Bending forming device for multiplanar tube

A technology for bending and forming pipe fittings, which is applied in the field of bending and forming devices for space pipe fittings, can solve the problems of high difficulty in decision-making of process parameters, and achieve the effects of improving surface quality, strong operability, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

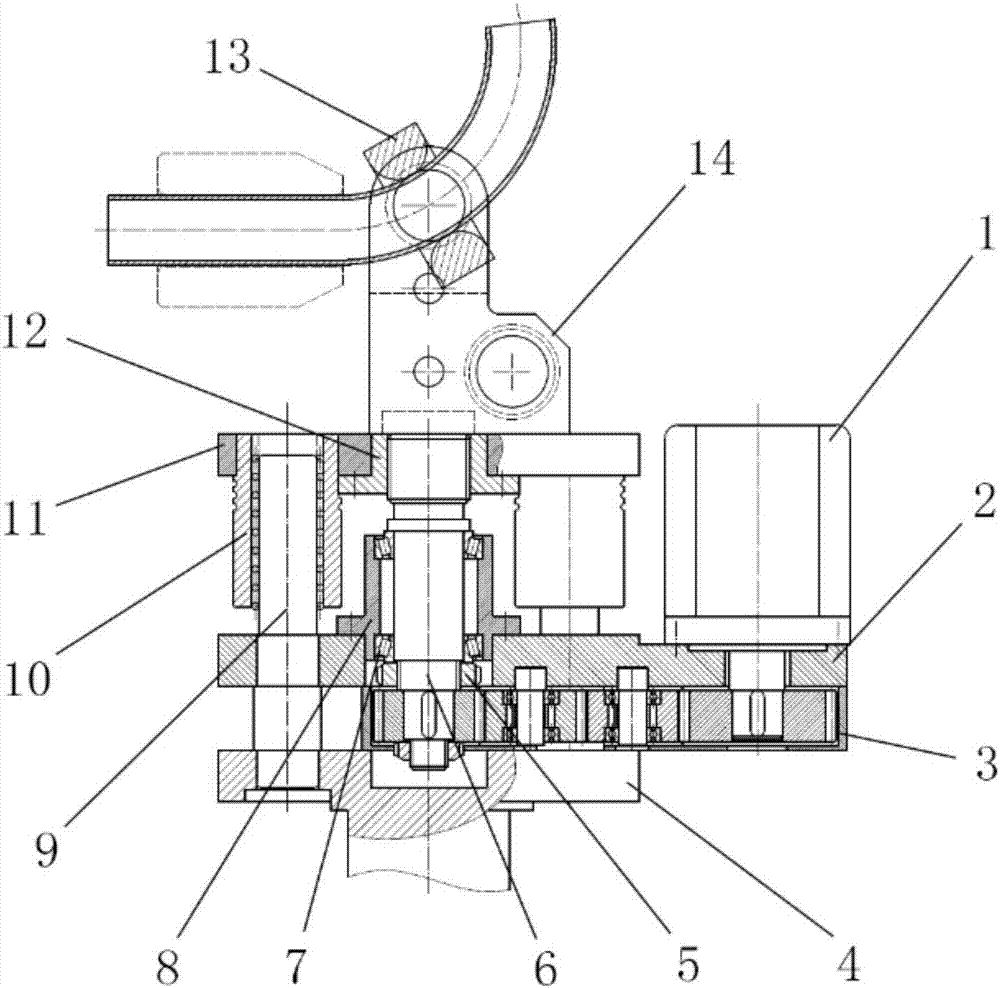

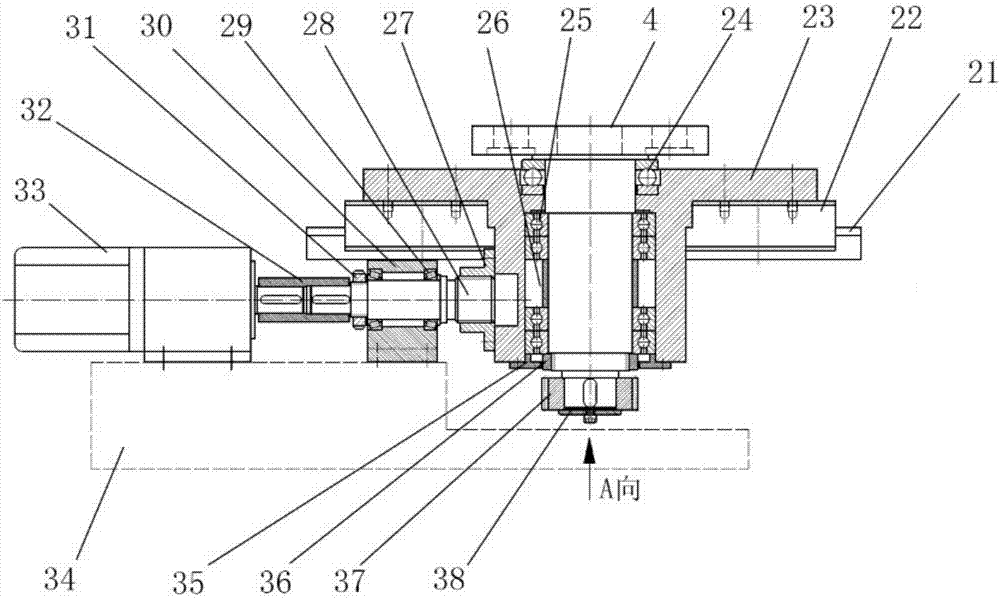

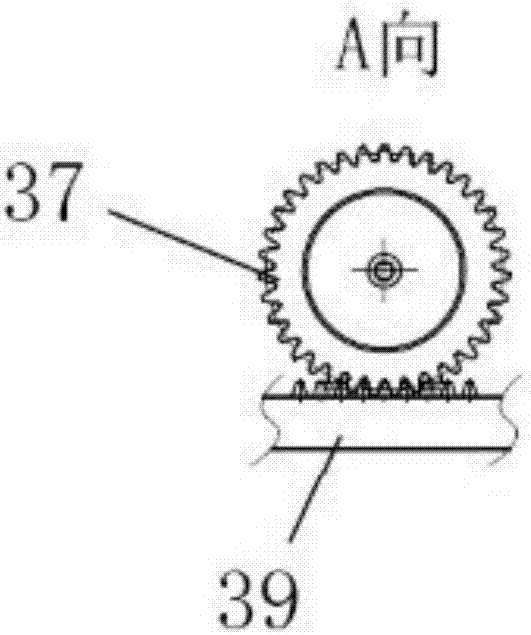

[0051] like Figure 6 As shown, when in use, the pipe fittings to be bent are fixed by the fixed die, so that the feeding direction of the bending forming is set perpendicular to the slide rail 21, even if the pipe fittings to be bent are arranged along the Z direction, and then the pipe fittings to be bent are passed through The bending die 13 has a through hole, so that the axis of the bending die 13 is consistent with the axis of the pipe to be bent and formed, and then the bending die 13 is controlled to rotate along the Oy axis and move and position along the Ox axis through the X-direction control module, and the setting is driven by the Y-direction control module The X-direction control module on the Y-direction control module rotates along the Ox axis, moves and locates along the axis Oy, moves arbitrarily in the xOy plane through the Y-direction control module and the X-direction control module, and automatically determines the bending according to the amount of moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com