Low-melting metal cable connection device, and use method thereof, connection structure

A low-melting-point metal and cable connection technology, applied in the direction of welding/welding connection, etc., can solve the problems of inconvenient cable connection, complicated connection process, poor cable connection effect, etc., to improve power transmission efficiency, safe connection, and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

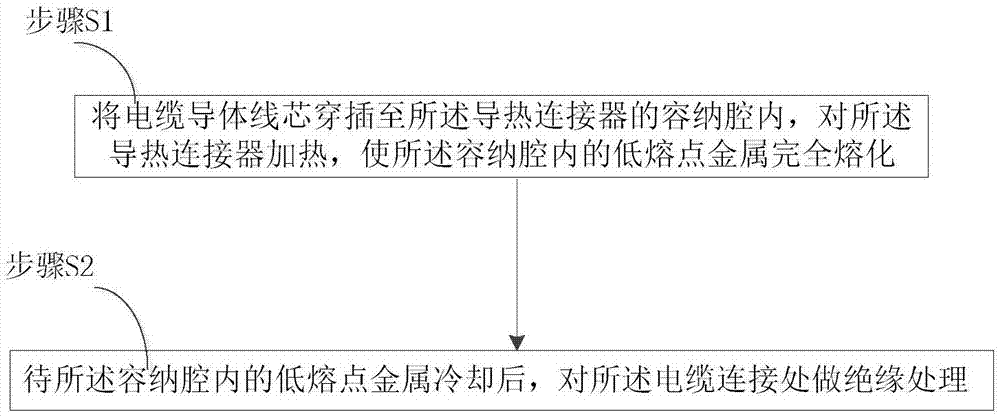

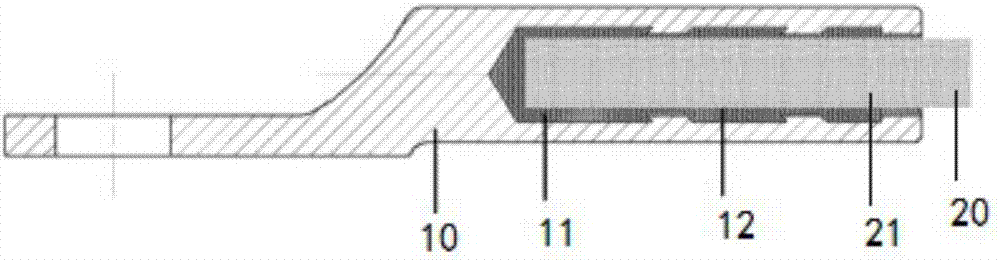

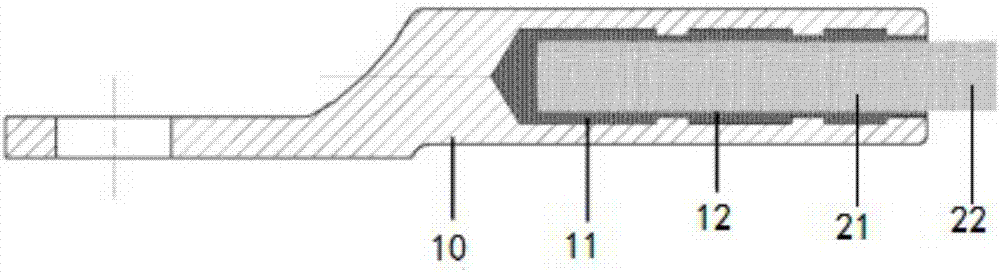

[0057] see figure 2 and image 3 Shown is a schematic diagram of a low melting point alloy cable connection structure used between cable terminal connections. A low-melting-point alloy cable connection structure of the present invention includes a heat-conducting connector 10 and a cable 20, wherein the heat-conducting connector 10 is provided with a housing cavity 11, and a low-melting-point metal 12 is packaged in the housing cavity 11; the cable 20 includes The conductive wire core 21 , the surface of the conductive wire core 21 is coated with flux; the cable 20 is inserted into the accommodating cavity 11 , and the low melting point metal 12 is wrapped around the conductive wire core 21 .

[0058] Since cables generally have an insulating layer, shielding layer, protective layer and filling layer, the specific operation method in this embodiment is to first strip off the insulating layer, shielding layer, protective layer, and filling layer of the cable to make the condu...

Embodiment 2

[0065] see Figure 4 and Figure 5 Shown is a schematic diagram of a low-melting-point alloy cable connection structure used in the mid-end connection of the cable. A low-melting-point alloy cable connection structure of the present invention includes a heat-conducting connector 10 and a cable 20, wherein the heat-conducting connector 10 is provided with a housing cavity 11, and a low-melting-point metal 12 is packaged in the housing cavity 11; the cable 20 includes The conductive wire core 21 , the surface of the conductive wire core 21 is coated with flux; the cable 20 is inserted into the accommodating cavity 11 , and the low melting point metal 12 is wrapped around the conductive wire core 21 .

[0066] Since cables generally have an insulating layer, shielding layer, protective layer and filling layer, the specific operation method in this embodiment is to first strip off the insulating layer, shielding layer, protective layer, and filling layer of the cable to make the ...

Embodiment 3

[0073] see Figure 6Shown is a schematic diagram of a low-melting-point alloy cable connection structure used in the mid-end connection of the cable. A low-melting-point alloy cable connection structure of the present invention includes a heat-conducting connector 10 and a cable 20, wherein the heat-conducting connector 10 is provided with a housing cavity 11, and a low-melting-point metal 12 is packaged in the housing cavity 11; the cable 20 includes The conductive wire core 21 , the surface of the conductive wire core 21 is coated with flux; the cable 20 is inserted into the accommodating cavity 11 , and the low melting point metal 12 is wrapped around the conductive wire core 21 .

[0074] First, strip off the insulation layer, shielding layer, protective layer, and filling layer of the cable to expose the cable metal conductor core; evenly coat a layer of flux and other substances on the two cable metal conductor cores to achieve removal after heating. The purpose of remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com