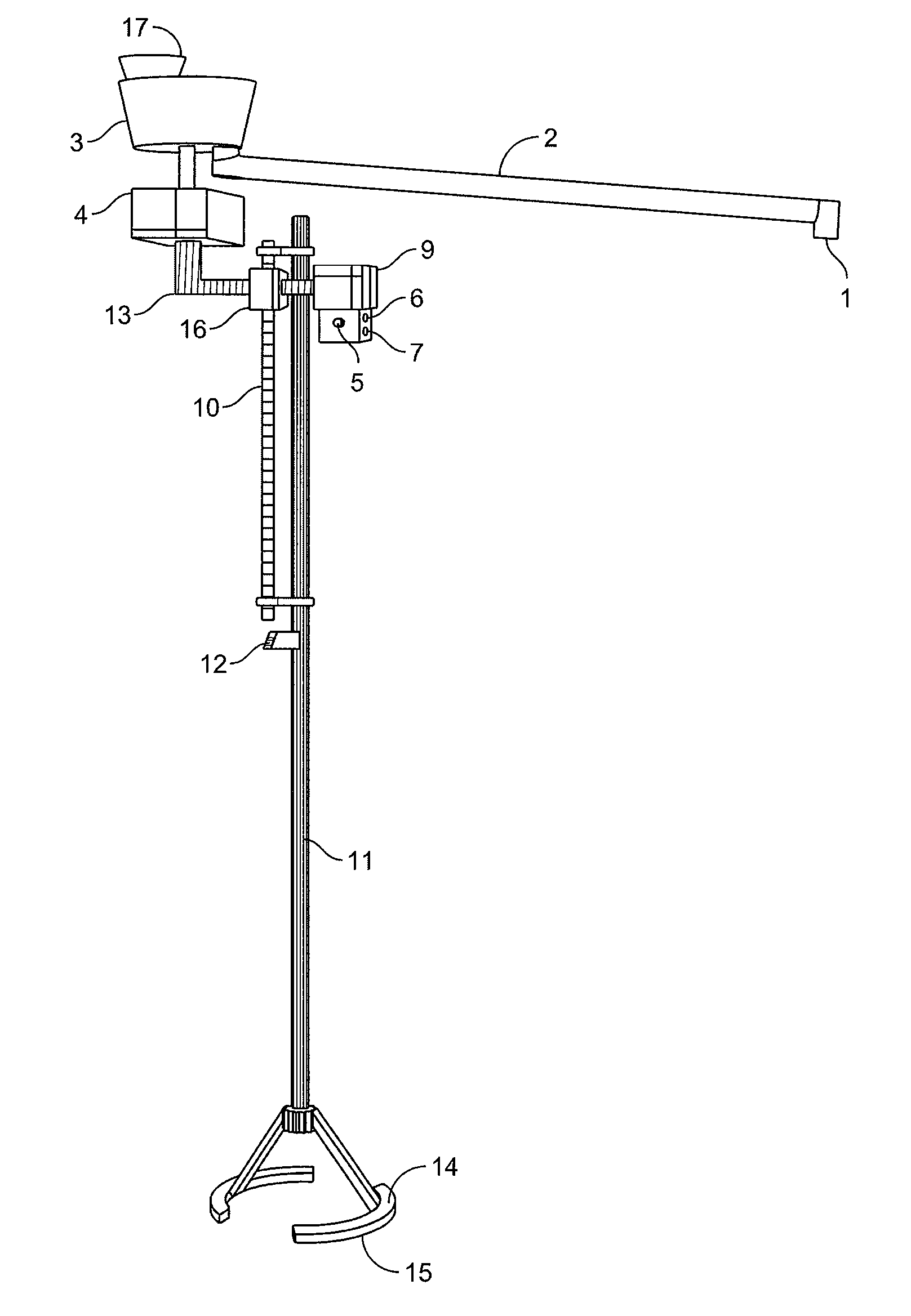

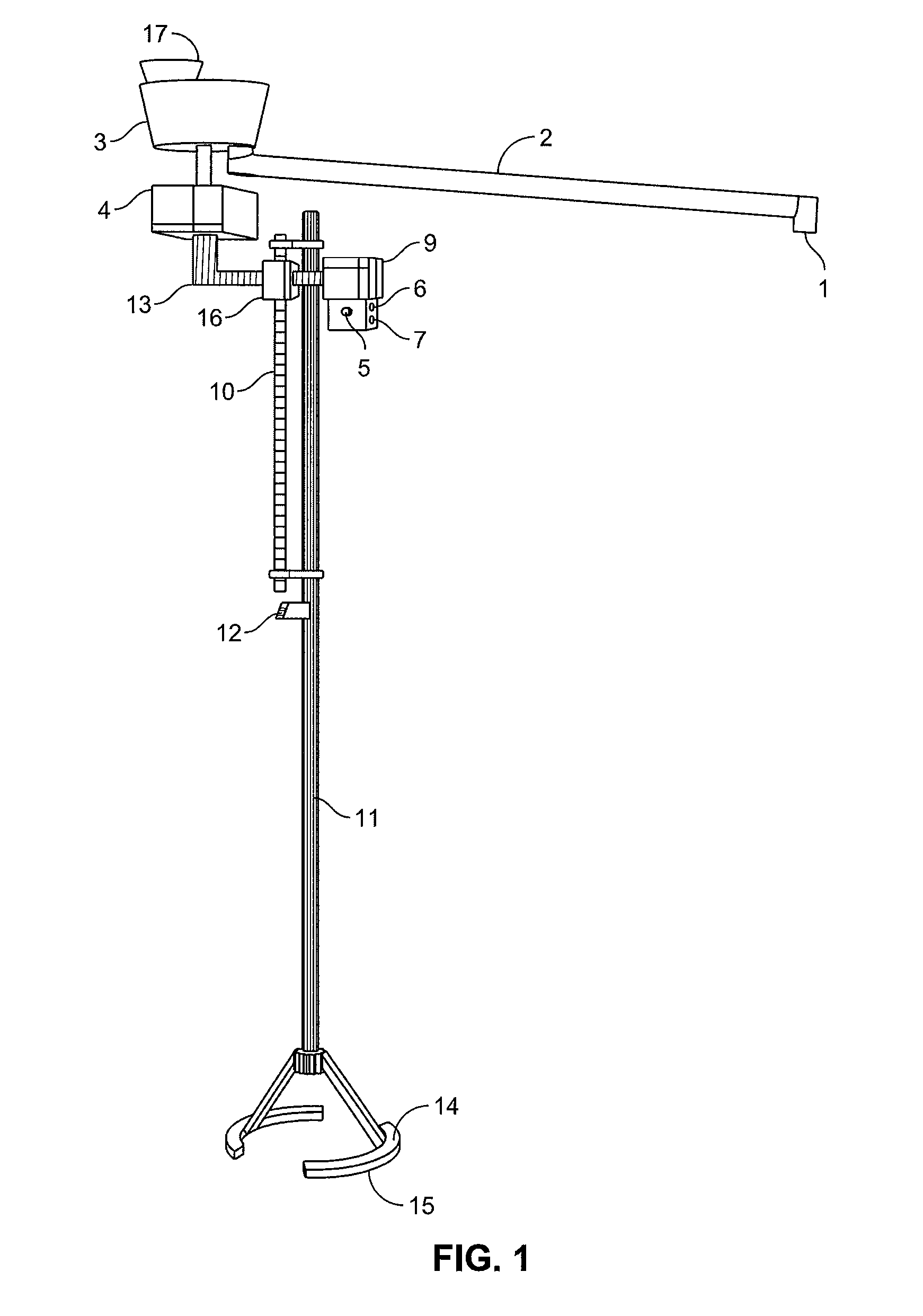

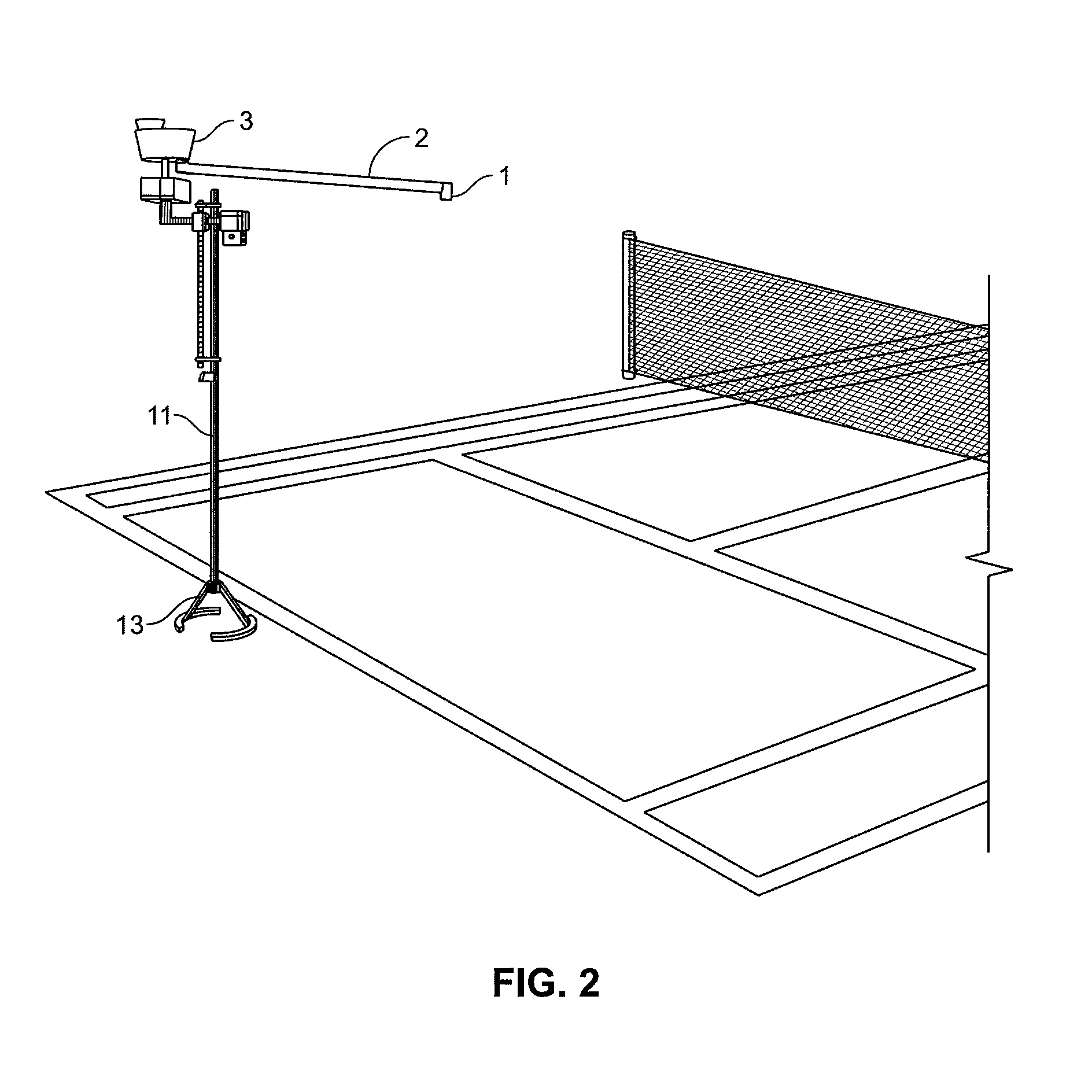

Tennis ball delivery device

InactiveUS20060196488A1Reduce manufacturing costEasy to carryBall sportsAmmunition loadingBall releaseBiological activation

A tennis ball delivery device for use in practicing one's tennis stroke. The device includes an adjustable frame, at least one declining ball delivery conduit carried by the frame in an upper portion thereof, a declining ball discharge shoot carried by and communicating with the delivery conduit and a ball release mechanism carried by the discharge conduit. The release mechanism allows a single ball to fall from the shoot in response to the activation thereof. A depending handle that can be easily struck by the player's racket in initiating their tennis stroke is operatively connected to the release mechanism so as to effect the release of the ball.

Owner:IDEABOY

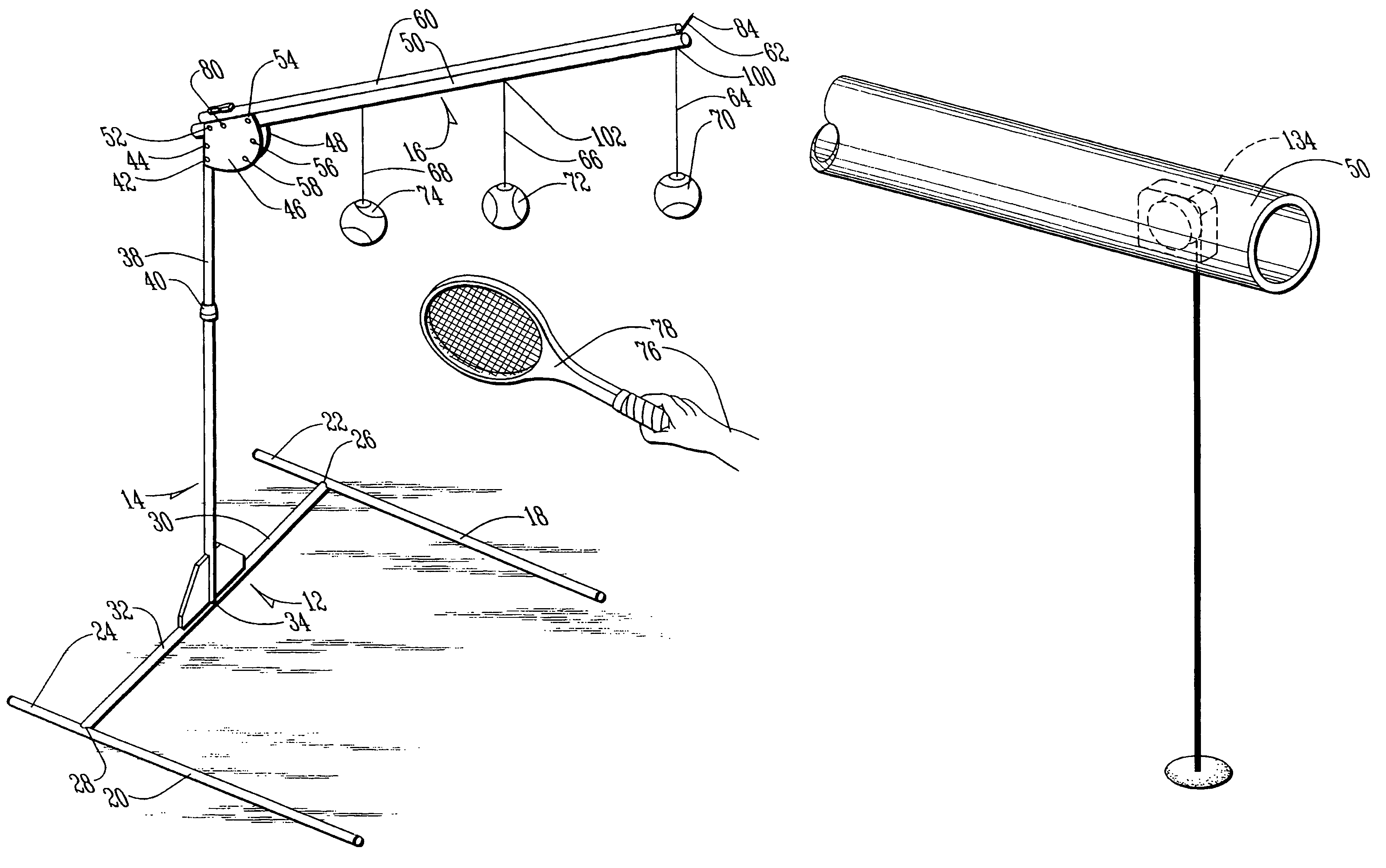

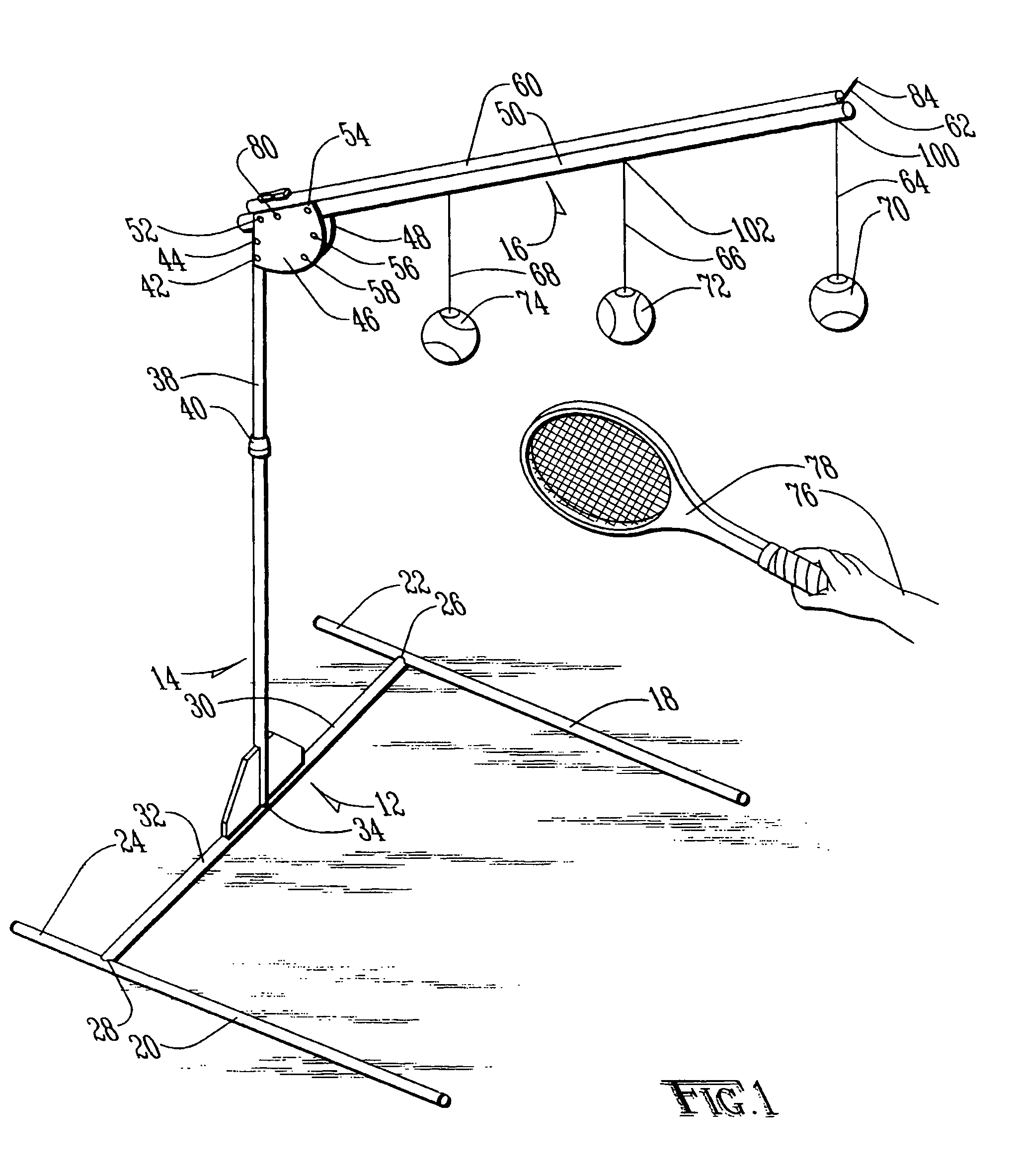

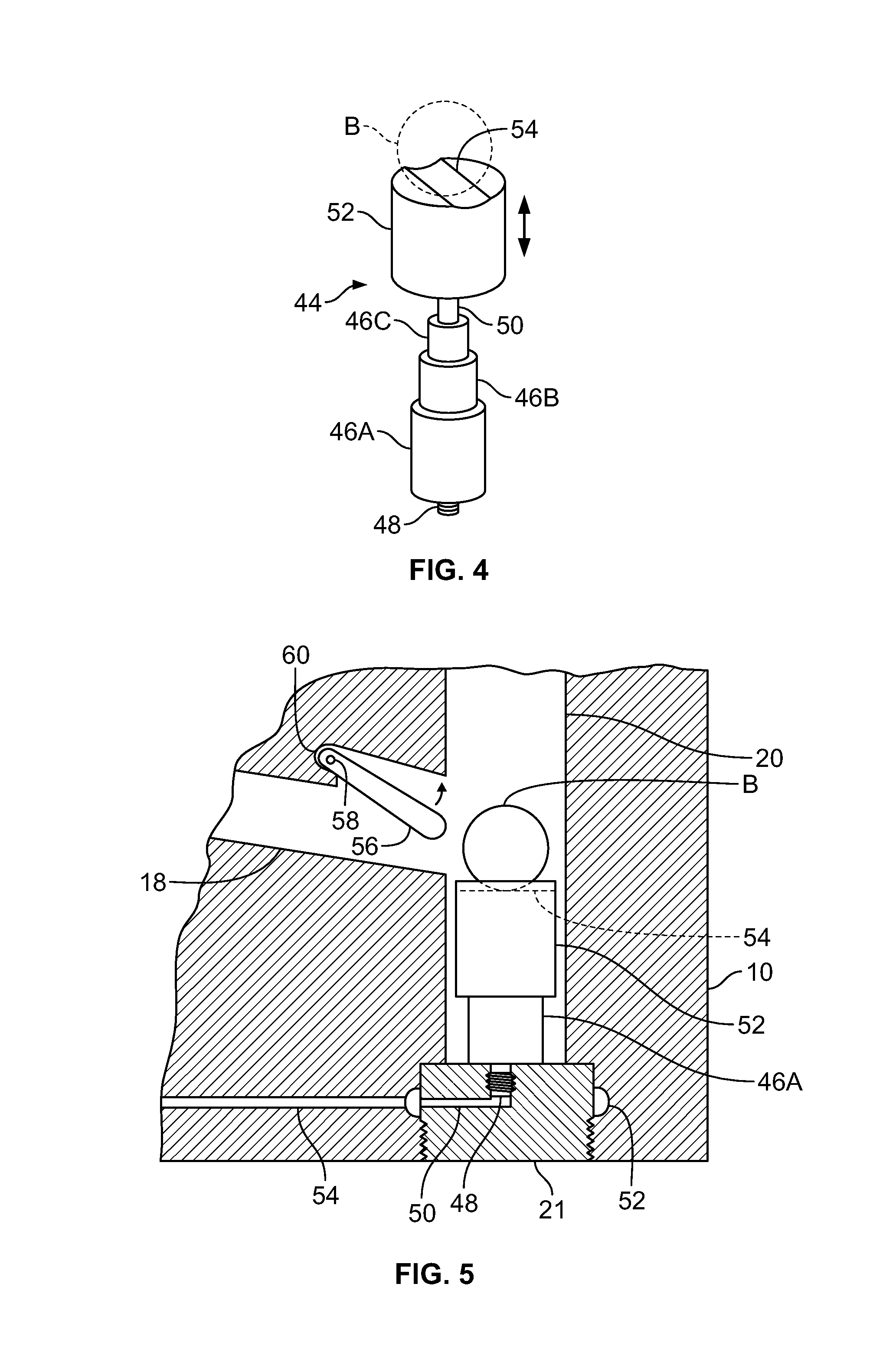

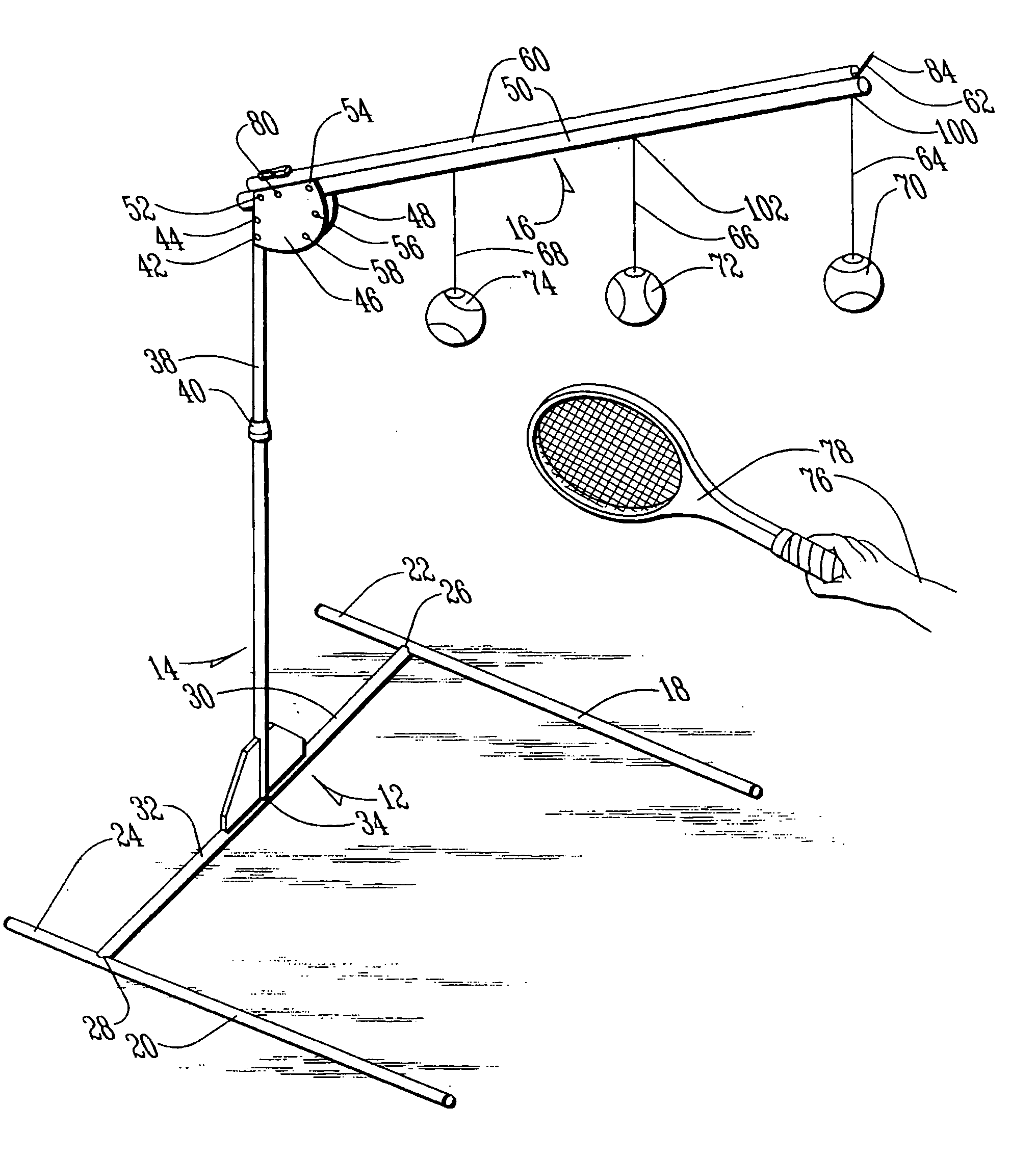

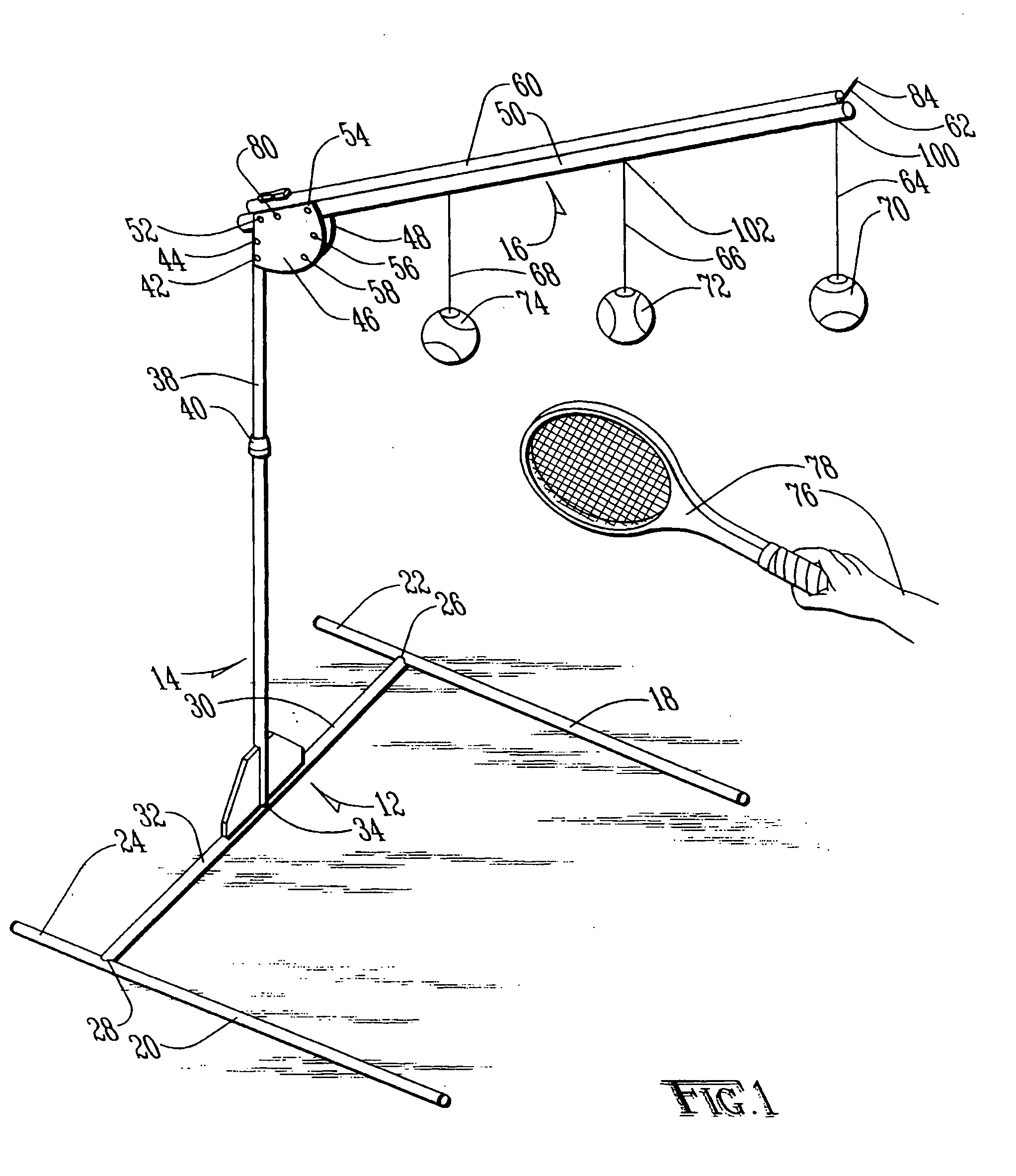

Athletic training device

Tennis balls are releasably connected to a string depending from a support. When the user strikes the ball, the ball releases from the string and the string automatically retracts into the support to reduce interference of the string with a user's subsequent stroke. The system is fully adjustable to replicate shots ranging from a ground shot to an overhead service. The system is lightweight, portable, and adaptable to a plurality of sports.

Owner:WOODS DENNIS W

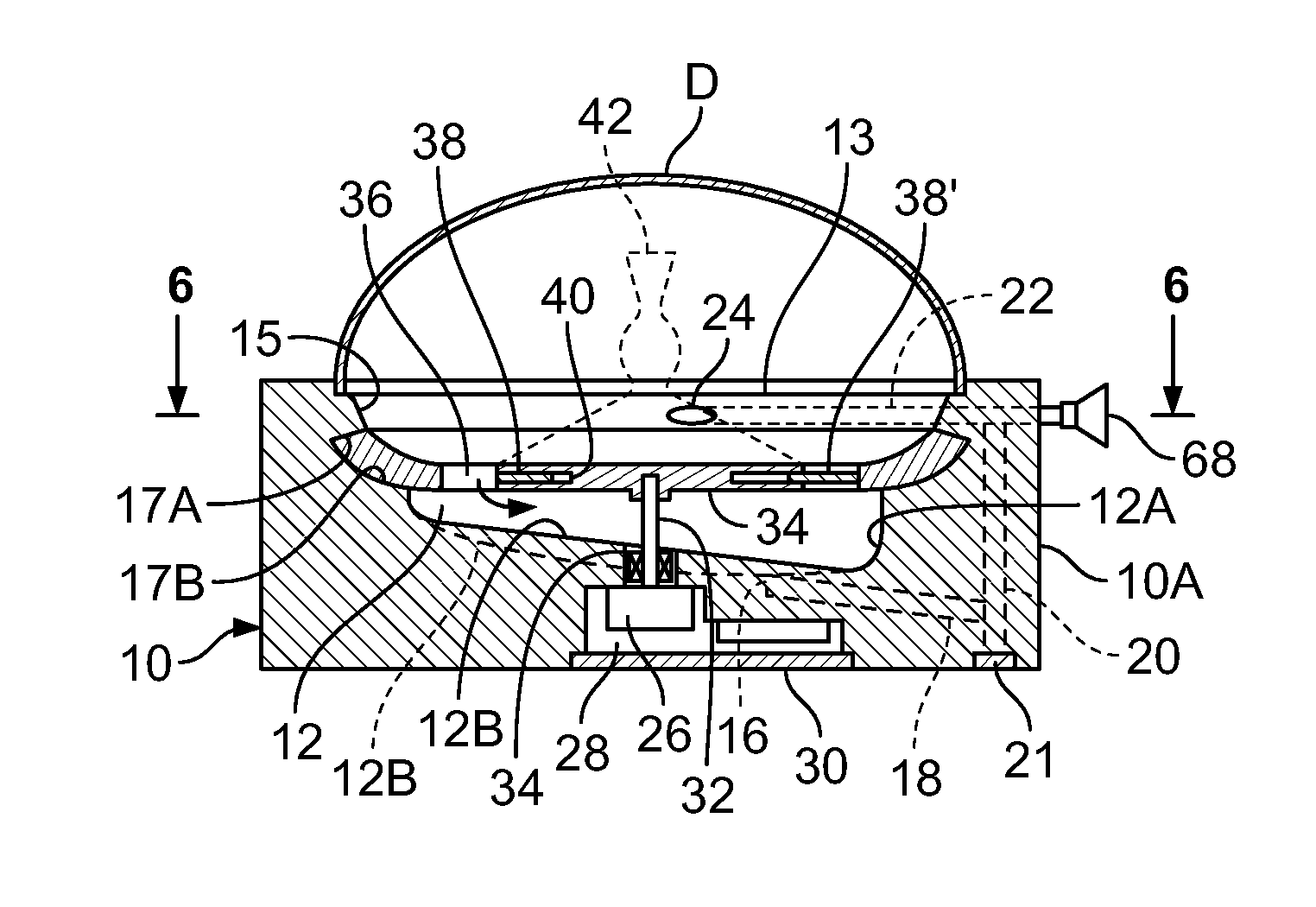

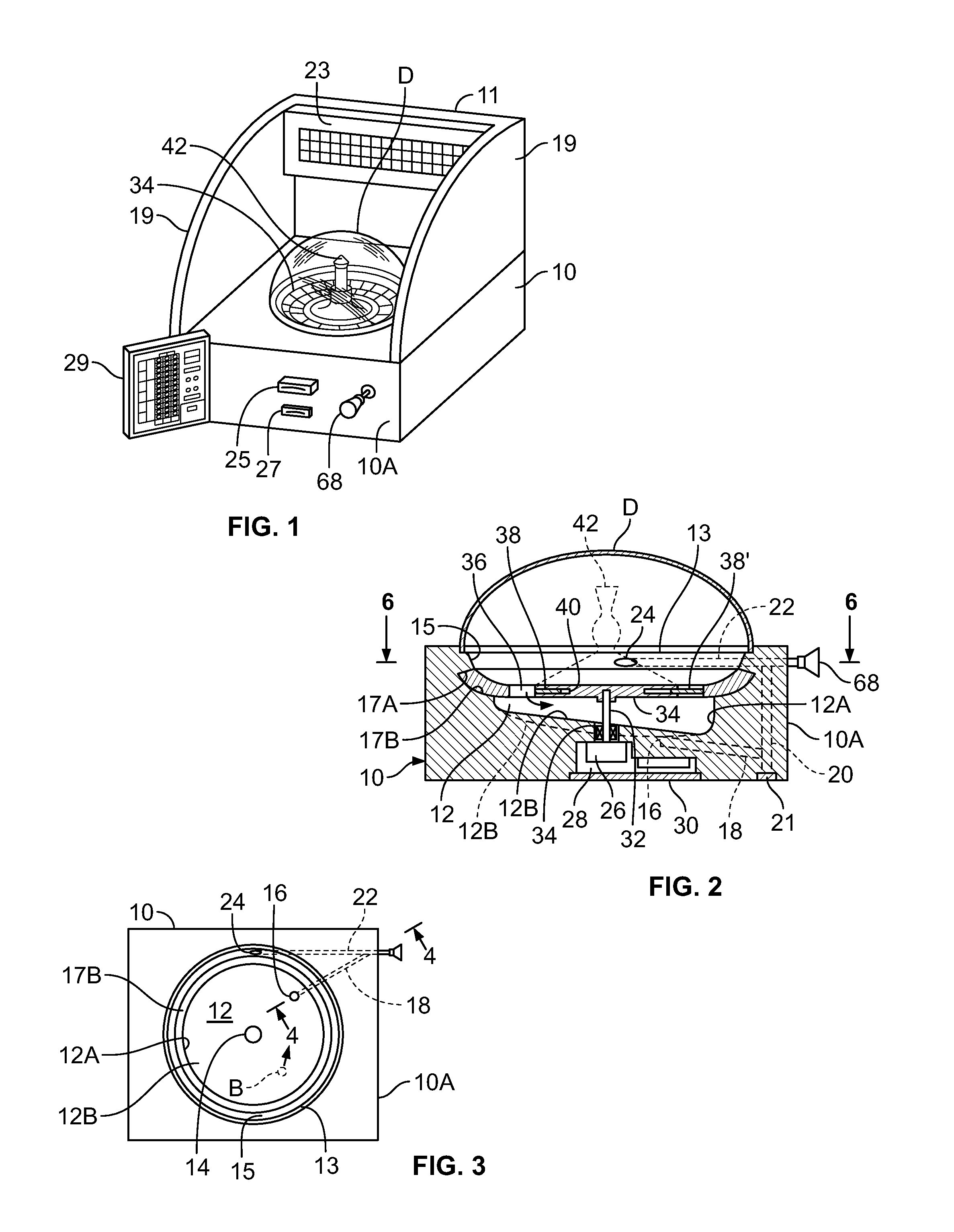

Game machine

A game machine has a controller with one or more consoles for recording a player's bet. The machine also has a motor-driven, concave wheel with a plurality of circumferentially spaced compartments. Each compartment can hold temporarily and release the ball. The wheel can produce an outcome signal indicating ball rest position. The controller can signal whether a player's bet has won based on the outcome signal. The base supporting the wheel has a return track for sending the ball released from the wheel to one or more elevators. The elevator can lift the ball to an associated ball striker that can propel the ball back to the wheel. The machine can have one or more stations for propelling the ball.

Owner:PAGLIUCA HENRY

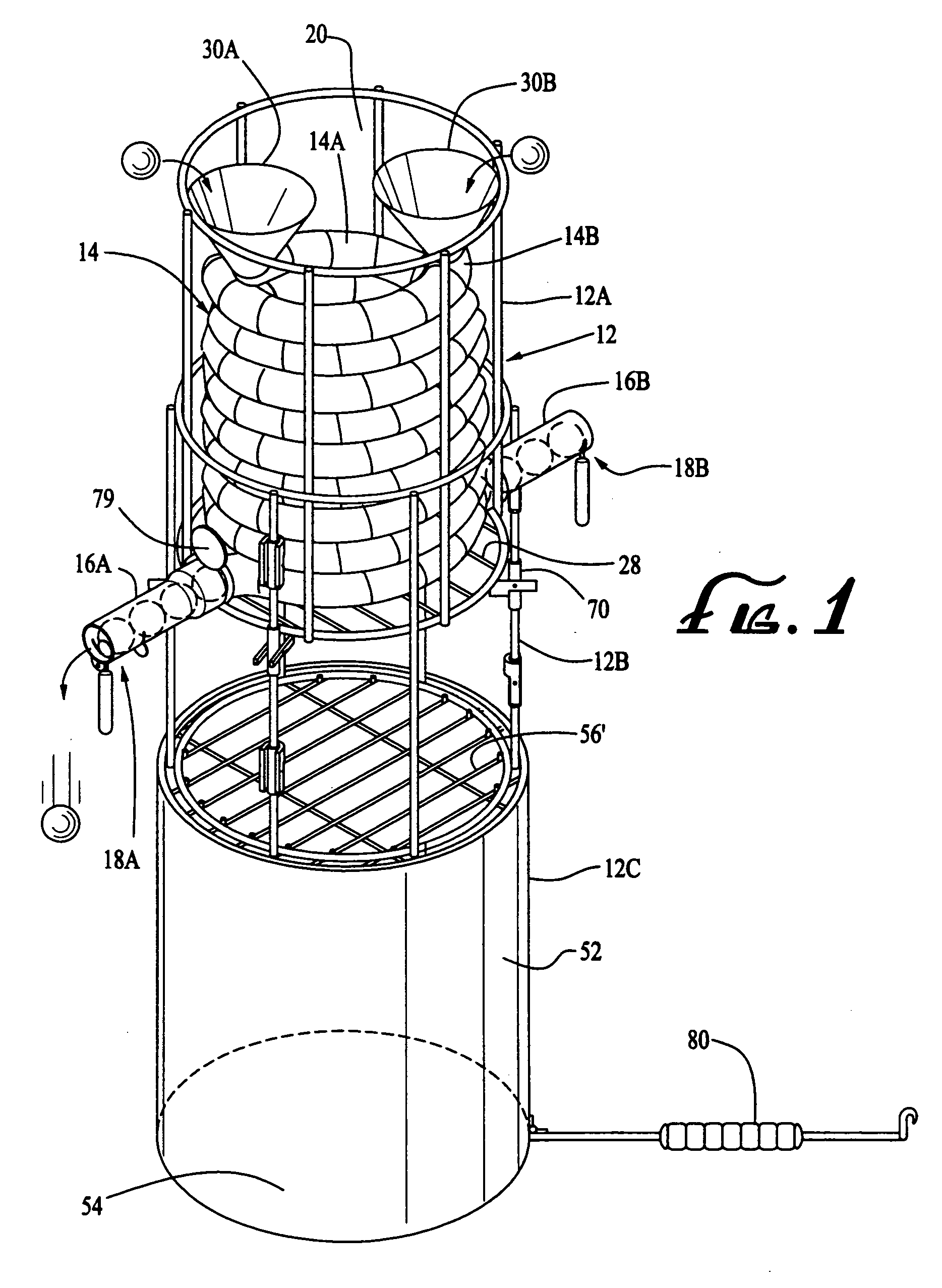

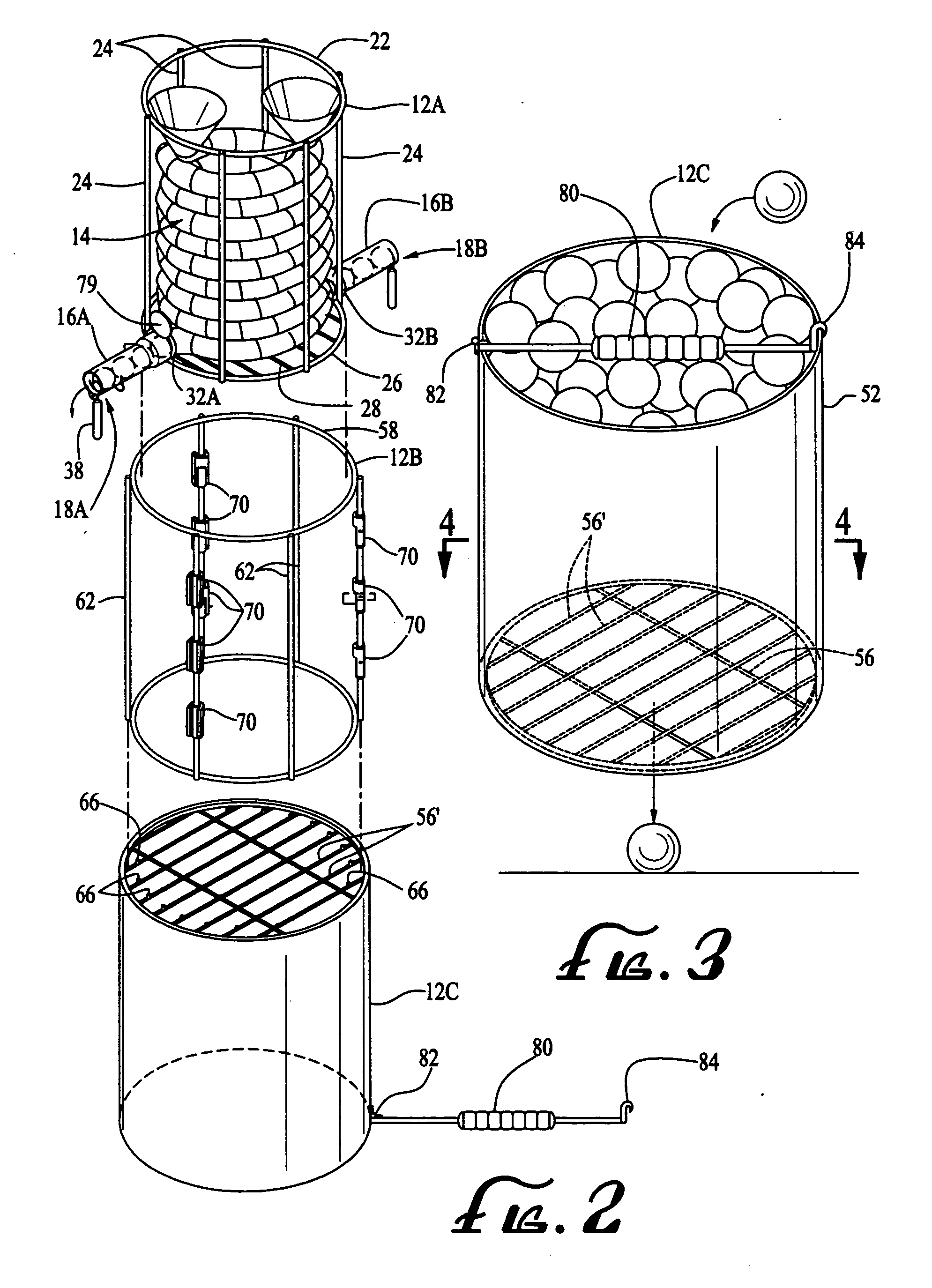

Golf ball dispensing and teeing device

A golf ball dispensing and teeing device comprising a ball receptacle for retaining a suitably large quantity of golf balls and delivering them to a ball release mechanism. The ball release comprises an actuator for release of balls from the ball receptacle onto a pivoting ball delivery mechanism, and a pivoting trigger member that controls the release such that balls are released individually. The trigger member is biased to provide a push to the ball and the ball delivery mechanism. The ball delivery mechanism is an elongated track or ramp, and the weight of the golf ball on the track and the push from the trigger member causes the track to pivot downward, such that the ball rolls down the track. A ball teeing structure is provided at the end of the track, and comprises a spout member of generally tubular configuration that stops the lateral movement of the ball and controls its position in the vertical direction. A cut-out is provided on the interior side of the spout to insure there is no contact between the ball and the spout when the spout pivots back to the neutral position. An alignment ring is provided about the base of the spout, which corresponds to an alignment indicator provided on a specialized golf tee.

Owner:HINES STEVEN WAYNE +1

Forward locking pull pin

A pull pin is configured to lock in a forward position to prevent accidental or undesirable retraction of the pull pin. The pull pin has a housing, a pull pin shaft, an inner shaft, a first and second spring, and at least one ball bearing. The housing has a ball locking space, which holds the ball bearing between the locking space and a ball aperture formed in the pull pin shaft to thereby lock the pull pin shaft in the forward position. Only upon the application of an external force to the inner shaft, which aligns a ball release portion with the ball aperture, can the ball bearing move into the ball release portion and thereby move out of said locking space, allowing for the retraction of the pull pin shaft.

Owner:PIVOT POINT

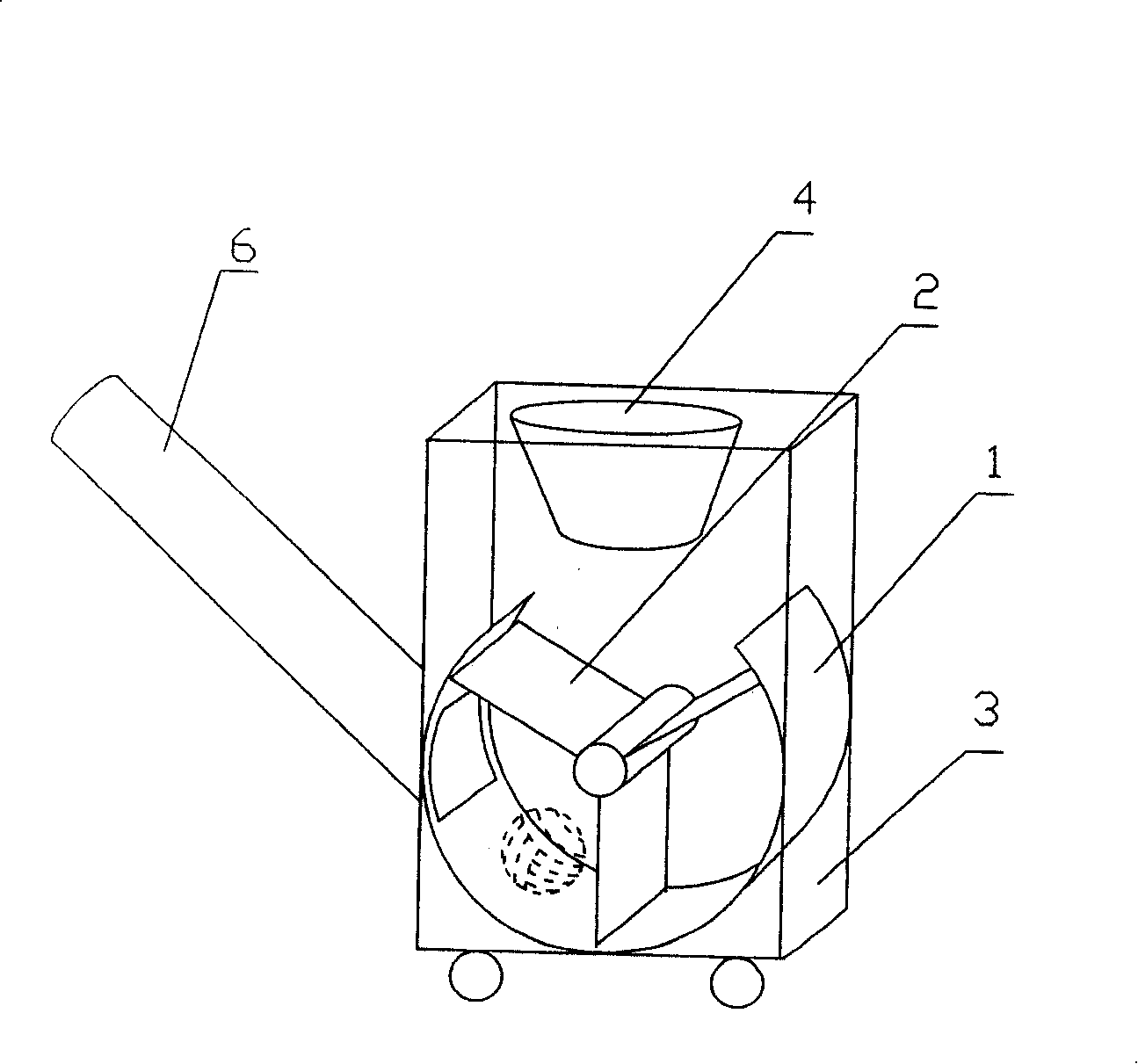

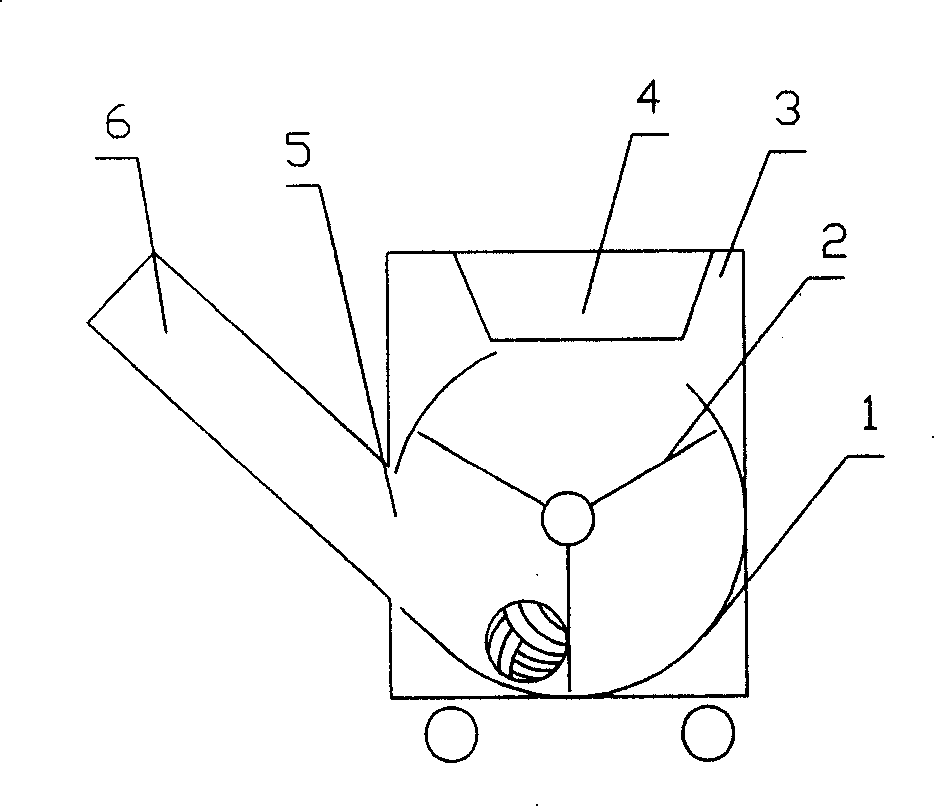

Vollyball exercising machines

InactiveCN101181666ASolve various technical trainingSimple structureSport apparatusPhysical educationBall release

The invention discloses a volleyball trainer which consists of a shell 3, a ball hitting paddle 2, a ball releasing tube 5 and a motor 7, etc. and is characterized in that a ball intake port is arranged above the shell 3 which is internally provided with an arc wall 1; two side walls of the arc wall 1 and the shell 3 form a volleyball launching chamber a central axial point of which is provided with the ball hitting paddle 2 with the motor 7 which is arranged on the shell 3; the other side wall of the shell 3 is provided with the ball releasing tube 6 which is connected with a ball releasing hole 5 at the side of the shell 3. The device of the invention has simple structure and convenient use and effectively solves the problems of various technical movement training of volleyball teaching by a single player, thereby meeting the demands of physical education teaching of various schools and physical education and training of athlete teams.

Owner:CHINA JILIANG UNIV

Coupling device with configurable actuator

Owner:WILSON GREATBATCH LTD

Athletic training device

Tennis balls are releasably connected to a string depending from a support. When the user strikes the ball, the ball releases from the string and the string automatically retracts into the support to reduce interference of the string with a user's subsequent stroke. The system is fully adjustable to replicate shots ranging from a ground shot to an overhead service. The system is lightweight, portable, and adaptable to a plurality of sports.

Owner:WOODS DENNIS W

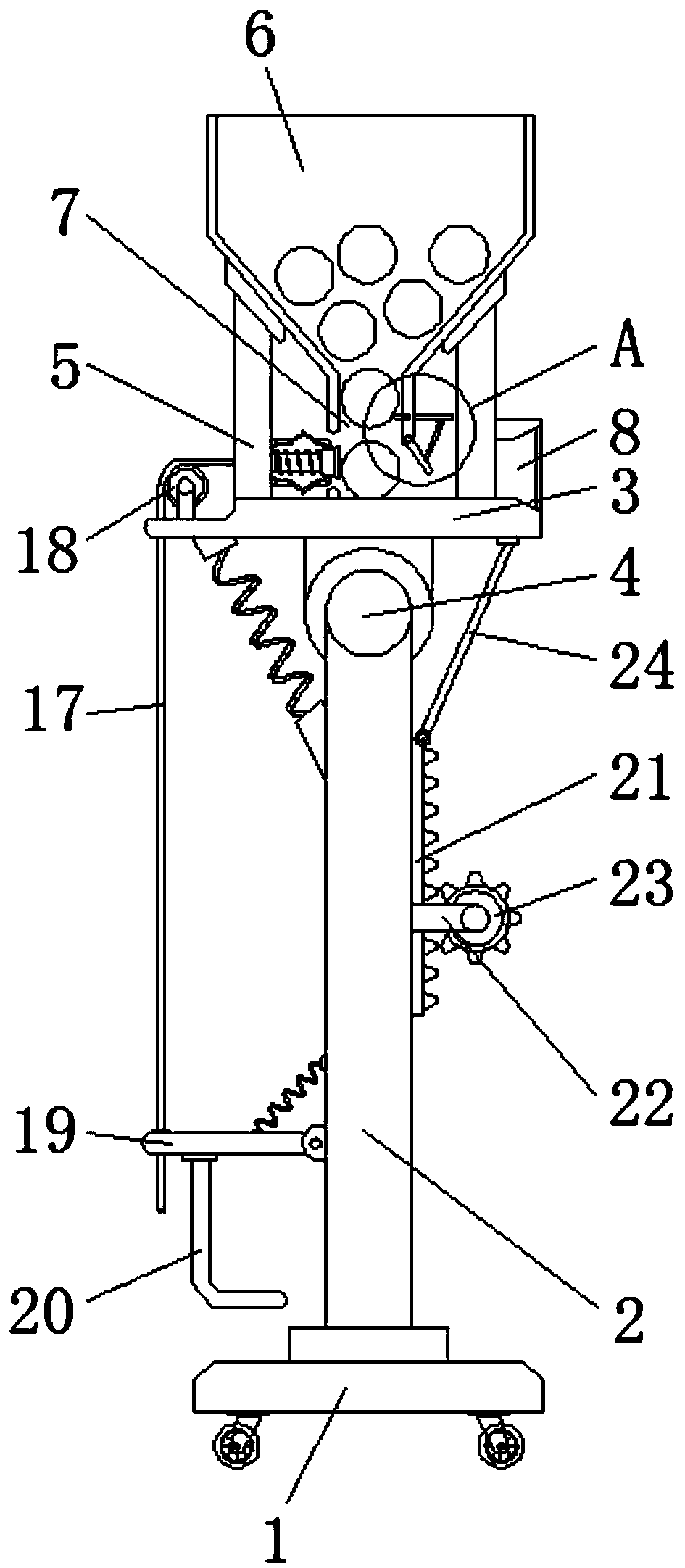

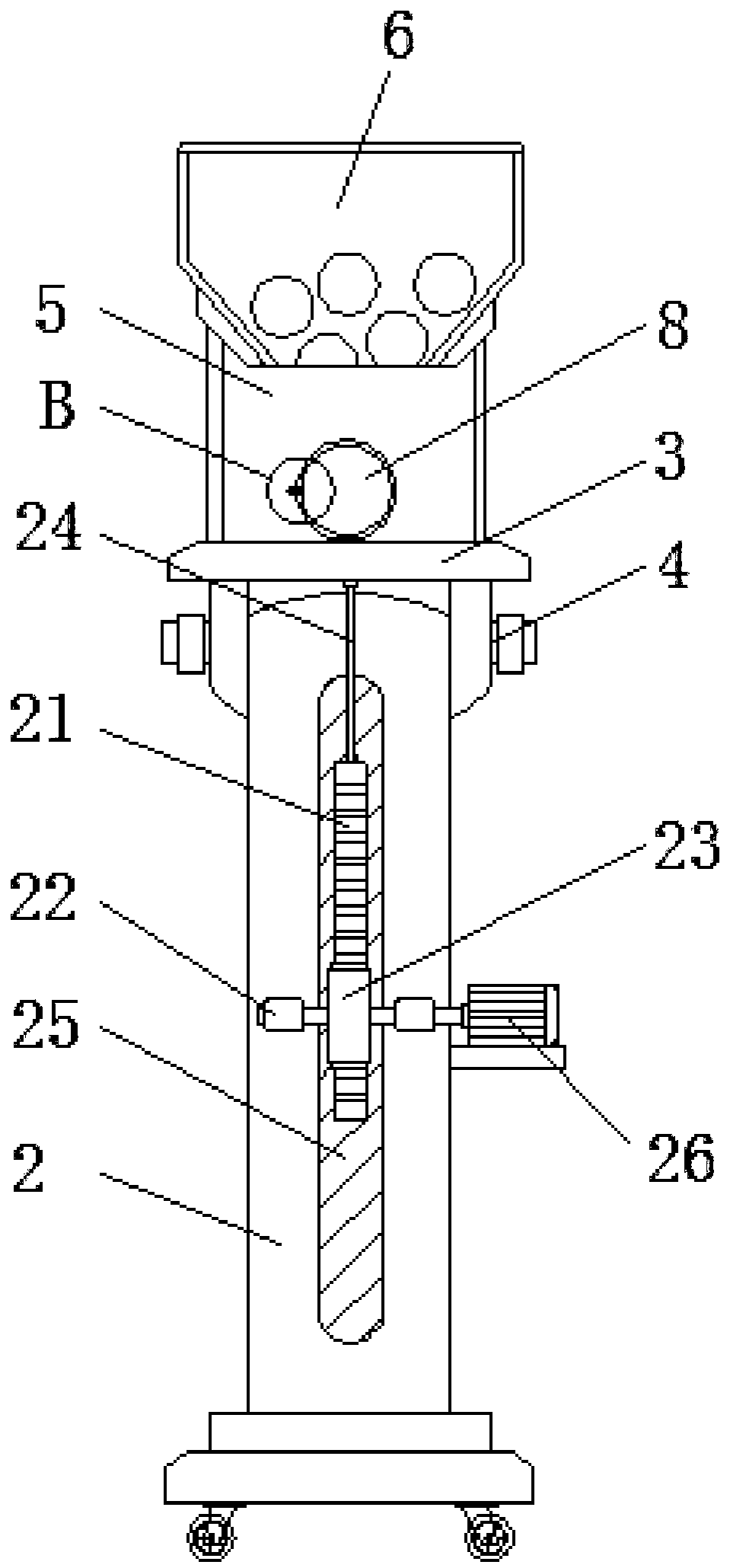

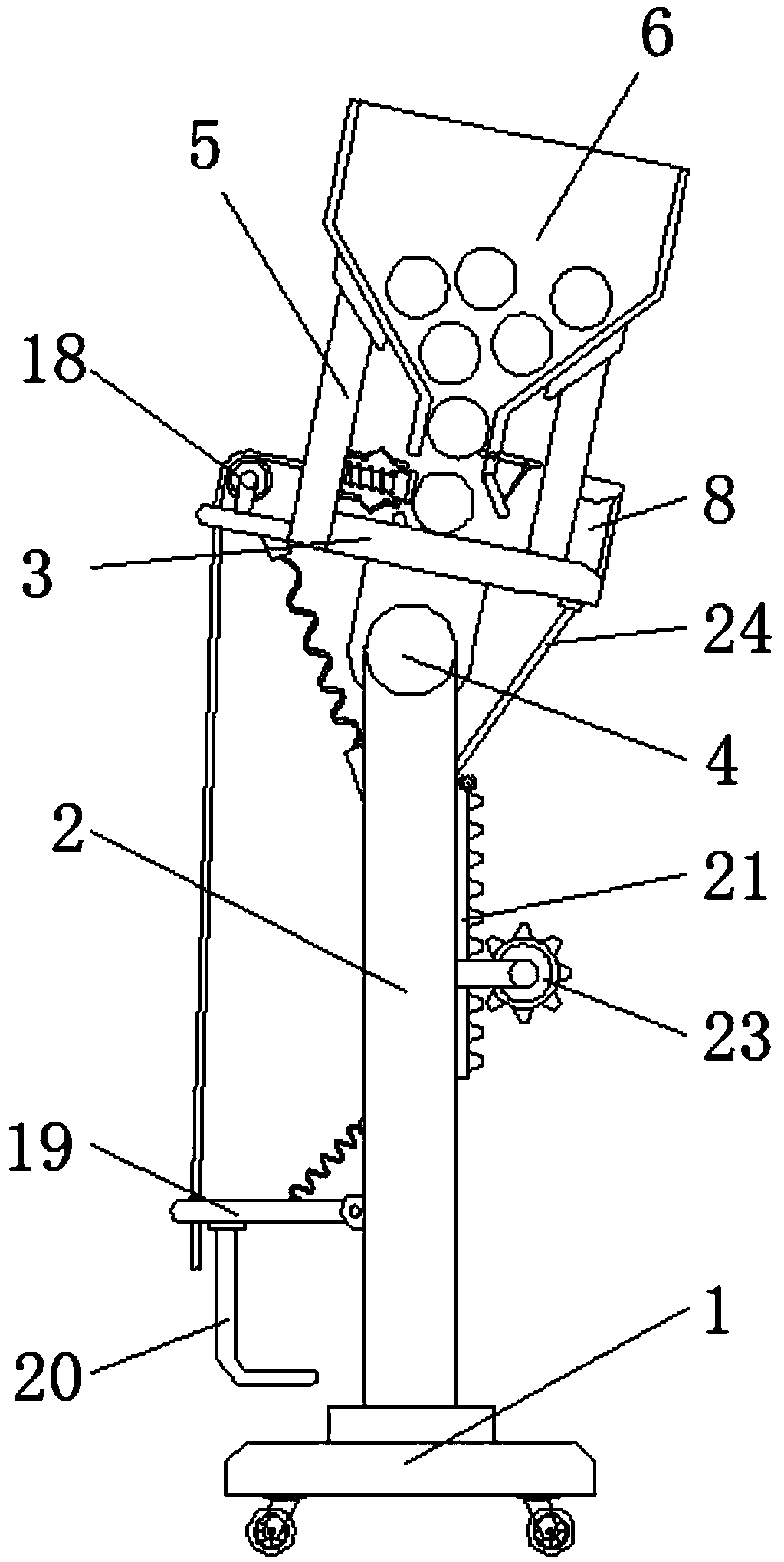

Serving device for volleyball training teaching

A servingdevice for volleyball training teaching is disclosed, and includes the base and the forward and reverse motors, a support column is fixed above the base, and the upper part of the supportingcolumn is connected with the supporting platform through a connecting bolt, a support plate is fixed above the support table, a ball release frame is connected above the support plate, and a lower ball opening is arranged below the ball placing frame, the left side of the rotating gear is connected with a rack, a sliding groove is arranged on the surface of the support column, a finite position plate is arranged on the lower right of the ball placing frame, a groove is arranged on the surface of the support plate, a fixing clamp bar is fixed inside the groove, a rotating protrusion is connected on the outer side of the fixing clamp bar, and a third spring is connected between the fixing clamp bar and the rotating protrusion. The serving device for volleyball training teaching can automatically supplement the dispatched ball, and can dispatch a revolving ball similar to the actual combat, at the same time, the firing angle of the ball can be adjusted, so that the device is more convenient for teachers to use.

Owner:嵊州市森拓新材料有限公司

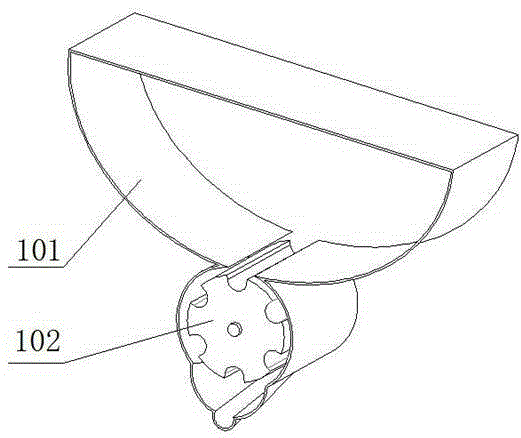

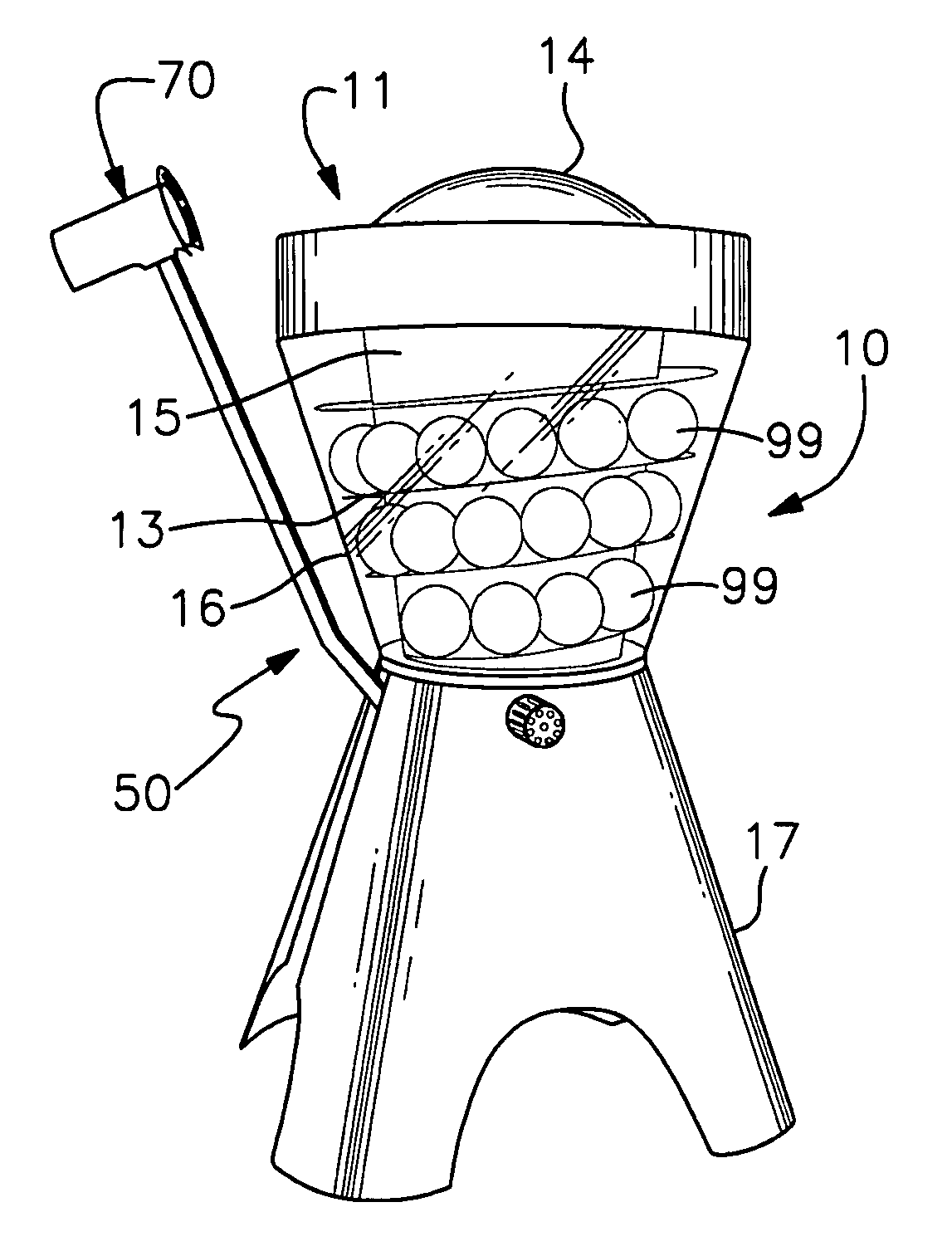

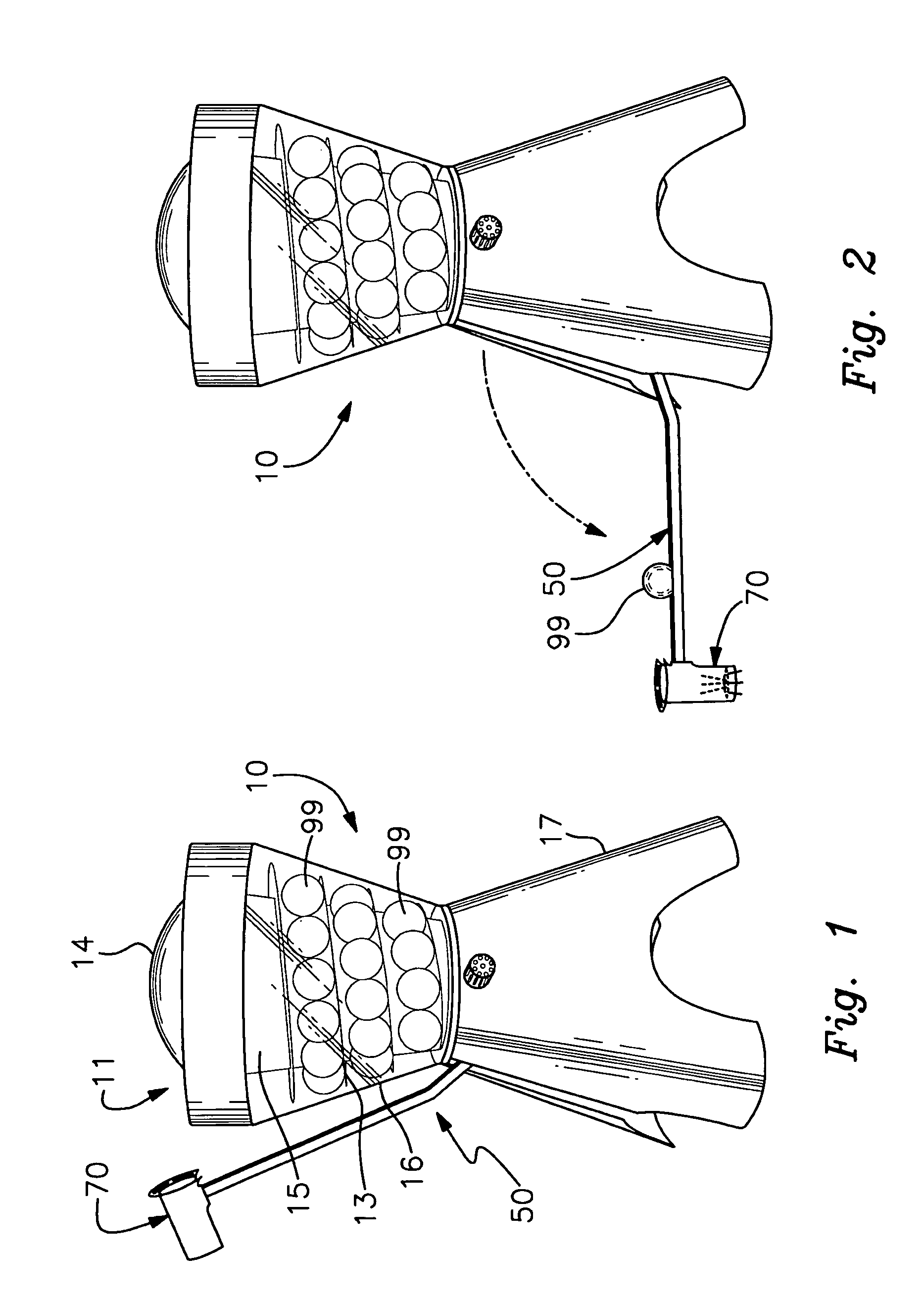

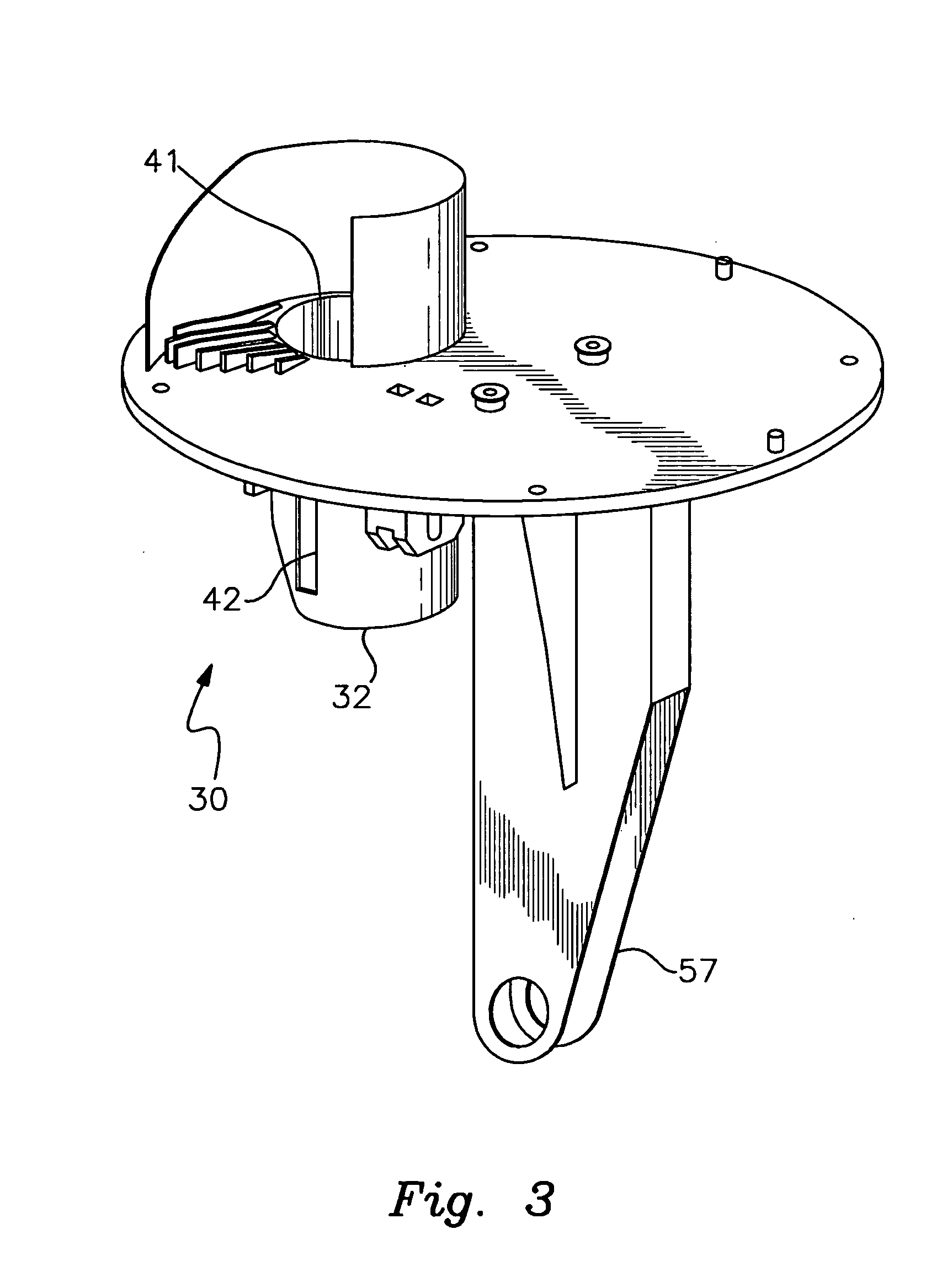

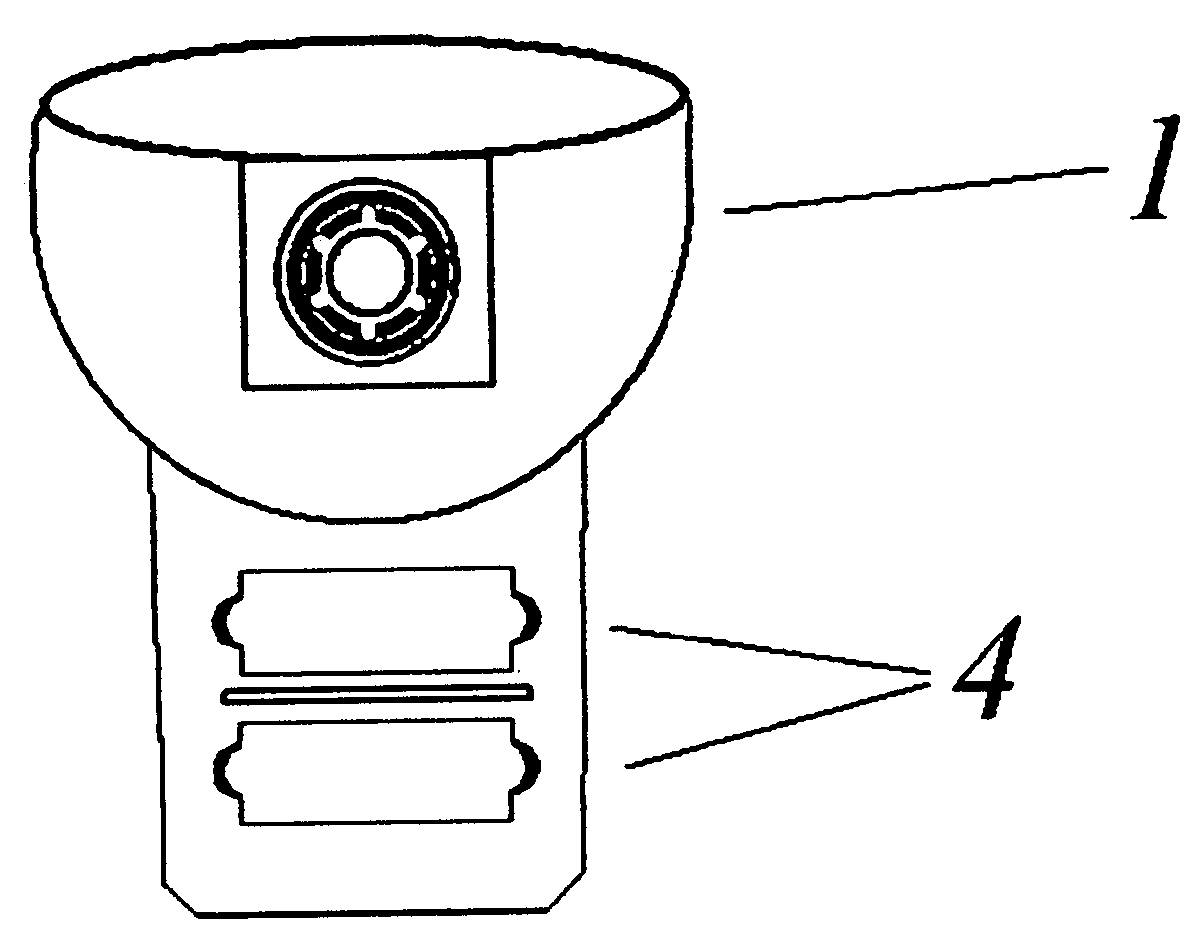

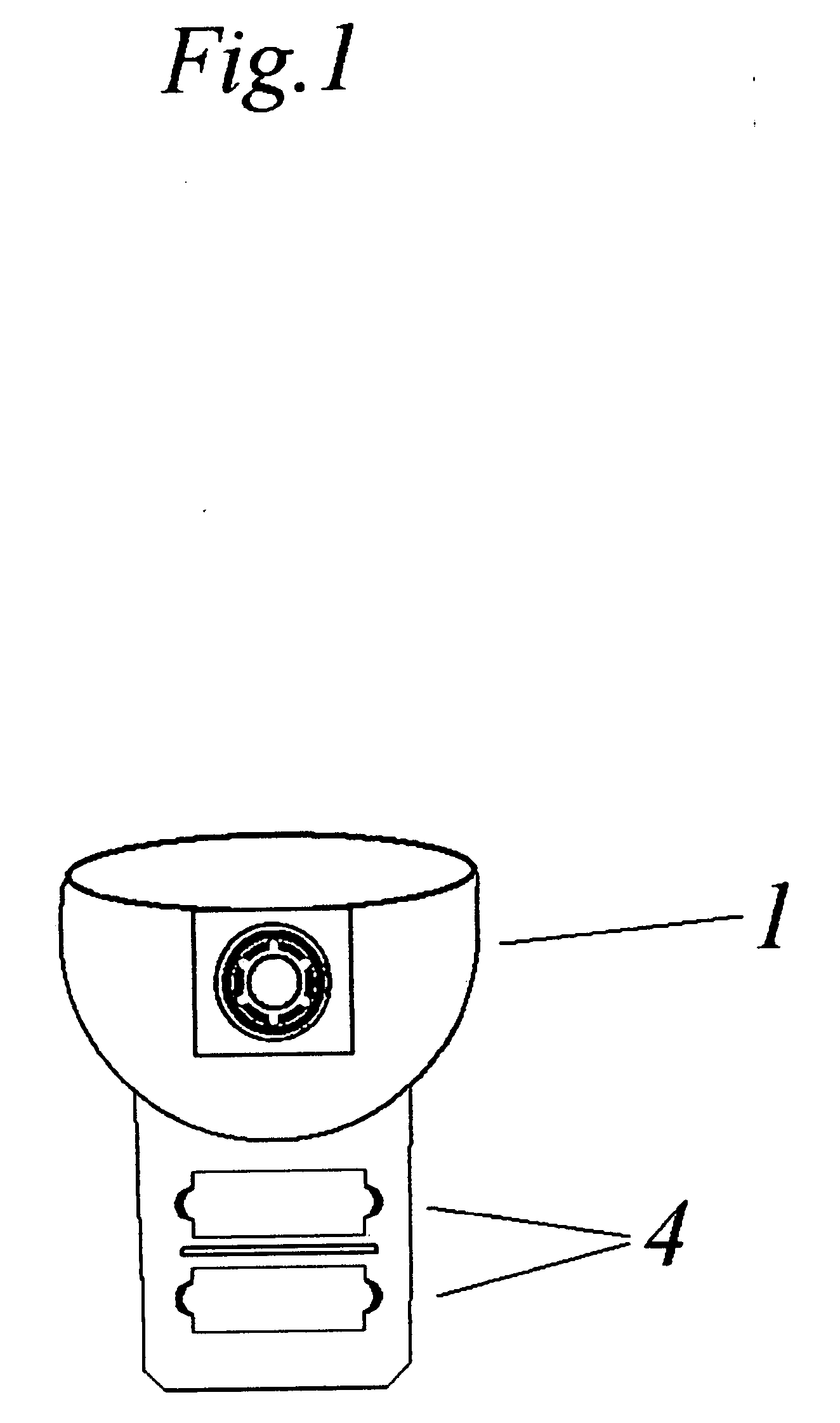

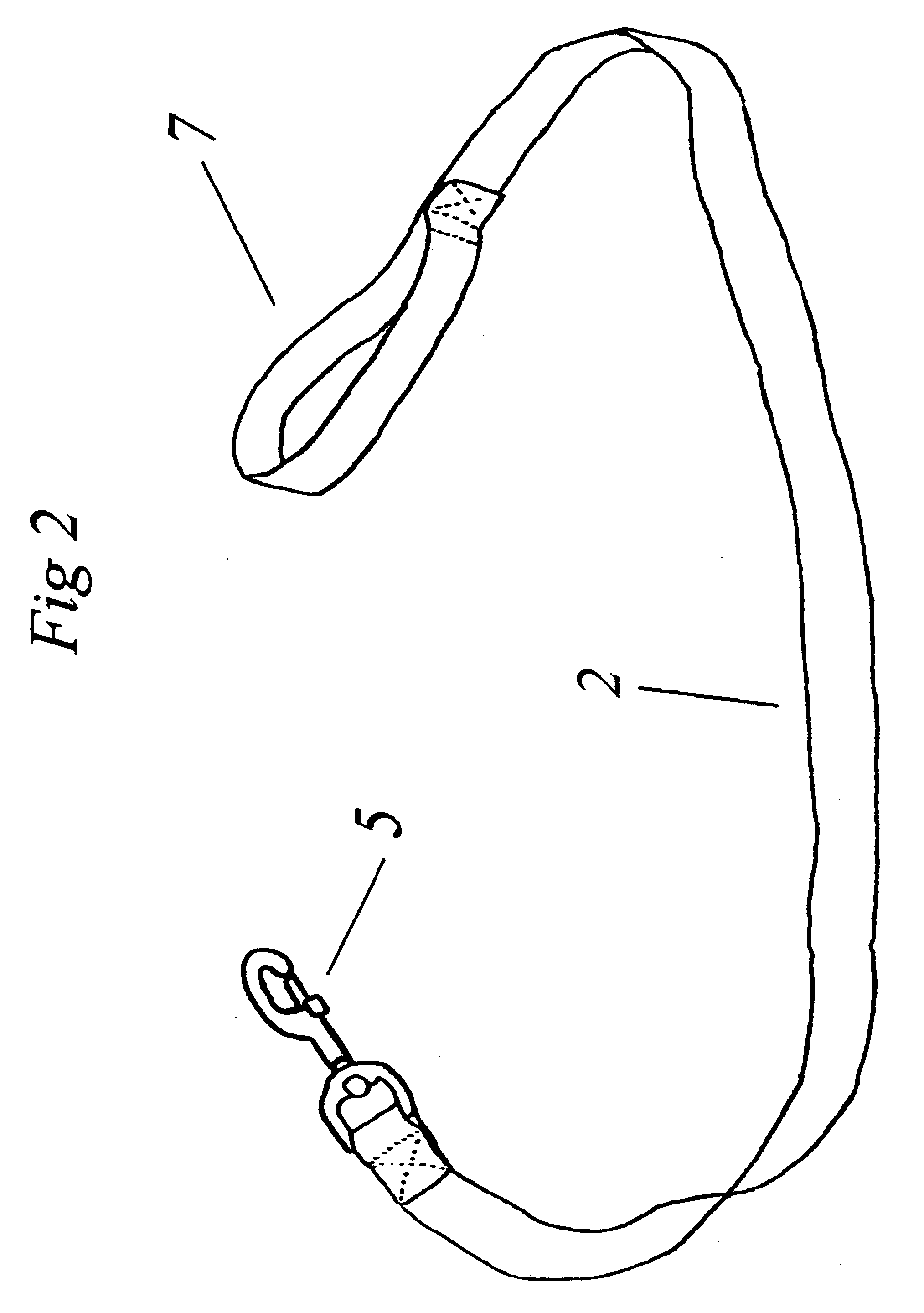

Ball thrower

The ball throwing device (1) (FIG. 1) can be attached to a dog leash (2) (FIG. 2) or purposely made length of strap (3) (FIG. 10) using the purposely designed handle on the ball throwing device (4) (FIG. 1) or loop (15) (FIG. 10) or cord lock handle (12) (FIG. 19). With the ball throwing device (1) (FIG. 11) securely attached to a dog leash (2), the clasp end of the dog leash (5) can then be connected to a supplied retaining ring (6) located on the leash handle (7). The ball throwing device can be used for picking up a ball (8) (FIG. 6) hands free. This is achieved by placing the ball throwing device (1) over a ball (8) (FIG. 9) and pressing down firmly. The ball throwing device (1) fits neatly over the ball (8) and is able to hold the ball securely. The ball throwing device (1) (FIG. 5) could have an adjustable mechanism (9) or (FIG. 22) threaded knob (13) entering a threaded washer (14) for the purpose of controlling the distance that a ball (8) can be thrown. This can be achieved by rotating an adjuster knob (10) (FIG. 5) or (13) (FIG. 22), which is located on the outside edge of the housing cup hemisphere. The adjuster knob (10) (FIG. 5), which when rotated, causes a tapered inner plate (9) (FIG. 3) located on the inside of the housing cup (11) to revolve (FIG. 4) and can be used to decrease the overall size of the housing cup's (1) (FIG. 5) inner casing hemisphere (11). The threaded knob (13) (FIG. 22) can also be used to decrease the overall size of the inner casing hemisphere (11) by rotating the threaded knob (13) inward. With the ball throwing device (1) (FIG. 12) attached or incorporated into a dog lead (2) (FIG. 11) or strap (3) FIG. 10), the lead / strap can be swung in a forward / over arm throwing motion (FIG. 12), allowing the ball (8) to be projected. The projection of a ball is achieved by the ball releasing from the housing cup (1) through the use of centrifugal force. The distance a ball (8) can be thrown depends on which position the adjuster mechanism plate (9) (FIG. 14) is set. With the adjuster knob (10) rotated so that the tapered inner plate (9) (FIG. 3) is recessed and in the downward position, the tapered plate (9) falls behind the line of the inner casing hemisphere (11) (FIG. 14). The adjuster, whilst in the downward position, causes no interference with the ball (8) held within the housing cup (1) and enables the ball (8) to release and exit from the ball throwing device (1) with less force and momentum that is applied through the over arm swinging action of the leash (2) or strap (3) (FIG. 12). With the adjuster mechanism (9) (FIG. 4) in the upward position, the tapered inner plate (9) (FIG. 15) falls to the outside line of the housing cup's inner casing hemisphere (11). The tapered plate (9) (FIG. 5) whilst in this upward position, reduces the overall size of the inner casing hemisphere (11) which in turn, interferes and tightens the ball (8) (FIG. 9) against the housing cup's inner casing hemisphere (11) therefore holding the ball (8) inside the housing cup (1) more securely. The upward position of the tapered plate (9) (FIG. 5) also requires the user to apply more force to the over arm throwing action (FIG. 12) to enable the ball (8) to release and exit from the ball throwing device (1) with greater force and momentum, which in turn results in the ball (8) travelling further. The ball throwing device (1) (FIG. 6) is designed so that it can be held on the dog leash (2) whilst not in use, with or without the ball (8) inserted (FIG. 16). This feature enables the user to avoid having to place the dirty, messy ball (8) in their pocket or bag.

Owner:CATTLIN BRETT

Pressure actuated frack ball releasing tool

In a fracking context the object that will ultimately block a passage in an isolation device is introduced into the zone with the bottom hole assembly. The object is not released until the guns fire to create a pressure spike in the borehole that triggers the object retaining device to release the object. The retaining device is placed in close proximity to the isolation device and its setting tool to allow a larger object and passage in the isolation device to be used. If the guns misfire, the object is not released and comes out with the guns. The replacement guns can be pumped in because the passage in the isolation device has stayed open during the misfire. Direct and indirect object release in response to pressure created from the firing of the guns is contemplated.

Owner:BAKER HUGHES INC

Cementing head

A tool for dropping one or more balls and then one or more darts features a closable ball drop opening that works automatically after the ball release to minimize damage to the subsequently released dart. A retainer keeps the darts from coming back up above the dart launcher in the event of a pressure surge in the well. The dart launcher features a dedicated movable barrel for each dart that can be locked in a fully misaligned and fully aligned position with the casing or tubular. A handle is retained to the dart housing and can be manipulated to defeat the lock and rotate a given barrel. The darts may be inspected in their respective barrels before launch and the launch order is variable.

Owner:BAKER HUGHES INC

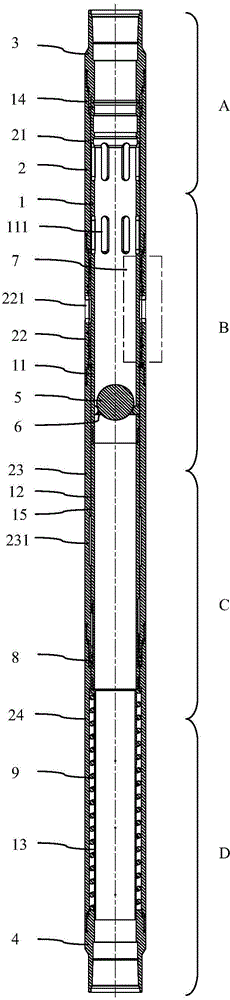

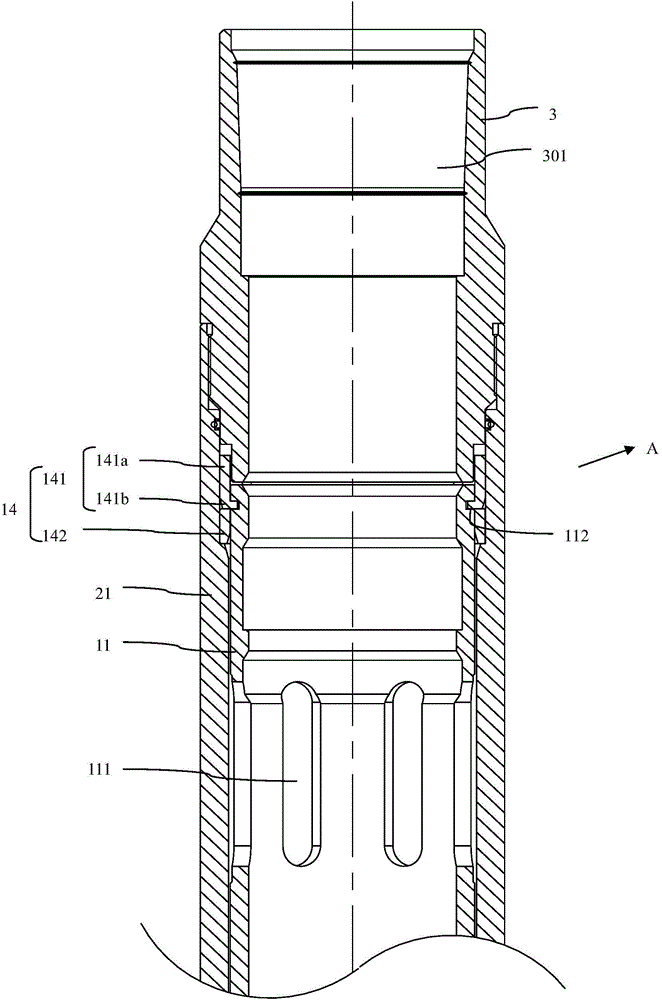

Ball seat assembly and ball-pitching sliding sleeve type fracturing device

ActiveCN105840163AReduce construction costsHigh degree of automationFluid removalWell/borehole valve arrangementsType fractureBall release

The invention relates to a ball seat assembly and a ball-pitching sliding sleeve type fracturing device. The ball-pitching sliding sleeve type fracturing device comprises an inner sleeve, and outer sleeve, a fracturing ball, and the ball seat assembly. The inner sleeve is slidably sleeved in the outer sleeve. The inner sleeve and the outer sleeve are respectively provided with fracturing windows. The inner sleeve slides to open or close the fracturing window. The inner side surface of the outer sleeve is provided with a fracturing ball releasing groove. The fracturing ball is pitched on the ball seat assembly. When the ball seat assembly moves to the fracturing ball releasing groove, the fracturing ball generates thrust under the action of external forces, to push a plurality of ball seat supports to move outward along a radial direction, and the fracturing ball passes through the ball seat assembly and falls into a next section of the ball-pitching sliding sleeve type fracturing device. Using the ball-pitching sliding sleeve type fracturing device can realize an objective of fracturing an infinite layer section by just pitching a ball, and construction cost is reduced and yield of a single well is increased. The device solves defects in the prior art of range limitation of a fracturing sliding sleeve and influence of sliding of the inner sleeve after a shear pin is cut off.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

Tennis ball delivery device

InactiveUS7244198B2Reduce manufacturing costEasy to carryBall sportsAmmunition loadingBall releaseBiological activation

A tennis ball delivery device for use in practicing one's tennis stroke. The device includes an adjustable frame, at least one declining ball delivery conduit carried by the frame in an upper portion thereof, a declining ball discharge shoot carried by and communicating with the delivery conduit and a ball release mechanism carried by the discharge conduit. The release mechanism allows a single ball to fall from the shoot in response to the activation thereof. A depending handle that can be easily struck by the player's racket in initiating their tennis stroke is operatively connected to the release mechanism so as to effect the release of the ball.

Owner:IDEABOY

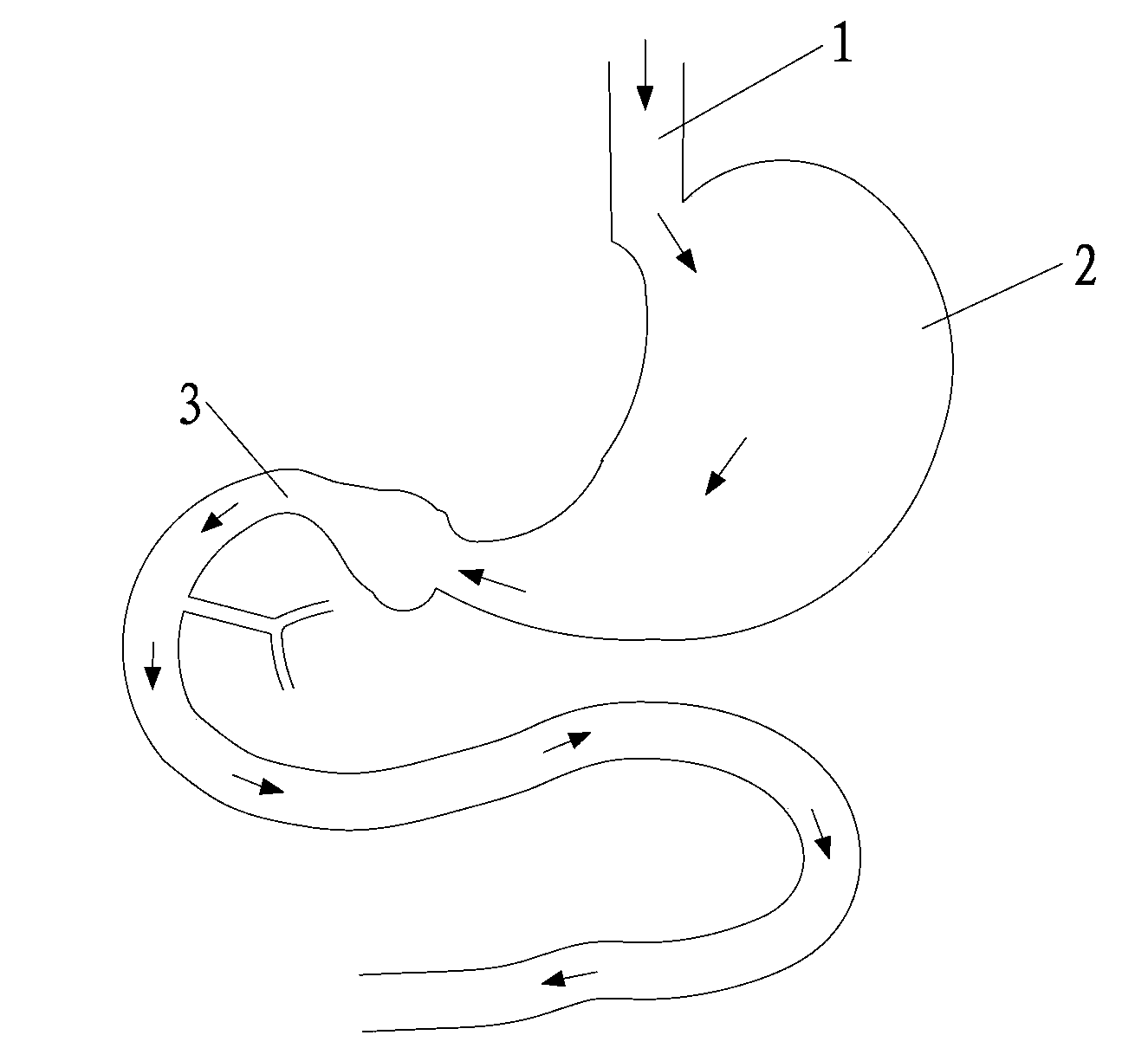

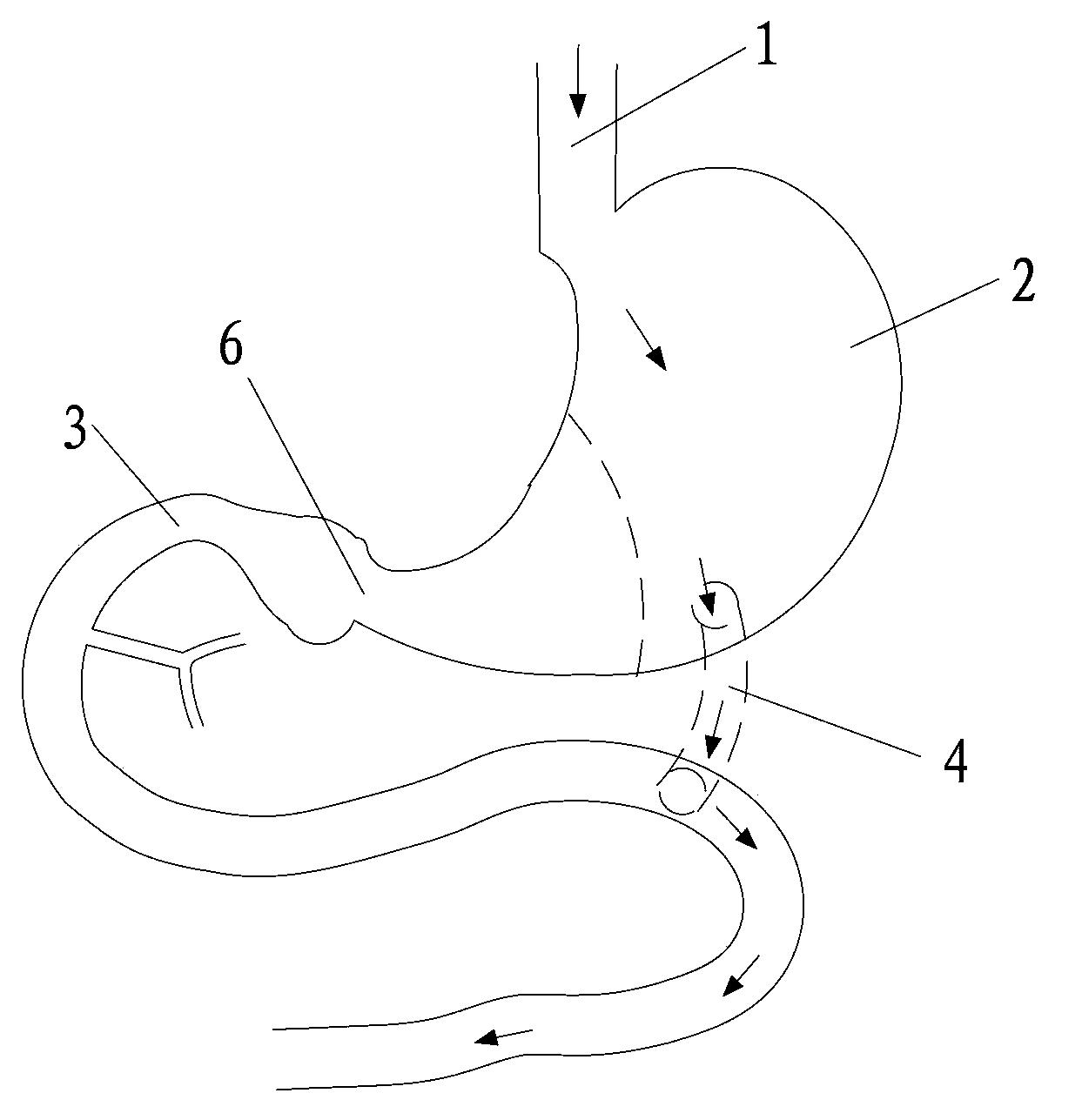

Stomach food diverter

ActiveCN103479454ASimple structureReduce manufacturing costNon-surgical orthopedic devicesTreatment effectMedical expenses

The invention discloses a stomach food diverter which comprises a membrane releasing ball, ball releasing wires, a membrane pipe, a first bracket, an outer shell, an inner shell, a pushing pipe and a bracket pipe, wherein the outer shell, the inner shell, the pushing pipe and the bracket pipe are sheathed together from outside to inside; one end of the inner shell, one end of the pushing pipe and one end of the bracket pipe are positioned in the outer shell and extend out of an oral cavity, and the other end of the inner shell, the other end of the pushing pipe and the other end of the bracket pipe extend out of the outer shell; one end of the outer shell is abutted against the membrane releasing ball; one end of the pushing pipe and one end of the membrane pipe are connected with the membrane releasing ball by the ball releasing wires; the membrane pipe in a folded shape is positioned in the outer shell; the first bracket is connected with the other end of the membrane pipe and positioned on the bracket pipe. The stomach food diverter disclosed by the invention has the advantages of simple structure, low manufacturing cost, convenience in operation and convenience in popularization and use. Additionally, a treatment effect of a stomach diversion operation is achieved without performing the operation on a patient, the pain of the patient is relieved, and medical expenses are reduced for the patient. In addition, a certain weight loss effect on an obese patient is achieved.

Owner:HANGZHOU TANGJI MEDICAL TECH CO LTD

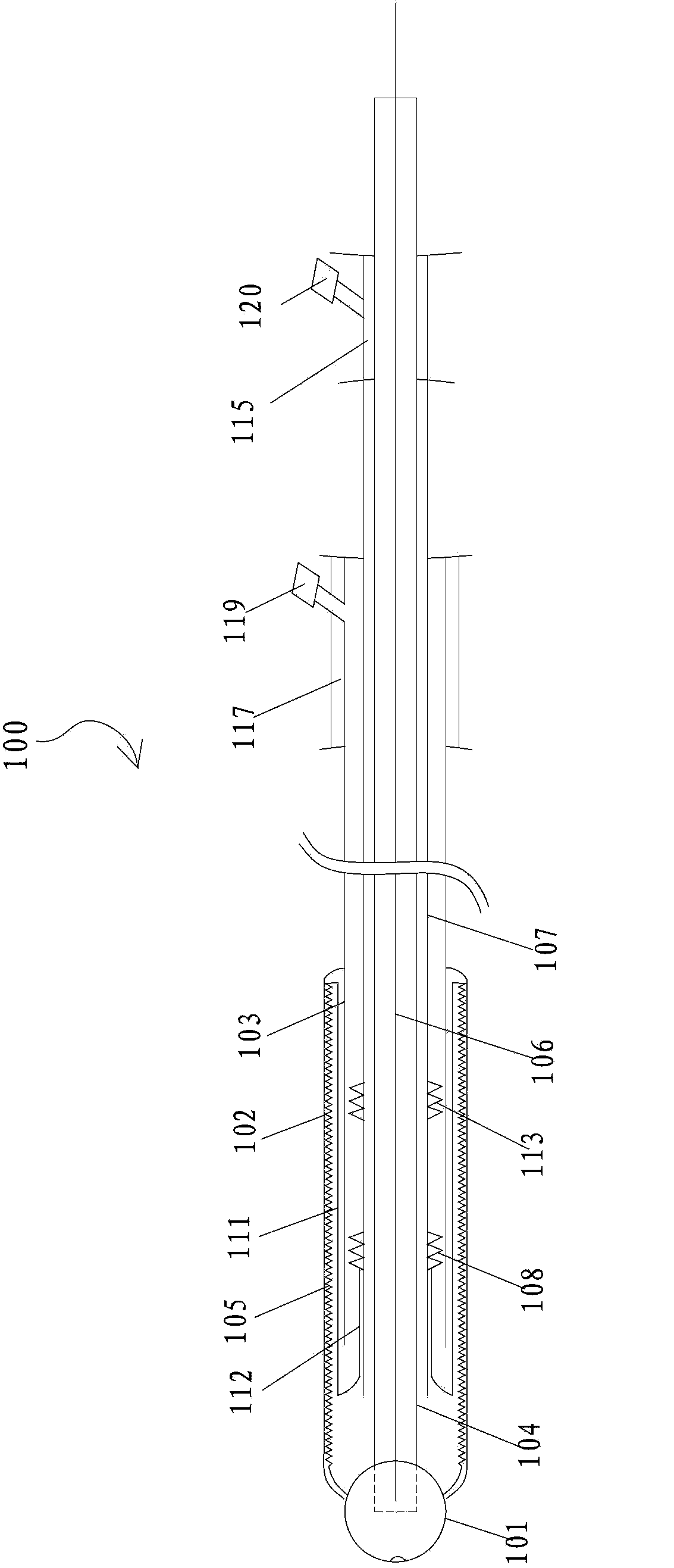

Tennis serve ball machine cum training device

This invention, called Serve Assist, is an electro-mechanical ball machine for practicing the tennis serve. It helps a tennis student to practice serves by consistently dropping the ball in the desired location. It operates in one of two modes, an Auto-feed mode in which it drops the balls in the magazine via an overhead ball release canister at regular intervals or in an Auto-sense mode where the ball is released by the detection of the student's rising tossing arm. The invention also marks the desired height of contact on the dropping ball with a laser and provides visual feedback if the ball is being struck lower than optimum. It aids the student by developing a kinetic and visual memory of the correct ball toss position and point of contact.

Owner:BALASUBRAMANYAN RAMESH

Pressure Actuated Frack Ball Releasing Tool

In a fracking context the object that will ultimately block a passage in an isolation device is introduced into the zone with the bottom hole assembly. The object is not released until the guns fire to create a pressure spike in the borehole that triggers the object retaining device to release the object. The retaining device is placed in close proximity to the isolation device and its setting tool to allow a larger object and passage in the isolation device to be used. If the guns misfire, the object is not released and comes out with the guns. The replacement guns can be pumped in because the passage in the isolation device has stayed open during the misfire. Direct and indirect object release in response to pressure created from the firing of the guns is contemplated.

Owner:BAKER HUGHES INC

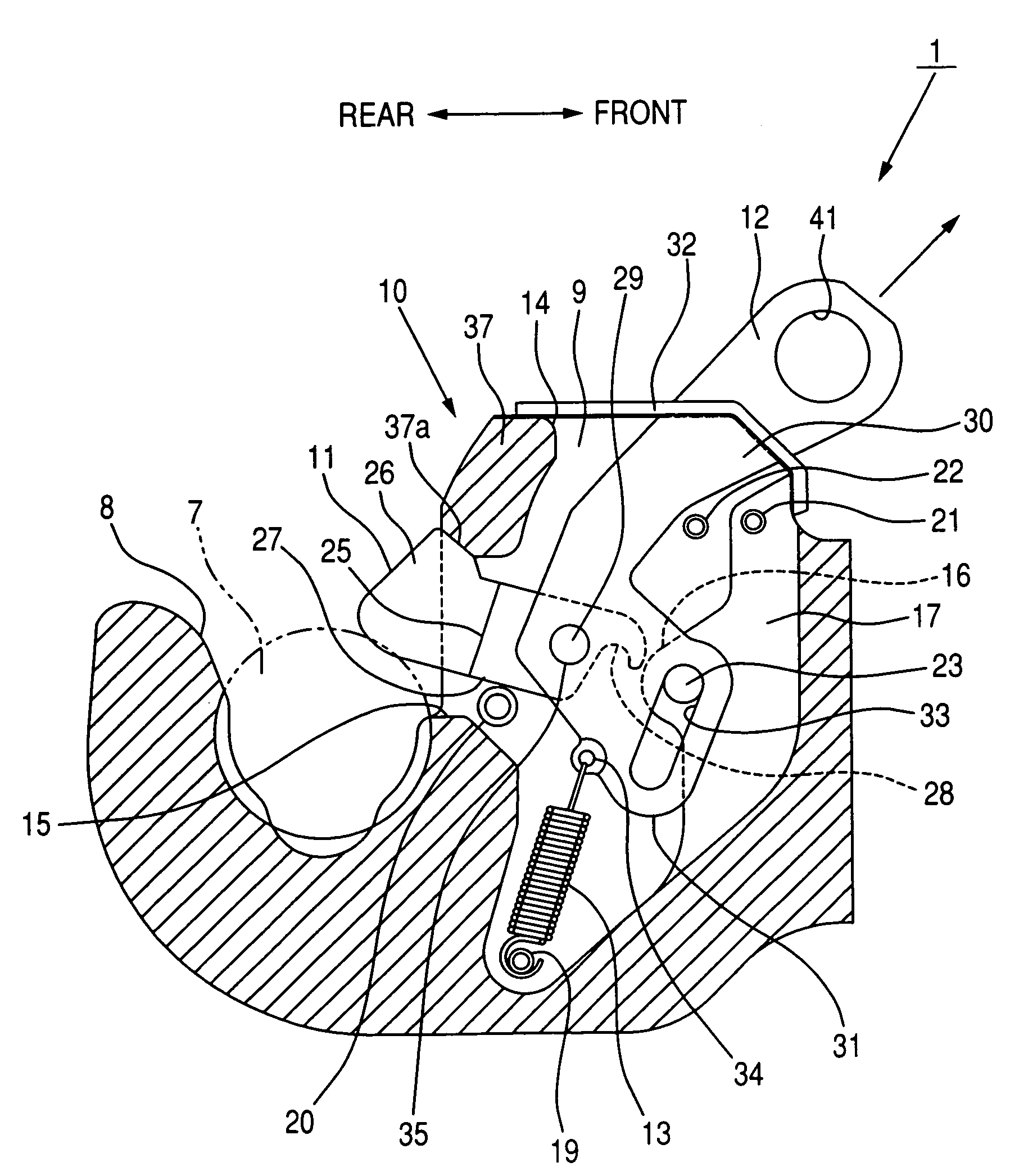

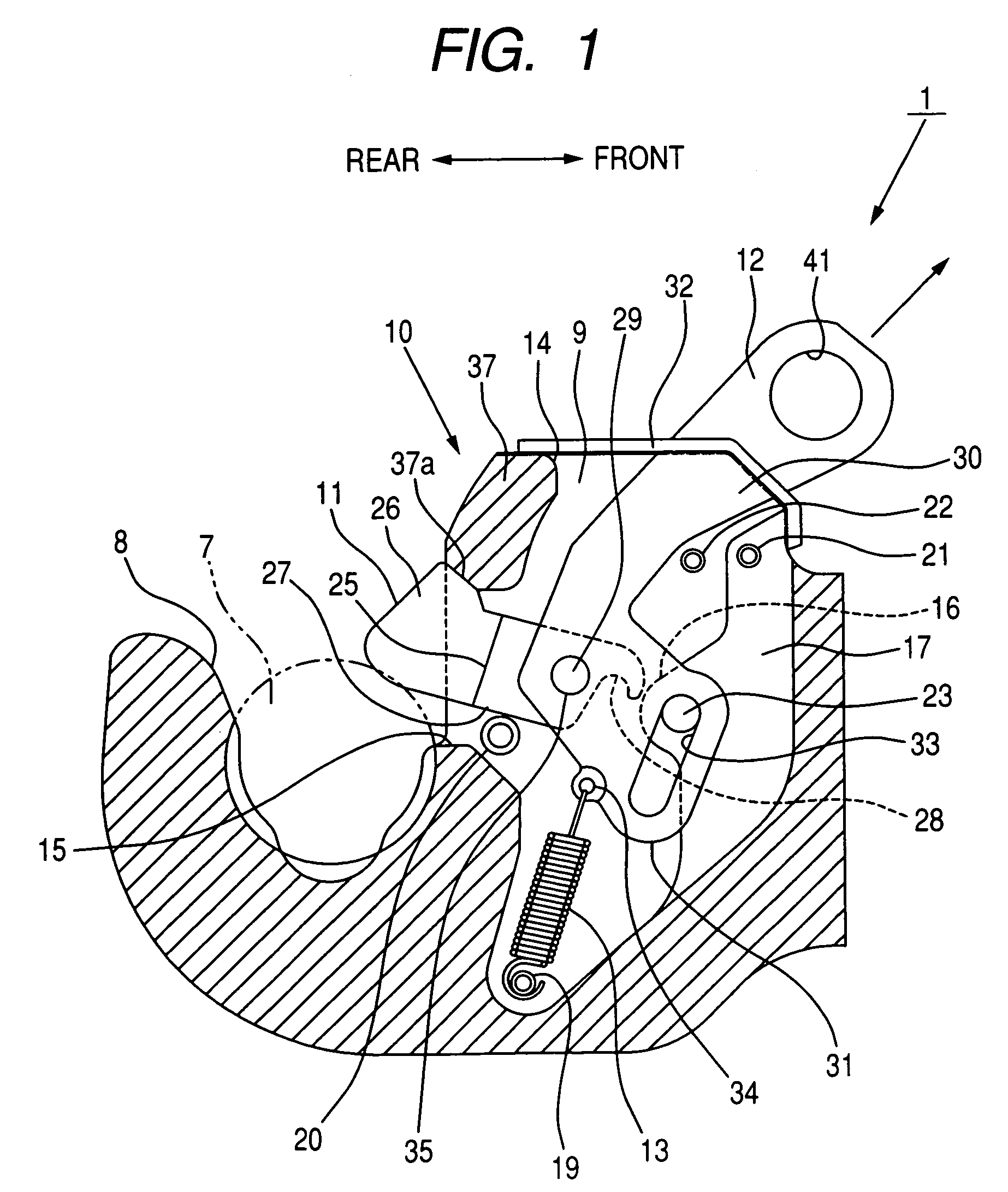

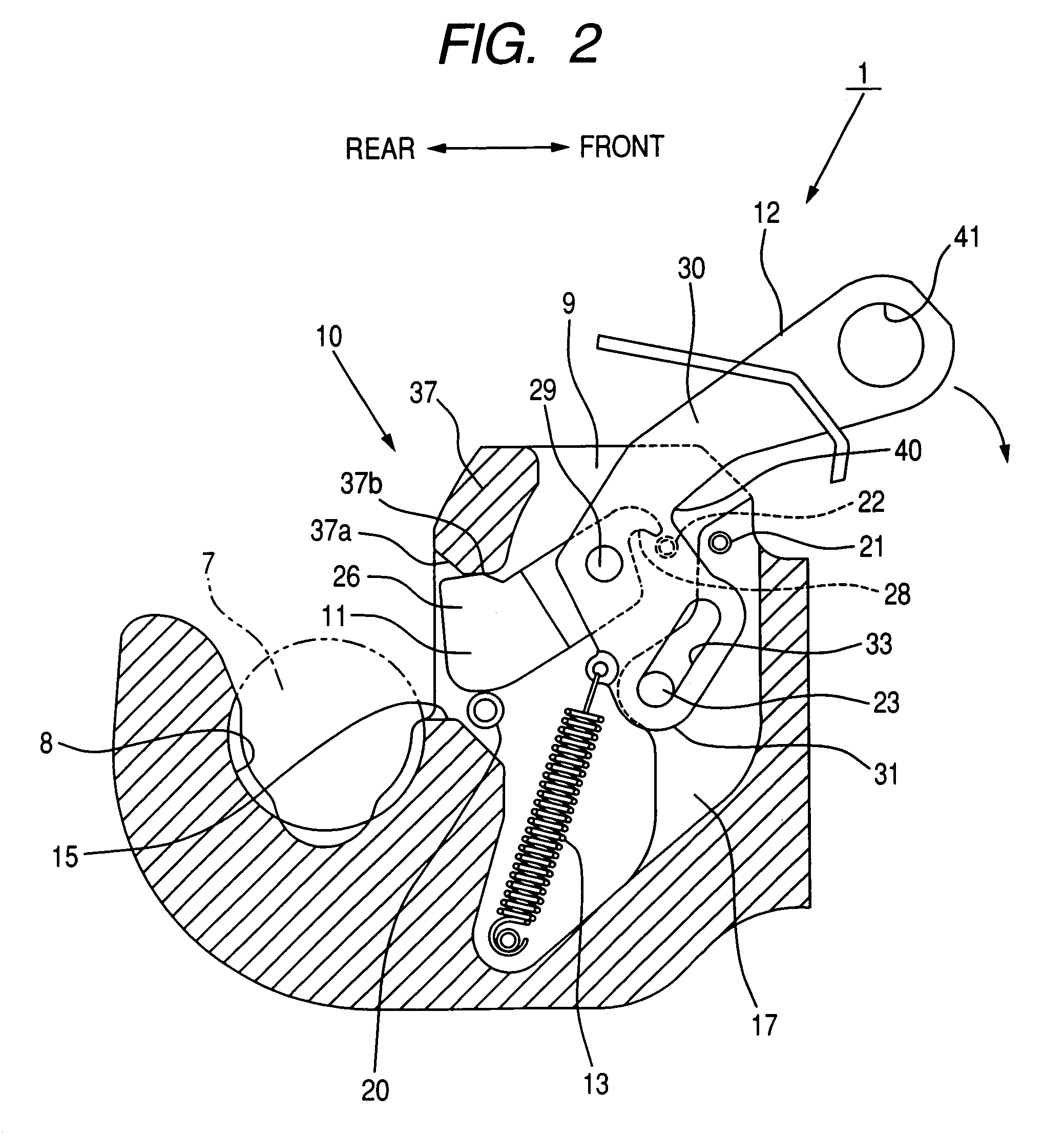

Device for coupling implement to agricultural tractor

The invention relates to a device for a coupling an agricultural implement to an agricultural tractor, in which the operation to release the coupling between the agricultural implement and the agricultural tractor can be easily implemented.When the coupling of the agricultural tractor and the agricultural implement is released, first, a control lever of a coupling hook is slid upward against the urging force of a spring until a second guide pin reaches the lower end of a slit. Next, the control lever is turned forward around the second guide pin until a bent portion of the upper portion and the lower portion of the control lever comes into contact with a first guide pin. As a result, the rear end of a stopper is retracted into a cavity in the hook main body of the device through a second opening so as to slide to the coupling-ball-releasing position, and a groove of the stopper is hooked to a hooking pin so as to be fixed.

Owner:KABUSHIKI KAISHA DELICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com