Corner connecting fitting for surface tubes

A corner connection and corner joint technology, applied in building structures, stepped structures, buildings, etc., can solve the problems of adapting and adjusting the angle range, unable to meet the building structure, affecting the installation efficiency, etc., to improve the installation efficiency and visual effect. Improved, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

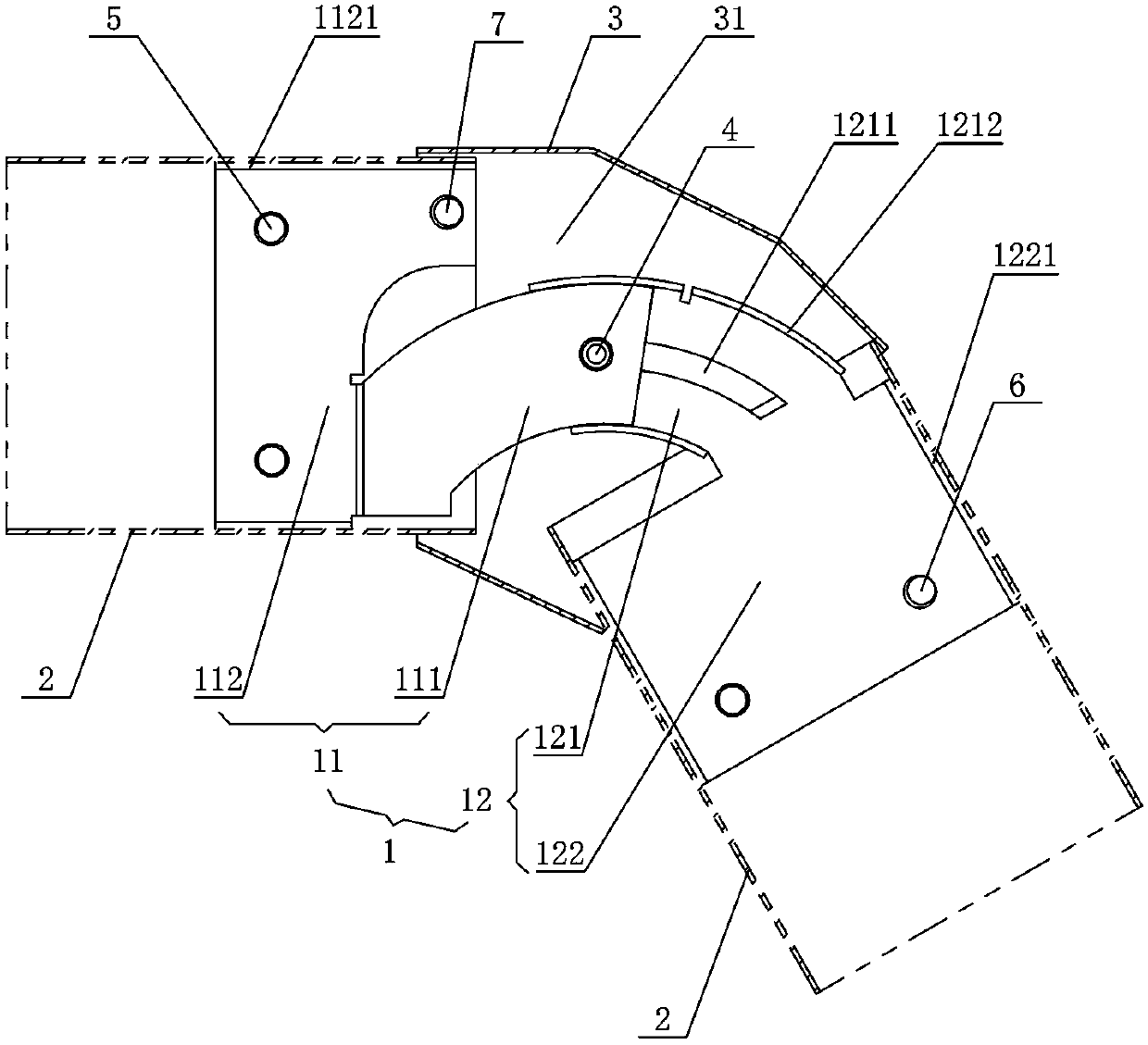

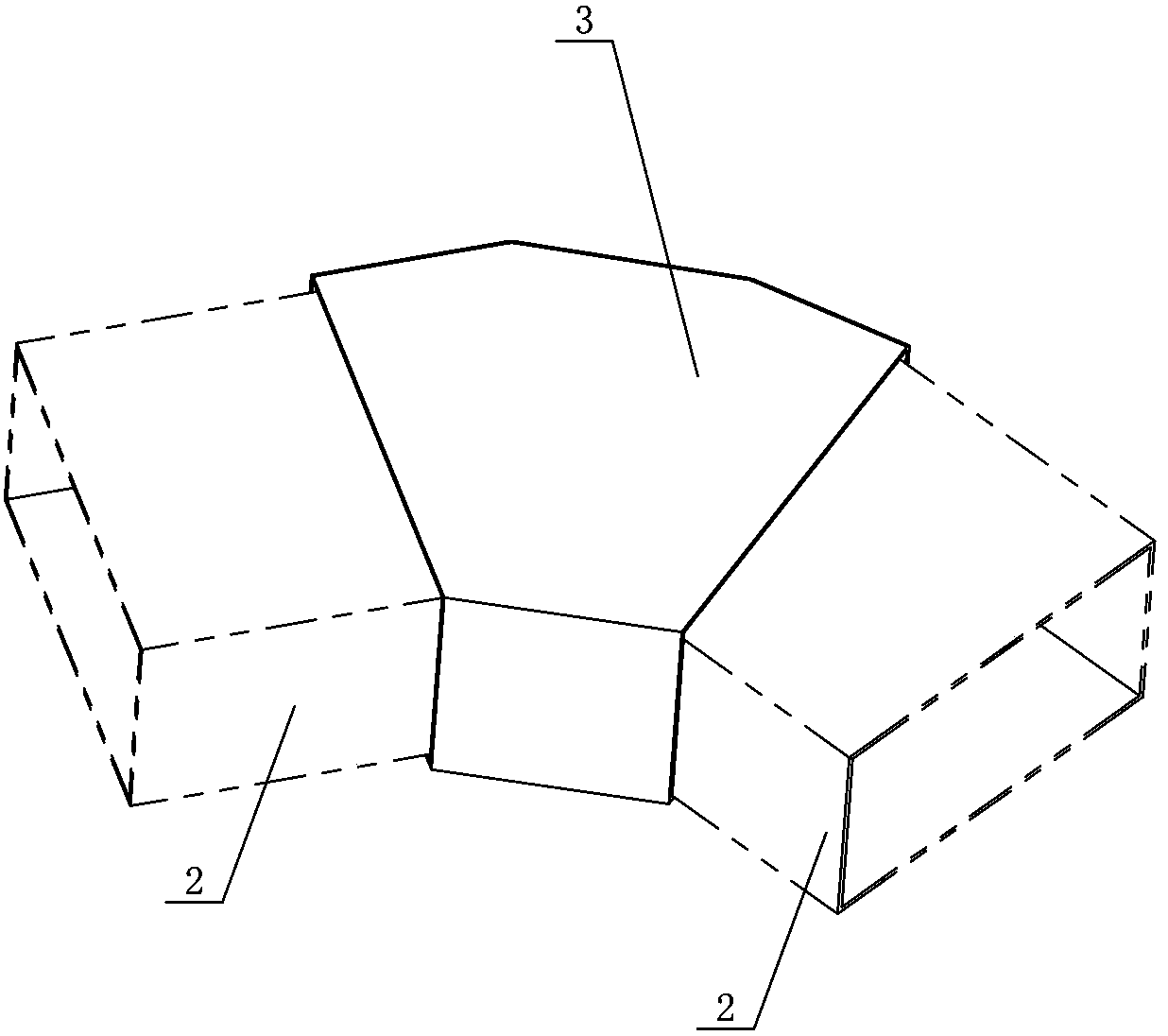

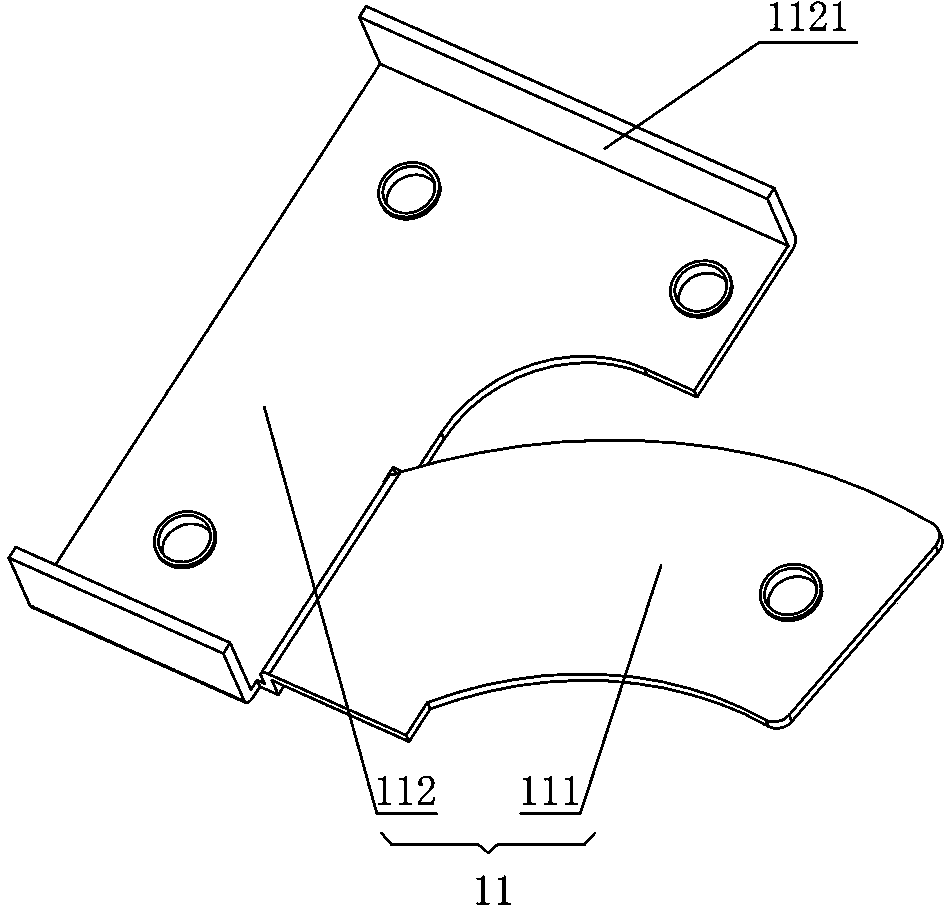

[0030] Figure 1 to Figure 7 It shows the first embodiment of the corner connection fittings for surface pipes of the present invention, the connection fittings include a corner joint 1, the corner joint 1 includes a connecting female part 11 and a connecting sub-part 12, and the connecting female part 11 and the connecting sub-part 12 are respectively inserted into the two surface tubes 2 and fixedly connected with the surface tubes 2. The connecting parent part 11 is provided with a first sliding part 111 extending to the outside of the surface tube 2, and the connecting child part 12 is provided with the first sliding part 111. The second sliding part 121 that cooperates with the first sliding part 111 and can slide in an arc shape along the first sliding part 111 has a simple structure and is easy to install. The combination of the second sliding part 121 and the first sliding part 111 The second sliding part 121 can slide along the first sliding part 111, that is, the ang...

Embodiment 2

[0040] Figure 8 to Figure 9It shows the second embodiment of the corner connection fitting for surface pipes of the present invention, which is basically the same as Embodiment 1, the difference is only that: the first sliding part 111 is bent on both sides for connecting with the second sliding part 111. The flange 1111 that the rotating part 121 is against, the flange 1111 is set so that when the first fastener 4 is tightened, the flange 1111 will be stretched and deformed to be tightly connected with the arc-shaped rib 1212, which greatly improves the connection. The fastening effect between the parent part 11 and the connecting sub-part 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com